Threaded metal yielding anchor rod device

A kind of technology of letting the pressure bolt and thread type, applied in the installation of bolts, mining equipment, earth-moving drilling and other directions, can solve the limitation of the tensile strength of the elongation anchor cable, the pressure can not be continuously carried out, and the deformation of the rock mass is lost. Can wait for the problem to achieve the effect of good integration, good pressure effect, and full contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

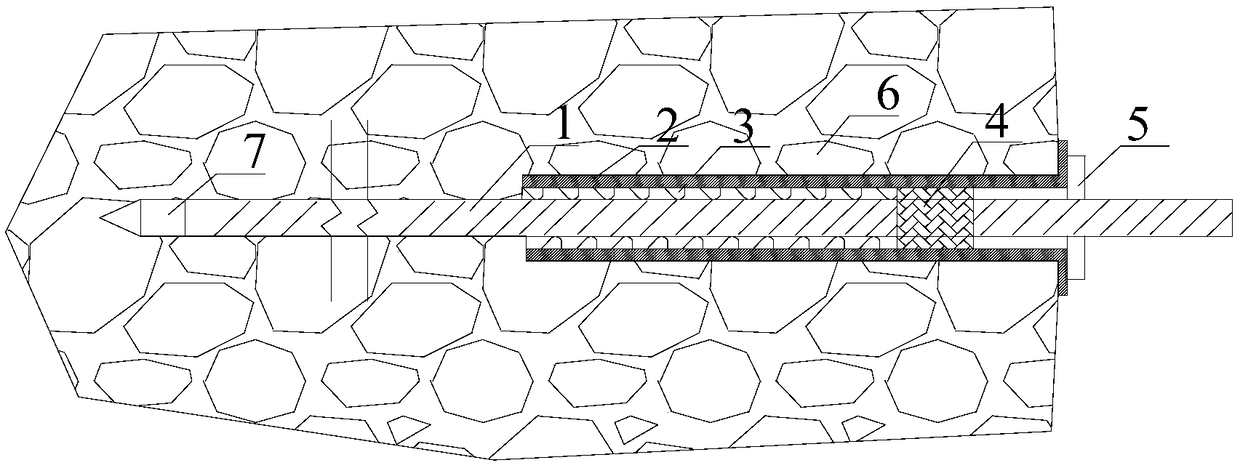

[0037] The following further describes the present invention in detail with reference to specific embodiments, which is an explanation rather than a limitation to the present invention.

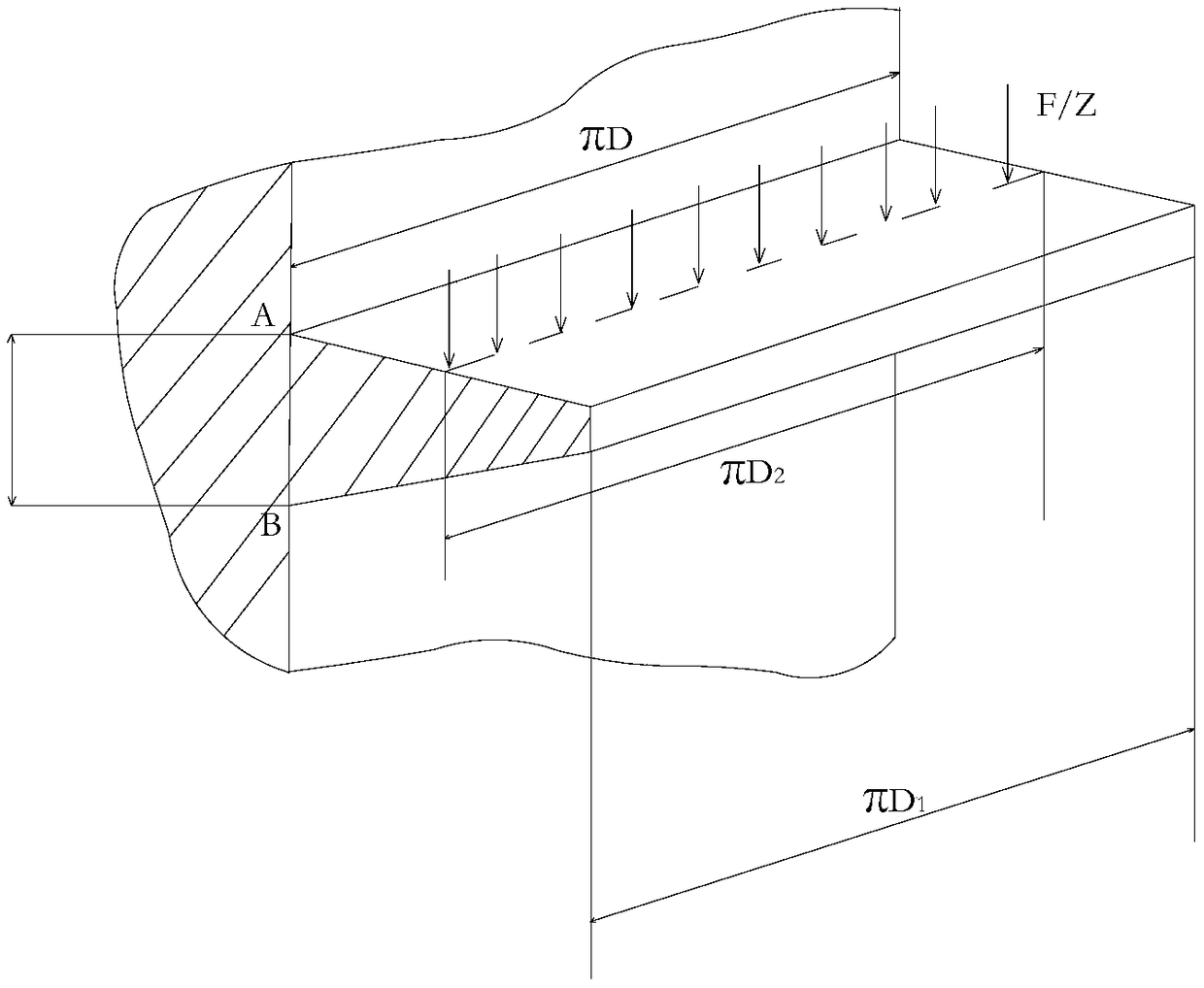

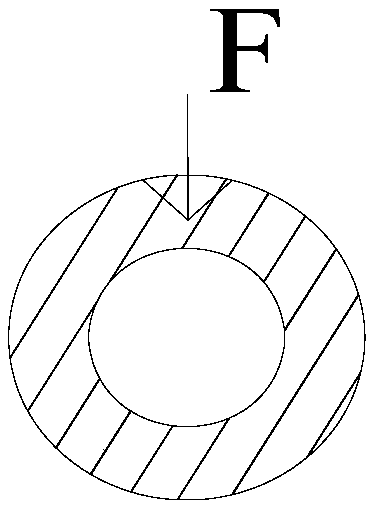

[0038] The threaded metal pressure letting bolt device of the present invention includes a fixed anchor head 7, an anchor rod body 1, a metal head 4, a metal protective sleeve 2 and a threaded pressure letting ring 3.

[0039] The thread allows the pressure ring 3 to be arranged in the metal protective sleeve 2 in the form of an internal thread, and the thread allows the pressure ring 3 and the metal protective sleeve 2 to be integrally formed. In this embodiment, a metal rod is used to directly turn a metal protective sleeve 2 with a threaded pressure ring 3 through turning. In addition, in this embodiment, the thread makes one side tooth surface of the pressure ring 3 a curved surface, and the other side tooth surface is a vertical surface perpendicular to the axial direction of the metal protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com