Connecting structure of prefabricated concrete wall body

A prefabricated concrete and connection structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of affecting mechanical performance, complex structure, affecting performance, etc., and achieve the goal of improving performance, continuous force, and improving integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

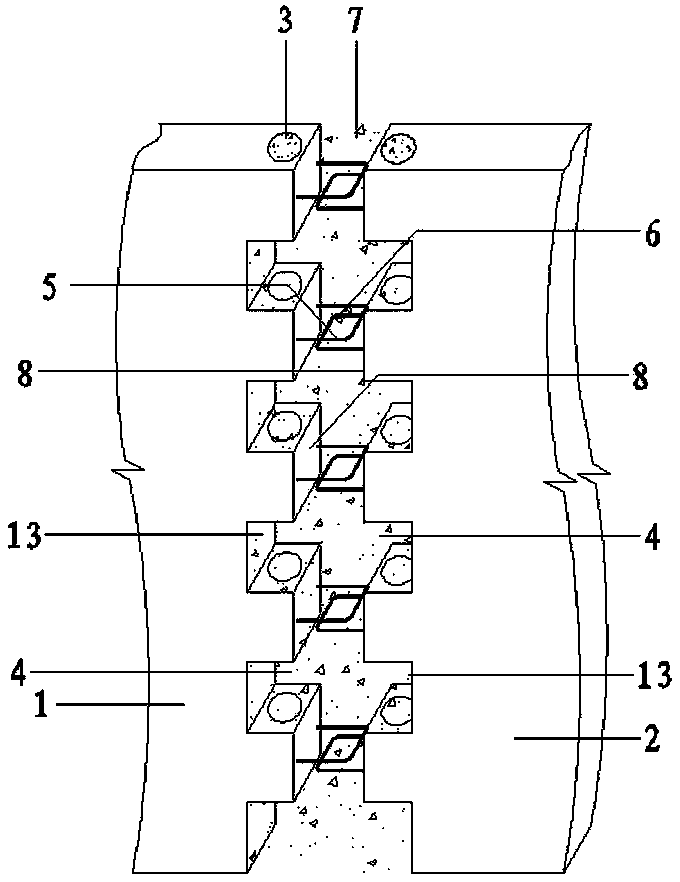

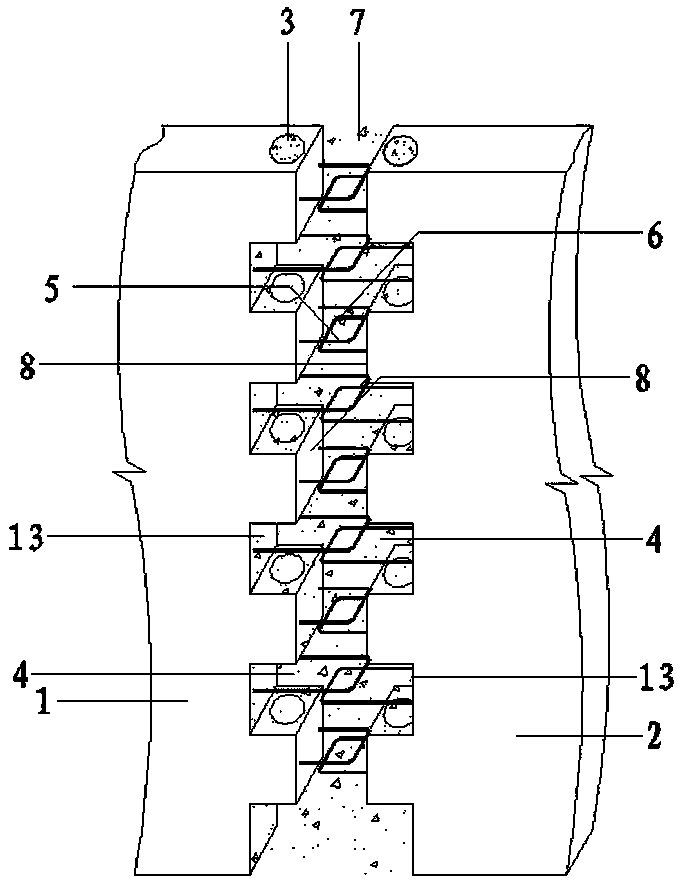

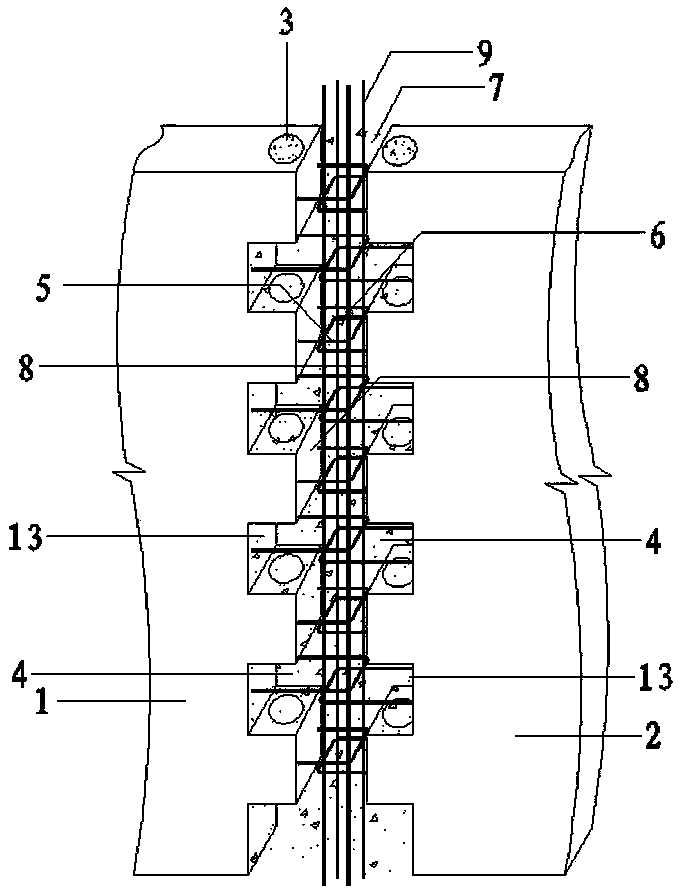

[0030] Such as figure 1 In the shown embodiment, the connecting structure of the precast concrete wall includes a first precast concrete wall 1 and a second precast concrete wall 2, and the first precast concrete wall 1 and the second precast concrete wall 2 are located near the end face 8 A longitudinal through hole 3 is provided at the center, and the cross section of the hole is circular or rectangular, or other shapes; the end faces of the first precast concrete wall 1 and the second precast concrete wall 2 are oppositely provided with several transverse grooves 4, and the transverse The side view of the groove is rectangular, trapezoidal, etc., figure 1 The center is rectangular; the top surface 13 of the transverse groove 4 extends into the wall inside the longitudinal hole; the end face 8 of the first prefabricated concrete wall 1 is provided with a first U-shaped steel bar 5 protruding outward from the wall, extending to a distance close to The position of the end fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com