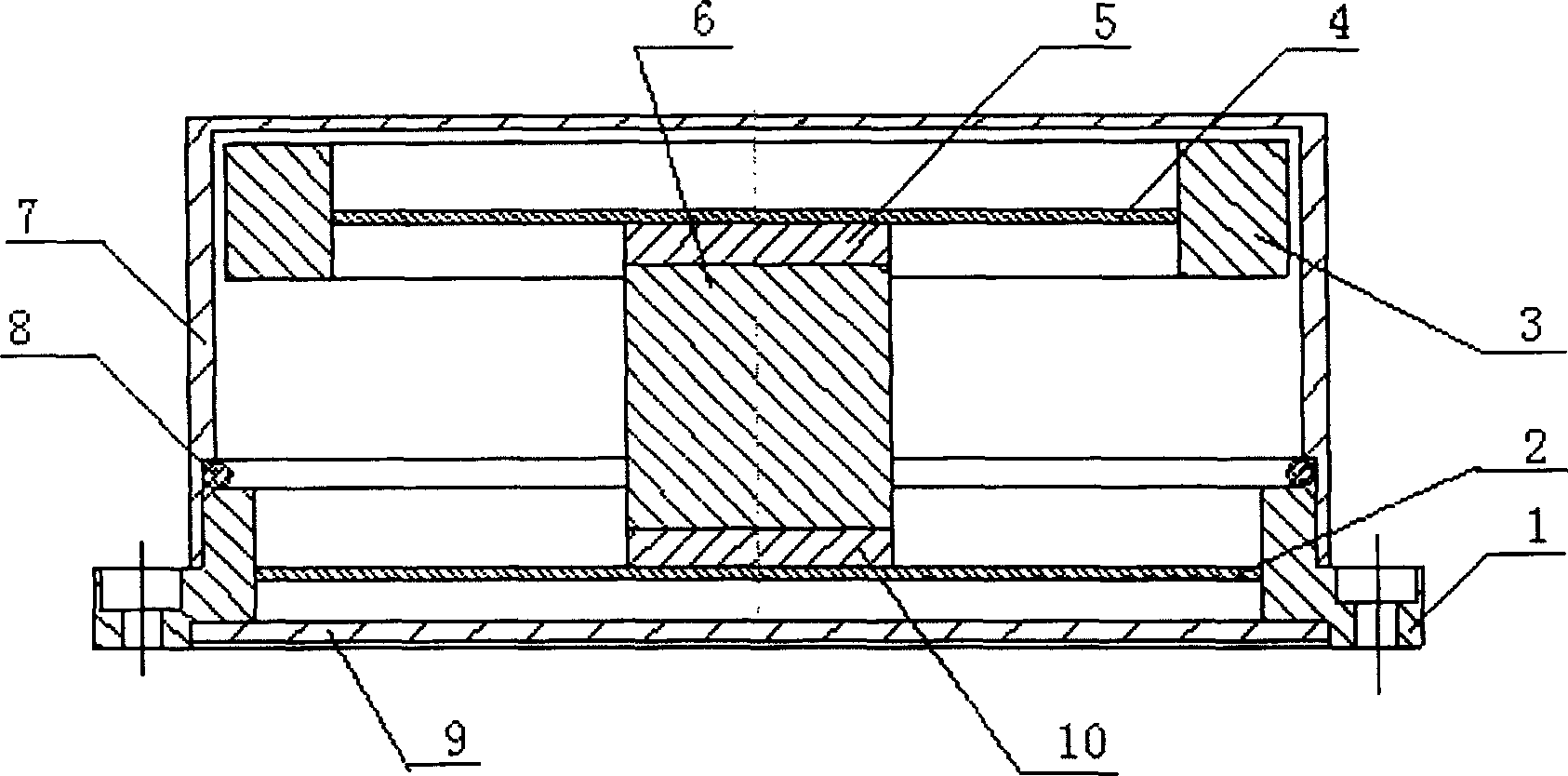

Six-axle acceleration sensor with dual E-shaped circular membranes and cross beam structure

A technology of acceleration sensor and cross beam, which is applied in the direction of multi-dimensional acceleration measurement and acceleration measurement using inertial force, etc., can solve the problem of not being able to obtain contact force information, achieve the effect of obtaining angular acceleration information and overcoming strong coupling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

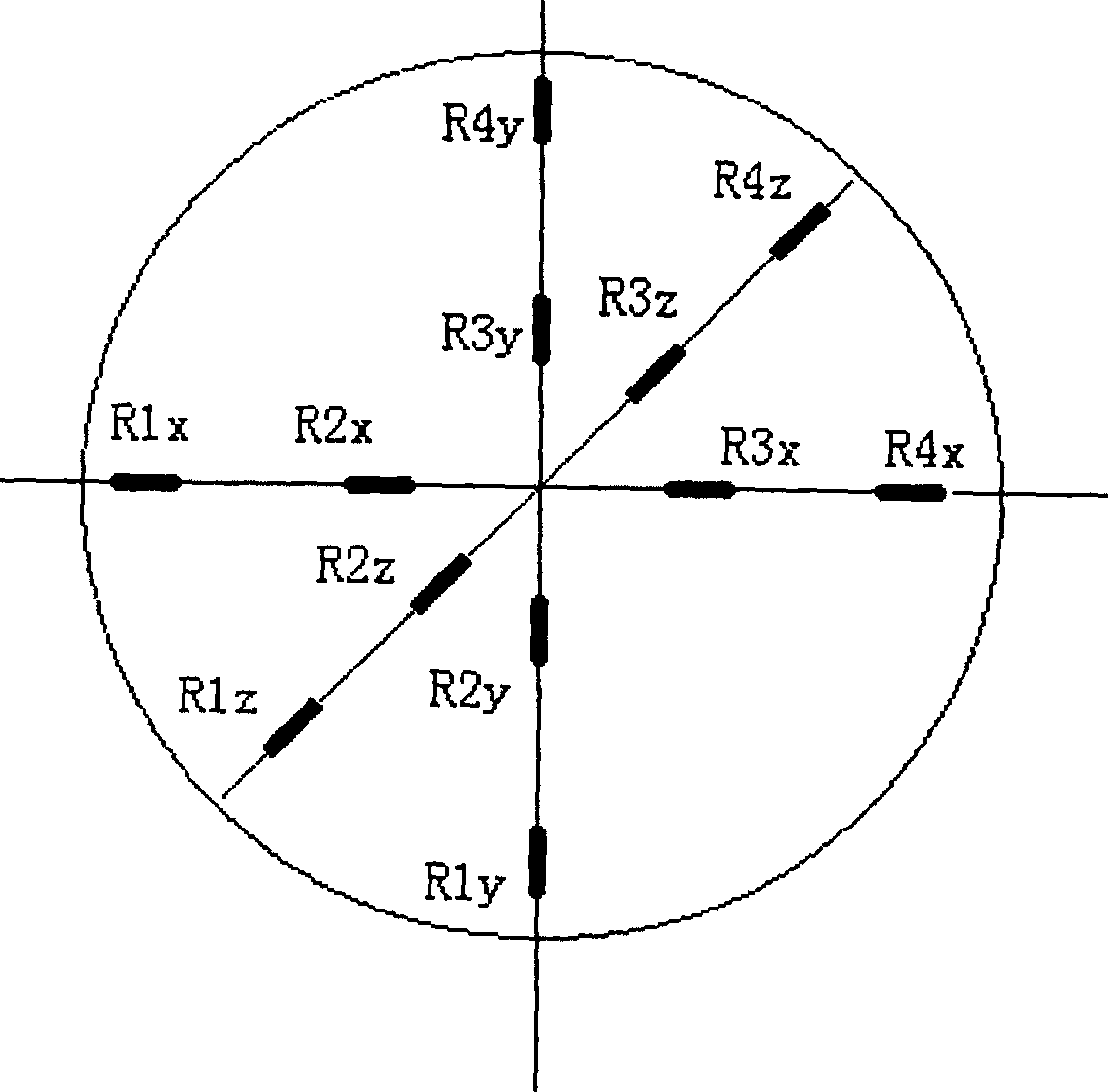

[0064] Specific embodiments: the present invention adopts the thick film process, and uses the screen printing technology to print the force sensitive resistor paste and the conductor paste on the specific position of the ceramic substrate of the E-shaped circular diaphragm and the cross beam, and forms 24 thick plates after sintering. The membrane strain resistance constitutes six groups of bridges for obtaining six-dimensional acceleration information respectively.

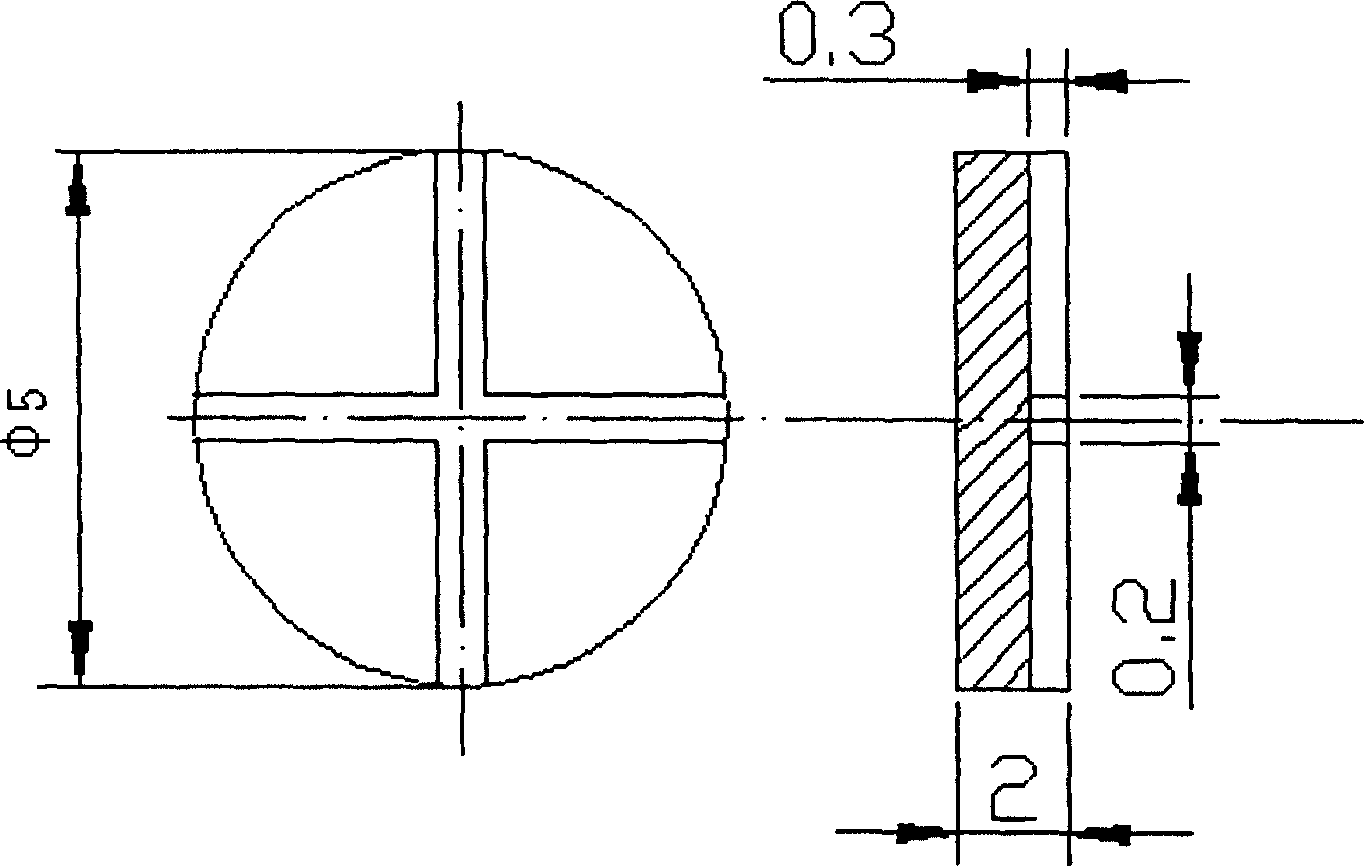

[0065] In order to realize the measurement of small range and high sensitivity, the thickness of the E-type circular diaphragm is 0.2-0.4mm, and the thickness of the cross beam is 0.2-0.4mm. When metal is used as the elastic body, the upper and lower E-shaped circular membranes and the middle cross beam can be processed into an integrated structure, and the three-dimensional linear acceleration and three-dimensional angular acceleration information can be realized by pasting the strain gauge resistance according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com