Patents

Literature

64results about How to "Reduce production investment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

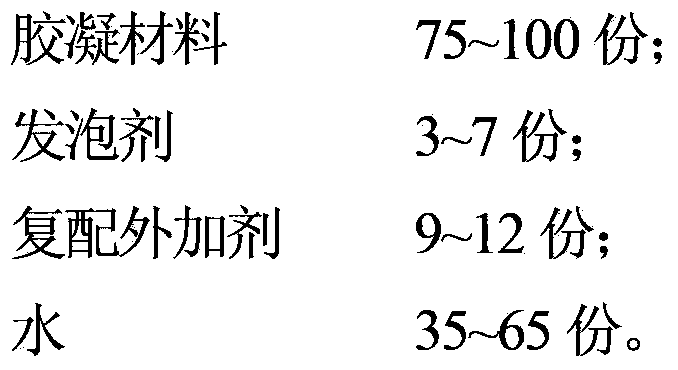

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

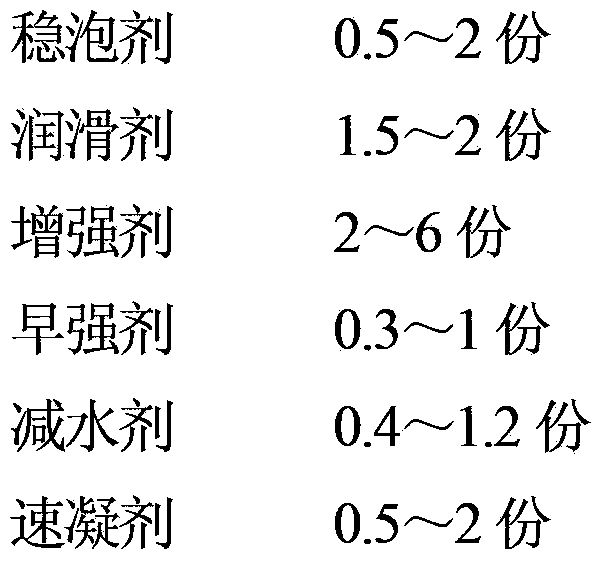

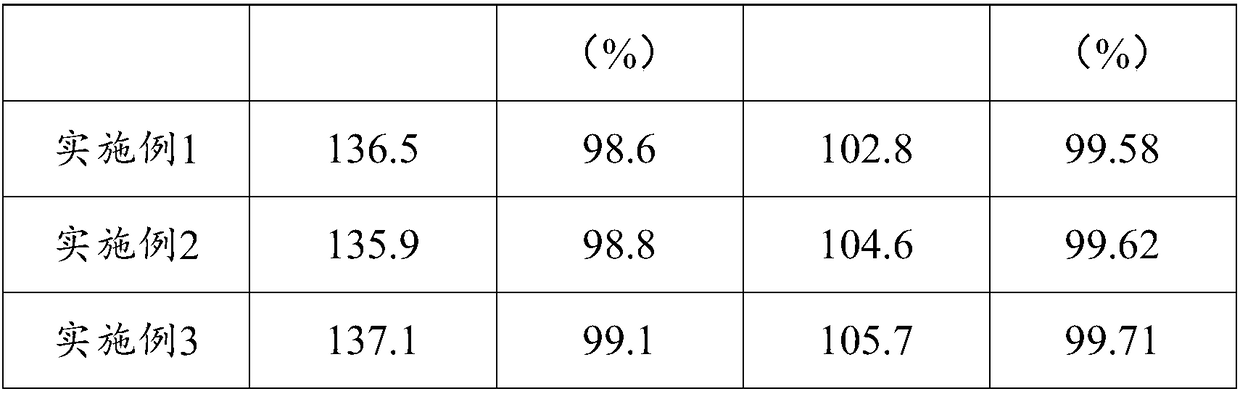

Production method of vanadic oxide

The invention relates to a production method of vanadic oxide, belonging to the field of resource recovery and solving the technical problem of providing a production method of the vanadic oxide. The production method of vanadic oxide comprises the following steps of a, extraction: extracting on immersion liquid which contains vanadic acid by taking a mixture formed from tertiary amine, sulfonated kerosene and tributyl phosphate as an extractant; b, washing: washing a loading organic phase; c, back extraction: carrying out the back extraction on the washed loading organic phase by taking a sodium carbonate solution as a back-extractant, wherein an obtained supernatant is a regenerated organic phase, and an obtained subnatant is back extraction liquid; d, acidic ammonium salt vanadium precipitation: stirring the back extraction liquid to obtain precipitates; e, washing the precipitates; calcining the washed precipitates to obtain the vanadic oxide. The product obtained through the production method is high in grade, and the purity of the final vanadic oxide achieves more than 99.99%. According to the production method, the recovery rate of an integral production process exceeds 76%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

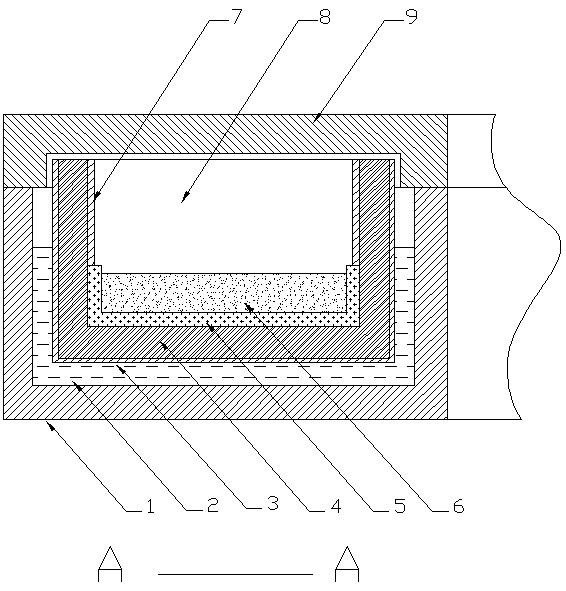

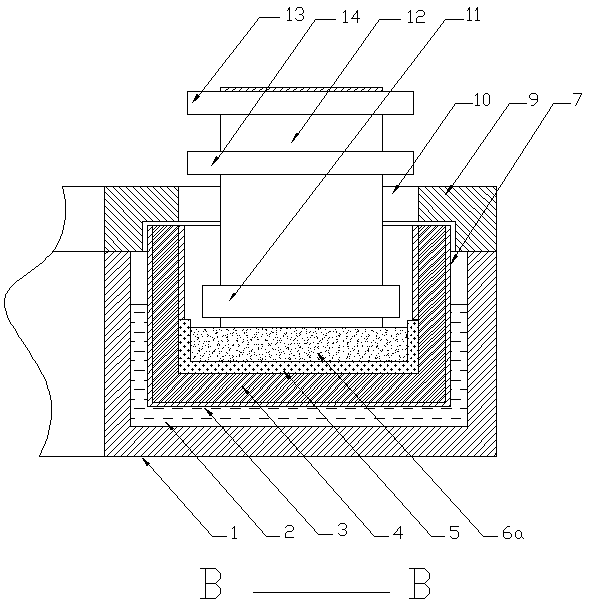

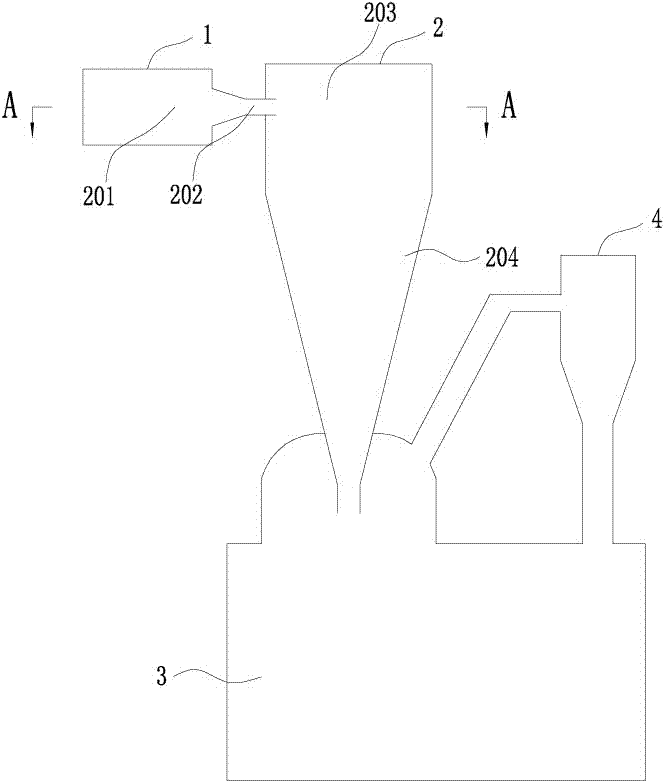

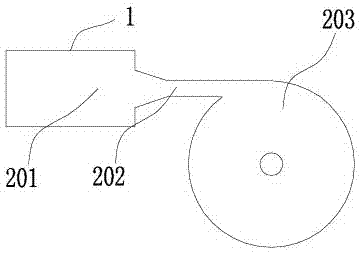

Permanent magnet with corrosion resistant coating and powder nanometer spraying method thereof

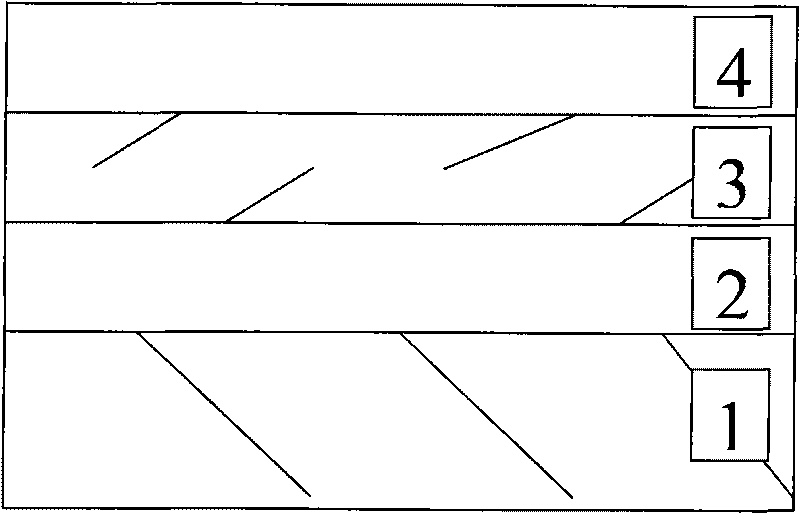

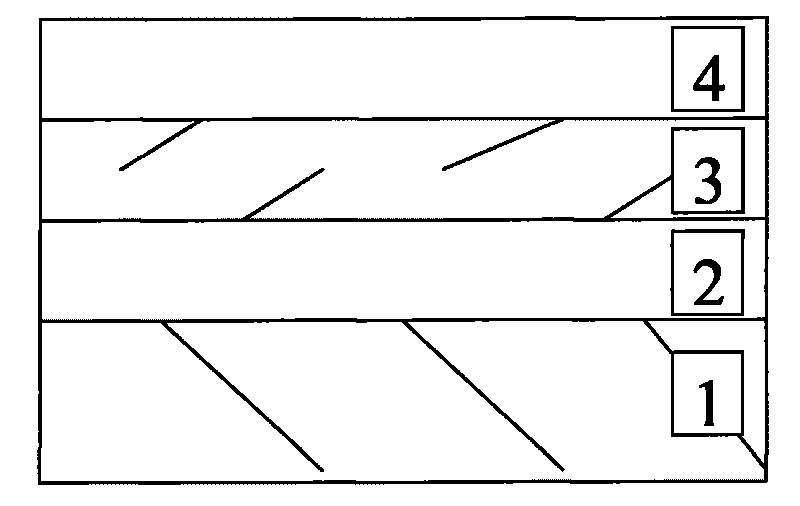

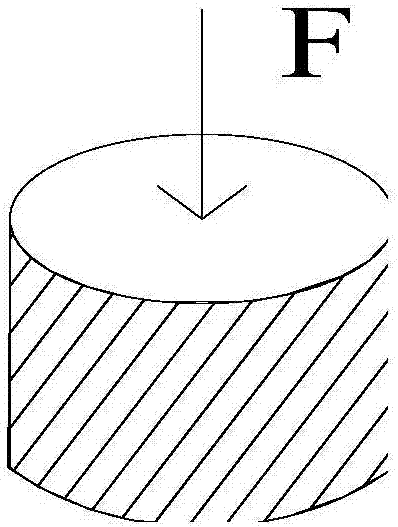

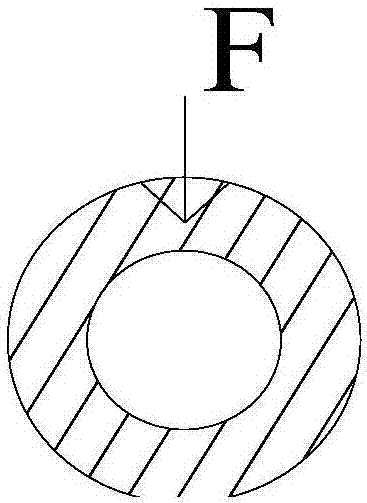

ActiveCN101728043AOperational securityEasy to operateLiquid surface applicatorsLiquid/solution decomposition chemical coatingAlloyMaterials science

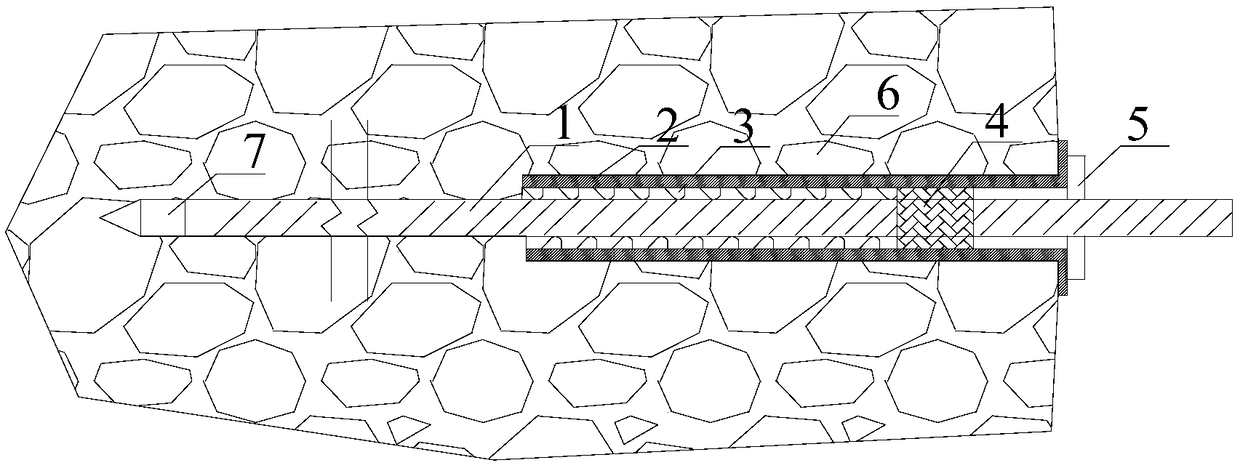

The invention provides a permanent magnet with a corrosion resistant coating. The permanent magnet comprises a permanent magnetic material base body 1, an organic matter bottom layer 2, an organic matter transition layer 3 and a nanometer silver layer 4, and also comprises a powder nanometer spraying method for the permanent magnet with the corrosion resistant coating. As the metal base body is isolated from the contacted outside corrosion media through the inner and outer alloy layers, the metal base body is difficult to corrode and has good humidity and heat resistance property, and then the service life of the permanent magnet is prolonged. As the coating is thin, the influence on the magnet is small, and the magnet shielding does not exist. The product investment cost is reduced, and the safety production is ensured.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Production method of solid superacid catalyst so42-/sb-sno2

InactiveCN102294252ALow reaction temperatureReduce production investment costsFatty-oils/fats refiningCatalyst activation/preparationAcid valueReaction temperature

The invention discloses a production method of a solid super acidic catalyst S04<2-> / Sb-SnO2, which comprises the following steps: (1) preparing Fe3O4 magnetic nanoparticles; (2) preparing an Sb-SnO2 colloid; (3) preparing Fe3O4 / Sb-SnO2 covering powder; and (4) preparing a magnetic solid super acidic catalyst S04<2-> / Sb-SnO2. In the invention, antimony doped tin oxide is used for preparing the magnetic solid super acidic catalyst S04<2-> / Sb-SnO2, a Hammett tracer method is used for carrying out acid strength characterization on solid super acid, the acid strength H0 is less than -13.8, and issuper acid. The magnetic super solid acidic catalyst S04<2-> / Sb-SnO2 disclosed by the invention can be applied in high-acid-value rice bran oil pre-esterification deacidification, so that the original reaction temperature can be reduced to 70 DEG C from more than 200 DEG C before non-strong super acidification, the esterification efficiency can reach over 90%, and the production investment and the management cost can be effectively reduced.

Owner:QIANXINAN HENGLI NEW ENERGY TECH

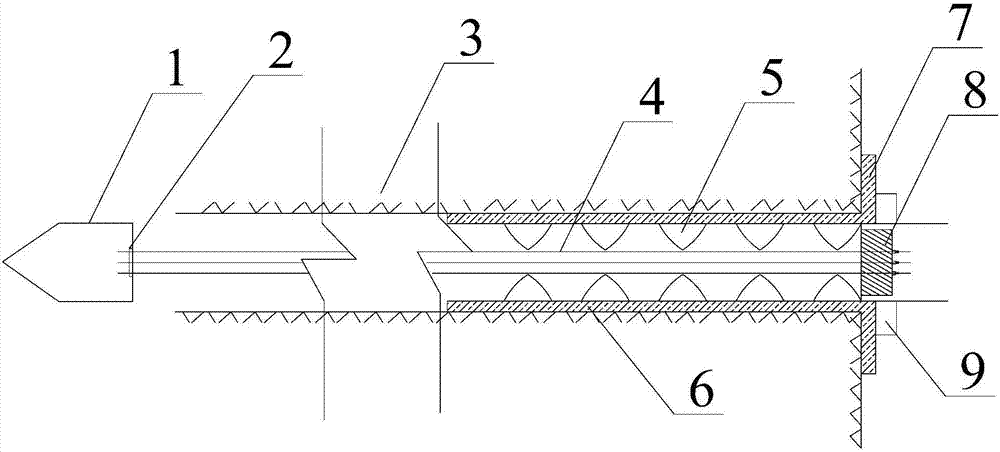

Internal resistance type metal shear-resisting yield anchor cable device

PendingCN107083772AImprove shear deformationPrevent rock layer detachment from deformationBulkheads/pilesAnchoring boltsType metalEngineering

The invention discloses an internal resistance type metal shear-resisting yield anchor cable device. The internal resistance type metal shear-resisting anchor cable pressing device comprises a fixed anchorage head, a shear-resisting yield device and an anchor cable lock tool; the fixed anchorage head is arranged in the surrounding rock, and is connected with the anchor cable lock tool on a surrounding rock drill port through a plurality of steel strands, the anchor cable lock tool is used for exerting prestress to the shear-resisting yield device to form an anchorage structure, the shear-resisting yield device is arranged on the steel strands, a metal protection sleeve and a metal yield ring are included, the surrounding rock drill port is sleeved with the metal protection sleeve, the metal yield ring is arranged in the metal protection sleeve, one ends of the steel strands penetrate the metal yield ring to be connected with the fixed anchorage head, the other end of each steel strand is connected with a metal speed reduction head on the surrounding rock drill port, and the metal speed reduction head loses the rock body deformation capacity of the surrounding rock through shear damage of the metal yield ring. The whole device has the multiple effects of deep layer rock control, rock layer separation deformation prevention, shear resistance, graded constant resistance and the like, and the beneficial effects of being rapid and convenient to mount, stable in property, easy to popularize and the like are achieved.

Owner:SHAANXI COAL & CHEM TECH INST

Magnetic rheology liquid and preparing method

InactiveCN1660982AImprove thixotropyImprove the lubrication effectAdditivesMaterials scienceMagnetic field

A magnetic rheologic liquid as a multifunctional lubricating grease is prepared from diluted or semi-fluid lubricating grease, superfine magnetic field response sensitive particles, antioxidizing agent and metallic antirust agent through sequential mixing and stirring.

Owner:吕崇耀

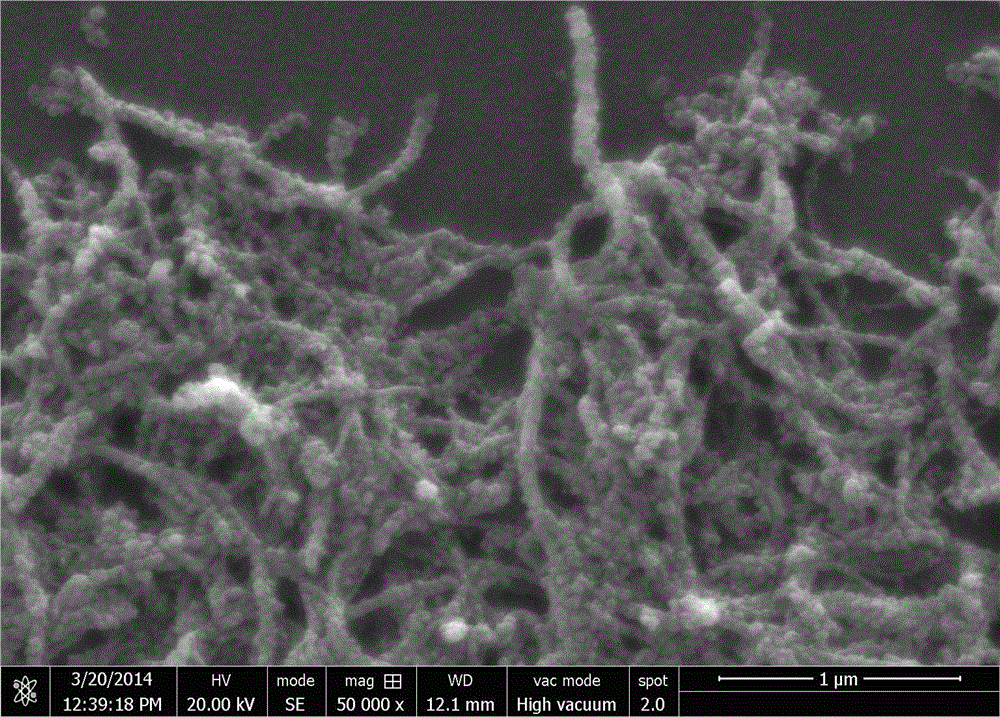

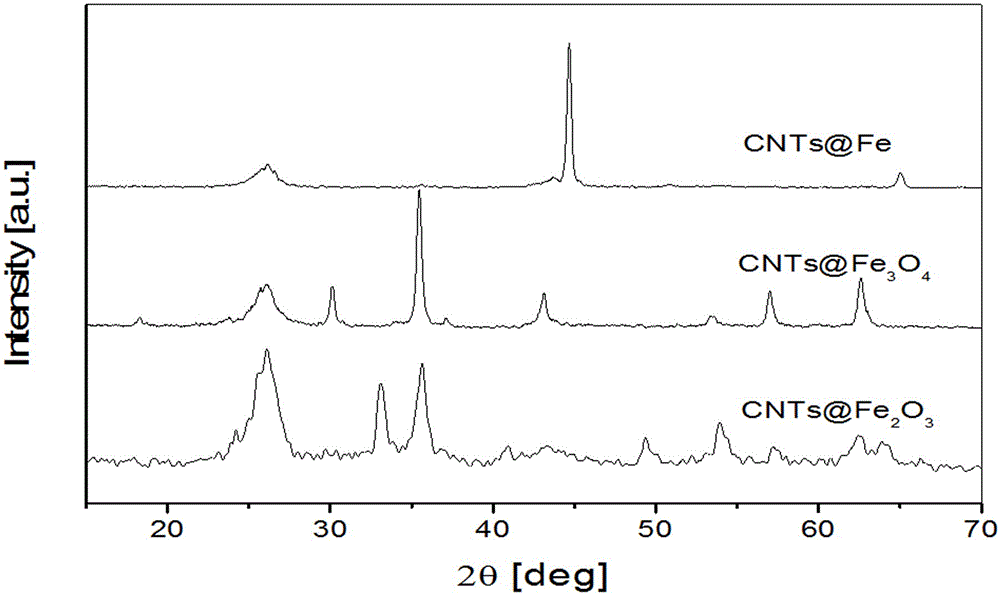

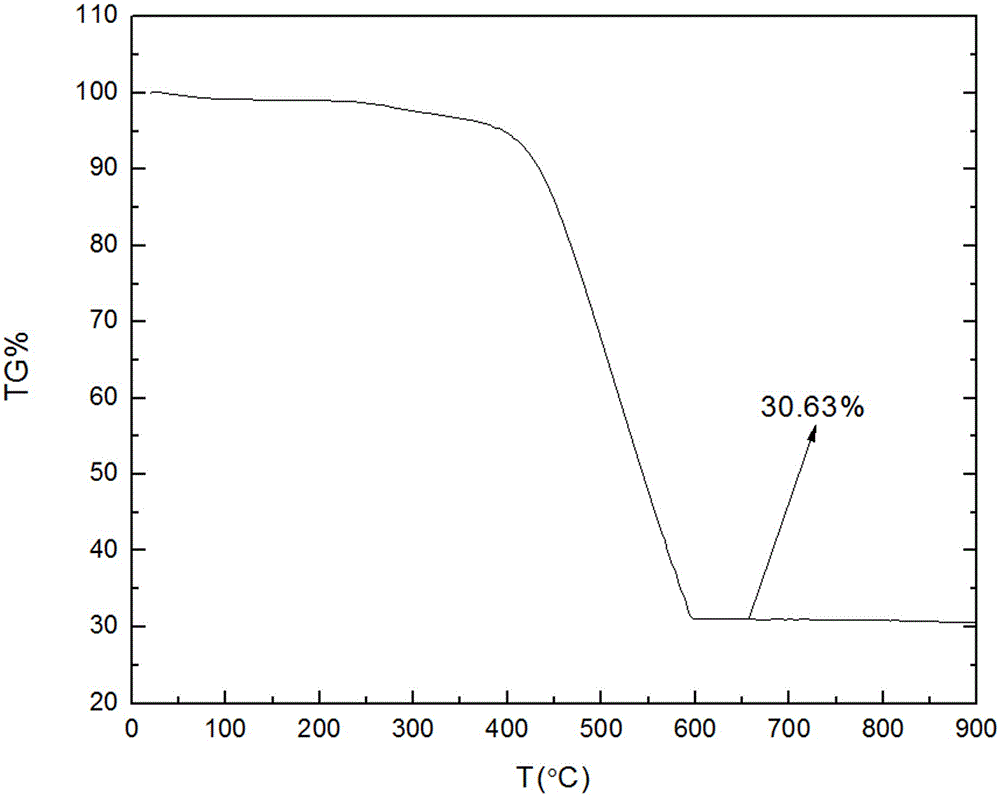

Carbon nanotube uniformly and stably loaded with iron-containing nano particles and preparation method of carbon nanotube

The invention relates to a carbon nanotube uniformly and stably loaded with iron-containing nano particles and a preparation method of the carbon nanotube. According to the invention, the carbon nanotube is prepared through the following steps: with a hydroxylated or carboxylation modified multiwalled or single-walled carbon nanotube, a non-ionic polymer surfactant, and an organic iron compound as raw materials and ethyl alcohol or methanol as a medium, reaction is carried out in a high-pressure reaction kettle with the filling amount of 80% for 4-24 h, and the product is heated for 5 minutes to 2 h under the conditions of 250-800 DEG C and inert gas protection. The obtained carbon nanotube uniformly and stably loaded with the iron-containing nano particles is characterized in that the iron-containing nano particles are uniformly loaded on the outer surface of the carbon nanotube, the nano particles are one of ferric oxide, ferroferric oxide, and iron, narrow in particle size distribution, and 5-20 nm in average particle size, and can be stably loaded on the carbon nanotube under the effects of severe mechanical dispersion or ultrasonic dispersion, and the carbon nanotube has a good application prospect in the fields of catalysis, sensors, electromagnetic shielding material, new energy material, biotechnology, high-performance composite material and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

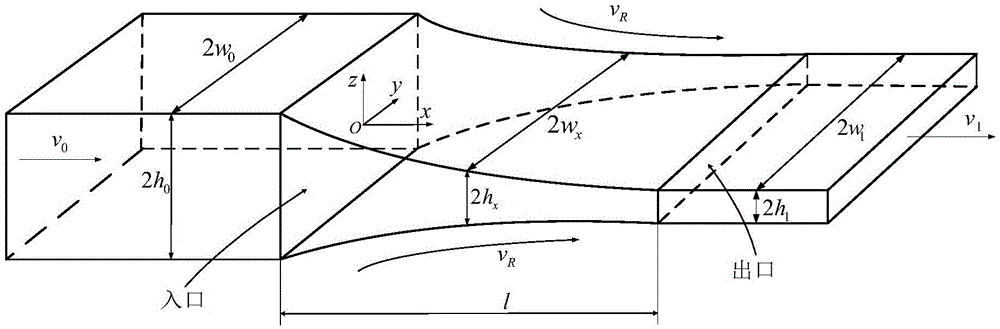

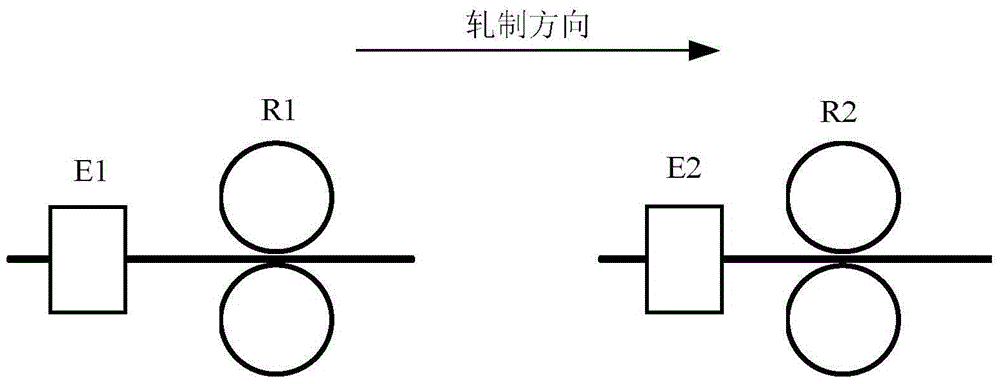

Method for predicting rolling force and thickness of each layer of cold-rolled metal composite plate

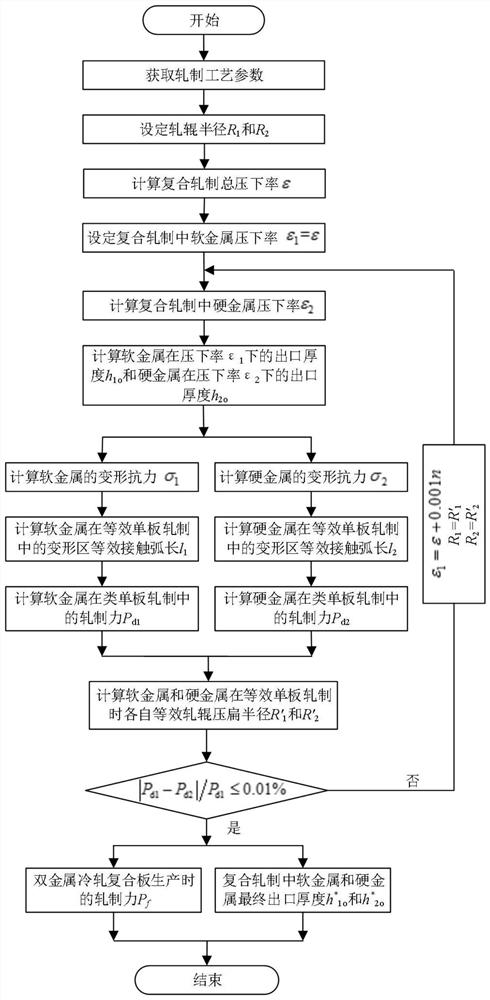

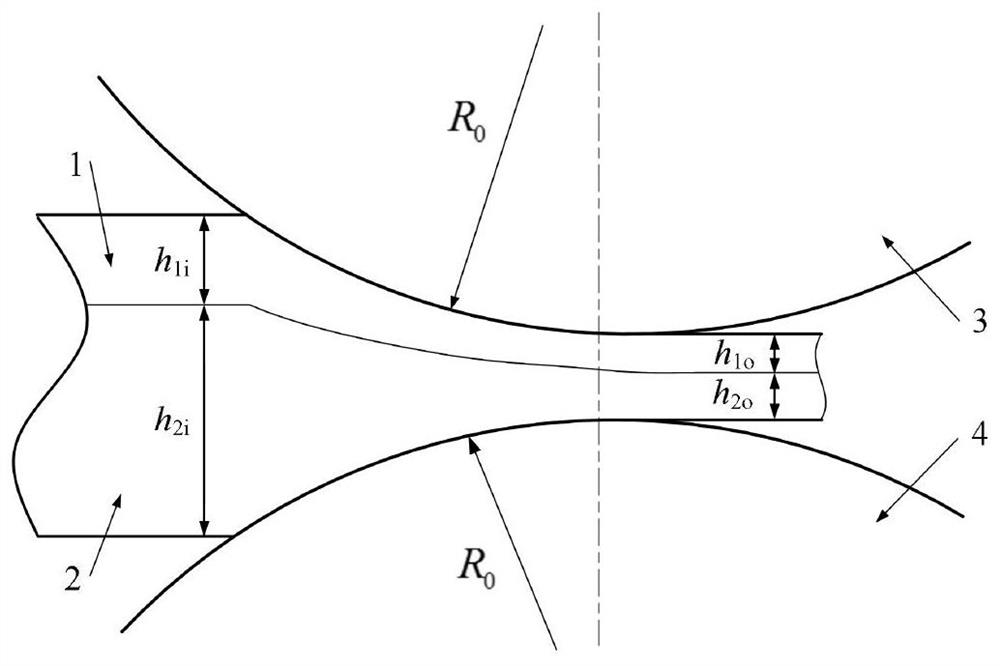

ActiveCN112453071AEasy to predictEasy to chooseRoll force/gap control deviceMetal rolling arrangementsSingle plateMetal

The invention discloses a method for predicting the rolling force and the thickness of each layer of a cold-rolled metal composite plate, and belongs to the technical field of composite plate rolling.The method comprises the following steps that firstly, composite plate rolling process parameters are obtained; the roller radii of a soft metal plate blank and a hard metal plate blank used in the calculation of the rolling force of respective equivalent veneer rolling are set, and the total reduction rate of composite rolling, the reduction rates of the soft metal plate blank and the hard metalplate blank, and the outlet thicknesses at the reduction rates are calculated respectively; rolling force generated when the soft metal and hard metal plate blanks is rolled from the inlet thicknessto the outlet thickness in the equivalent veneer rolling process is calculated; whether the rolling force meets the convergence condition or not is judged, and if not, recalculation is conducted tillthe convergence condition is met; the rolling force during production of the bimetal cold-rolled composite plate is obtained; and the final outlet thicknesses of the soft metal and hard metal plate blanks are calculated. According to the method, the rolling force and the thickness of each layer of the cold-rolled metal composite plate are predicted, and the rolling force and the thickness of eachlayer obtained through calculation are basically close to actual values.

Owner:TAIYUAN UNIV OF TECH

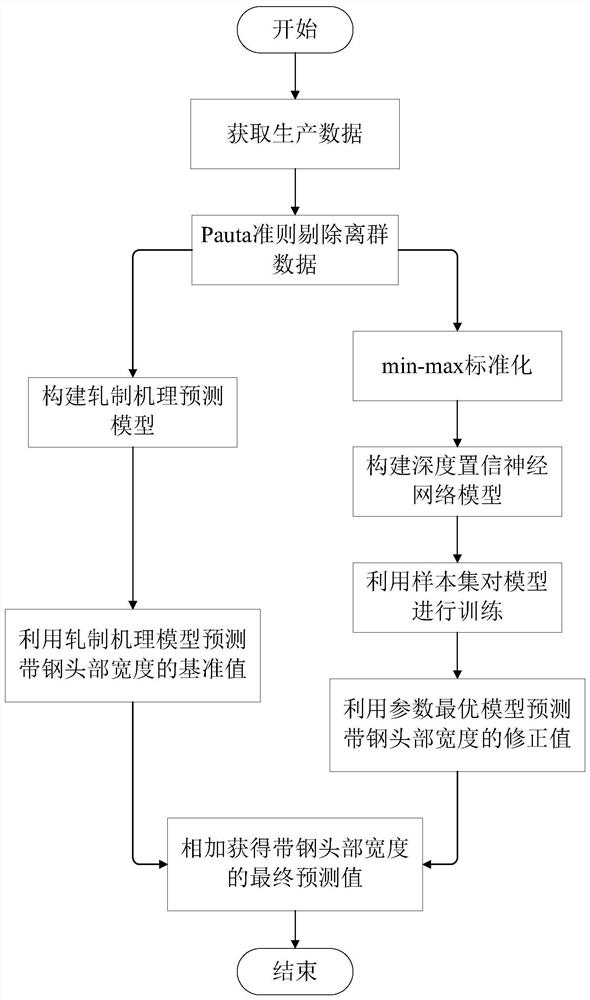

Method for calculating temperature of core of hot continuous rolling intermediate billet

ActiveCN109013717AImproving the Accuracy of Temperature ForecastingSolve the problem that cannot be directly measured onlineTemperature control deviceMeasuring devicesAutomatic controlCore temperature

The invention provides a method for calculating the temperature of a core of a hot continuous rolling intermediate billet, and relates to the technical field of automatic steel rolling control. The method comprises the steps that rolled piece average temperature is calculated according to rolling force speed, width and thickness obtained through actual measurement of a rough rolling area tail rolling pass; the temperature drop losses of a rolled piece on a transportation roller bed is calculated through air cooling temperature drop, the average temperature of the rolled piece is obtained, andin combination with the surface temperature of the rolled piece at any position of the middle roller bed, the core temperature of the rolled piece can be calculated. The method is safe and reliable, the calculation precision is high, the method can be successfully applied to the calculation process of the temperature of the core of the hot continuous rolling intermediate billet, the problem that the temperature of the core of the intermediate billet cannot be only measured in the actual process is solved, and the production investment cost is reduced; and meanwhile the calculation precision ofthe temperature is guaranteed, and a good basis is provided for online precise control of the thickness of the finished product.

Owner:NORTHEASTERN UNIV

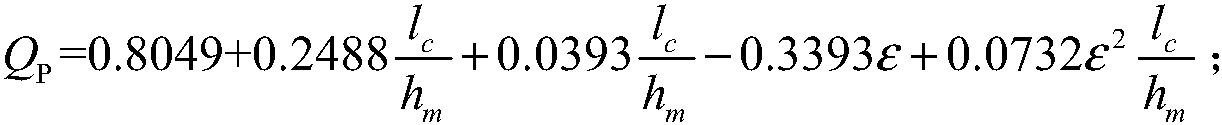

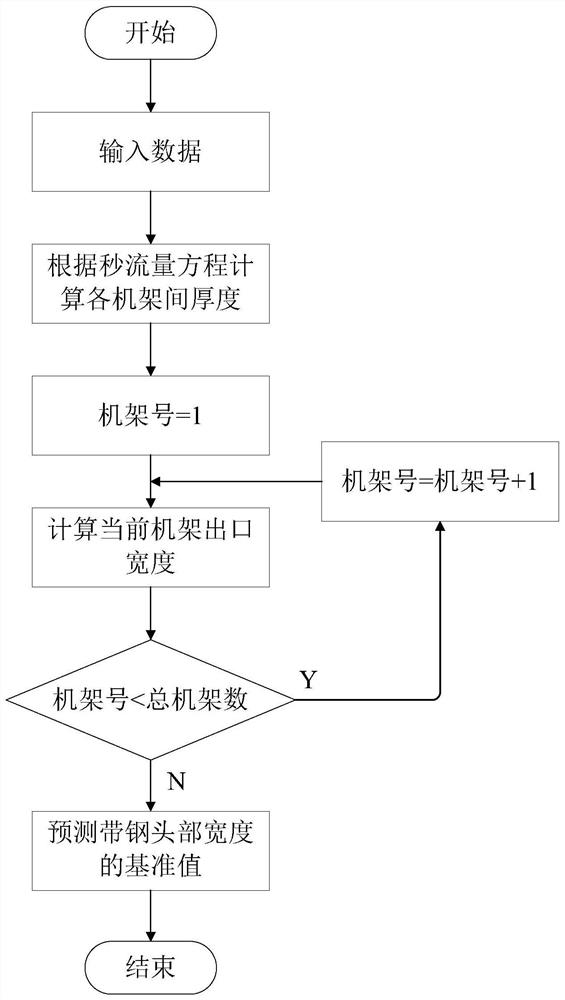

Hot continuous rolling strip steel head width prediction method fusing rolling mechanism and deep learning

ActiveCN113102516AEasy maintenanceIncrease credibilityMetal rolling stand detailsRoll mill control devicesHidden layerAlgorithm

The invention provides a hot continuous rolling strip steel head width prediction method fusing a rolling mechanism and deep learning. The method comprises the following steps of firstly obtaining production data of a hot continuous rolling site, and using a Pauta criterion to remove outlier data, and obtaining sample data; and screening influence factor data according to influence factors of rolling broadening, then constructing a rolling mechanism prediction model of each machine rack, calculating a prediction reference value of the hot continuous rolling strip steel head width according to the influence factor data, and constructing a deep belief neural network model to predict a correction value of the strip steel head width, and finally, adding the predicted reference value of the strip steel head width to the predicted correction value to obtain a final predicted value of the measurement position of the strip steel head width at an outlet. According to the method, the rolling mechanism and the deep belief neural network are fused to predict the strip steel head width, the problems that a prediction model based on a traditional single hidden layer neural network has low prediction precision and is easy to fall into a local extreme value are solved, and a good foundation is provided for optimization of a process automation level setting model.

Owner:NORTHEASTERN UNIV

Process for preparing superfine high-activity metakaolin by utilizing vertical high-pressure mill

InactiveCN102060302ALow investment costReduce production investment costsAluminium silicatesChemical industryGranularityKaolin clay

The invention relates to a process for preparing superfine high-activity metakaolin by utilizing a vertical high-pressure mill, which is characterized by comprising the following steps of: firstly, crushing crude ore of metakaolin into 325+ / -30 meshes, grinding the crushed crude ore by the vertical high-pressure mill to obtain a superfine high-activity metakaolin powdery material with a particle size of 2-2.5mum, then conveying the superfine metakaolin to a rotary kiln feeding system by a fan, adding the superfine metakaolin into a rotary kiln by an automatic feeding machine, then carrying out high-temperature calcining on the superfine metakaolin in the rotary kiln with the temperature of 600-900 DEG C and the calcining time of 1-4 h, and preparing a superfine metakaolin product. The process has the advantages that the production cost is greatly reduced, the occupied area is only 50% of that of a ball mill system, the production efficiency is high, the energy is saved, the environment is protected, the granularity of a product is fine and uniform, the particle size of the product is 2.1-3.0mum, the minimum particle size can be controlled to be 2mum, and the uniformity is over 90%.

Owner:INNER MONGOLIA TIANZHIJIAO KAOLIN CO LTD

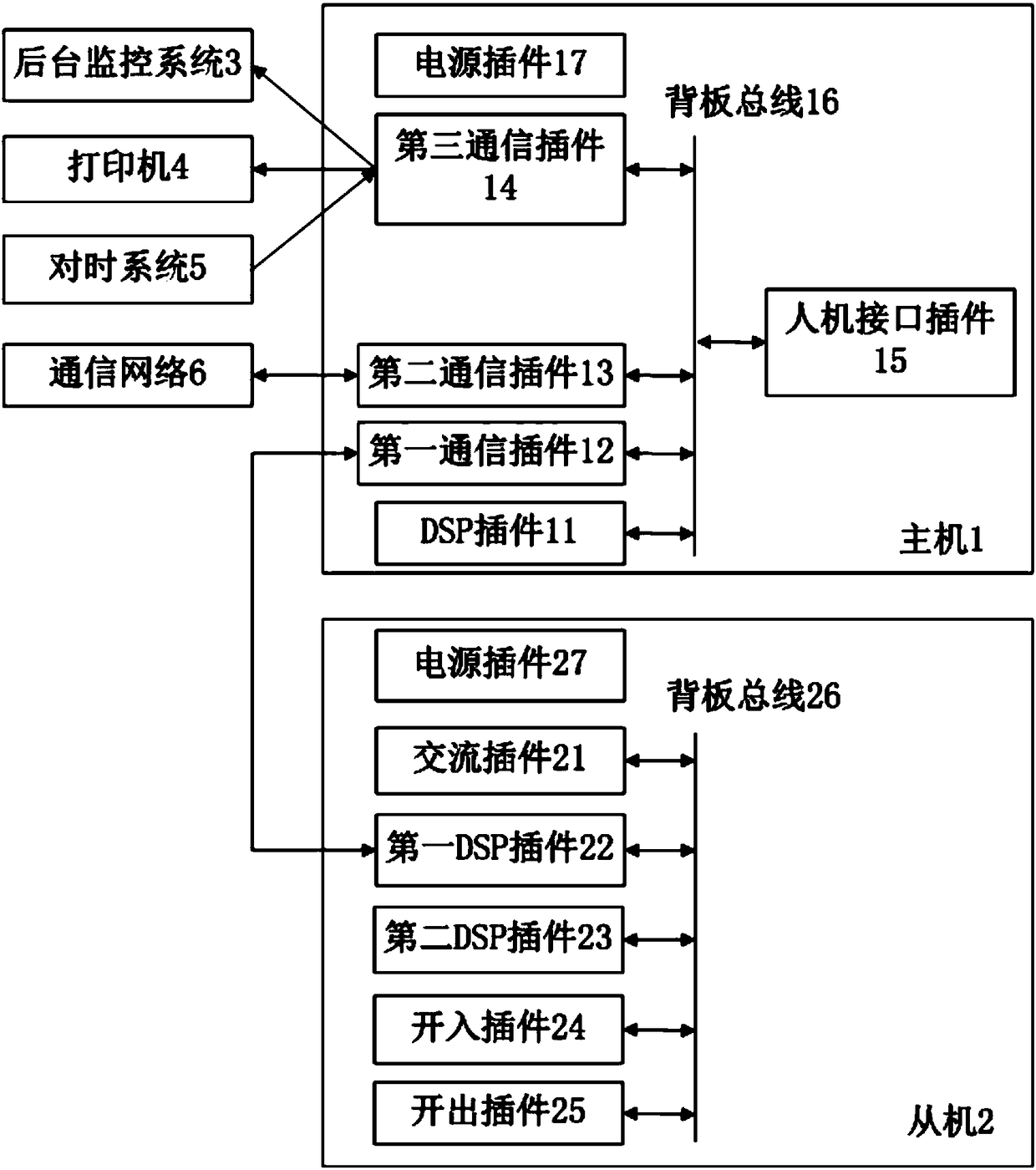

Safety automatic device integrating bus tie backup power automatic switching and main transformer backup power automatic switching functions

ActiveCN108599095AReduce production investment costsEfficient use ofEmergency protective arrangement detailsInformation technology support systemSecondary loopPower grid

The invention provides a safety automatic device integrating bus tie backup power automatic switching and main transformer backup power automatic switching functions, which comprises a host machine and a slave machine. The host machine comprises a DSP plug-in and a communication plug-in; the slave machine comprises a DSP plug-in, an alternating current plug-in, an input plug-in and an output plug-in; the communication plug-in in the host machine is in communication connection with the slave machine; the DSP plug-in in the host machine transmits a tripping and closing command to the slave machine by the communication plug-in; the alternating current plug-in in the slave machine is used for acquiring a signal and uploading the signal to the DSP plug-in of the slave machine after carrying outprocessing; the input plug-in acquires switch quantity signals of a bus tie switch and an in-transformer switch and uploads the switch quantity signals to the DSP plug-in of the slave machine; the DSP plug-in of the slave machine uploads a current digital signal, a voltage digital signal and the switch quantity signals to the host machine; and the output plug-in is used for transmitting the tripping and closing command to the bus tie switch and the in-transformer switch. According to the invention, production investment cost of a power grid can be reduced, workload of the device in the operation and maintenance process is reduced, and utilization of secondary circuit resources of main transformer backup power automatic switching and bus tie backup power automatic switching in a transformer substation is optimized.

Owner:SHENZHEN POWER SUPPLY BUREAU

Threaded metal yielding anchor rod device

InactiveCN109505640AContinuous forceContinuous yielding effectAnchoring boltsContinuous/uninterruptedScrew thread

The invention provides a threaded metal yielding anchor rod device including a fixed anchor head, an anchor rod body, a metal head, a metal protection sleeve and a thread yielding ring. The thread yielding ring is disposed in the metal protection sleeve in the form of an internal thread, and the diameter of the metal head is greater than the minor diameter of the thread yielding ring and smaller than the internal diameter of the metal protection sleeve. During the use, the fixed anchor head is mounted in a drilled hole of a surrounding rock, and the metal protection sleeve is mounted in a drilled hole port of the surrounding rock; one end of the anchor rod body passes through the thread yielding ring and is connected with the fixed anchor head, the other end is connected with the metal head, and the metal head is placed in the metal protection sleeve. The thread yielding ring is disposed in the metal protection sleeve in the form of the internal thread, since the thread is continuous and uninterrupted and there is no gap between two yielding rings, when the metal head causes axial deformation of the thread yielding ring, an acting force is continuous, a stable and continuous yielding effect is generated, and the yielding effect is improved.

Owner:SHAANXI COAL & CHEM TECH INST

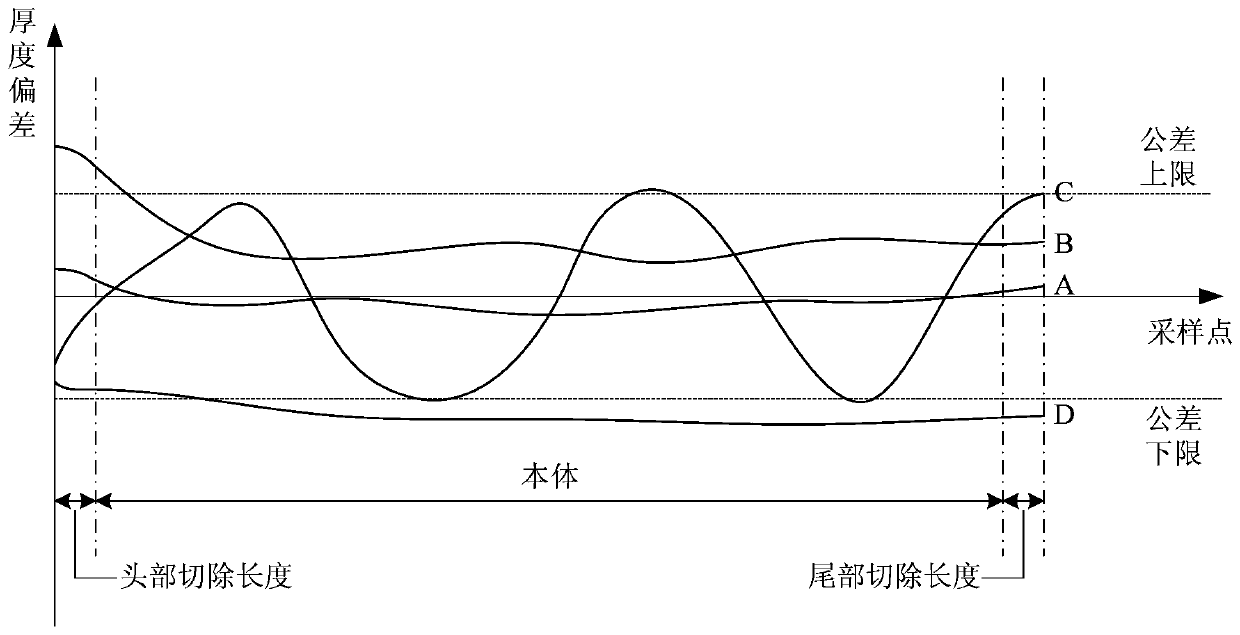

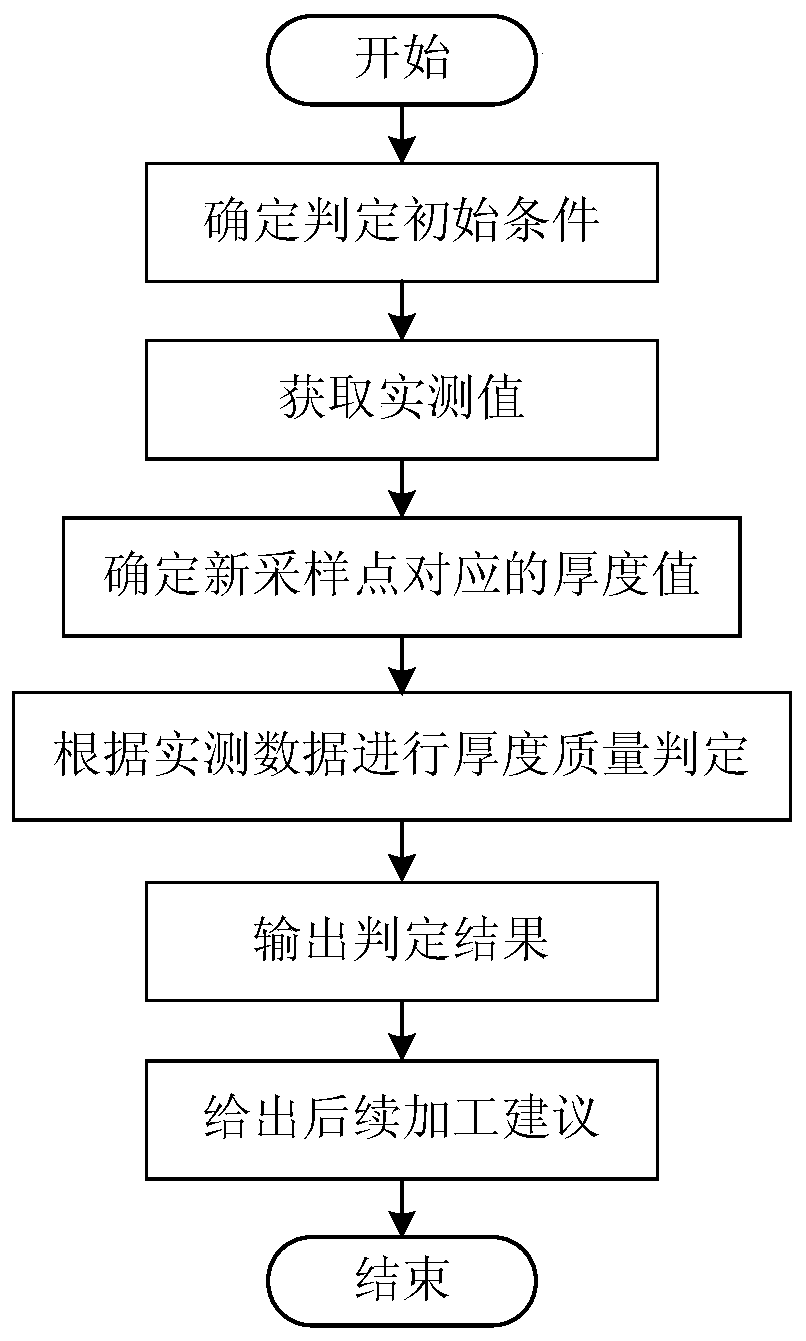

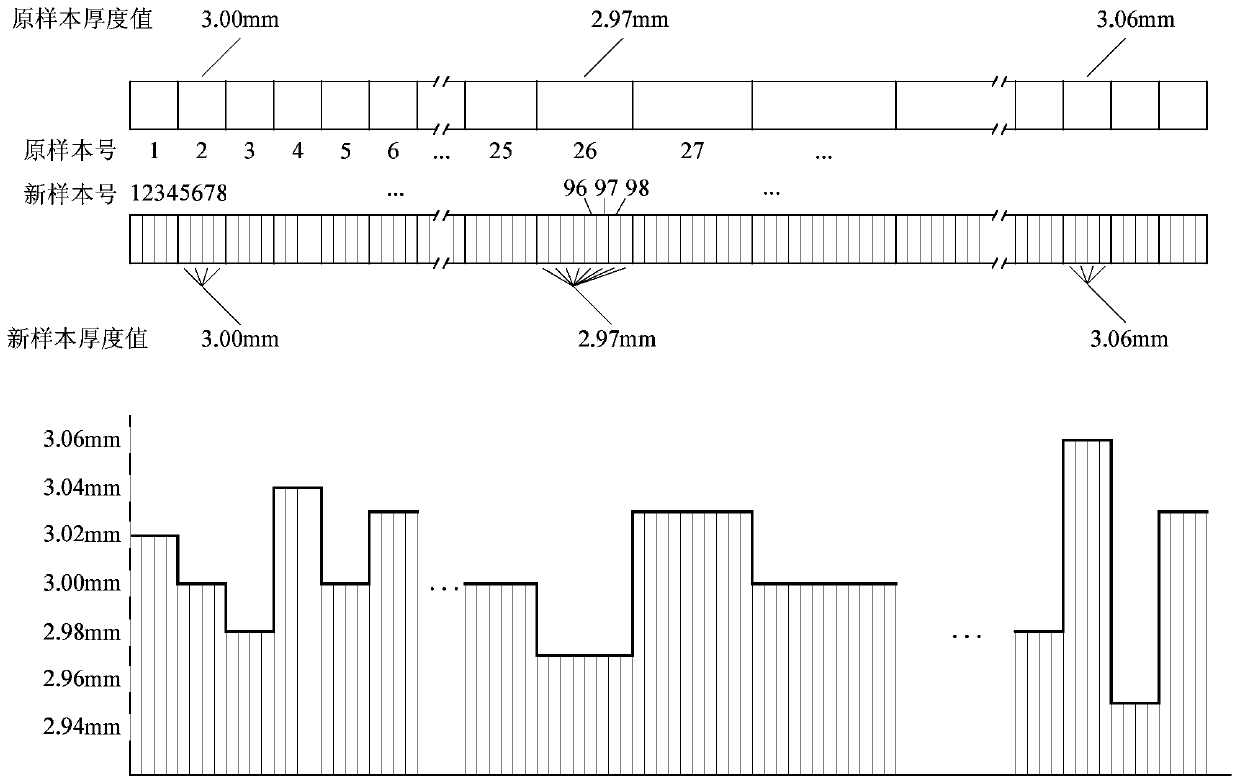

Plate and strip rolling process on-line quality judgment method

ActiveCN110404977AImprove product qualityReduce production investment costsRoll mill control devicesMeasuring devicesAutomatic controlMeasuring instrument

The invention provides a plate and strip rolling process on-line quality judgment method, and relates to the technical field of rolling automatic control. According to the method, after measured dataare obtained from a thickness measuring instrument, sampling point dividing is carried out again according to the reference length by calculating the sampling length corresponding to sampling points,the standard deviation and the yield of the thickness quality of all parts of a head, a body and a tail of a rolled piece, comparison with the target yield is made, and grades of qualified products and non-qualified products are obtained; and subsequent processing suggestions are further given to the rolled piece in manners of cutting and slitting the head and the tail and the like. The plate andstrip rolling process on-line quality judgment method can conduct comprehensive judgment the thickness quality of the rolled piece, solves the deficiency existing in a traditional thickness determination mode and provides an effective means for online judgment of the thickness quality of hot rolled products.

Owner:NORTHEASTERN UNIV

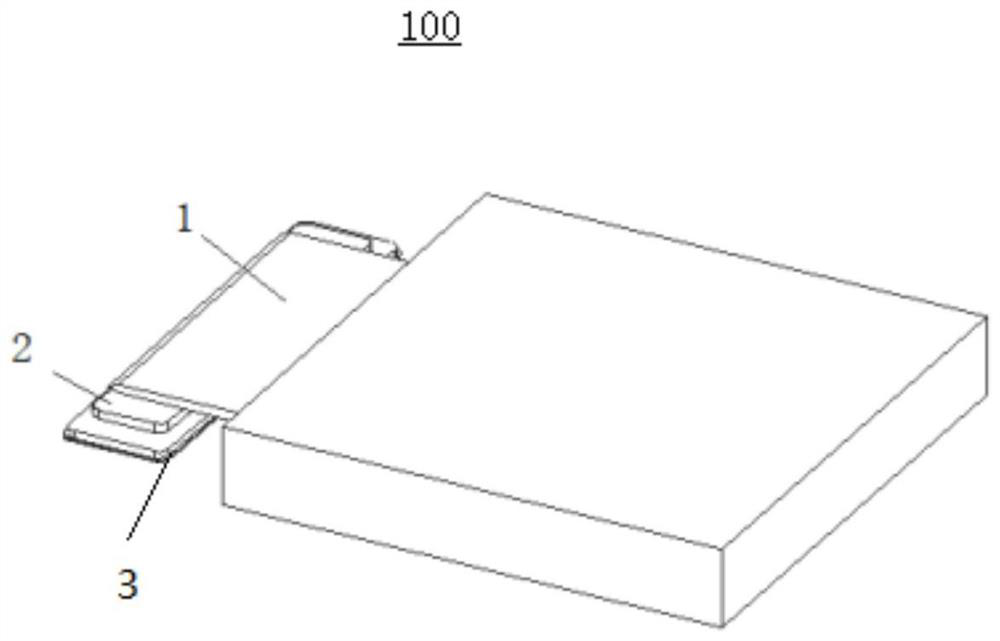

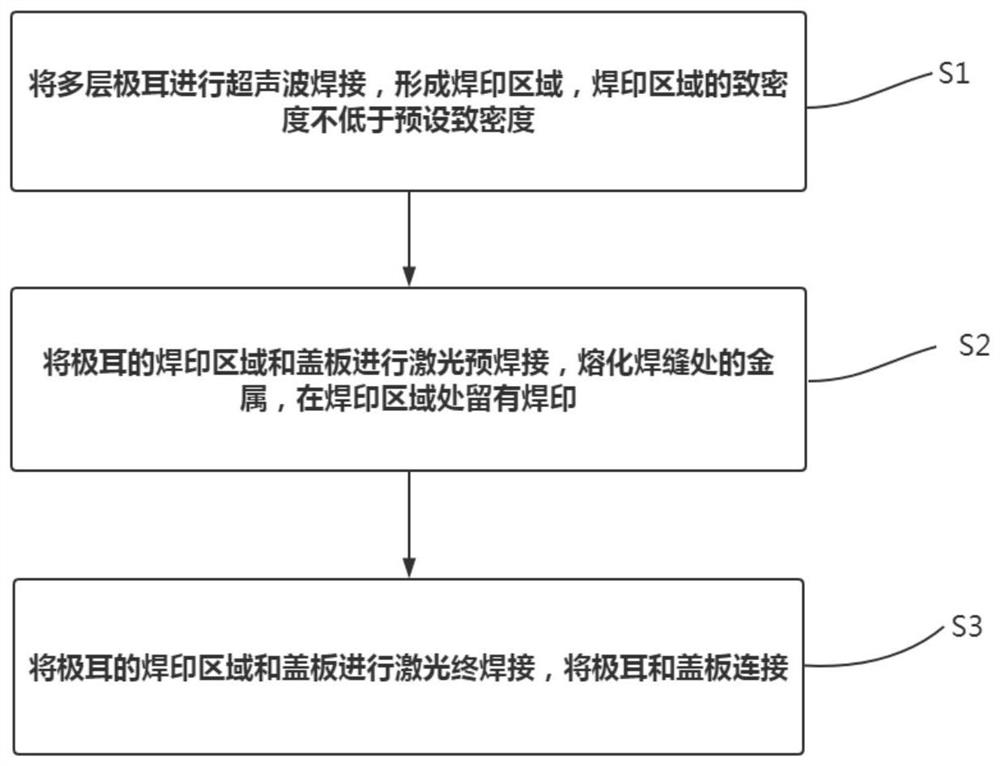

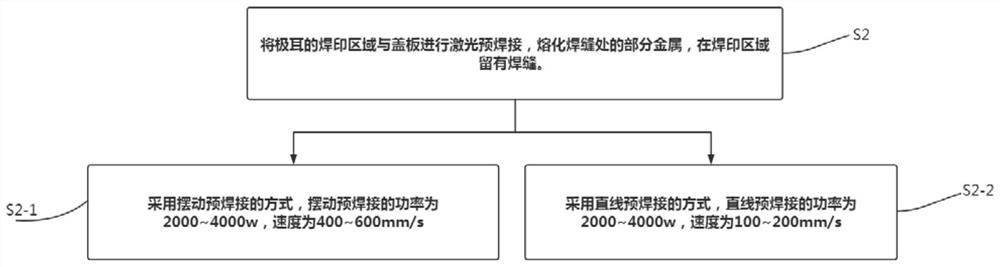

Welding method of tabs and cover plate and battery assembly

PendingCN113458635AEasy to connectReduce investmentCell component detailsWelding/soldering/cutting articlesUltrasonic weldingElectrical battery

The invention discloses a welding method for tabs and a cover plate and an electrode assembly. The welding method comprises the following steps: carrying out ultrasonic welding on multiple layers of tabs to form a welding printing area, wherein the density of the welding printing area is not lower than preset density; carrying out laser pre-welding on the welding area of the tabs and the cover plate, melting part of metal at a welding seam, and reserving a welding mark at the welding area; and performing laser final welding on the welding area of the tabs and the cover plate, and connecting the tabs with the cover plate. Therefore, according to the welding method, the tabs can be directly connected with the cover plate without adding a protection sheet and a transition sheet, so that the weight of a battery can be reduced, the volume specific capacity and the weight specific capacity of the battery are improved, the pseudo soldering risk is reduced; and meanwhile, the whole technological process can be optimized, a protection sheet manufacturing process and a transition sheet process are omitted, the production process can be simplified, and the battery production cost can be reduced.

Owner:BYD CO LTD

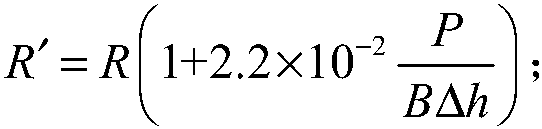

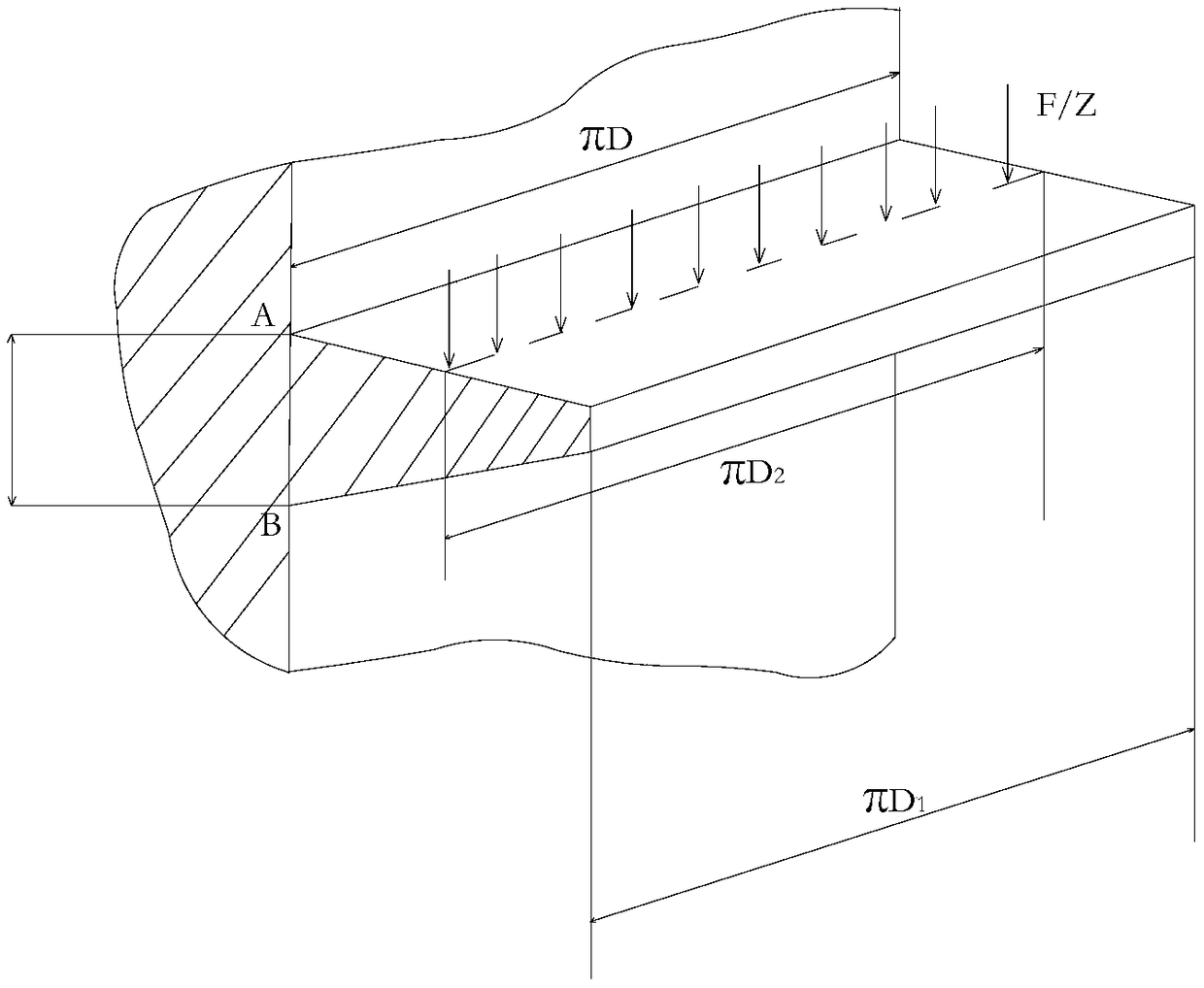

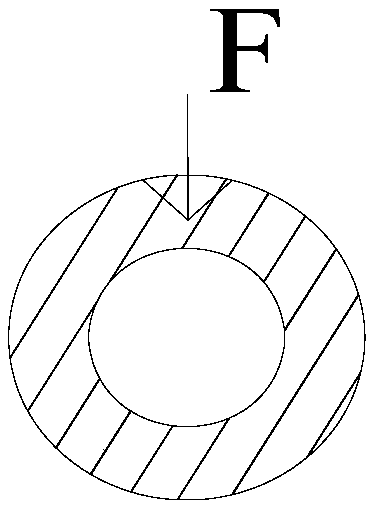

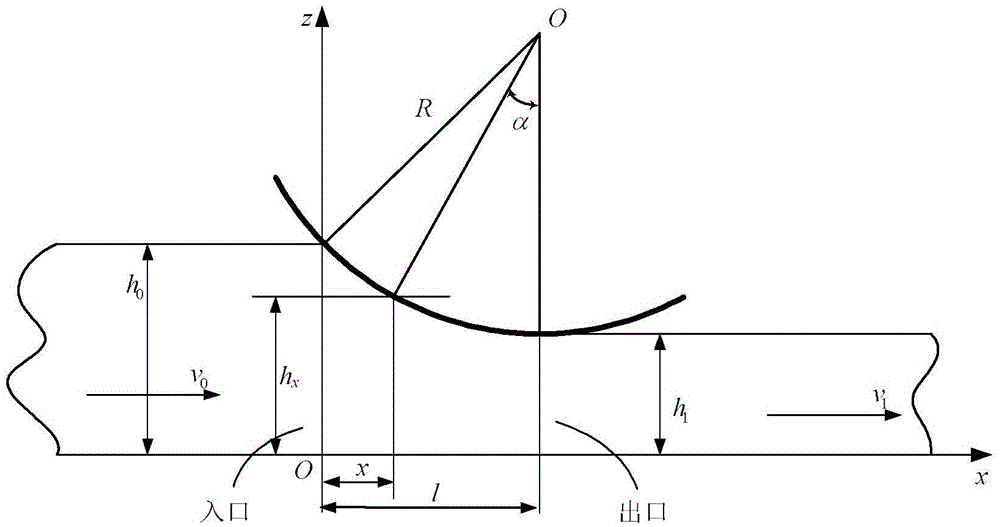

Hot-rolled strip steel width prediction method

ActiveCN105583238ASolve the problem of predicting the widening of slab after rollingAccurate calculationMeasuring devicesMetal rolling arrangementsStrip steelHot rolled

The invention provides a hot-rolled strip steel width prediction method. The hot-rolled strip steel width prediction method comprises the following steps: an outlet thickness, an inlet thickness, an inlet width and an inlet temperature of a hot-rolled plate blank are determined according to technological procedure data in one pass of hot rolling; an inlet speed of the hot-rolled plate blank and a roller speed are detected to obtain a roller radius and a friction factor between a roller and the plate blank; and a strip steel after-rolled width is predicted by using a width prediction model of the hot-rolled plate blank in any position of a rolling deformation area. The hot-rolled strip steel width prediction method predicts the broadening condition of the hot-rolled steel strip; the obtained strip steel after-rolled width is more close to an actual scene value; and the hot-rolled strip steel width prediction method has theoretical value and actual application value incapable of being replaced by a numerical value fitting method. On the basis of comprehensively considering all process parameters in the rolling process, the hot-rolled strip steel width prediction method precisely predicts the strip steel after-rolled width in the rolling process, and solves the problem of prediction of the plate blank after-rolled width under different production conditions. The hot-rolled strip steel width prediction method can obtain the after-rolled width through online calculation, and improves the width control precision when saving the production investment cost.

Owner:NORTHEASTERN UNIV

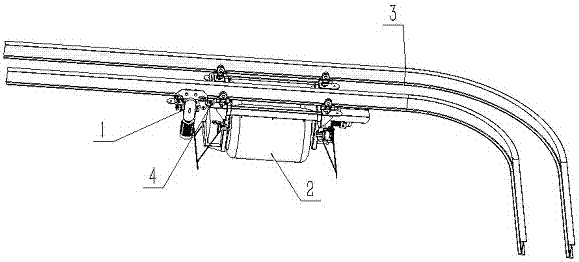

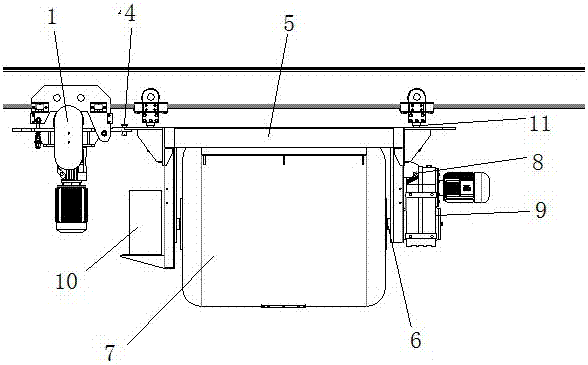

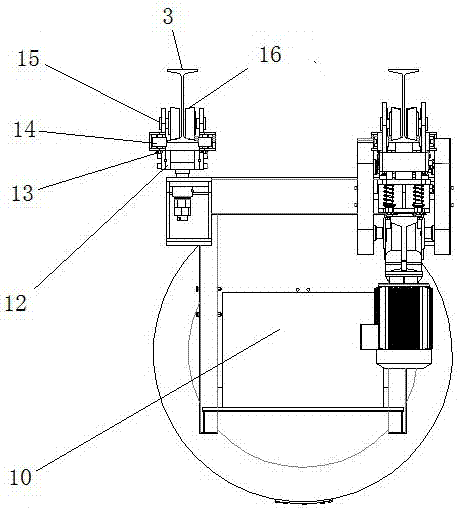

High-speed concrete transportation equipment

The invention relates to high-speed concrete transportation equipment. The high-speed concrete transportation equipment is characterized in that a power distribution cabinet (10) is mounted on one side of a main frame (5); a rotary driving speed reducer (9) is fixed on the other side of the main frame (5); a storage tank (7) and a rotating main shaft (6) finish a rotating action under the effect of the rotary driving speed reducer (9); driven walking wheels (16) are respectively mounted on two inner sides of an operation rail (3); a power device (1) uses a driving rubber wheel fixed frame (24) as a main body; a walking driving speed reducer (23) is fixed at the bottom of the driving rubber wheel fixed frame (24); a high-speed shuttle carrier (2) and a power combination (1) are connected through a connecting pin shaft (4); and the power device (1) drives the whole high-speed shuttle carrier (2) to drive on the operation rail (3). The high-speed concrete transportation equipment is fast in transportation speed and high in efficiency, effectively improves the production field environment, improves the production efficiency, reduces the production cost, and improves the production safety.

Owner:DEZHOU HAITIAN ELECTROMECHANICAL TECH

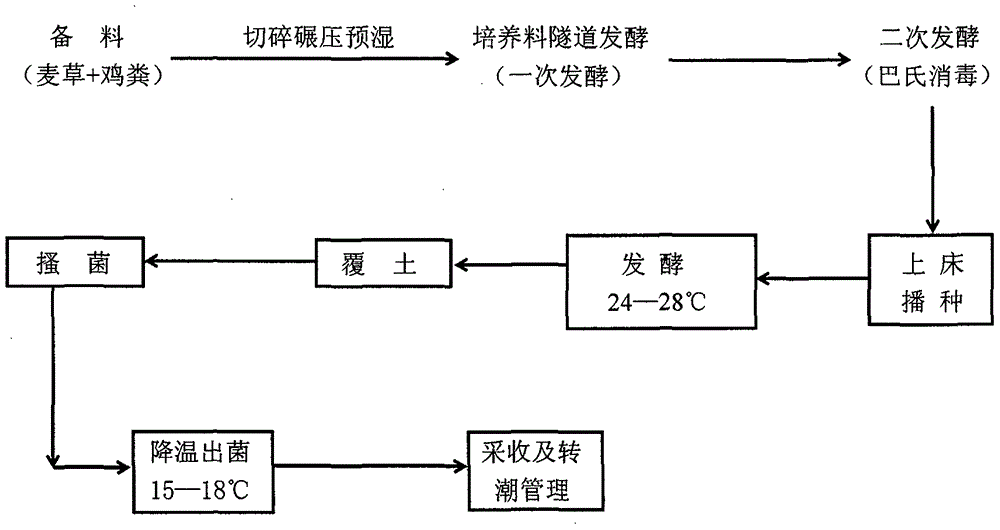

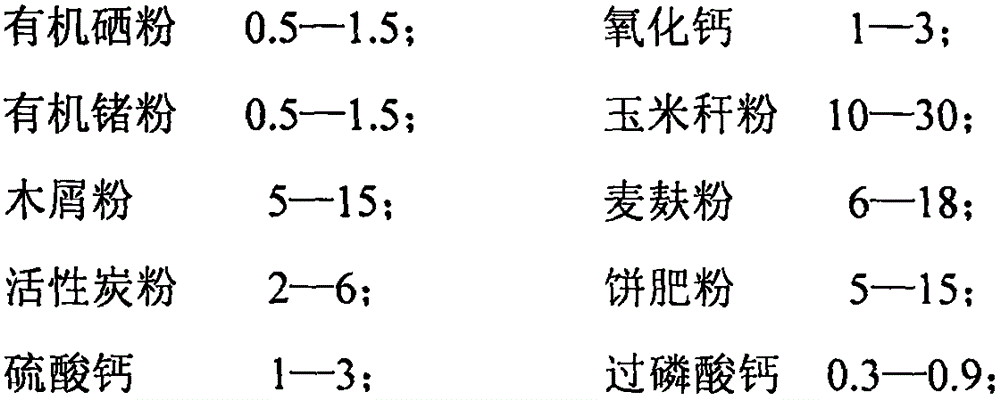

Method for industrial cultivation of base materials used for selenium-rich domestic fungi from industrial and agricultural waste residues, straw and manure

InactiveCN105948883ABacteria fastFruiting earlySuperphosphatesCalcareous fertilisersPlant stalkAgricultural engineering

The invention discloses a method for industrial cultivation of base materials used for selenium-rich domestic fungi from industrial and agricultural waste residues, straw and manure, belonging to the field of peasant-benefiting production and utilization technology for selenium-rich domestic fungus base materials produced through scientific industrial cultivation. A base material for oyster mushrooms is cultivated from slag and corn stalk. Waste alkaline residues and sugar grass stalk are used for cultivation of a base material for Lentinula edodes. Waste ferromanganese slag and bean stalk are used for cultivation of a base material for Pleurotus nebrodensis. Waste cobalt molybdate slag and castor-oil plant stalk are used for cultivation of a base material for Coprinus comatus. Waste ferrosilicon slag and sesame stalk are used for cultivation of a base material for Pleurotus eryngii. Waste zinc slag and tobacco stalk are used for cultivation of a base material for Agaricus brasiliensis. Blast furnace slag and dried wheat straw are used for cultivation of a base material for Agaricus bisporus. Rare earth element slag and manure-free amino acid fertilizer are used for cultivation of a base material for Agaricus bisporus. The method employing concentrated fermentation in an industrial production mode is simple and easy to operate, saves labor, time and energy, improves the quality of the base materials, reduces labor intensity of peasants in cultivation of mushrooms, guarantees yield increase, income increase and the quality of fresh mushrooms, overcomes problems in recycling of industrial and agricultural waste, enhances environmental pollution, increases the income of peasants and improves human health.

Owner:NANTONG SNAKEBITE THERAPY INST

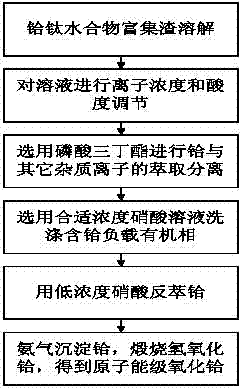

Method for preparing hafnium oxide from hafnium-titanium enrichment slag

The invention provides a method for preparing hafnium oxide from hafnium-titanium enrichment slag. The method comprises: 1, dissolving hafnium-titanium enrichment slag with 65% concentrated nitric acid; 2, adjusting the hafnium ion concentration and the acidity of the solution obtained in the step 1; 3, carrying out extraction separation on hafnium and other impurity ions in the solution obtained in the step 2 by selecting tributyl phosphate; 4, washing a hafnium-containing loaded organic phase; 5, carrying out reverse extraction on the loaded organic phase obtained in the step 4; and 6, introducing ammonia gas and precipitating hafnium, and calcining hafnium hydroxide to prepare the atomic level hafnium oxide. The method of the present invention has characteristics of short process, low investment cost, low production cost, high product purity, high added value, wide promotion application value, and the like.

Owner:XIAN RAREALLOYS

A kind of vanadium nitrogen alloy and preparation method thereof

The invention belongs to the technical field of metallurgy and particularly relates to vanadium-nitrogen alloy and a preparation method thereof. The problems that vanadium-nitrogen alloy prepared through low-density vanadium trioxide is too low in purity and the like in the prior art are solved. The preparation method of the vanadium-nitrogen alloy comprises the steps of material grinding, material mixing, forming, pellet calcinating and the like. According to the preparation method of the vanadium-nitrogen alloy, raw material composition and proportioning are adjusted; vanadium pentoxide and an iron-based sintering auxiliary are added; the carbon thermal reduction reaction gibbs free energy is reduced through the vanadium pentoxide, and the nitriding deoxidizing process is promoted; the contact wetting angle of liquid Fe3C generated through reaction between the iron-based sintering auxiliary and graphite powder and a carbide is small, and the wetting effect is obvious; liquid phase intensifying sintering is conducted, so that the density of the vanadium-nitrogen alloy is improved; and the preparation method is easy to operate, free of waste and capable of significantly reducing the production cost.

Owner:SICHUAN PAN YAN TECH

Synthesis method of m-xylylene diisocyanate (MXDI)

InactiveCN108484447AReduced reaction stepsReduce production investment costsOrganic compound preparationIsocyanic acid derivatives purification/separationSolventChemistry

The invention relates to the field of chemical products and chemical processes, in particular to an improved synthesis method of m-xylylene diisocyanate (MXDI). The method comprises the following steps: dropwise adding a m-xylylenediamine solution to a solid phosgene solution for reflux reaction, then dropwise adding another solid phosgene solution, performing continuous reaction under reflux state, cooling a product to room temperature, removing a solvent under reduced pressure, and rectifying to obtain MXDI. The method provided by the invention adopts direct solid light synthesis, and does not need to form salt, thereby reducing reaction steps and greatly lowering the production investment cost; with a clustering rectification manner, the equipment requirement is lowered by the increasedtower-to-tower diameter ratio, and no large rectifying tower is needed, so that the investment in utilities of steam, heat transfer oil and the like are extremely reduced while the production demandis satisfied. MXDI prepared by the method has the purity in 99.5% or higher, is colorless and transparent liquid, is high yield, and has strong market competitiveness.

Owner:江阴市万丰化工物资有限公司

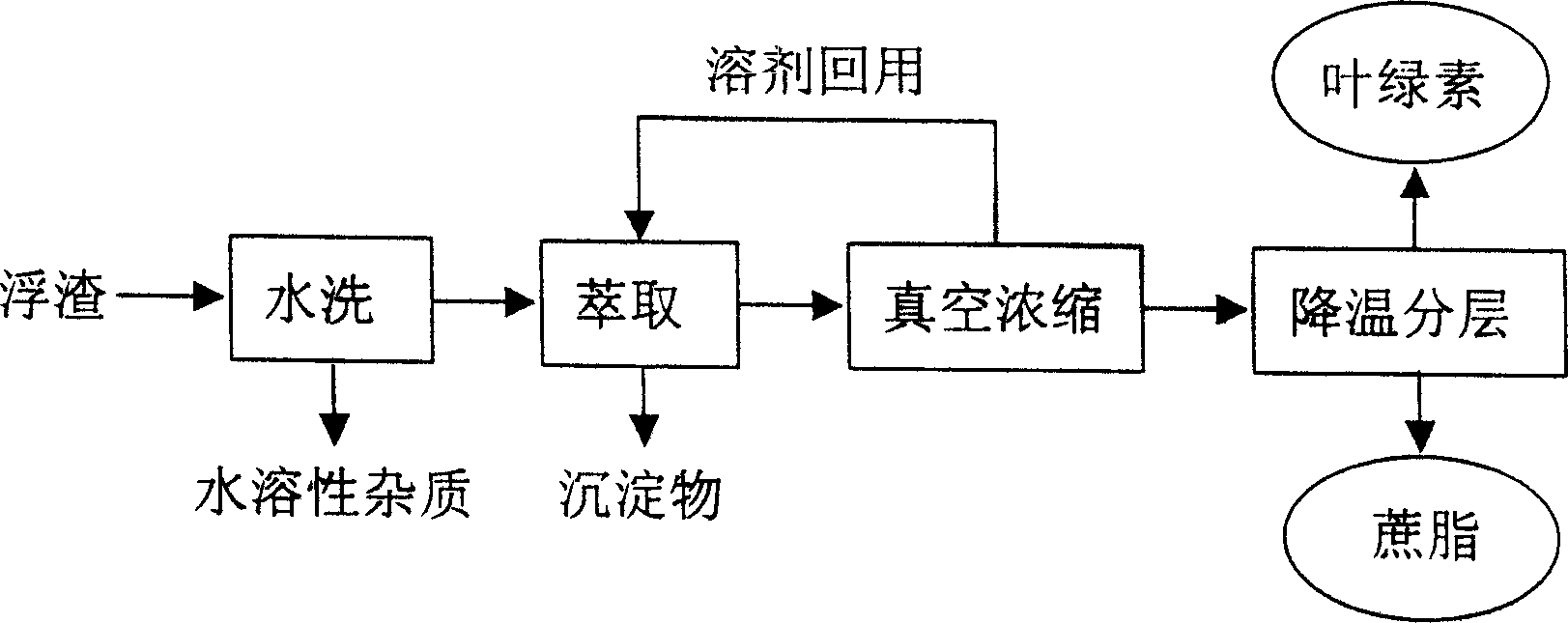

Method for concurrent extracting sugarcane fat and chlorophyll from dross in sugar-refiney by using solvent

InactiveCN1563009AReduce consumptionImprove recovery rates and product qualityZinc organic compoundsSolventChemistry

Sugar refinery floater is washed, and then added with organic solvent, then separating extraction liquid, recovering solvent, to obtain cane fat and chlorophyll. In this invention, utilized are the differences of oil-dissolving property, smelting points and solubilities in solvents of cane fat and chlorophyll to proceed parallel separation. Due to the floater treatment is placed in front of clarification, the negative affect of organic non-sugar matter such as cane-fat and chlorophyll to sugar-prodn. is eliminated. This invention prodn. method has advantages of: high product quality, low cost, suitable for phosphorous floating method, or up-floating and sulfurous acid method (or carbonic acid method) combination sugar refinery.

Owner:GUANGXI UNIV

Polyurethane lining plate and preparation method thereof

The invention relates to a polyurethane lining plate and a preparation method thereof, and belongs to the field of wear-resistance protection of equipment. The polyurethane lining plate consists of a prepolymer and a curing agent containing an ether bond at a weight ratio of 100 to (8-12), wherein the prepolymer is prepared from the following raw materials in parts by weight of 100 parts of polyhydric alcohol, 35-50 parts of isocyanate, 5-10 parts of silicon carbide particles, 0.3-0.8 part of an organotin catalyst and 0.04-0.15 part of a coupling agent. With the adoption of the polyurethane lining plate provided by the invention, the structural strength of a polyurethane elastomer is improved and the hydrolysis property of the polyurethane elastomer is reduced; the wear resistance of the product is effectively improved; the softness of the ether bond is improved and the rigidity of the ether bond is realized, so that not only can various physical and mechanical properties of the elastomer be ensured, but also the hydrolysis resistance stability and strength of the polyurethane lining plate are improved, the impact deformation is prevented and the more firm structure is realized; the mounting and dismounting processes are simple and convenient, the processing intensity of an inner liner of the equipment is reduced, and the lining plate is convenient to replace; the shut-down time for maintenance of the equipment is shortened, the investment cost caused by equipment production is reduced, and the production efficiency is improved.

Owner:BIRTLEY TIANJIN IND EQUIP

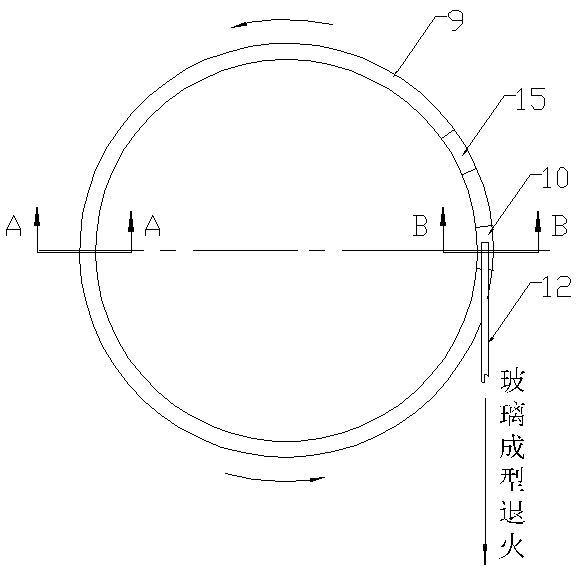

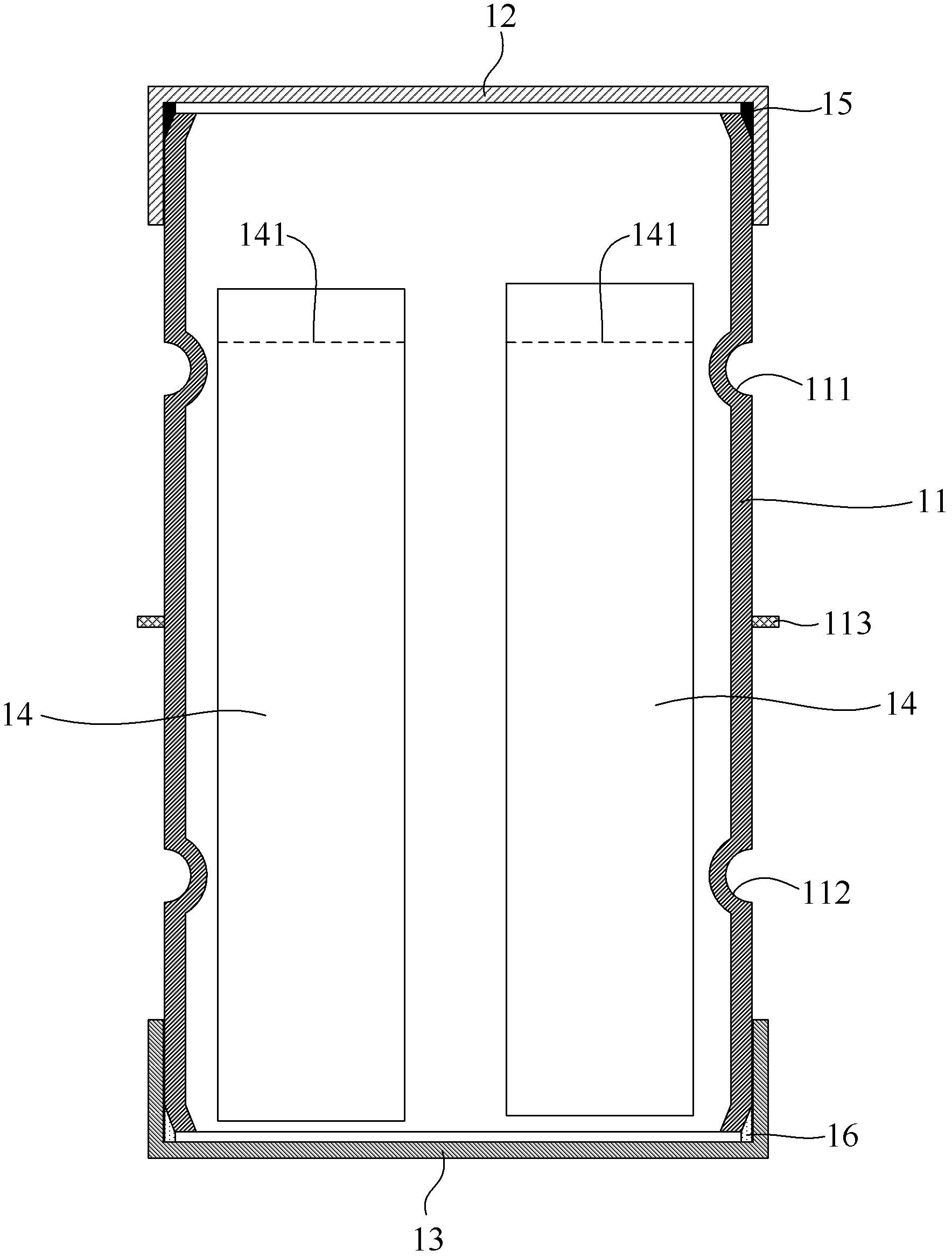

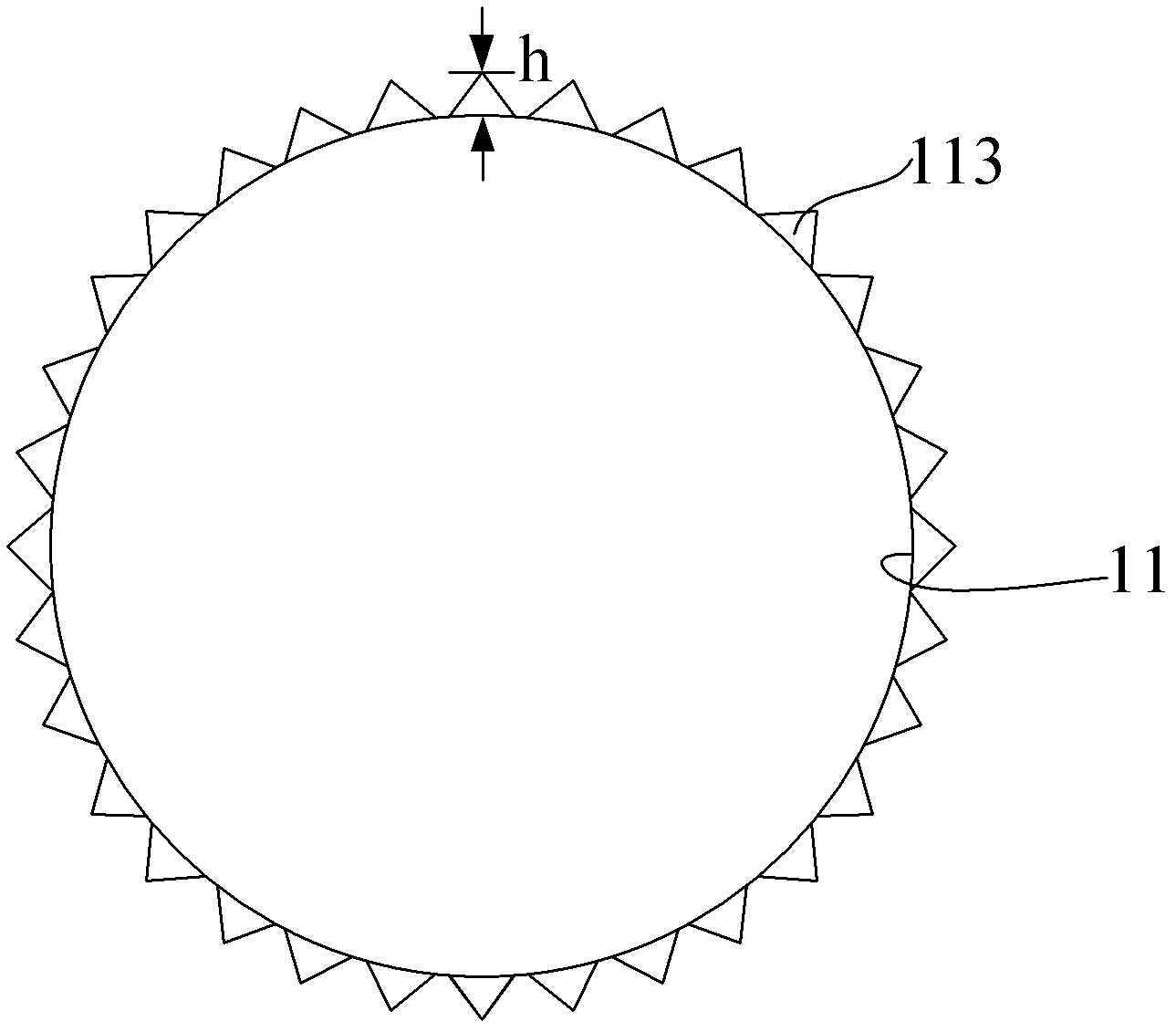

Dielectric material continuous microwave sintering or melting forming method and equipment

InactiveCN110375543AEmission reductionReduce pollutionScreening rooms/chambersRotary drum furnacesMicrowave ovenRefractory

The invention provides a dielectric material continuous microwave sintering or melting forming method and equipment. The dielectric material continuous microwave sintering or melting forming method ischaracterized in that structure layers which comprise a metal shell microwave reflection material layer / a heat preservation material layer / a microwave transmission refractory material layer are adopted to combine and form a furnace bottom structure of a microwave oven; the furnace bottom is enabled to continuously run, and through a feeding hole formed in the top of a static fixed furnace top, dielectric raw materials which are required to be sintered or fused, and can absorb microwaves are continuously and uniformly laid and covered on the microwave transmission refractory material layer; and through a microwave source arranged on the static and fixed furnace top or the furnace side, microwaves are guided into a furnace cavity of the microwave oven, and the microwaves are uniformly radiated on the furnace bottom through direct irradiation and reflection; and the dielectric raw materials at the uppermost layer at the bottom of the furnace are heated by first absorbing microwaves, andthe microwaves which are not completely absorbed are finally absorbed by the dielectric raw materials after being reflected in the metal shell in the oven cavity of the microwave oven, so that the purpose of sintering or melting the dielectric raw materials capable of absorbing the microwaves at normal temperature is achieved.

Owner:徐林波

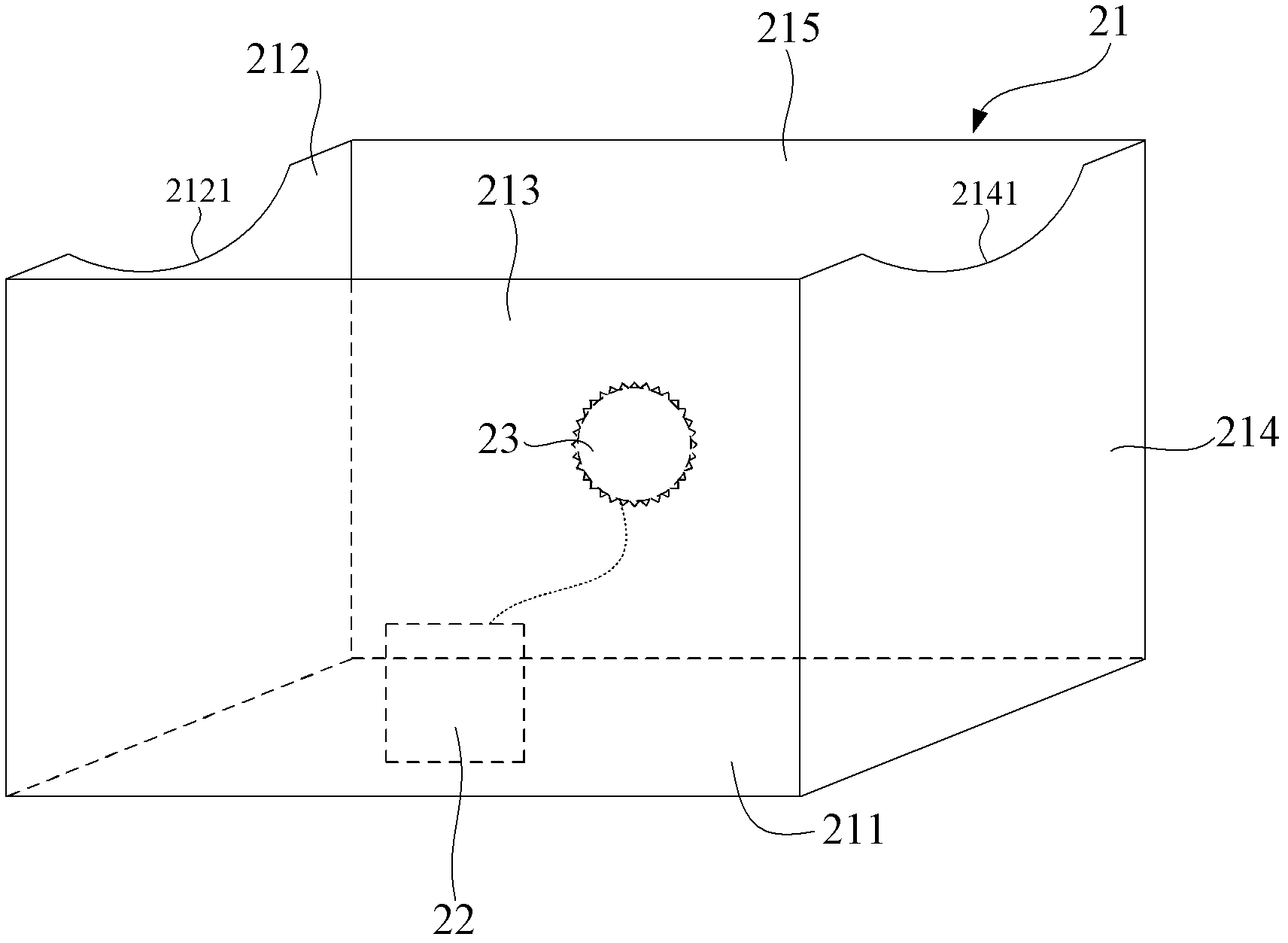

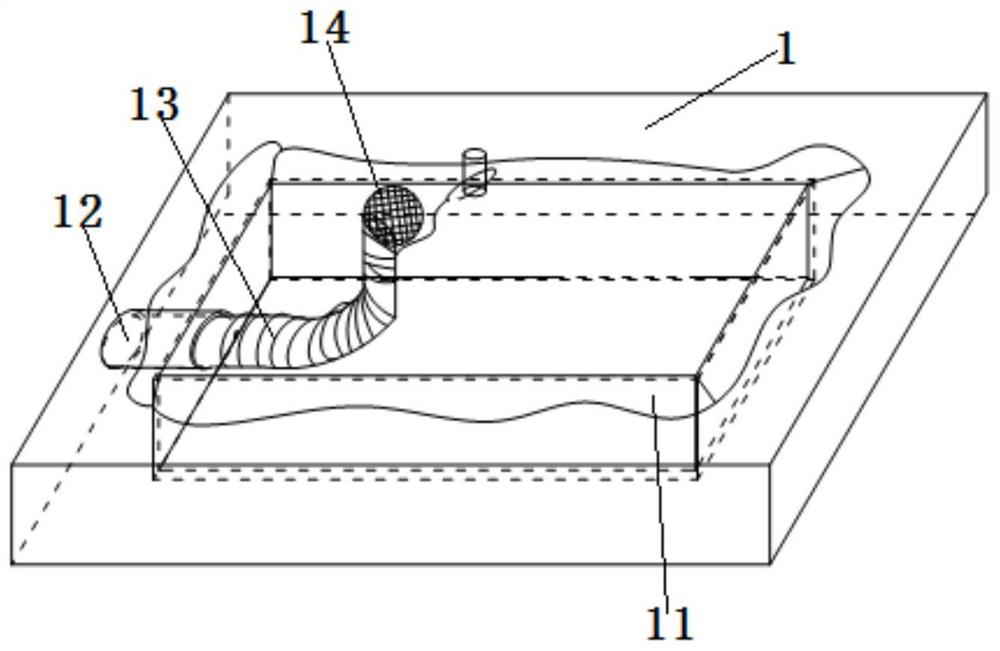

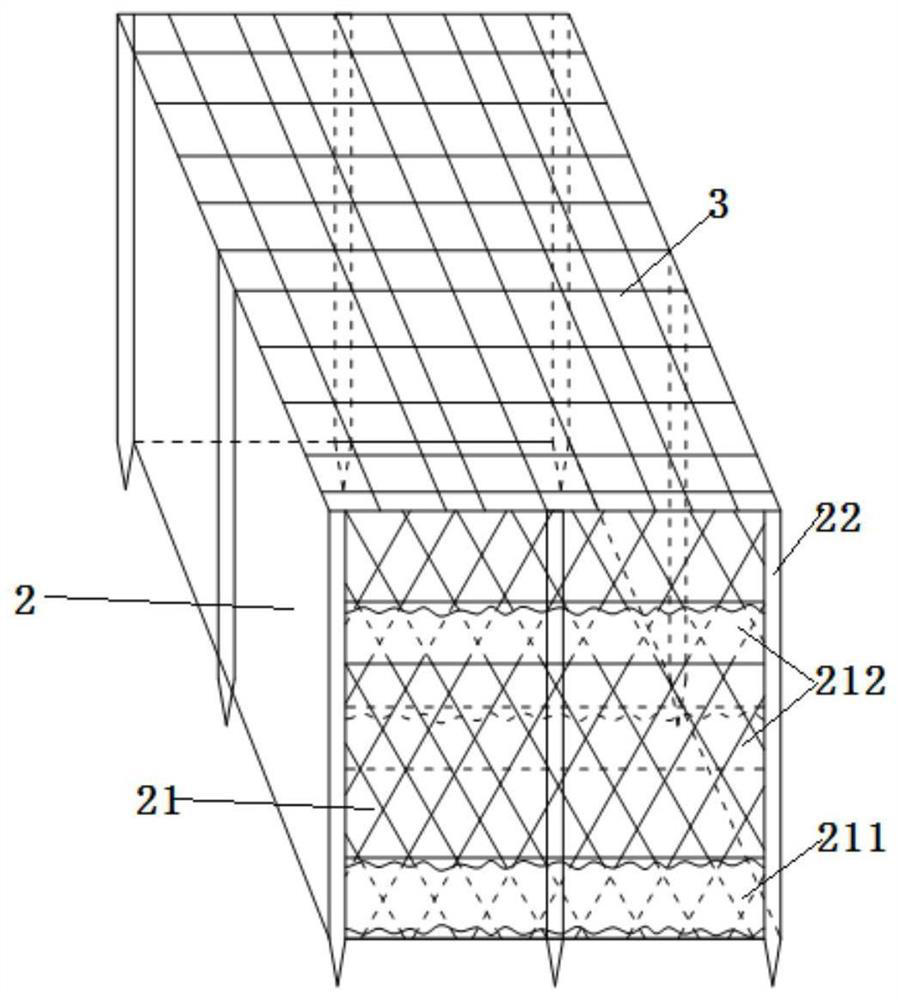

Container, system and method for blending mixture

ActiveCN102872742AImprove reliabilityEliminates the step of weighing individual componentsRotating receptacle mixersTransportation and packagingEngineeringMechanical engineering

The invention relates to a container, a system and a method for blending a mixture. The container comprises a container body and accommodating bags, wherein the accommodating bags are arranged in the container body; the container body comprises a body, a first end cover and a second end cover; the first end cover and the second end cover are arranged at two ends of the body respectively and are hermetically connected with the body; a first annular groove, a second annular groove and an annular gear rack are arranged on the outer side wall of the body; the annular gear rack is positioned between the first annular groove and the second annular groove; and each component of the mixture to be blended is accommodated in the respective accommodating bag hermetically, and the weight of each component meets the requirement of the blending ratio of the mixture to be blended.

Owner:SEMICON MFG INT (SHANGHAI) CORP

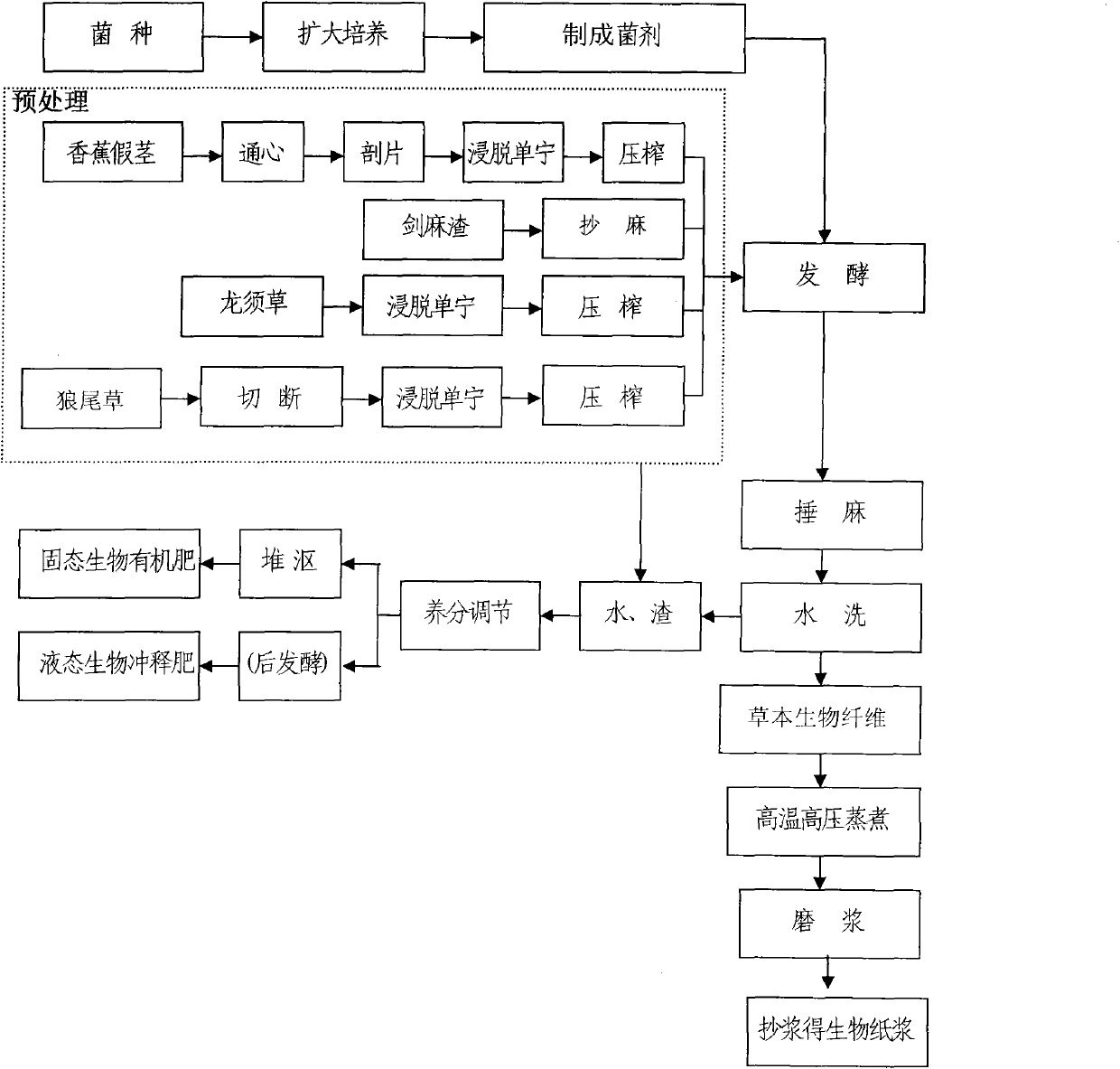

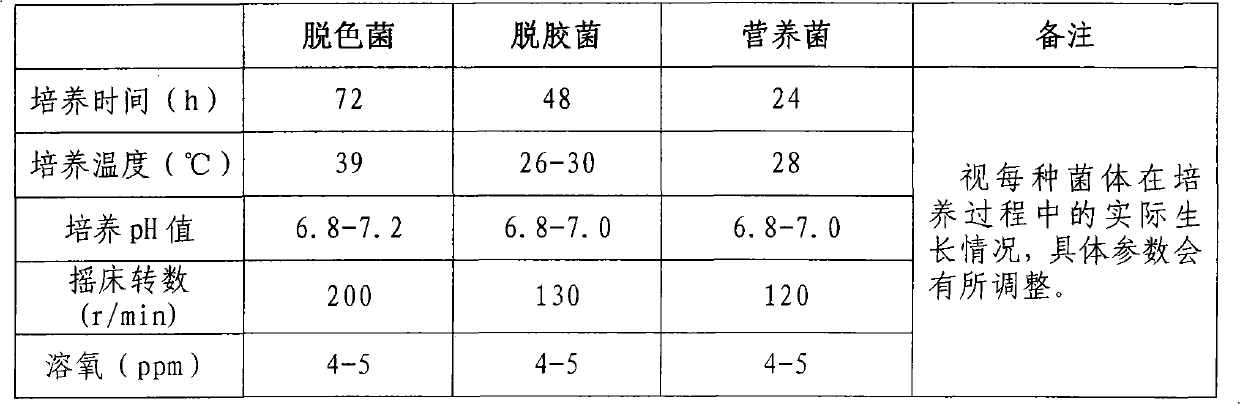

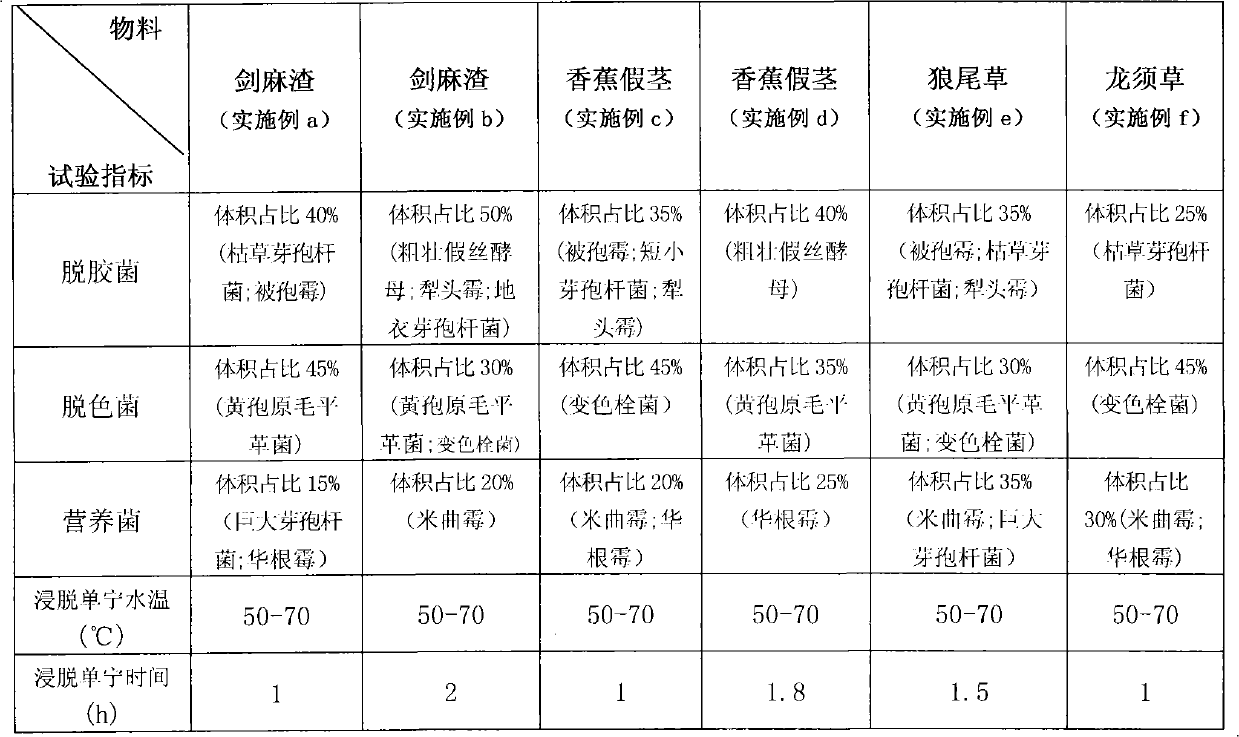

Method for preparing herbal biological fiber and biological paper pulp

InactiveCN102174399BNo antagonistic effectRealize industrial productionFungiBio-organic fraction processingBiotechnologyCellulose

Owner:GUANGXI SAIER PAPER IND

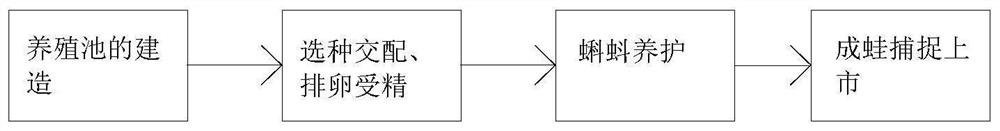

Artificial breeding method of rana nigromaculata

The invention discloses an artificial breeding method for rana nigromaculata, and belongs to the technical field of frog breeding. The artificial breeding method comprises the following steps of (1) breeding pond building; (2) seed selection, mating, ovulation and fertilization; (3) tadpole caring; and (4) adult frog catching for marketing. According to the artificial breeding method, the rana nigromaculata is ecologically and industrially bred in a natural ecological environment, the breeding yield of the rana nigromaculata is greatly increased, the rana nigromaculata is conveniently fed by utilizing the controllability of the growth cycle of hermetia illucens larvae, the growth and development of the rana nigromaculata are accelerated due to the rich nutritional value, the disease resistance and stress resistance are enhanced, and the feed cost is reduced; and meanwhile, breeding water in the breeding pond cannot be polluted, real green ecological breeding is achieved, and the methodhas the characteristics of being simple in breeding technology, low in production investment cost, convenient to breed and manage, good in controllability, purely natural, free of pollution and the like, and has wide market prospects.

Owner:淮南市九方皋科技咨询有限公司

Process for extracting Ga from Ga-containing ore

The invention relates to a method for extracting gallium in gallium-containing minerals. In the present invention, the minerals containing aluminum oxide such as bauxite are used as the extractant of gallium, and gallium is extracted into aluminum by utilizing the similar properties of aluminum and gallium, and then the existing technology is used to separate aluminum and silicon, and then the aluminum and gallium, the method of extracting aluminum and gallium respectively, therefore, the present invention fully utilizes existing aluminum smelting, gallium smelting equipment and technology, reduces technical difficulty and production investment cost, makes it easy to realize industrialized production; In addition, the present invention is due to Aluminum smelting and gallium smelting are carried out at the same time, which also reduces production costs and is conducive to improving the competitiveness of enterprises. The invention is a convenient and practical method for extracting gallium in gallium-containing minerals, which is effective and has remarkable economic and social benefits. It can be used as a method for extracting gallium from various gallium-containing minerals, or as a smelting step in the continuous smelting of gallium-containing and various metal minerals.

Owner:GUANGDONG IND TECHN COLLEGE

Production apparatus and method for liquid silicon

The invention discloses a production apparatus and method for liquid silicon. The production apparatus comprises a plasma generator, a reactor, a silicon liquid loader and a tail gas separation system, which are successively connected with each other, wherein a gas condensing zone, a liquid drop forming zone and a liquid drop growing zone are successively formed in the reactor. According to the method, a material is subjected to conversion from an atomic material to tiny silicon liquid drops to large silicon liquid drops to silicon liquid in the apparatus; most silicon substances are collectedin a liquid form; and only a small part of silicon substances form silica micropowder and are then discharged from the tail gas separation system. With the production apparatus and method in the invention, a high-purity liquid silicon material can be directly obtained; operation procedures are simple; and the liquid silicon material can be directly conveyed to a downstream ingot casting, Czochralski crystal growing or silicon wafer preparation procedure, so investment cost for polysilicon production can be greatly reduced, stable and long-term operation of the production apparatus is ensured,and output is increased.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

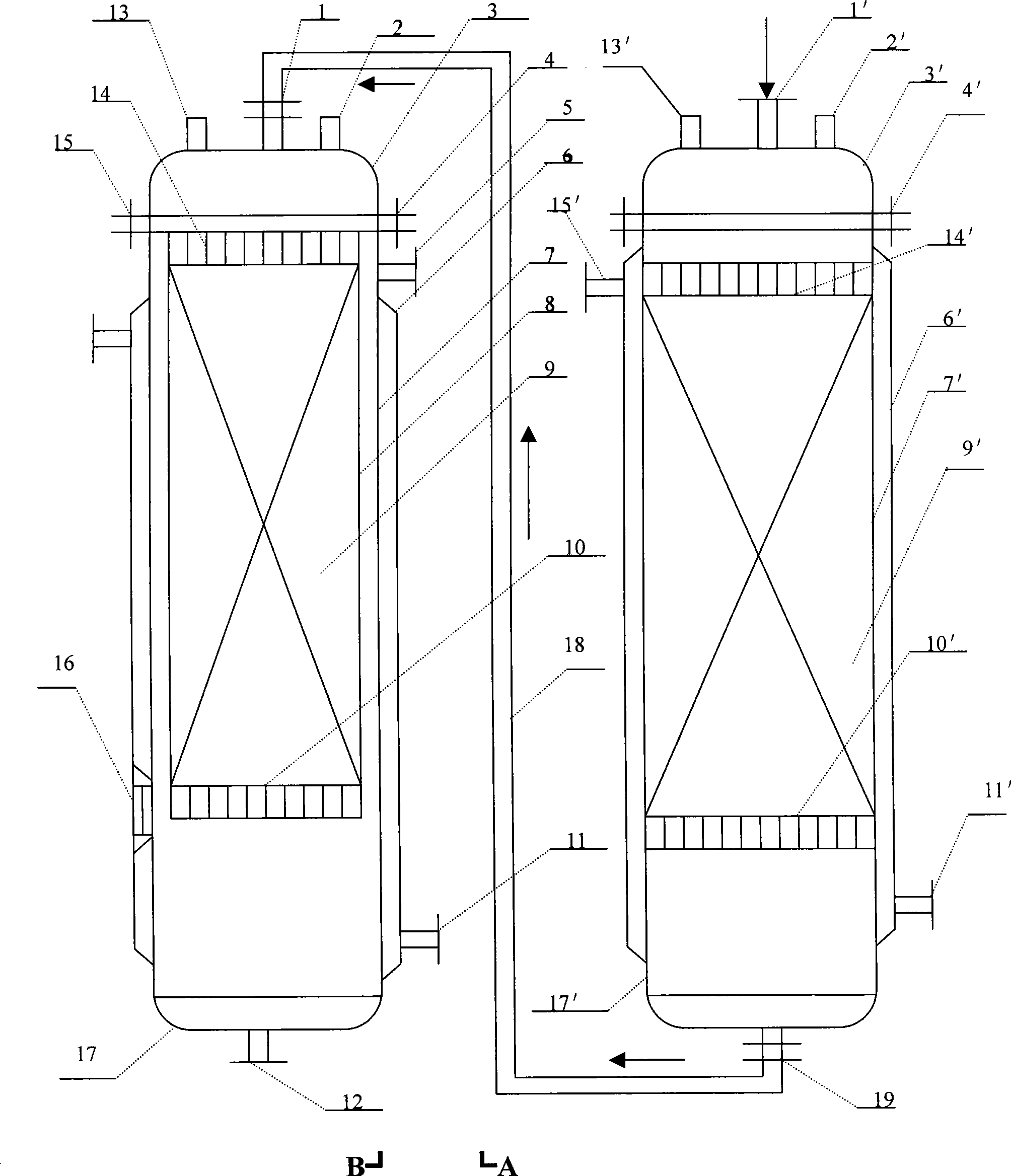

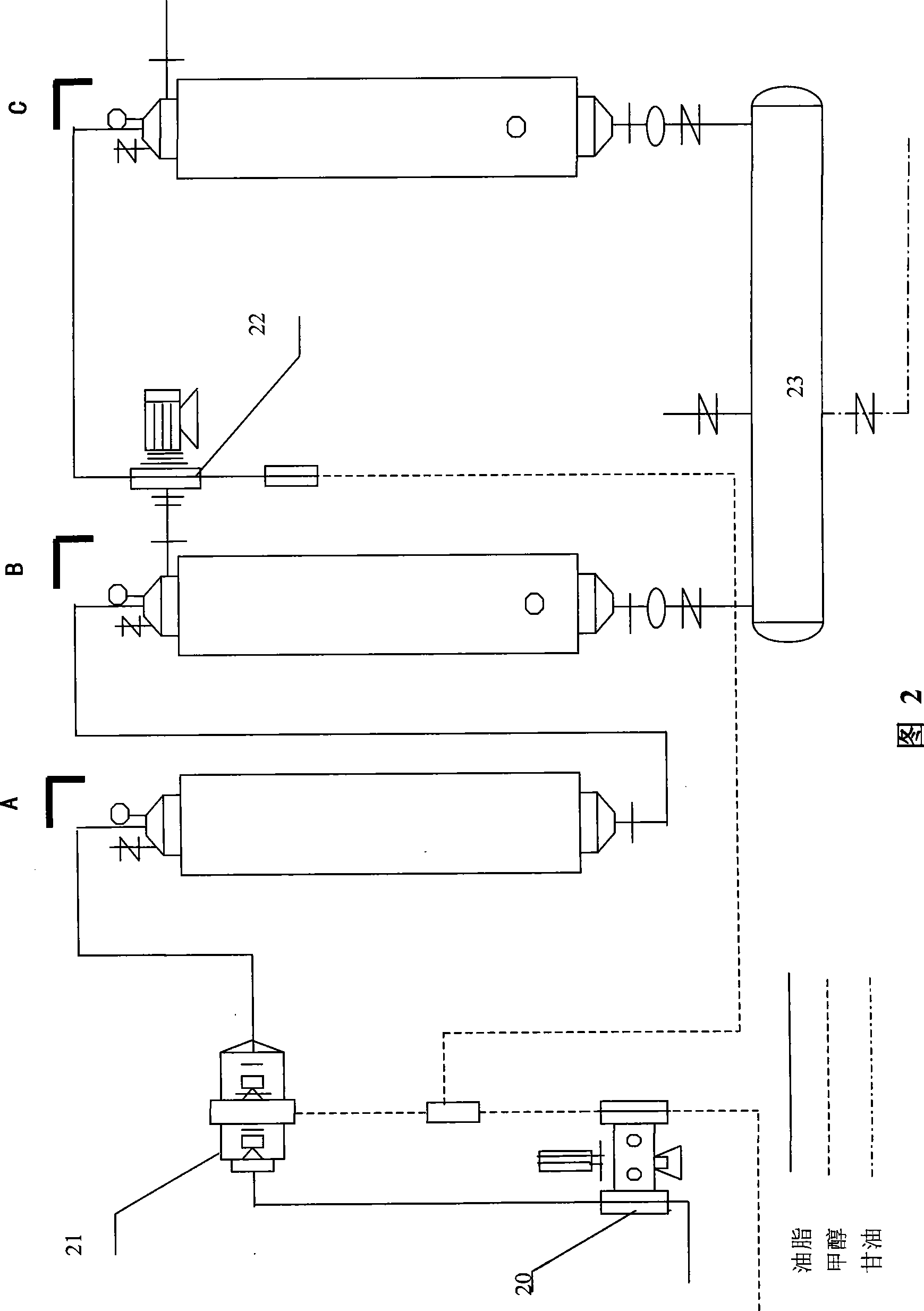

Glycerol subsidence coupling ester exchange continuous reaction apparatus

InactiveCN101423457ARealize Interface SeparationAvoid heat lossPreparation by ester-hydroxy reactionBiofuelsBiodieselGlycerol

The invention relates to a preparation device for biodiesel, in particular to a special reaction device utilizing neutral grease for an ester exchange reaction. An ester exchange continuous type reaction device is to increase a reactor behind the prior reactor; a guide flow cylinder is arranged in the reactor; a reaction product in the previous reactor enters the reactor and then passes through the guide flow cylinder in the reactor first; the bottom of the guide flow cylinder is provided with a material tray; a filler is placed on the material tray; the bottom of the reactor is provided with a glycerin outlet; and a discharge outlet at the upper part of the reactor is connected with a device for a subsequent process. Through the innovation of an internal structure of the reactor, the device realizes the effective separation of glycerin during the ester exchange reaction, improves the once-through conversion rate of the biodiesel, and simplifies the production flow.

Owner:湖南欣林生物油脂工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com