Automatic force application device and method for gap measurement of air-floating rotor gyroscope dynamic pressure motor

A technology of dynamic pressure motor and force application device, which is applied in the field of precise detection of aerospace inertial devices, can solve the problems of being unsuitable for rapid batch measurement and low degree of automation, and achieve the effects of avoiding errors, improving measurement efficiency, and realizing closed-loop control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

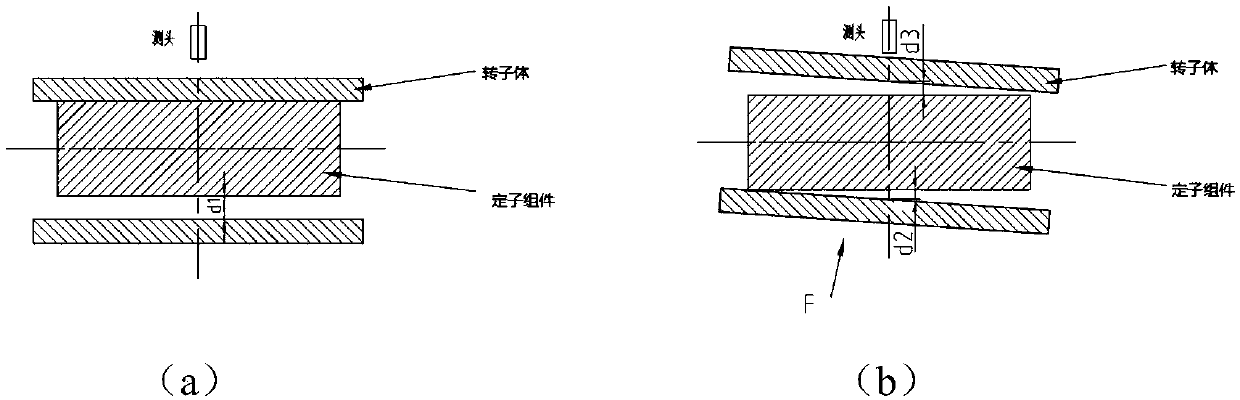

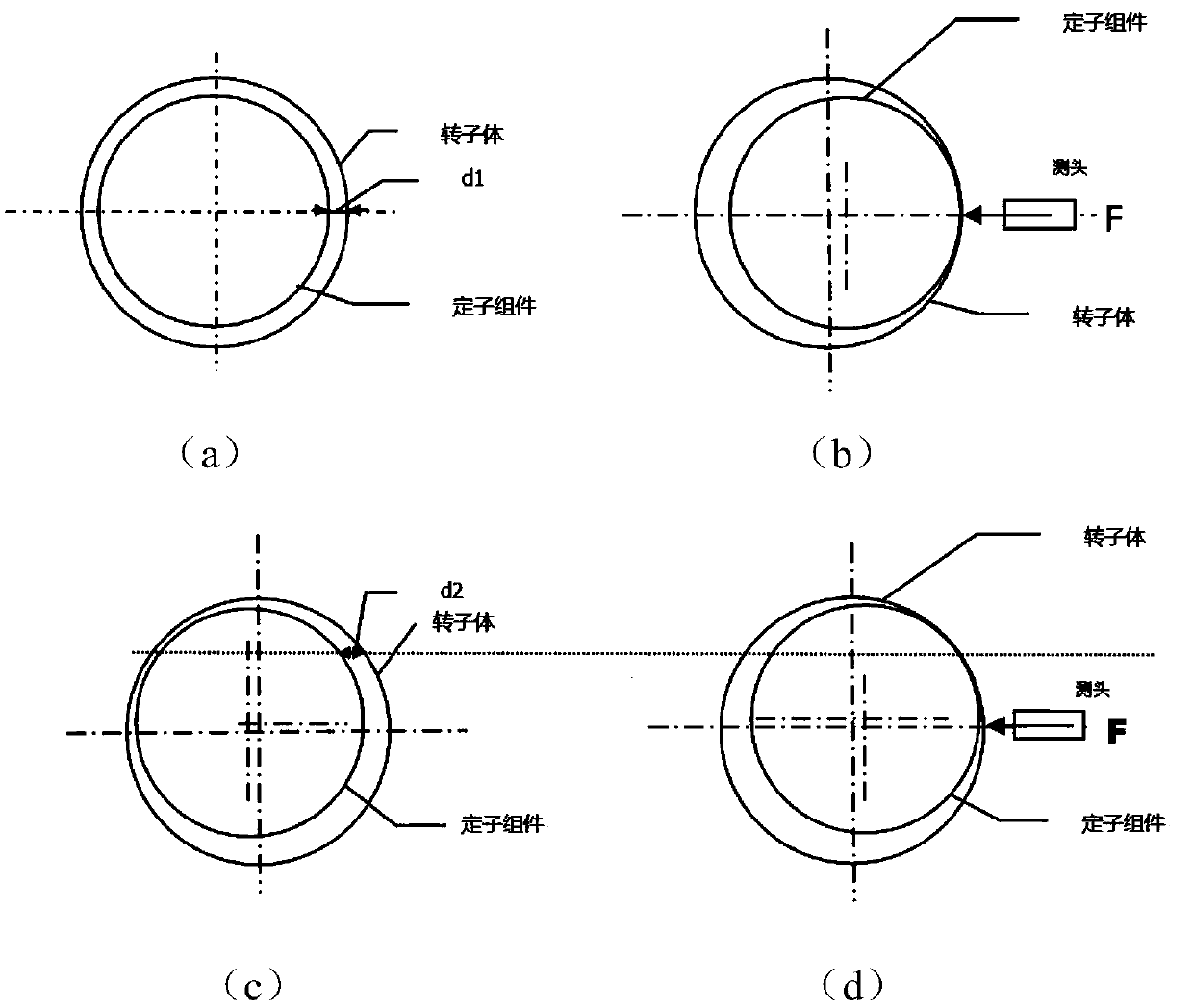

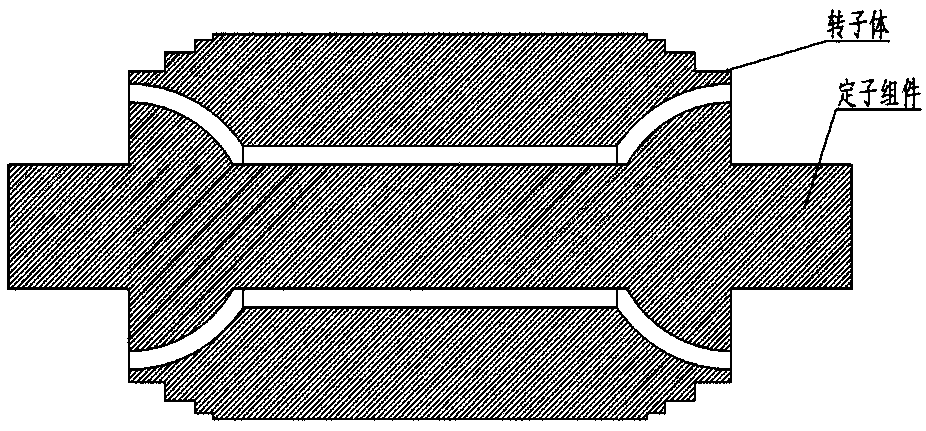

[0032] An automatic force application device for gap measurement of air-floating rotor gyroscope dynamic pressure motor, including a three-axis precision displacement platform, a control circuit, a force sensor mounting plate 12, a dynamic pressure motor 8, a left fixing device, and a right fixing device , Flat plate 1, middle clamping device.

[0033]The three-axis precision displacement platform includes a Z-axis precision displacement platform 2, a Y-axis precision displacement platform 3 and an X-axis precision displacement platform 13; the Z-axis precision displacement platform 2 is fixedly installed on the flat plate 1, and the X-axis precision displacement platform 13 is fixed Installed on the plate 1 and connected above the end of the Z-axis precision displacement platform 2; one end of the Y-axis precision displacement platform 3 is connected to the end of the X-axis precision displacement platform 13 and fixed on the top of the X-axis precision displacement platform 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com