Impact-resistant lightweight density gradient composite material, fan containment casing, preparation method and application thereof

A technology of density gradient and composite materials, applied in chemical instruments and methods, transportation and packaging, synthetic resin layered products, etc., can solve the problems of high manufacturing cost, late start of research, thick casing structure, etc., and achieve improved impact resistance performance, reduced structural weight, and high-speed impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

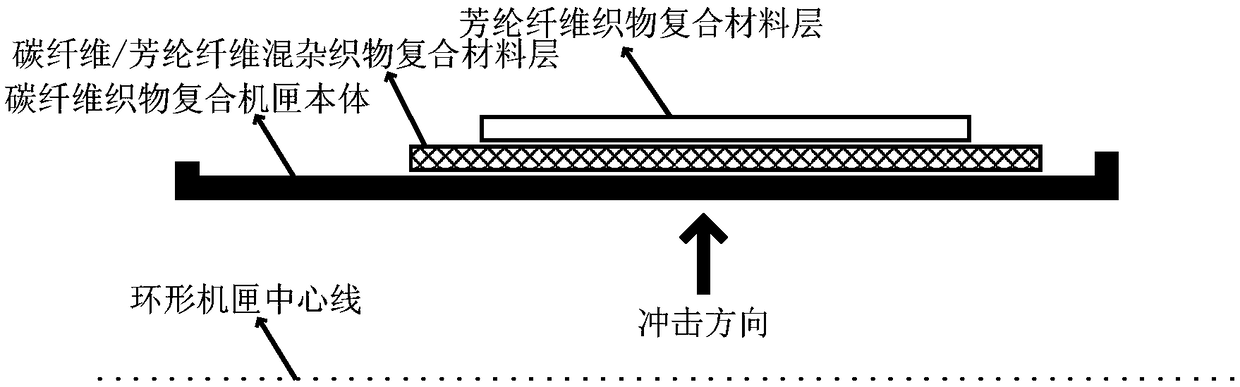

[0047] The preparation method of the lightweight impact-resistant density gradient composite material of the present invention specifically comprises the following steps:

[0048] (1) Lay or wrap carbon fiber fabric prepreg, carbon fiber and aramid hybrid fiber fabric prepreg and aramid fiber fabric prepreg on the forming mold in sequence, and perform pre-compacting by absorbing glue, wherein the glue-absorbing prepreg The compaction temperature is 50°C-80°C, the holding time is 0.5h-2.5h, and the pressure is 0.2MPa-0.5MPa; two pre-compaction processes are set up, one after the carbon fiber fabric prepreg layer is completed, and After the carbon fiber and aramid hybrid fiber fabric prepreg layup is completed, the adhesive pre-compaction is carried out in the form of vacuum bag / autoclave. When absorbing adhesive, the vacuum gauge pressure is not greater than -0.097MPa, and the heating rate is 20°C-120 ℃ / h, pressurize to 0.2-0.3MPa when the temperature rises to 60-80℃, and then ...

Embodiment 1

[0070] The reinforcing fibers of composite materials containing the case are carbon fiber fabrics, carbon fiber / aramid blended fabrics, and aramid fiber fabrics, and the resin is epoxy resin cured at a medium temperature of 130°C.

[0071] The volume ratio of the carbon fiber / aramid blended fabric is mixed according to the ratio of 1:1, and the density of the mixed knitted fabric composite material is 1.45g / cm 3 .

[0072] Use cutting equipment to cut the three kinds of fabric prepregs according to a certain width, and through the winding machine, under a certain tension, according to the design layer angle and thickness requirements, different fabric prepregs are wound layer by layer to the forming positive. On the mold, wherein, the thickness of the carbon fiber fabric layer is 14mm, the thickness of the carbon fiber / aramid fiber mixed fabric layer is 2mm, and the thickness of the aramid fiber fabric layer is 10mm. After winding to the required thickness, cover the insulati...

Embodiment 2

[0075] The reinforcing fibers of composite materials containing the case are carbon fiber fabrics, carbon fiber / aramid blended fabrics, and aramid fiber fabrics, and the resin is epoxy resin cured at a medium temperature of 130°C.

[0076] The volume ratio of the carbon fiber / aramid blended fabric is mixed according to the ratio of 1:2, and the density of the mixed knitted fabric composite material is 1.40g / cm 3 .

[0077] Use cutting equipment to cut the three kinds of fabric prepregs according to a certain width, and through the winding machine, under a certain tension, according to the design layer angle and thickness requirements, different fabric prepregs are wound layer by layer to the forming positive. On the mold, wherein, the thickness of the carbon fiber fabric layer is 18mm, the thickness of the carbon fiber / aramid fiber mixed fabric layer is 6mm, and the thickness of the aramid fiber fabric layer is 12mm. After winding to the required thickness, cover the isolatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com