Cable take-up device and use method thereof

A technology of winding device and cable reel, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of troublesome production operations, slipping of reels, time-consuming and labor-intensive, etc., to reduce working costs, The effect of reducing energy loss and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

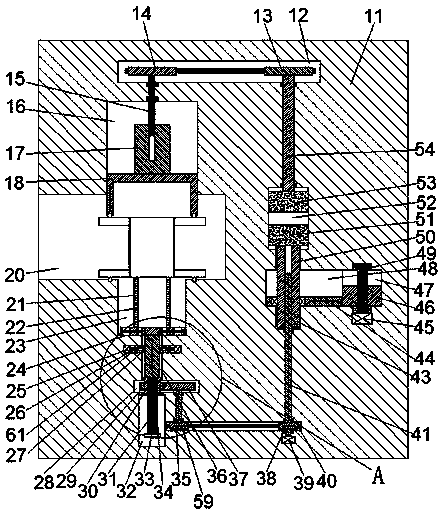

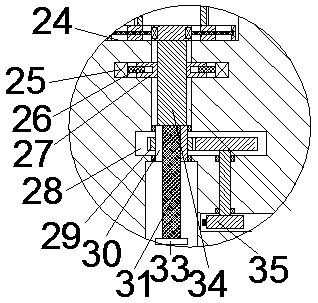

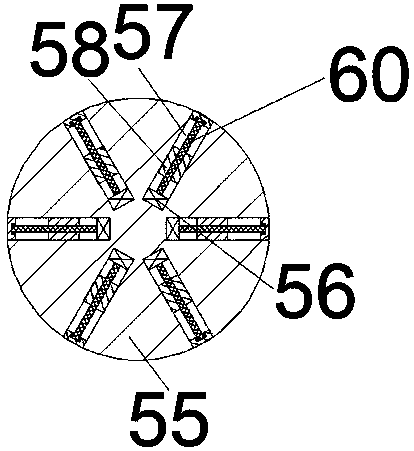

[0016] Combine below Figure 1-3 The present invention is described in detail, and for the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017] refer to Figure 1-3A cable winding device according to an embodiment of the present invention includes a base body 11, a first cavity 40 is arranged in the base body 11, a first pulley 38 is installed in the first cavity 40, and a first pulley 38 is installed in the first cavity 40. A drive motor 39 connected to the first pulley 38 through a rotating shaft is installed in the lower end wall of a cavity 40, and a spline shaft 41 extending up and down is rotatably installed in the upper end wall of the first cavity 40, so The lower end of the spline shaft 41 extends into the first cavity 40 and is fixedly connected with the first pulley 38. A second cavity 48 is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com