Internal resistance type metal shear-resisting yield anchor cable device

A metal and anchor cable technology, applied in the installation of anchor rods, sheet pile walls, mining equipment, etc., can solve the problems of elongation anchor cable pullout force limitation, loss of rock mass deformation energy, surrounding rock instability, etc., to achieve Low cost, prevent rock layer separation and deformation, and improve the effect of shear deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

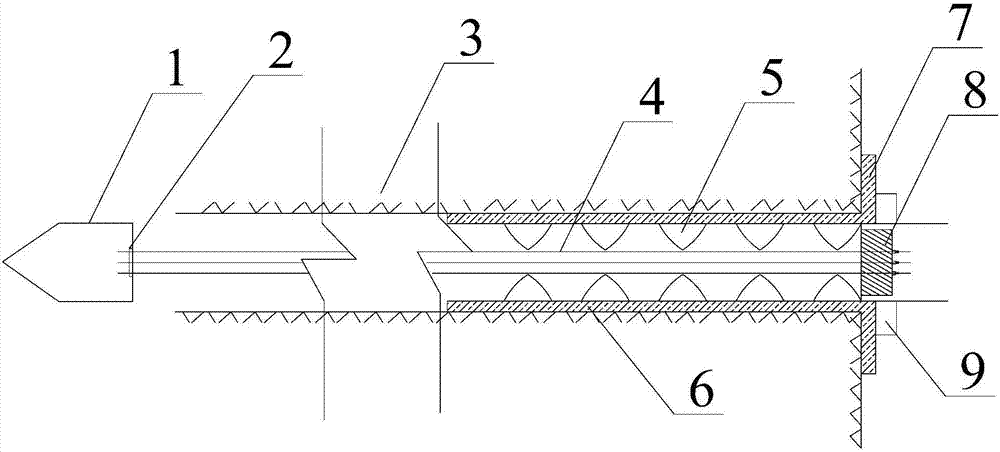

[0066] Such as image 3 As shown, it includes a fixed anchor head 1, a fixed end 2, a steel strand 4, a metal pressure ring 5, a metal protection sleeve 6, a backing plate 7, a metal deceleration head 8 and an anchor cable lock 9.

[0067] The metal protection sleeve 6 and the outer backing plate 7 are integrally molded and poured. Drilling operations are carried out in the surrounding rock 3 with a drilling machine. The fixed anchor head 1 is placed in the deep part of the surrounding rock 3 through the drill hole, and the steel strand 4 Connect the fixed end 2 and the fixed anchor head 1, insert the metal protective sleeve 6 into the surrounding rock 3 until the outer backing plate 7 catches the hole position, and apply a pre-stressed force on the steel strand 4 by installing the anchor cable lock 9 . Push the metal deceleration head 8 to the metal pressure ring 5 after the tightening force.

[0068] In order to fix the metal protection sleeve 6 inside the surrounding rock ...

Embodiment 2

[0070] Such as Figure 4 As shown, it includes a fixed anchor head 1, a fixed end 2, a steel strand 4, a metal pressure ring 5, a metal protection sleeve 6, a backing plate 7, a metal deceleration head 8 and an anchor cable lock 9.

[0071] Use a drilling machine to drill in the surrounding rock 3, the fixed anchor head 1 is placed in the deep part of the surrounding rock 3 through drilling, the steel strand 4 is connected through the fixed end 2 and the fixed anchor head 1, and the secondary reaming Insert the metal protection sleeve 6 into the surrounding rock 3 after operation, the length of the reaming range depends on the length of the metal protection sleeve, until the metal protection sleeve 6 is completely inserted into the surrounding rock 3, and the hole position is equipped with a backing plate 7 and an anchor cable lock 9 installation, after applying a pre-tightening force to the exposed steel strand 4, push the metal deceleration head 8 to the metal pressure ring ...

Embodiment 3

[0073] Such as Figure 5 As shown, it includes a fixed anchor head 1, a fixed end 2, a steel strand 4, a metal pressure ring 5, a metal protection sleeve 6, a backing plate 7, a metal deceleration head 8 and an anchor cable lock 9.

[0074] Drilling operations are carried out in the surrounding rock 3 using a drilling machine, the fixed anchor head 1 is placed in the deep part of the surrounding rock 3 through drilling, the steel strand 4 is connected through the fixed end 2 and the fixed anchor head 1, and the metal protective sleeve The barrel 6 is placed at the orifice, and there is no need to carry out the reaming operation. After applying a pre-tightening force to the exposed steel strand 4, the metal deceleration head 8 is pushed to the metal pressure ring 5.

[0075] The internal resistance type metal anti-shear pressure anchor cable device of the present invention, the metal protection sleeve 6 is inserted into the bottom end of the drilled hole to install the backing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com