Patents

Literature

87results about How to "Overcome stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

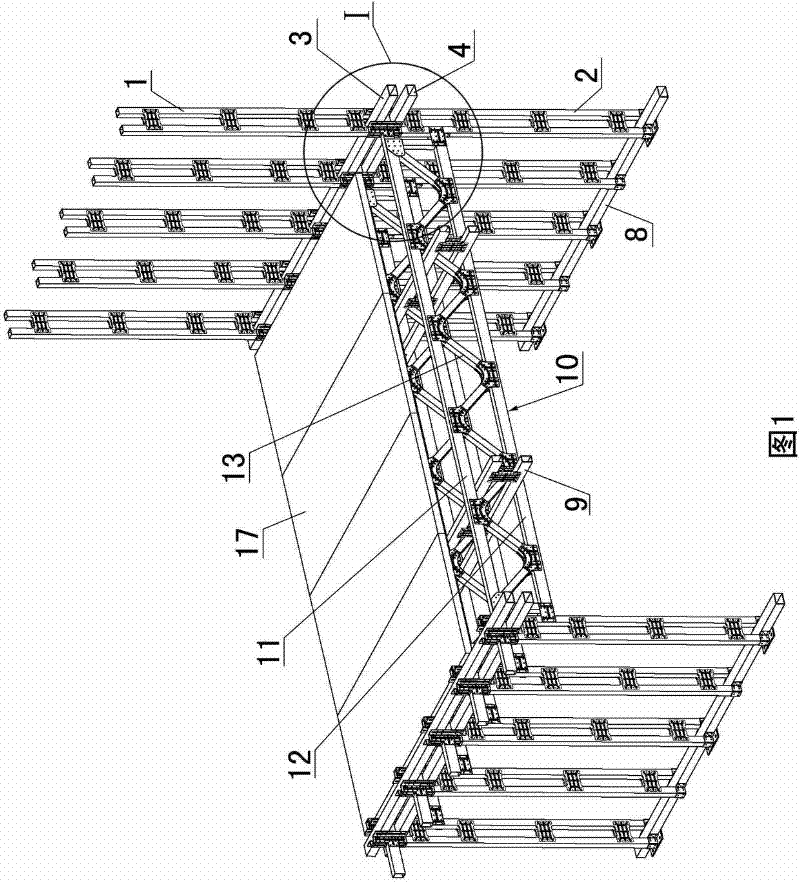

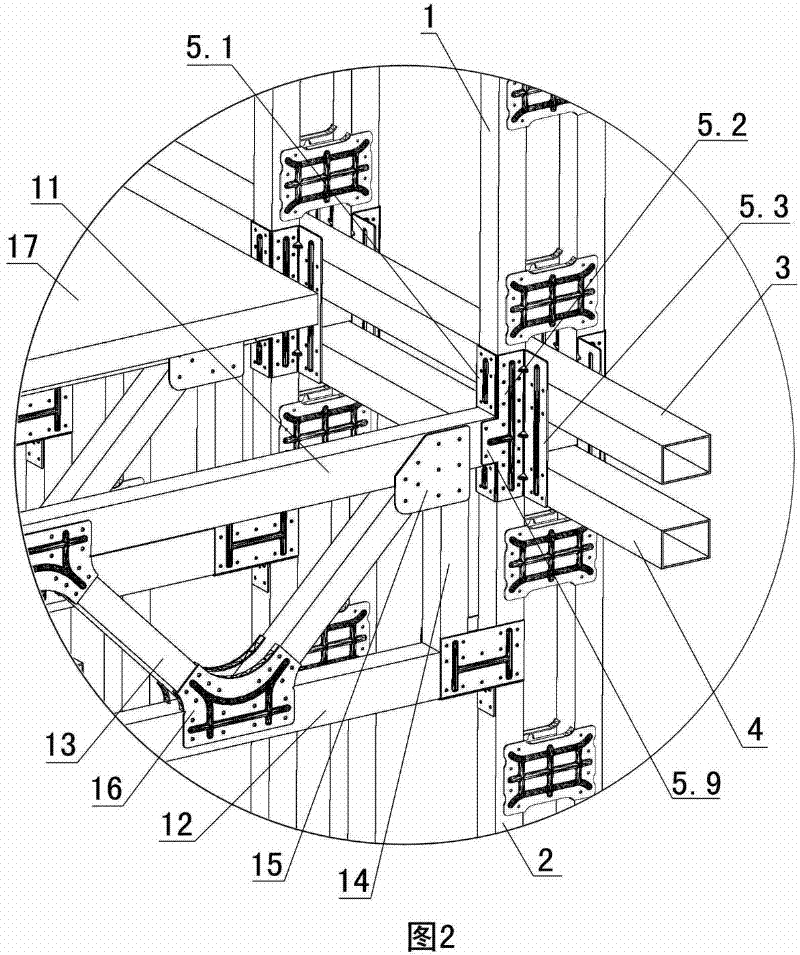

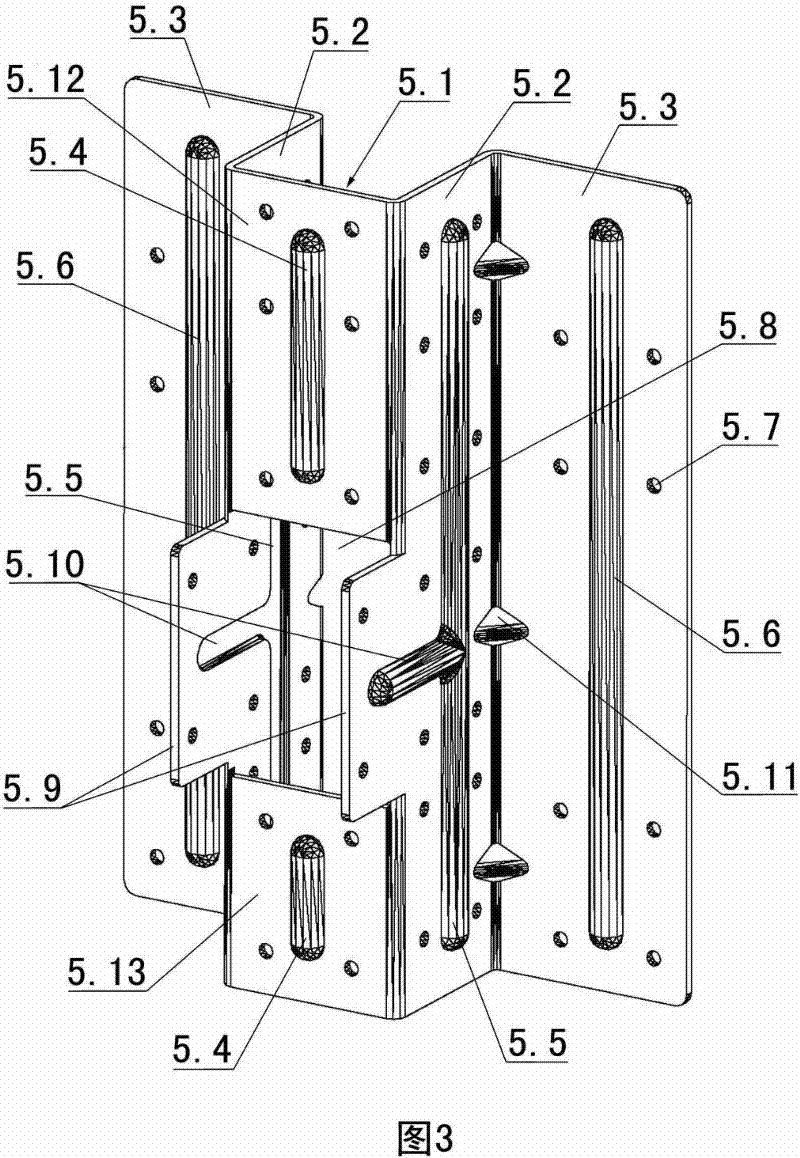

Truss combined beam and upper and layer connected light steel structure and construction method thereof

InactiveCN102359180ATroubleshoot simultaneous connectionsSolve the shortcomings that the pressure is not easy to meet the force requirementsGirdersJoistsRear quarterKeel

The invention discloses a truss combined beam and upper and layer connected light steel structure and a construction method thereof. The light steel structure comprises upper wall sheet columns distributed at intervals, lower wall sheet columns distributed at intervals, upper wall sheet column lower connecting pipes connected among the lower parts of the upper wall sheet columns, lower wall sheet column upper connecting pipes connected among the upper parts of the lower wall sheet columns, and truss combined beams connected between the upper wall sheet columns and the lower wall sheet columns through upper and lower connectors, wherein the upper and lower connectors are beam passing buckles, the web plates of the beam passing buckles consist of upper web plates and lower web plates, a square connecting port is formed between the upper web plates and the lower web plates, upper chord member connecting plates are extended from the left and right sides of the square connecting ports, and the upper chord member connecting plates and side plates of the beam passing buckles are positioned in the same plane. Through the light steel structure, the structural stability of a light steel keel house system is enhanced, and the floor surface beams, the connecting pipes and the floor panels do not easily vibrate.

Owner:筑巢(北京)科技有限公司

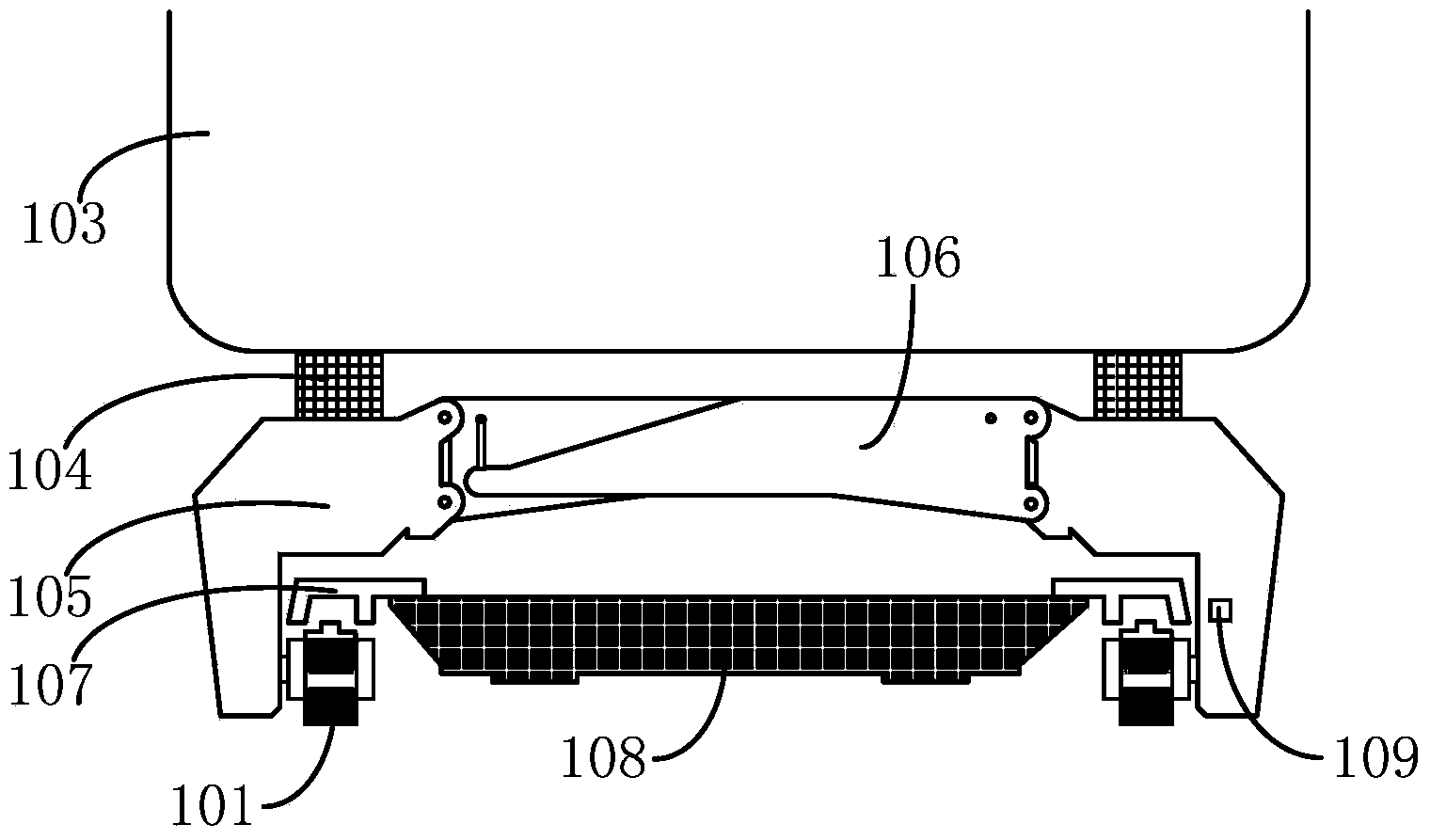

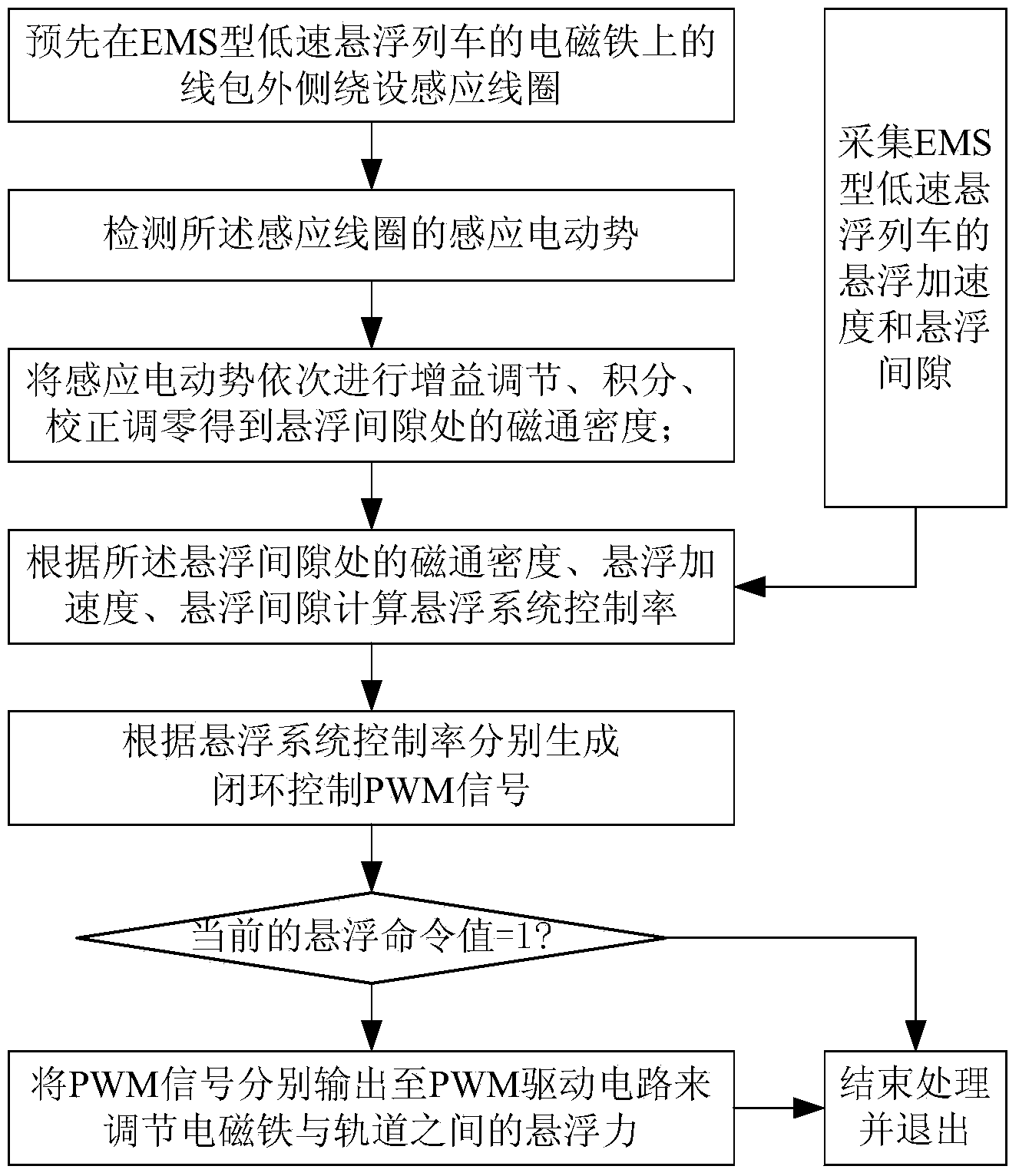

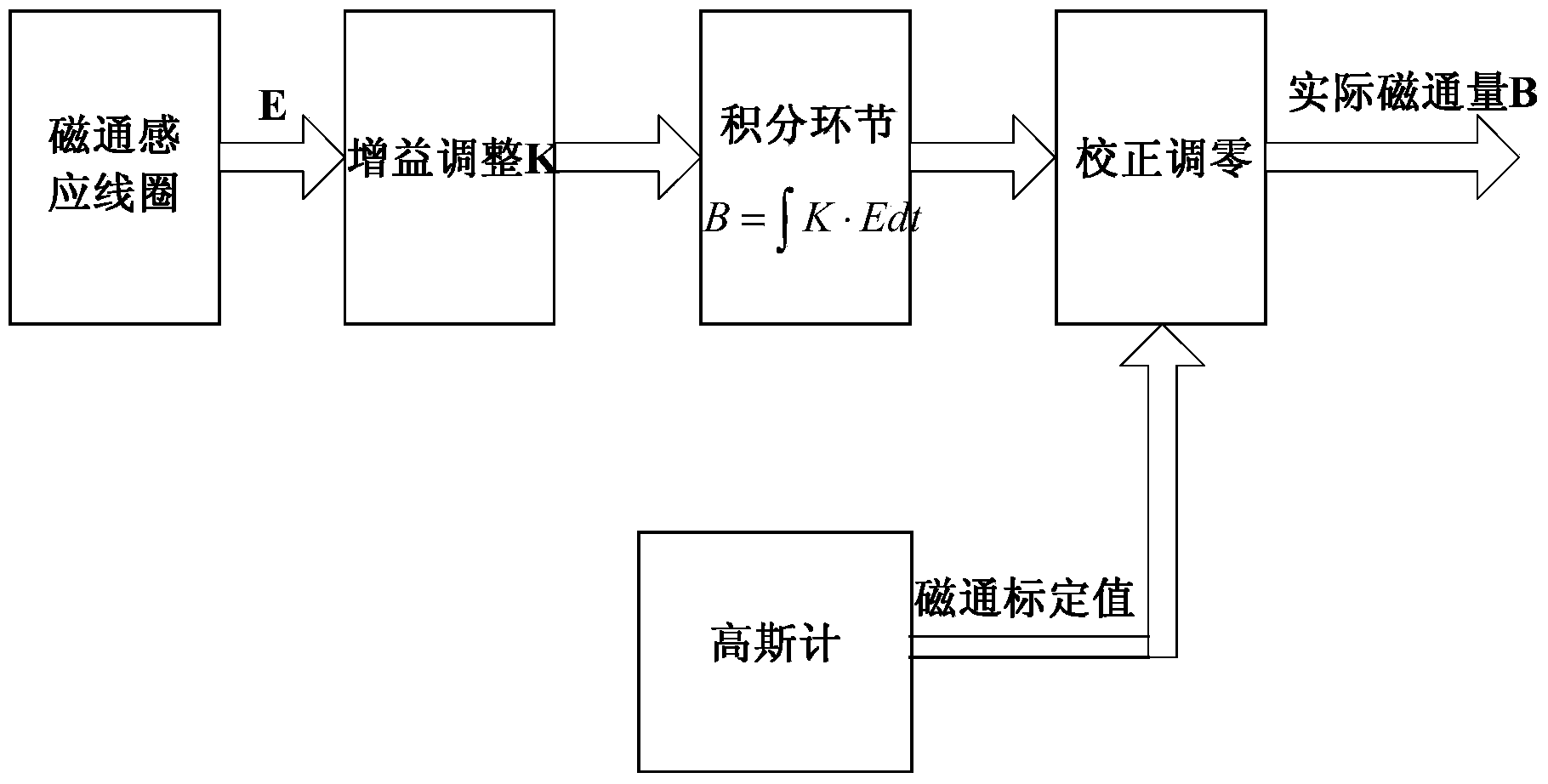

Magnetic flux feedback suspension control method and device of EMS type low-speed aerotrain

The invention discloses a magnetic flux feedback suspension control method and device of an EMS type low-speed aerotrain. The method comprises the following implementation steps: collecting and obtaining the magnetic flux density at the position of a suspension gap through a magnetic flux induction coil a, and collecting the suspension accelerated speed and the suspension gap; calculating a suspension system control rate according to the magnetic flux density, the suspension accelerated speed and the suspension gap; generating a closed loop to control PWM signals according to the suspension system control rate, and respectively outputting the PWM signals to a PWM driving circuit to adjust the suspension force between a suspension electromagnet and a track. The device comprises a sensor set, a data collection board, a suspension controller and the PWM driving circuit, wherein the sensor set, the data collection board, the suspension controller and the PWM driving circuit are sequentially connected. The method and device have the advantages of being good in suspension control stability, high in sensitivity, low in control bandwidth, capable of improving the stability and robustness of the suspension control system, simple, easy to implement, strong in anti-jamming capability, good in expandability, and flexible in implementation.

Owner:NAT UNIV OF DEFENSE TECH

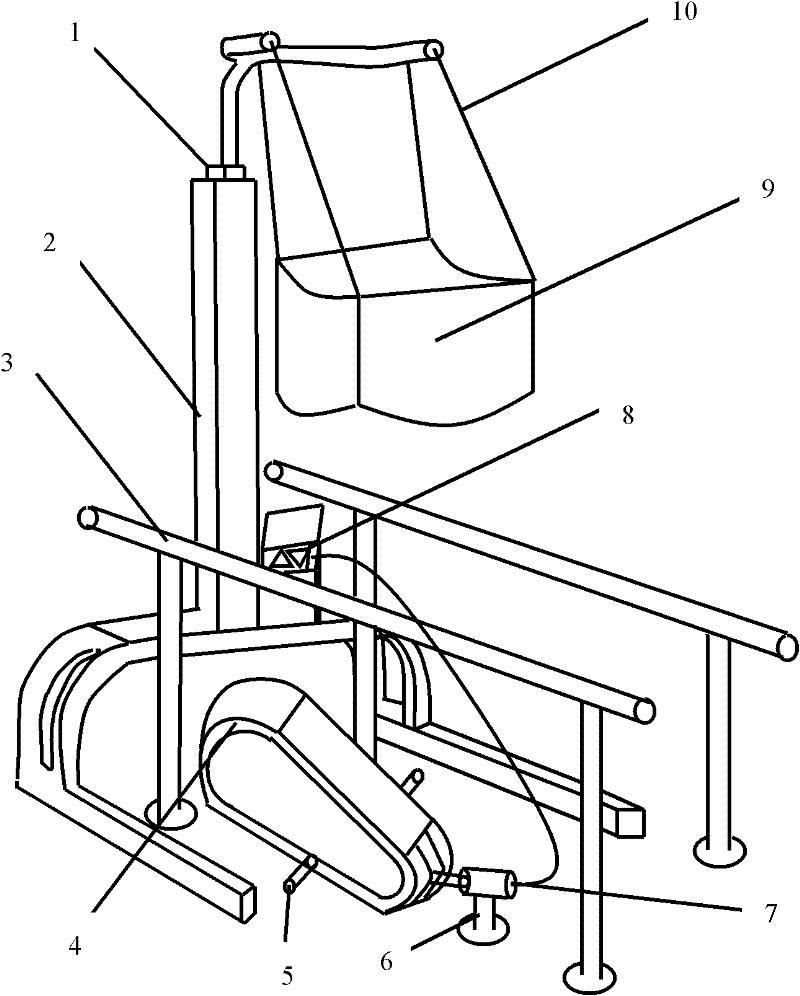

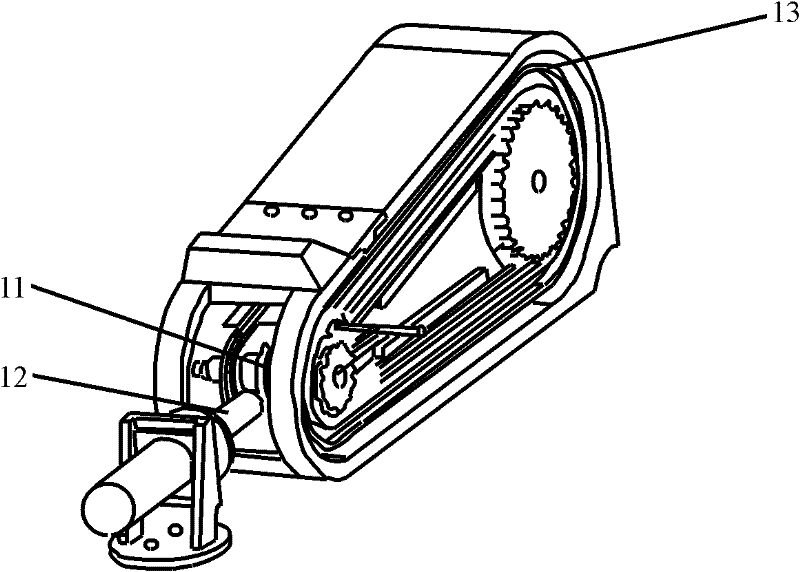

Gait rehabilitation training robot

ActiveCN102225033AAchieve compound movement trainingAchieve rehabilitationChiropractic devicesGait simulationThree-dimensional space

The invention discloses a gait rehabilitation training robot. The robot is characterized by comprising a weight reduction device, a gait simulative generator, a given motion trail and a personal computer. The weight reduction device and the gait simulative generator are installed on a pedal lever through a pair of protective boots worn by a trainer, and the pedal lever operates according to the given motion trail at a set speed in a set training pattern; the center line of the given motion trail is a closed curved trail fitting the walking of lower limbs of people, which is obtained by projecting the motion trail of an ankle joint in a three-dimensional space during normal walking into a two-dimensional space plane; and the personal computer is used for controlling the real-time speed of the gait simulative generator and selecting different training modes. By the adoption of the gait rehabilitation training robot disclosed by the invention, the problem of the consistency between the rehabilitation training gait trail and naturally walking gait trail of people can be solved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

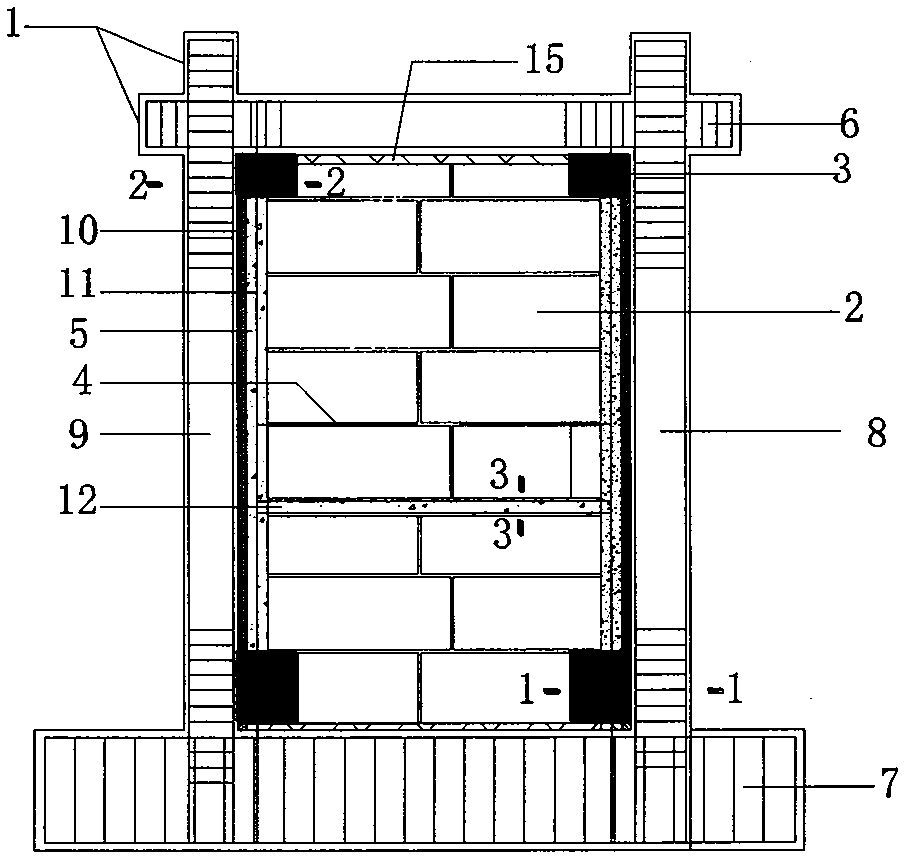

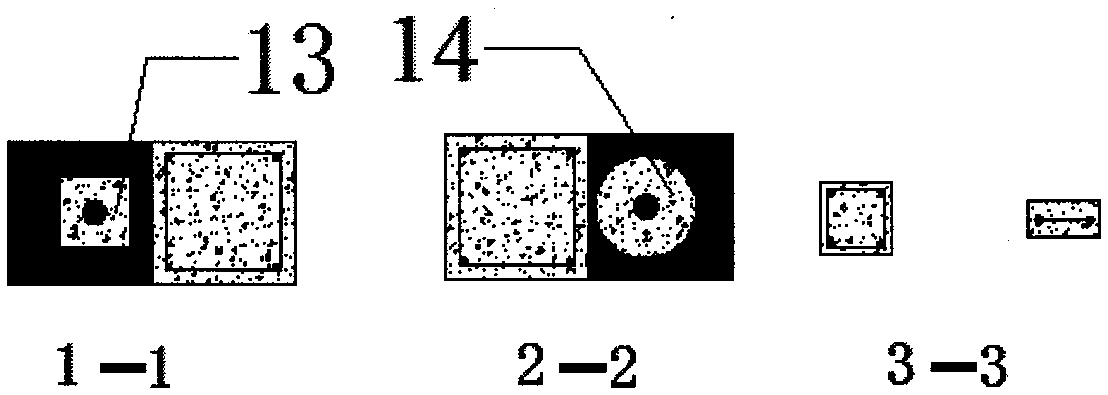

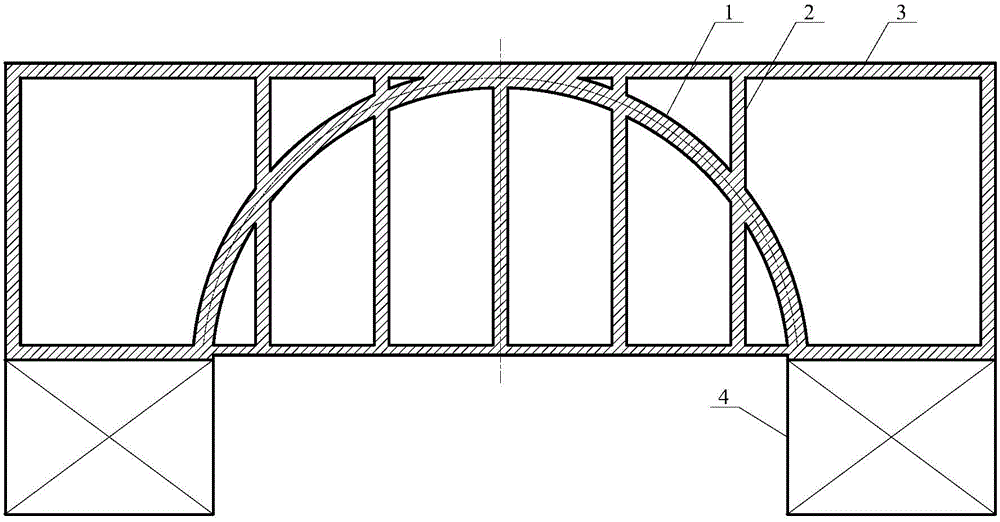

Deformation-controllable frame filling wall and construction method thereof

InactiveCN105507454AReduce earthquake forceProtection securityWallsShock proofingRebarDeformation control

The invention discloses a deformation-controllable frame filling wall which is mainly composed of a frame 1, a filling wall 2, deformation control parts 3, horizontal tie bars 4, restraint columns 5 and horizontal connection beams 12. The deformation-controllable frame filling wall is characterized in that the frame 1 is composed of a frame upper beam 6, a frame lower beam 7, a frame left column 8 and a frame right column 9, the filling wall 2 is a brickwork filling wall which is built by bricks (clay bricks and hollow bricks) or concrete building blocks, the deformation control parts 3 are arranged at positions where four corners of the filling wall contact with joints of the frame, the filling wall 2 is connected with the frame left column 8 and the frame left column 9 through a flexible material 10, and connected with the frame upper beam 6 and the frame lower beam 7 through an elastic connection material 15, the restraint columns 5 are arranged at positions where the filling wall 2 is connected with the flexible material 10, and the horizontal tie bars 4 which are arranged in the height direction of the filling wall are connected with the restraint columns. When the height of the filling wall is large, horizontal tie beams 12 can be arranged in the filling wall, and two ends of the horizontal tie beams 12 are connected with the restraint columns 5.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

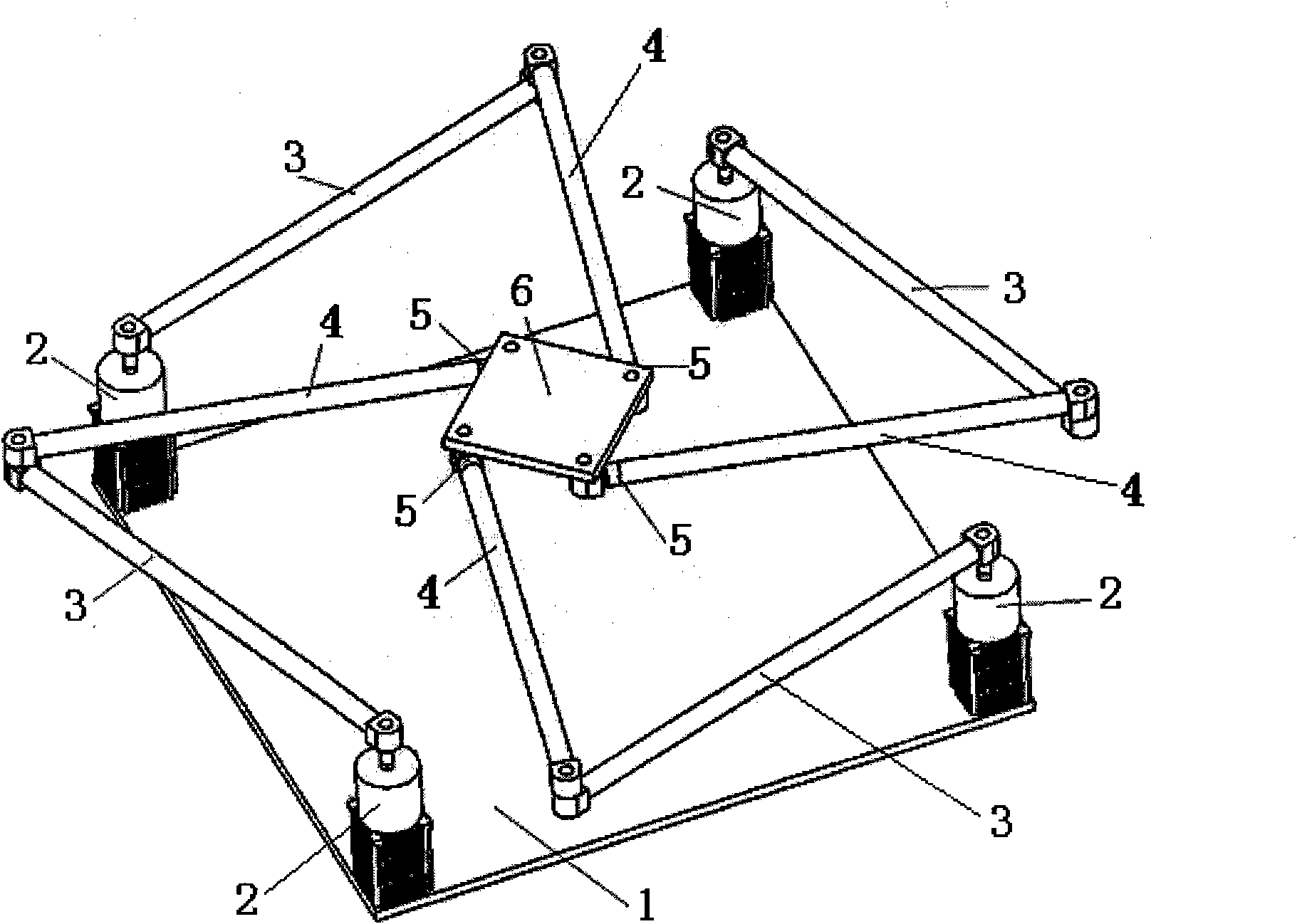

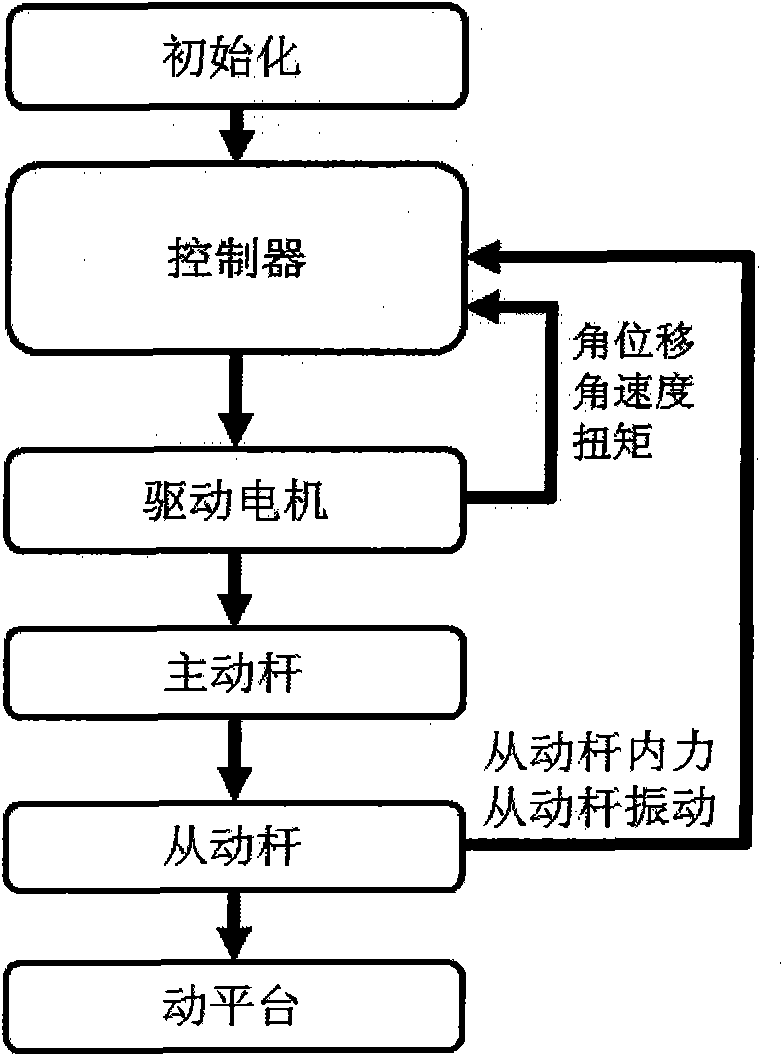

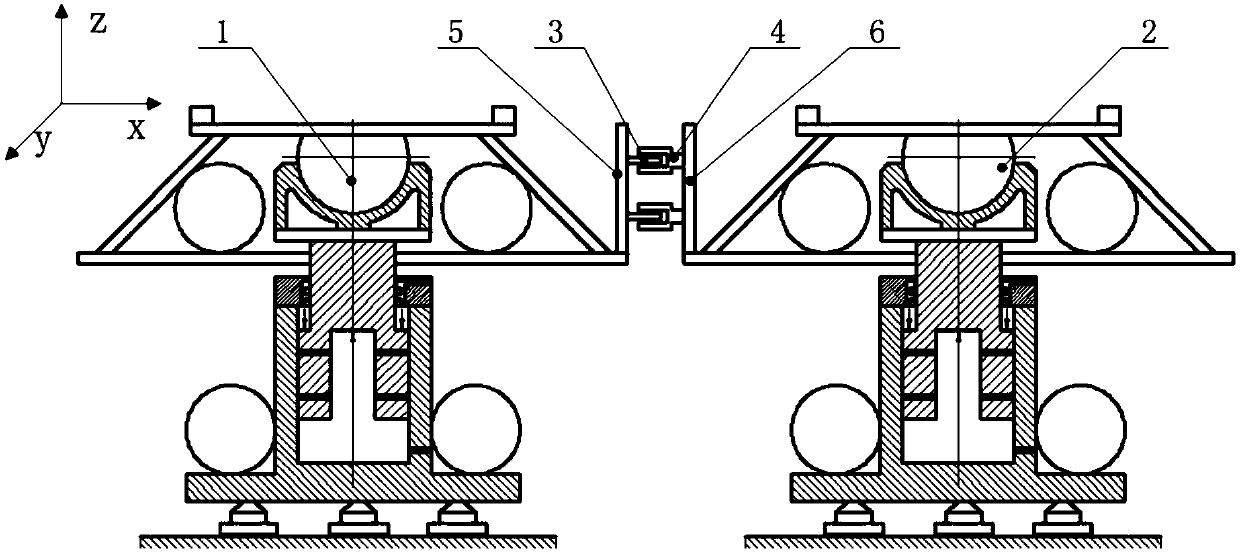

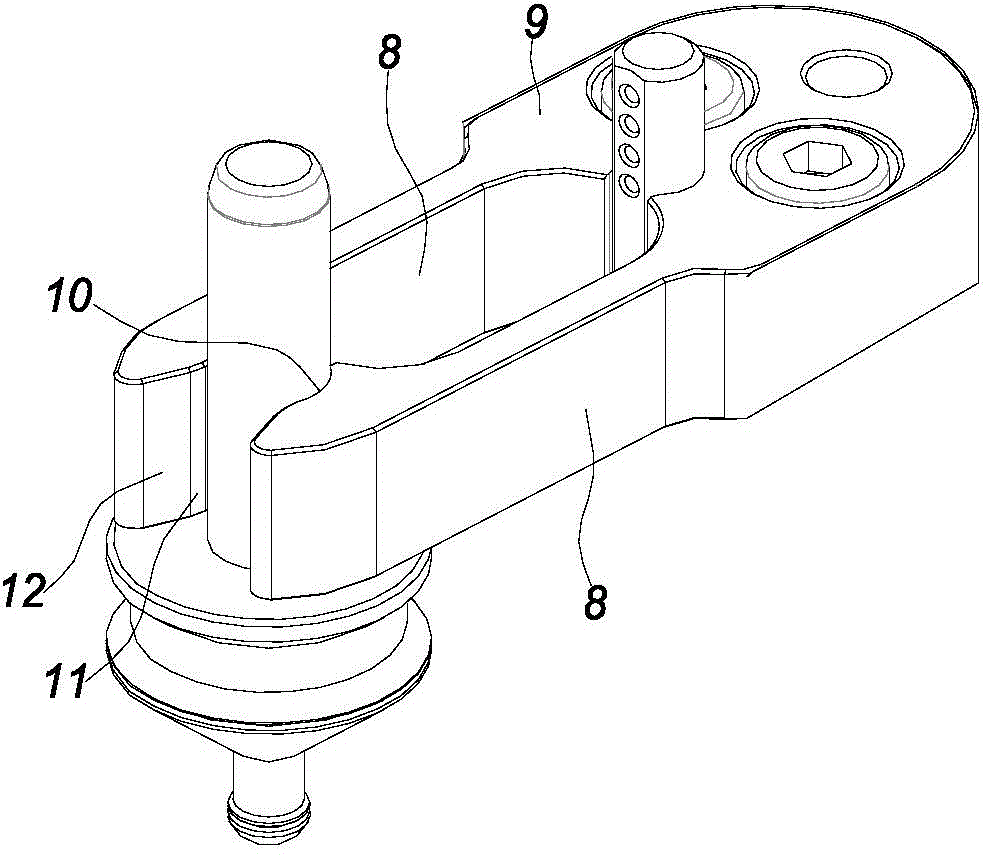

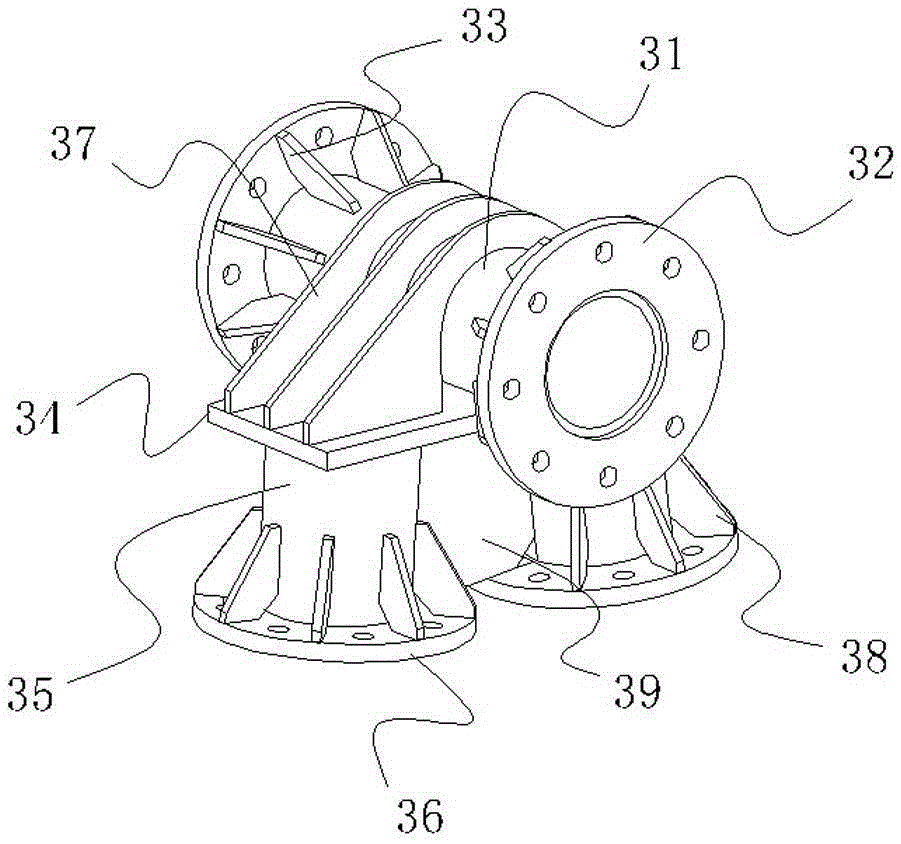

Redundant parallel robot system

InactiveCN101844349AOvercome stiffnessOvercome the shortcomings of the organization out of controlProgramme-controlled manipulatorRobotic systemsHigh stiffness

The invention relates to a redundant parallel robot system. The redundant parallel robot system is characterized by comprising a static platform, wherein four drive motors are fixedly arranged on the static platform; the four drive motors are in common connection with a controller; each drive motor is fixedly connected with a driving lever respectively; each driving lever is connected with a driven lever through a revolute pair to form a branched chain respectively; each driven lever is fixedly connected with a sensor respectively; and each sensor is in common connection with a moving platform through a revolute pair respectively. The redundant parallel robot system has the advantages of simple structure, large work space, high stiffness and high dynamic property, and can be used for manufacturing a plurality of types of mechanical equipment such as manipulators, machine tools, experimental platforms for researching force control and the like, so the redundant parallel robot system has a wide application prospect and a development potentiality in the fields of machining, assembly, mechanical kinetics scientific research and the like.

Owner:TSINGHUA UNIV

True triaxial testing device for servo control rock

InactiveCN102252910AThe result is accurateCollect test data in real timeMaterial strength using tensile/compressive forcesAxial pressurePressure load

The invention discloses a true triaxial testing device for a servo control high-stress rock. The true triaxial testing device disclosed by the invention comprises a counter-force frame, an axial pressure loading system, a confining pressure loading system and a measuring and acquisition control system, wherein hydraulic pillows are installed at the periphery of the inner surface of the rectangular counter-force frame and sheathed outside a columnar rock specimen on the scene; the columnar rock specimen has the dimension range: the length is 30-100cm, the width is 30-100cm and the height is 60-150cm; one end of a measuring rod is arranged in the side center of the columnar rock specimen, and the other end of the measuring rod passes through the counter-force frame and is connected with the measuring and acquisition control system; and the hydraulic pillows are connected with a confining pressure loading servo control system. The device disclosed by the invention provides high confining pressure by utilizing the rock large-dimension specimen on the site in an underground chamber and loading the hydraulic pillows, can bear complicated stress and can independently load servo control to obtain the comprehensive intensity of the rock.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION +1

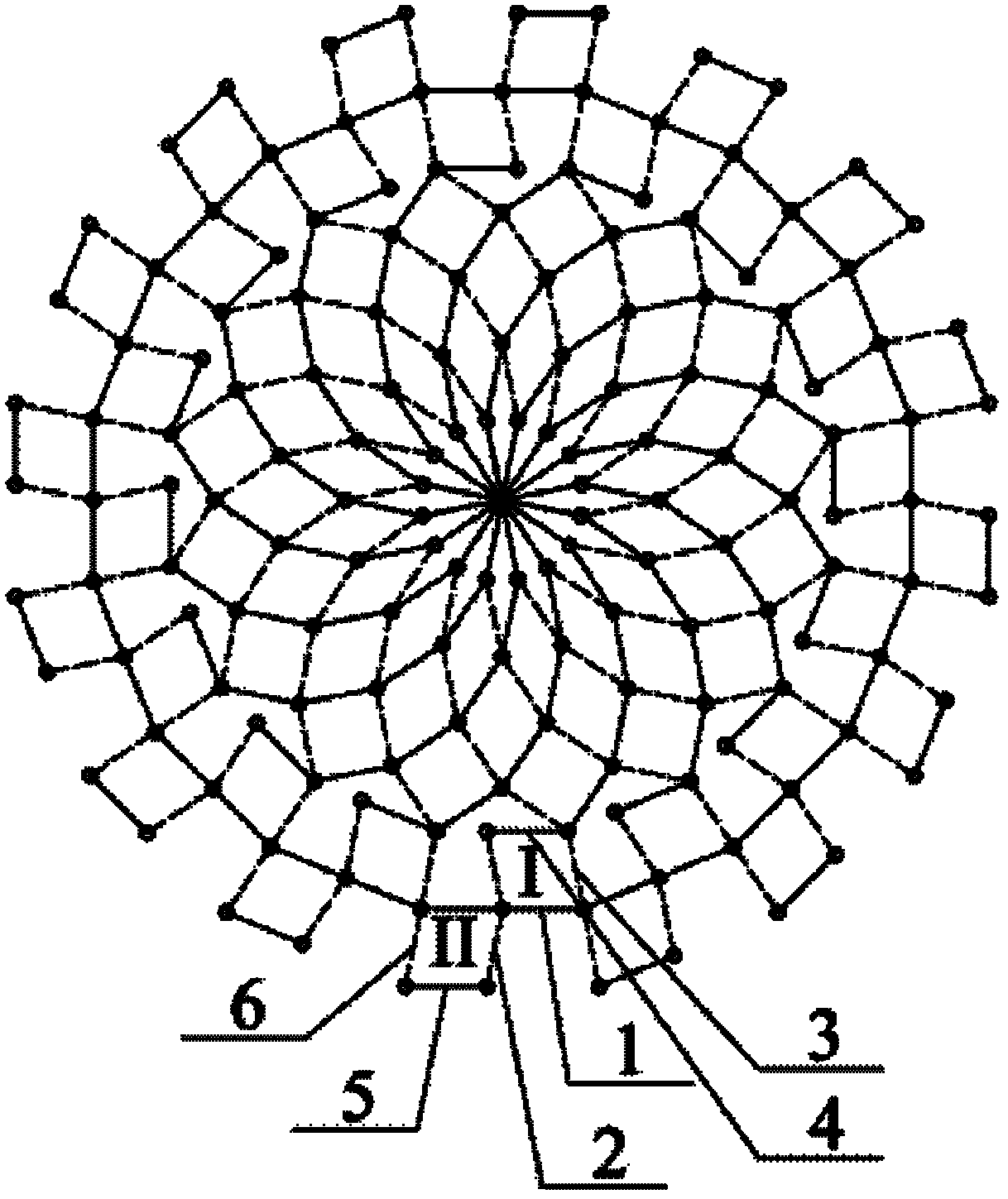

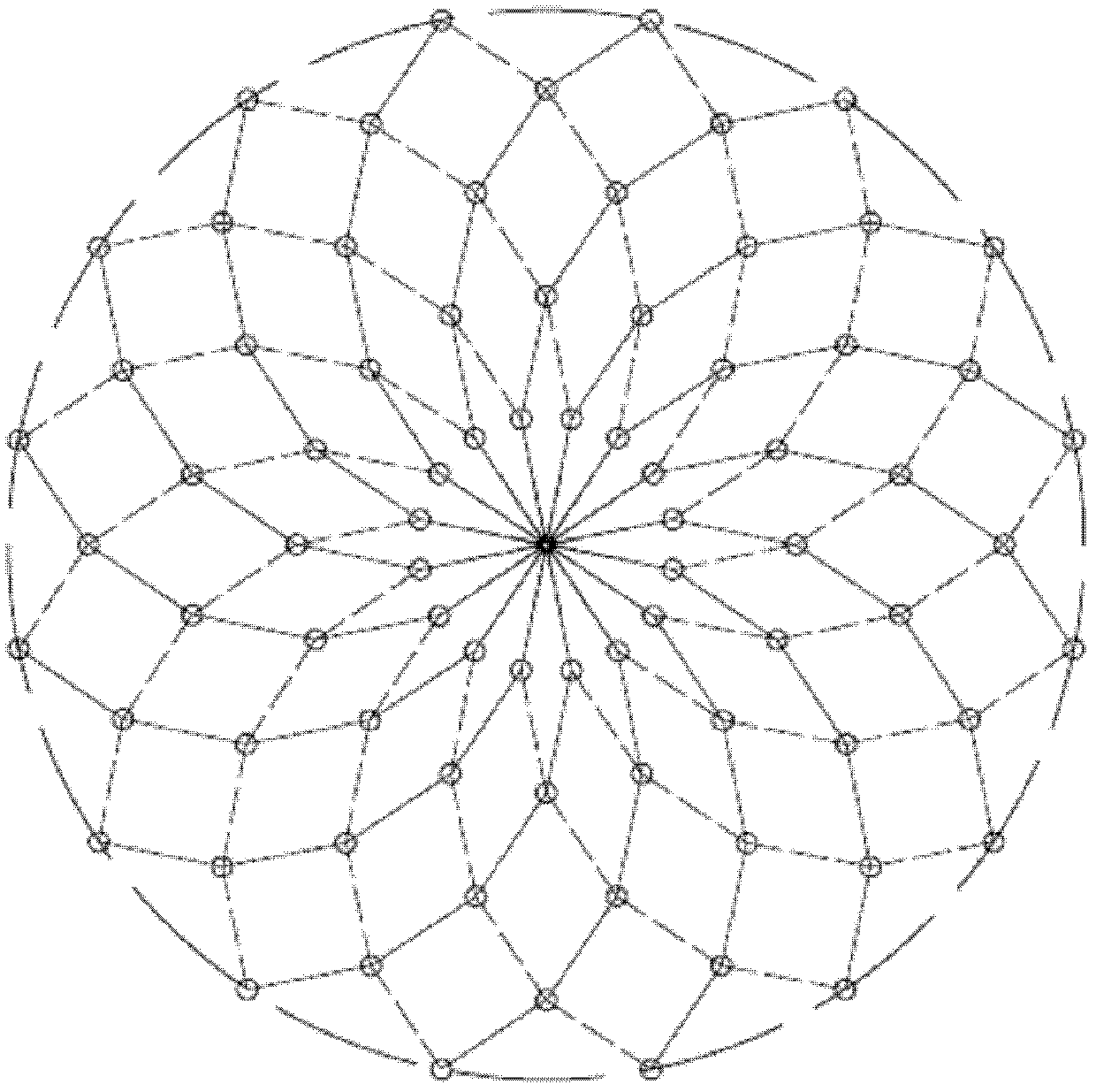

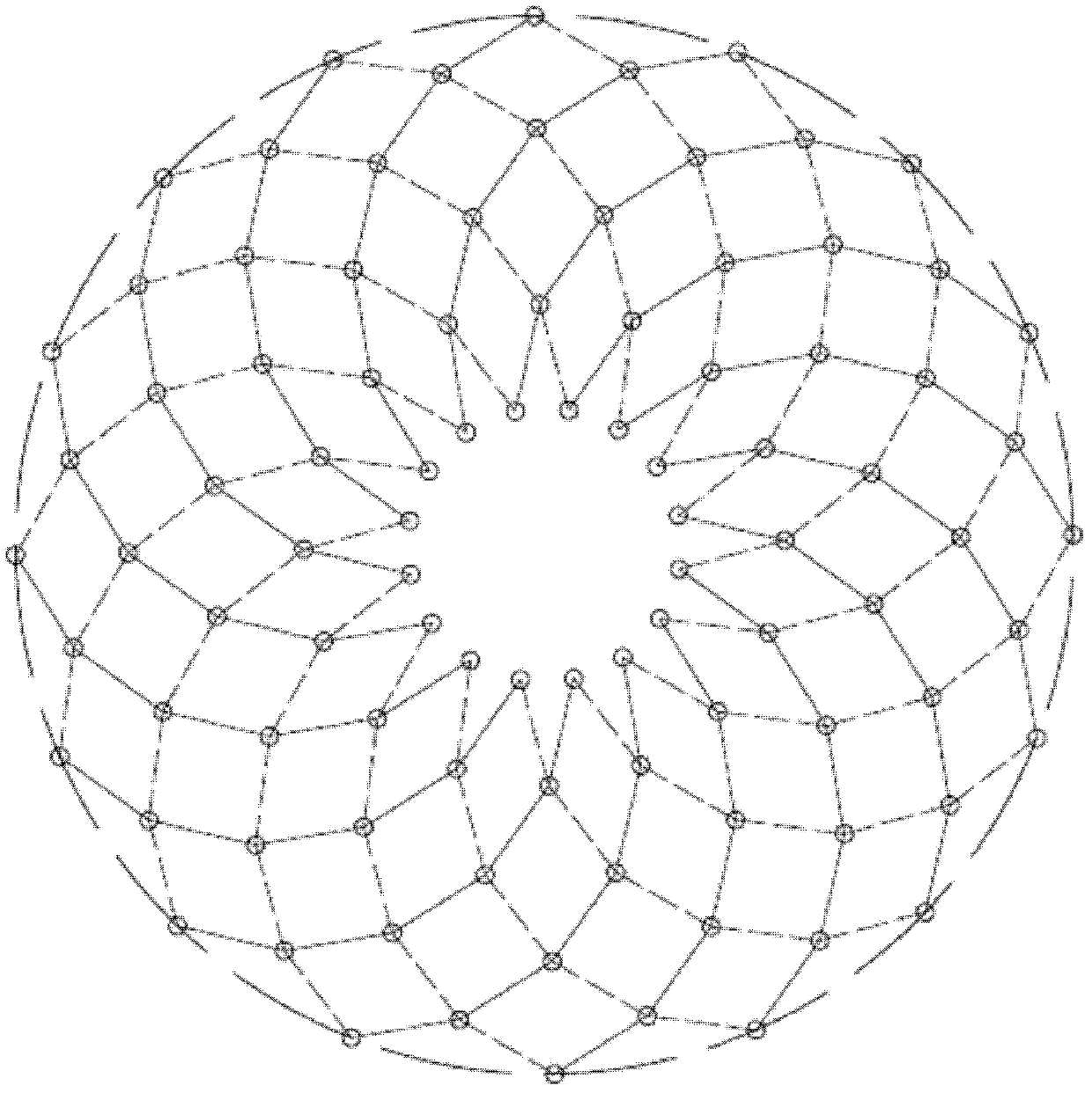

Radially retractable roof structure

InactiveCN102704608ARealize opening and closingOvercome stiffnessBuilding roofsRadial motionSupport point

The invention discloses a radially retractable roof structure, which comprises a radially retractable net frame. A single-freedom-degree circular connecting rod mechanism is arranged outside the radially retractable net frame and comprises equilateral n-side polygon rod combination consisting of n straight rods connected end to end, wherein the n is not smaller than 3 and not larger than 720, each straight rod is provided with a connecting rod mechanism unit, and each connecting rod mechanism unit consists of an internal parallelogram mechanism and an external parallelogram mechanism. The radially retractable roof structure has the advantages that the roof is retracted by effect of the radially retractable net frame. During retraction of the roof, the equilateral n-side polygon rod combination outside the radially retractable net frame is fixed, supporting points on the equilateral n-side polygon rod combination of the radially retractable roof structure cannot be subjected to radial movement during radially retracting process of the roof structure, and thus, supporting conditions are simplified. In addition, since the roof is driven to retract by the aid of the single-freedom-degree circular connecting rod mechanisms, the quantity of driving devices is reduced.

Owner:SOUTHEAST UNIV

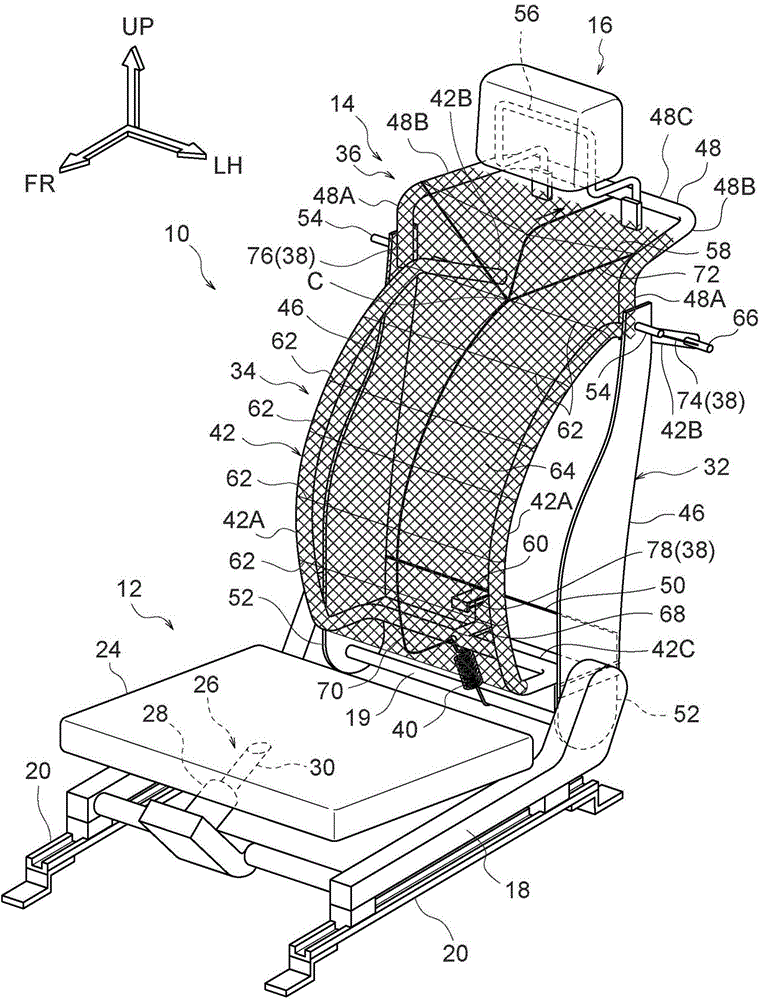

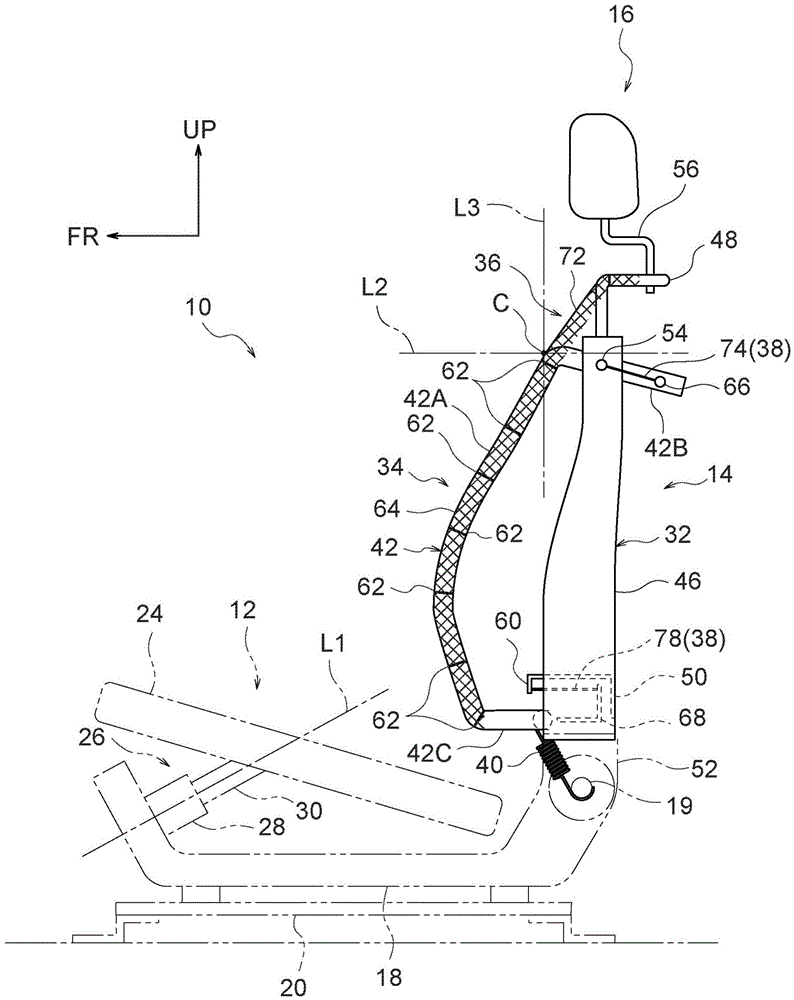

Vehicle seat

Owner:TOYOTA JIDOSHA KK

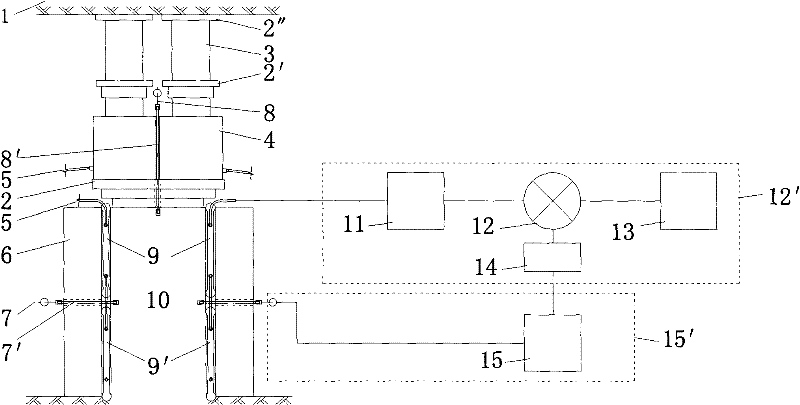

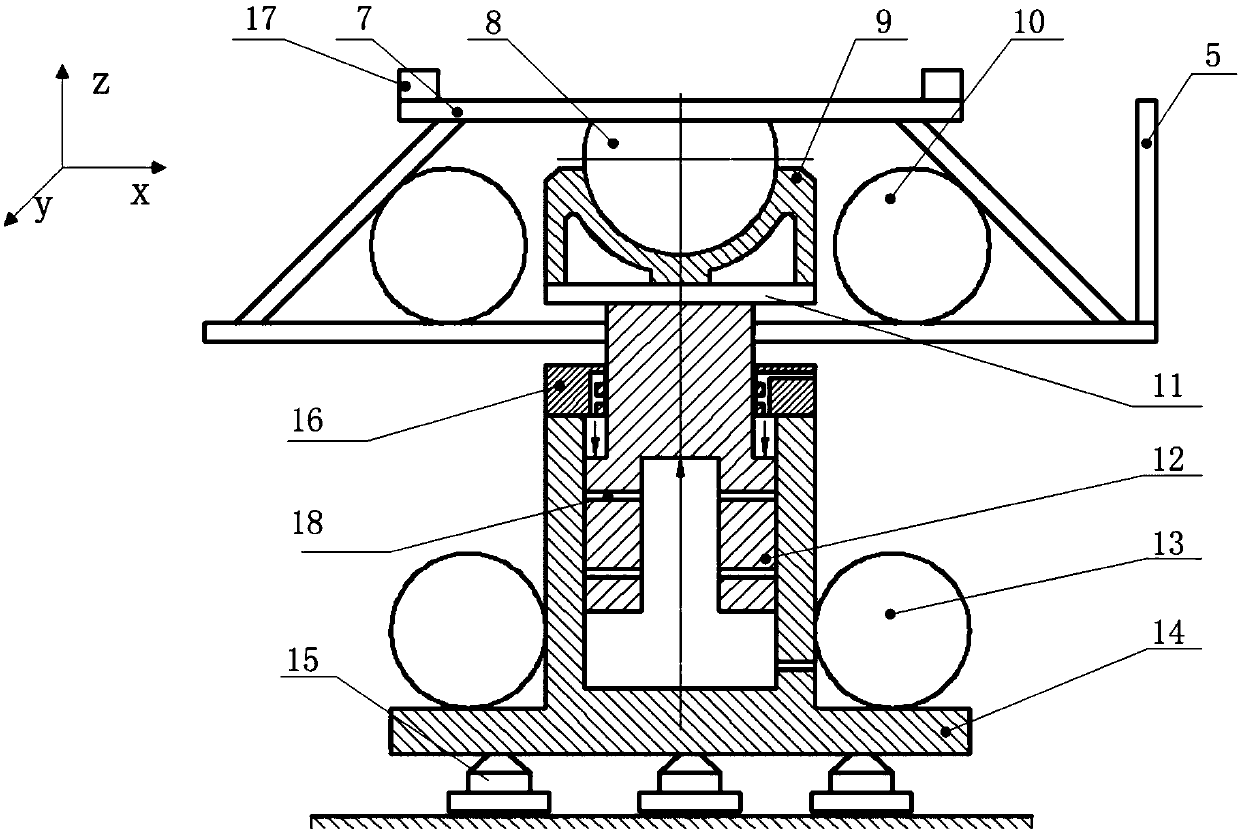

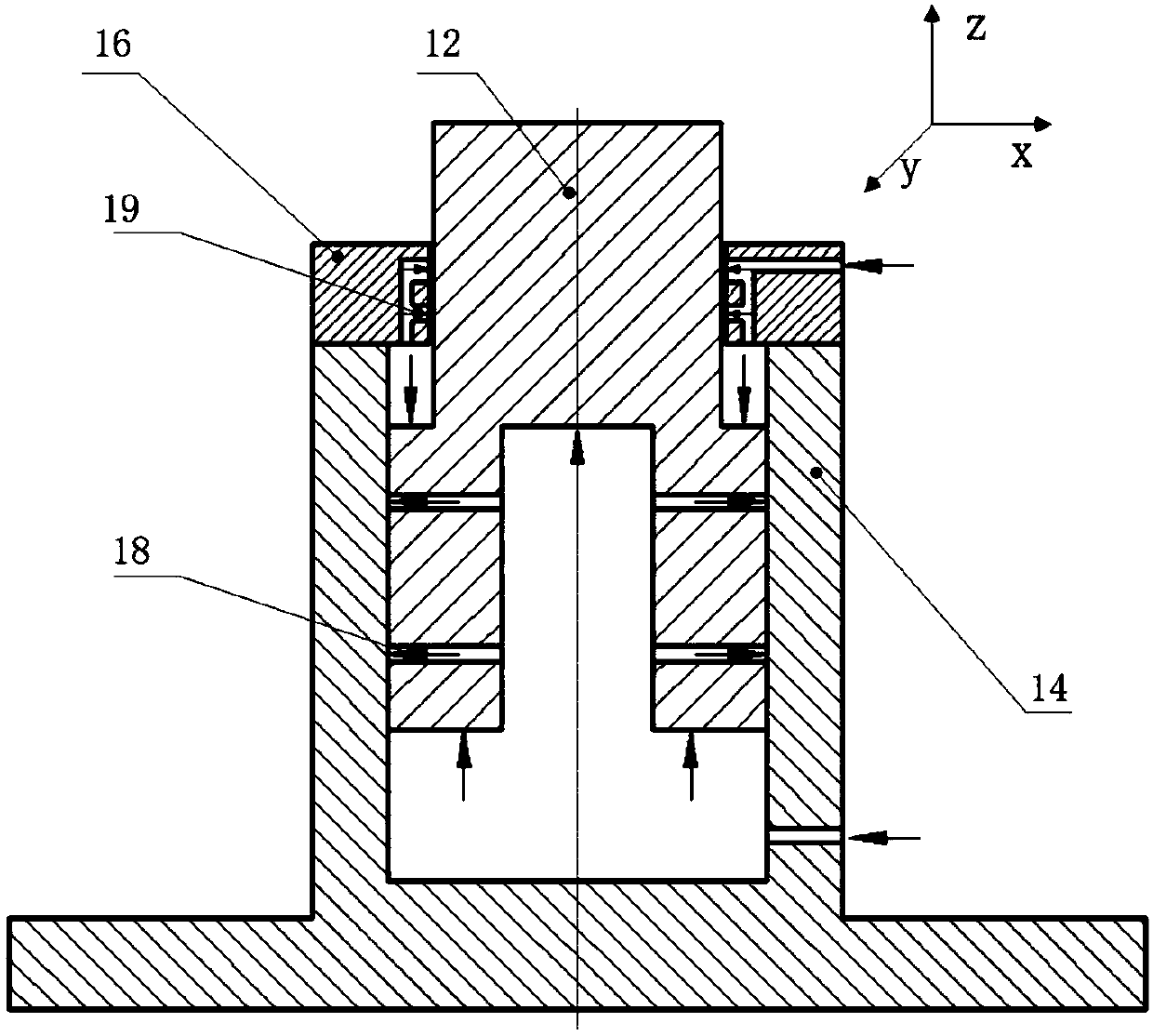

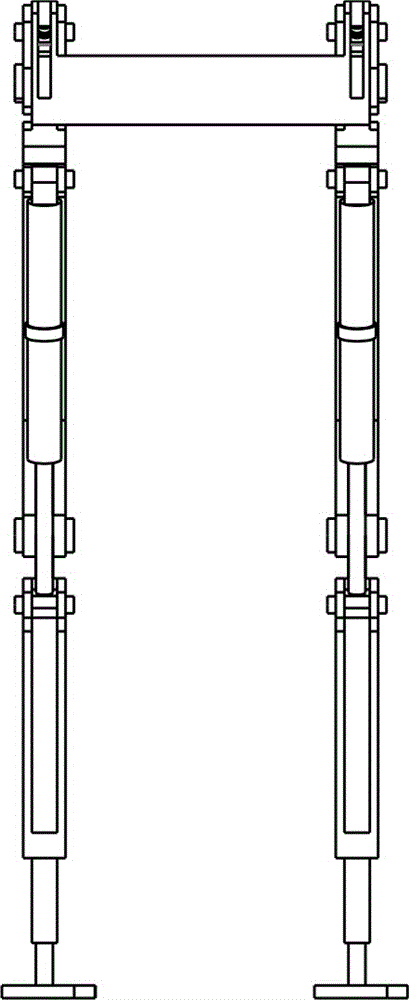

Double-super-satellite platform ground simulation equipment based on differential air flotation vertical control

ActiveCN109649702AReduce frictionUnlimited service lifeCosmonautic condition simulationsBall bearingSimulation

The invention provides a double-super-satellite platform ground simulation equipment based on differential air flotation vertical control, and belongs to the field of spacecraft physical simulation. Rx and Ry and Rz degree-of-freedom rotation of a rotating platform is realized by the aid of an air flotation ball bearing, X and Y degree-of-freedom movement of a load cabin air flotation platform anda platform cabin air flotation platform is realized by the aid of a plane air flotation bearing, a support vertical column and a horizontal moving platform jointly form an air flotation structure bythe aid of orifices formed in the support vertical column, and air suspension support, vertical guide and vertically upward pressure control drive of the support vertical column are realized. Verticalguide and vertically downward pressure control drive of the support vertical column are realized, differential air flotation vertical movement control of the support vertical column is further realized, and the equipment has the advantages of six-degree-of-freedom non-contact support drive property, high stability, rapid response and the like and can be used for double-super-satellite platform attitude simulation, big-swing-angle mobility verification, movement imaging ground verification and the like.

Owner:SHANGHAI SATELLITE ENG INST

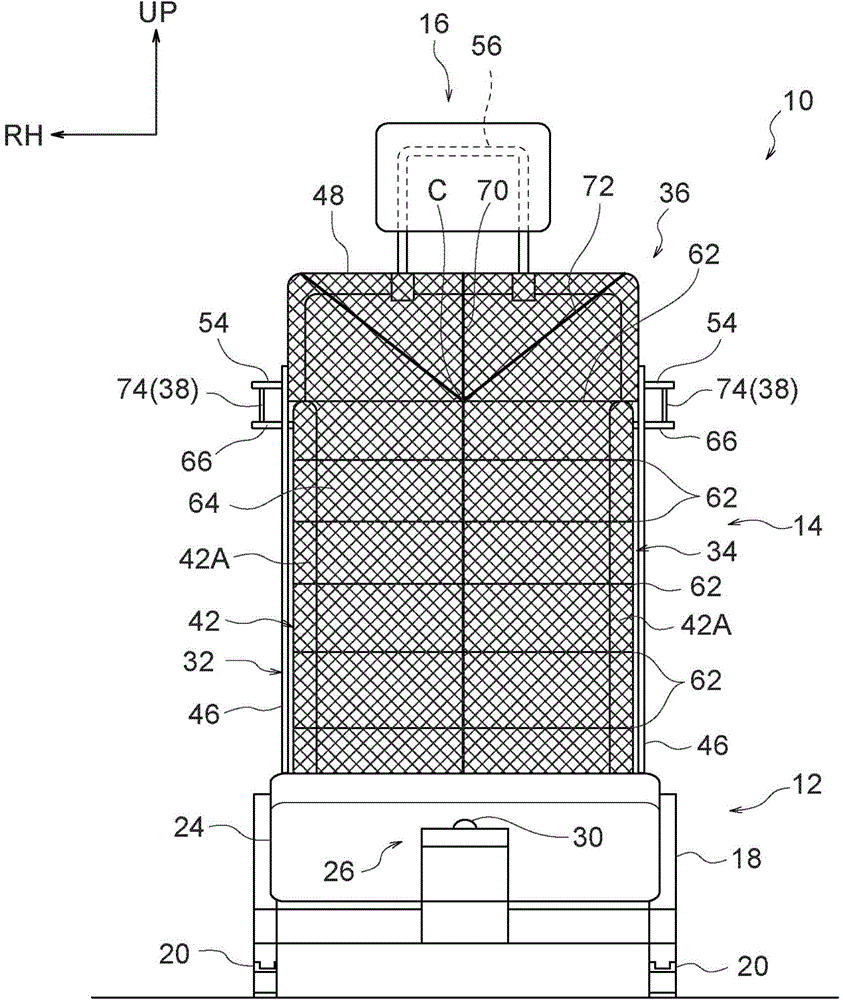

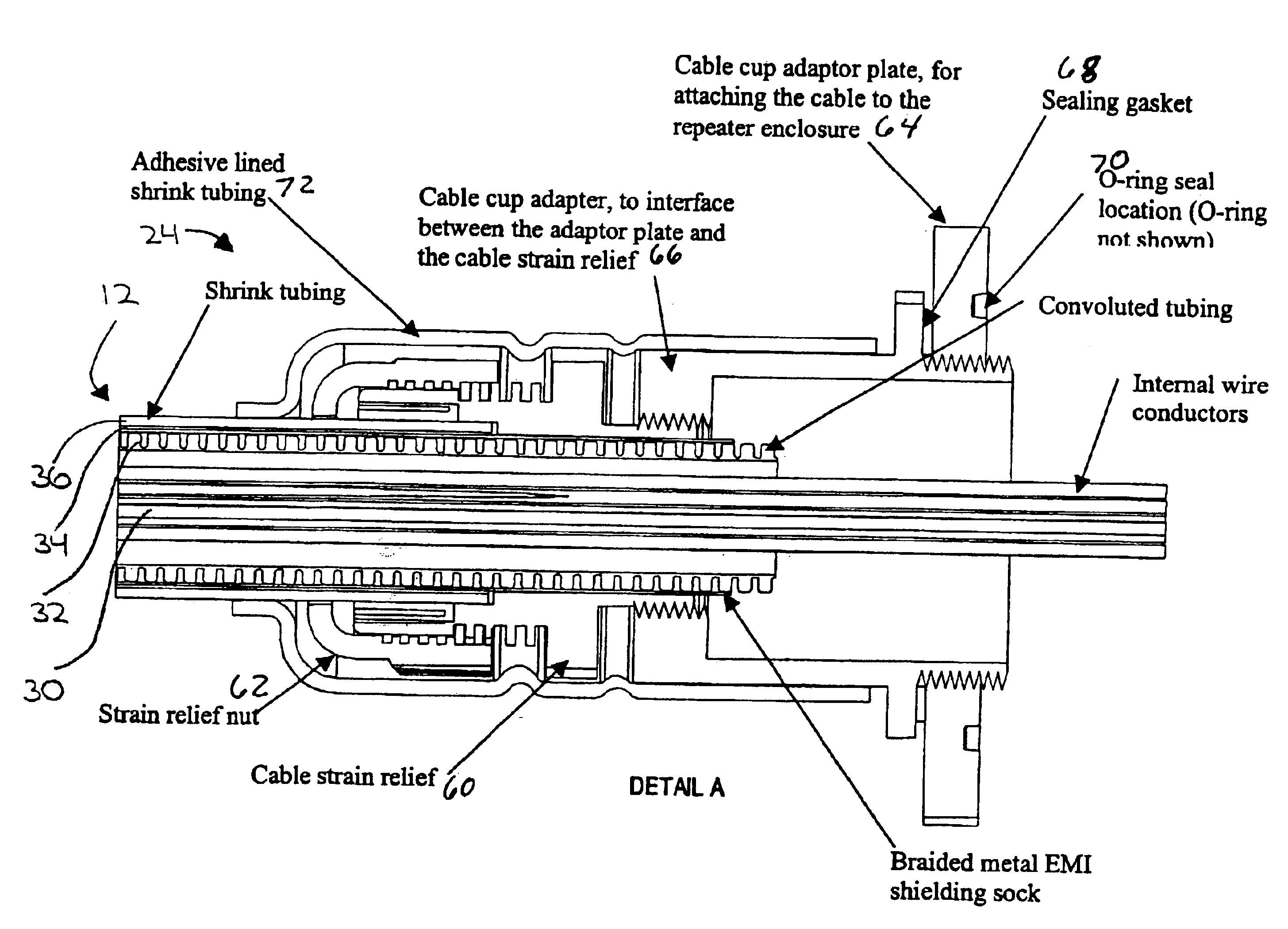

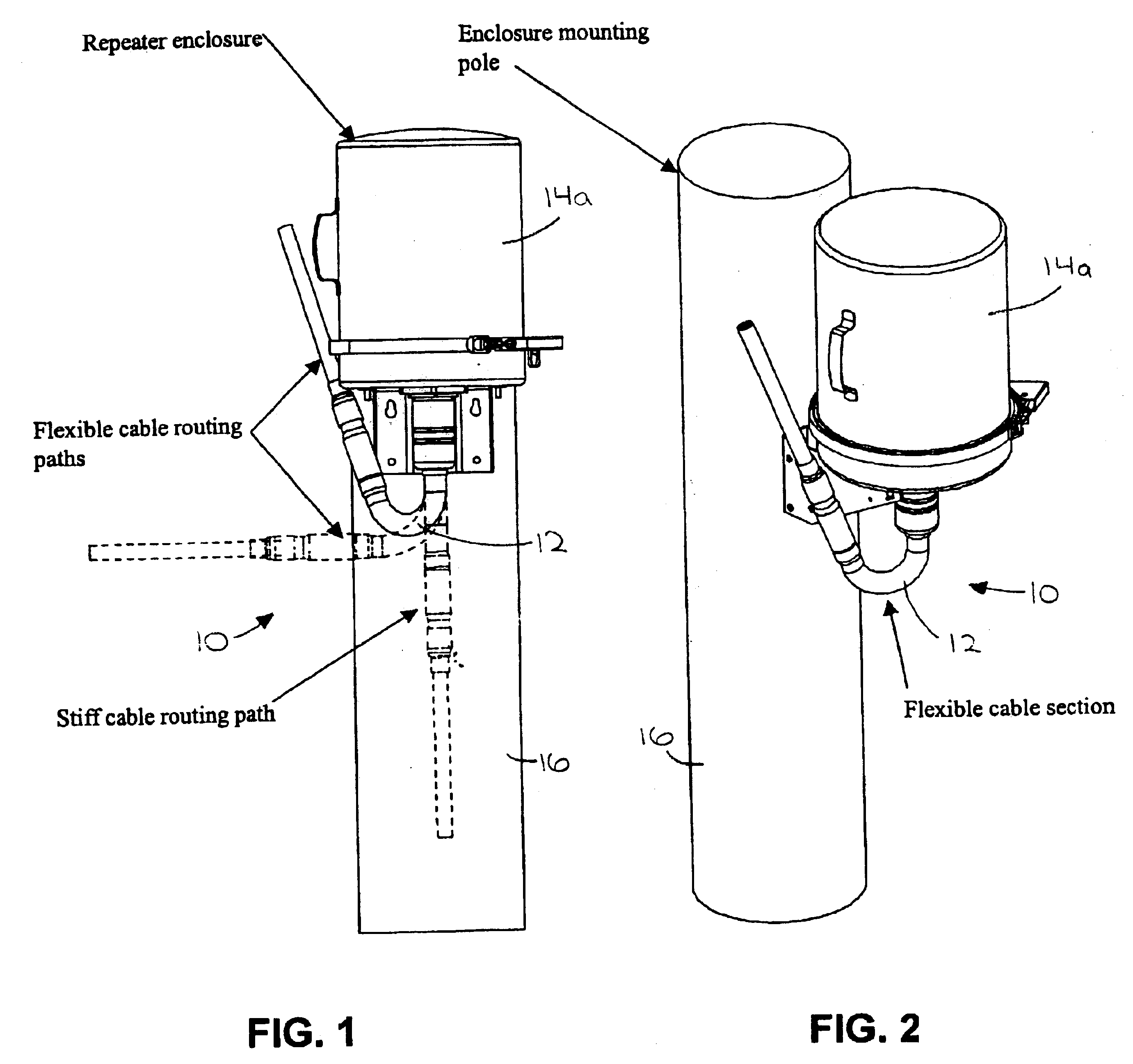

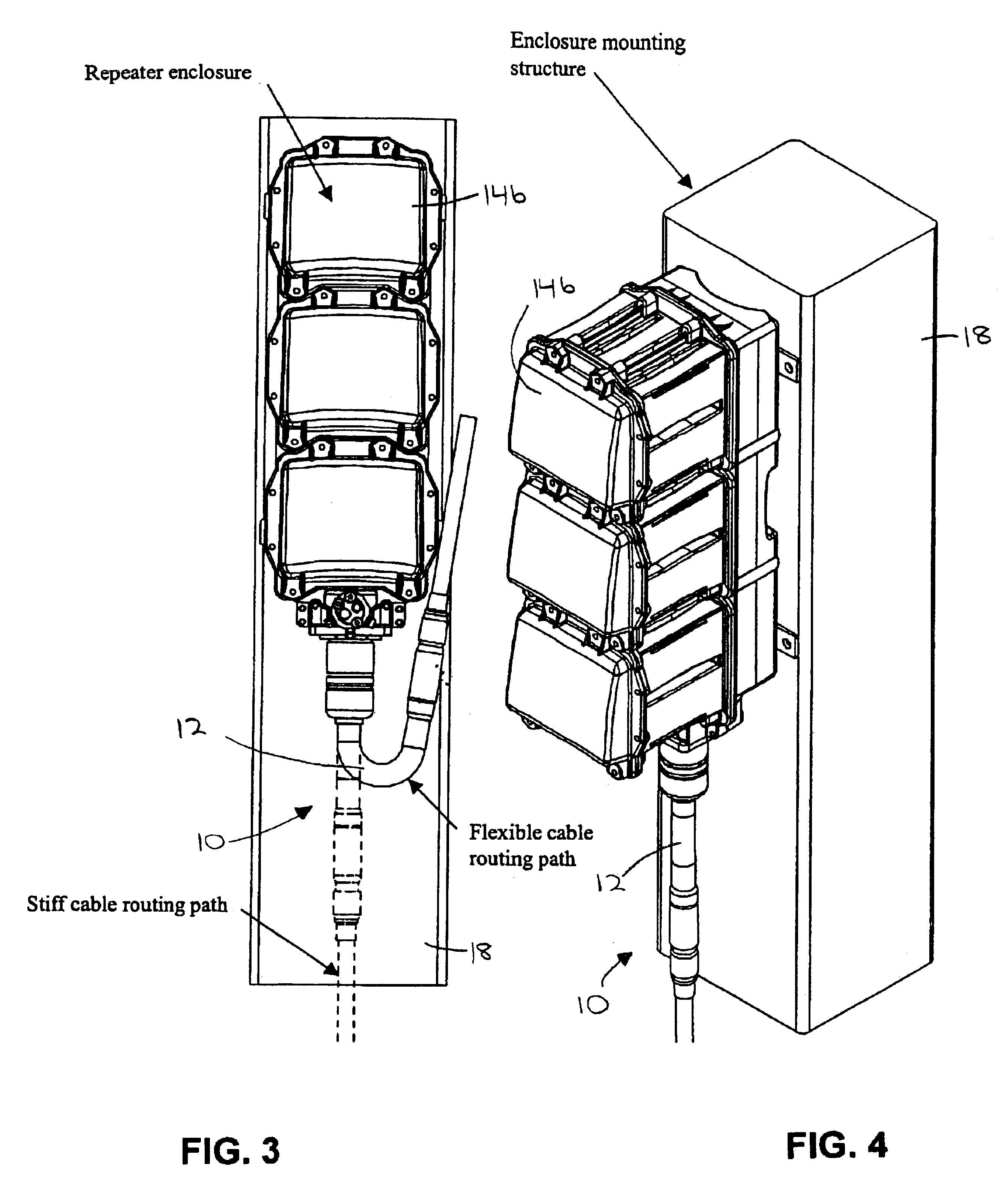

Flexible telecommunications cable for outside plant equipment

InactiveUS6870106B1Increase flexibilityFacilitates accommodating alignmentElectrically conductive connectionsCable junctionsElectrical conductorTelecommunications cable

A telecommunications cable section (12) for connection with telecommunications or signaling equipment or other outside plant equipment, wherein the cable section (12) comprises a plurality of conductors (30) surrounded by an intermediate layer of corrugated material (32). A flexible braided or mesh protective sheathing (34) substantially surrounds the intermediate layer (32). The braided sheathing (34) is preferably a braided or mesh sock or tubular sleeve or sleeve of copper or other metal or material. An exterior layer of substantially moisture-proof shrinkable tubing (36) substantially surrounds the braided sheathing (34).

Owner:SPECIAL PRODS

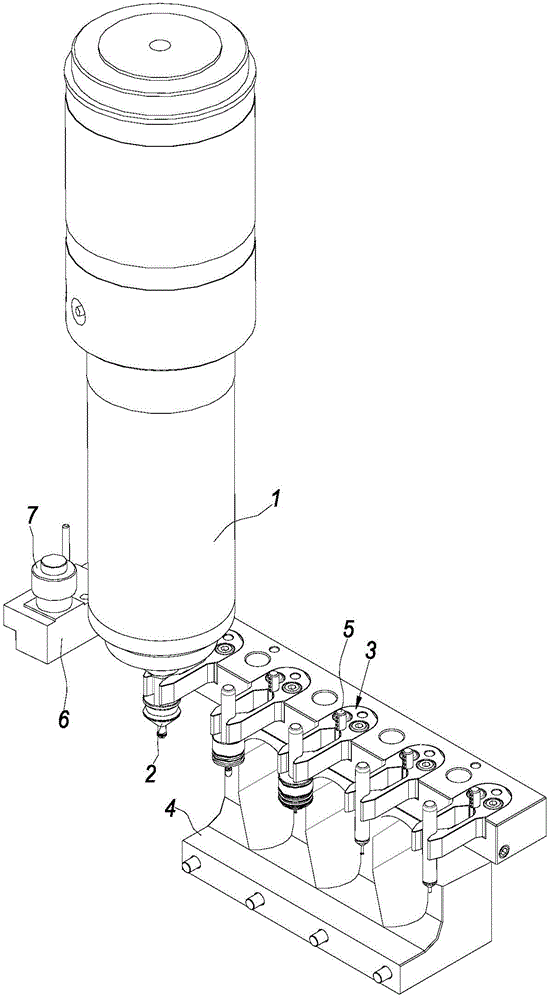

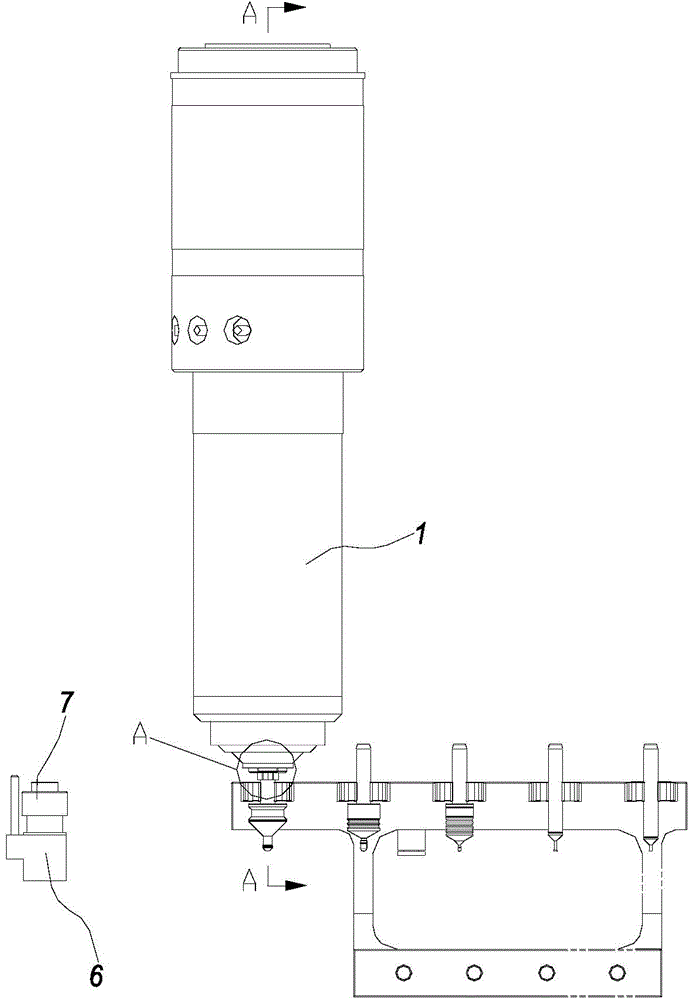

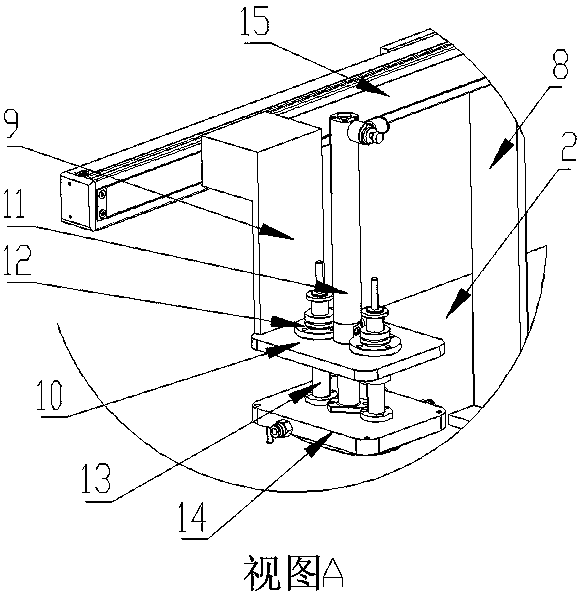

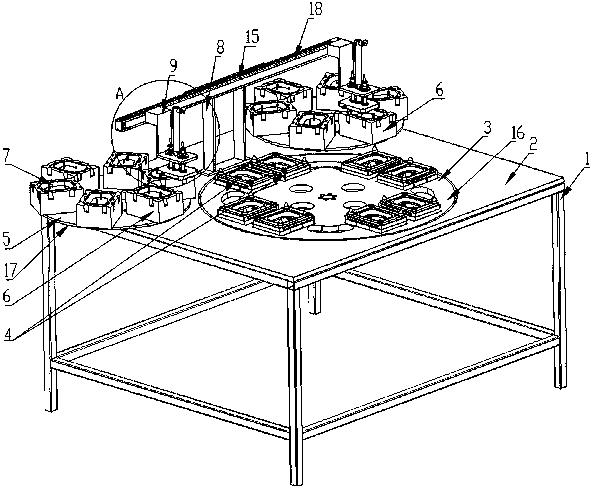

Superspeed motorized spindle automatic tool changer and superspeed motorized spindle automatic tool changing method

ActiveCN104128831AGuaranteed uptimeMany types of applicationsPositioning apparatusMetal-working holdersCalipers

The invention discloses a superspeed motorized spindle automatic tool changer. The superspeed motorized spindle automatic tool changer comprises a motorized spindle, calipers and a calipers installation base. The calipers can clamp a tool tightly and are installed in the calipers installation base. The motorized spindle is used for being detachably connected with the tool and moving the tool in or out of the calipers from the lateral portion of the calipers. The invention further discloses a superspeed motorized spindle automatic tool changing method. The superspeed motorized spindle automatic tool changing method comprises the steps that the motorized spindle is moved to the front end of the calipers, and the tool is pushed into the calipers to be clamped tightly; the motorized spindle is separated from the tool and is moved to a tool changing detector to carry out tool changing logic checking; after tool changing is detected to be successful, the motorized spindle is moved to the upper end of next calipers, the tool is installed in a chuck of a spring clamping tool, and the chuck of the spring clamping tool on the motorized spindle clamps the tool; the motorized spindle and the clamped tool are transversely moved out of the calipers, the length of the tool is measured, and tool changing is finished. The tool is clamped reliably and positioned accurately, the tool changing precision of the motorized spindle is high, tool changing is accurate and efficient, and stability of motorized spindle running is guaranteed.

Owner:江西衡源智能装备股份有限公司

Production process for high-moisture-absorption polyester down-proof fabric used for home textiles

ActiveCN107099908AGood flexibilityImprove compactnessSucessive textile treatmentsHeating/cooling textile fabricsPolyesterFiber

The invention relates to a production process for a high-moisture-absorption polyester down-proof fabric used for home textiles. The production process includes the following steps that weaving is conducted, wherein polyester DTY silk serves as warp yarn, sea-island fibers serve as weft yarn, and weaving is conducted on a water-jet loom; the sea-island fibers refer to PET, the island refers to COPET, the on-loom warp density is 137-200 per inch, the weft density is 100-200 per inch, and a gray fabric is formed by weaving; one side of the fabric is brushed; refining and splitting are conducted, the brushed fabric is fed into an overflow dyeing machine, splitting is conducted in the overflow dyeing machine, and the softness and compactness of the fabric are improved; water washing and plastification are conducted, fluffing and setting are conducted, the fabric obtained after water washing and plastification is subjected to pad-roll processing with a polyester bulking agent before passing through a setting machine, and a finished fabric product is formed after being subjected to setting through the setting machine. The process does not require the high-count and high-density weaving process required by a traditional down-proof fabric, so that the gray fabric weaving production difficulty is low, at the same time, the disadvantages that the coated down-proof fabric production process requires coating operation and thus causes long production process, hard hand feeling and easy-to-fall-off coatings are overcome, and therefore the production process is more suitable for the down-proof fabric used for the home textiles.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

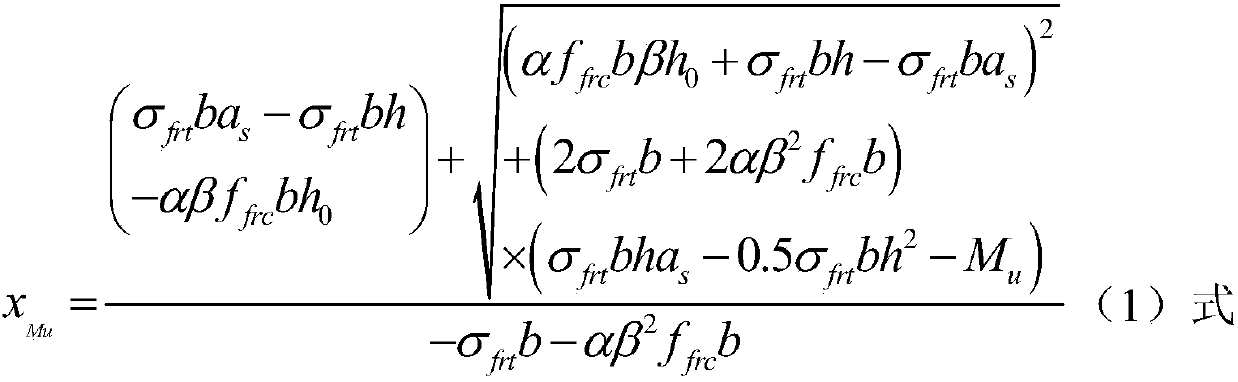

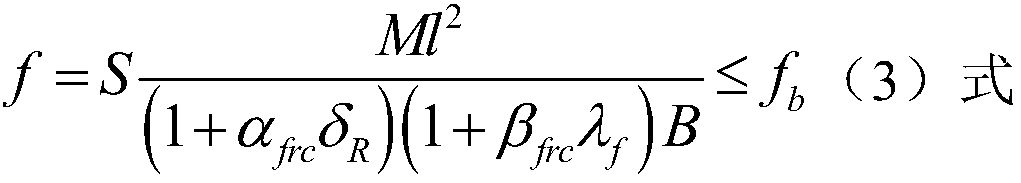

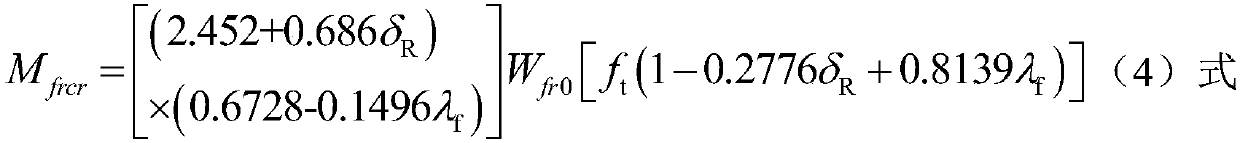

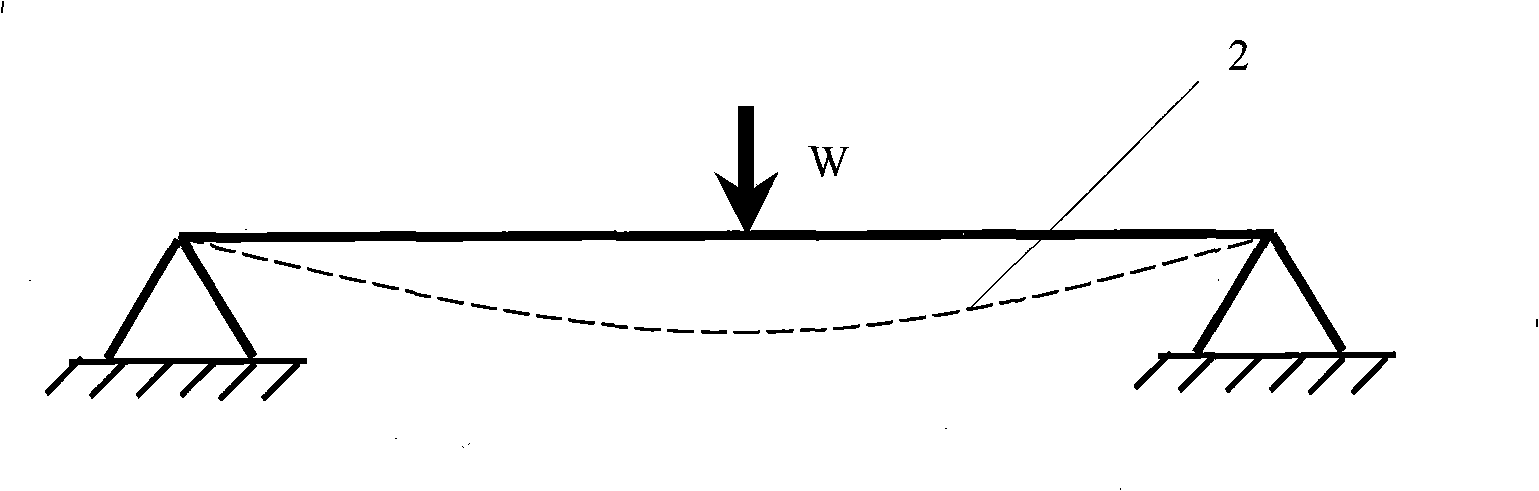

Design method of steel fiber recycled concrete beam

ActiveCN107563049AOvercoming easy cracking and poor stiffnessGuaranteed structural stabilitySpecial data processing applicationsRebarStructural stability

The invention belongs to the technical field of architectural design structures, particularly relates to a design method of a steel fiber recycled concrete beam, and mainly provides a novel design structure method of steel fiber recycled concrete to effectively solve the technical problems of easy cracking and poor stiffness of the recycled concrete. The design method of the steel fiber recycled concrete beam comprises the steps of 1, determining the sectional width b and sectional height h of the designed reinforcement steel fiber recycled concrete beam; 2, determining the reinforcement ratiopMu of the reinforcement steel fiber recycled concrete beam; 3, determining the deflection value f of the reinforcement steel fiber recycled concrete beam; 4, conducting cracking checking calculation; 5, calculating the width of cracks. The design structure method not only effectively solves the technical problems of easy cracking and poor stiffness of the recycled concrete, but also effectivelyensures the structural stability of the steel fiber recycled concrete, and meanwhile the method is also effectively applied to weighing or non-weighing structure beams.

Owner:ZHENGZHOU UNIV +1

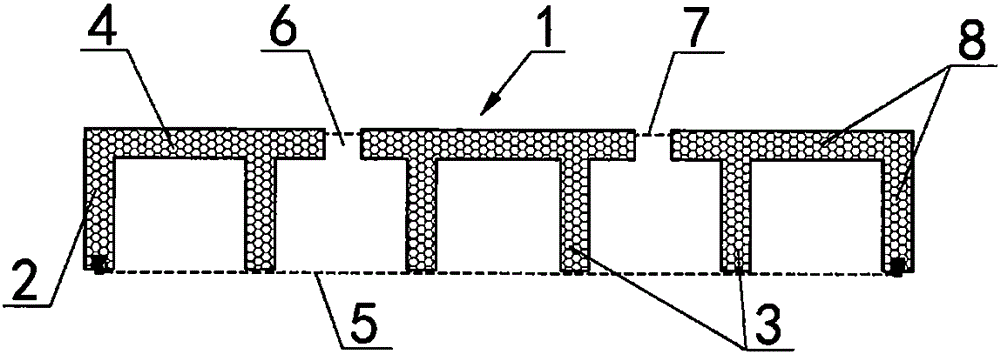

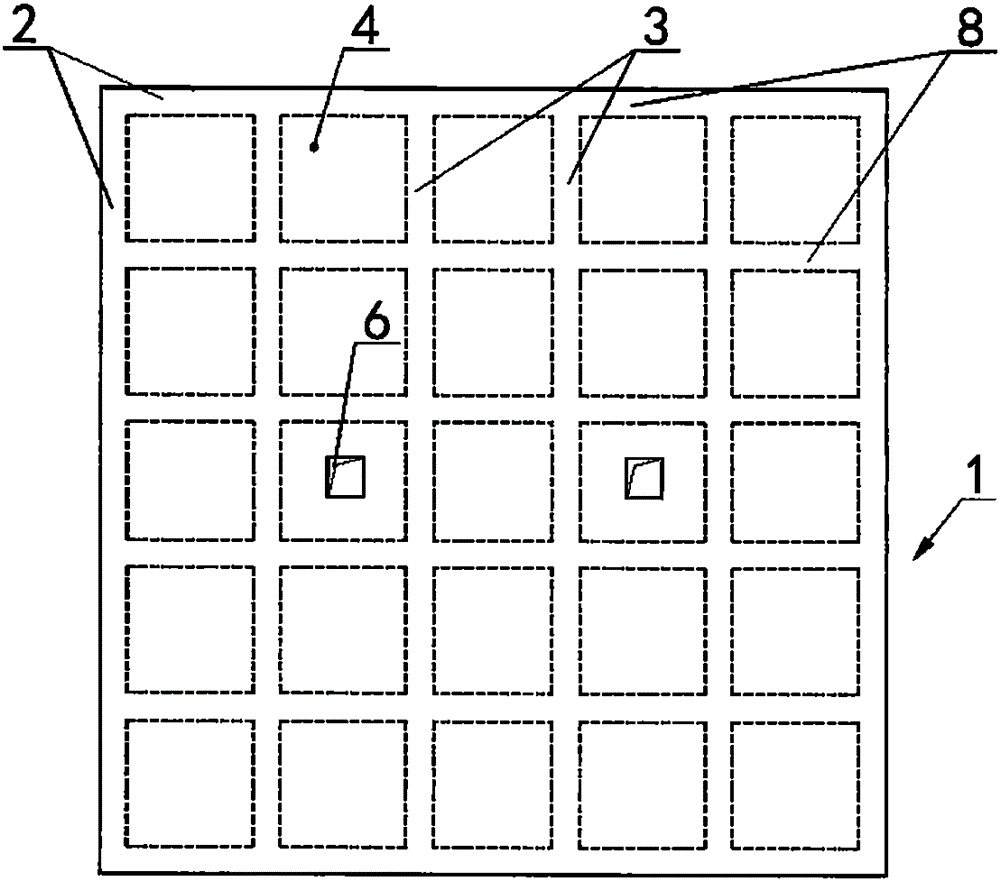

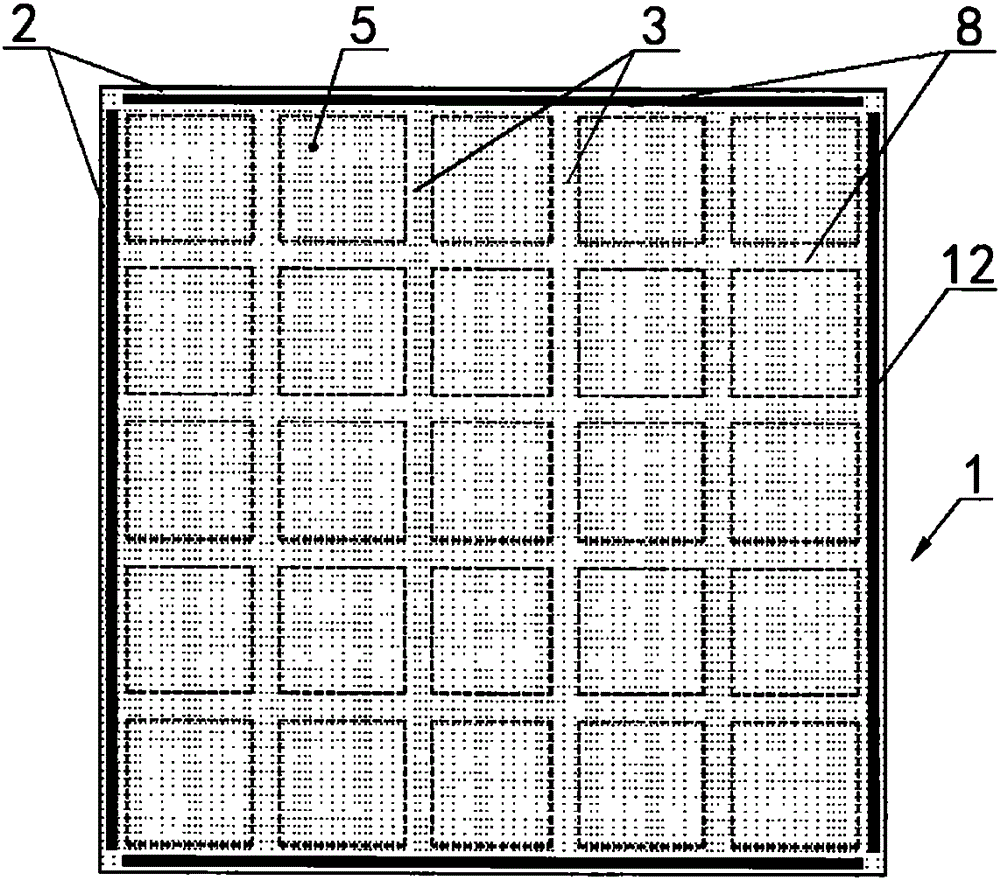

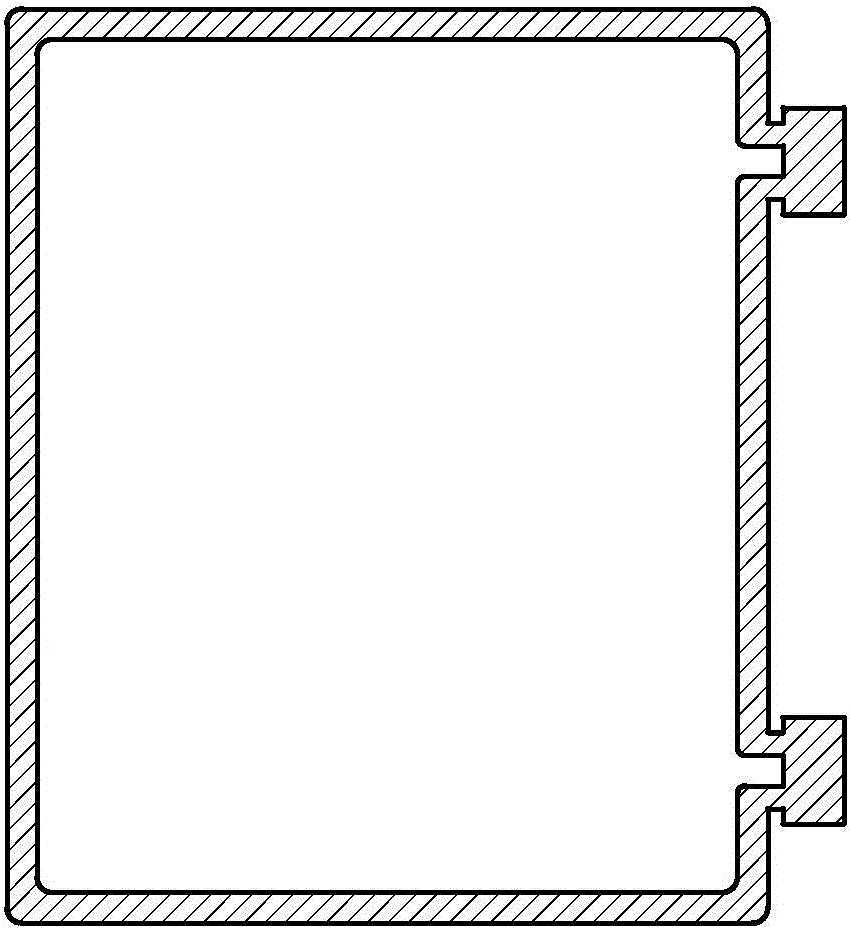

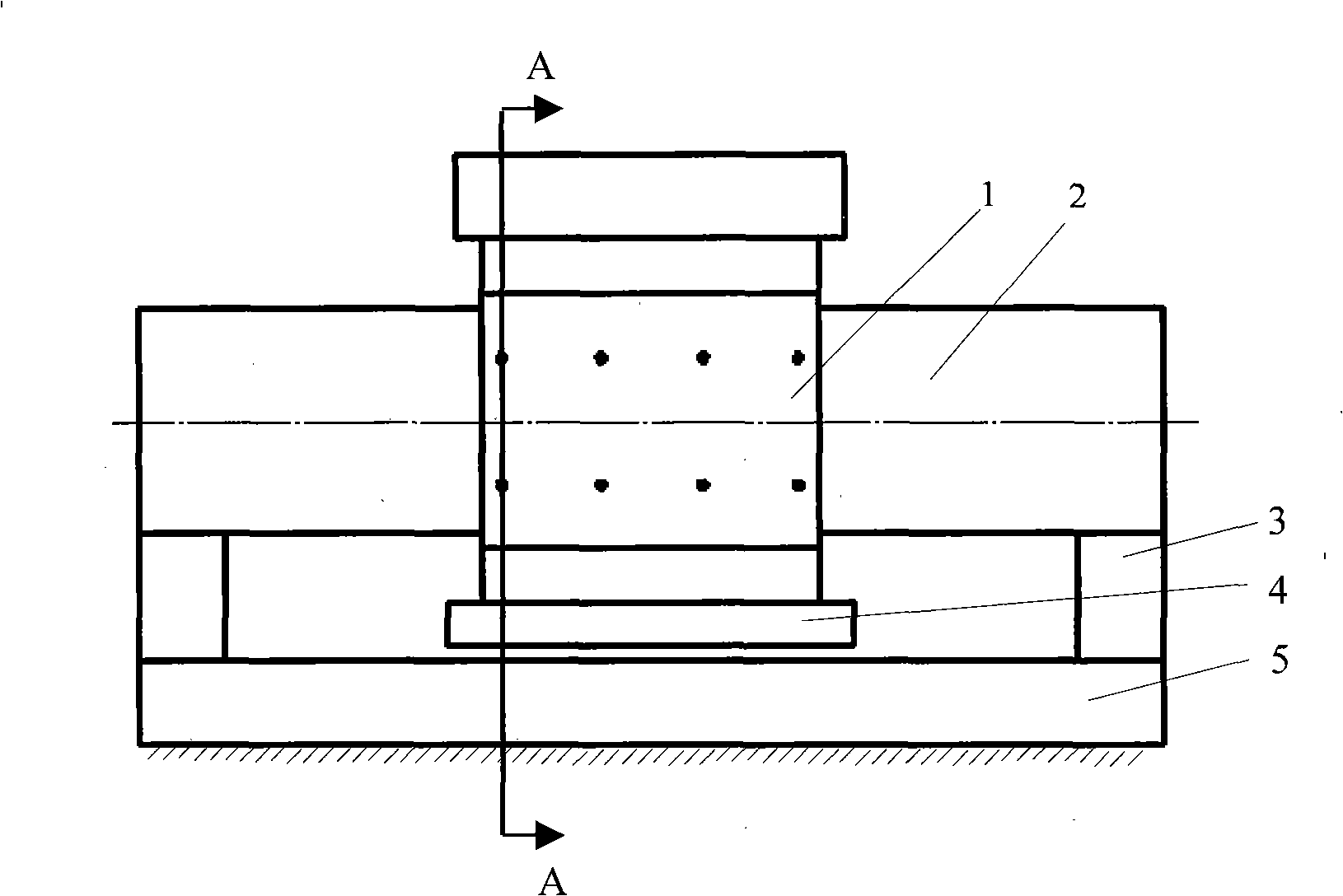

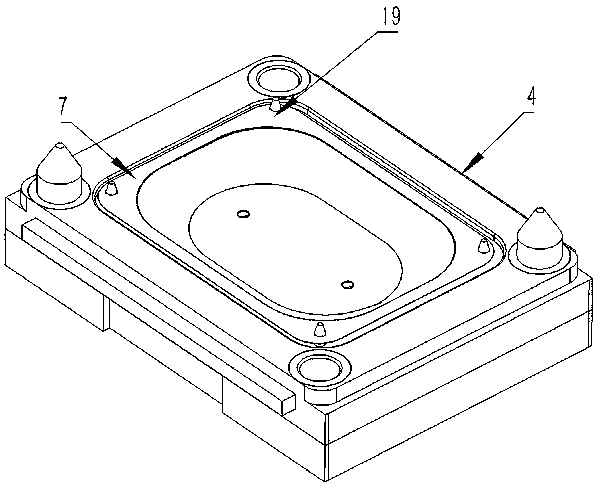

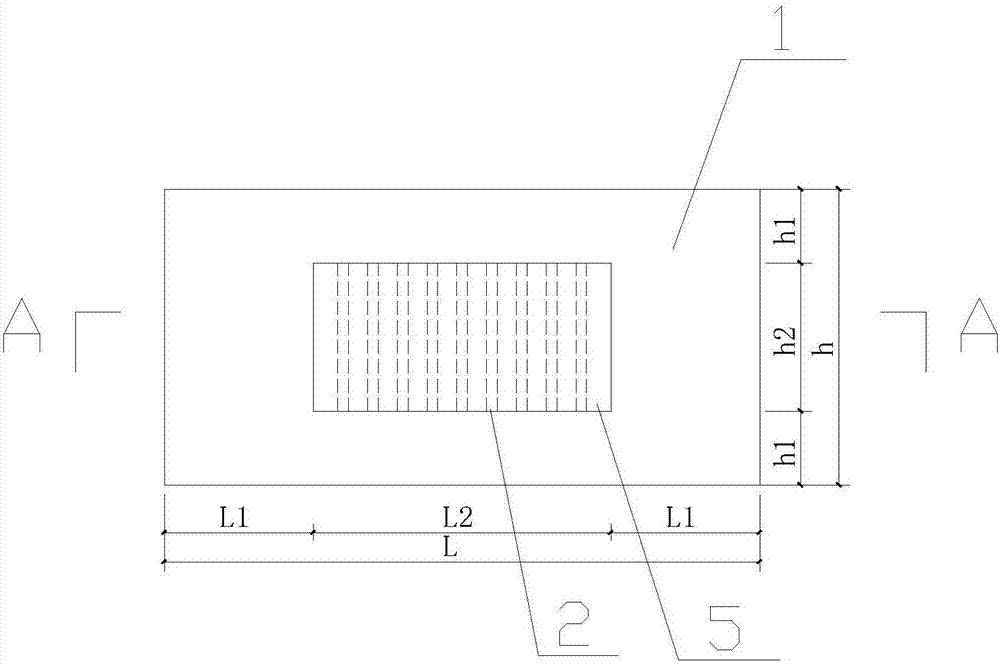

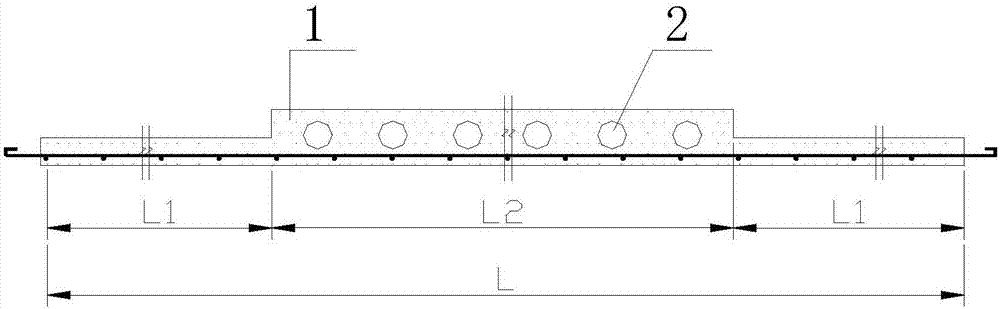

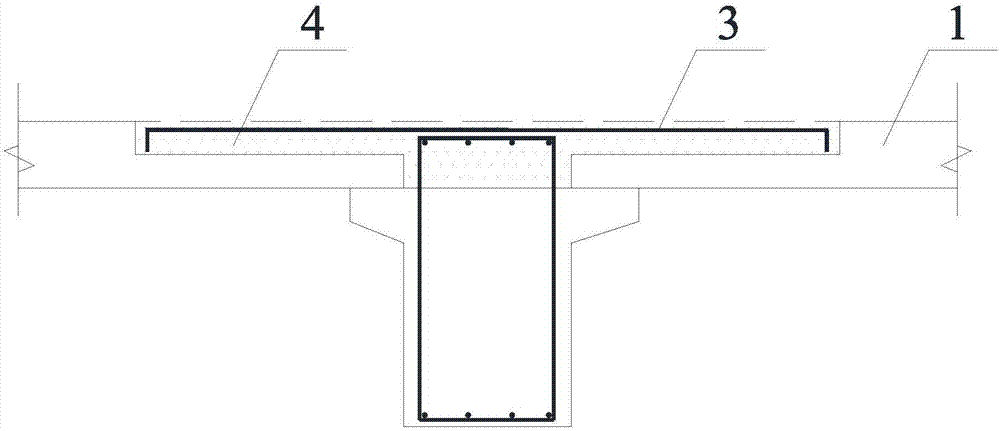

Filling box with bottom ventilation net and upper part exhaust holes

The invention relates to a filling box with a bottom ventilation net and upper part exhaust holes and a manufacturing method of the filling box, and belongs to the field of building construction. The filling box (1) comprises side frame plates (2), stiffening inner plates (3), a top cover plate (4) and the ventilation net (5), wherein the four side frame plates (2) in end-to-end connection define a rectangular plane; more than one stiffening inner plate is at least arranged in each direction; the stiffening inner plates in different directions are in mutual orthogonality; at least one exhaust hole (6) is formed in the top cover plate; an exhaust net (7) is arranged in each exhaust hole; the top cover plate, the stiffening inner plates and the side plate plates made of nonmetallic materials form a box-shaped structure (8) with an open bottom surface together; the ventilation net is fixed on the bottom of the box-shaped structure in various connecting modes; and the ventilation net and the exhaust nets are made of metal or plastic materials. The filling box provided by the invention has the advantages that the production, the transportation and the installation are very convenient; the mechanical property is good; and a hollow floor slab formed by the product has high reliability, good earthquake-resistant performance and good anti-crack performance.

Owner:北京东方京宁建材科技有限公司

Preparation method of carbon fiber reinforced resin composite material

ActiveCN105965989ALow raw material costImprove fracture toughnessLaminationLamination apparatusEpoxyUltimate tensile strength

The invention discloses a preparation method of a carbon fiber reinforced resin composite material. A PAN-based carbon fiber carbon cloth-epoxy resin prepreg, an asphalt-based carbon fiber felt body, and a thermoplastic resin film / thin plate are overlapped; hot-press molding is carried out, and the carbon fiber reinforced resin composite material is prepared. The composite material mainly employs the asphalt-based carbon fiber felt body of low cost as a reinforcement, so that the cost of raw materials of the composite material is reduced; asphalt-based carbon fibers in a prefabricated body are in random arrangement, so the level of isotropy is high; after the raw materials and the thermoplastic resin are compounded, fracture toughness properties and repairability of the composite material are improved. A certain amount of PAN-based carbon fiber carbon prepreg interlayer is added into the composite material, so that after solidification, strength and rigidity of the integral composite material are better.

Owner:湖南东映碳材料科技股份有限公司

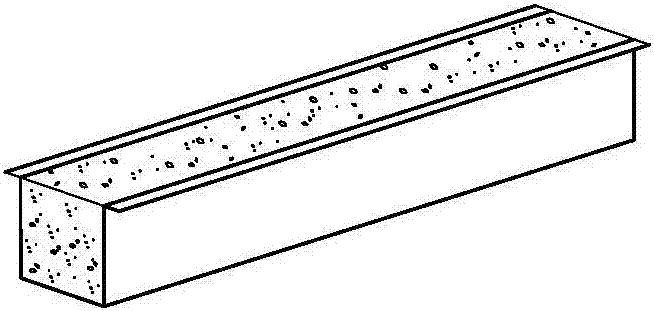

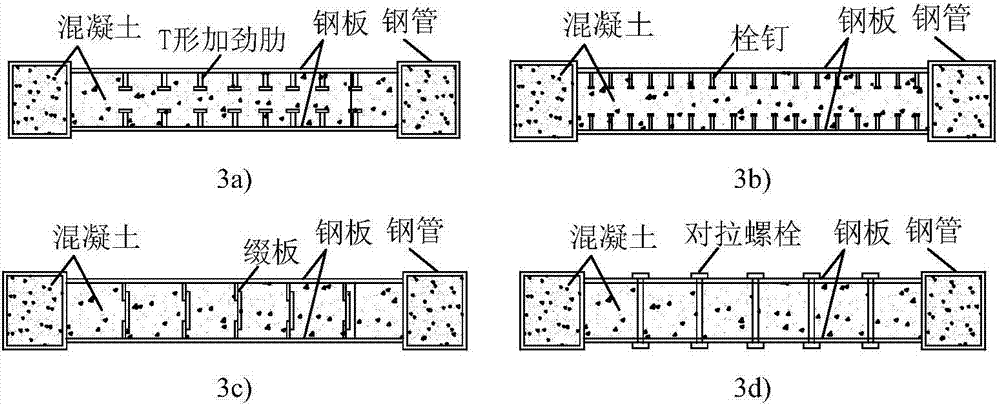

Fabricated super-high-rise steel-concrete combination residence

InactiveCN107882178AOvercome stiffnessOvercome the defect of poor ductilityStrutsWallsResidenceBuckling-restrained brace

The invention belongs to the technical field of buildings and particularly relates to a fabricated super-high-rise steel-concrete combination residence. The advantages that formworks are omitted, ductility is good and the rigidity is large of a steel-concrete combined structure are utilized, the defects that as for a fabricated concrete structure, the resistant-lateral rigidity is small and the ductility is poor, as for a fabricated steel structure, deformation is large, and as for an existing fabricated steel-concrete combination structure prefabricated member, the structure is complex and cast-in-place shear walls are adopted are overcome, and an innovated fabricated steel-concrete combination structure system is applied to the fabricated super-high-rise residence. The fabricated super-high-rise steel-concrete combination residence is composed of concrete-filled steel pipe combination columns, externally-wrapped steel-concrete combination beams, steel plate combination shear walls and energy-dissipation-type concrete-filled steel pipe combination buckling constraint supports to serve as the structure system of the super-high-rise residence, and thus the defects that as for the fabricated concrete structure, the resistant-lateral rigidity is small and the ductility is poor, and as for the fabricated steel structure, deformation is large are overcome.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Low-viscosity perfusion adhesive for repairing concrete crack and preparation method thereof

ActiveCN108384497ALow viscosityGood flexibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveRoom temperature

The invention discloses a low-viscosity perfusion adhesive for repairing a concrete crack and a preparation method thereof. The low-viscosity perfusion adhesive for repairing the concrete crack is prepared from a component A and a component B in a mass ratio of 100 to 3, wherein, in parts by mass, the component A is prepared from 100 parts of cardanol epoxy resin, 1.2 to 9.7 parts of ester thinner, 0.5 to 1 part of surfactant and 1 to 1.5 parts of antifoaming agent; the component B is prepared from 25 to 37 parts of compound amine curing agent, 1 to 3 parts of coupling agent and 1 to 2 parts of accelerant. The cardanol epoxy resin of the low-viscosity perfusion adhesive is low in room-temperature viscosity; as the cardanol has a low-temperature-resistant characteristic, the cardanol epoxyresin is slightly influenced in viscosity by a temperature change, and is particularly suitable to use in a low-temperature environment; the excellent flexible performance is provided for the epoxy resin by the longer carbon chain of the cardanol; when a seam injection adhesive is confected, a flexibilizer can be allowed not to be extra added any more; in addition, a synthetic raw material cashewnut shell liquid of the low-viscosity perfusion adhesive is a potential renewable resource, and the production cost is enabled to tend to cheapness.

Owner:中冶武汉冶金建筑研究院有限公司

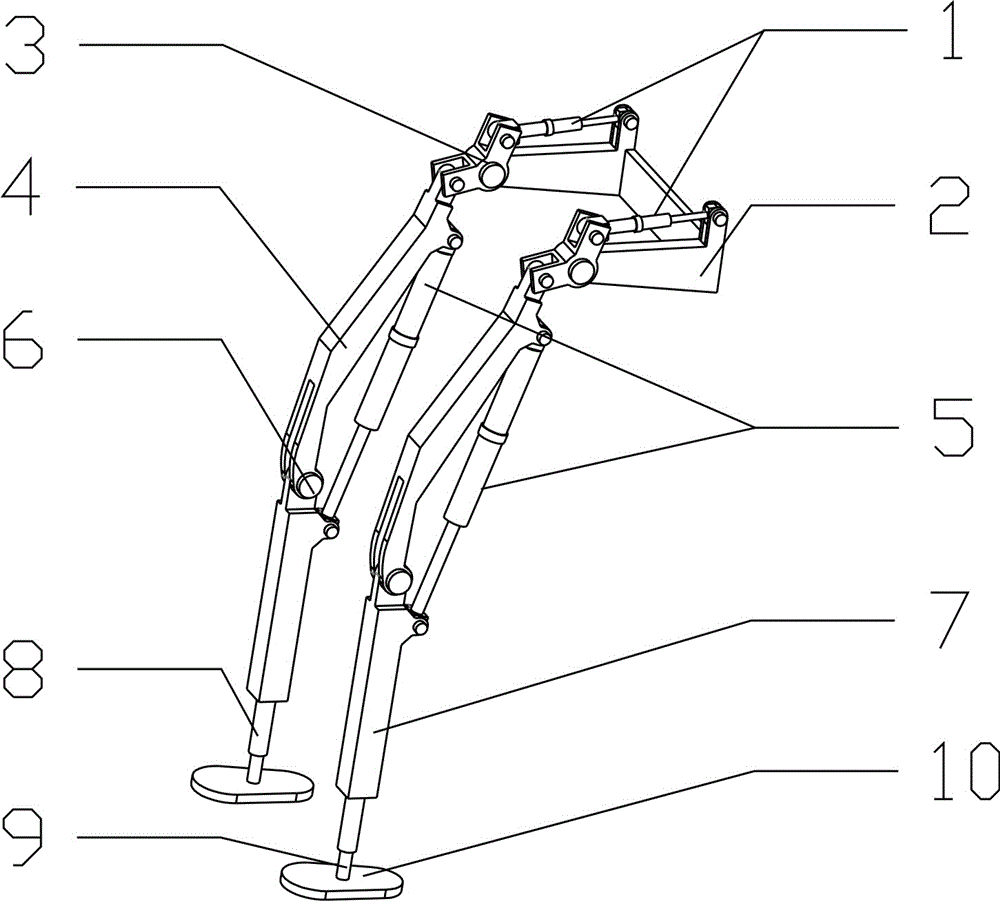

Assisting exoskeleton mechanism system for lower limbs

InactiveCN106426116AImprove key featuresOvercome stiffnessProgramme-controlled manipulatorThighHydraulic cylinder

The invention discloses an assisting exoskeleton mechanism system for lower limbs. The assisting exoskeleton mechanism system is characterized by comprising hip joint gas-liquid cylinders, a rigid waistband, hip joint motors, thighs, knee joint gas-liquid cylinders, knee joint motors, shank outer rods, shank inner rods, ankle joint motors and soles. According to the assisting exoskeleton mechanism system disclosed by the invention, gas-liquid series cylinders are used to replace conventional pure hydraulic drive or pure gas-pressure drive to support hip joints and knee joints; the gas-liquid series cylinders are driven by air cylinders, so that system weight can be reduced, and drive speed can be increased; and hydraulic cylinders can overcome defects of low rigidity and poor stability of pure air cylinder drive. Therefore, the assisting exoskeleton mechanism system for the lower limbs provided by the invention has the advantages of good quick rapidity, high rigidity, strong stability, stable operation and the like, and can improve key characteristics of the assisting exoskeleton mechanism system fort the lower limbs.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

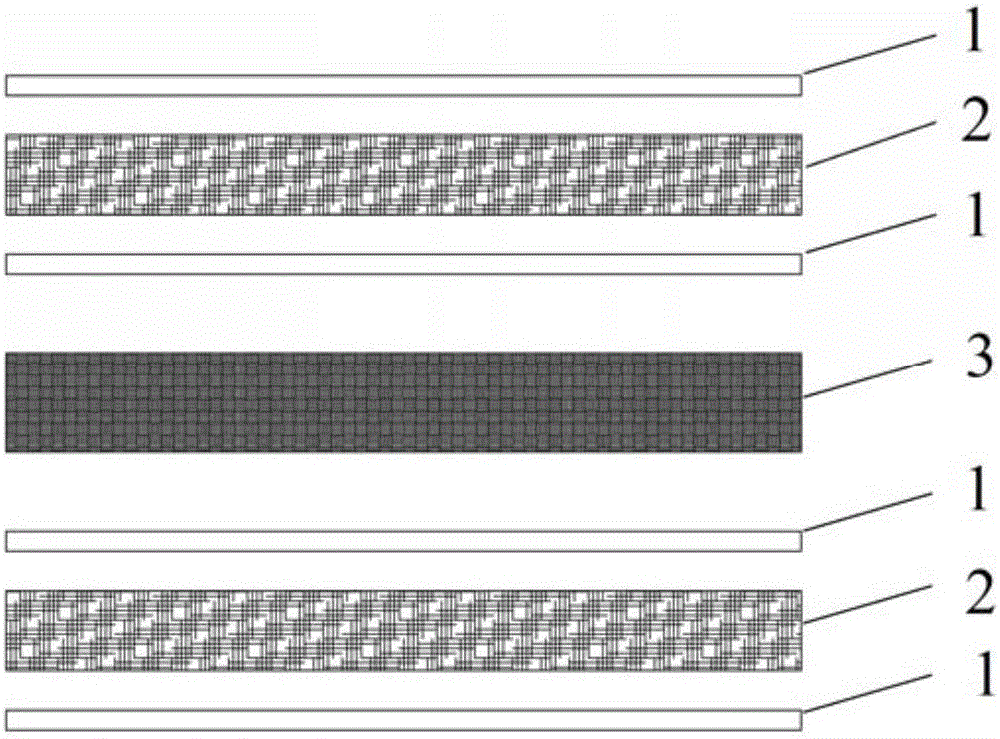

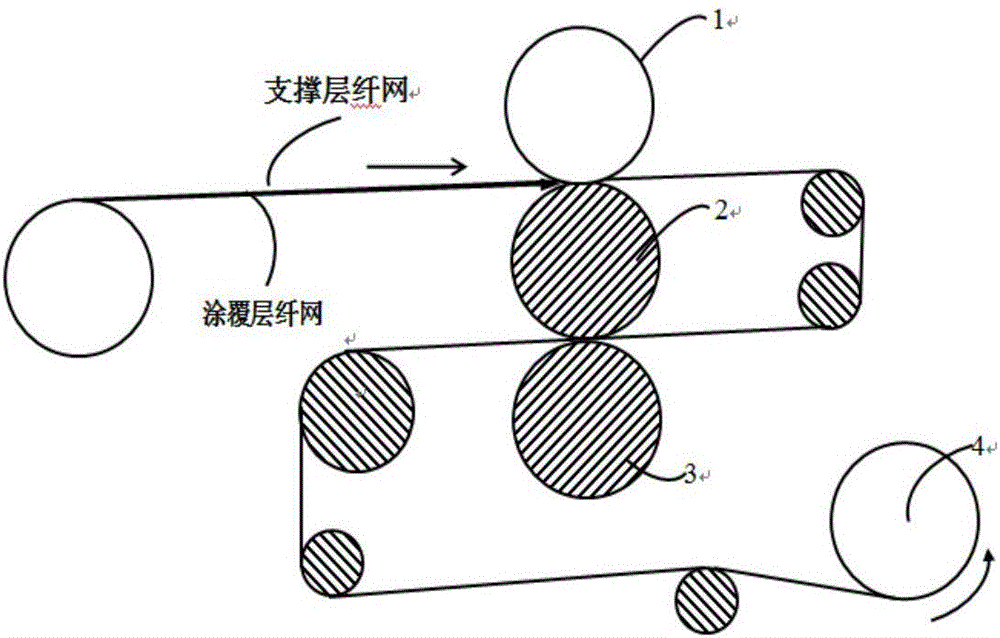

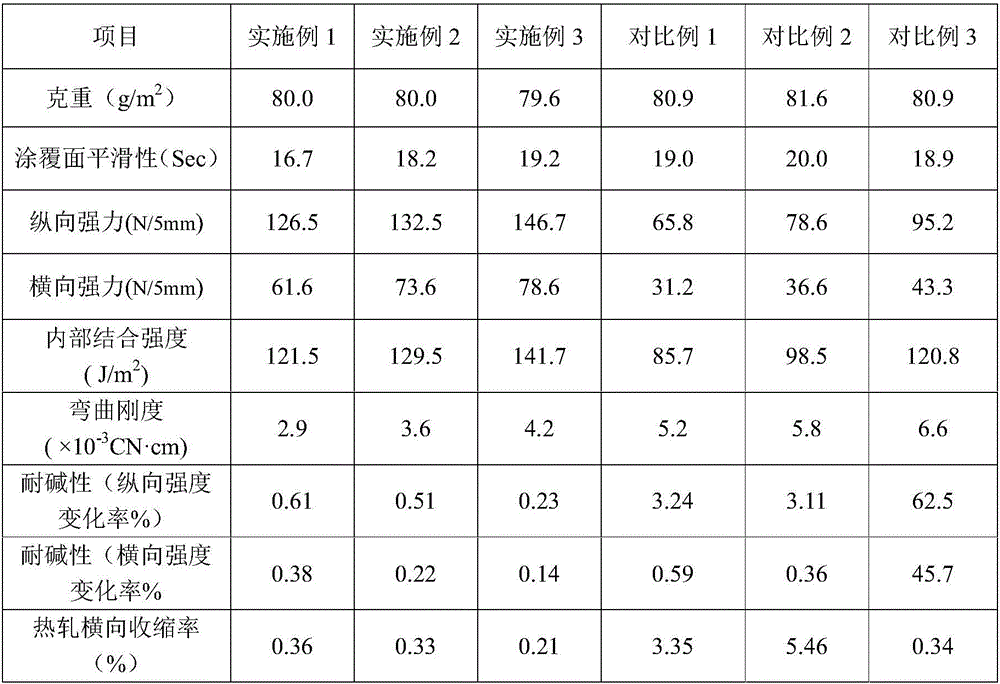

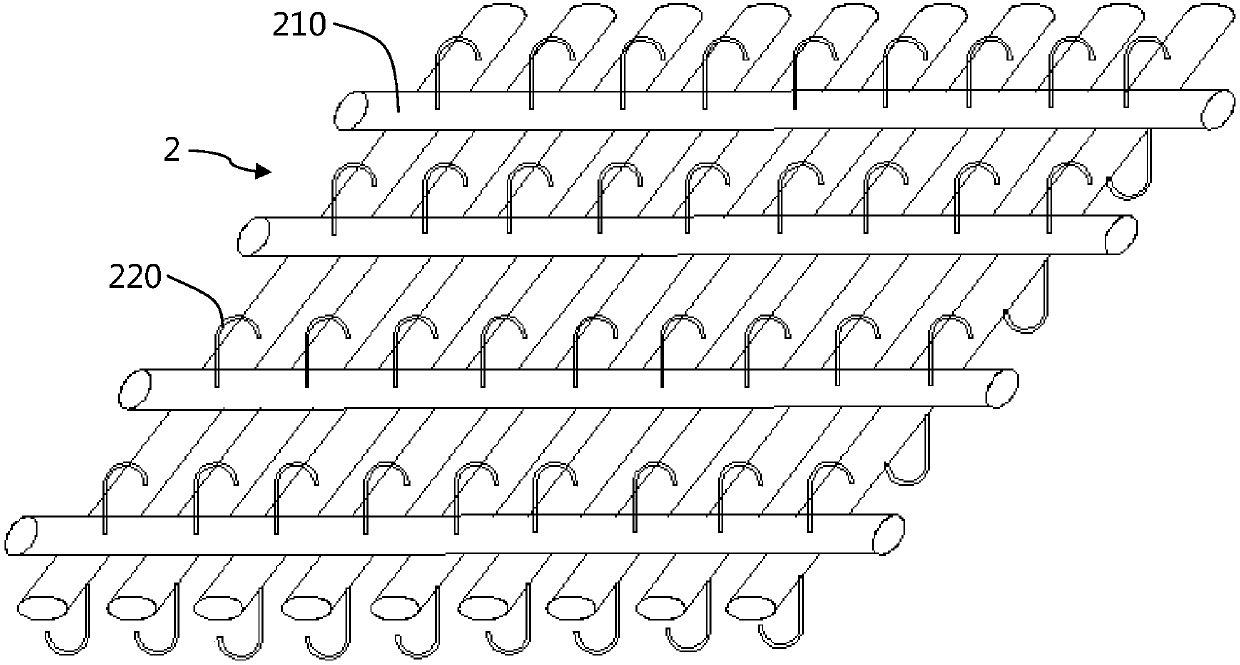

Double-layer alkali-resisting separation membrane support material and preparing method thereof

ActiveCN106582313ASolve the problem that it cannot be used in an alkaline environment for a long timeEffective tangleSemi-permeable membranesFibre typesHardnessSupport materials

The invention discloses a double-layer alkali-resisting separation membrane support material and a preparing method thereof. The double-layer alkali-resisting separation membrane support material comprises a coating layer and a support layer, and is prepared by spunlace and hot rolling calendaring. A thin diameter polypropylene fiber and a meldable fiber are adopted as raw materials by the coating layer, a thick diameter polypropylene fiber and a certain amount of meldable fiber are adopted as the raw materials by the support layer, through the steps of beating, pulp forming and the like, the raw materials are conveyed by different pulp supply systems to double-layer forming wet method equipment to prepare the pulp into a net respectively, and the double-layer alkali-resisting separation membrane support material is formed after spunlace and hot rolling calendarin. The double-layer alkali-resisting separation membrane support material adopts the technology, solves the problem that the double-layer separation membrane support body is poor in alkali resistance, prone to separated layers, low in strength, poor in flexibility and the like, and the double-layer separation membrane support material with an excellent alkaline resistant property, good interlayer binding force, a stable shape and state and moderate hardness and softness is prepared at low hot rolling pressure and temperature.

Owner:FOSHAN S L P SPECIAL MATERIALS +1

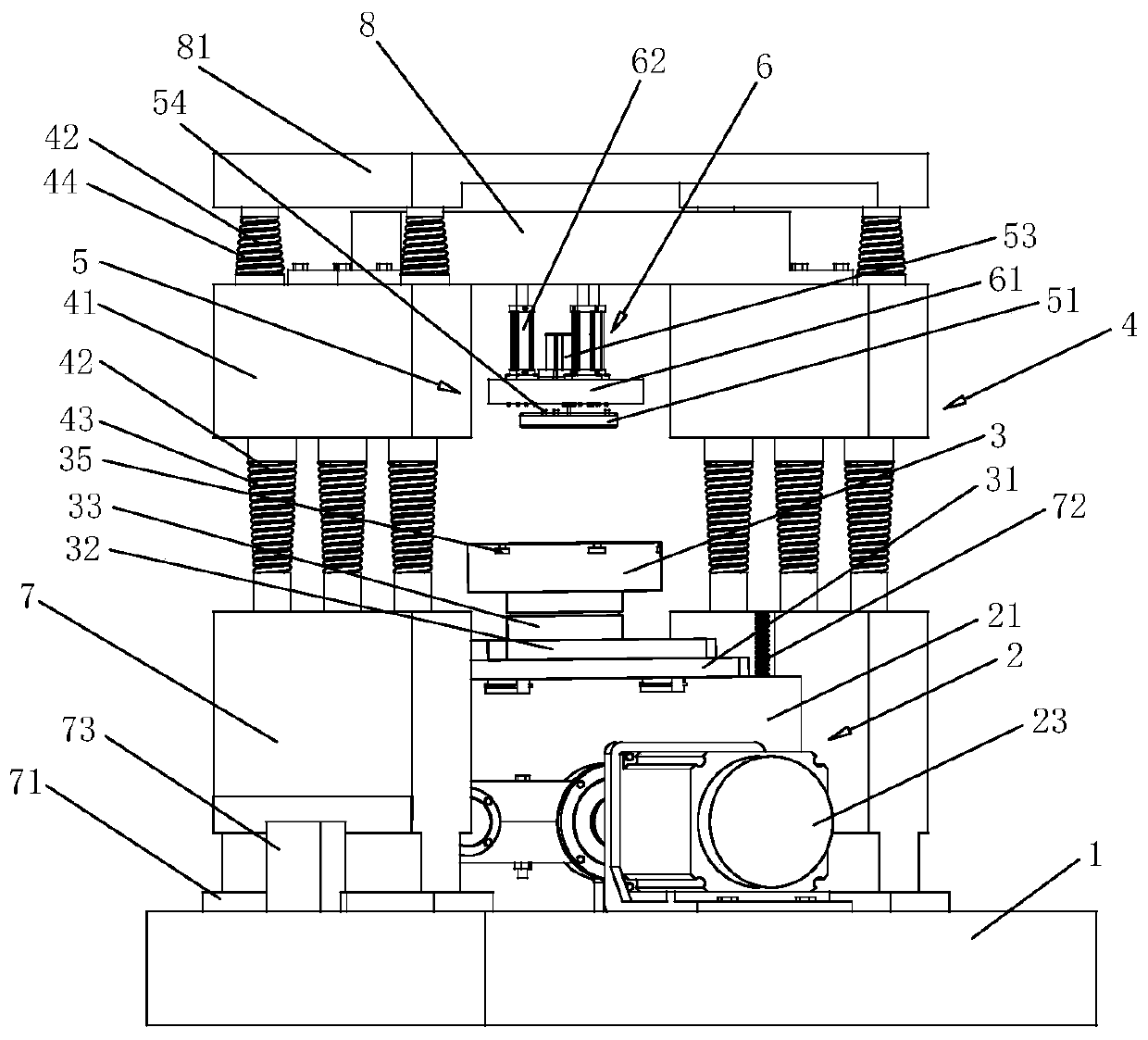

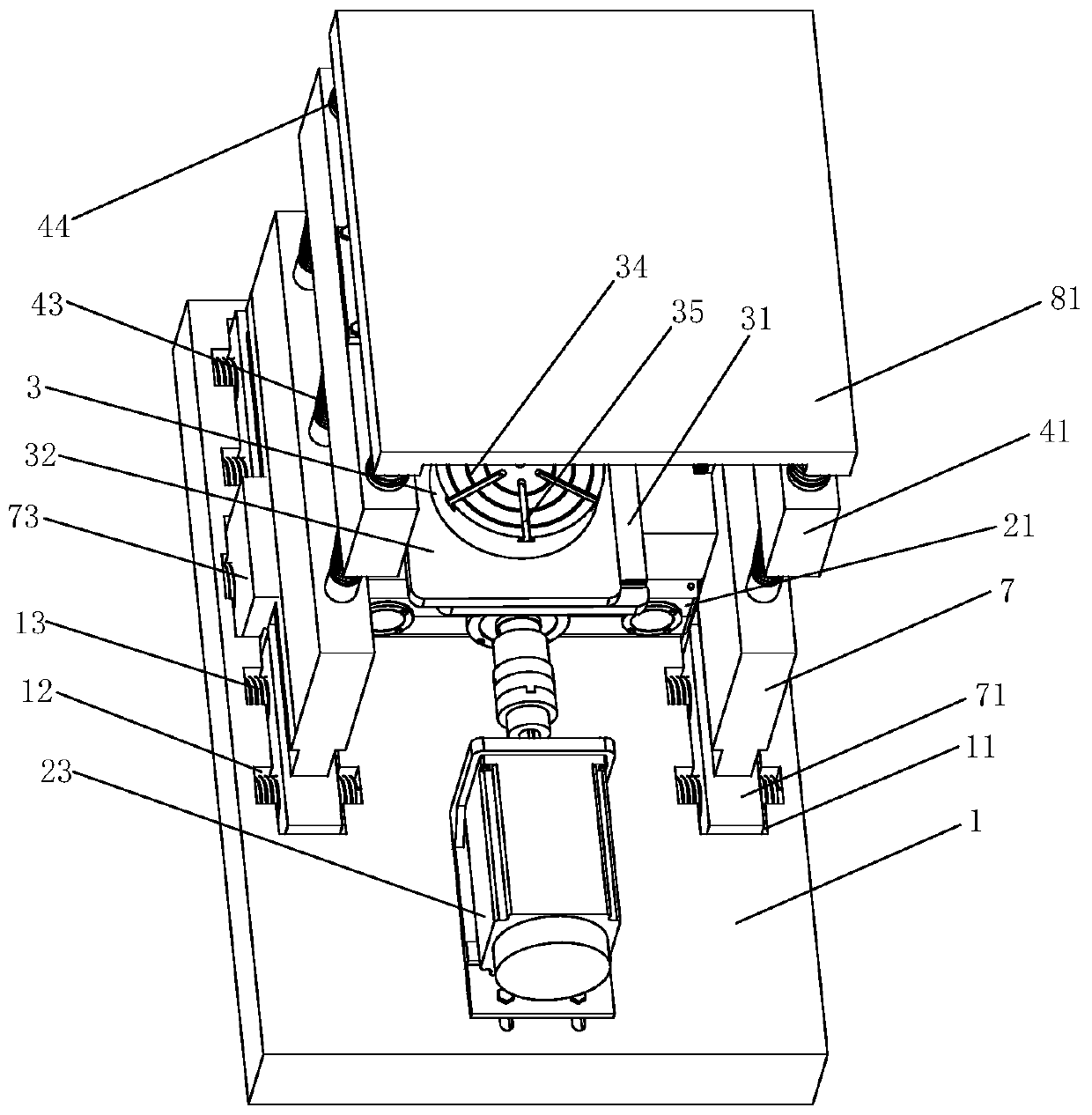

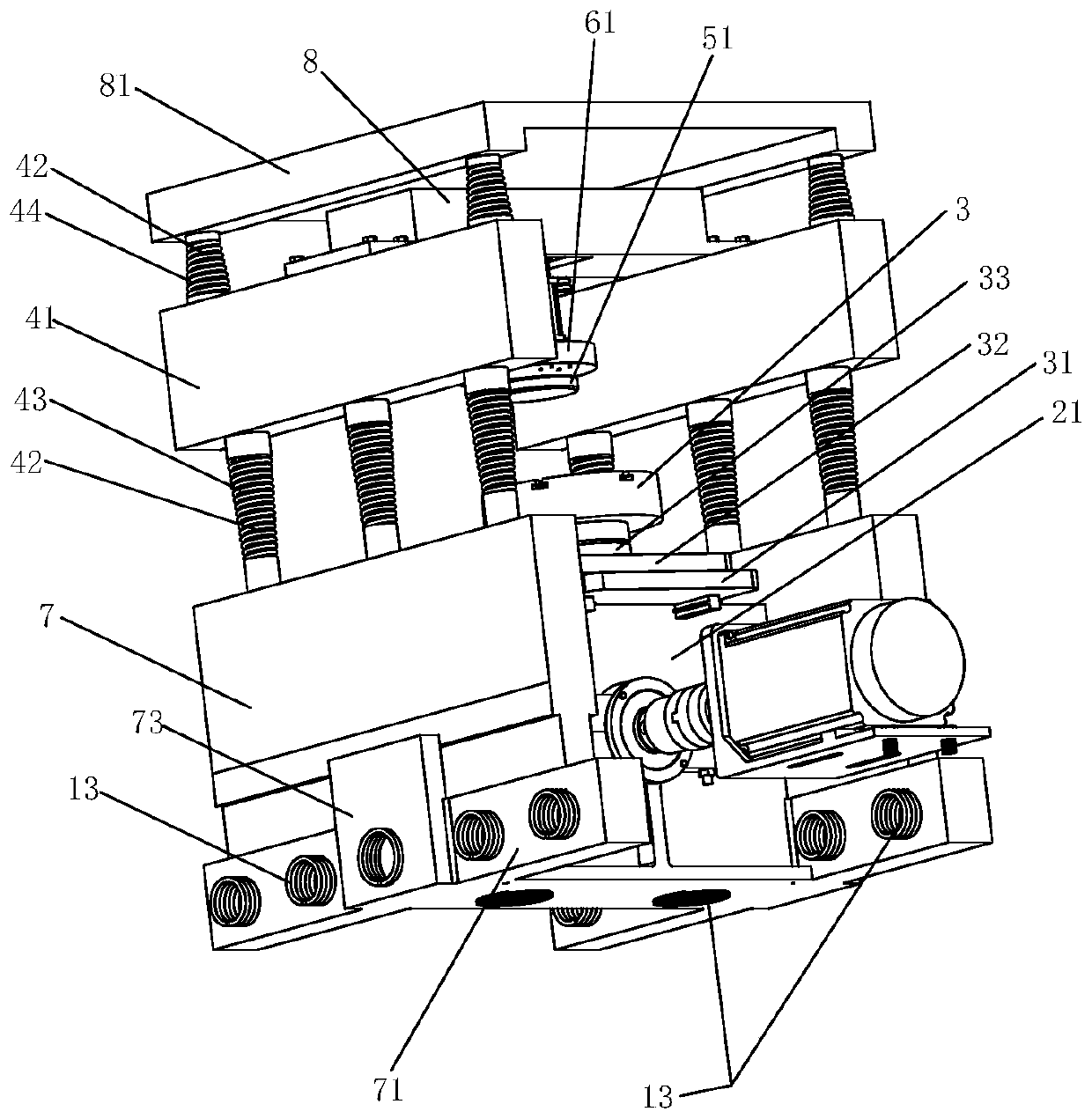

Free-form surface grinding and polishing device for micro-sized special-shaped precision parts

InactiveCN111300251AOvercome precisionOvercome stiffnessPolishing machinesGrinding drivesPolishingEngineering

The invention discloses a free-form surface grinding and polishing device for micro-sized special-shaped precision parts. The free-form surface grinding and polishing device comprises a base, two lifting vertical plates, a vertical plate driving mechanism, a rotating worktable, a vibration-damping support mechanism, a grinding mechanism and an angle adjusting mechanism; the two lifting vertical plates are arranged oppositely on both sides above the base; the lower ends of the lifting vertical plates are elastically and movably connected with the base; the vertical plate driving mechanism drives the two lifting vertical plates to move up and down simultaneously; the bottom of the rotating worktable is adjustably and fixedly connected with a gear box; and the grinding mechanism is located above the rotating worktable, and is adjustably and fixedly connected to the two lifting vertical plates through the angle adjustment mechanism and the vibration-damping support mechanism. A friction disc accurately moves according to a predetermined trajectory, the grinding and polishing pressure is accurately controlled, the posture adjustment is stable and flexible, and variable, the impact of vibration on the processing quality is eliminated, higher processing accuracy and surface quality are obtained, the degree of automation is high, the production efficiency is improved, and the consistency of processing quality is ensured.

Owner:SHANDONG UNIV OF SCI & TECH

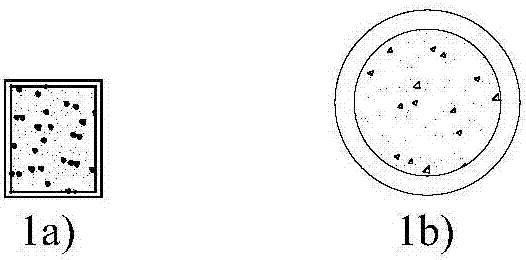

Press buckle type rock wool composite board and manufacturing method thereof

PendingCN107901529AEasy to useImprove insulation performanceSynthetic resin layered productsHeat proofingMaterials preparationComposite plate

The invention discloses a press buckle type rock wool composite board and a manufacturing method thereof, and belongs to the technical field of heat insulation material preparation. The composite board comprises rock wool base body layers, a reinforcing layer, a surface layer and a press buckle structure, wherein the reinforcing layer is arranged between the rock wool base body layers in a clampedway, and achieves the effects of supporting and reinforcement; the intensity of the rock wool base body layers is well enhanced, so that the overall intensity of the rock wool base body layers is improved by at least 100 times or higher; the surface layer is connected with the reinforcing layer through the press buckle structure, and is tightly attached onto the rock wool base body layer. Throughthe designed structure, the mode that the surface layer is adhered by polymer cement mortar in the prior art is changed; the polymer cement mortar is not used as much as possible; the emission of benzene and benzene derivatives is reduced; the use of the composite board is safer and more reliable; the heat insulation, sound insulation and fireproof effects are obvious.

Owner:MAANSHAN HONGDA INSULATION MATERIAL

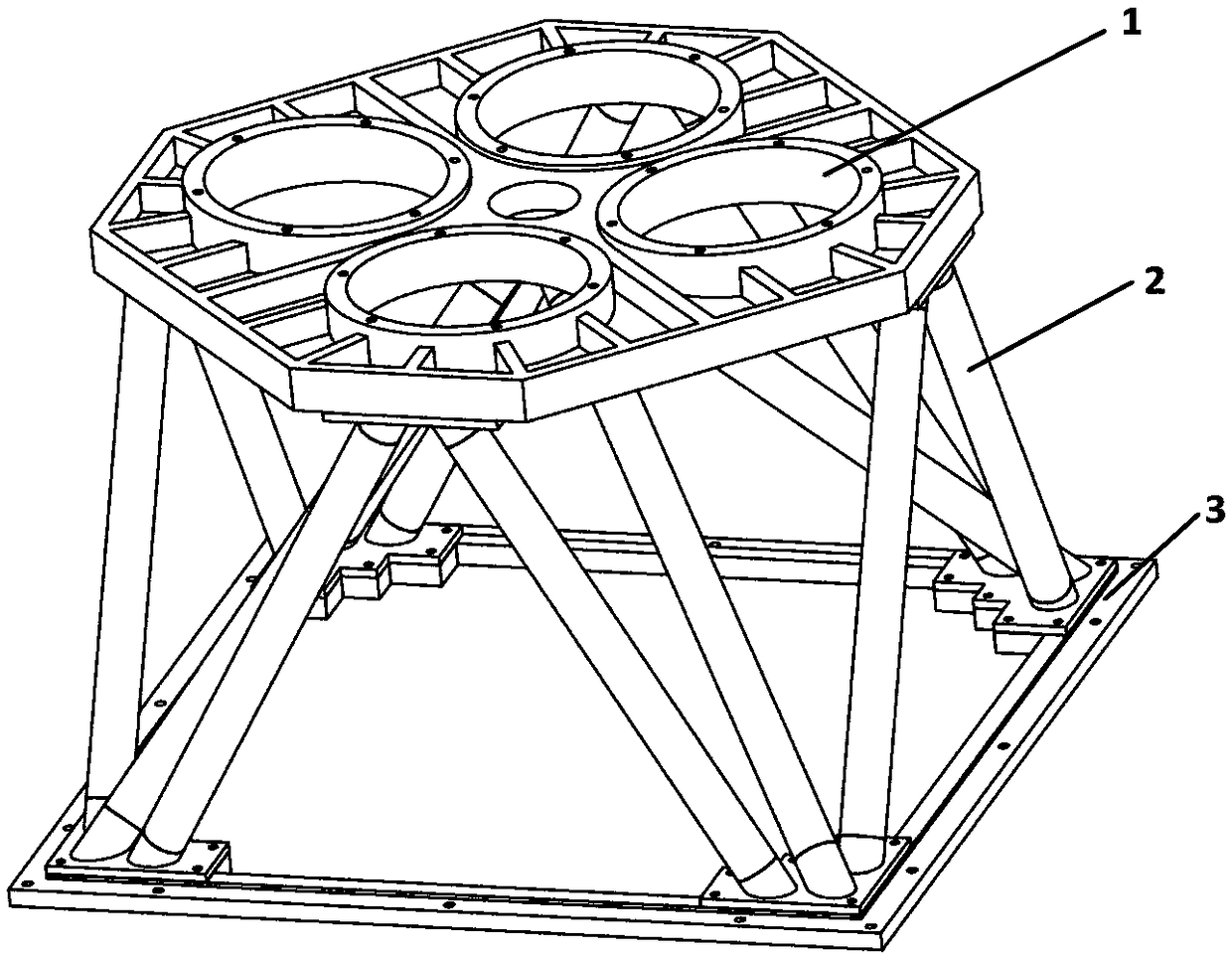

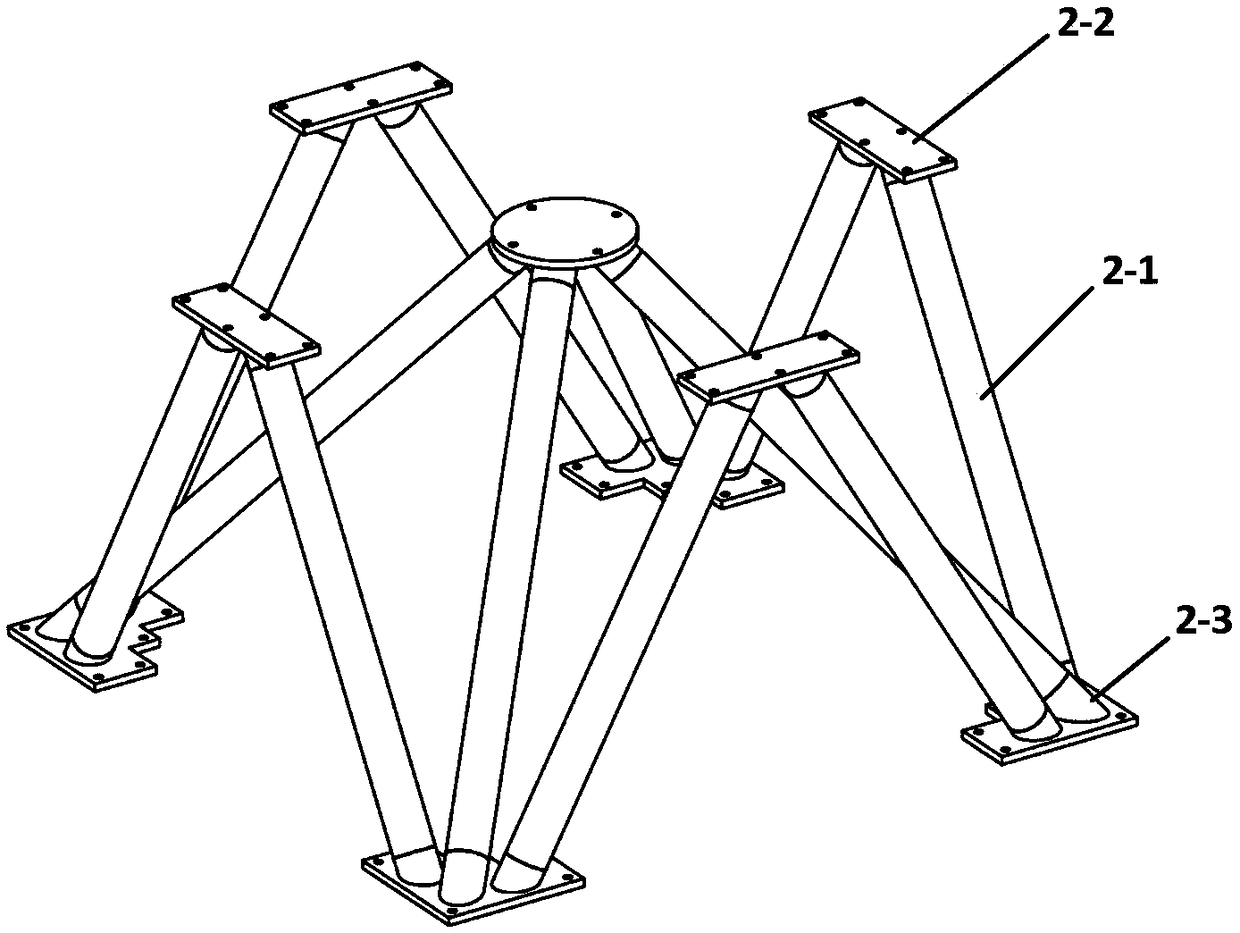

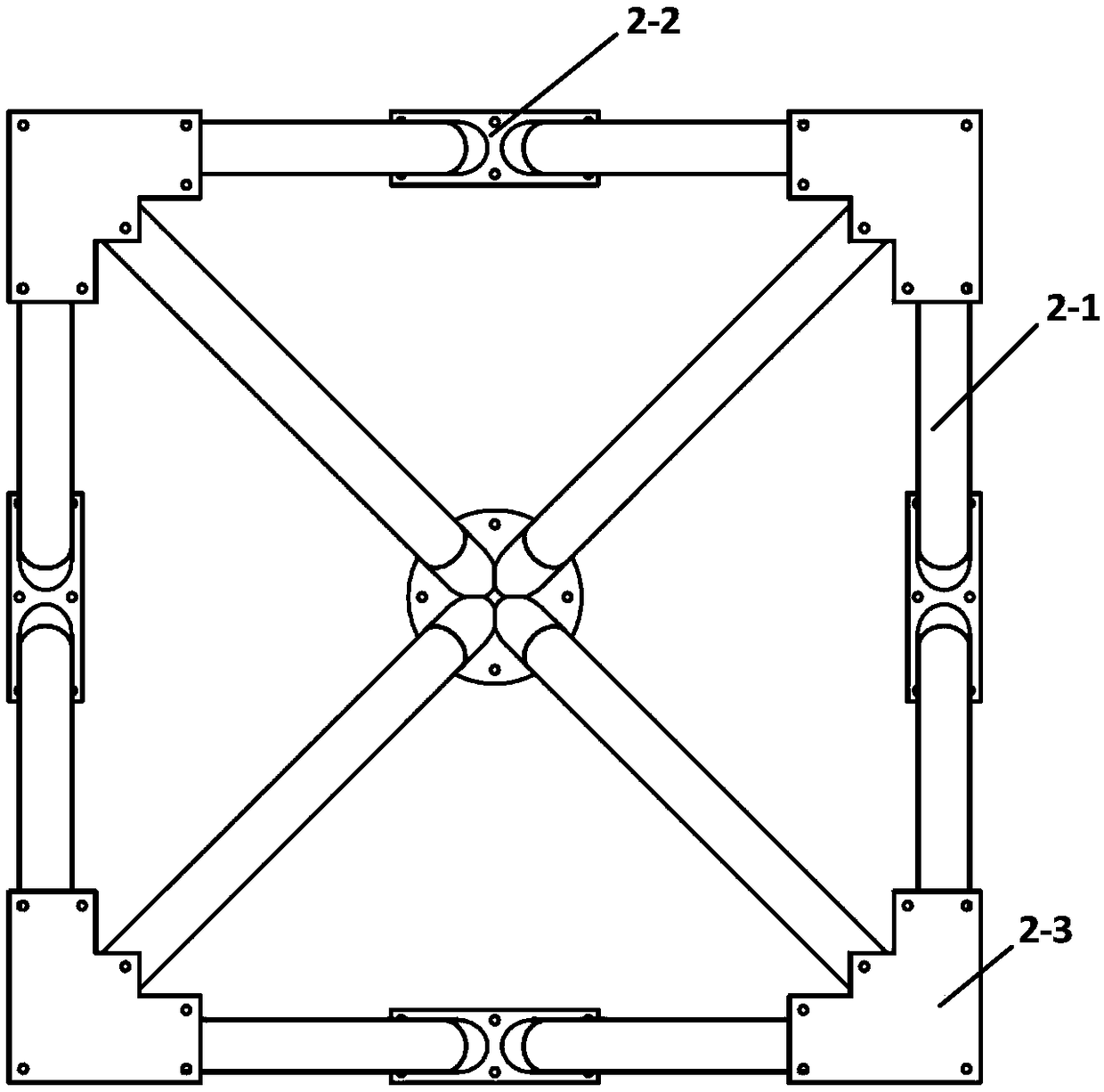

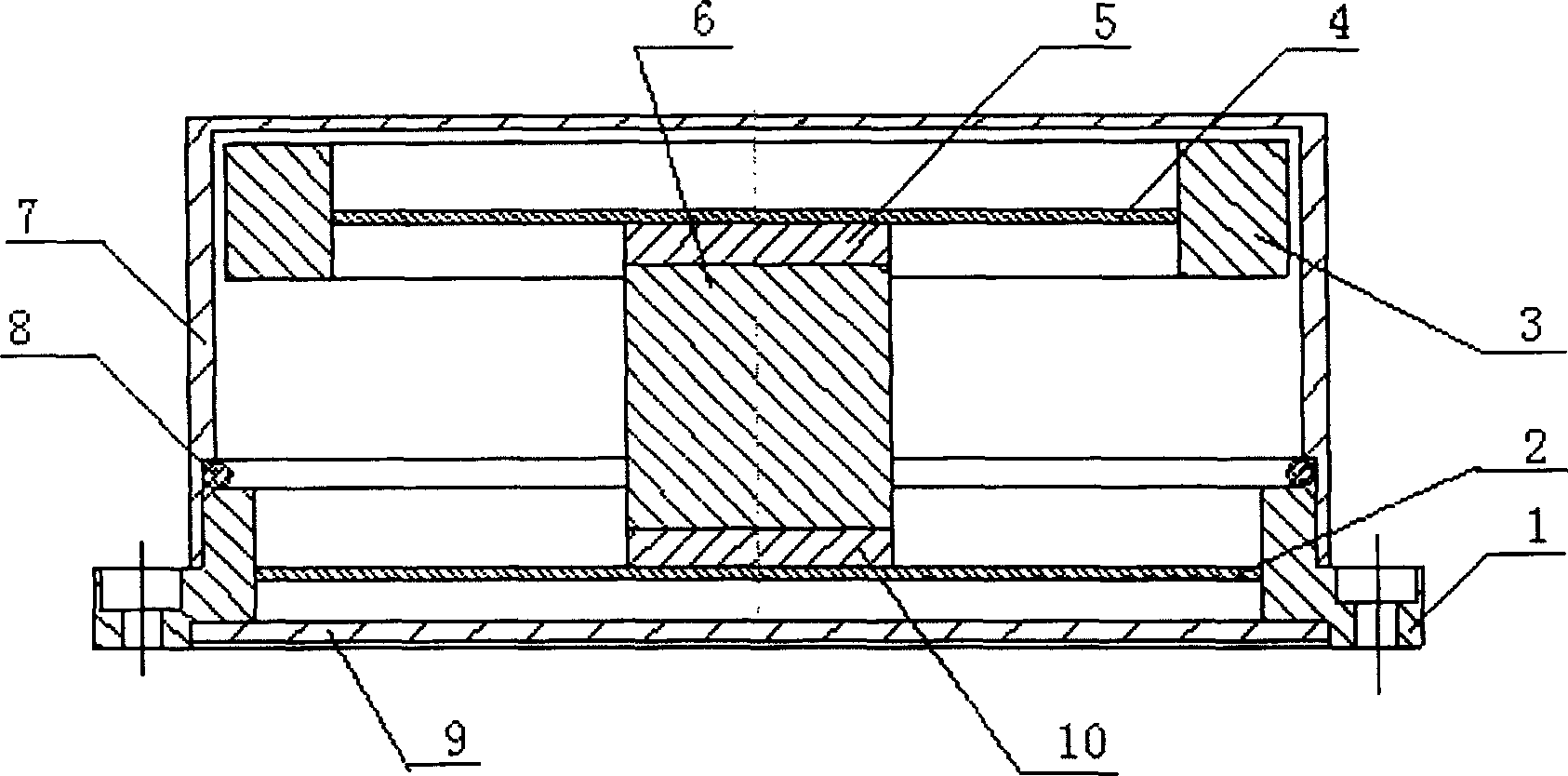

Truss type supporting structure of space wide camera

InactiveCN109442151AFulfilling Optical Imaging RequirementsOvercome stiffnessRod connectionsEngine bedsFixed frameHeat stability

The invention discloses a truss type supporting structure of a space wide camera. The truss type supporting structure comprises a camera frame, a truss assembly and a fixed frame, wherein the camera frame is connected with the fixed frame through the truss assembly; the fixed frame is provided with a threaded hole fixedly connected with a satellite platform; the truss assembly comprises 12 truss rods, 5 upper connectors and 4 lower connectors; the 5 upper connectors are 4 circumferentially uniformly distributed two-way connectors and 1 four-way connector arranged at the circumferential center;the 4 lower connectors are 4 circumferentially uniformly distributed three-way connectors; the four-way connector is connected with the 4 three-way connectors through the truss rods; the two-way connectors are connected with the two adjacent three-way connectors through the truss rods; the 12 truss rods are manufactured from a carbon fiber composite; and the upper connectors and the lower connectors are manufactured from a titanium alloy material. According to the truss type supporting structure, 4 high-resolution optical cameras can be mounted according to a certain angle, the large-mass cameras can be effectively supported, the detect that rigidity and heat stability of a conventional space camera supporting structure are relatively low is overcome, and optical imaging requirements of large-view field large-ground width space cameras are achieved.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

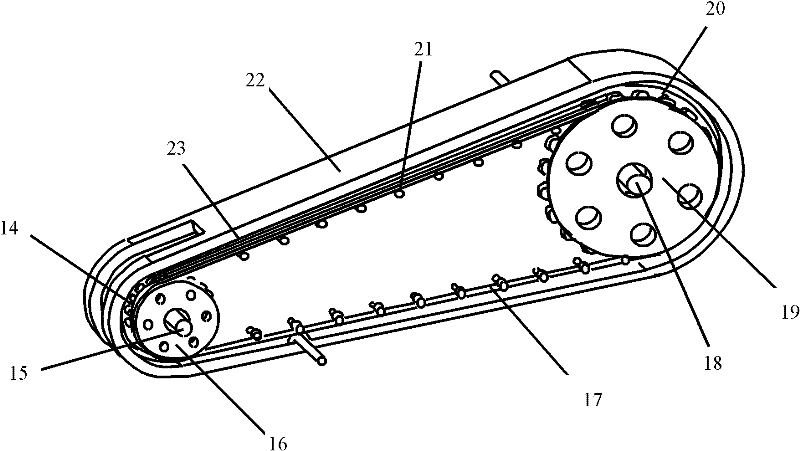

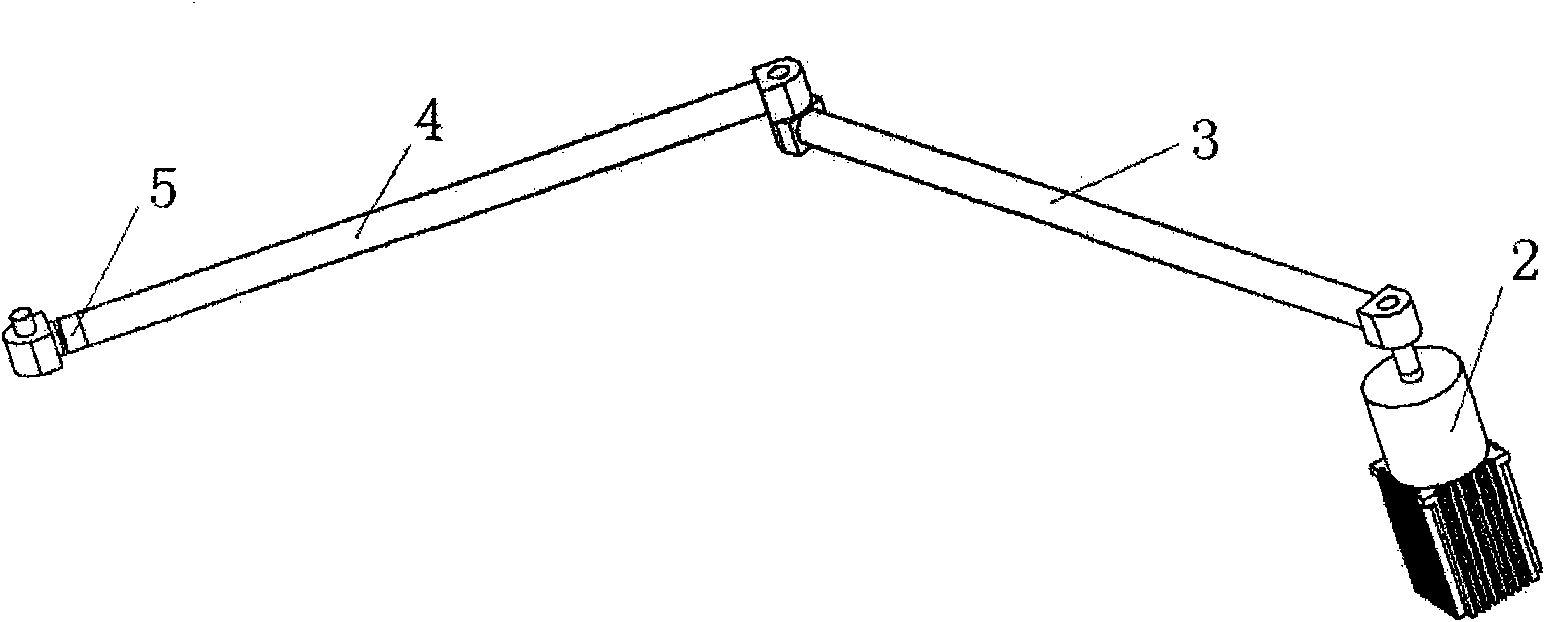

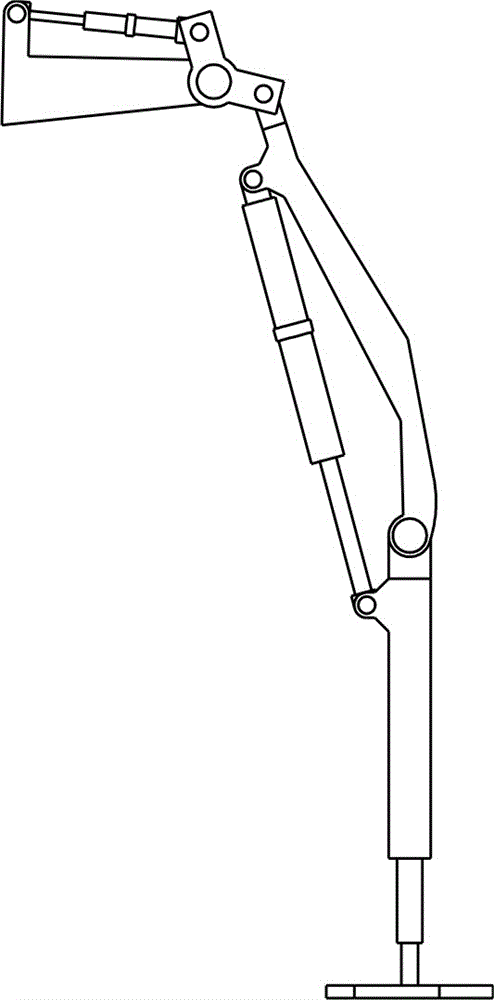

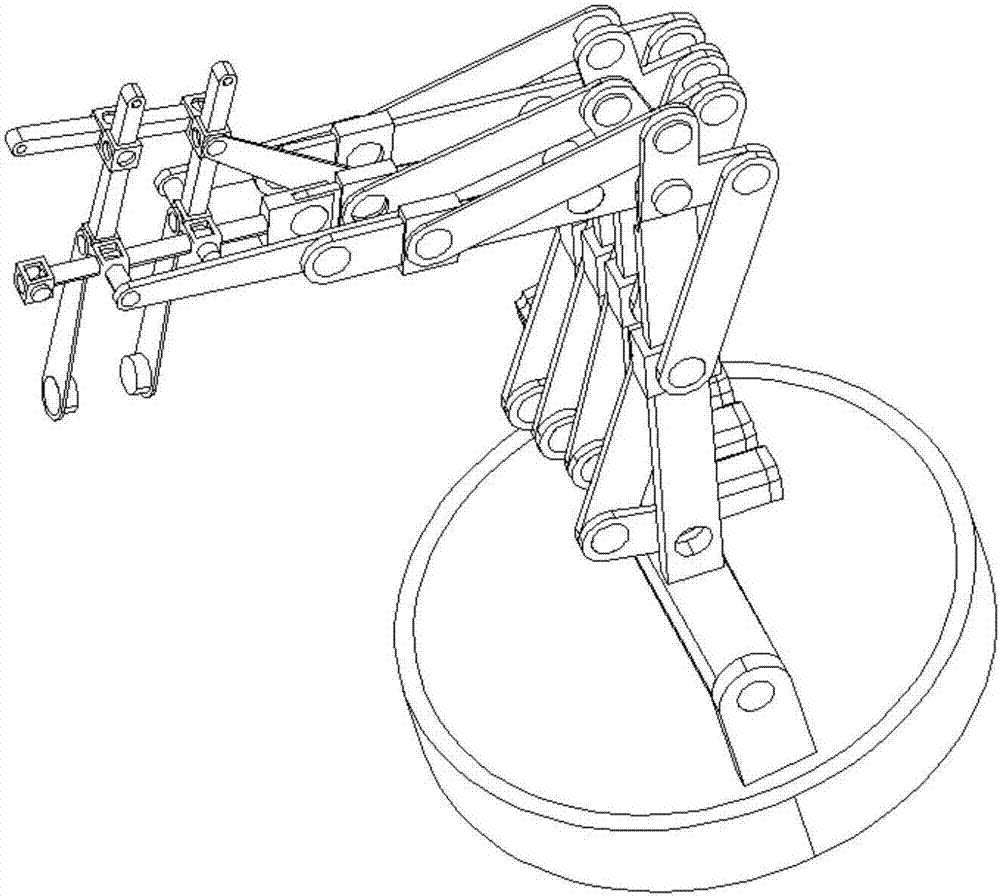

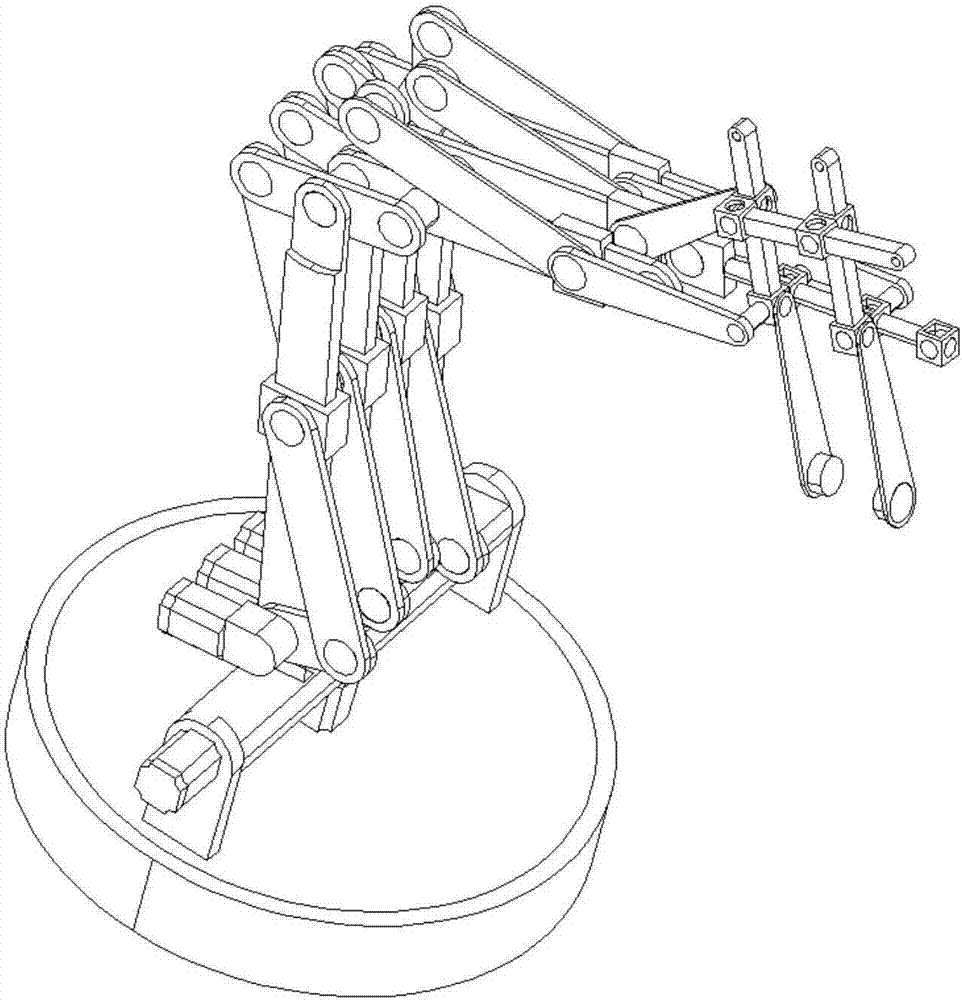

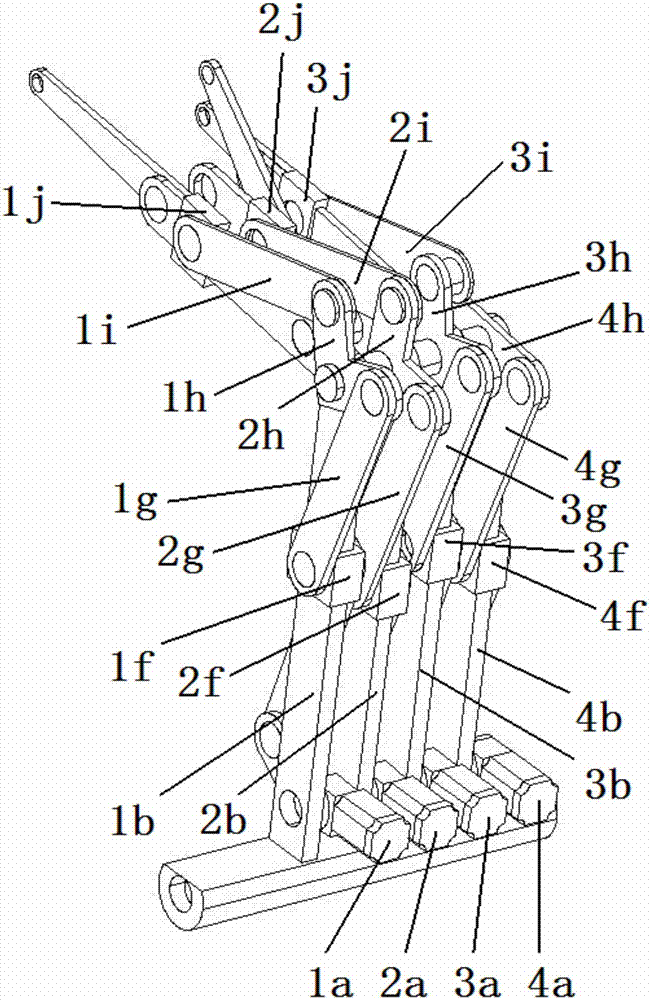

Four-degree-of-freedom controllable mechanism-type palletizing robot

InactiveCN107127743AOvercoming only plane drive transmissionOvercome stiffnessProgramme-controlled manipulatorStacking articlesElectric machinerySmall arms

The invention discloses a four-degree-of-freedom controllable mechanism-type palletizing robot. A first servo motor drives a first final-stage sliding sleeve to move back and forth on a small arm through a transmission chain containing a first driving rod; a second servo motor drives a second final-stage sliding sleeve to move up and down on a first guide rod through a transmission chain containing a second driving rod; a third servo motor drives a third final-stage sliding sleeve to move back and forth on the small arm through a transmission chain containing a third driving rod; movement of the first final-stage sliding sleeve, the second final-stage sliding sleeve and the third final-stage sliding sleeve is synthesized into clamping actions of a first clamping arm and a second clamping arm through the transmission chains; and a fourth servo motor controls a rotating shaft to act relative to the rising height employing a rotating pair IV as the center through a transmission chain containing a fourth driving rod, that is to say, the rising heights of the first clamping arm and the second clamping arm are controlled. The defects of large movement inertia, obvious residual oscillation and low high-speed work orientation accuracy due to the fact that a motor and a speed reducer are arranged on a joint in an existing welding robot are overcome.

Owner:GUANGXI UNIV

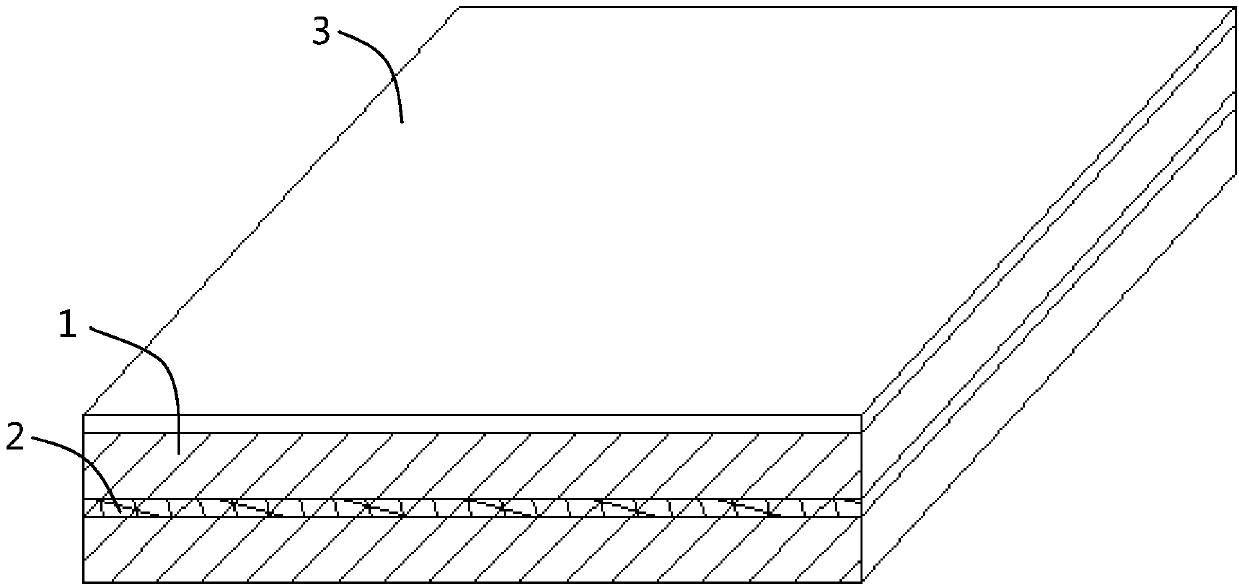

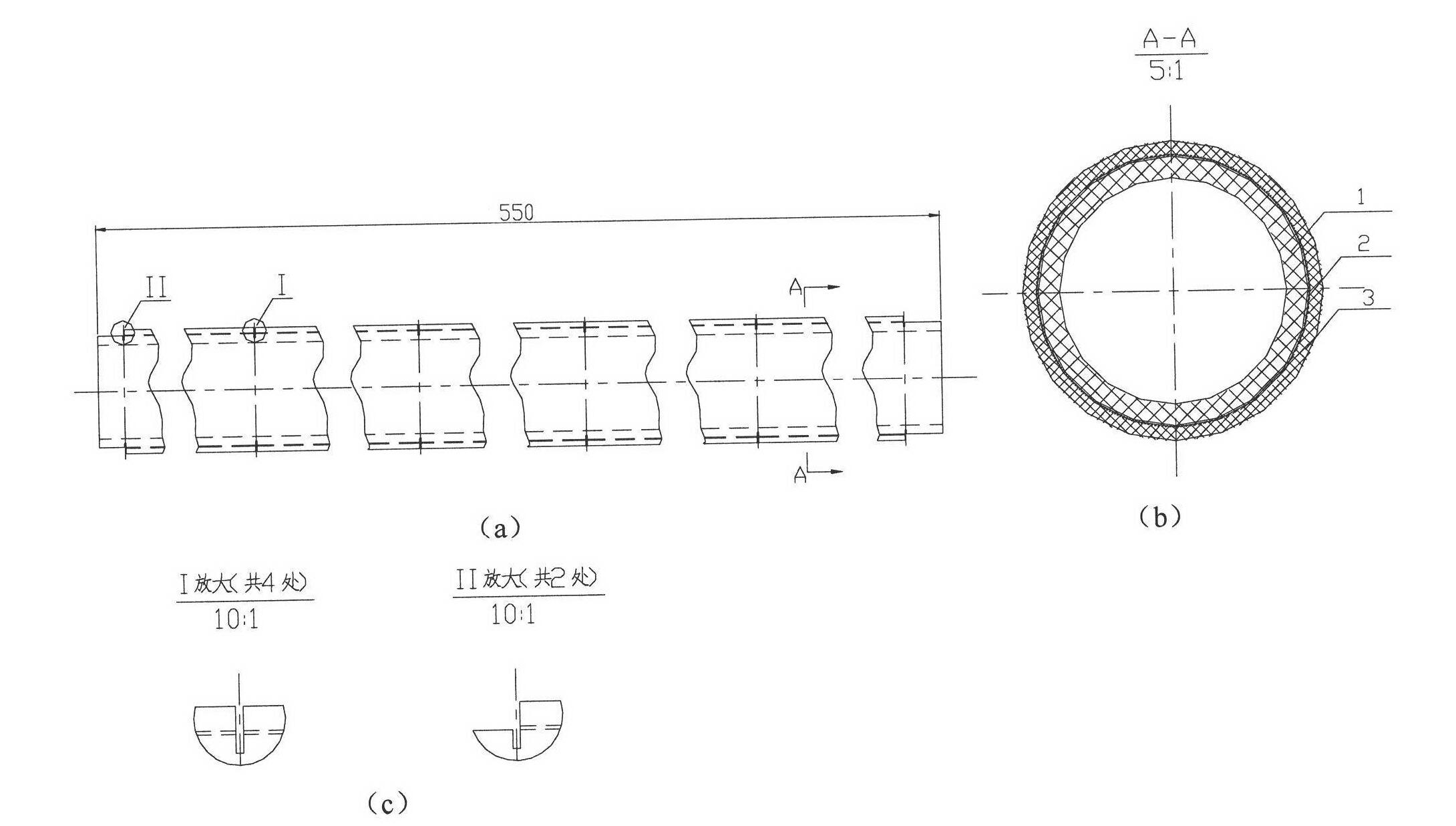

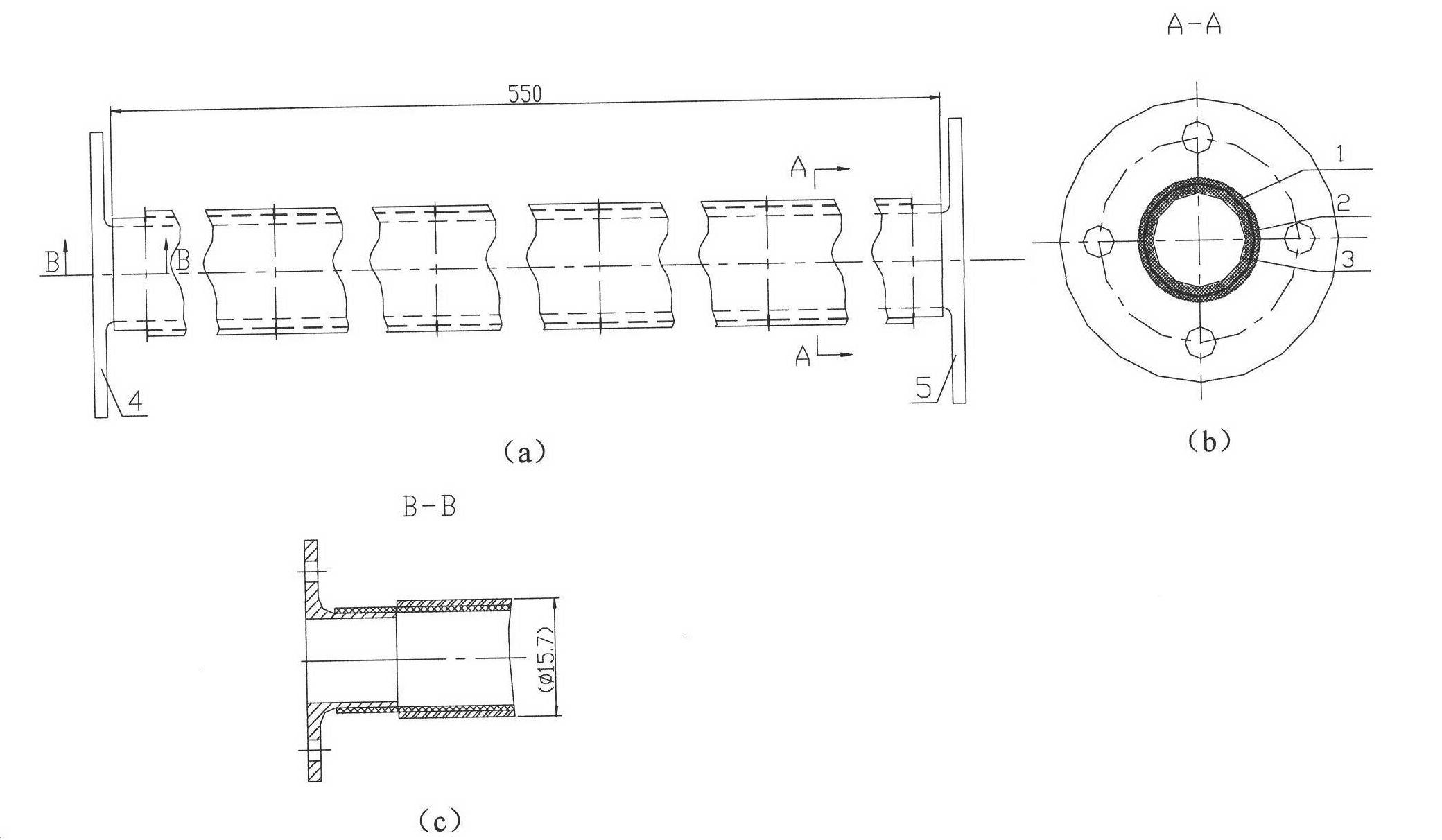

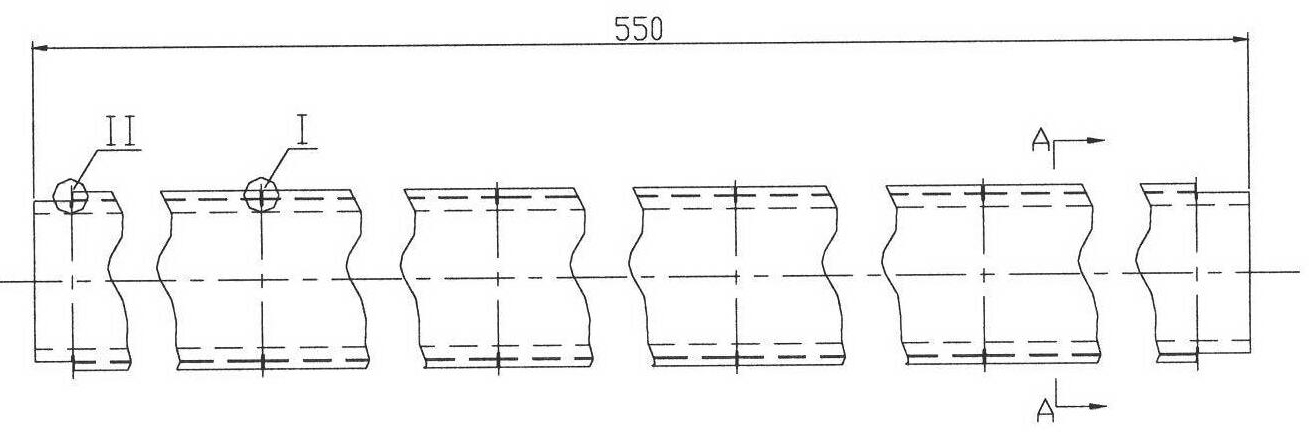

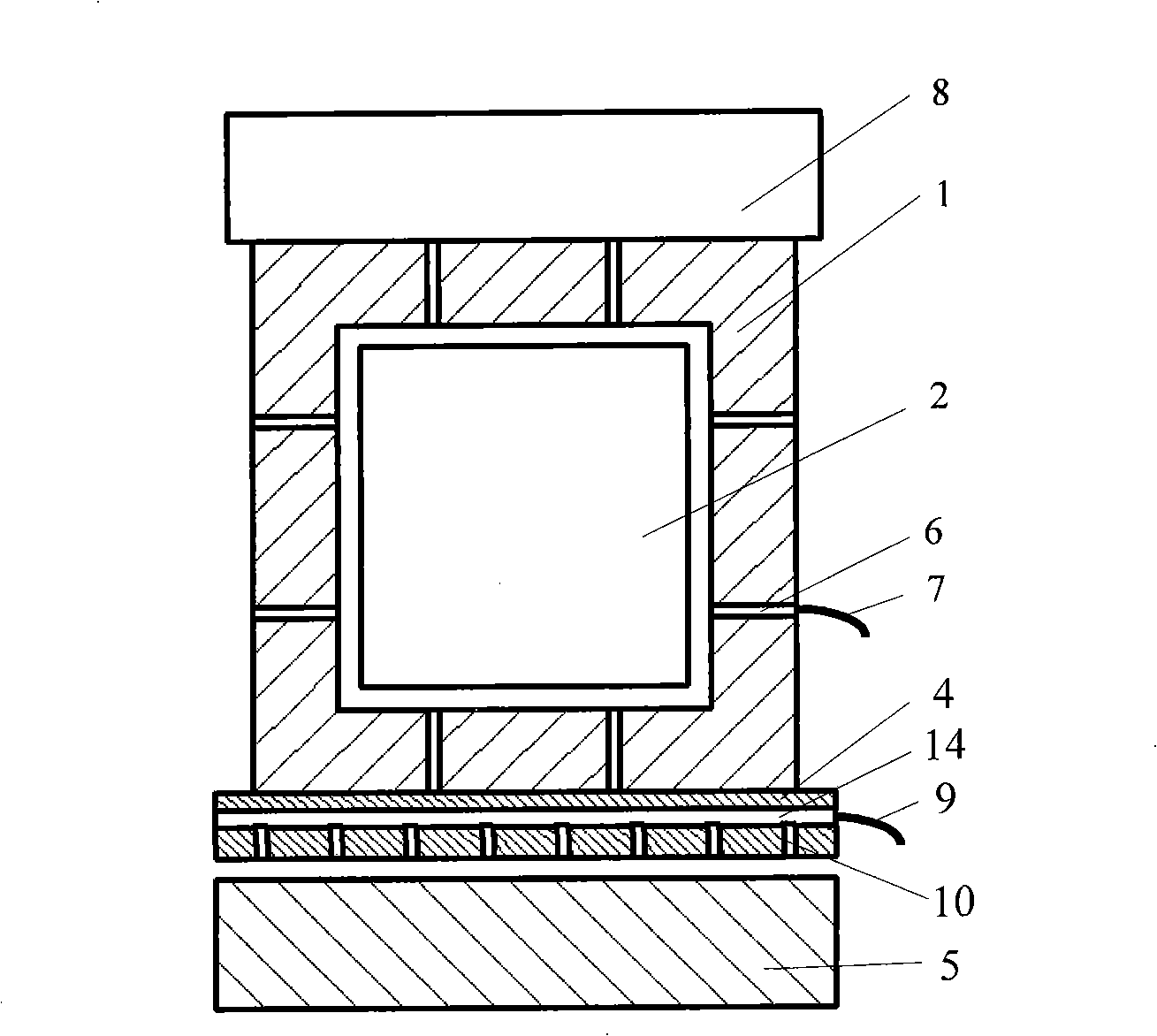

Composite material viscoelastic damping rod

ActiveCN102322493AGuaranteed axial strengthIncreased axial dampingSynthetic resin layered productsRubber-like material springsRubber materialViscoelastic damping

The invention relates to a composite material viscoelastic damping rod which comprises mounting flanges at two ends and an intermediate rod between the mounting flanges, wherein the intermediate rod comprises three layers which are a rod body (1), a viscoelastic damping layer (2) and a restraint layer (3) of T series high-intensity carbon fiber composite materials from inside to outside sequentially, and the length of the intermediate rod is 200-1000mm; a damping rubber material with the dissipation factor greater than 1 is selected for the viscoelastic damping layer (2) to be pasted to the outer part of the rod body (1); M series high-modulus carbon fiber composite materials are selected for the restraint layer (3), and the damping layer (2) and the restraint layer (3) are molded by adopting a co-curing technology; and the intermediate section is divided through opening a U-shaped groove out of the restraint layer (3), and the number of the sections of the intermediate rod at the length direction is 3-12.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

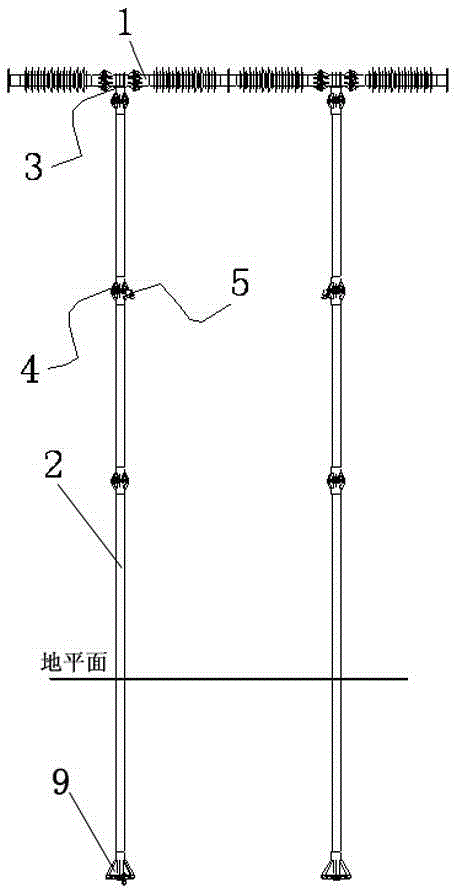

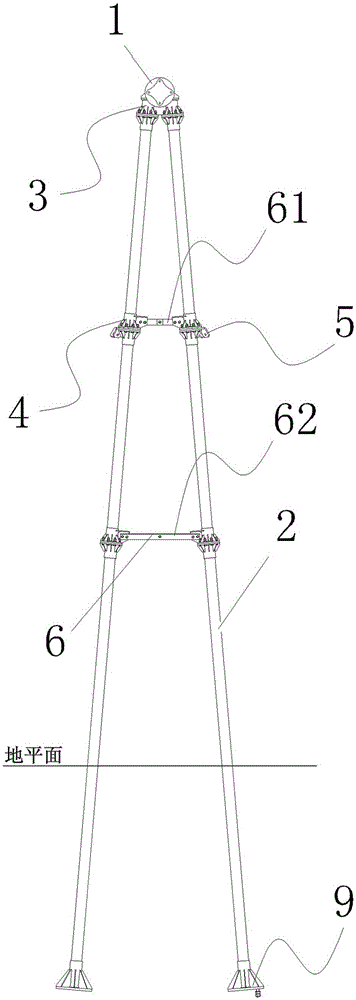

Composite material power transformation framework

The invention discloses a composite material power transformation framework which comprises a support pillar and an insulating cross beam arranged on the support pillar and is characterized in that the support pillar comprises a composite material circular tube; the insulating cross beam comprises a composite material round rod prepared through the pultrusion process; an insulating umbrella skirt is connected with the outer wall of the composite material round rod in a pressing manner; the composite material circular tube comprises a base layer, a strengthened layer, a buffer layer and an outer layer sequentially arranged from interior to exterior; the composite material power transformation framework has the beneficial effects of solving the problem that the existing composite material is poor in overall stability when applied to the power transformation framework, being light in weight, high in strength, stable in structure, convenient and fast in transportation and installation, corrosion resistant, salt mist and acid rain resistant, excellent in electric property, reliable in operation, capable of greatly reducing the framework span to realize compact arrangement, and small in later maintenance quantity.

Owner:STATE GRID CORP OF CHINA +3

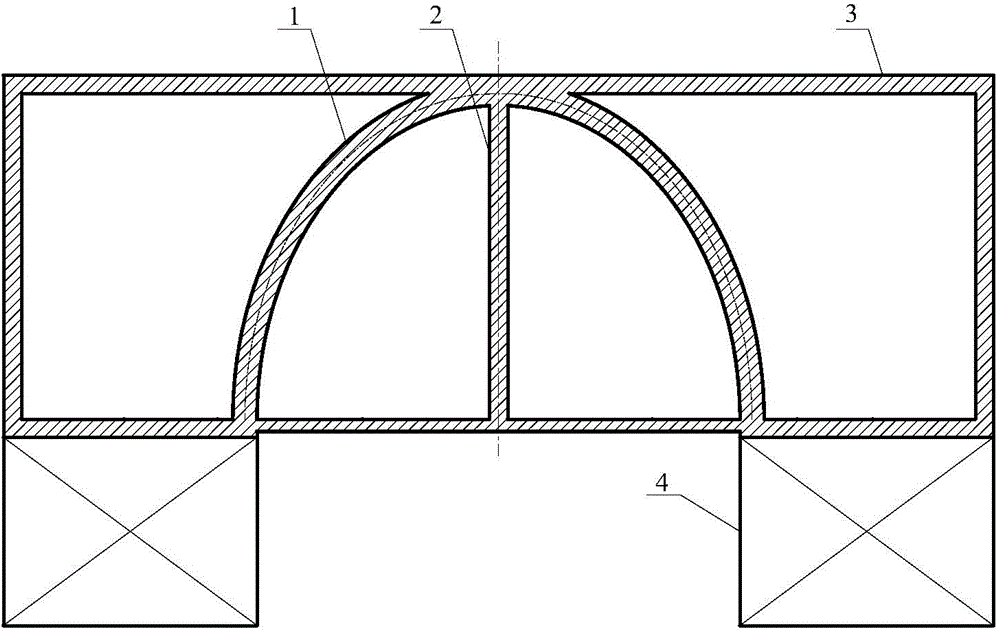

Light-weight machine tool transverse beam with reinforced arched rib plate

The invention discloses a light-weight machine tool transverse beam with a reinforced arched rib plate. The reinforced arched rib plate is used inside the transverse beam, a plurality of longitudinal partition plates are symmetrically distributed with the middle surface of the transverse beam as the reference, and the section of the transverse beam is a rectangular section. The light-weight machine tool transverse beam with the reinforced arched rib plate solves the problem that due to a common reinforced rib plate inside a transverse beam, the rigidity is constant, and materials are redundant, rigidity of the middle of the transverse beam is improved, the dynamic characteristic of the transverse beam is improved, the weight of the transverse beam is reduced, and the light weight design is achieved. Due to the fact that the widely-used rectangular section is adopted for the section of the transverse beam, the transverse beam is simple in structure, and can be conveniently assembled with parts such as stand columns, carriages and the like.

Owner:XI AN JIAOTONG UNIV

Horizontal gas/gas two-phase composite straight line reference method and apparatus based on gravity force balance

ActiveCN101403628AImprove support rigidityImprove stabilityMeasurement apparatus componentsGravitational forceEngineering

A horizontal gas-gas two phase composite beeline benchmark method and a device based on the gravity balance belong to the technical field of precision instruments and measurement. The method comprises the steps: a balance slideway is constructed below of an orientation slideway, which forms an open external gas support and acts on an anti-thrust plate in the lower part of a flotation guide cover, the gravity balance of the orientation slideway and the balance slideway is designed aiming at the load gravity, under the conditions of satisfying the load gravity of the balance slideway, and the gas film supporting stiffness arrives the maximum or is in the confirmed range of the gas film supporting stiffness; the device comprises the anti-thrust plate fixedly connected with lower part of the flotation guide cover, an anti-thrust flotation dual surface is formed between the anti-thrust plate and the balance slideway, the anti-thrust plate is provided with a throttle structure facing to the balance slideway which is parallel to the orientation slideway. The invention leads the flotation guide cover to have excellent stability, the slideway load capability and the supporting stiffness are greatly improved, the high linear accuracy of the slideway under big load and big stroke is ensured, the structure is simple, and the application scope is wide.

Owner:NANTONG MINGGUANG ELECTRIC WIRE

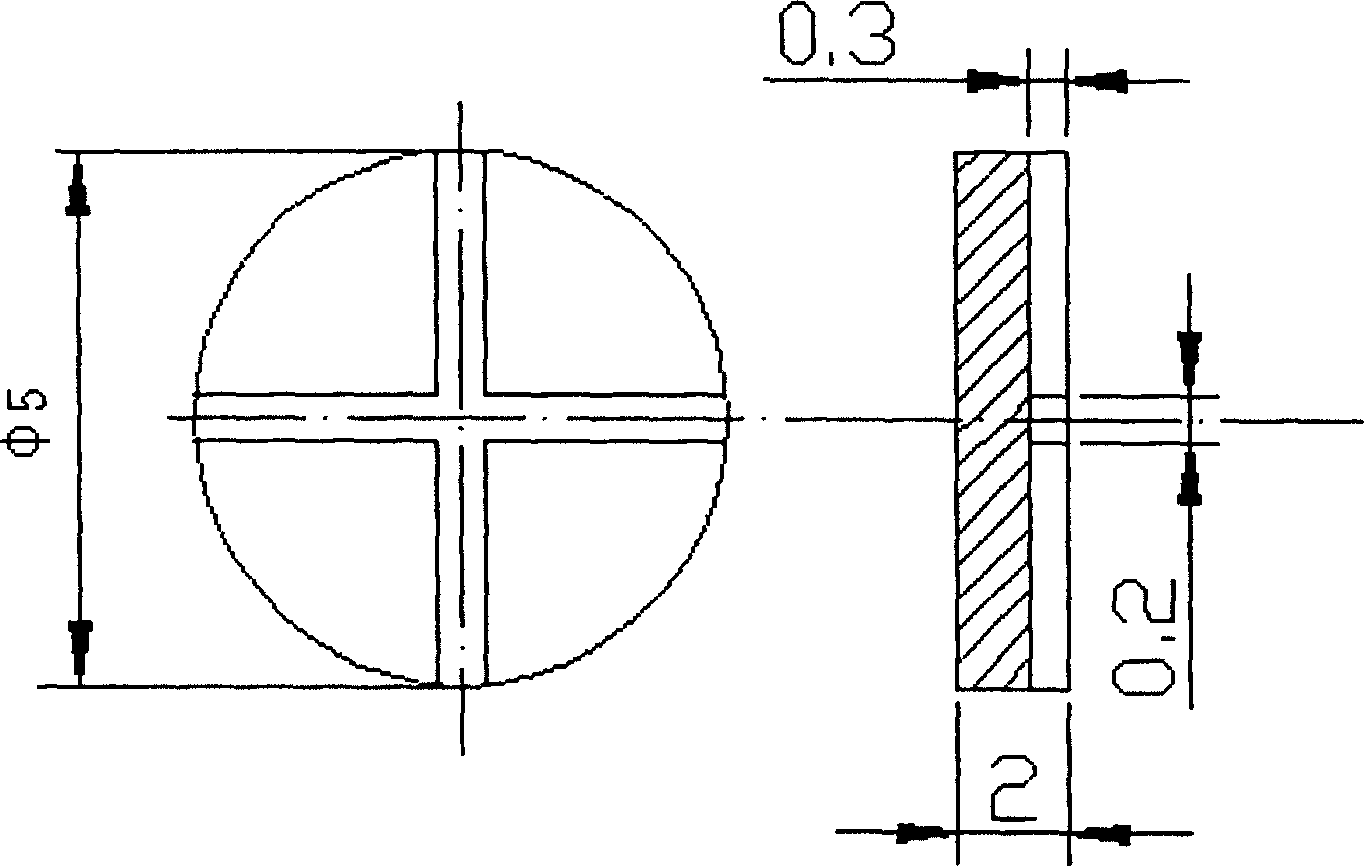

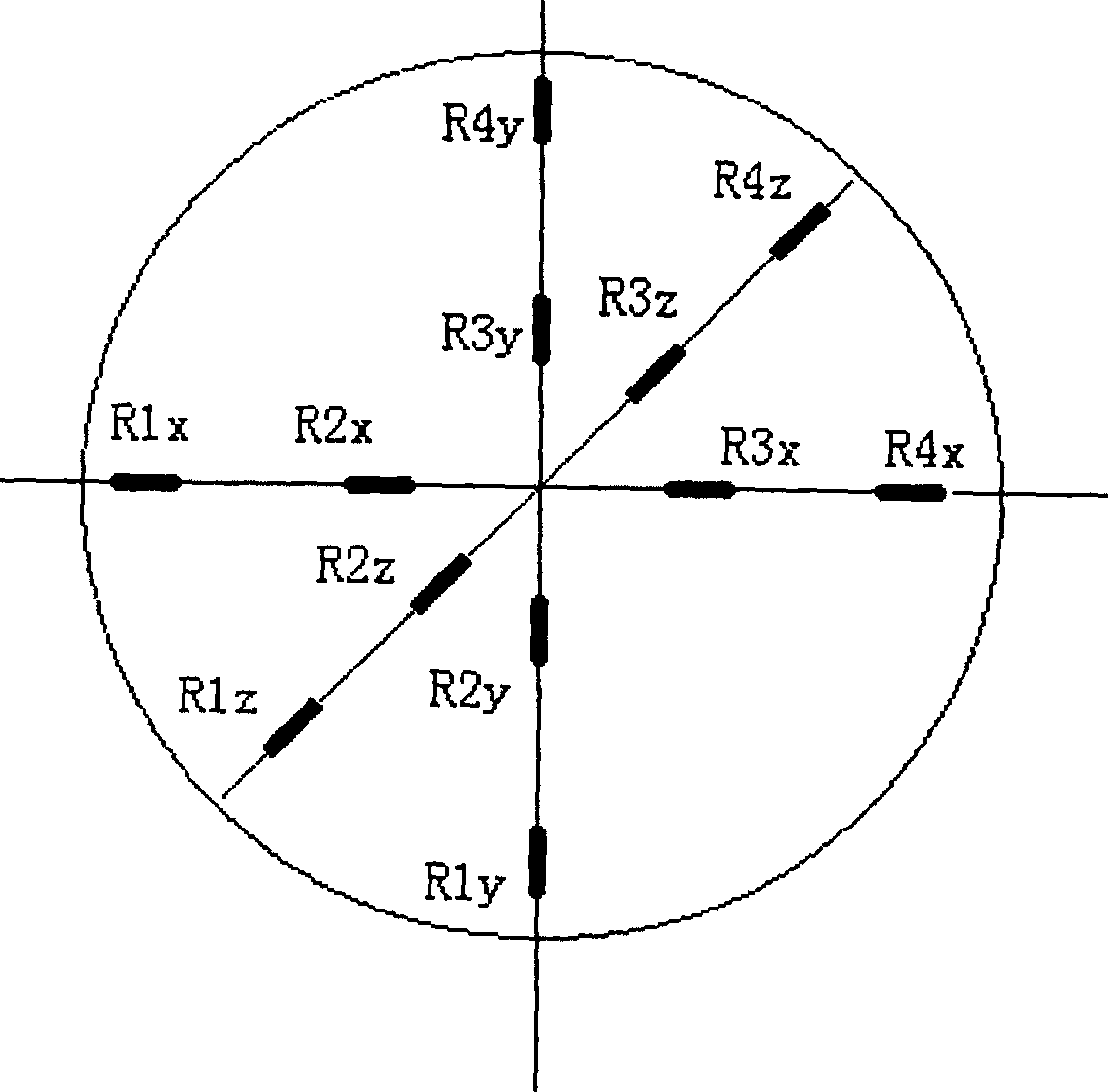

Six-axle acceleration sensor with dual E-shaped circular membranes and cross beam structure

InactiveCN1227535CSimple designMeet the use requirementsAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsClassical mechanicsThick film technology

A 6D acceleration sensor for measuring three axial accelerations and angular accelerations in 3D space coordinate system features that the thick-film technology is used, the dual E-shaped circular ceramic membranes and cross beam are used as sensitive elastic substance, and the force-sensitive thick-film resistors are sintered on the ceramic substance for bridging. It can be used for the robot.

Owner:HEFEI INST OF INTELLIGENT MACHINERY CHINESE ACAD OF SCI

Device for accurately taking membrane in single-piece mode

InactiveCN107891259AOvercome stiffnessOvercome Difficulty Maintaining Ideal ShapeMetal working apparatusRotary stageBiochemical engineering

The invention relates to a device for accurately taking membrane in a single-piece mode. According to the device, a clamp circulating mechanism, a membrane circulating feeding mechanism and a membranetransferring and sucking mechanism are correspondingly installed on a table plate of a machine frame set, a membrane carrier is installed on a membrane circulating feeding rotary table, and the membrane is placed on the membrane carrier; and a support in the membrane transferring and sucking mechanism is fixed on the table plate, a transferring module is arranged on the support, and a sliding block fixing block is arranged on the transferring module. According to the device, by taking the membrane accurately in the single-piece mode, the problem that an ideal shape is difficult to maintain because the soft rigidity of the membrane is insufficient is solved, the membrane can be accurately positioned, the assembly automation of the membrane can be realized, meanwhile, the manual work is replaced, the product is prevented from being damaged, the efficiency is high, labor is saved, and the cost is saved.

Owner:江西宝群电子科技有限公司

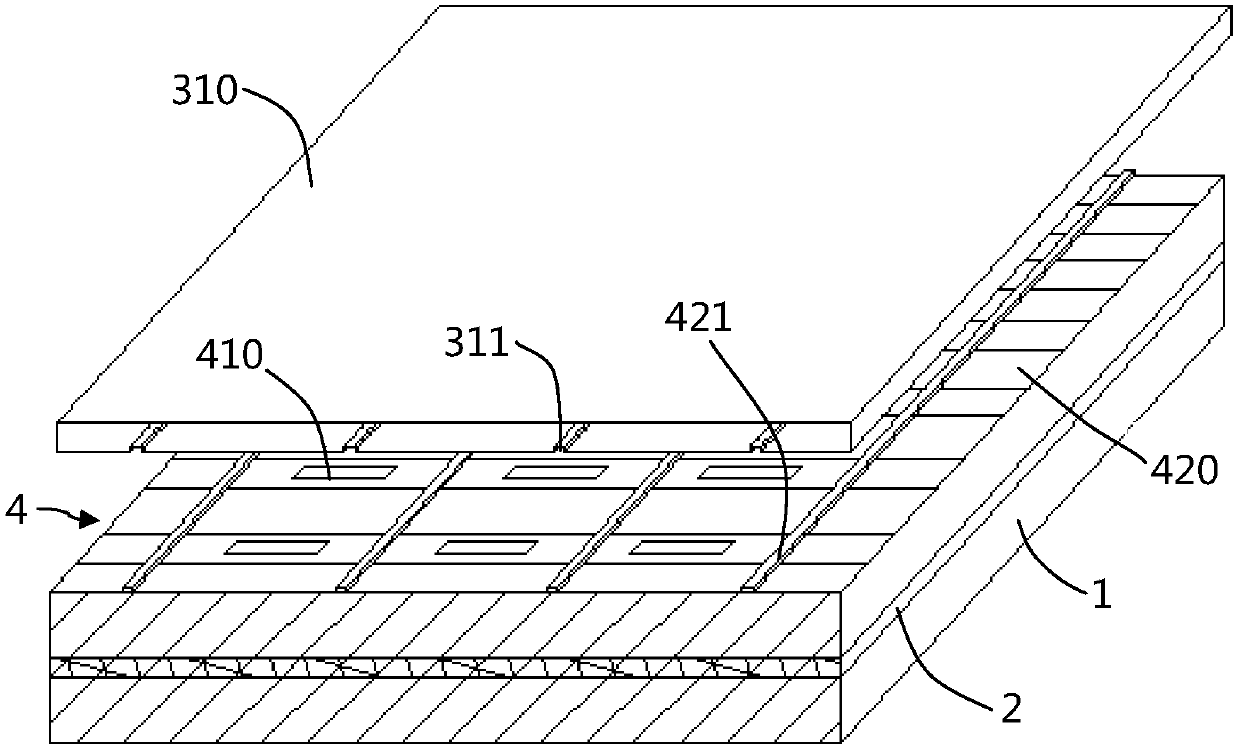

Partially-overlapped laminated plate with holes

The invention discloses a partially-overlapped laminated plate with holes. The partially-overlapped laminated plate comprises a prefabricated plate, negative ribs and cast-in-place concrete. A middle completely prefabricated part is arranged at the middle portion of the prefabricated plate. A plurality of hollow holes vertically penetrating the middle completely prefabricated part are formed in the middle completely prefabricated part. The hollow holes are cylindrical, and parts needing to be overlapped are arranged on the periphery of the prefabricated plate and located on the outer side of the middle completely prefabricated part, and the overlapped parts are subjected to face roughening treatment. The left side and the right side or one side of a reinforced concrete overlapped beam is provided with the prefabricated plate. The prefabricated plate, the negative ribs and the reinforced concrete overlapped beam are fixedly connected through the cast-in-place concrete. The middle part of the prefabricated plate is completely prefabricated, the hollow holes are arranged, the structure stress is good, and the weight is small. The reserved hollow holes can conveniently serve as channels for a cable, a wire and a water pipe; the workload of the prefabricated part is increased, the construction work of the field casting-in-place part is reduced, and industrialization and construction quality control are facilitated.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com