Partially-overlapped laminated plate with holes

A technology of laminated slabs with holes, which is applied to floors, building components, buildings, etc., can solve the problems of advanced stress of steel bars and not too thin prefabricated parts, and achieve light weight, which is conducive to industrialization and construction quality control, and reduces structural loads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

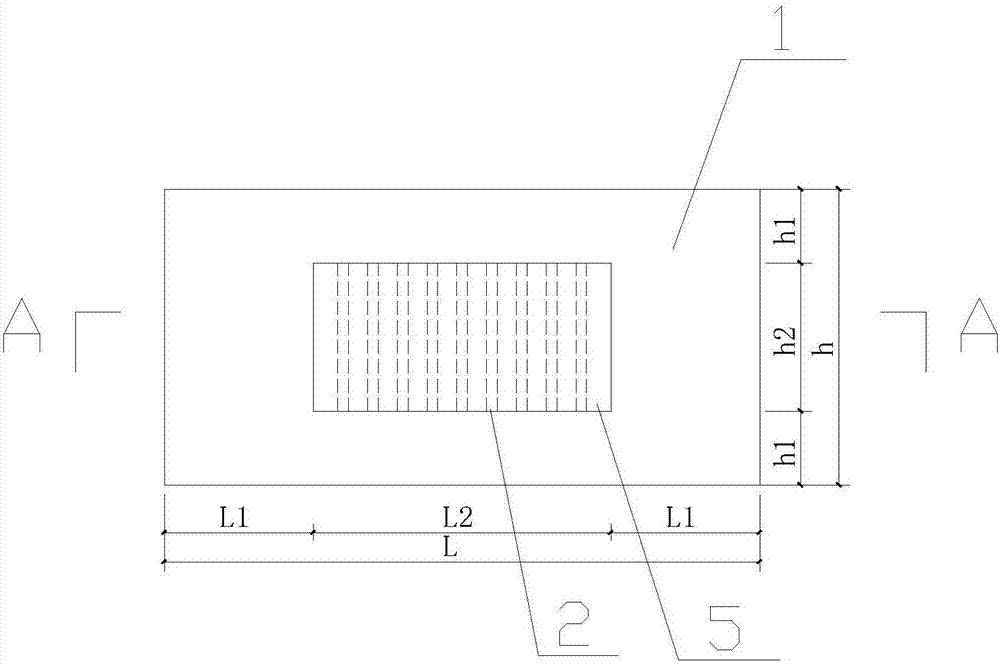

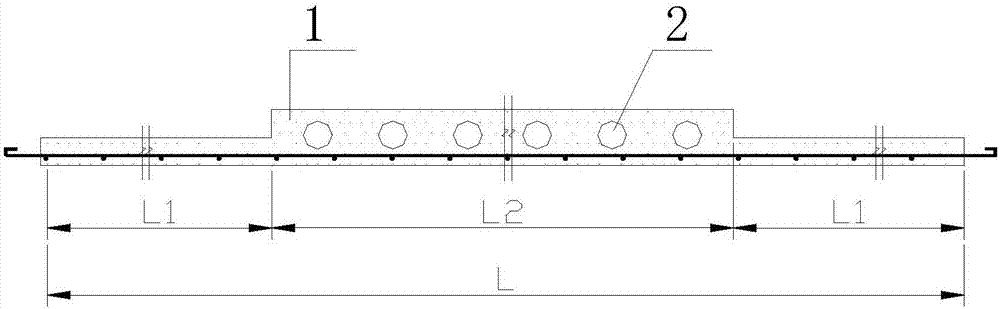

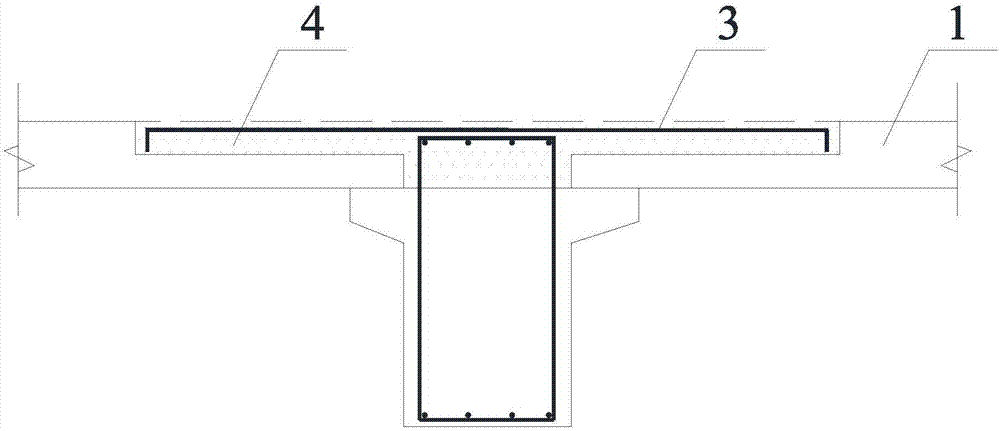

[0033] see Figure 1-3 , a partially laminated laminated slab with holes, including a prefabricated slab 1, negative reinforcement 3 and cast-in-place concrete 4; the middle part of the prefabricated slab 1 is provided with a central prefabricated part 5, and the middle part of the complete prefabricated part 5 is provided with a plurality of Vertically through the hollow hole 2 of the complete prefabricated part 5 in the middle part, the hollow hole 2 is cylindrical, the complete prefabricated part 5 in the middle part is rectangular, a plurality of hollow holes 2 are evenly arranged along the length direction of the complete prefabricated part 5 in the middle part, and the prefabricated plate 1 is surrounded by parts that need to be superimposed, and the parts that need to be superimposed are located around the outside of the fully prefabricated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com