A UAV front landing gear compartment based on catapult take-off

A technology of landing gear cabin and nose landing gear, which is applied in the direction of fuselage frame, fuselage bulkhead, aircraft parts, etc. It can solve the problems of torsional load and structural weight increase of the landing cabin section, and achieve the force transmission route and direct, The effect of continuous force and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

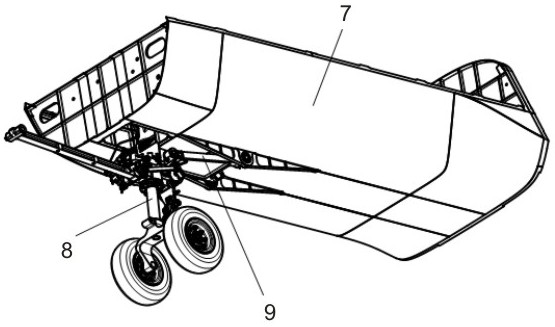

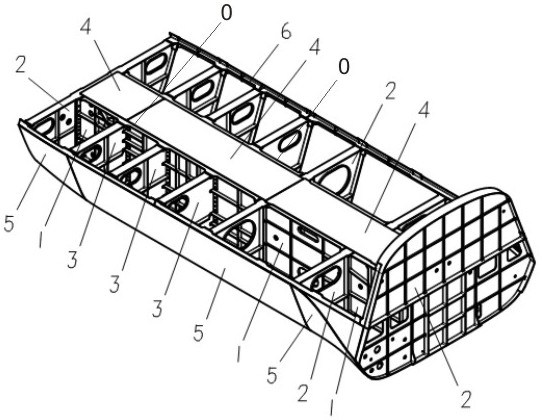

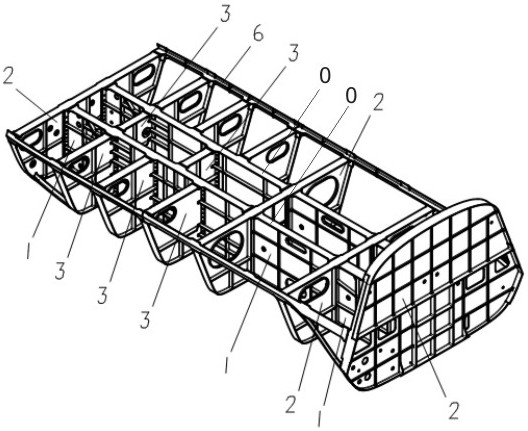

[0029] combined with Figure 1-4 Shown, a kind of unmanned aerial vehicle front landing gear section based on catapult take-off, comprises strip-shaped landing gear compartment and landing gear, and described landing gear compartment comprises bulkhead 2 at two ends and the girder 6 that connects bulkhead 2, and The outer skin 7 is covered; the middle part of the landing gear cabin is provided with a landing gear fixing cabin, and the skeleton of the landing gear fixing cabin includes four main beams 0, and the main beams 0 are fixedly connected with the partition frame 2, Both sides of the main beam 0 and the bulkhead 2 are provided with partitions 3; the main beam 0 and the partition 3 form an integral wall beam 1, and the wall beam 1 is hinged with a landing gear The main pillar 8 and the landing gear slant strut 9, and the skin 7 at the lower part of the fixed compartment of the landing gear is provided with an opening suitable for the landing gear.

[0030] Implementatio...

Embodiment 2

[0035] On the basis of Embodiment 1, further, a plurality of bulkheads 2 are provided between the wall plate beam 1 and the girder 6, and the bulkheads 2 outside the fixed compartment of the landing gear are provided with bulkheads. plate 3.

[0036] Implementation principle:

[0037]The transverse member formed by the bulkhead 2 and the bulkhead 3 in the middle divides the enclosed box body of the landing gear cabin into several, and the transverse member provides transverse support to the longitudinal wall beam 1 and improves the opening The overall rigidity of the box body and the closed box body increases the ability to bear torque, and at the same time disperses the concentrated force transmitted from the wall plate beam 1, and disperses and transmits the concentrated force of the instantaneous impact and large overload, which increases the overall strength of the present invention. For strength and stiffness, the cross members are framed thin plates without adding too m...

Embodiment 3

[0040] On the basis of Embodiment 1 or 2, further, the upper surface of the landing gear compartment is the floor 4 fixed on the bulkhead 2 , the main beam 0 and the main beam 6 .

[0041] Implementation principle:

[0042] By setting the upper surface of the landing gear cabin as the floor 4 that is airtightly connected with the skin, the landing gear cabin becomes a thin-walled semi-monocoque structure. After the floor 4 is set, the load-carrying capacity of the upper part is strengthened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com