Patents

Literature

72 results about "Circular diaphragm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

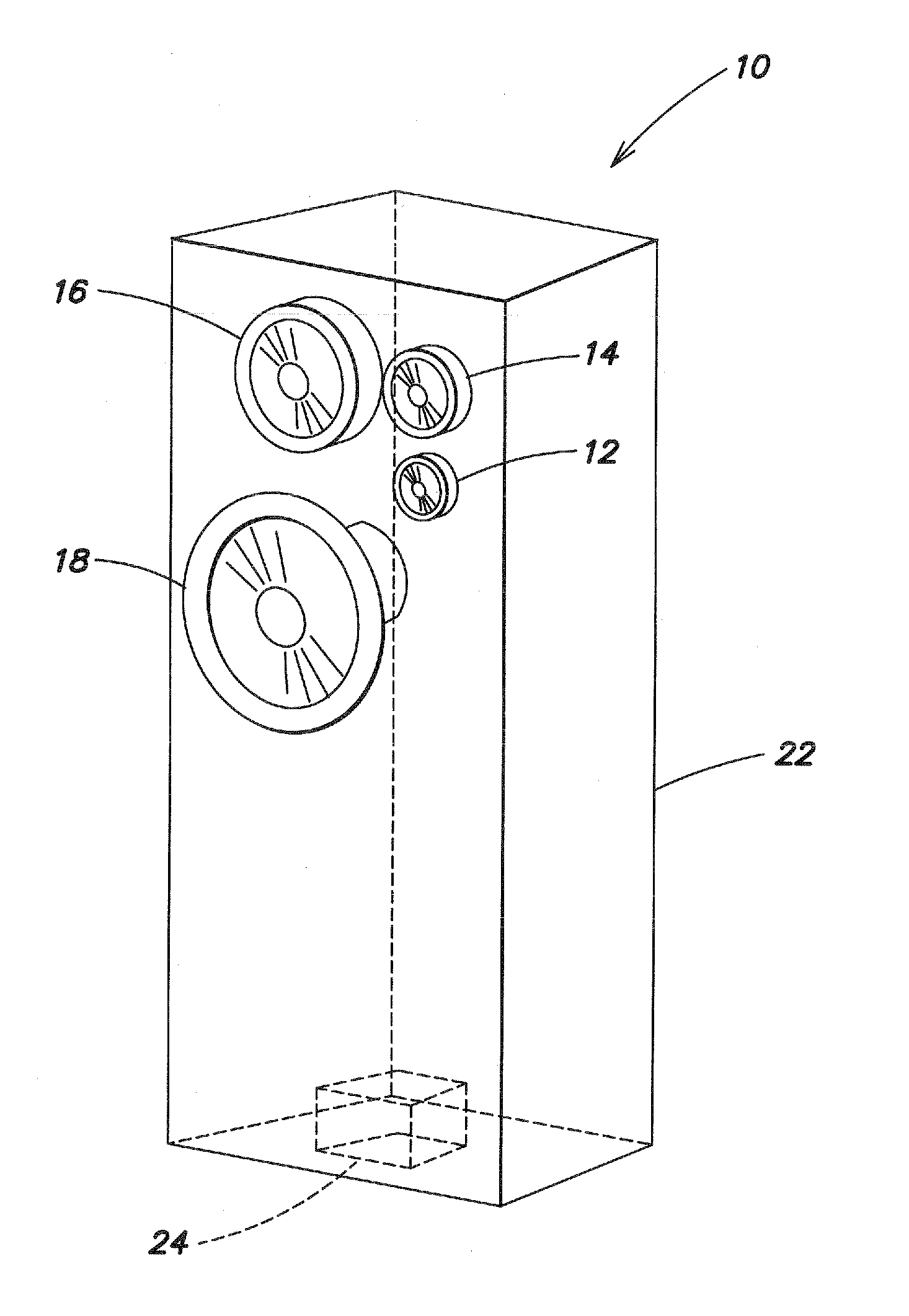

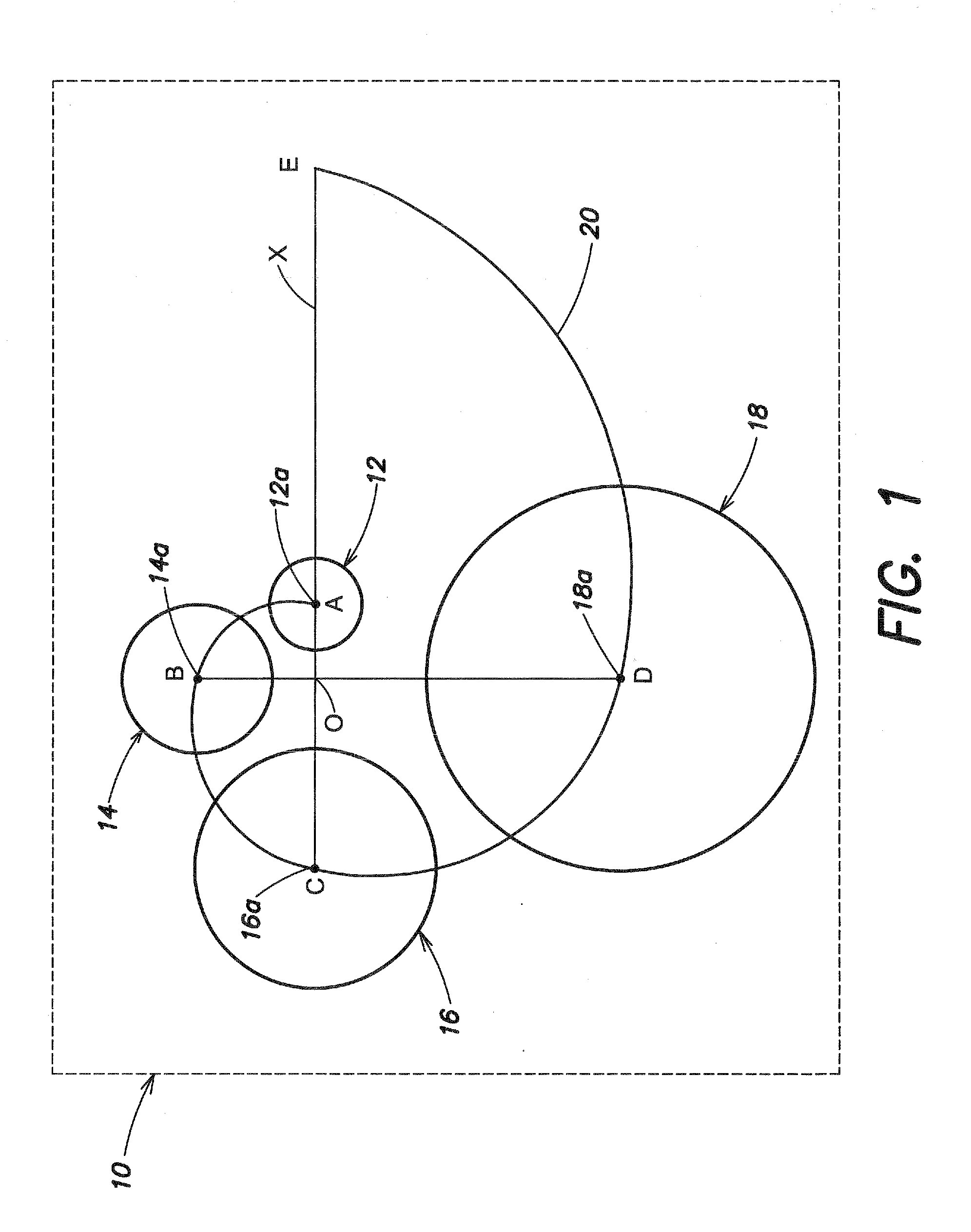

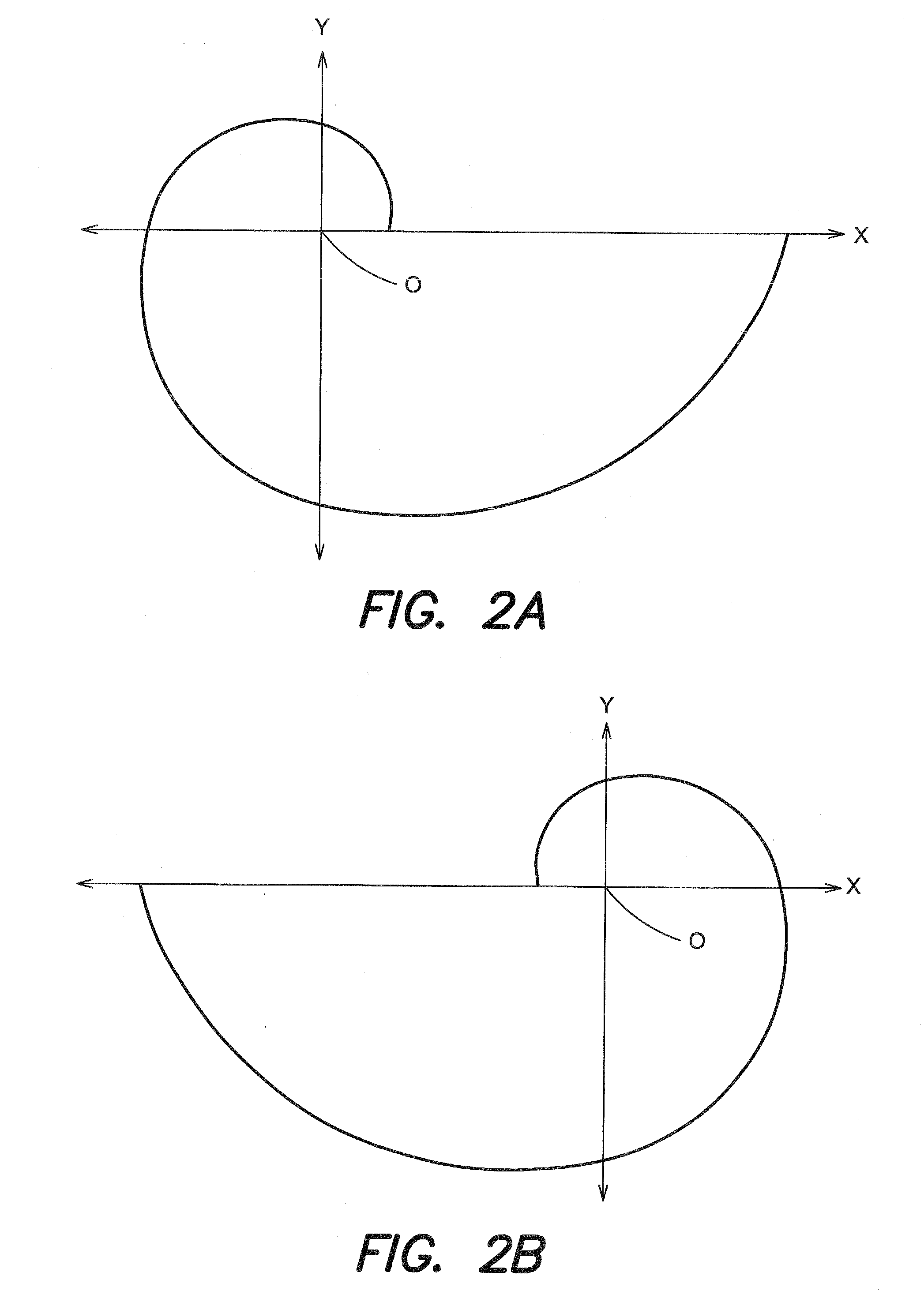

Sound reproduction systems and method for arranging transducers therein

InactiveUS20120063628A1Single transducer incorporationPiezoelectric/electrostrictive microphonesTransducerEngineering

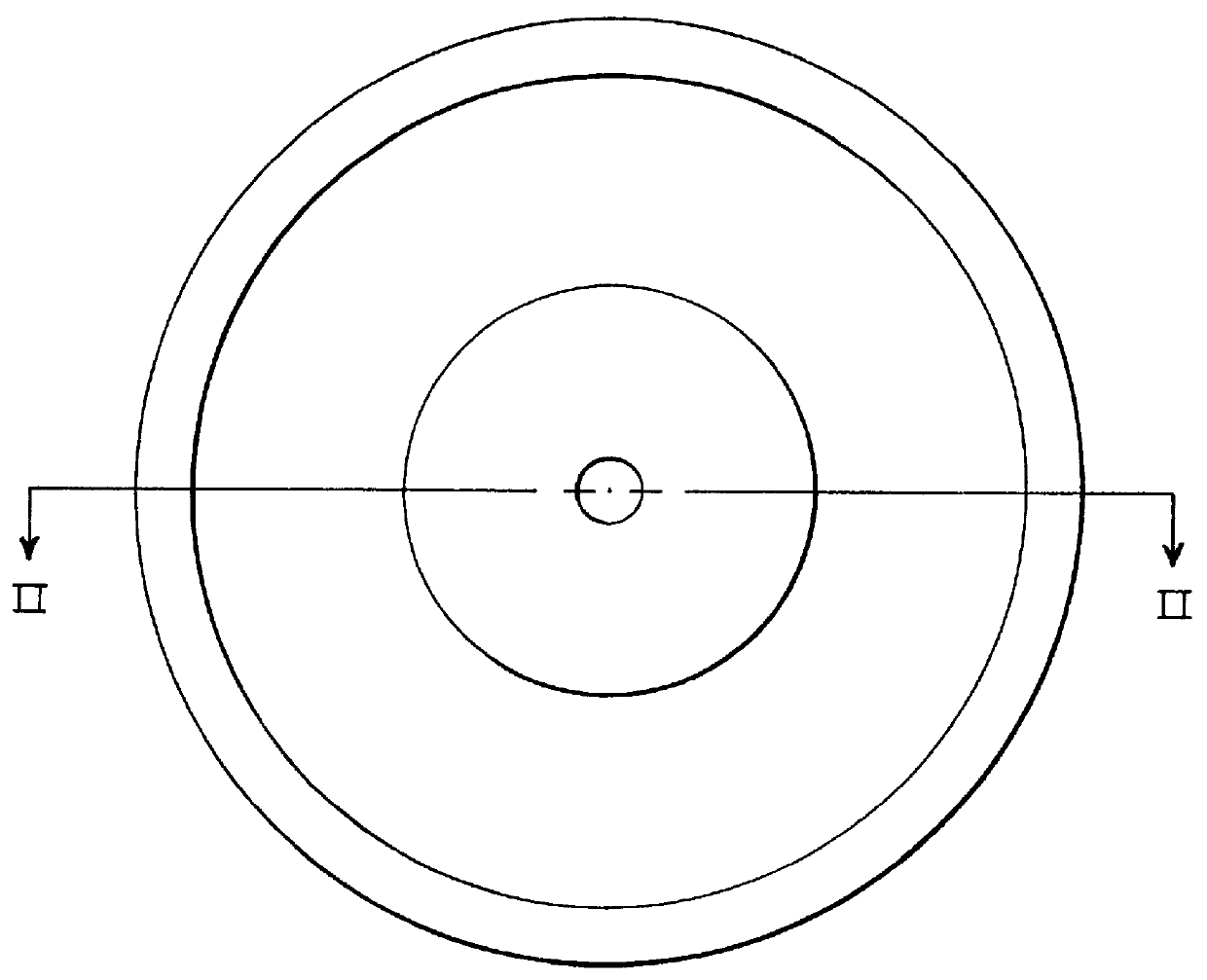

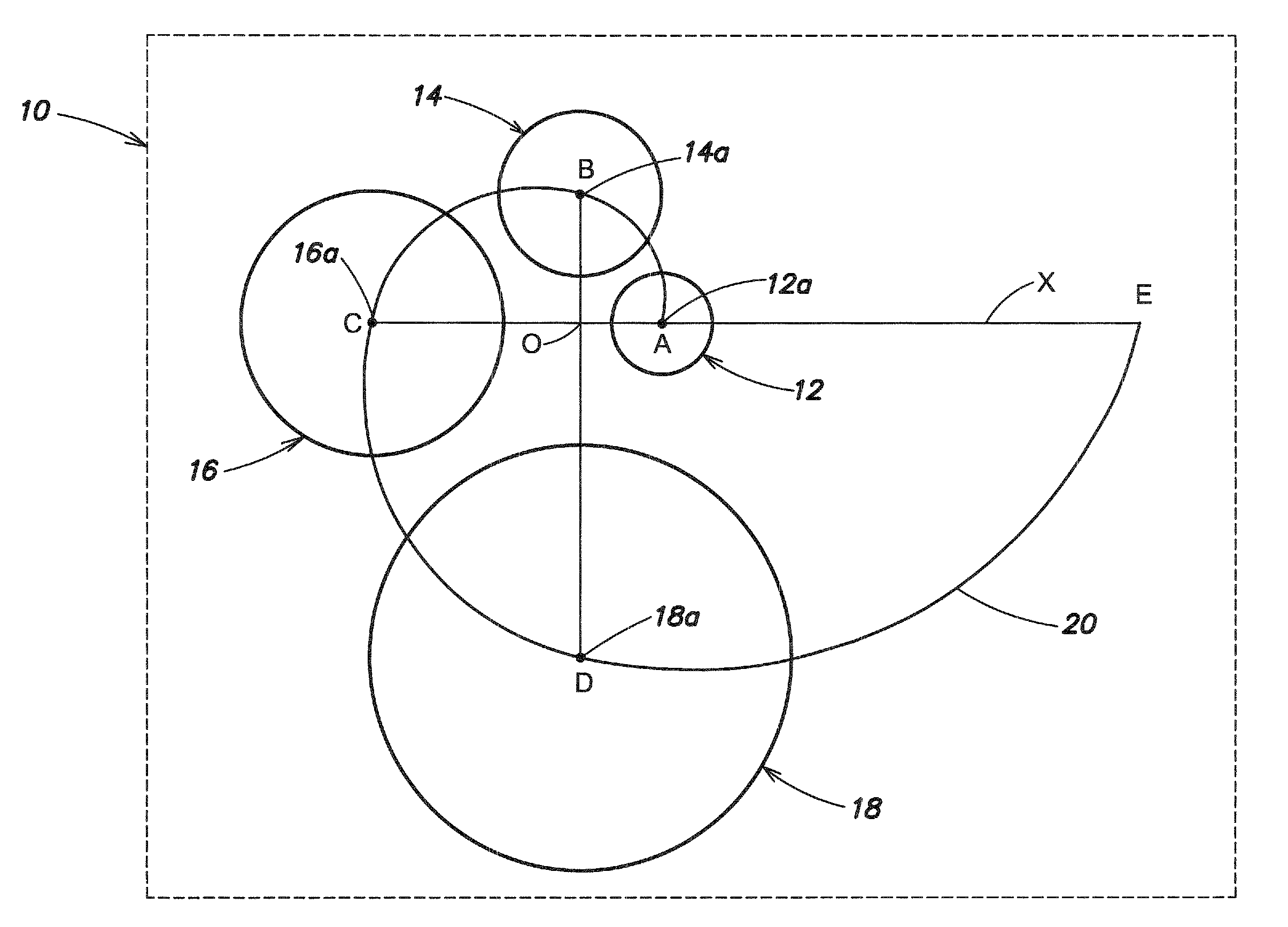

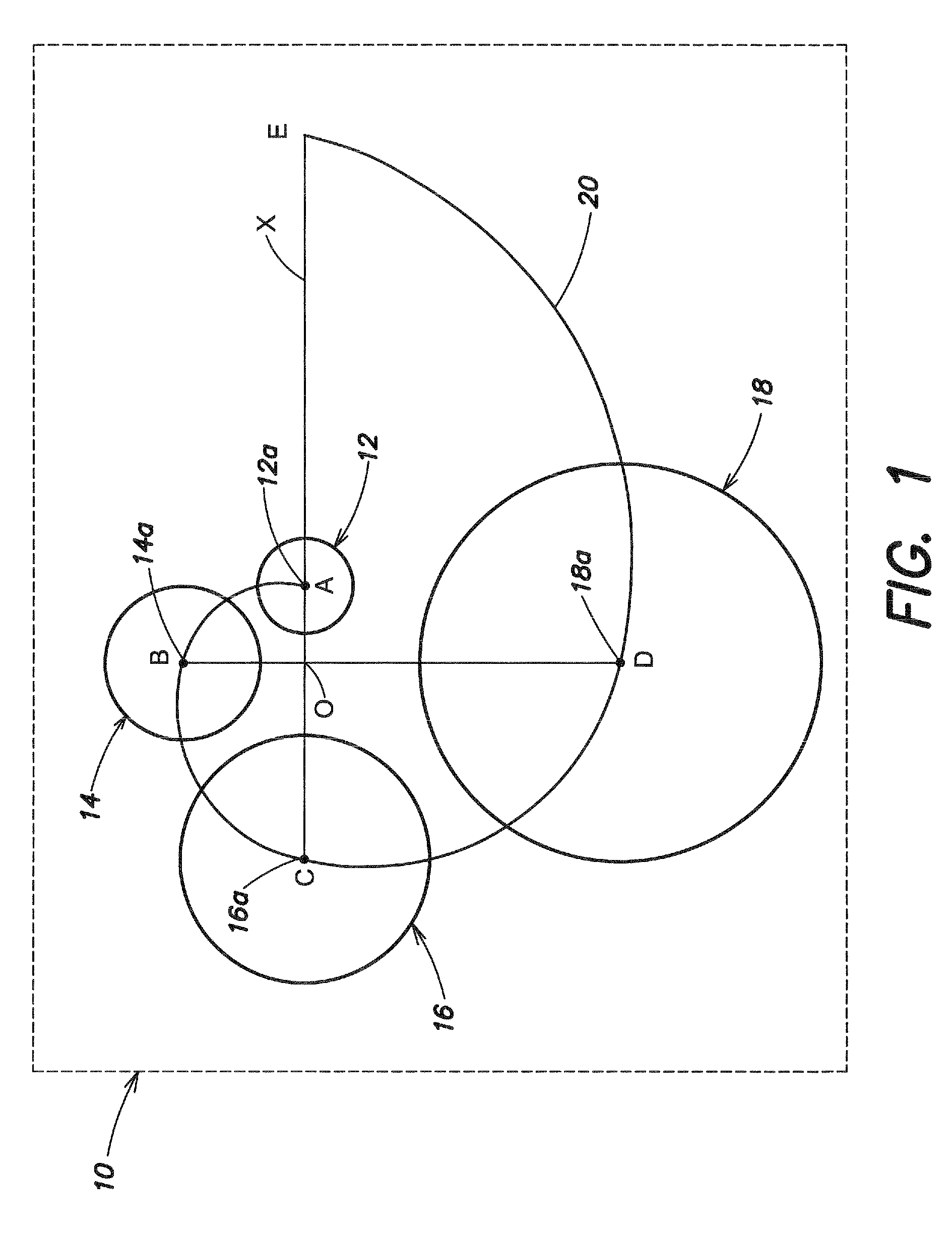

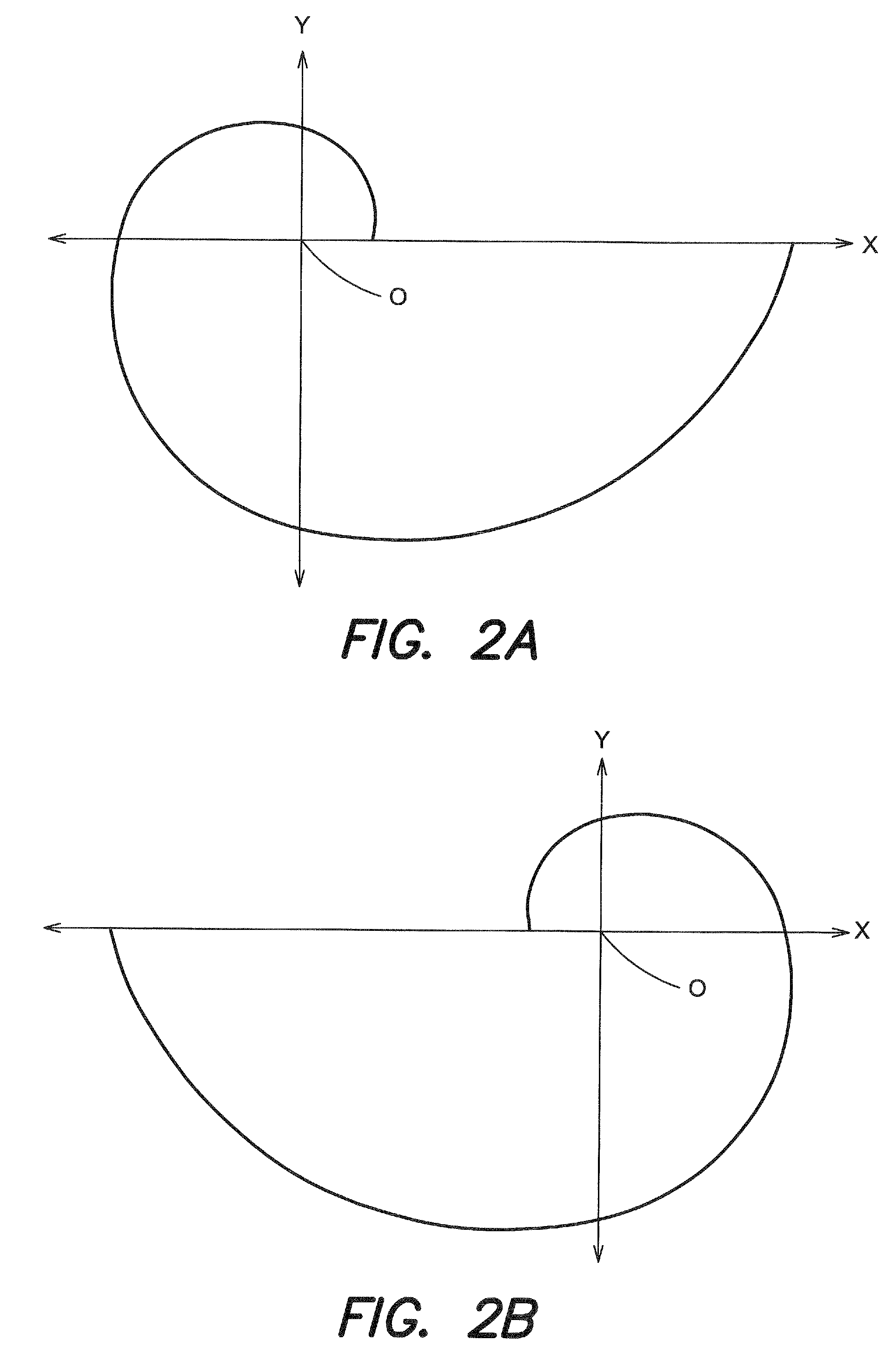

Loudspeaker system including a housing and at least four transducers arranged therein. Each transducer includes a substantially circular diaphragm and the diaphragms are constructed with specific sizes such that the ratio of a diameter of each diaphragm to the diameter of an immediately larger diaphragm is between 1:1 and 1:Phi2 (Phi=1+√5 / 2), preferably 1:Phi, and the ratio of the diameter of each diaphragm to an immediately smaller diaphragm is between 1:1 and 1:(1 / Phi2), preferably 1:1 / Phi. Moreover, the diaphragms are arranged such that centers thereof lie on a spiral, clockwise or counterclockwise, in ascending size order with the center of the smallest diaphragm being closest to the pole of the spiral. A microphone and single-diaphragm loudspeaker in which the diaphragm has a spiral shape are also disclosed.

Owner:RIZZELLO FRANK

Diaphragm with modified insert

InactiveUS6142062AEasy to useReduce pointsFlexible wall reciprocating enginesEngine diaphragmsElastomerEngineering

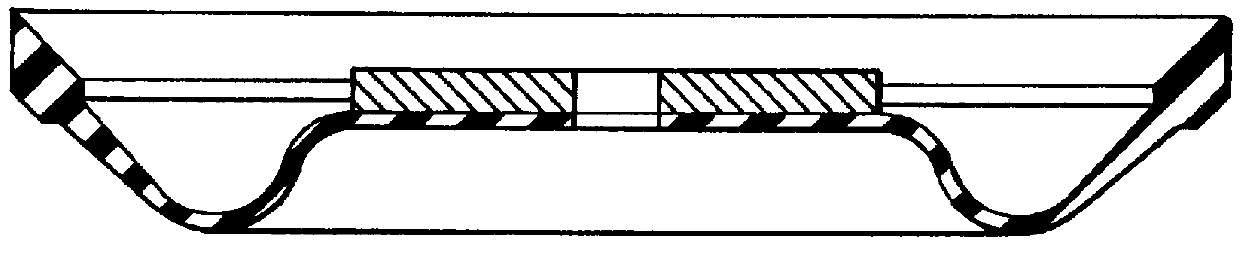

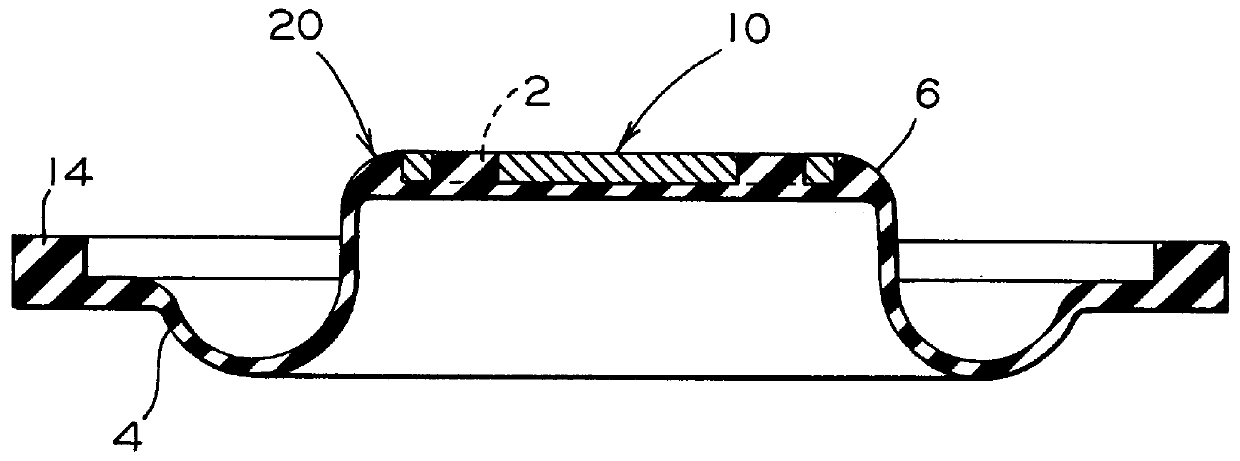

The present invention provides a diaphragm member for use in certain valve assemblies. Such diaphragm member comprises a generally circular diaphragm having a first predetermined diameter and having a first surface and a second surface. Such generally circular diaphragm is formed from at least one layer of a preselected elastomeric material. Such generally circular diaphragm includes a nonflexing center portion, a generally annular flexure portion extending around an outer periphery of such nonflexing center portion and a non flexing outer portion extending around an outer periphery of such generally annular flexure portion, such non flexing outer portion is engageable with a body portion of such valve assembly. Such diaphragm member further includes a generally circular insert member, having a second predetermined diameter, disposed within the first surface of such nonflexing center portion of such generally circular diaphragm. Such generally circular insert member has a plurality of apertures formed through such generally circular insert member, such plurality of apertures provide a predetermined open area for receiving a predetermined rubber compound for bonding such generally circular insert member to such nonflexing center portion of such generally circular diaphragm.

Owner:WESTINGHOUSE AIR BRAKE CO

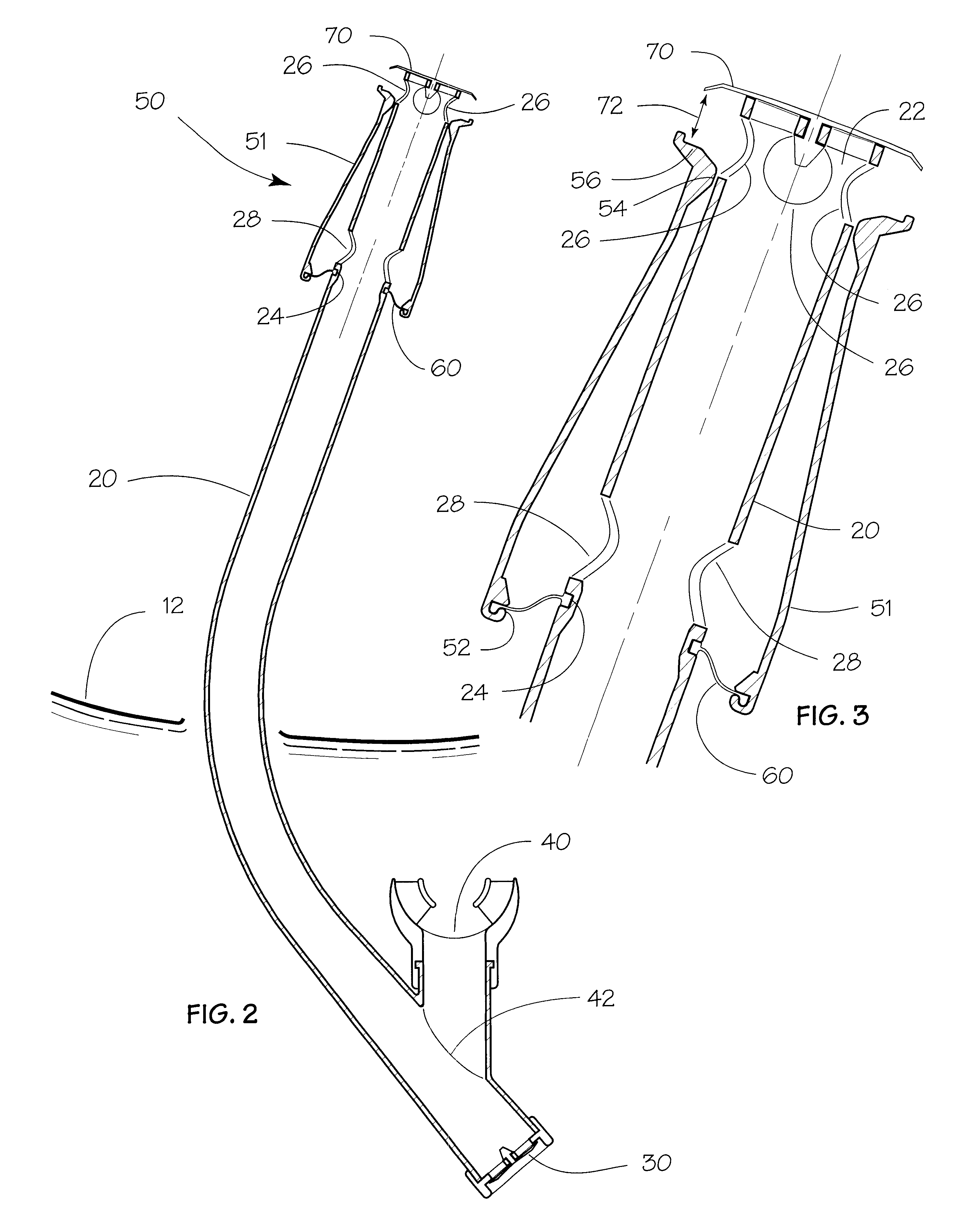

Dryest snorkel

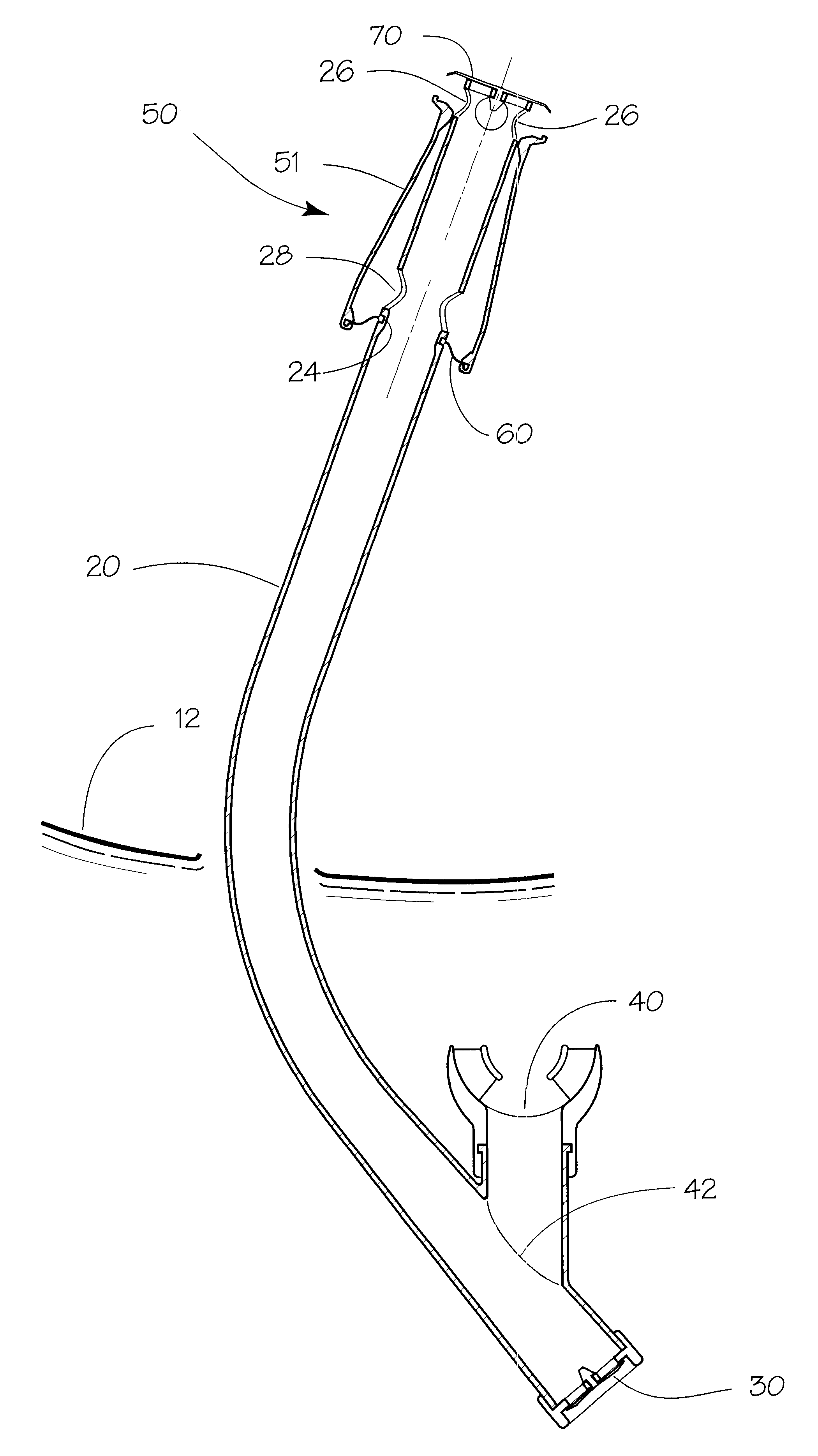

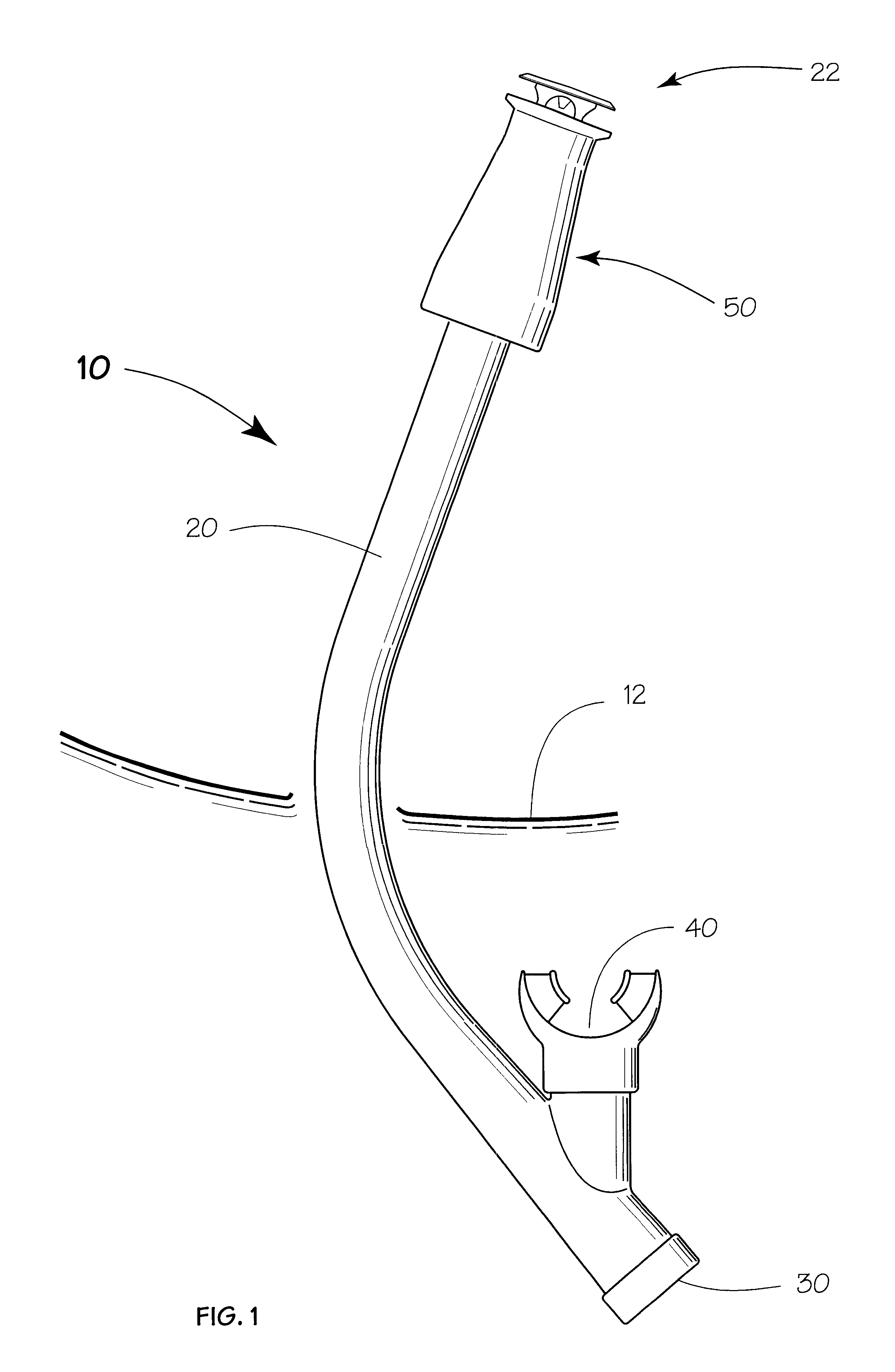

The instant invention is a skin diving snorkel having a conduit with an end above the water surface, and an underwater end that terminates in a mouthpiece. The mouthpiece provides a flow path between the conduit and the interior of the diver's mouth. A buoyant chamber, separate from the conduit, surrounds and is coaxial with the conduit above water end. A lower opening in the chamber is joined to the conduit by a convoluted diaphragm. The convoluted diaphragm provides a flexible and watertight barrier that enables the chamber to be easily buoyed a short distance upward, guided by the snorkel conduit. The conduit's open end protrudes loosely through an upper opening in the chamber. The conduit open end carries a flexible circular diaphragm which, when it makes contact with the upper opening of the buoyed chamber, serves as a check valve allowing exhalation flow from the conduit to ambient, but blocks the flow of water into the snorkel. In addition, an optional purge valve adjacent the conduit's underwater end also allows flow from the conduit to ambient, but not in the reverse direction.

Owner:CHRISTIANSON TONY

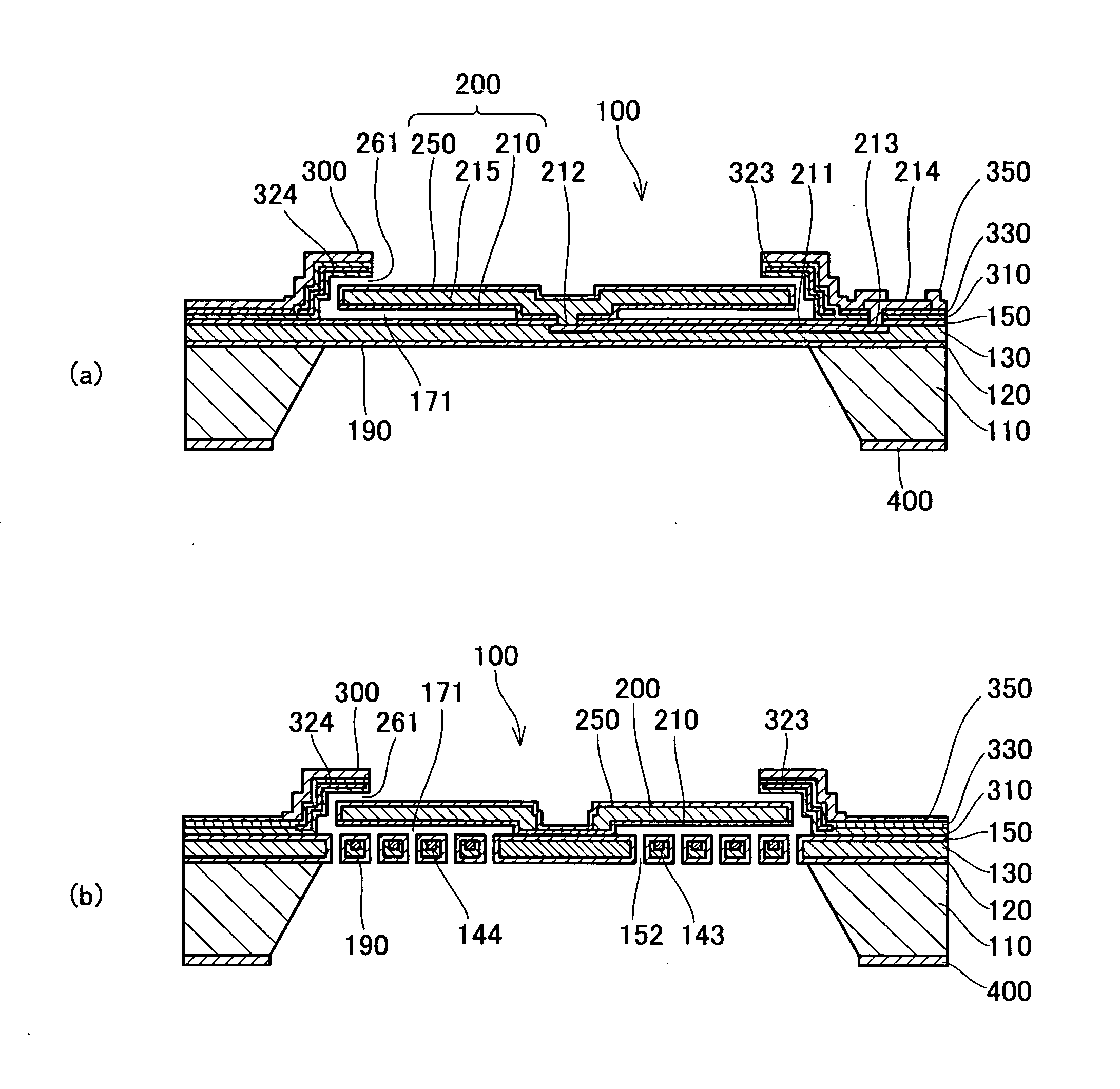

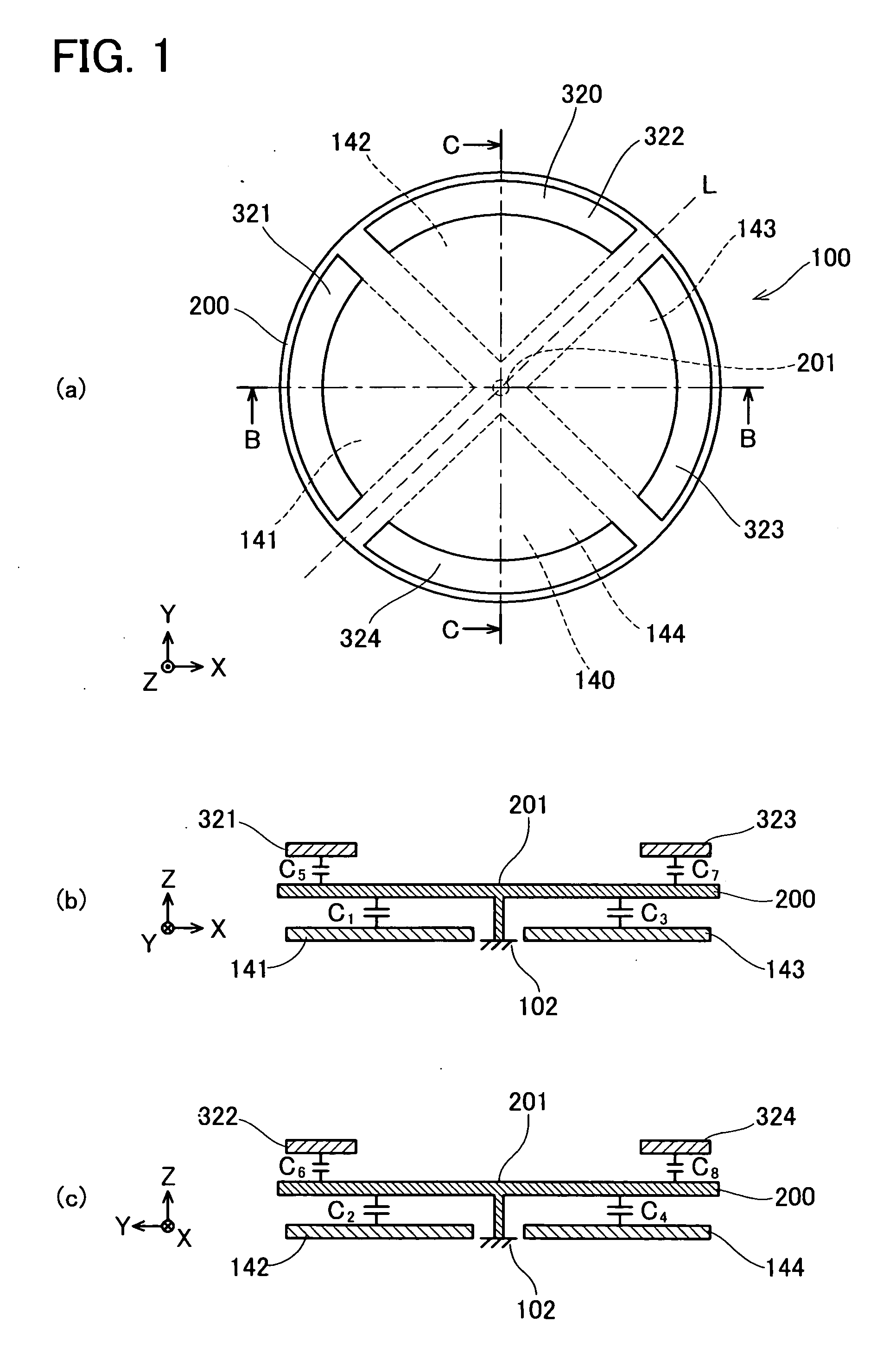

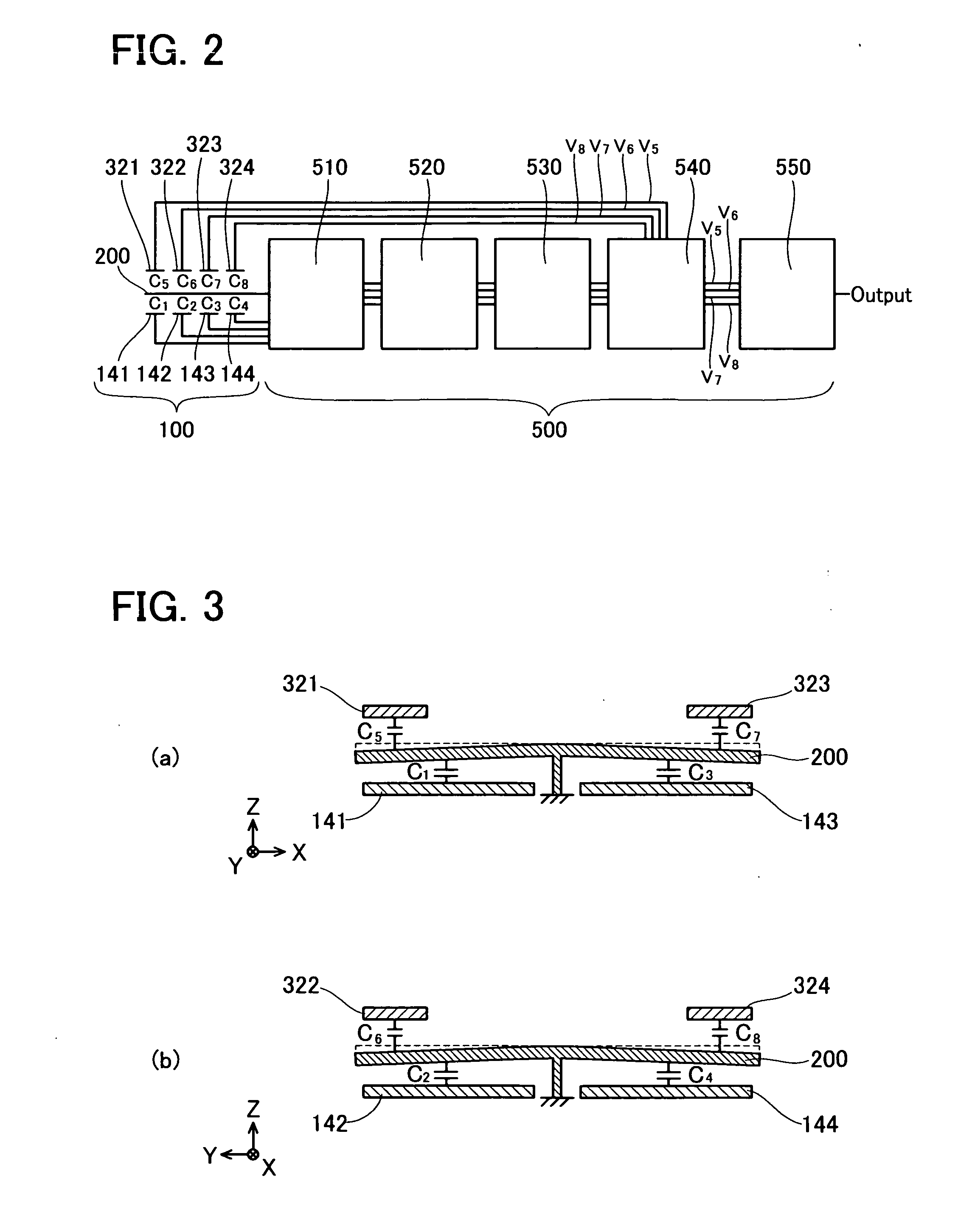

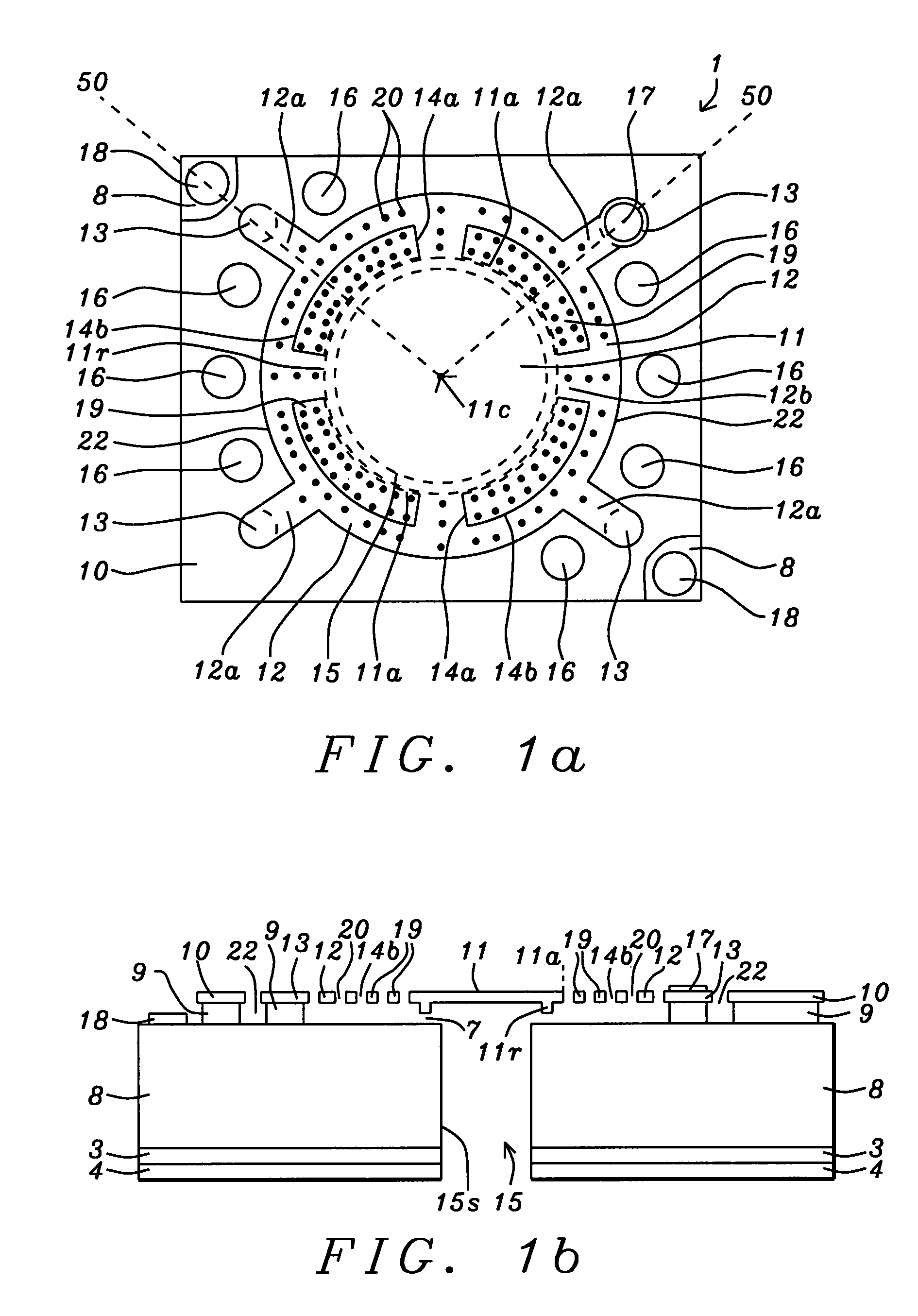

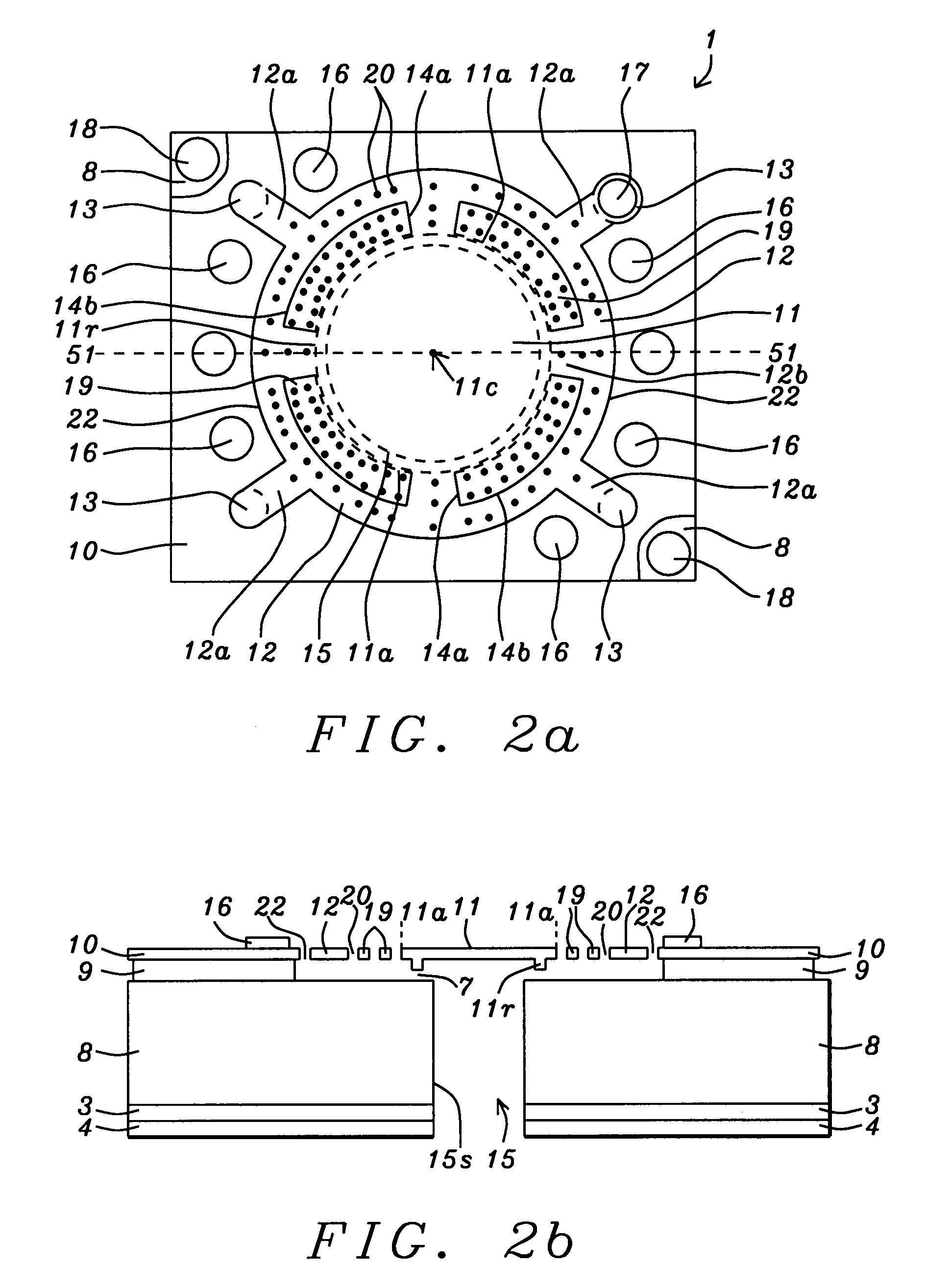

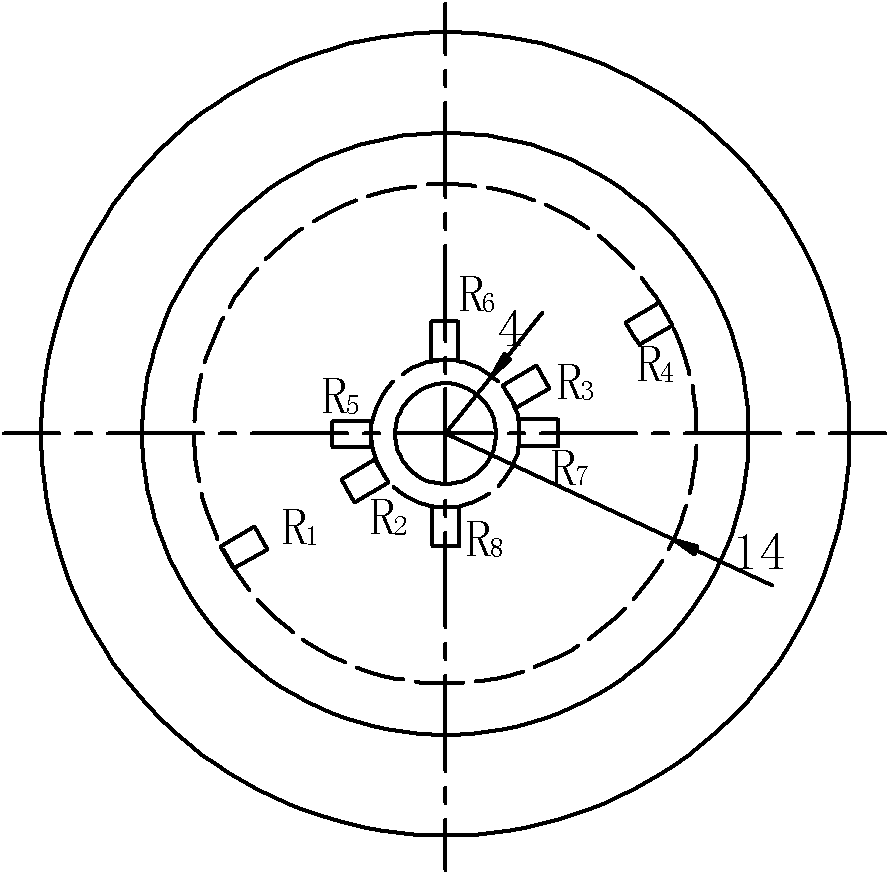

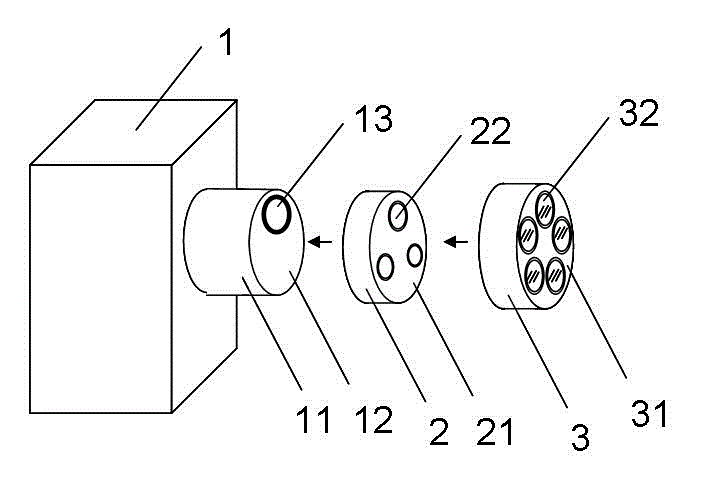

Microphone and a method of manufacturing a microphone

InactiveUS20060284516A1Small sizePiezoelectric/electrostriction/magnetostriction machinesElectrostatic transducer microphonesCapacitanceEngineering

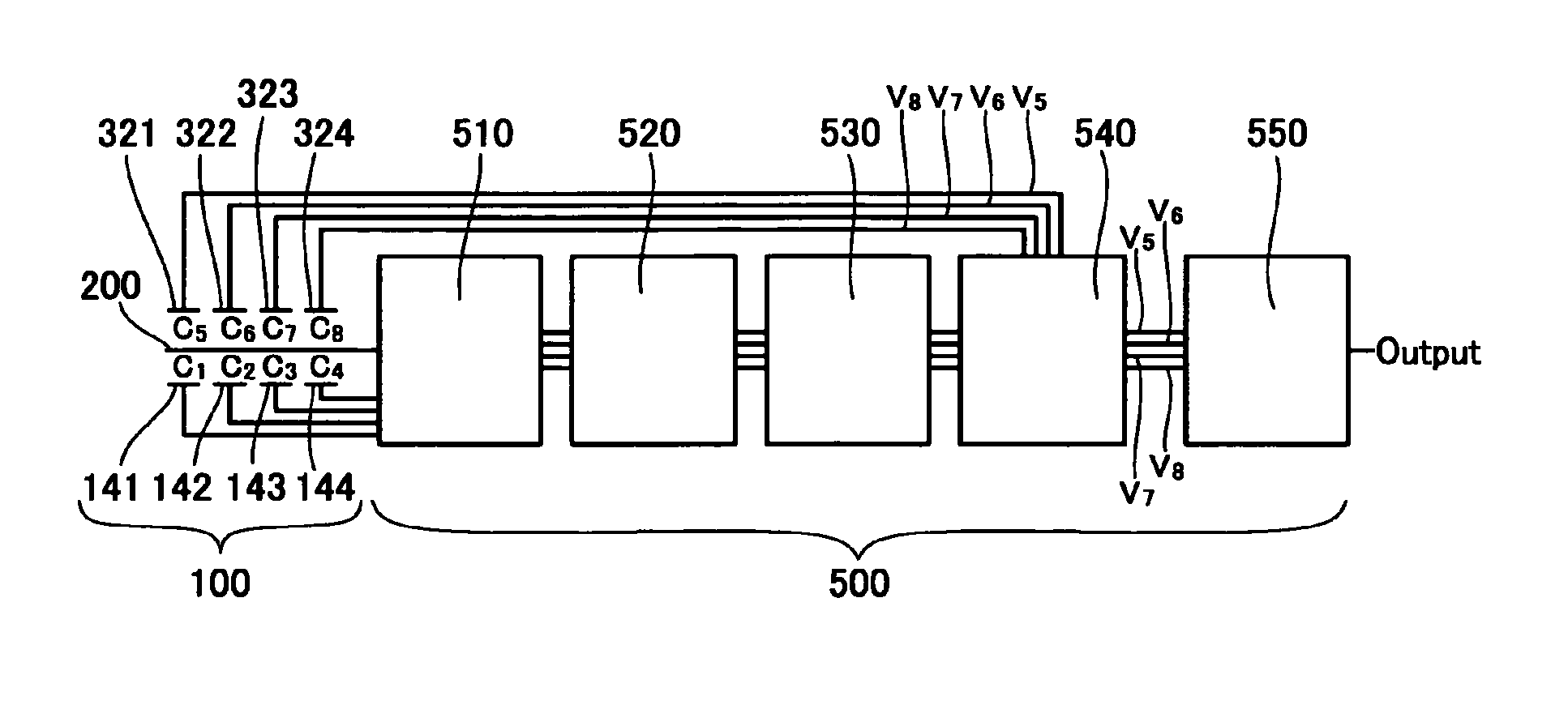

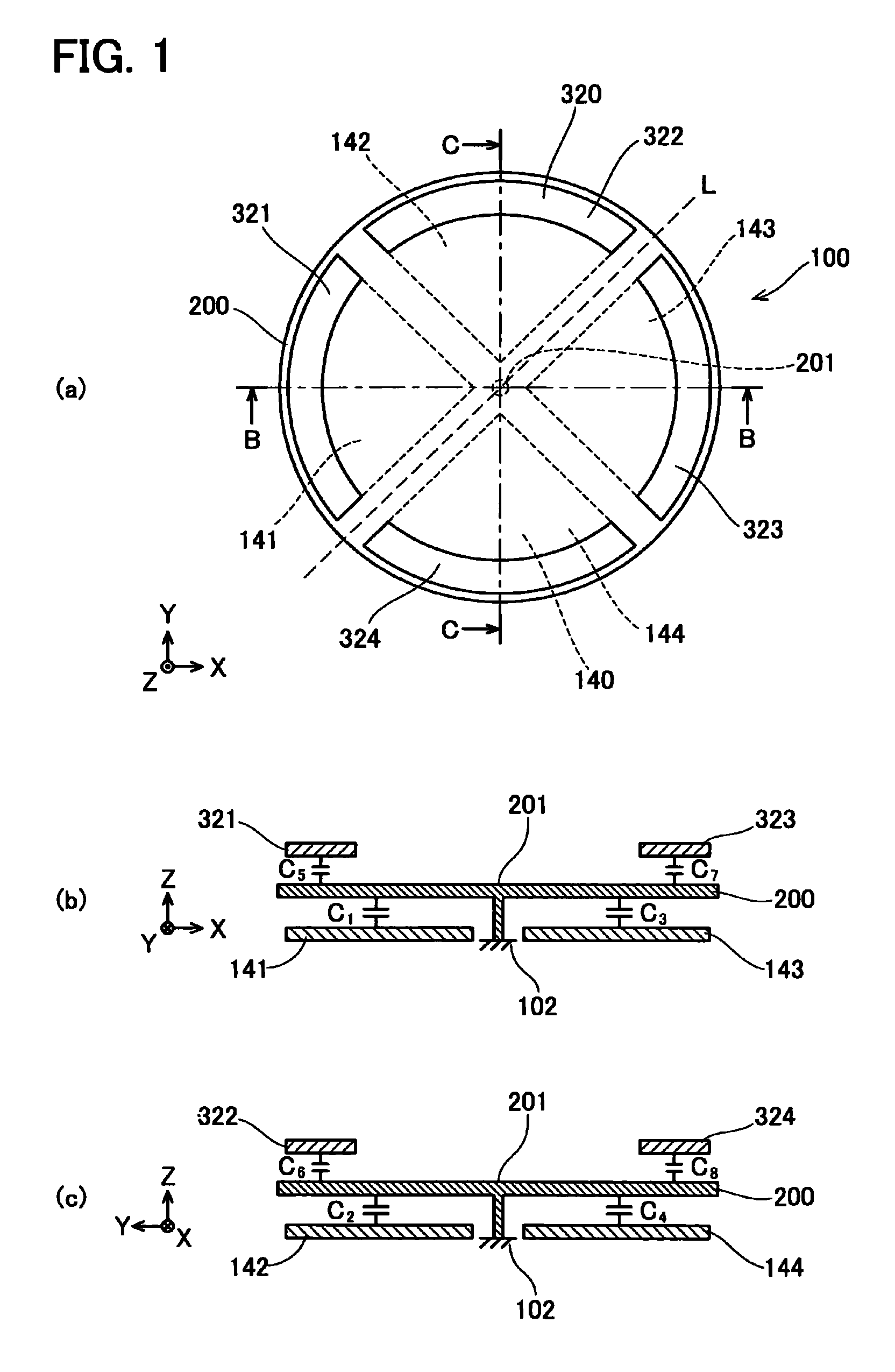

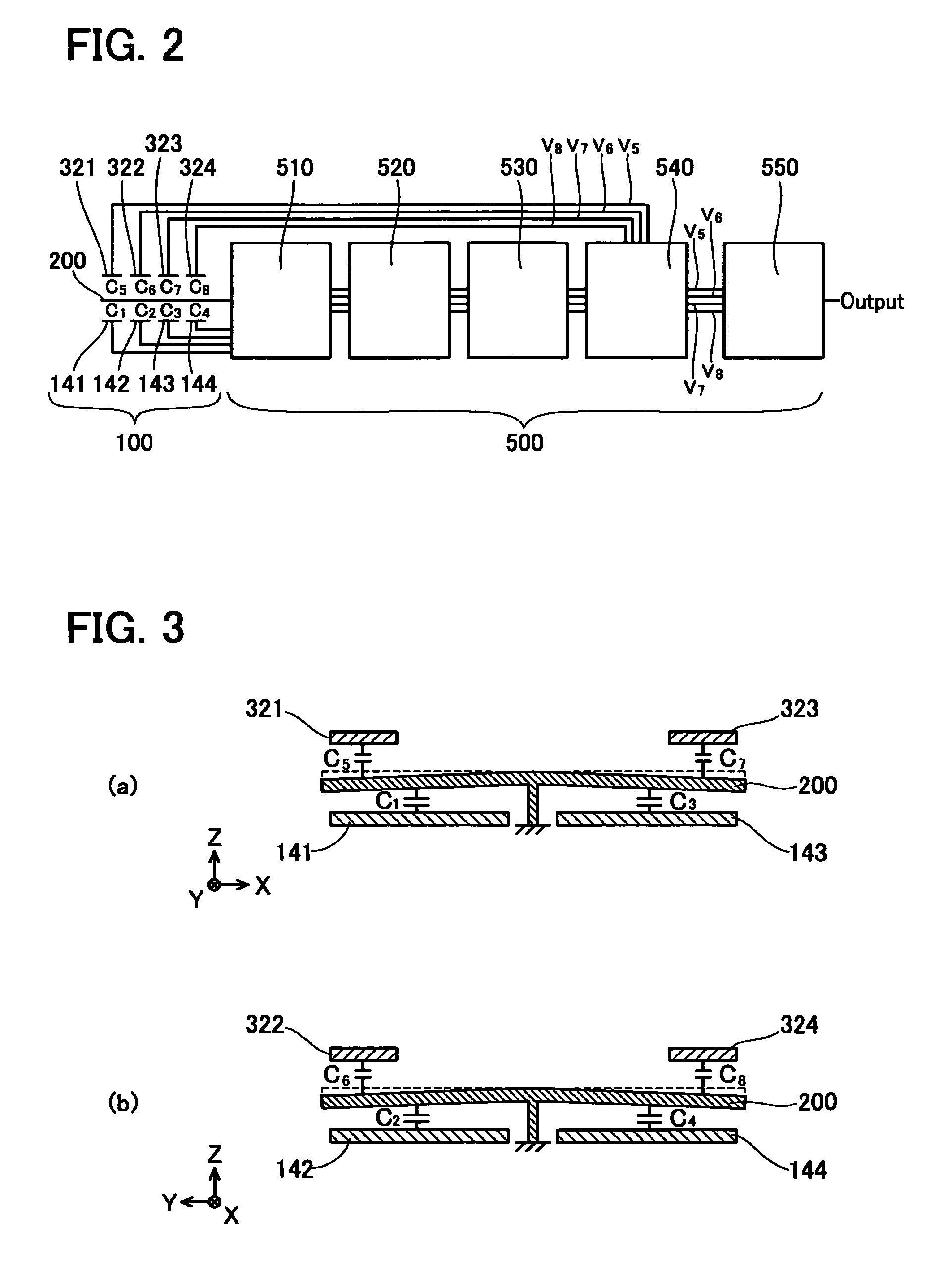

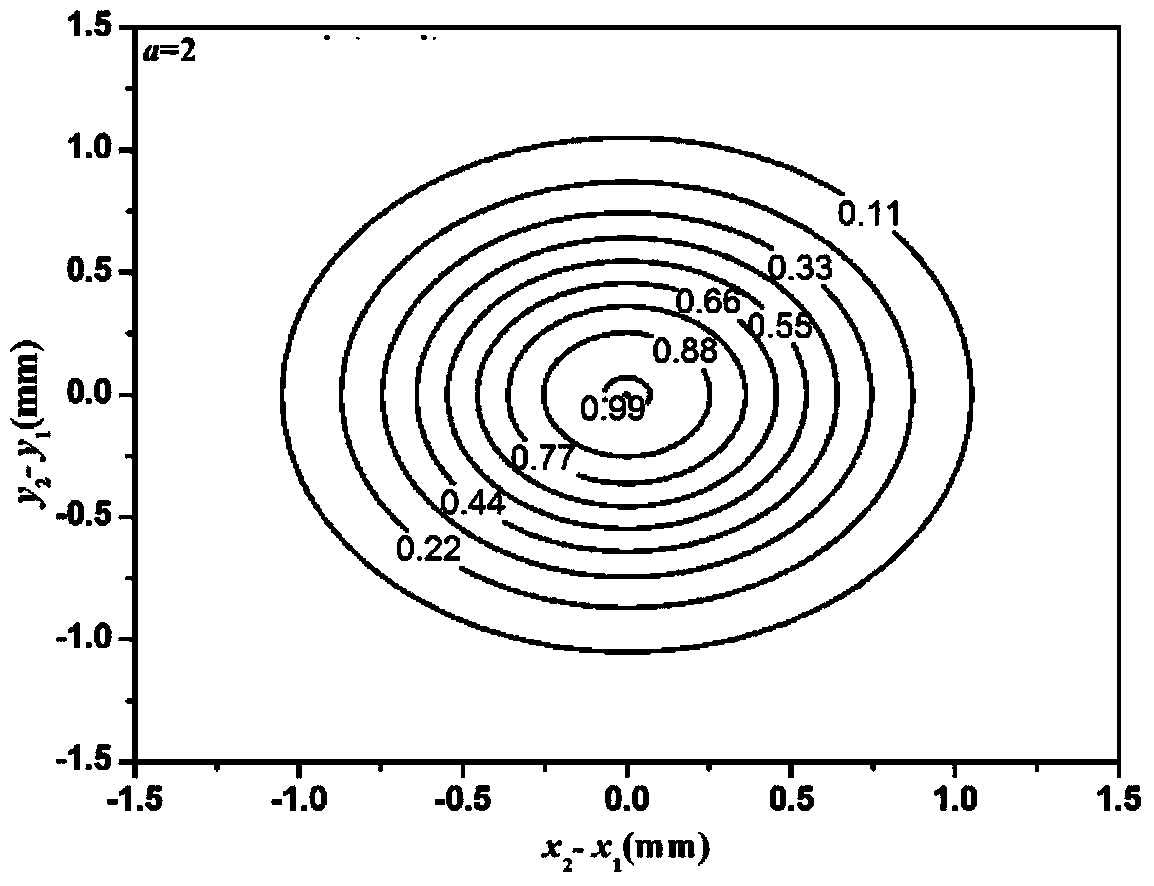

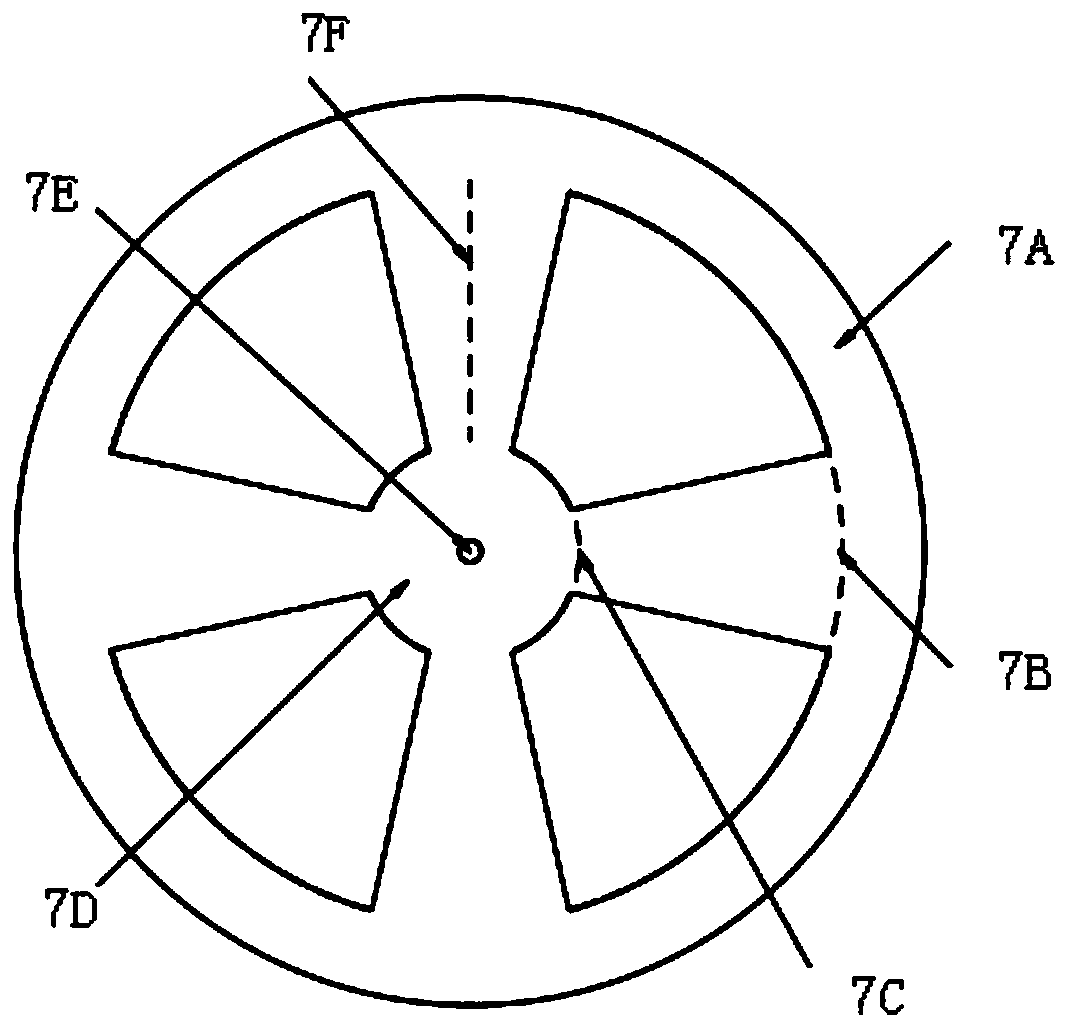

A microphone that may identify the direction along which acoustic waves propagate with one diaphragm, and which has superior durability is provided. The microphone comprises a circular diaphragm. The diaphragm is supported at the center portion thereof. When the diaphragm receives acoustic waves, each position around the center thereof will vibrate with a phase depending upon the direction of the acoustic waves. First electrodes are arranged on one of the surfaces of the diaphragm. Second electrodes are arranged so that each second electrode faces corresponding first electrode with gap. Each first electrode and corresponding second electrode facing thereto form a first capacitor. Third electrodes are arranged on the other surface of the diaphragm. Fourth electrodes are arranged so that each fourth electrode faces corresponding third electrode with gap. Each third electrode and corresponding fourth electrode facing thereto form a second capacitor. The controller applies a voltage to each of the second capacitors so that the capacitance of each of the first capacitors will be a constant value. The controller identifies the direction along which the acoustic waves propagate based on the difference in the voltages applied to each of the second capacitors. Vibration of the diaphragm will be inhibited by the voltages applied to the second capacitors while the direction is identified based on the voltages. The durability of the diaphragm can be improved.

Owner:TOKYO UNIV OF THE +1

Microphone and a method of manufacturing a microphone

InactiveUS7888840B2Small sizePiezoelectric/electrostriction/magnetostriction machinesElectrostatic transducer microphonesCapacitanceAcoustic wave

A microphone that identifies the direction along which acoustic waves propagate with one diaphragm, and has superior durability is provided. The microphone includes a circular diaphragm supported at a center portion thereof. When the diaphragm receives acoustic waves, each position around the center thereof will vibrate with a phase depending upon the direction of the acoustic waves. First electrodes are arranged on one surface of the diaphragm and second electrodes are arranged facing corresponding first electrodes to form a first capacitor. Third electrodes are arranged on the other surface of the diaphragm and fourth electrodes are arranged facing corresponding third electrodes to form a second capacitor. A controller applies a voltage to the second capacitors so that the capacitance of the first capacitors will be constant and identifies the direction along which the acoustic waves propagate based on the difference in the voltages applied to each of the second capacitors.

Owner:TOKYO UNIV OF THE +1

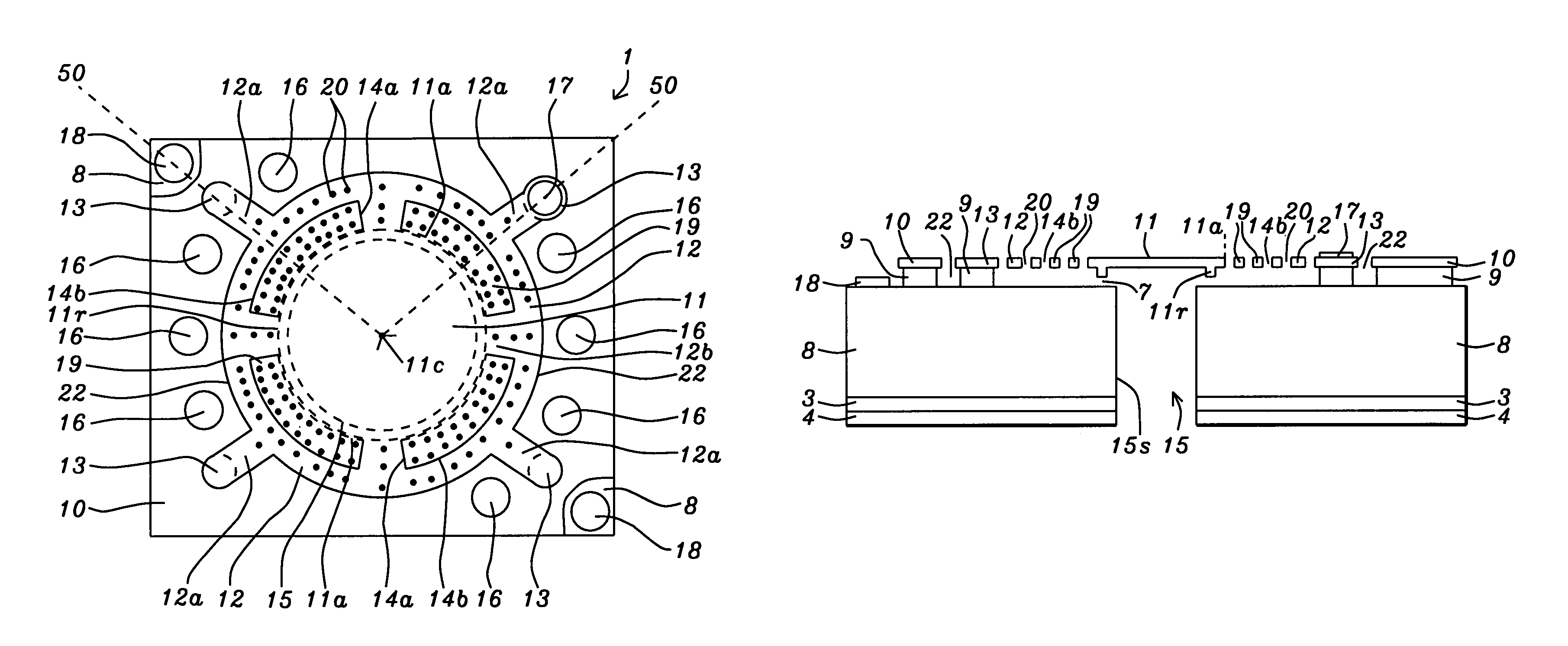

Silicon microphone with enhanced impact proof structure using bonding wires

ActiveUS8045733B2Large movementReduce complexityPiezoelectric/electrostrictive microphonesSemiconductor/solid-state device manufacturingIn planePliability

Owner:SHANDONG GETTOP ACOUSTIC

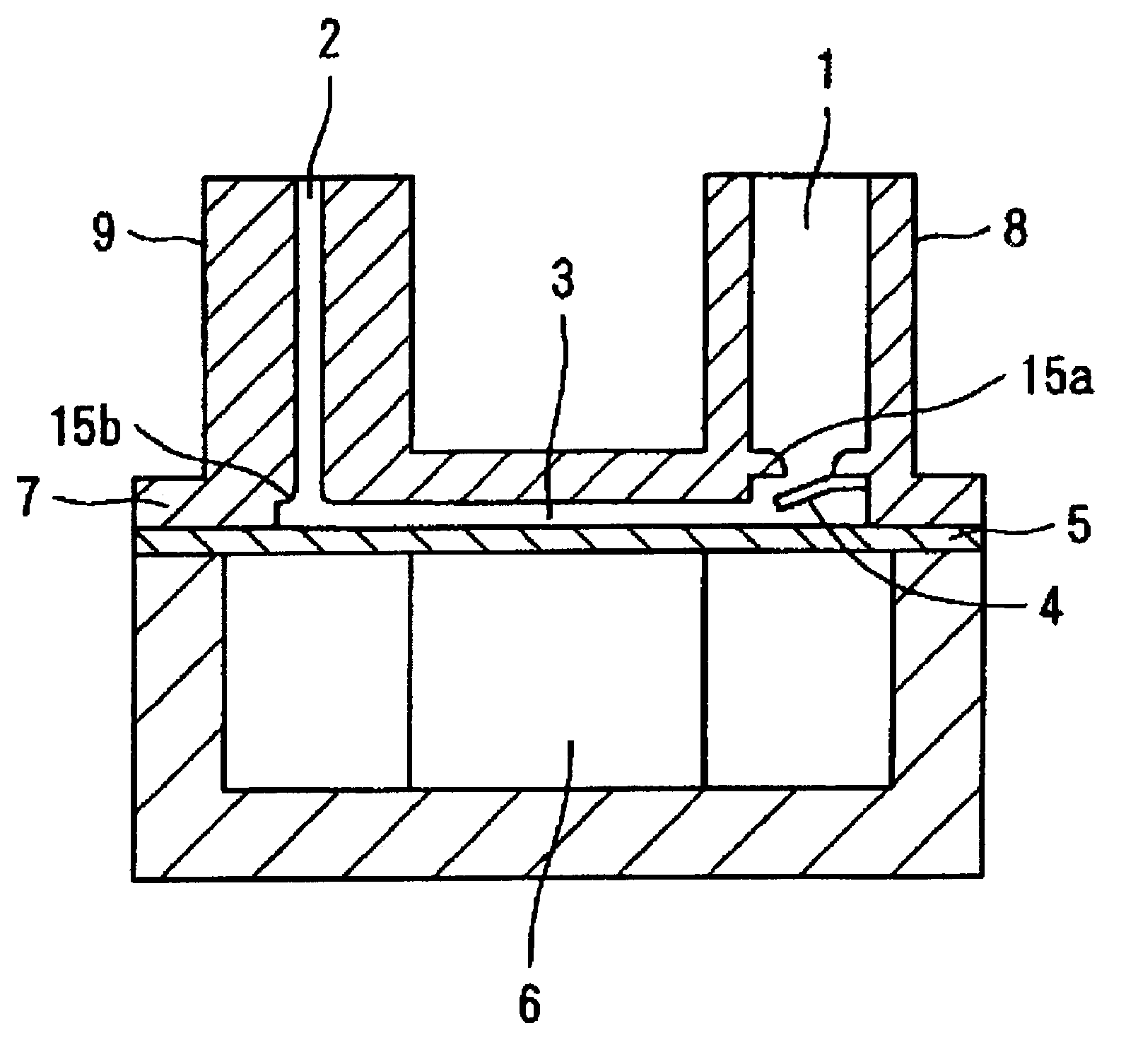

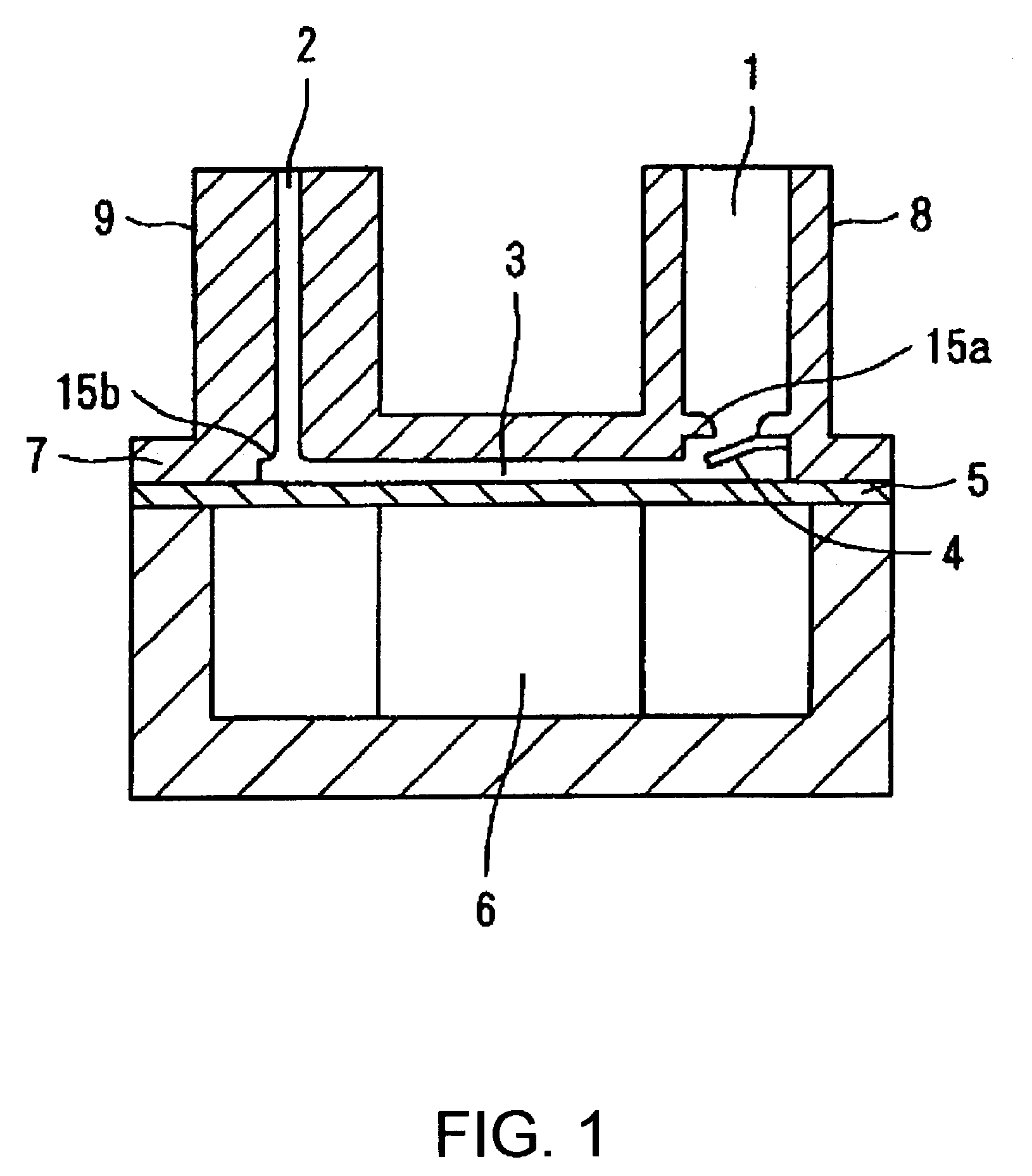

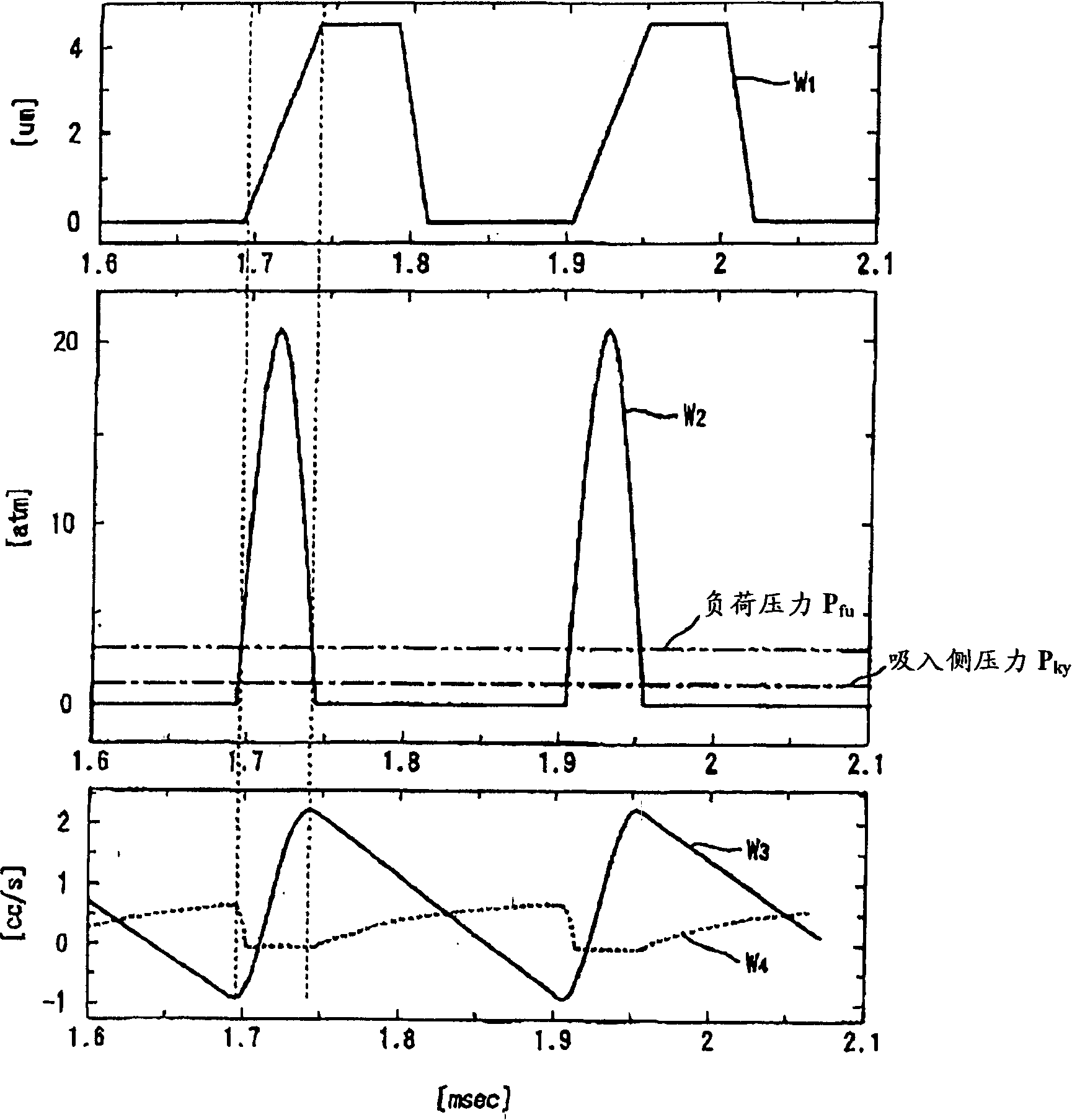

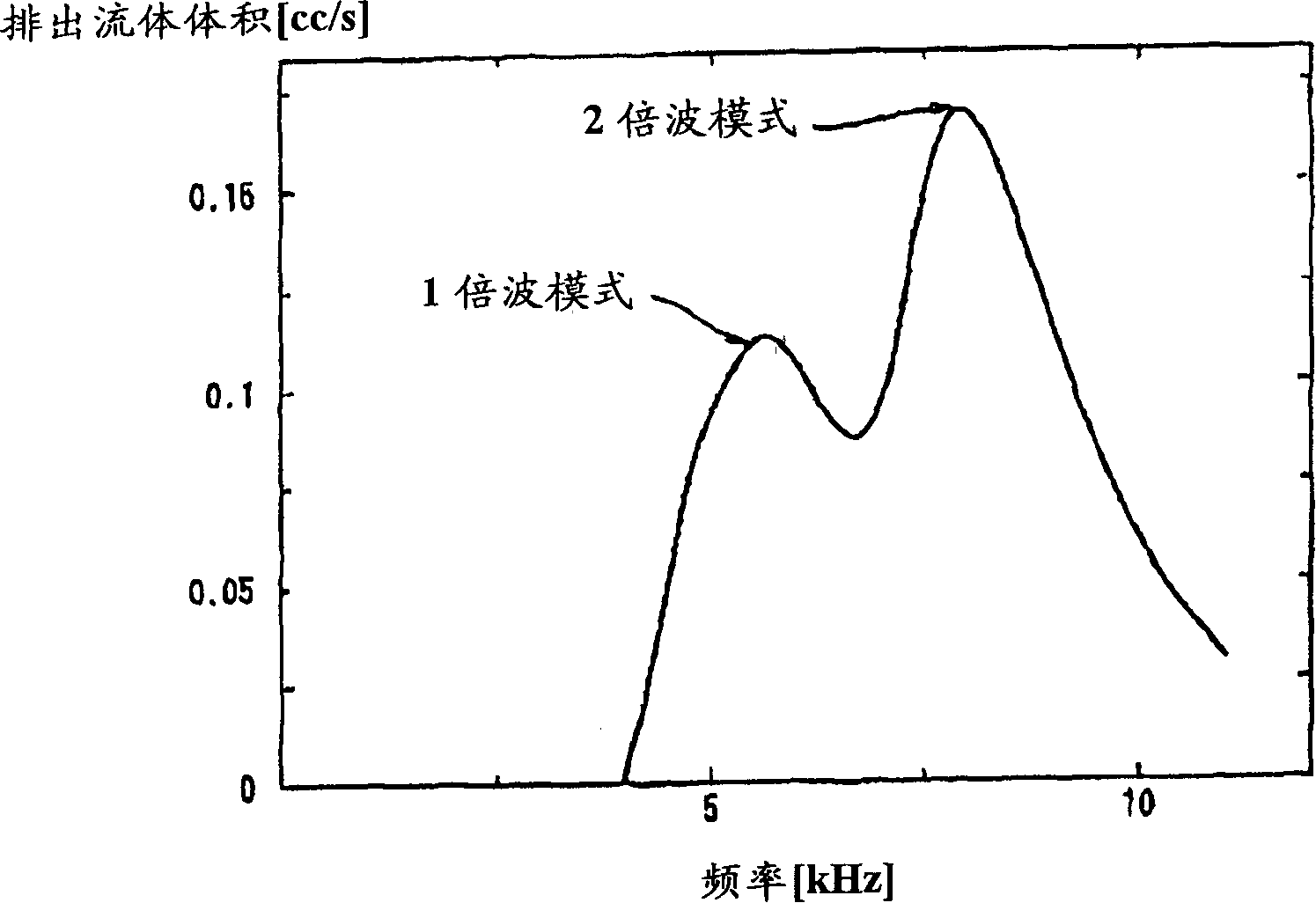

Pump

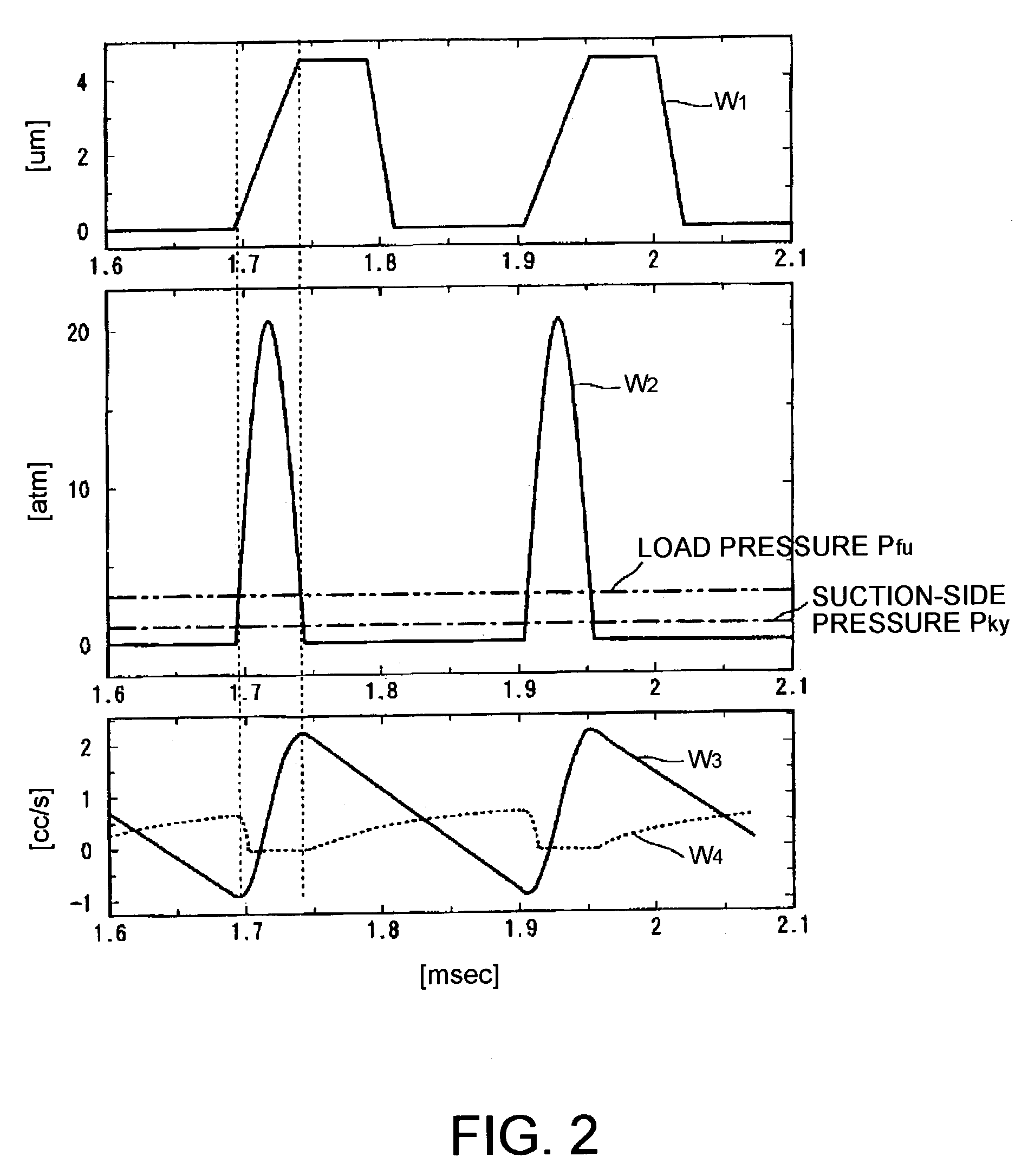

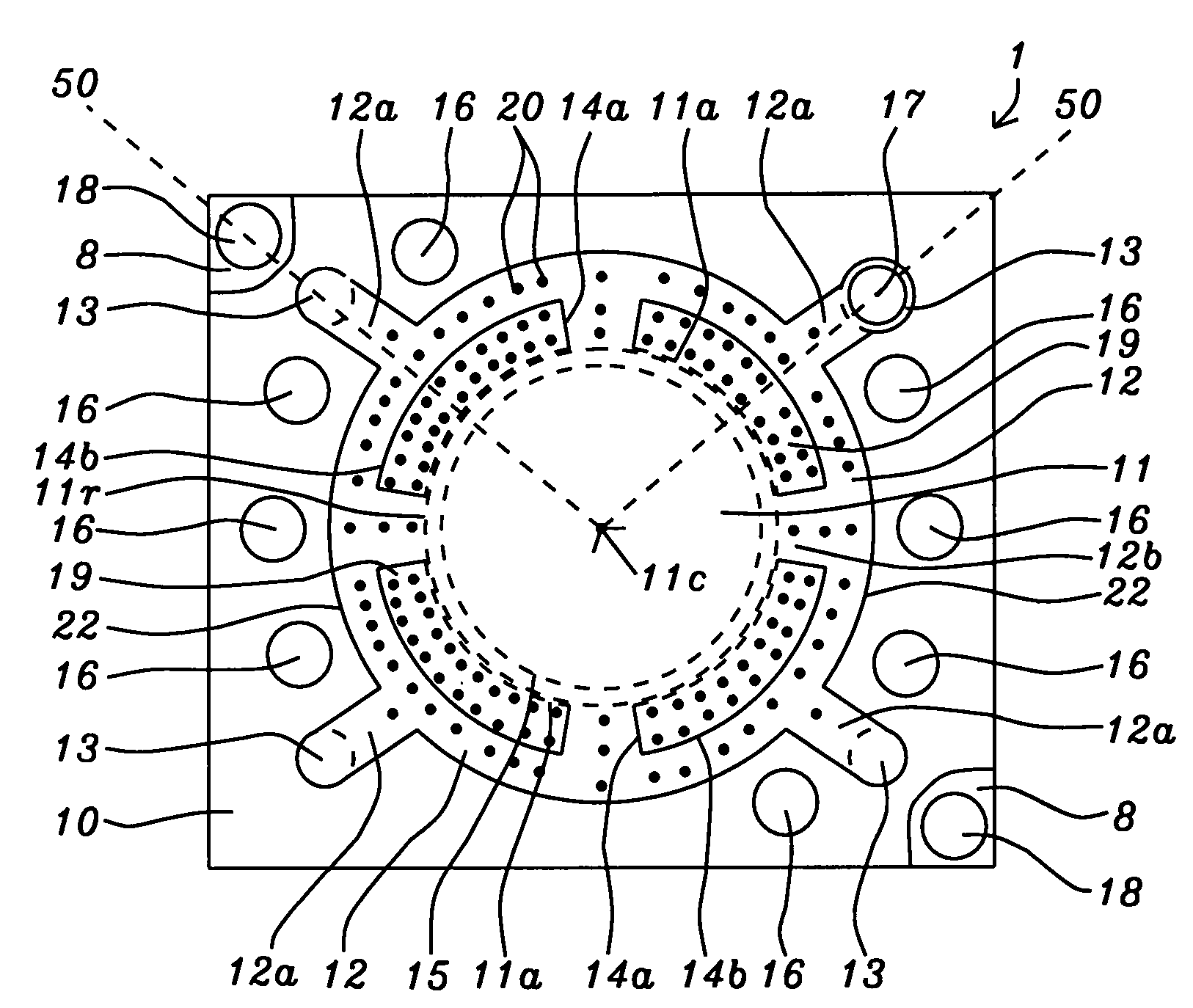

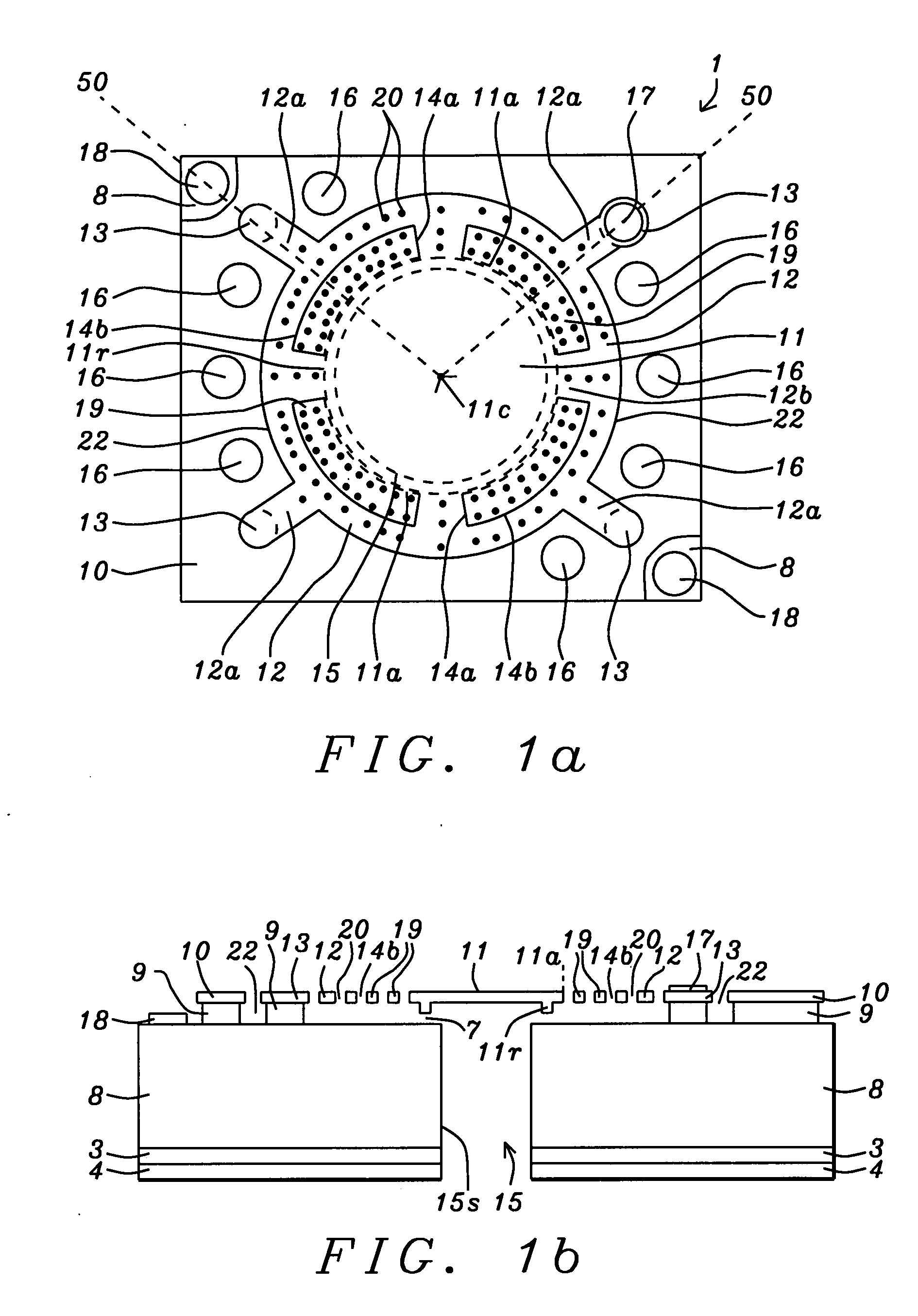

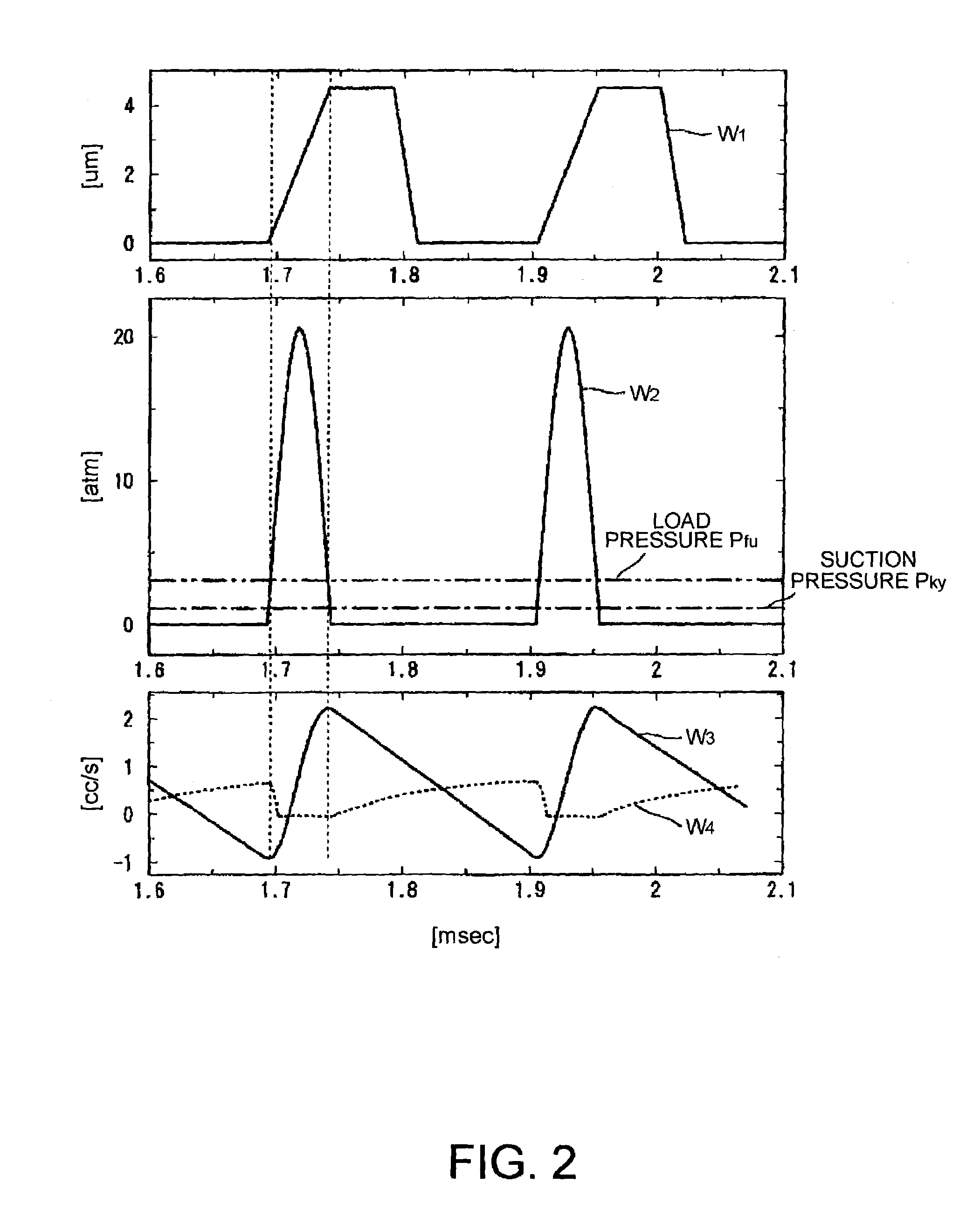

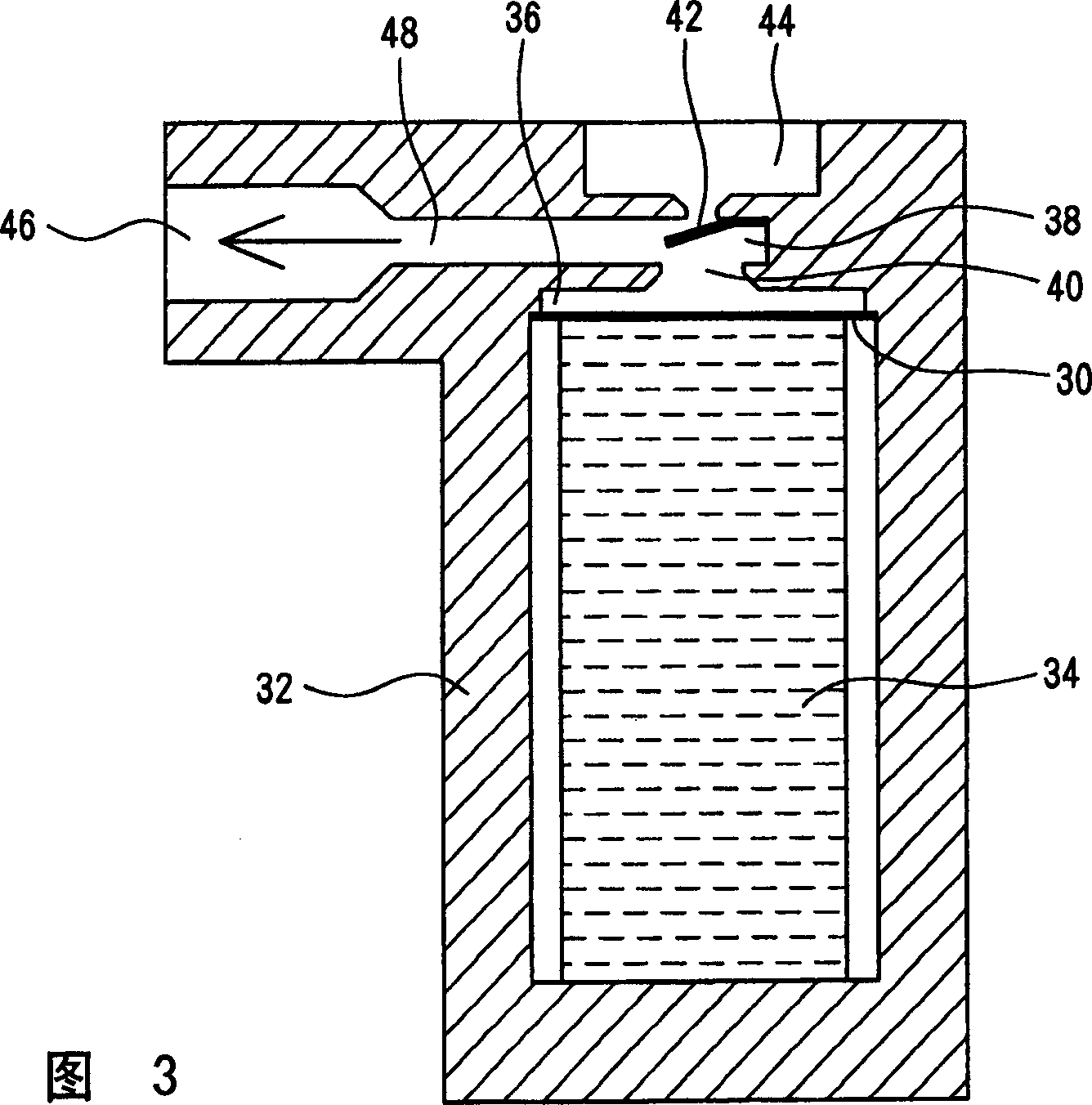

ActiveUS7059836B2Little resistanceA large amountPositive displacement pump componentsPump controlElectricityPump chamber

The invention provides a pump which has reduced pressure loss by using fewer mechanical on-off valves, which has increased reliability, which can be used under a high load pressure, which can be driven at a high frequency, and which has good drive efficiency by increasing discharge fluid volume per pumping period. A circular diaphragm, disposed at the bottom portion of a case, has its outer peripheral edge secured to and supported by the case. A piezoelectric device to move the diaphragm is disposed at the bottom surface of the diaphragm. A space between the diaphragm and the top wall of the case is a pump chamber. An inlet flow path, having a check valve serving as a fluid resistor disposed thereat, and an outlet flow path, which opens to the pump chamber during operation of the pump, open towards the pump chamber. In the pump, driving of the piezoelectric device is controlled so that an average displacement velocity in a pump chamber volume reducing step of the diaphragm becomes a velocity at which the diaphragm reaches the reached-displacement-position in a time equal to or less than ½ and equal to or greater than 1 / 10 of a natural vibration period T of fluid inside the pump chamber and the outlet flow path.

Owner:SEIKO EPSON CORP

Silicon microphone with enhanced impact proof structure using bonding wires

ActiveUS20090092273A1Large movementReduce complexityPiezoelectric/electrostrictive microphonesSemiconductor/solid-state device manufacturingIn planePliability

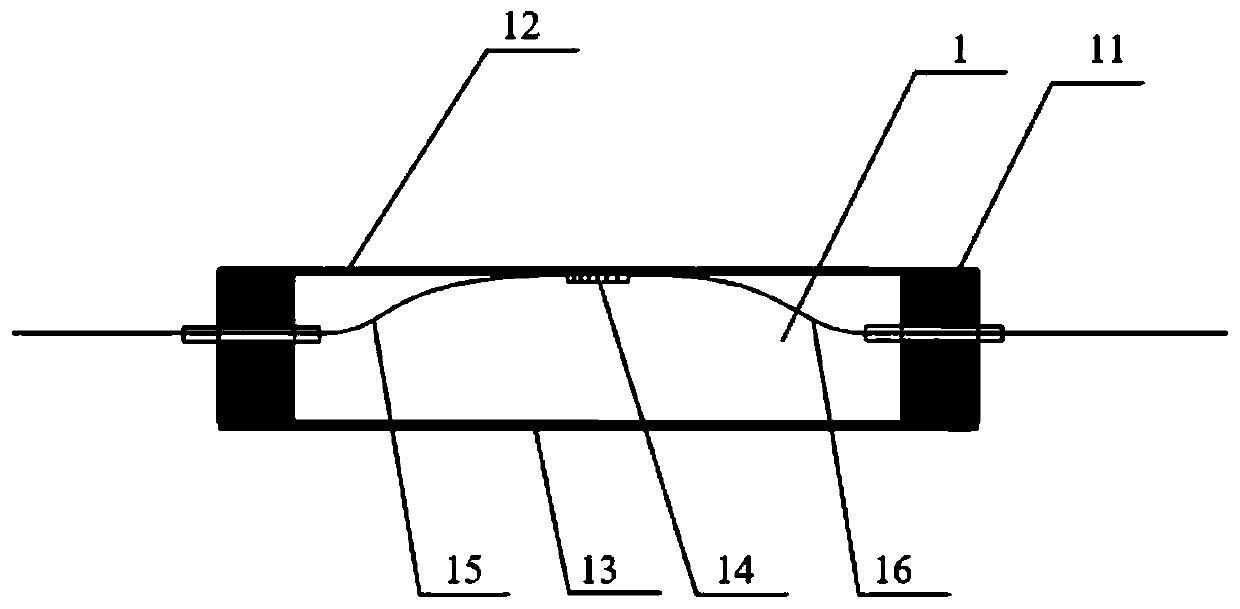

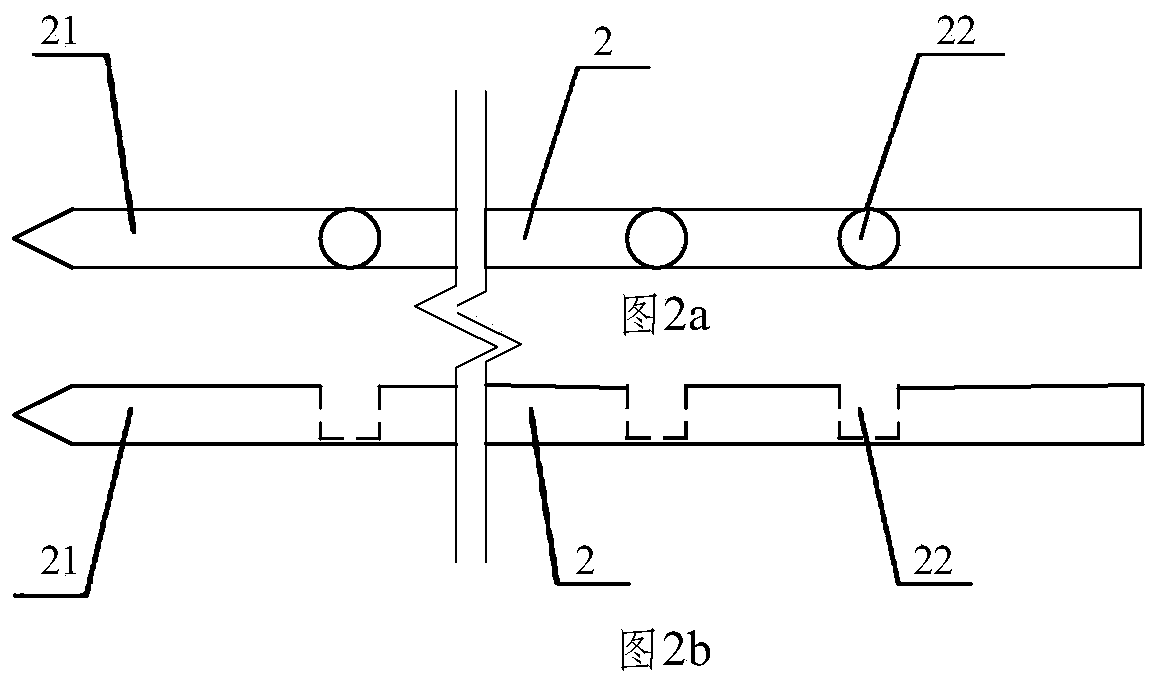

A backplateless silicon microphone and a wire protection method for improved impact resistance are disclosed. A circular diaphragm is surrounded by a circular spring having a plurality of slots and perforations to facilitate air damping reduction, release of in-plane stress, and improve out-plane flexibility. Anchored at a substrate, the circular spring holds the silicon microphone suspended over a backside hole in the substrate but allows the diaphragm to vibrate perpendicular to the substrate. A microphone variable capacitor is formed between the perforated spring and substrate. Slot size is minimized to prevent particles from entering an underlying air gap. A plurality of “n” bonding pads near the outer edge of the circular spring are connected by “n / 2” bonding wires that serve as a stopper to restrict an upward motion of the diaphragm. The bonding wires may cross each other to enable lower loop height for more effective resistance to impact.

Owner:SHANDONG GETTOP ACOUSTIC

Optic fiber bragg grating sensor

InactiveUS20080317401A1High sensitivityFluid pressure measurement by electric/magnetic elementsConverting sensor outputFiberGrating

The optic fiber Bragg grating (FBG) sensor comprises of an elastic circular diaphragm and one or two FBG attached to the bottom surface of the elastic circular diaphragm. Two ends of the FBG are connected to an optic fiber for signal transmission. The FBG sensor readouts are independent of temperature fluctuation. The FBG sensor mechanism according to the present invention may be applied for various purposes such as a gauge pressure transducer, differential pressure transducer, load cell and displacement transducer with distributive capabilities.

Owner:NAT CHIAO TUNG UNIV

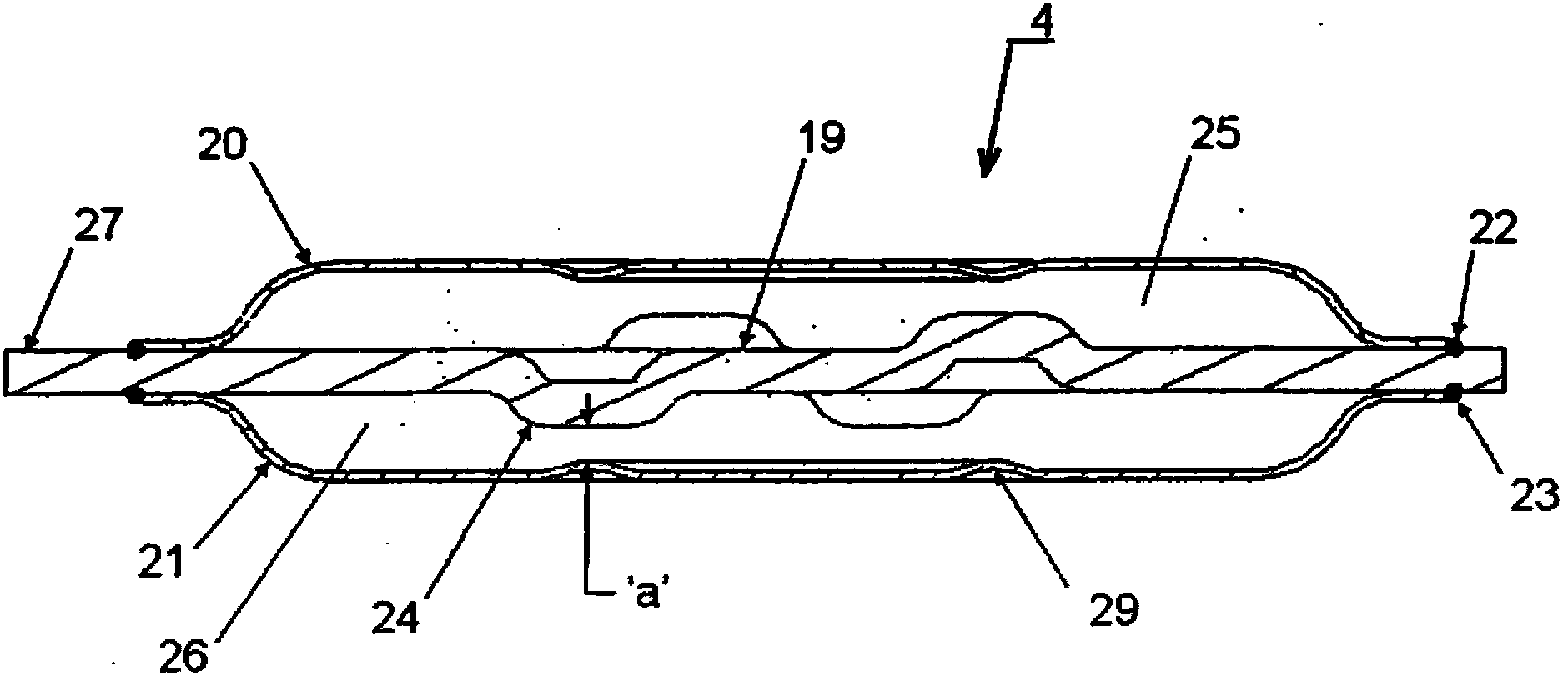

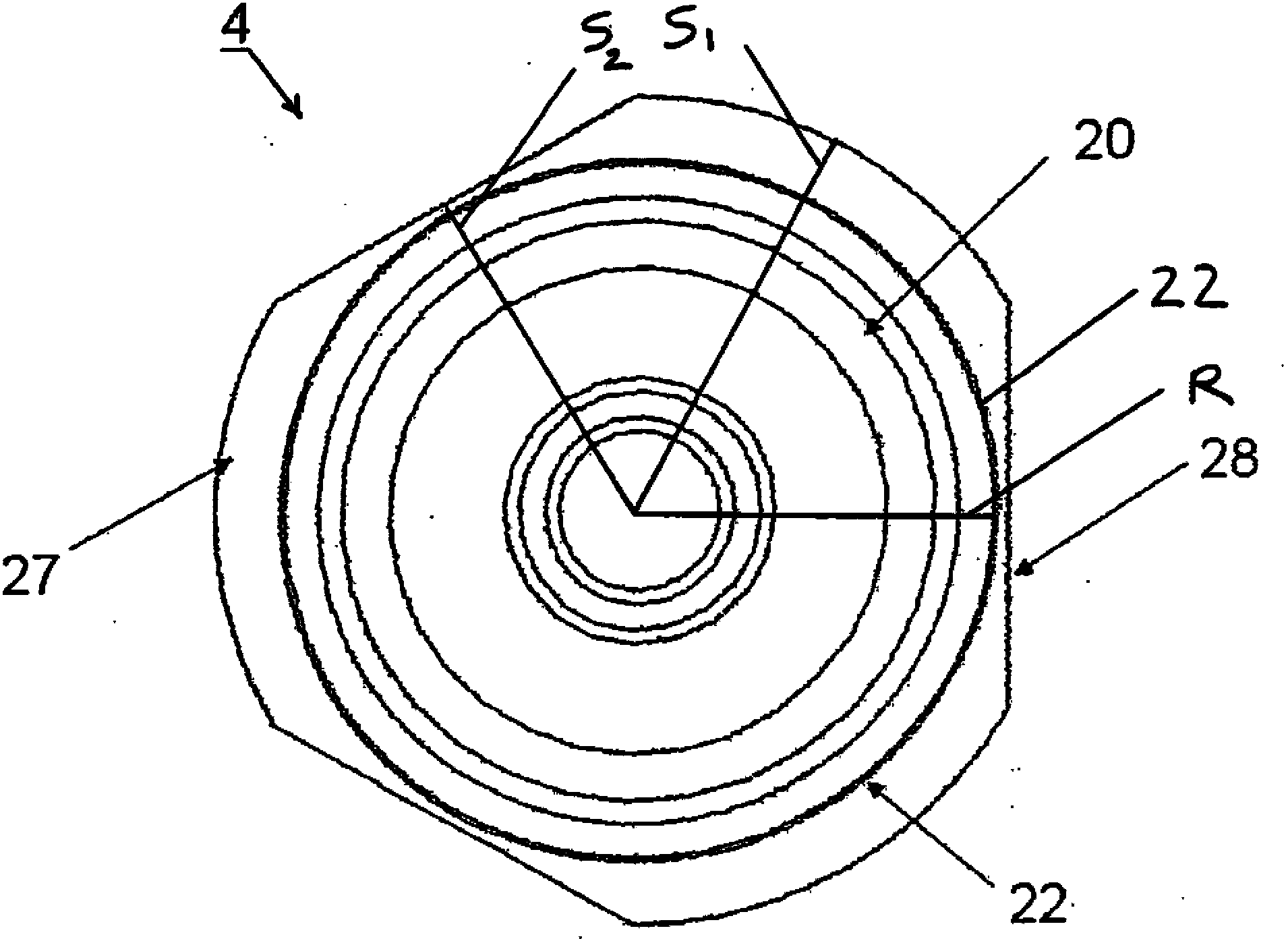

Three element diaphragm damper for fuel pump

A damper assembly for a fuel pump includes at least one diaphragm assembly formed by joining two metal diaphragms to respective two sides of an imperforate central plate, thereby creating a pair of closely spaced diaphragms, each acting upon its own gas volume. Preferably, the diaphragm assembly has (a) a rigid, relatively thick circular or polygonal central plate, (b) a first circular diaphragm having a rim portion sealingly secured as by welding to the plate and a relatively thin, flexible, convex portion projecting from one side of the plate and defining a first pressurized gas volume, and (c) a second circular diaphragm having a rim portion sealingly secured as by welding to the plate and a relatively thin, flexible, convex portion projecting from the other side of the plate and defining an independent second pressurized gas volume.

Owner:斯塔纳迪恩公司

Combined membrane, stethoscope head matched with same as well as matching component of both

ActiveCN101647712AImprove recovery effectPrecise positioningStethoscopeSound producing devicesSTETHOSCOPE HEADEngineering

The invention relates to a medical instrument accessory, in particular to a stethophone accessory. The invention discloses a combined membrane which comprises a round membrane and a fixer. The fixer comprises three parts including a big ring, a small ring and a connecting part, wherein the big ring is arranged below the connecting part, the small ring is arranged above the connecting part and radially provided with a ring slot, and the outer edge of the round membrane is positioned in the ring slot. The invention also provides a stethoscope head which comprises a stethoscope head body and a cylinder, wherein the cylinder and the stethoscope head body are integrated into a whole, the end surface of the cylinder is provided with an axial ring slot and a sound collecting surface; and a soundguide hole and a fixing hole are arranged on the sound collecting surface. The membrane has the advantages of good restoration and accurate positioning; the stethoscope head is easy to install and hasstrong tightness; and users can acutely acquire a matching structure of multitone only by changing force applied on the stethoscope head body.

Owner:单希杰

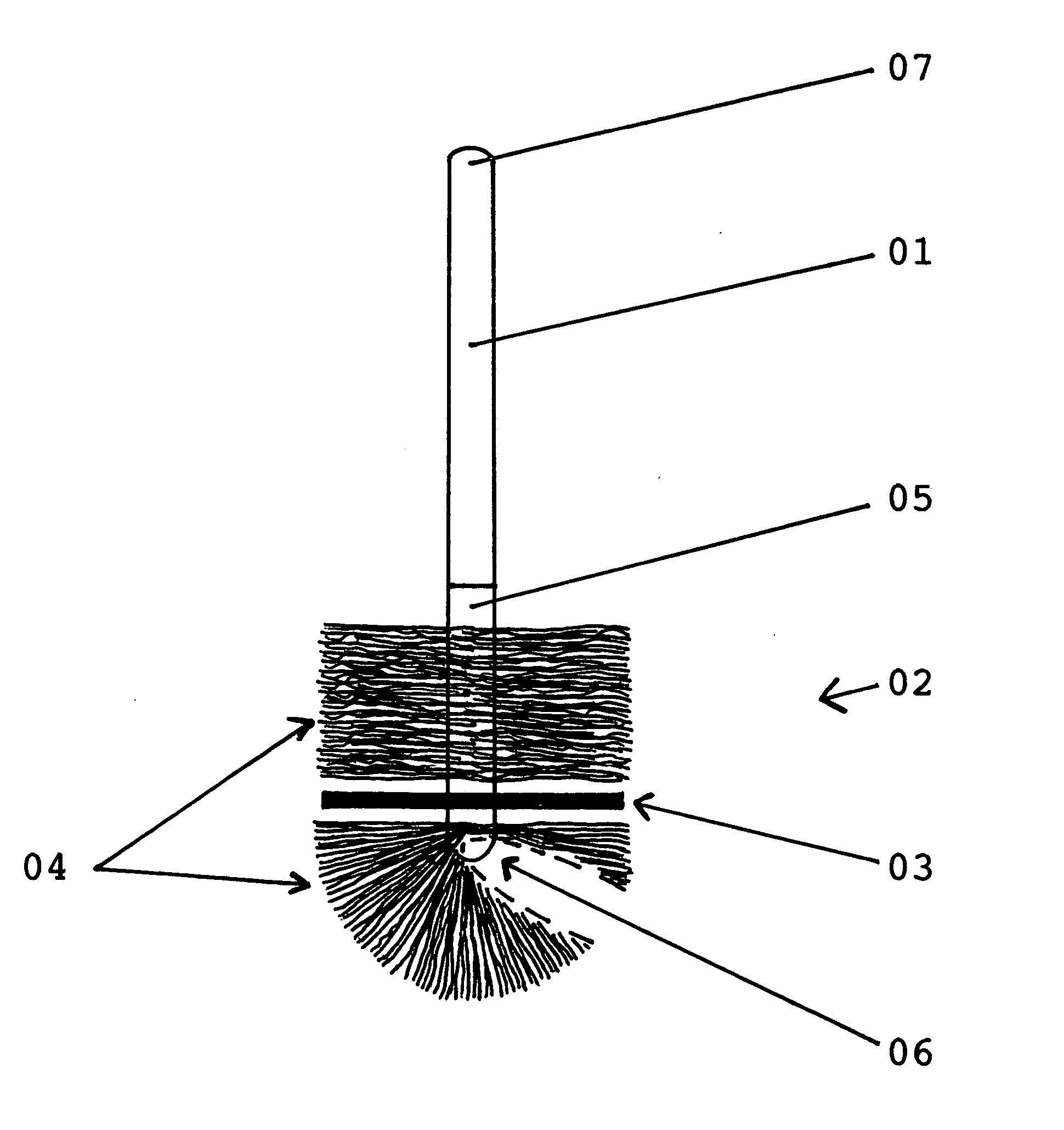

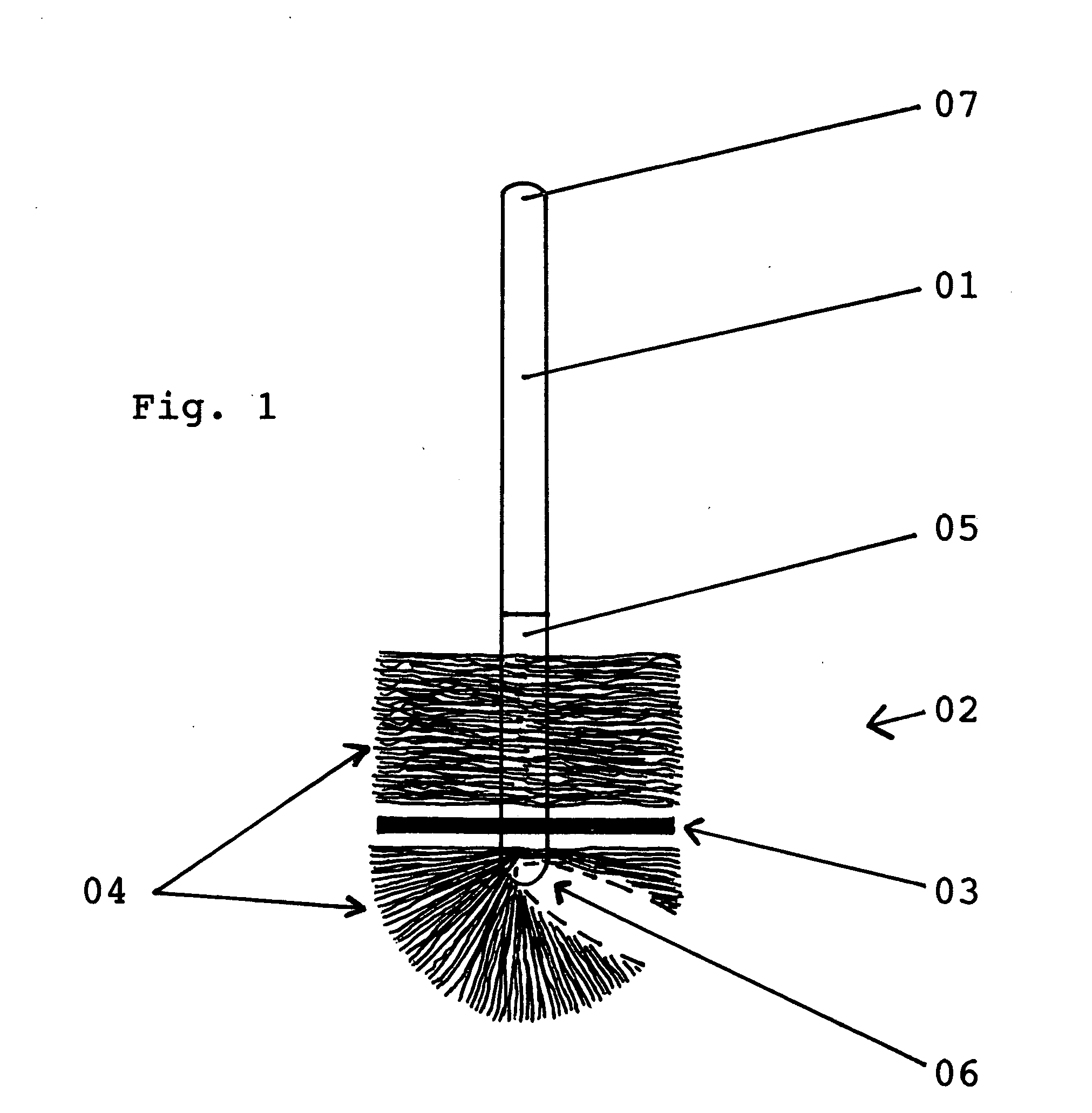

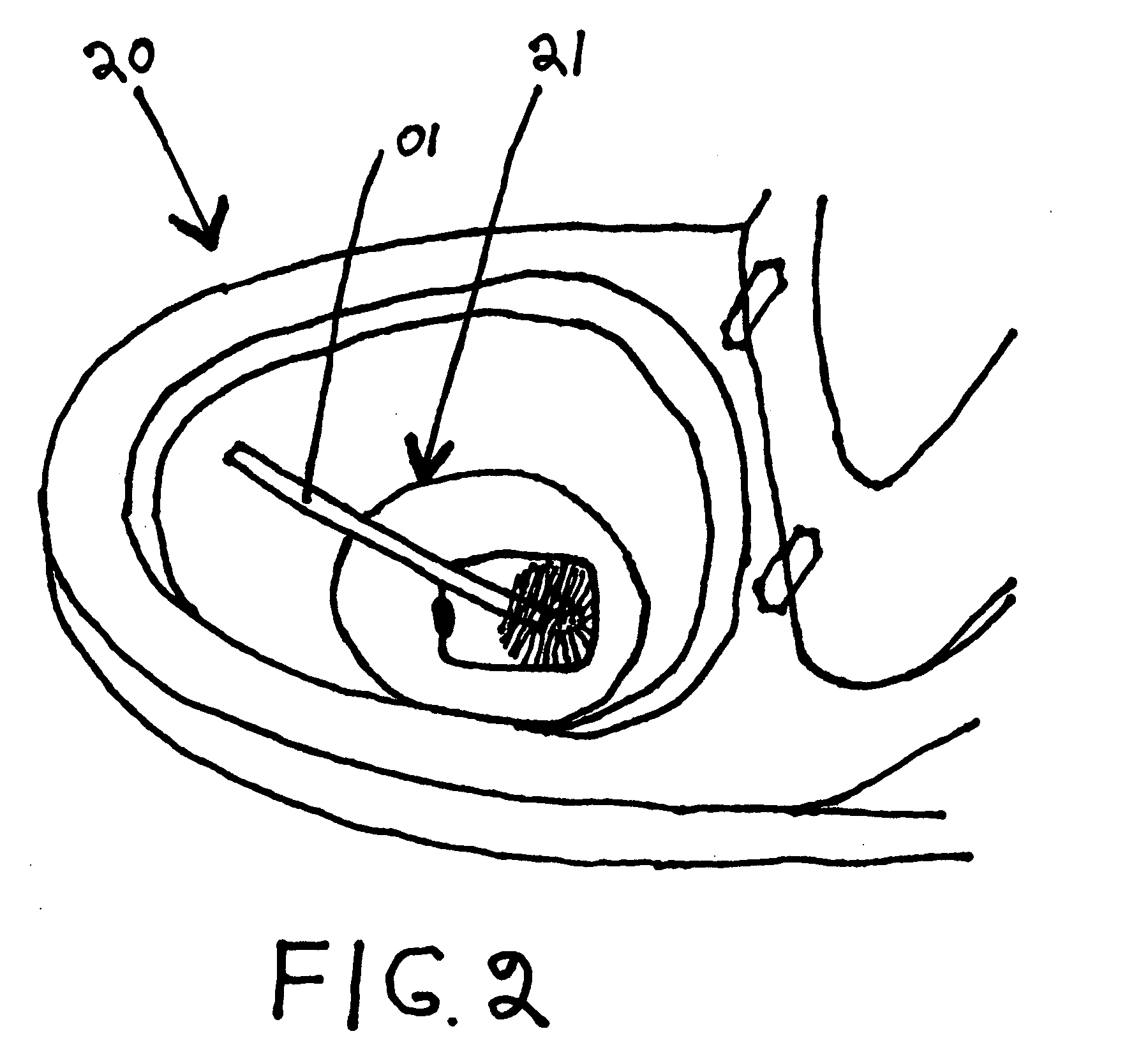

Toilet cleaning brush with integral toilet plunger

InactiveUS20050125922A1Function increaseBrush bodiesHollow article cleaningWater savingSurface cleaning

The current invention performs two functions: (1) it operates as a standard cylindrical toilet cleaning brush for toilet-surface-cleaning, and (2) it operates as a toilet plunger for toilet-trap-unclogging. In one embodiment, it is a conventional cylindrical toilet cleaning brush combined with a circular diaphragm. As toilets become more water-efficient, they become more prone to clogging. This invention greatly reduces the aggravation associated with water-saving toilets by providing a toilet-trap-unclogging function discreetly at hand.

Owner:SZARAWARSKI STEVEN JAMES

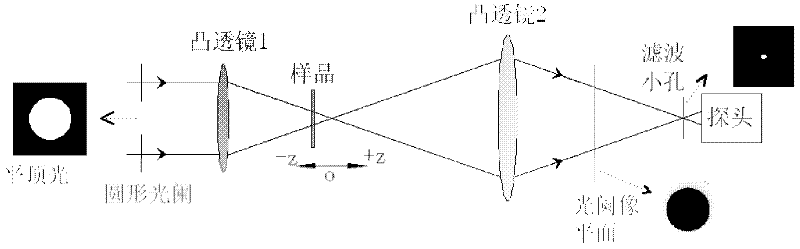

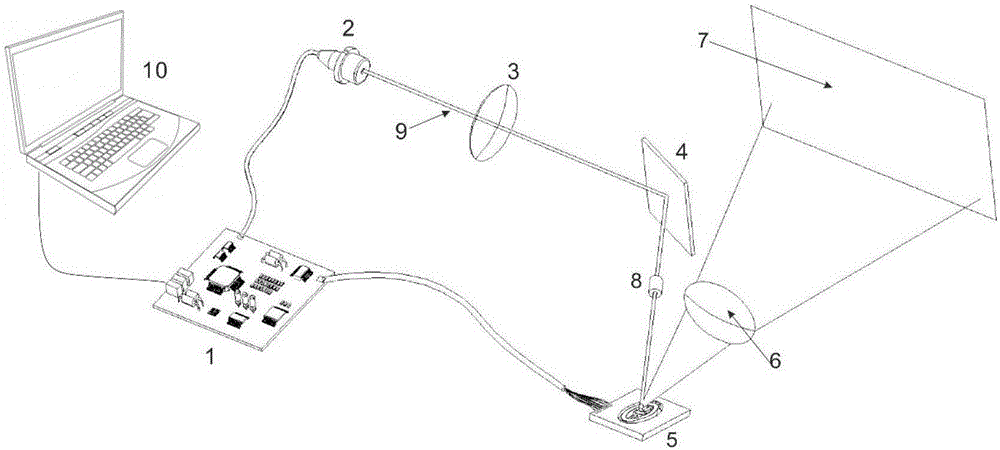

High-sensitivity frequency domain filtering baffle plate Z-scan method for measuring material nonlinearity

InactiveCN102692382AImprove noise immunityReduce linear backgroundMaterial analysis by optical meansInformation processingPhotonics

The invention discloses a high-sensitivity frequency domain filtering baffle plate Z-scan method for measuring the material nonlinearity, and belongs to the fields of nonlinear photonic material and nonlinear optical information processing. The method of the invention comprises: the focus of a lens forms an image through another lens, and a filtering pinhole is arranged at the point of the image; and a circular diaphragm forms an image through a lens set formed by the above two lenses, and a coaxial circular baffle plate is arranged in the image plane. During the action of pulse laser, a sample moves from side to side near the focus of the lens. Through measuring the non-linear transmittance of an opening, the baffle plate, and the filtering pinhole, the non-linear absorption coefficient and the non-linear refraction coefficient of the material can be determined. The method of the invention is characterized by simple work measurement system optical path, obvious stray light influence filtering effect, high measuring sensitivity, and simple data processing, and can measure non-linear absorption and non-linear refraction at the same time.

Owner:SUZHOU MICRONANO LASER PHOTON TECH CO LTD

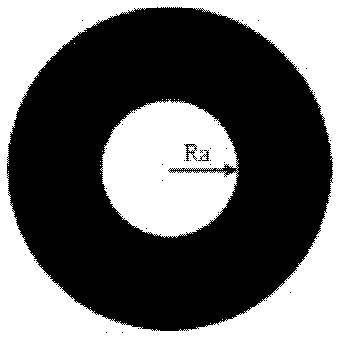

Cosine-gauss correlative light beam generation system and method and measuring equipment of cosine-gauss correlative light beam

InactiveCN103592768ACompact structureImprove maneuverabilityPhotometryOptical elementsBeam expanderInformation transmission

The invention discloses a cosine-gauss correlative light beam generation system and method and measuring equipment of a cosine-gauss correlative light beam, wherein the cosine-gauss correlative light beam is a cosine-gauss correlative partly-relevant gauss beam. The cosine-gauss correlative light beam generation system sequentially comprises a laser, a polarizing film, a beam expander, a liquid crystal spatial light modulator, a circular diaphragm, a focusing convex lens, a rotary ground glass piece, a collimation convex lens and a gauss filter, wherein multiple particles are arranged on the surface of the rotary ground glass piece, and the sizes of the particles conform with Gaussian statistical distribution. The cosine-gauss correlative light beam generation system is compact in structure, good in operability and broad in application range, and the generated cosine-gauss correlative partly-relevant gauss beam has broad application prospect in the fields of information transmission, industrial processing and the like.

Owner:SUZHOU UNIV

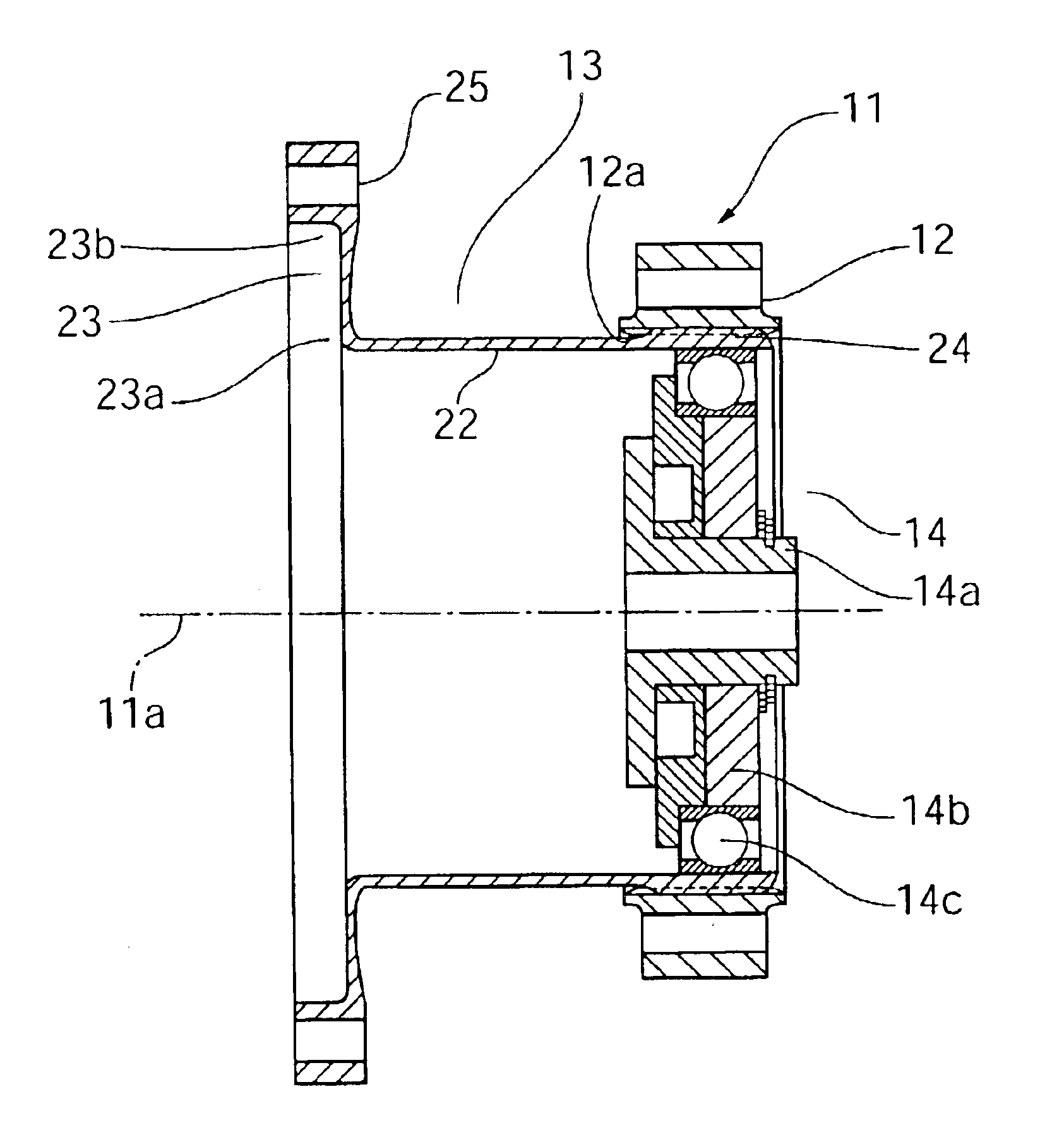

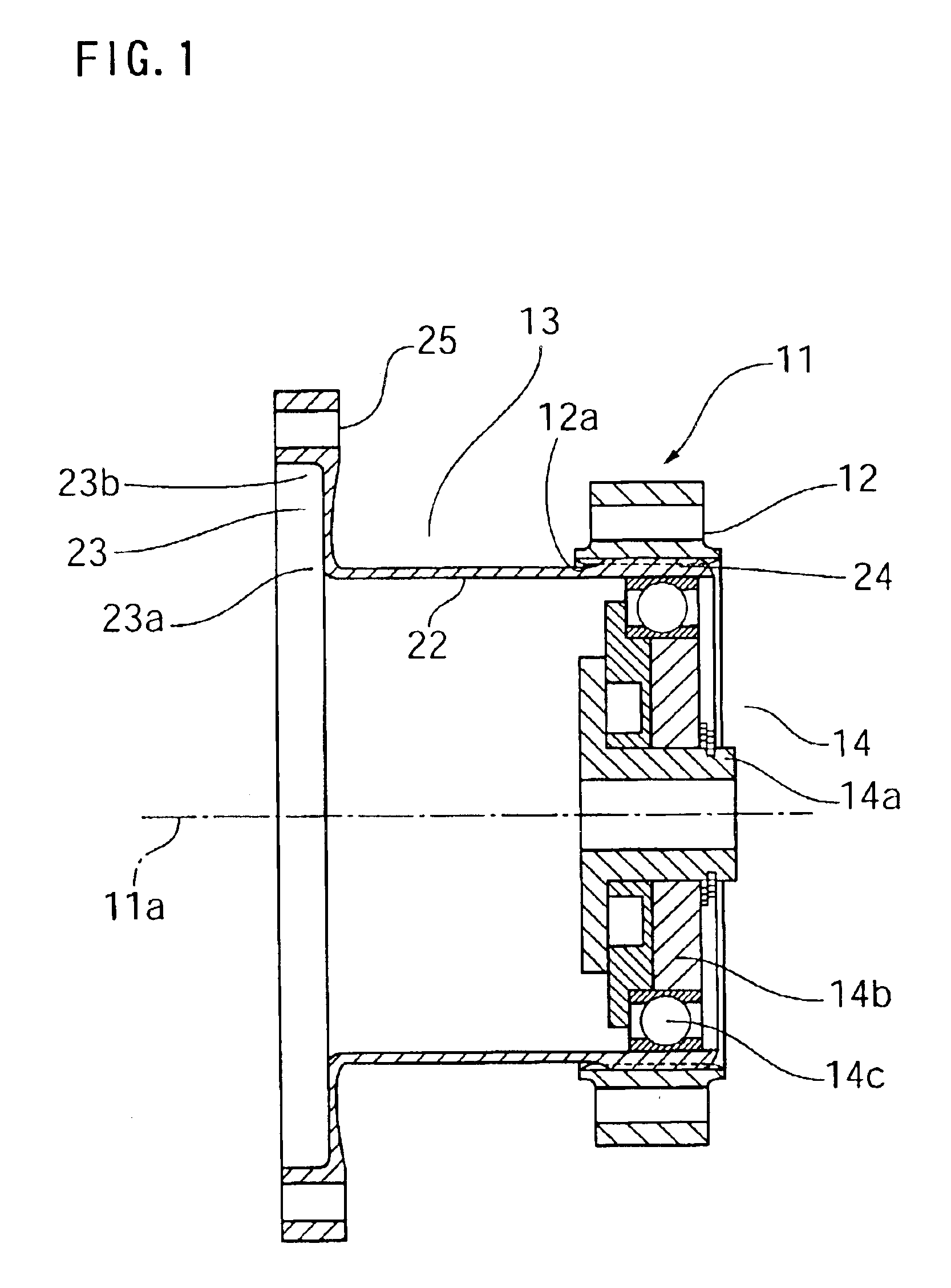

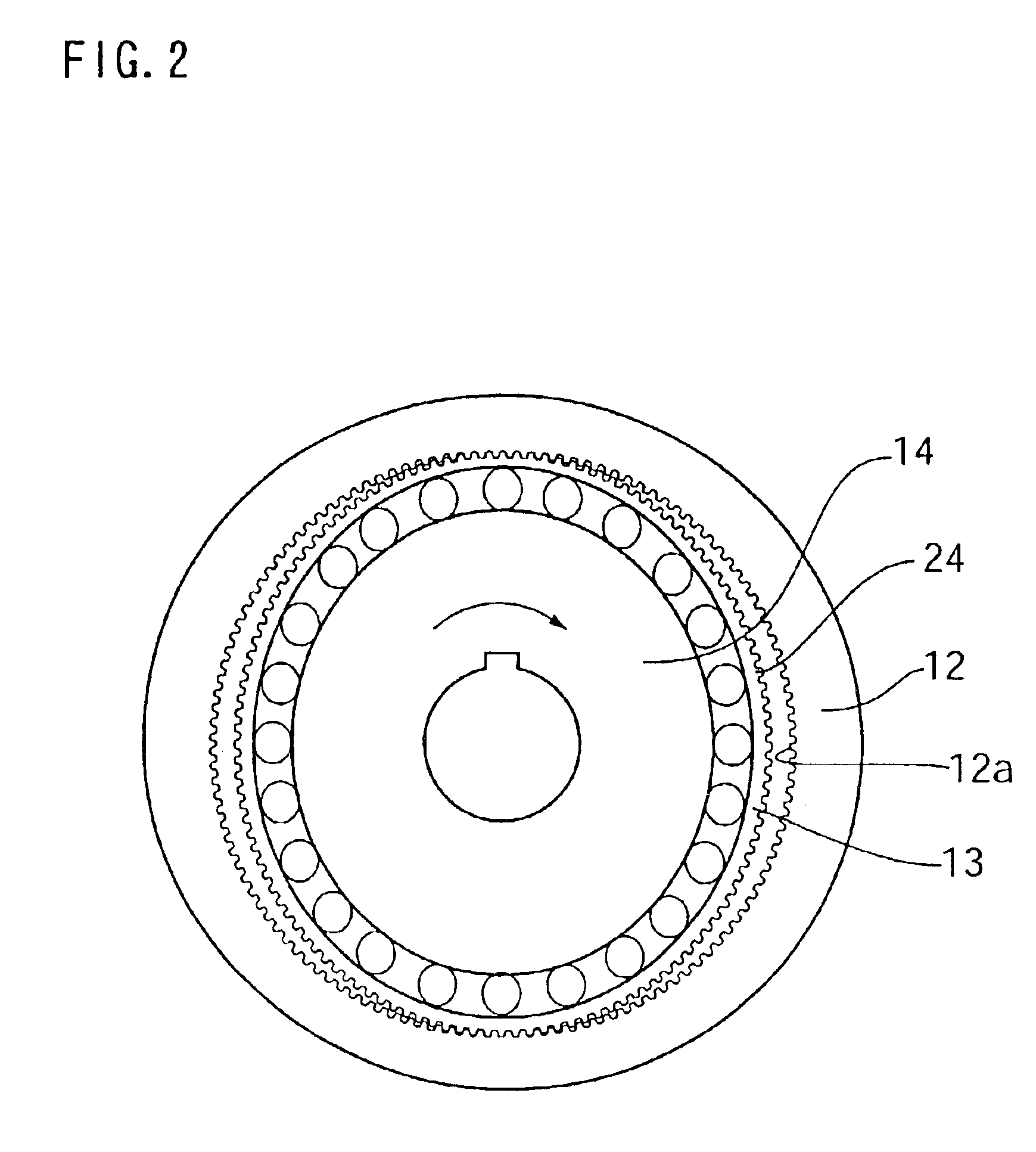

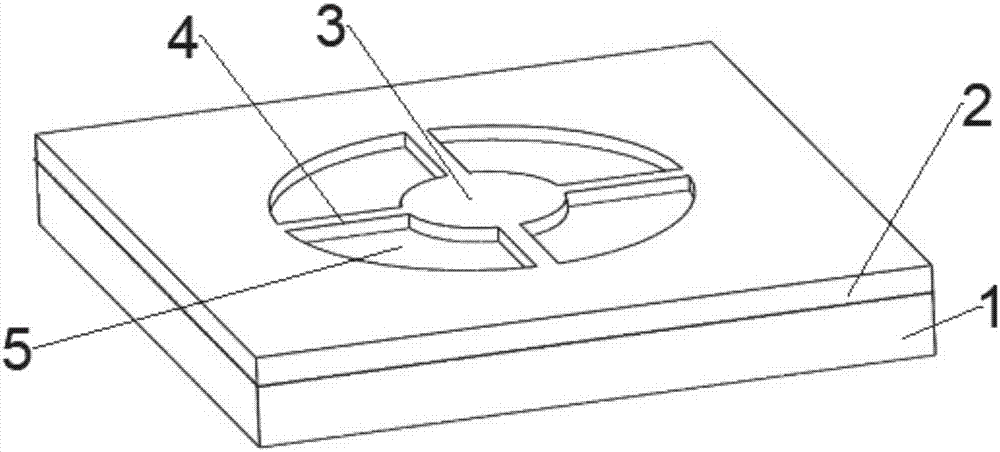

Pump

ActiveUS7056096B2Prevent excessive displacementImprove efficiencyPositive displacement pump componentsFlexible member pumpsCycle controlBiological activation

The invention provides a pump with high driving efficiency in which the number of mechanical switching valves is decreased to reduce pressure loss and increase reliability, and which is ready for high load pressure and high-frequency driving, and which increases the discharged fluid volume for one cycle of pumping. A circular diaphragm arranged on the bottom of a casing has the outer edge fixed to the casing. The diaphragm includes a piezoelectric element to move the diaphragm on the bottom surface thereof. The space between the diaphragm and the top wall of the casing serves as a pump chamber, wherein a suction channel and a discharge channel are opened to the pump chamber, the suction channel having a check valve serving as a fluid resistive element and the discharge channel being always communicated with the pump chamber, even during the operation of the pump. In the pump, the activation of the piezoelectric element is controlled by a cycle control device so as to provide the cycle of the diaphragm in which the volume and the pressure of the discharged fluid of the pump are increased.

Owner:SEIKO EPSON CORP

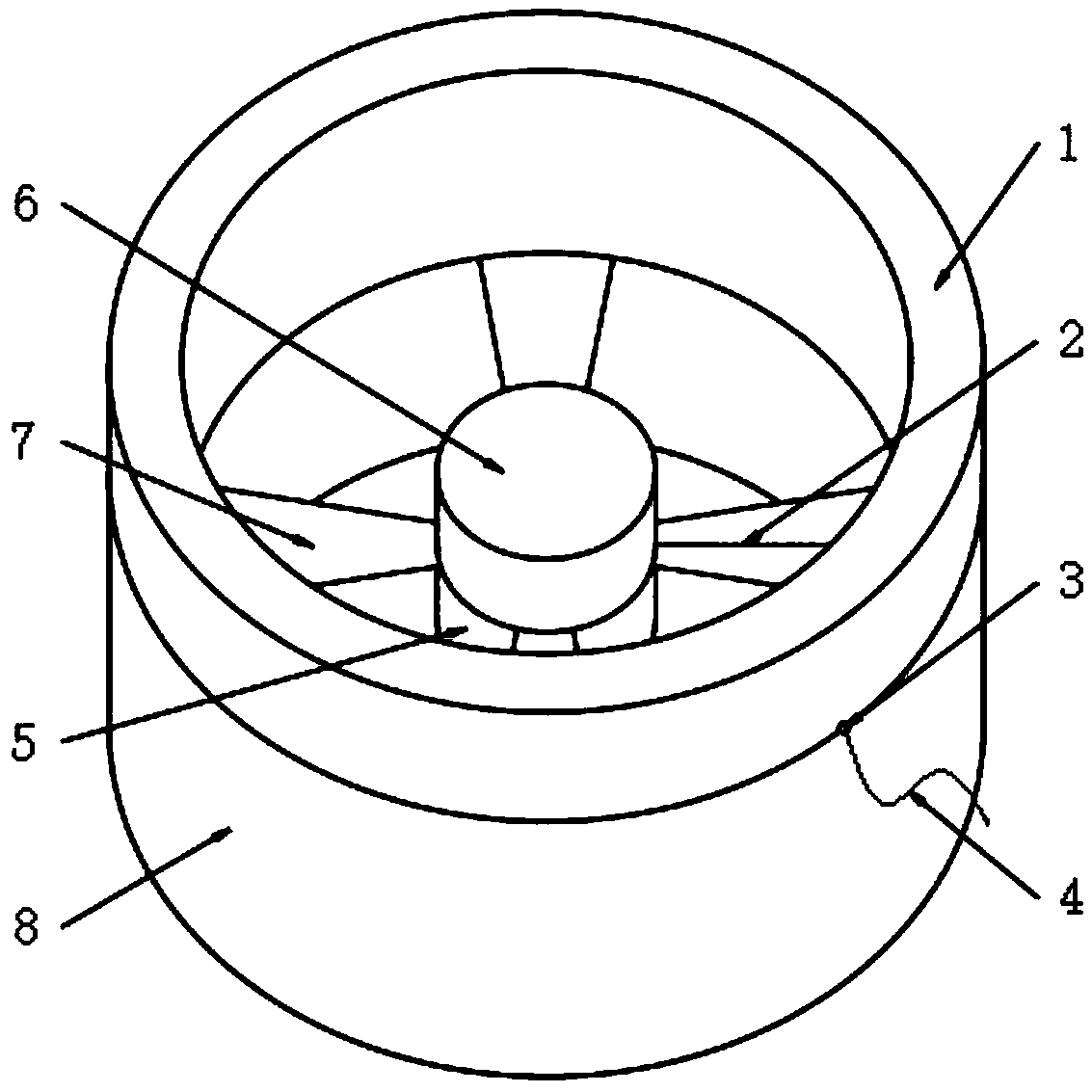

Silk hat shaped wave gear device

A flexible external gear of a silk hat shaped wave gear device has an annular body, external teeth formed on an outer circumferential portion of a first opening of the body, a circular diaphragm connected to a second opening portion of the body, and a circular boss connected to an outer circumferential end of the diaphragm. The shape of a connected portion of the diaphragm and the body is defined by a curved portion whose diameter decreases gradually from the diaphragm toward the body when viewed along a device axis. Since the body is wider on the diaphragm side, the wave generator 7 can be easily fitted into the flexible external gear from the diaphragm side.

Owner:HARMONIC DRIVE SYST IND CO LTD

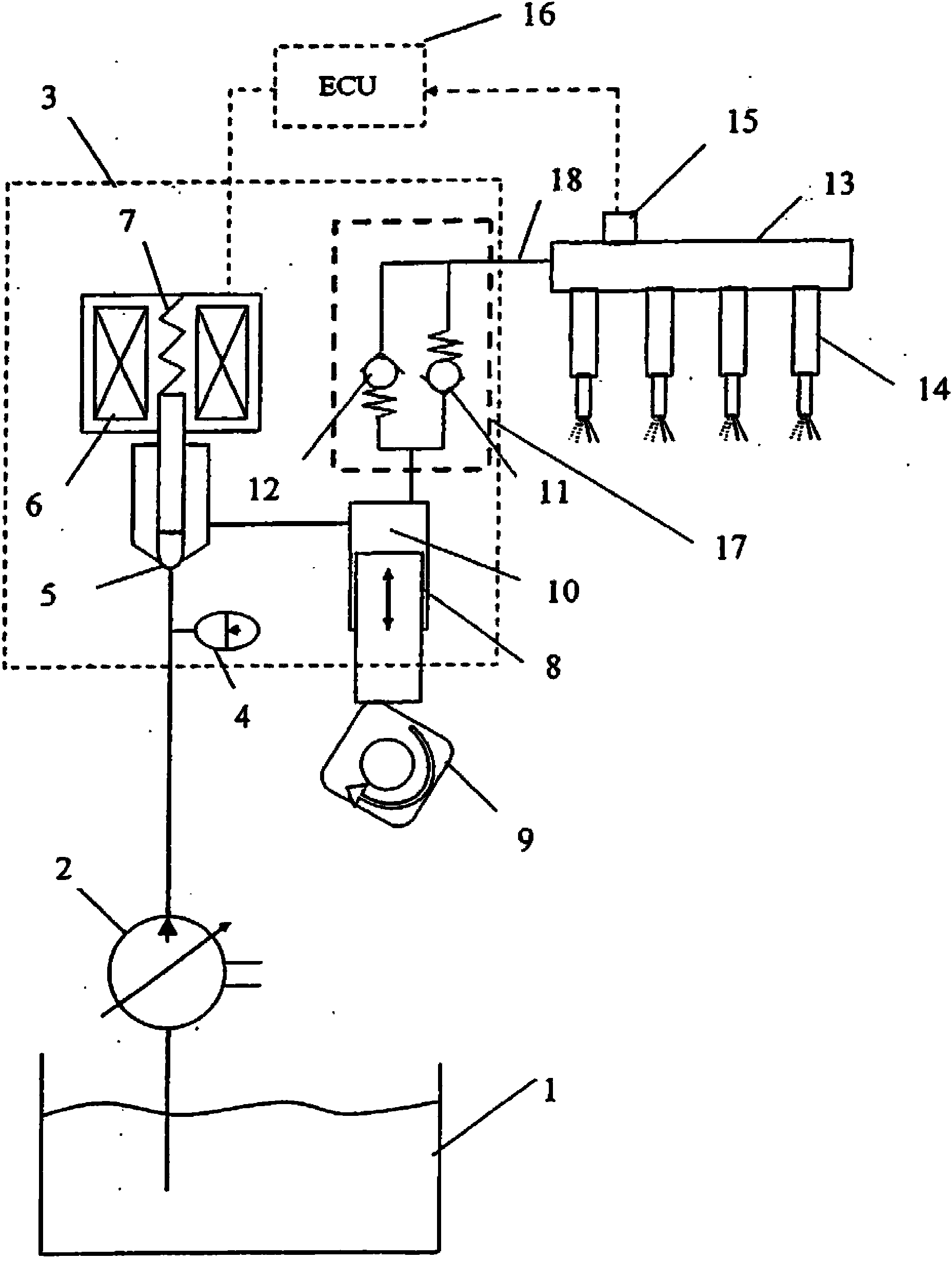

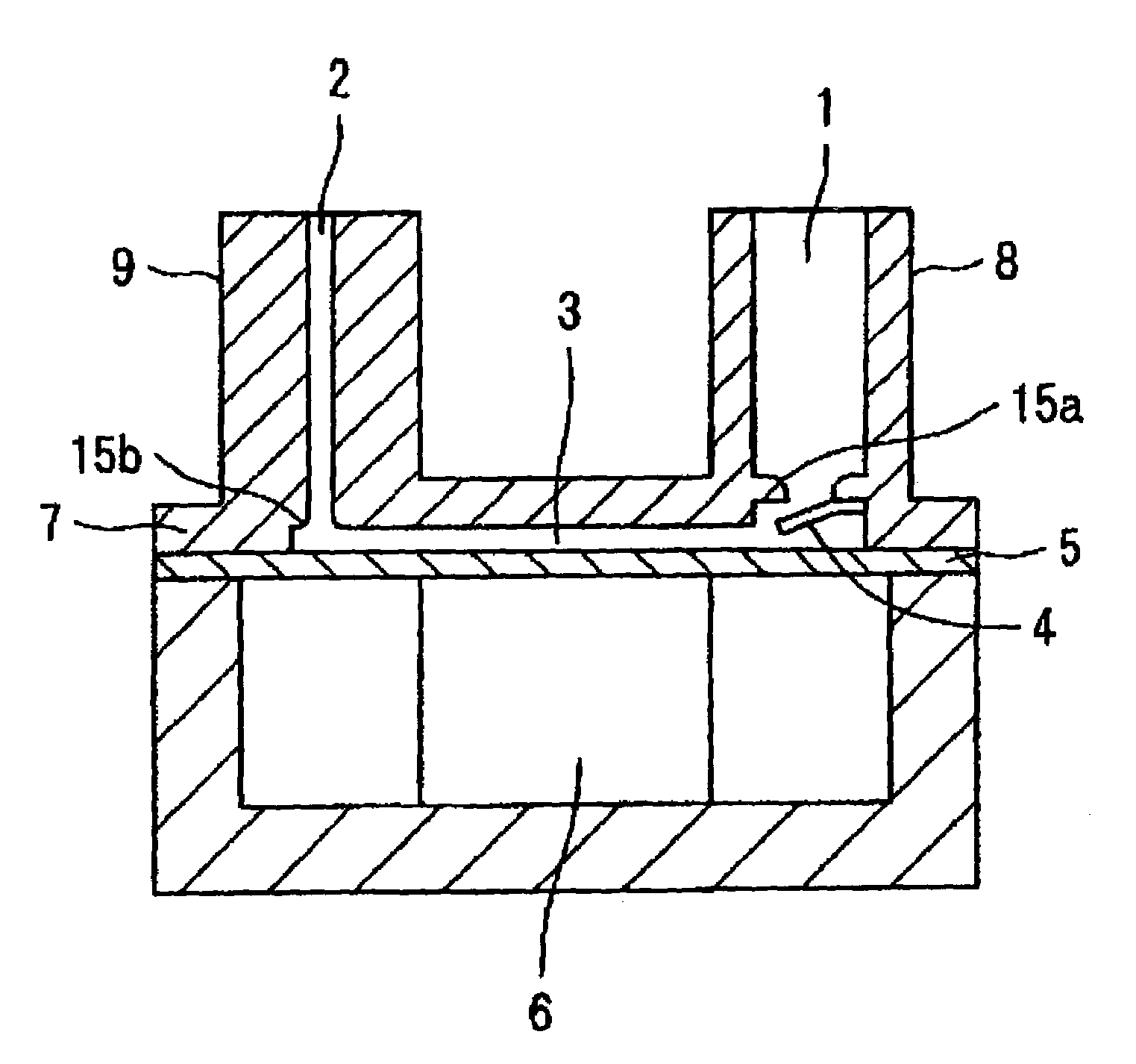

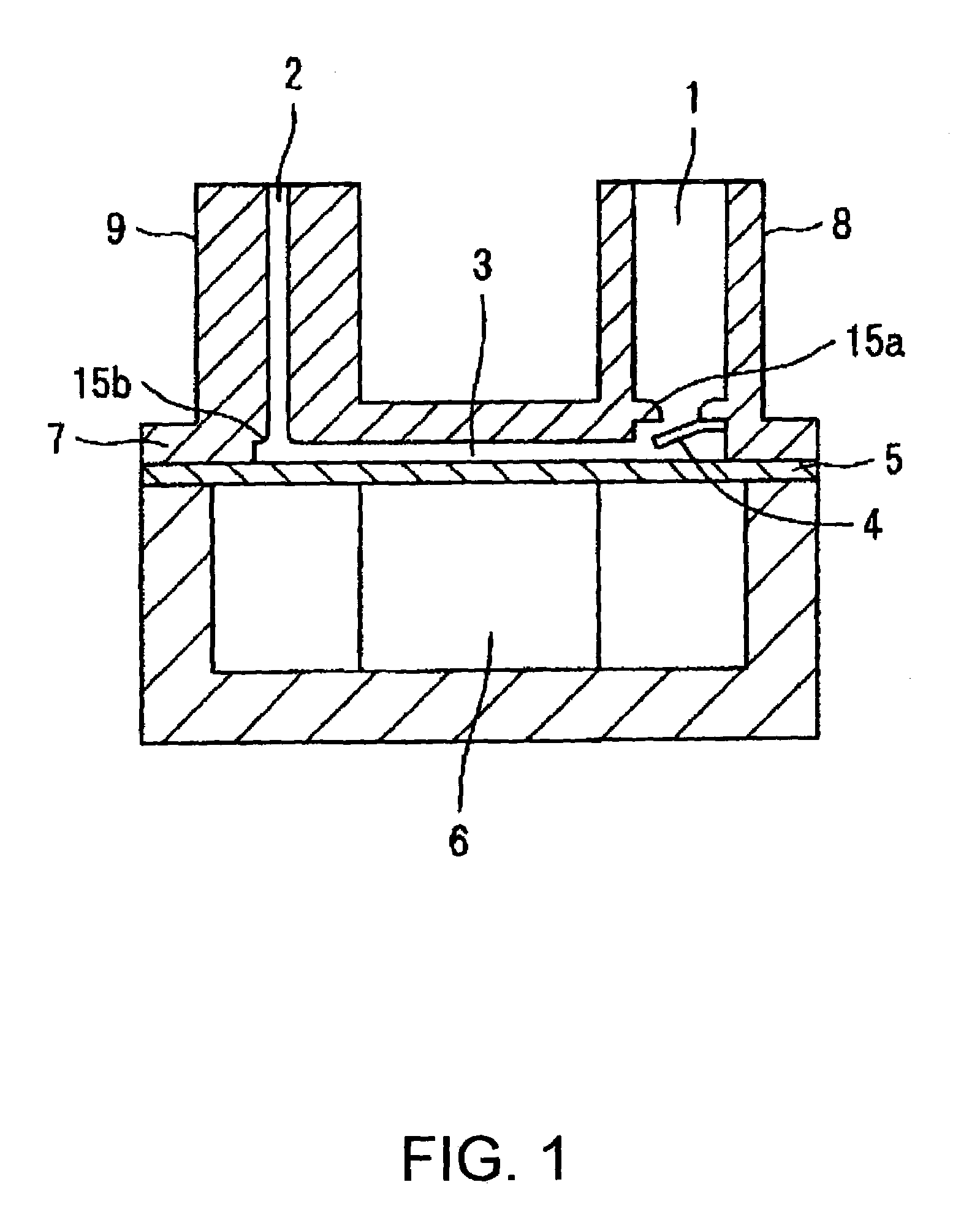

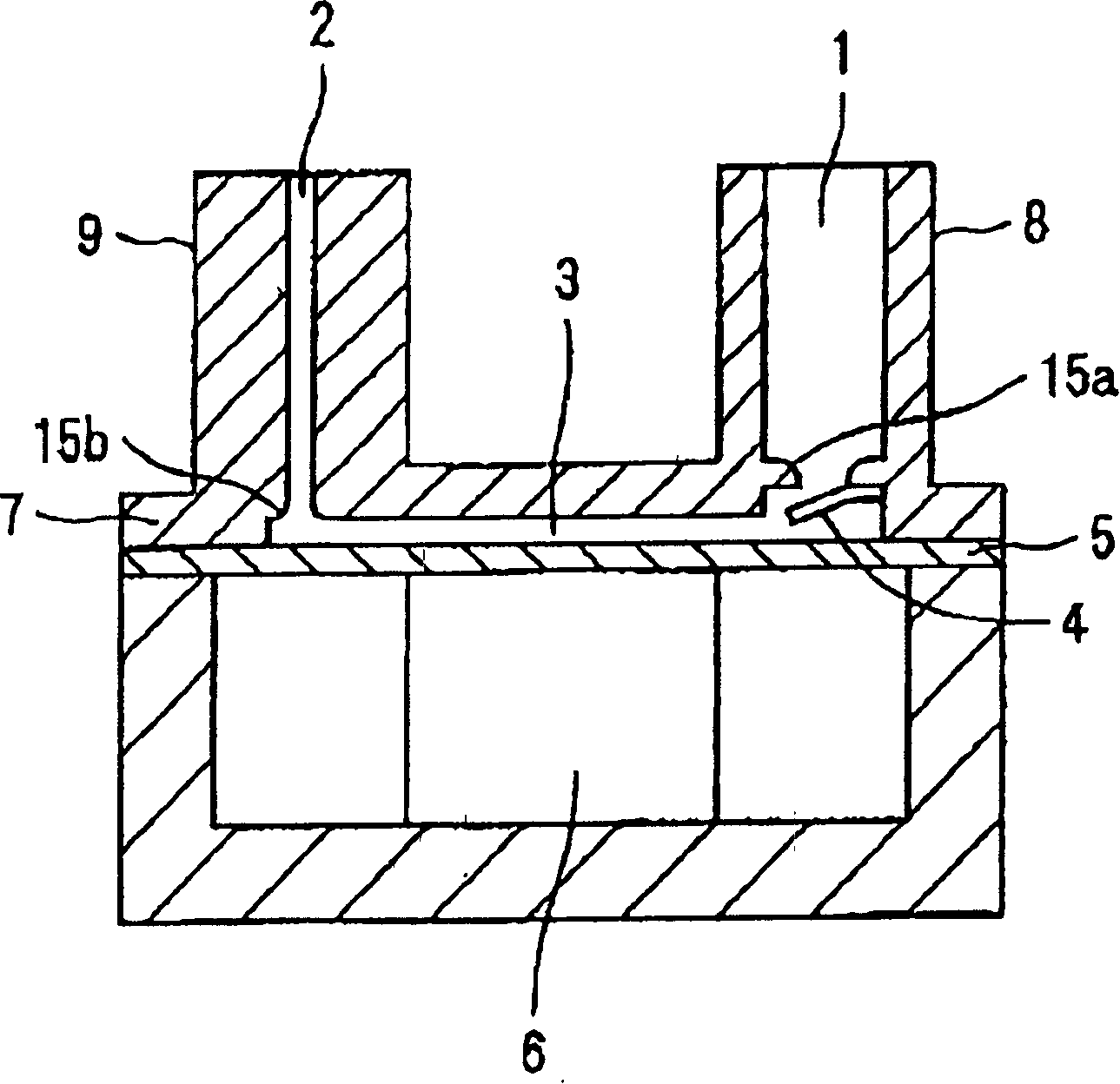

Pump

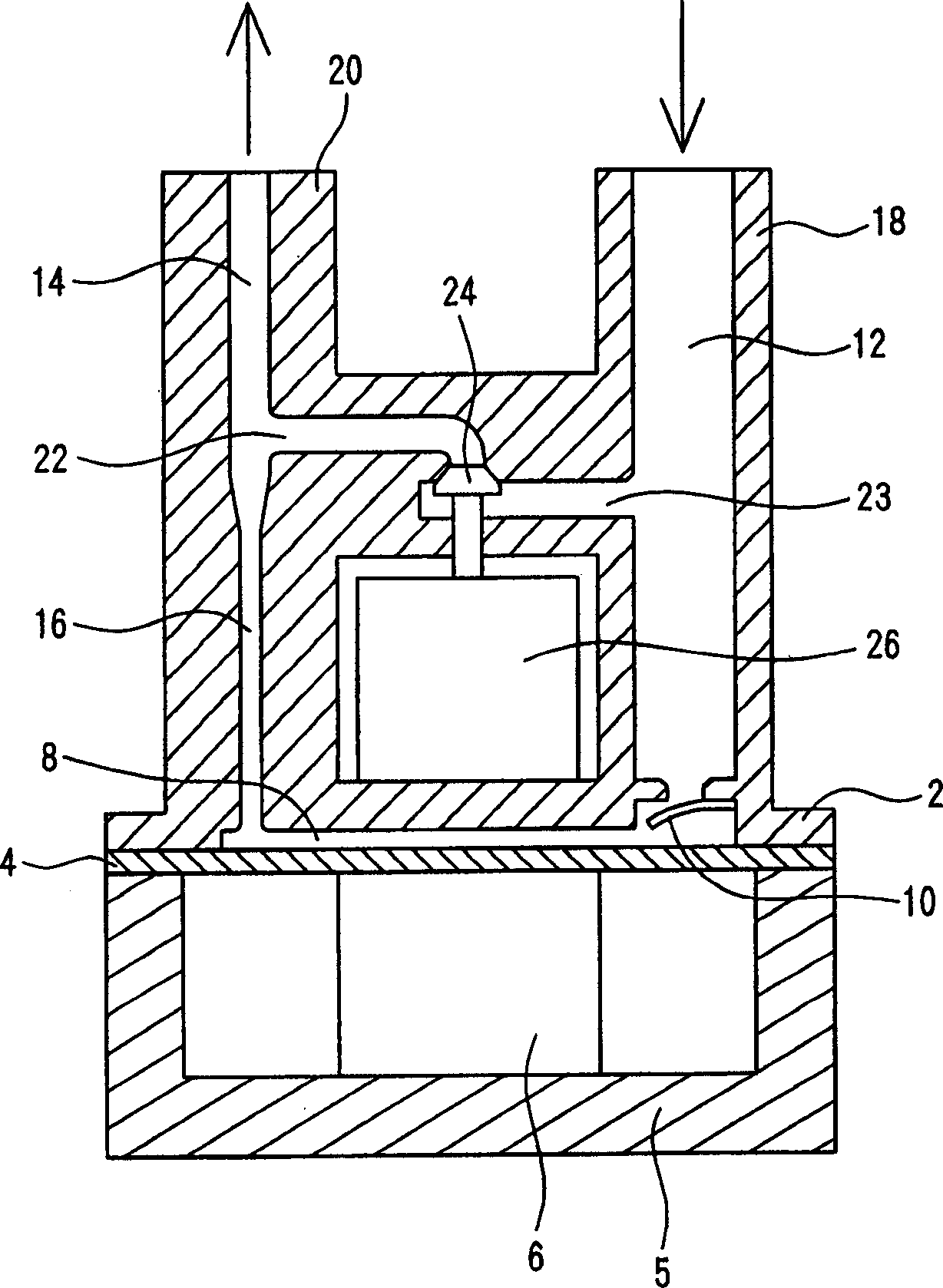

InactiveCN1469046APositive displacement pump componentsFlexible member pumpsPump chamberShape-memory alloy

A pump according to the present invention has a circular diaphragm 4 placed at the bottom of a casing 2. At the bottom of the diaphragm 4, a piezoelectric element 6 is installed in contact with the diaphragm 4. A narrow space between the diaphragm 4 and the top wall of the casing 2 constitutes a pumping chamber 8. An inlet flow path 12 and an outlet flow path 14 are open to the pumping chamber 8, wherein a check valve 10 is installed in the inlet flow path 12. Immediately downstream of the pumping chamber, the outlet flow path 14 has a narrow segment 16. The narrow segment 16 of the outlet flow path has 1 / 2 the diameter and 1 / 4 the cross sectional area of the outlet flow path 14. The outlet flow path 14 has a return inlet 22, which is connected to a return outlet 23 in the inlet flow path via an active valve 24. The active valve 24 is opened and closed freely by an actuator 26 made of shape-memory alloy.

Owner:SEIKO EPSON CORP

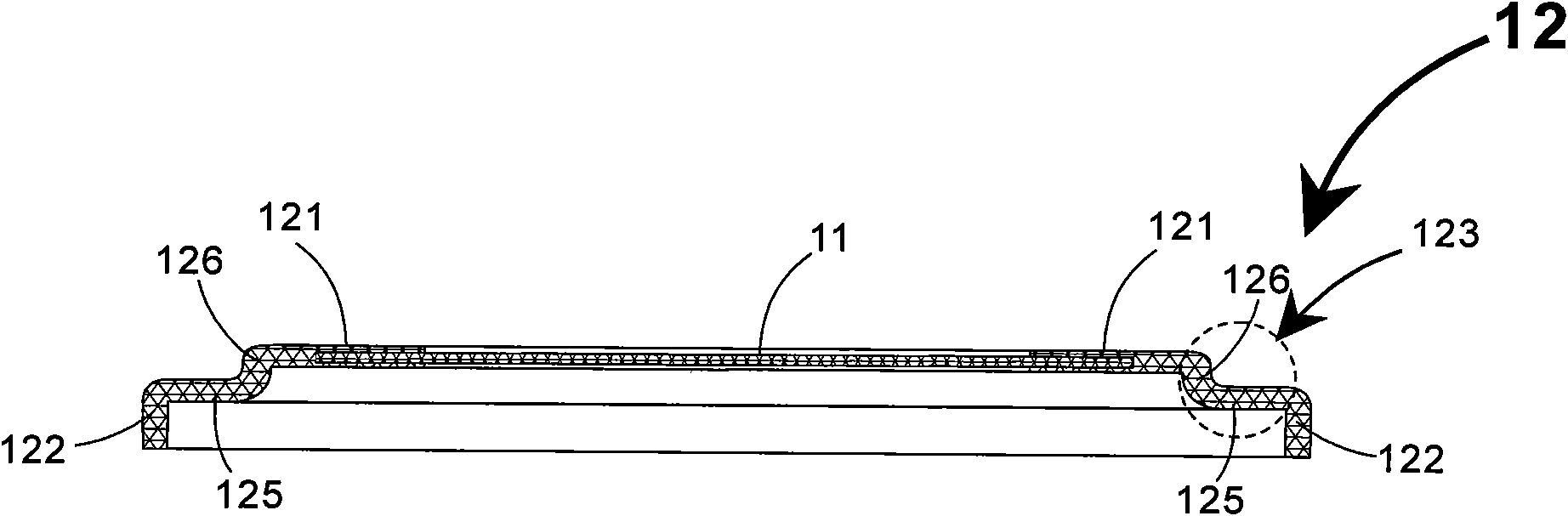

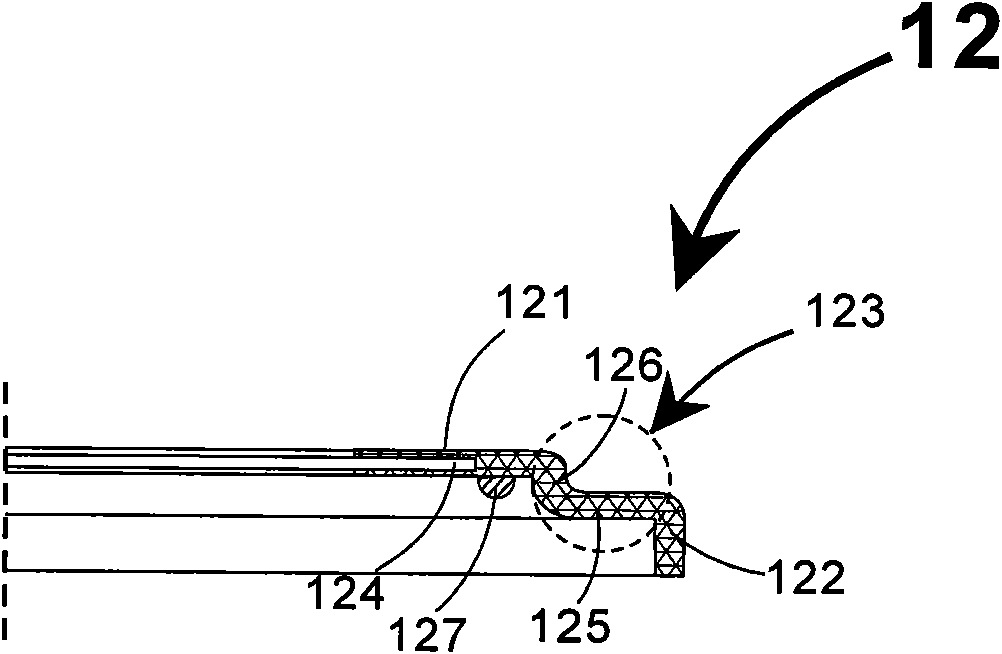

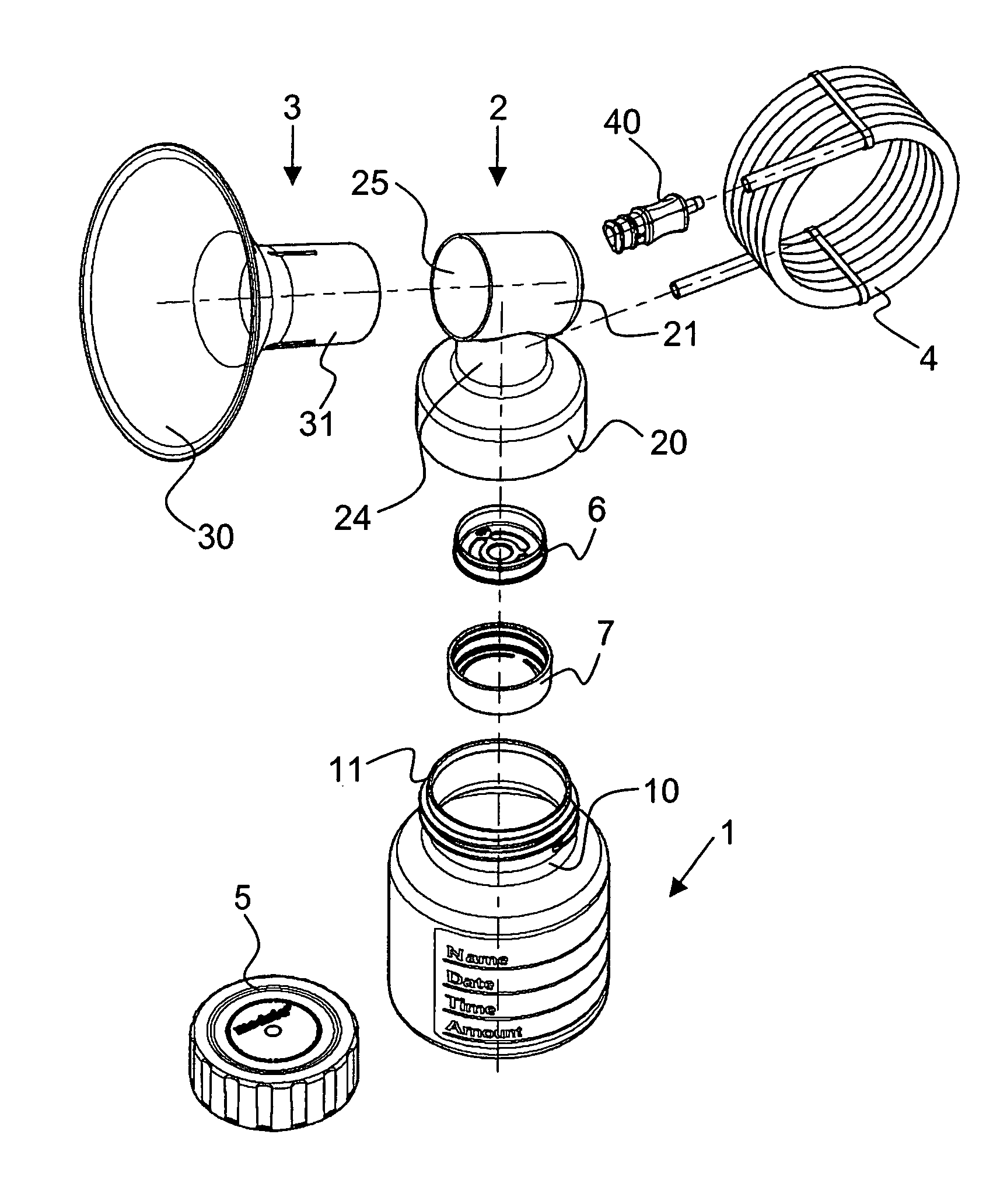

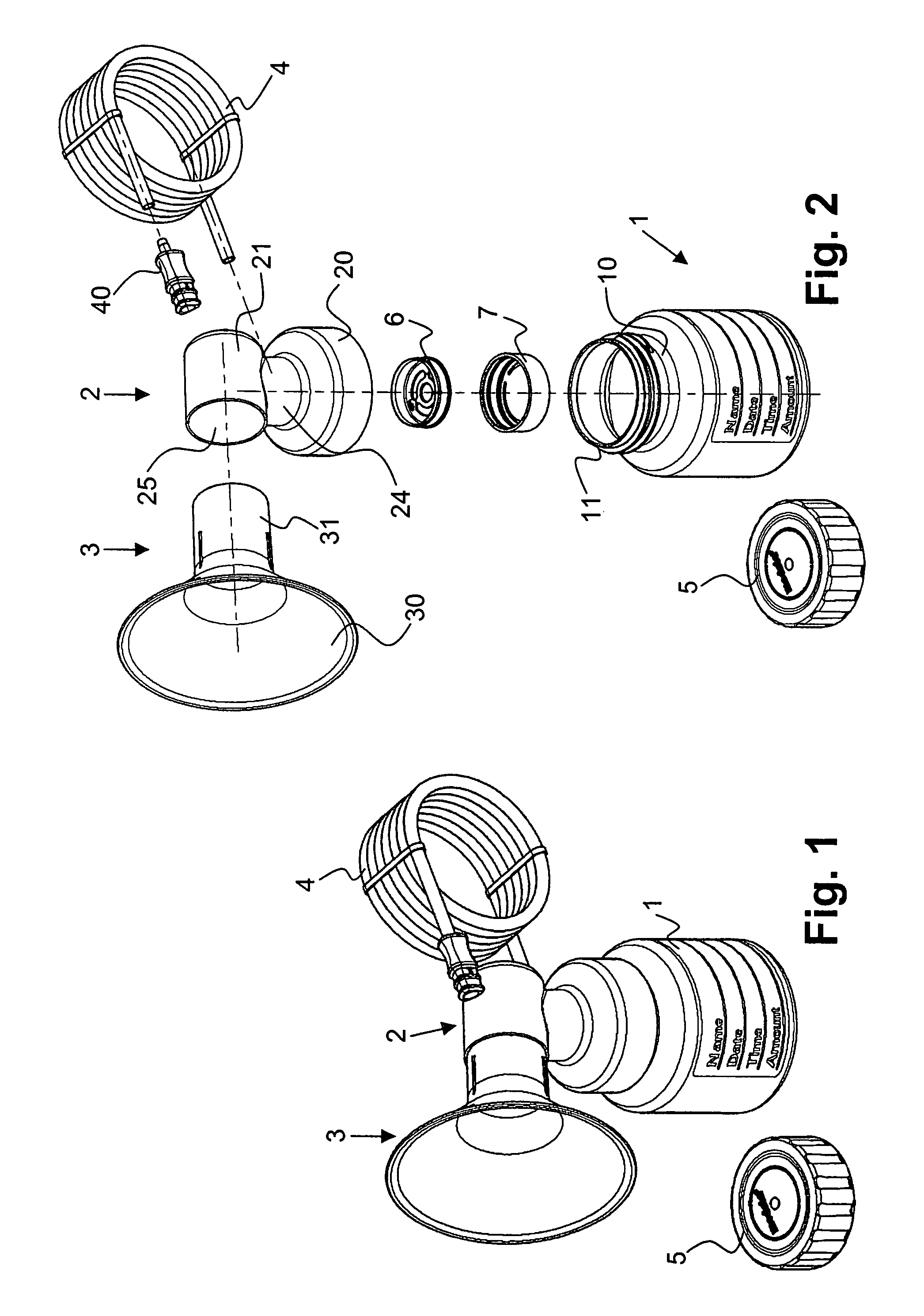

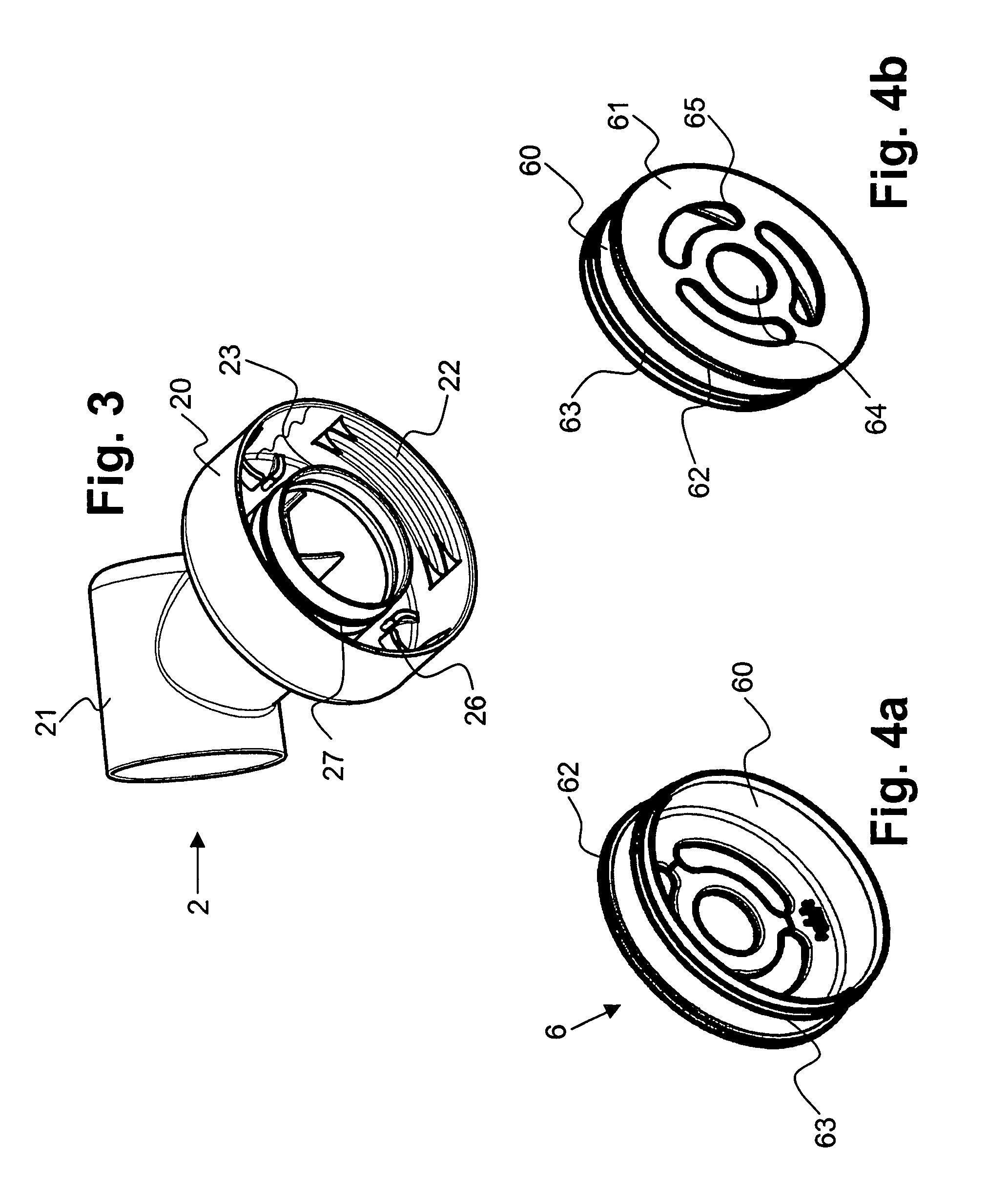

Valve, in particular for a breast shield set

ActiveUS8100854B2Low production costGuaranteed functionMilking pumpThin material handlingEngineeringVALVE PORT

The valve includes a valve seat and a valve body with a circular diaphragm. The valve body is arranged over the valve seat in order to close the latter sealingly when it bears on the valve seat. The valve seat and the valve body have openings which are offset relative to one another and which form a free passage when the diaphragm of the valve body lifts. The diaphragm of the valve body has elongate openings which are uniformly distributed along a circle in the periphery of the diaphragm, the circle having approximately the same center point as the diaphragm. The elongate openings are separated from one another by webs, the diaphragm being designed to be weaker in the area adjacent to these webs.

Owner:MEDELA HLDG AG

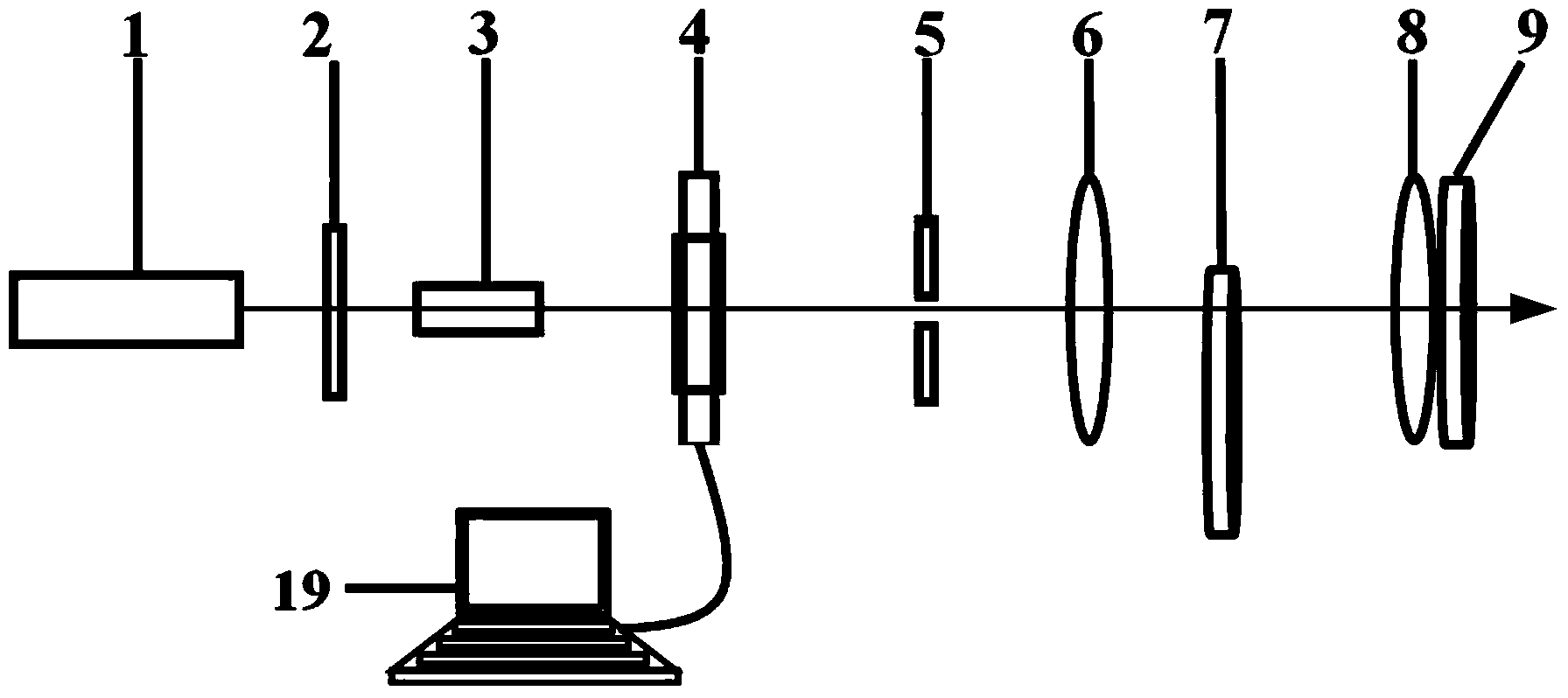

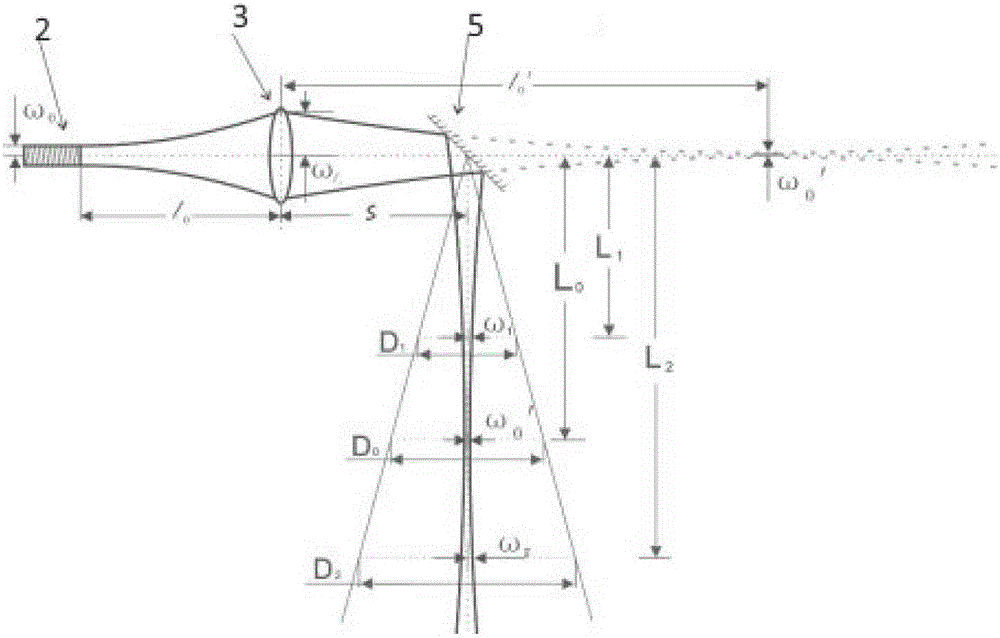

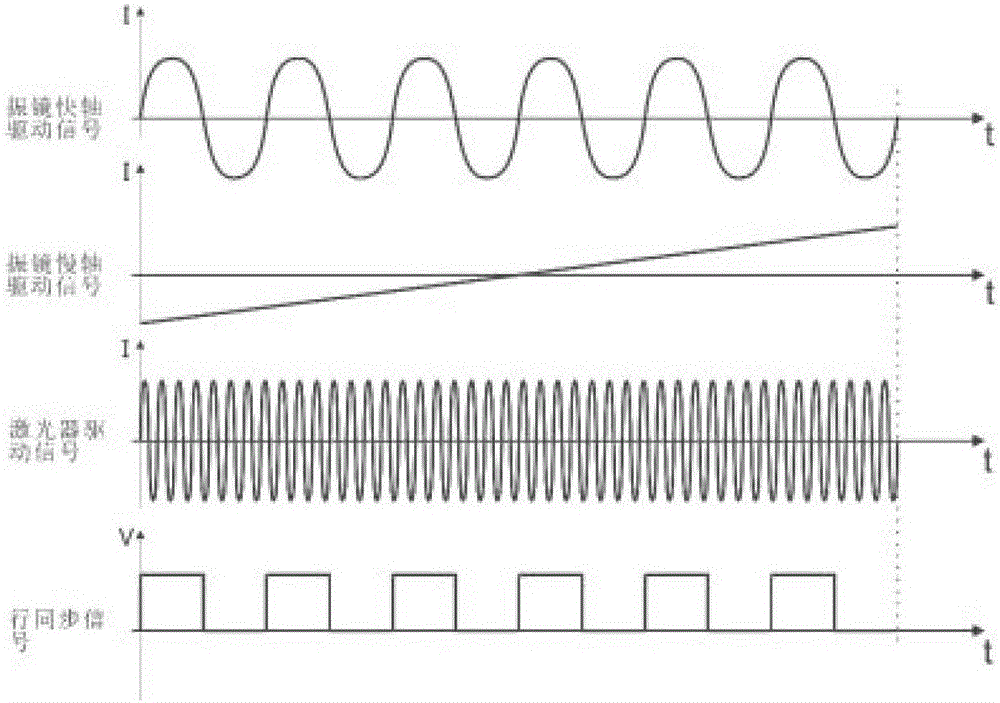

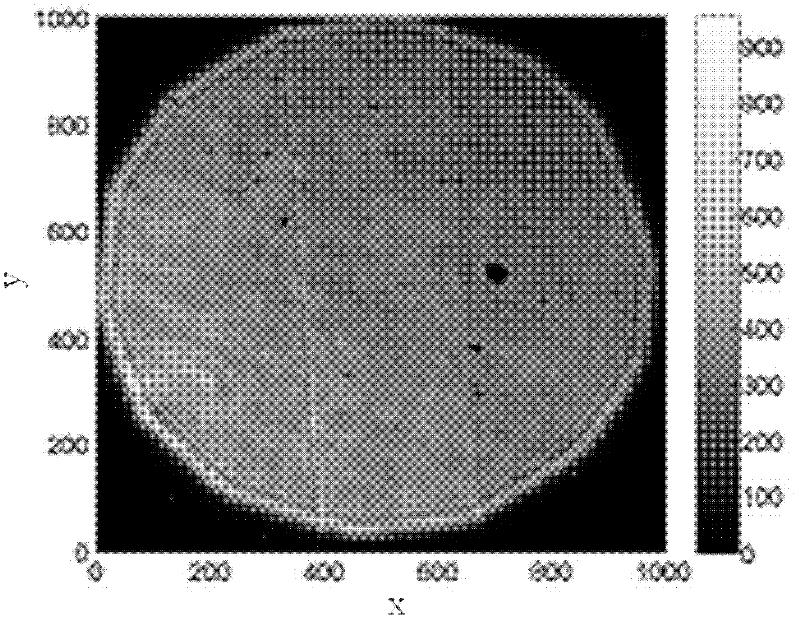

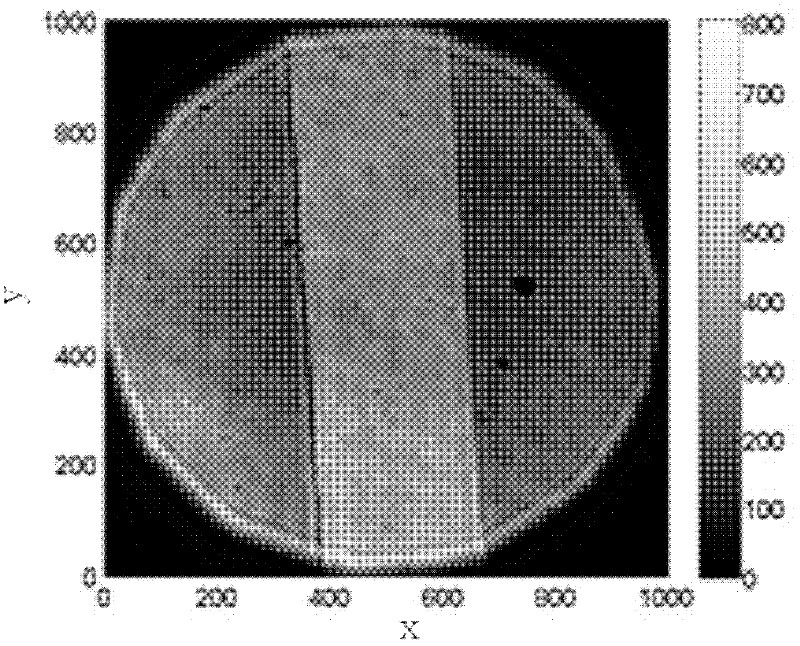

Method of simulating generating of large depth field programmable grating

ActiveCN106705889ASmall minimum pitchLarge depth of fieldUsing optical meansOptical elementsGratingPower flow

The invention discloses a method of simulating generating of large depth field programmable grating. A laser is used to emit a laser beam, and after focusing and collimating of a collimating lens, a collimating Gaussian laser beam capable of satisfying requirements is acquired. After primary specular reflection, the laser beam passes through a circular diaphragm, and is emitted into an MEMS vibration mirror. The laser beam is reflected to a surface of a measured object by the MEMS vibration mirror. Under control of a sinusoidal current signal generated by a driving board, the laser is used for the sinusoidal modulation of the brightness of the laser beam. Under excitation of a driving signal generated by the driving board, the MEMS vibration mirror is used for two-dimensional rotation, and therefore the laser beam is driven to carry out scanning, and grating images are generated. The cycle and the phase of the driving signal of the laser are changed to acquire the grating images of different cycles and different phases. The grating generated by adopting the above mentioned technical scheme has a programmable advantage of a digital grating and a high resolution advantage of a physical grating. The field depth of the generated grating is extended by more than ten times, and therefore a measuring range is greatly improved.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

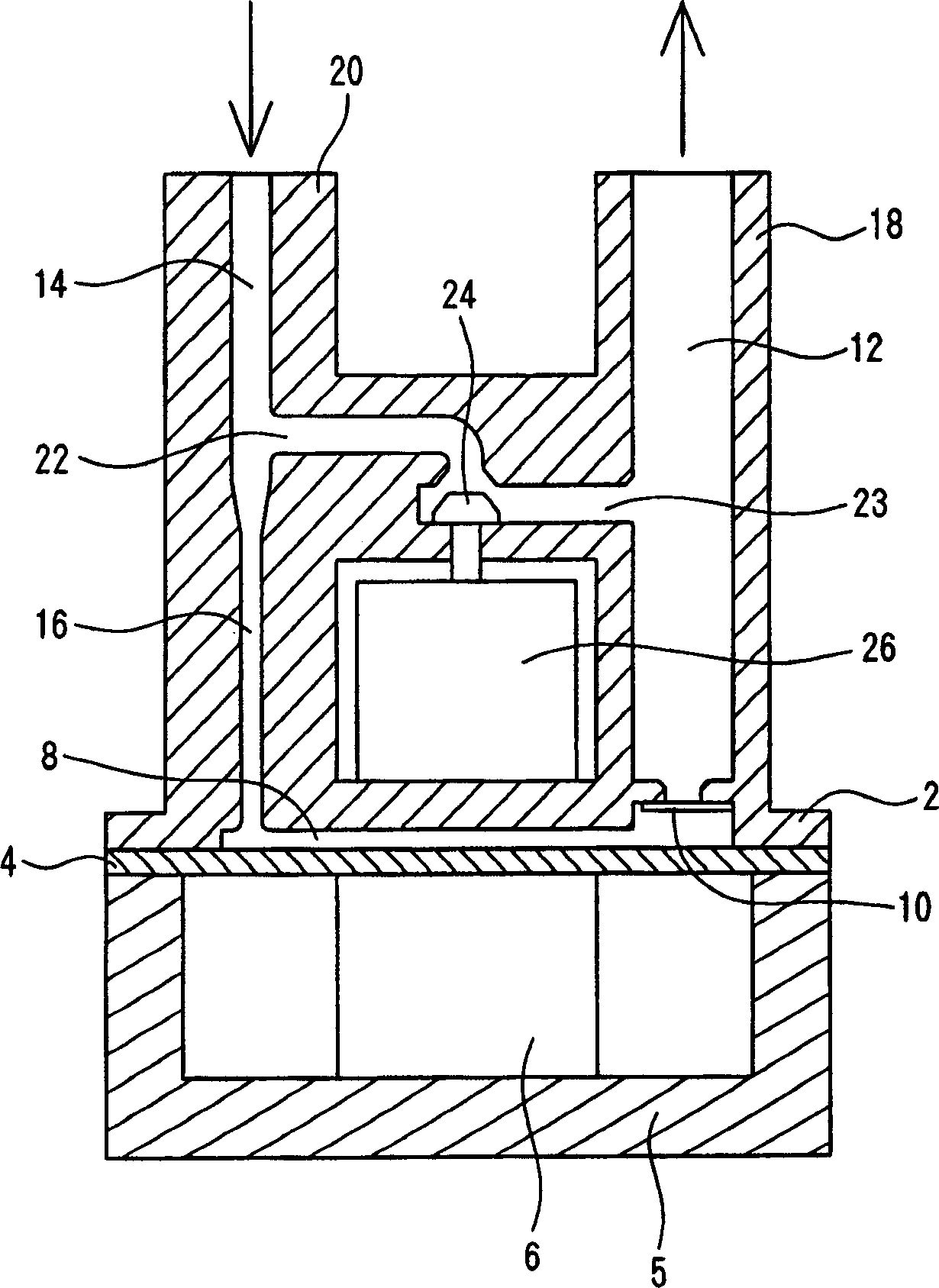

Pump

InactiveCN1467375AReduce the numberIncreased volume of discharged fluidFlexible member pumpsPump controlCycle controlEngineering

The invention provides a pump with high driving efficiency in which the number of mechanical switching valves is decreased to reduce pressure loss and increase reliability, and which is ready for high load pressure and high-frequency driving, and which increases the discharged fluid volume for one cycle of pumping. A circular diaphragm 5 arranged on the bottom of a casing 7 has the outer edge fixed to the casing 7. The diaphragm 5 includes a piezoelectric element 6 to move the diaphragm on the bottom surface thereof. The space between the diaphragm 5 and the top wall of the casing 7 serves as a pump chamber 3, wherein a suction channel 1 and a discharge channel 2 are opened to the pump chamber, the suction channel having a check valve 4 serving as a fluid resistive element and the discharge channel being always communicated with the pump chamber, even during the operation of the pump. In the pump, the activation of the piezoelectric element is controlled by a cycle control device so as to provide the cycle of the diaphragm in which the volume and the pressure of the discharged fluid of the pump are increased.

Owner:SEIKO EPSON CORP

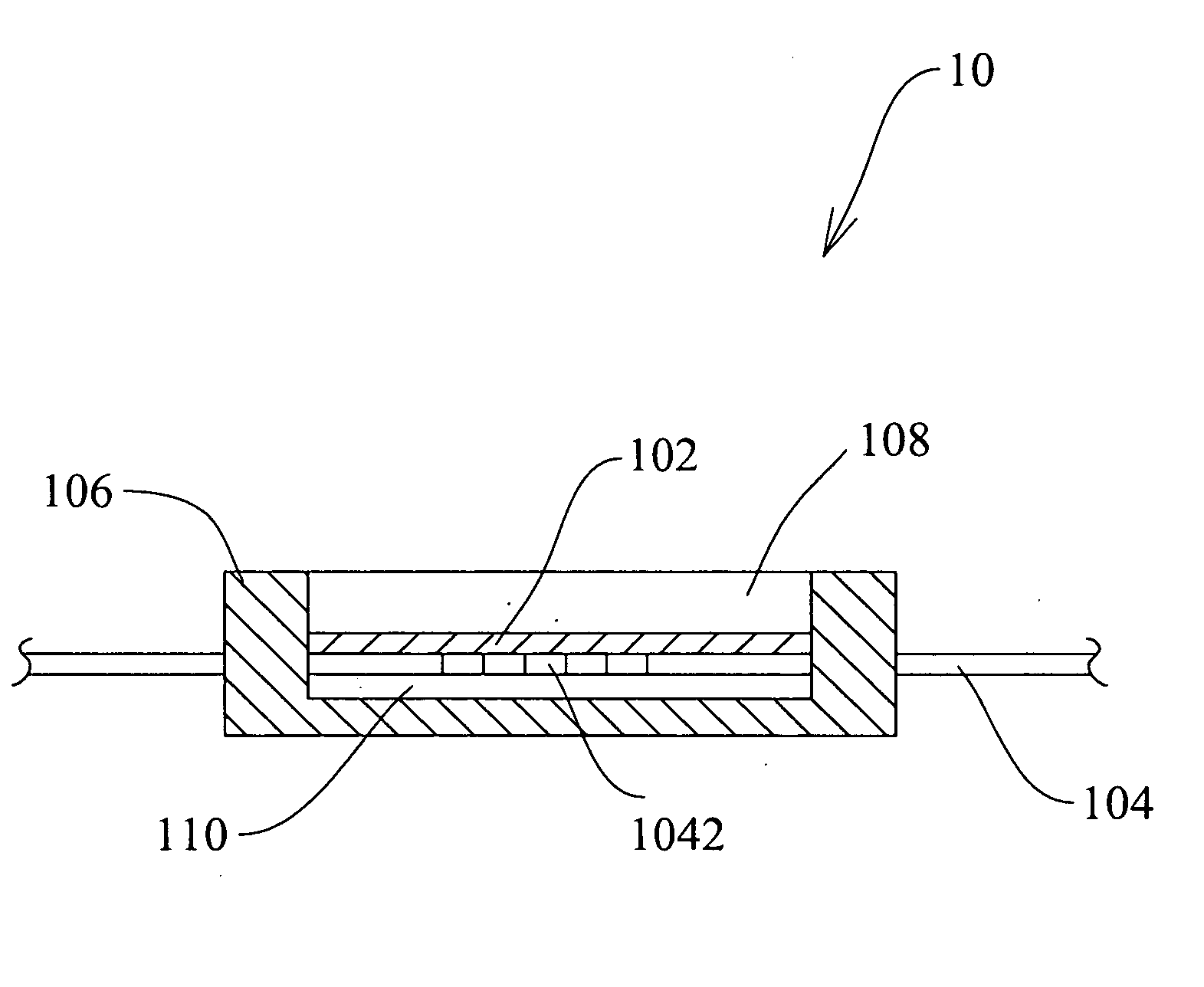

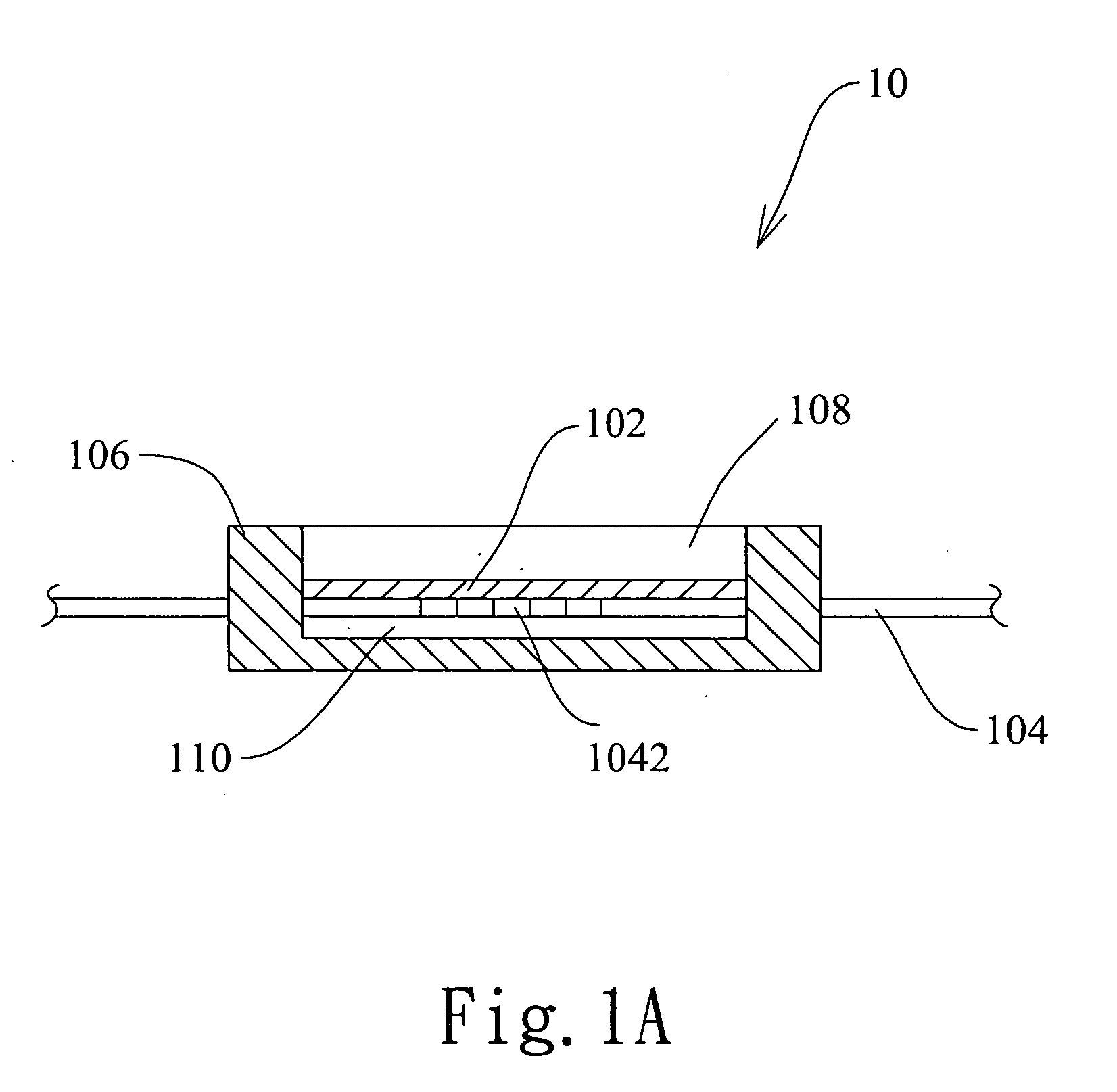

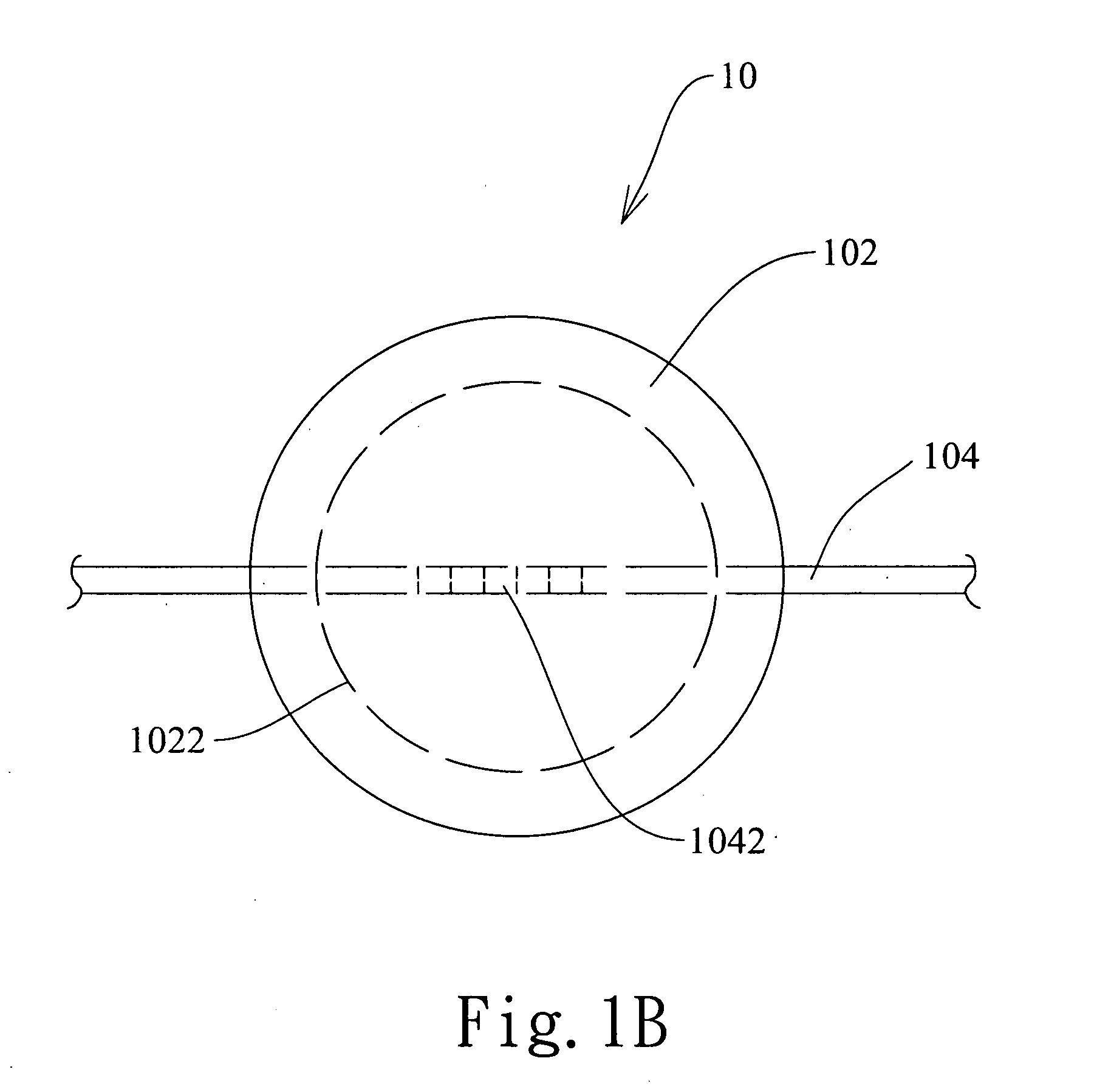

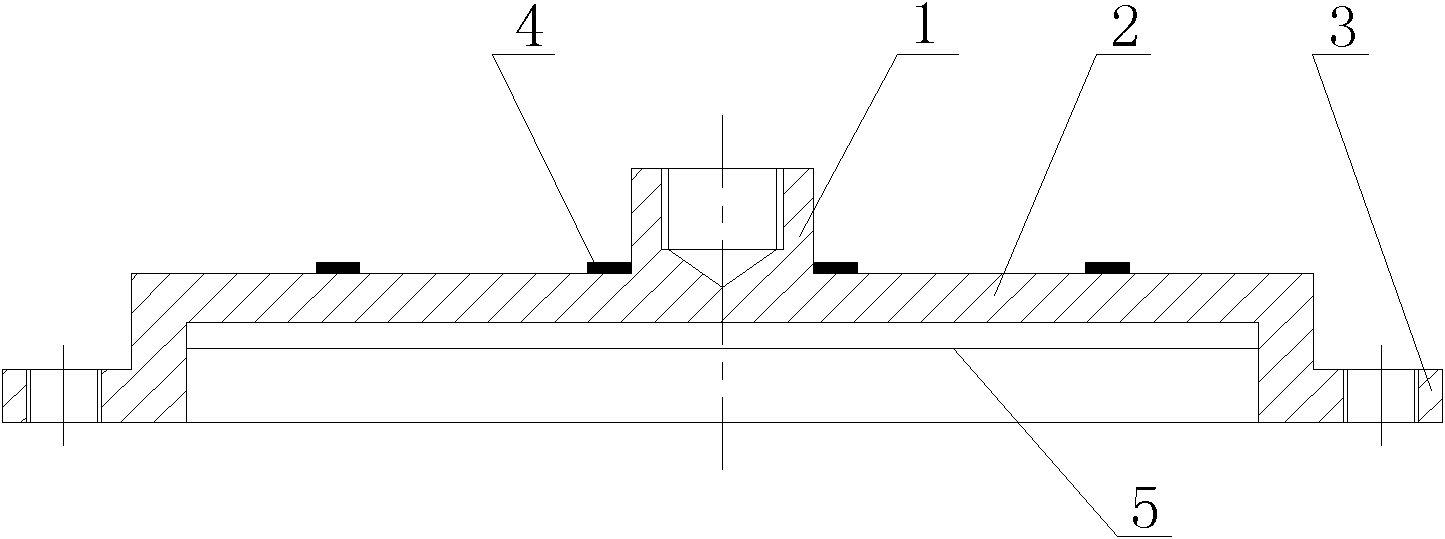

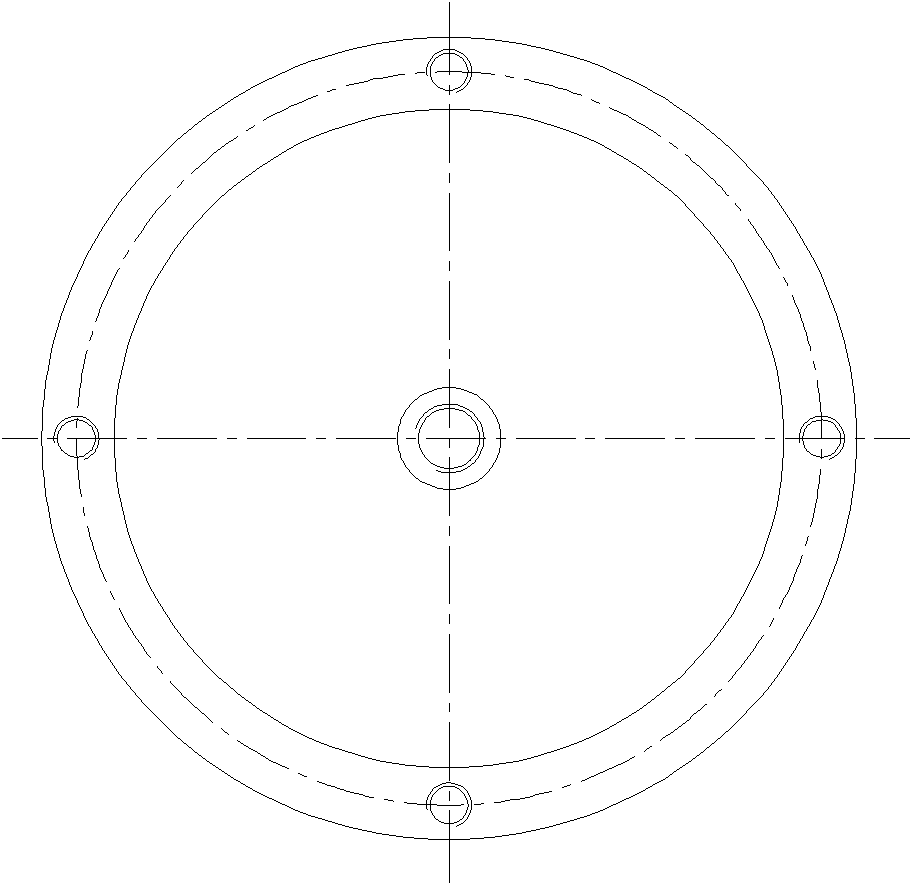

Micro skeleton two-dimensional force sensor and skeleton two-dimensional force sensing device

The invention discloses a micro skeleton two-dimensional force sensor and a skeleton two-dimensional force sensing device. The two-dimensional force sensor comprises a mechanical sensitive element, a hard centre, a strain gauge and a measurement circuit. The mechanical sensitive element is used for completing measurement on a skeleton two-dimensional force, namely realizing the measurement on axial tension and a radial shear force; the hard centre is positioned in the centre of the mechanical sensitive element for bearing and transmitting an external force; the strain gauge is attached to theupper surface of the mechanical sensitive element; and the measurement circuit converts and amplifies a signal. The skeleton two-dimensional force sensor designed by the invention can realize the measurement on the axial tension and the radial shear force on the fracture trauma section by matching an external skeletal fixation device. The mechanical sensitive element has an E-type circular diaphragm structure, and has the advantages of small size, high sensitivity and good linearity. The mechanical sensitive element with the simple structure particularly can be molded at one time into a whole, so that the rigidity is good, the cost is low and the dynamic performance is good.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Optical fiber grating acceleration sensor based on diaphragm type equal-strength cantilever beam structure

InactiveCN109556702ASolve the shortcomings of poor lateral anti-interference abilitySolve the shortcomings of low acceleration response sensitivityAcceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementResponse sensitivityGrating

The invention belongs to the technical field of an optical fiber sensor, and in particular relates to an optical fiber grating acceleration sensor based on a diaphragm type equal-strength cantilever beam structure. The acceleration sensor comprises a diaphragm and an inertial mass block which are disposed in a shell, and a sensing grating, wherein the inertial mass block is located in a geometriccenter of the diaphragm and is fixed below the diaphragm; the diaphragm is fixed on an inner wall of the shell; an interior of the diaphragm is cut into four symmetrical equal-strength cantilever beams; the sensing grating is disposed on an upper surface of one of the cantilever beams; and a tail fiber at one end of the sensing grating is connected with an external demodulation unit after passingthrough an optical fiber outlet. The sensor combines the advantages of the cantilever beam and the circular diaphragm to fundamentally solve the defects of poor lateral anti-interference capability ofthe traditional cantilever beam and low acceleration response sensitivity of the ordinary circular diaphragm; and the sensor has the advantages of reasonable design, simple structure, large measuringrange, simple processing and installation and high sensitivity and can be used for seismic exploration of oil and gas resources.

Owner:NORTHWEST UNIV +1

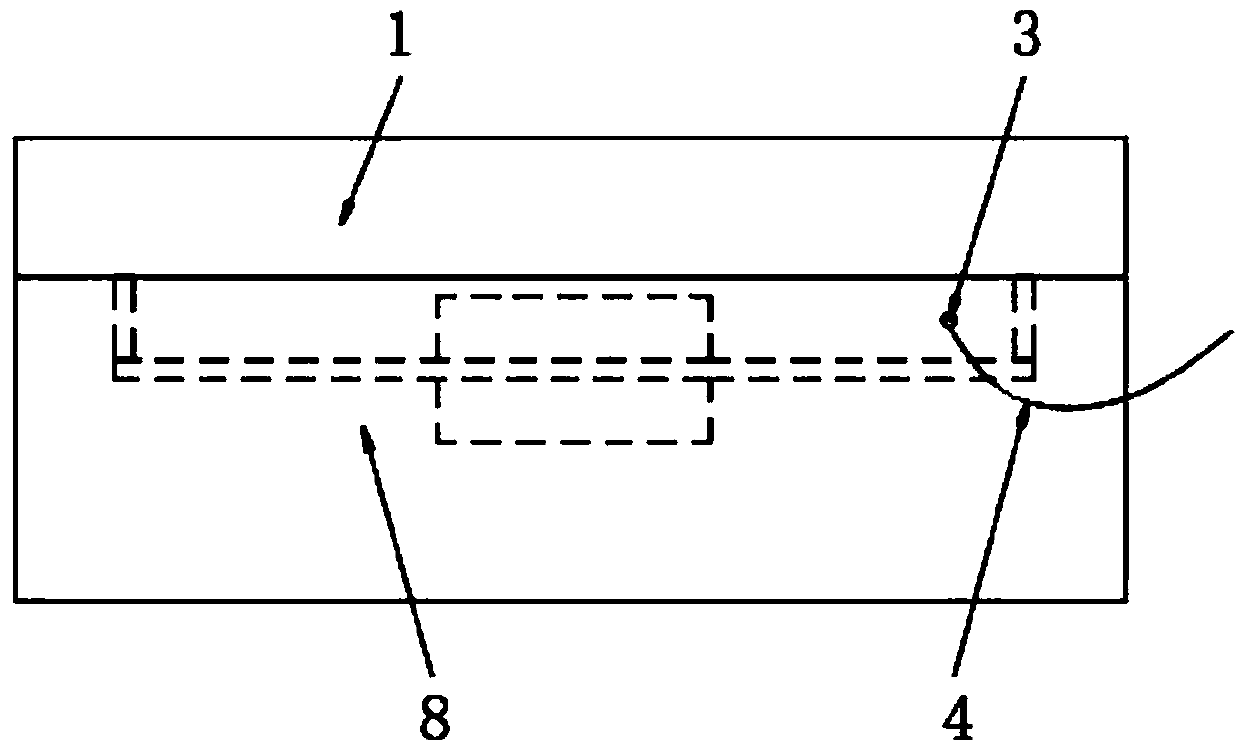

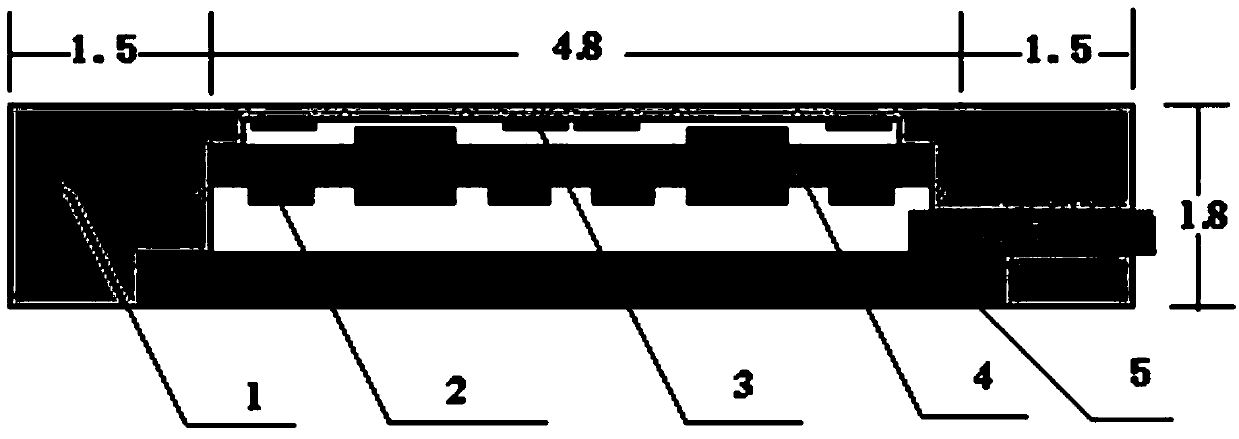

Embedded piezoresistive micro stress sensor

InactiveCN105953955ARealize real-time measurement of interface stressAchieving miniature contoursForce measurementStress measurementEngineering

The invention provides an embedded piezoresistive micro stress sensor which is composed of a shell, chip resistors, sensitive elements, printed electrodes and a baseplate. The shell is composed of an annular structural component of which the thickness is 1.8mm and the diameter is 7.8mm and a stainless steel circular film which is fixedly installed at one end of the annular structural component in an embedded way. Diffusion silicon piezoresistive sensitive elements are adopted to act as the sensitive elements. Two sensitive elements are arranged at the central position of the circular film. The other two sensitive elements are arranged at the edge position of the film. According to the designed piezoresistive micro stress sensor, a microelectronic micromechanical technology is adopted so that the flat micro contour of the stress sensor can be realized, and the stress sensor can be conveniently installed in a solid engine to perform interface stress measurement. Besides, the stress sensor has a tension and compression bidirectional measurement function so that the stress sensor can measure compression stress and can also measure tension stress.

Owner:XIAN AEROSPACE PROPULSION TESTING TECH RES INST

All-plastic miniature one-way valve and machining method thereof

InactiveCN107448648AImprove etching precisionSimple processLiquid surface applicatorsCheck valvesEtchingEngineering

The invention discloses an all-plastic miniature one-way valve. The all-plastic miniature one-way valve comprises a base plate and a valve membrane, the base plate is provided with a conical through hole, the valve membrane covers the side of the narrow opening end of the conical through hole and is provided with multiple through holes which are formed around a round diaphragm in an annular shape, the area of the round diaphragm is larger than that of the narrow opening end of the conical through hole, the narrow opening end of the conical through hole is totally covered, and a fluid flow path of a miniature one-way valve is constituted among the conical through hole of the base plate and the through holes around the round diaphragm on the valve membrane. The invention further discloses a machining method of the all-plastic miniature one-way valve. An all-plastic miniature one-way valve fine machining method is adopted to machine the base plate, valve opening thin film is graphically machined to form a valve opening channel, a complex chemical etching and mechanical machining method is avoided, the etching precision is high, the technology is simple, the operation is convenient, the production efficiency is high, the production cost is low, and the all-plastic miniature one-way valve and machining method thereof are suitable for batch production.

Owner:SHANGHAI INST OF TECH

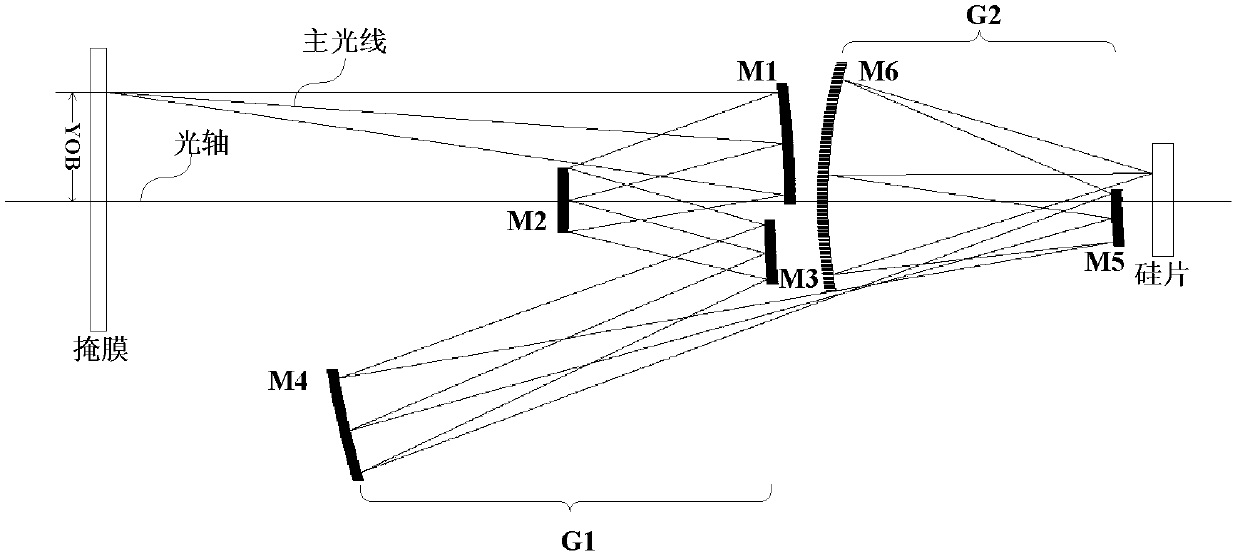

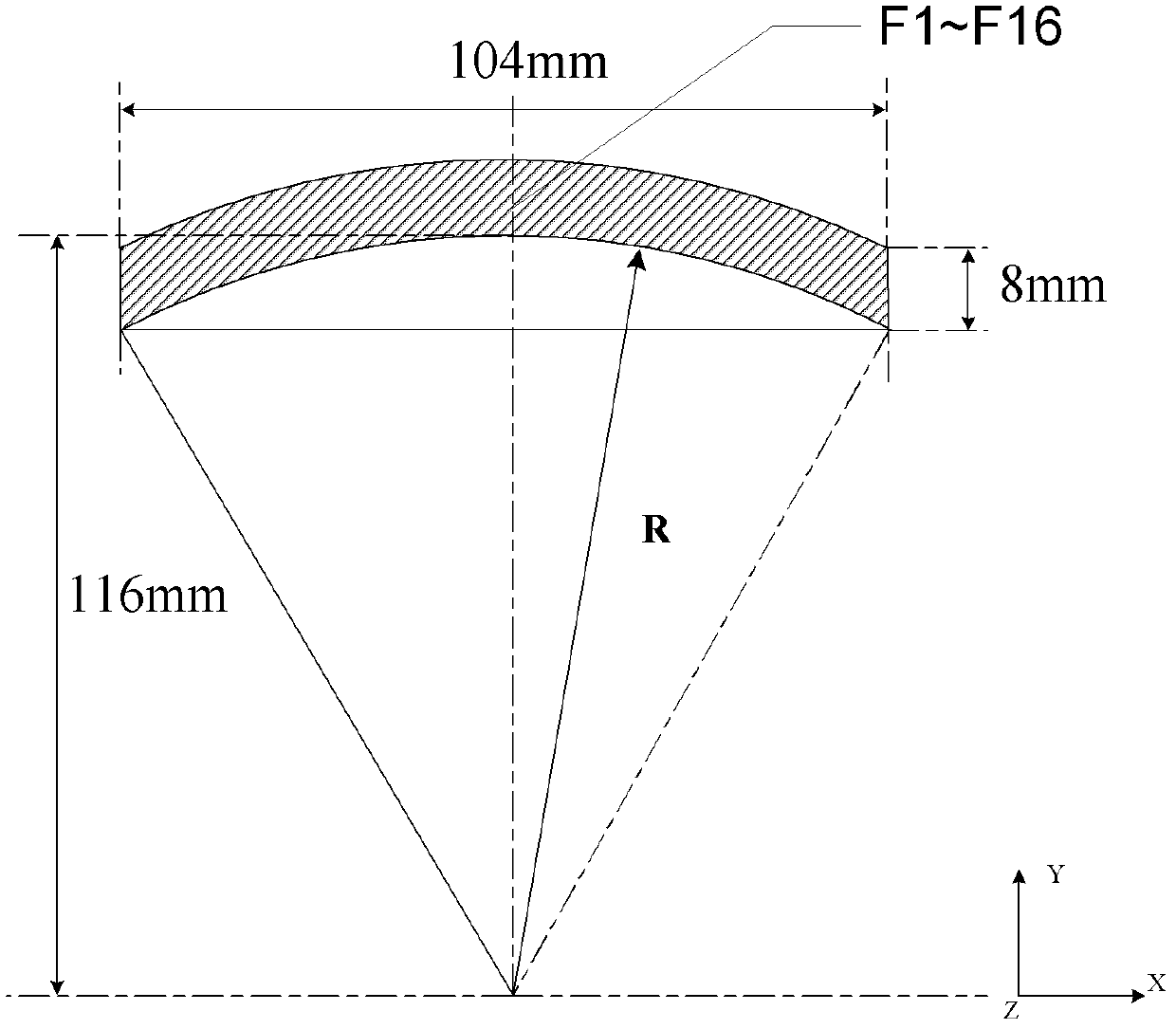

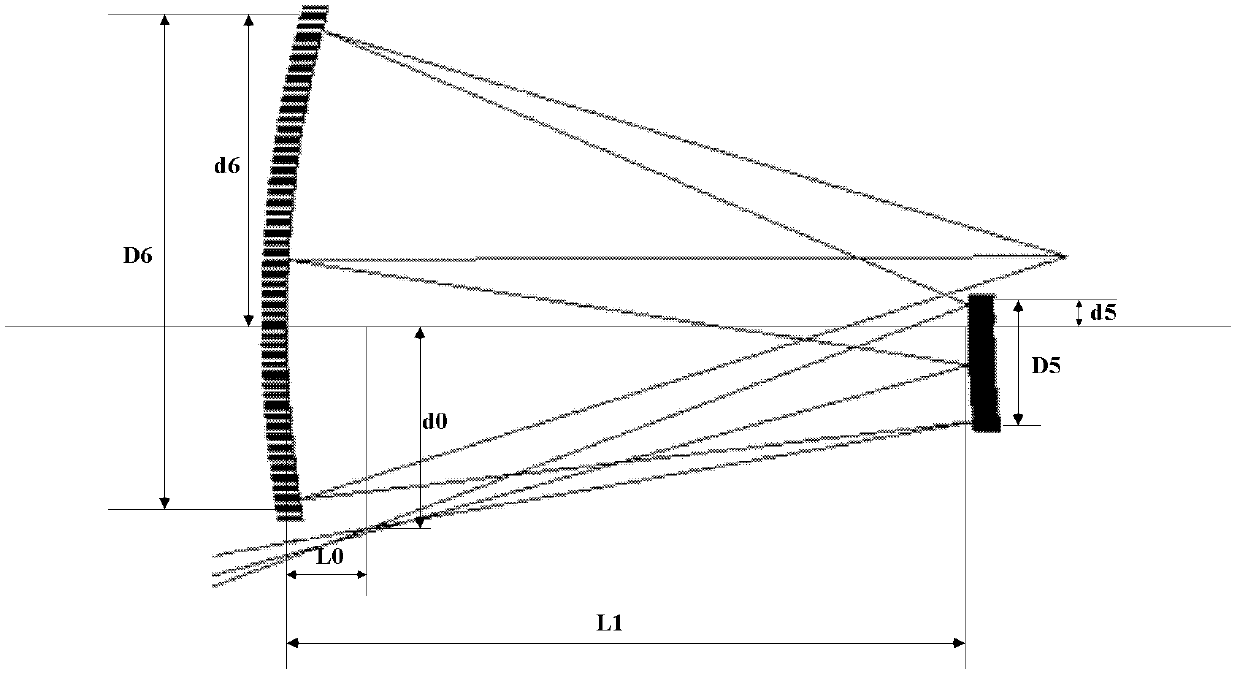

Extreme-ultraviolet-projection photoetching objective lens

ActiveCN102608737AGuaranteed yieldImprove photolithography resolutionPhotomechanical exposure apparatusMicrolithography exposure apparatusOptoelectronicsExtreme ultraviolet

The invention provides an extreme-ultraviolet-projection photoetching objective lens with a six-reflector structure. A first reflector M1, a circular diaphragm, a second reflector M2, a third reflector M3 and a fourth reflector M4 are arranged in a first reflector group, and a fifth reflector M5 and a sixth reflector M6 are arranged in a second reflector group; the first reflector group is used for forming an intermediary image between the fifth and sixth reflectors from an object plane; the second reflector group is used for forming an image on an image plane from the intermediary image so as to realize the 1 / 4 objective image narrowing power of a system; and the sixth reflector M6 does not shelter emergent light of the first reflector group, and the fifth reflector M5 does not shelter reflected light of the sixth reflector M6. According to the invention, through an improvement on the fifth and sixth reflectors, the fifth and sixth reflectors can form the image on the image plane of the extreme-ultraviolet-projection photoetching objective lens from the intermediary image without sheltering.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

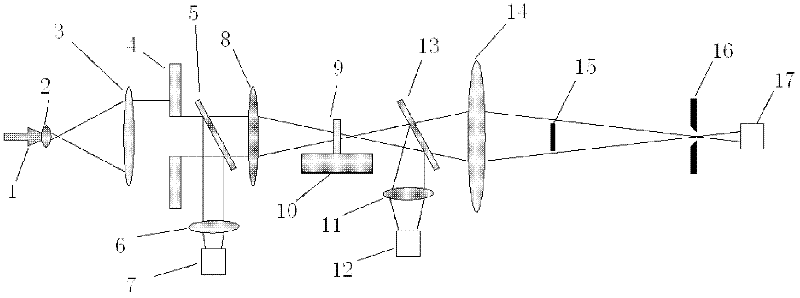

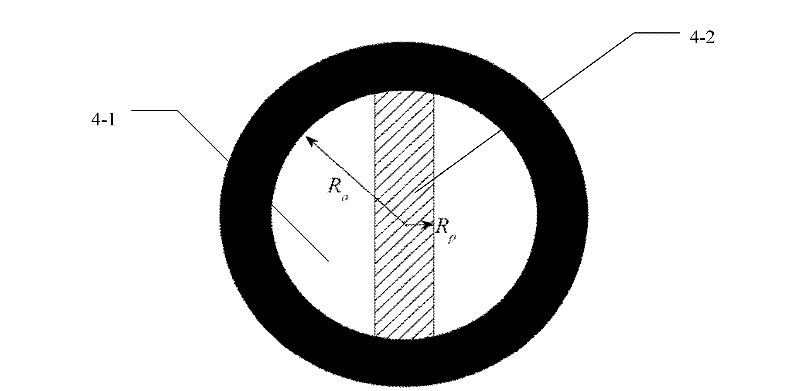

Bar-type phase diaphragm and 4f phase-concerned nonlinear imaging system and nonlinear refractive index metering method based on same

InactiveCN102636830AReduce the difficulty of manufacturing processReduce difficultyPhase-affecting property measurementsPolarising elementsBeam splitterRefractive index

The invention relates to a bar-type phase diaphragm and a 4f phase-concerned nonlinear imaging system and a nonlinear refractive index metering method based on the system, relating to the technical field of optics, and solving problems that a manufacturing process of a circular phase object is complex, requirements on light beams are high during the measurement of a Z scanning system, samples are broken easily due to repeated irradiation on a focus, the sensitivity is low and the error is large. The bar-type phase diaphragm consists of a bar-type phase object and a circular diaphragm. The 4f phase-concerned nonlinear imaging system of the bar-type phase diaphragm consists of a half wave plate, a polarization prism, a beam expander, a bar-type phase diaphragm, an image sensor, an energy referring system and a 4f imaging system. The energy referring system consists of a beam splitter, a second total-reflection mirror, a middle filtering sheet, a third convex lens, a third total-reflection mirror and a first total-reflection mirror. Two convex lenses of the 4f imaging system are coaxially and confocally arranged, the first convex lens is an incidence lens, and the second convex lens is an emergence lens. The 4f phase-concerned nonlinear imaging system disclosed by the invention is applied to the field of optical communication, optical information process and the like.

Owner:HARBIN INST OF TECH

Experimental light control device for determining Planck constant

The invention discloses an experimental light control device for determining Planck constant. The experimental light control device comprises a photoelectric tube dark box, a light-shading sleeve and a light-filtering sleeve cover, wherein a circular light inlet tube is connected to the photoelectric tube dark box, a circular light inlet hole is arranged near the circumference on the front end surface of the light inlet tube, the light-shading sleeve and the light-filtering sleeve cover are circular, a group of circular diaphragms with different diameters are distributed along the circumference on the sleeve end surface of the light-shading sleeve, and a group of circular light filters with the same diameter and different wavelengths are distributed along the circumference on the sleeve cover end surface of the light-filtering sleeve cover. The experimental light control device disclosed by the invention can be used for respectively combining the diaphragms with the different calibers with the light filters with the different wavelengths, further has the advantages of simple structure and convenience in operation, and is conductive to improving the experimental efficiency.

Owner:JIANGNAN UNIV

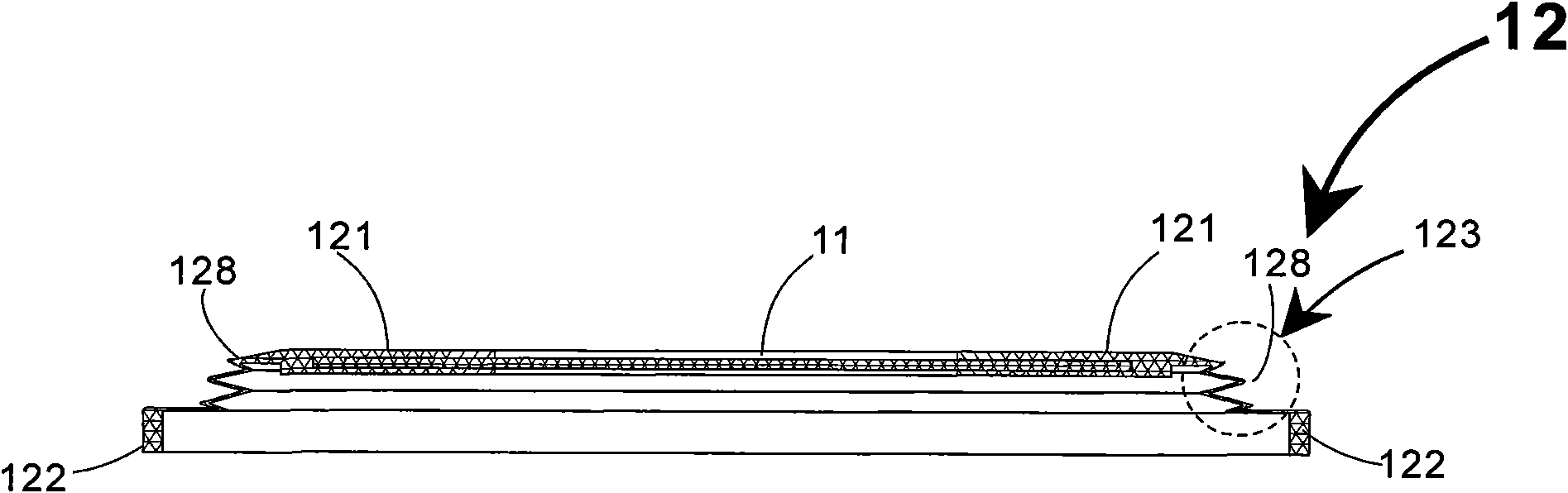

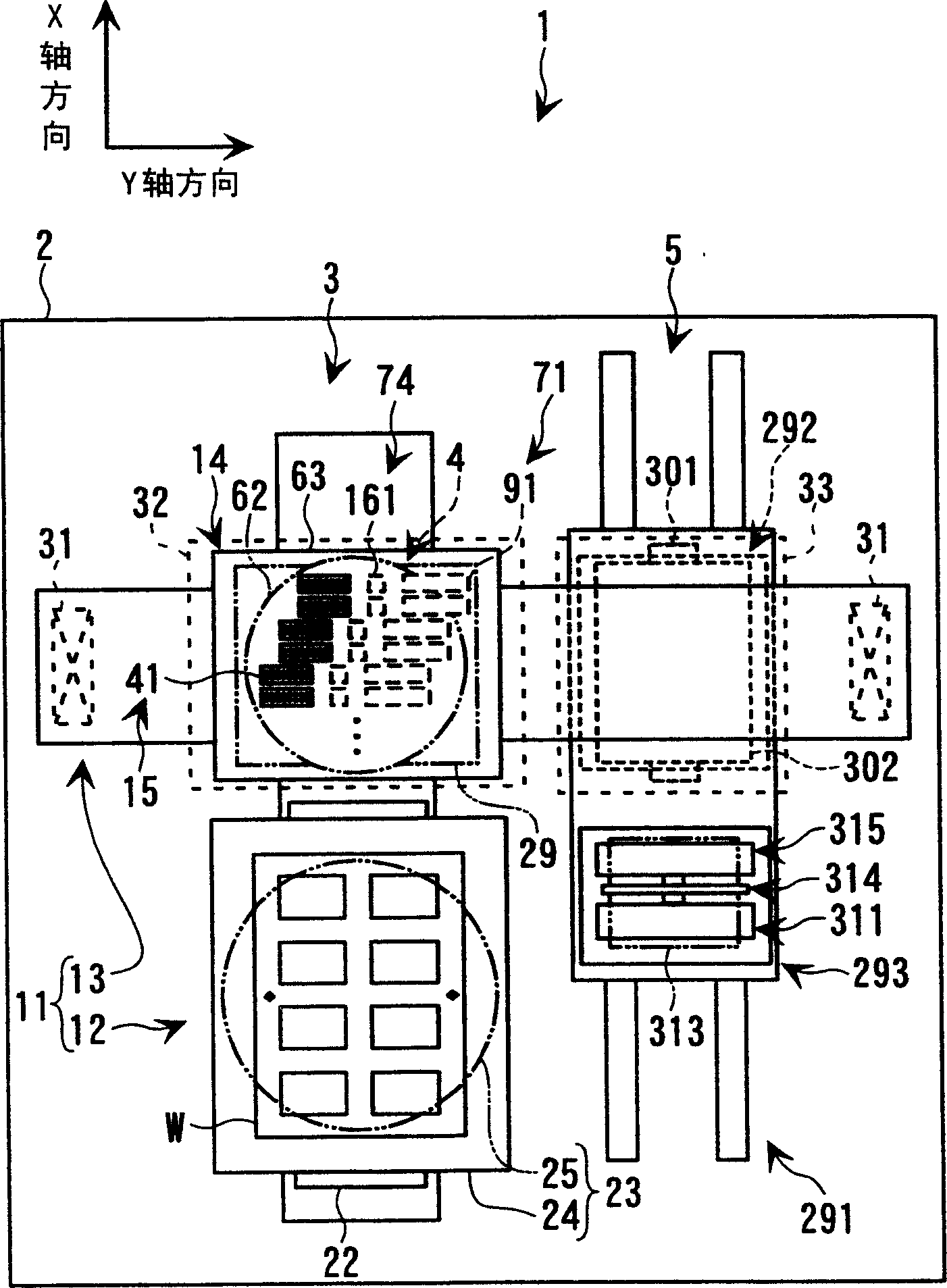

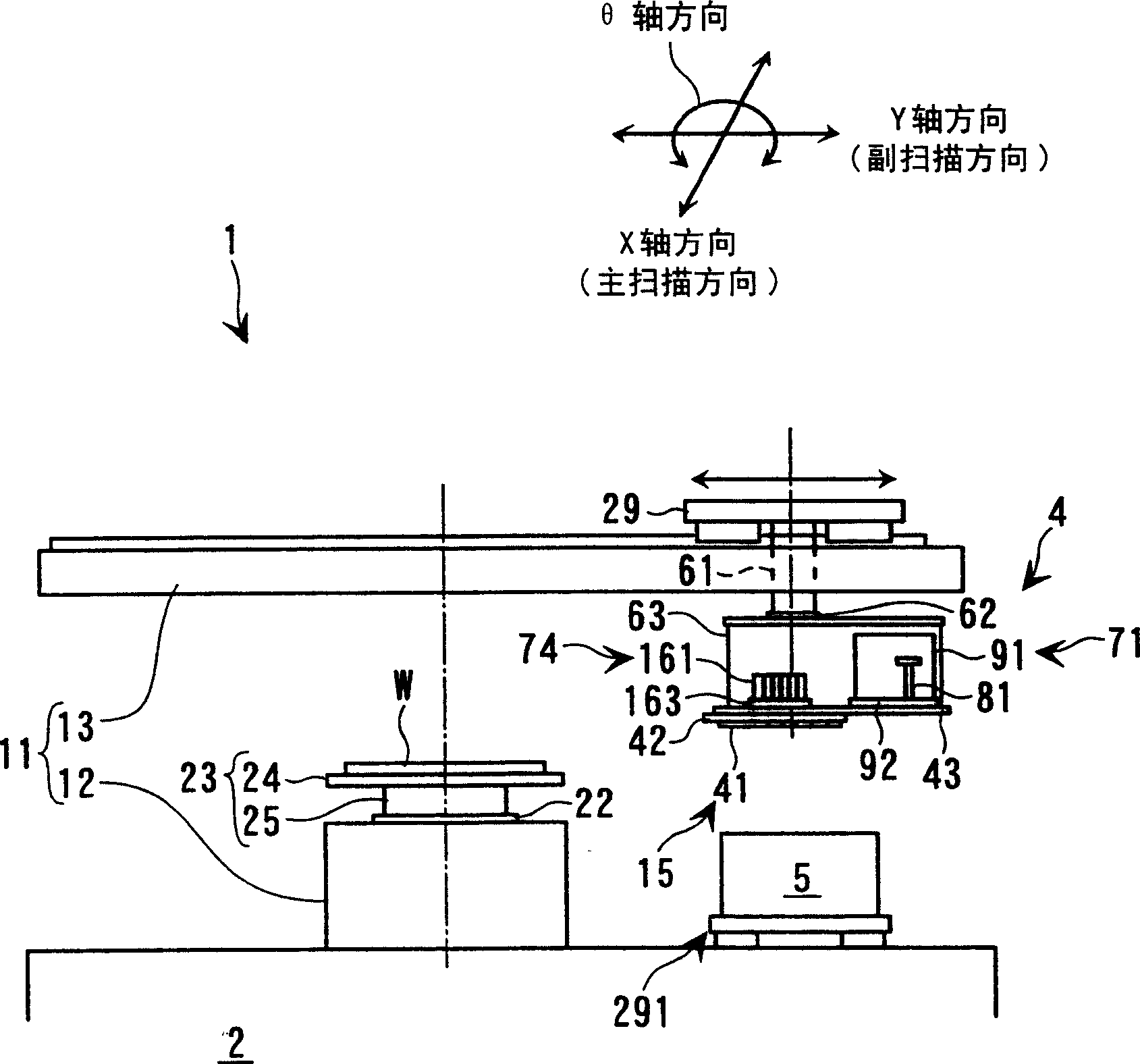

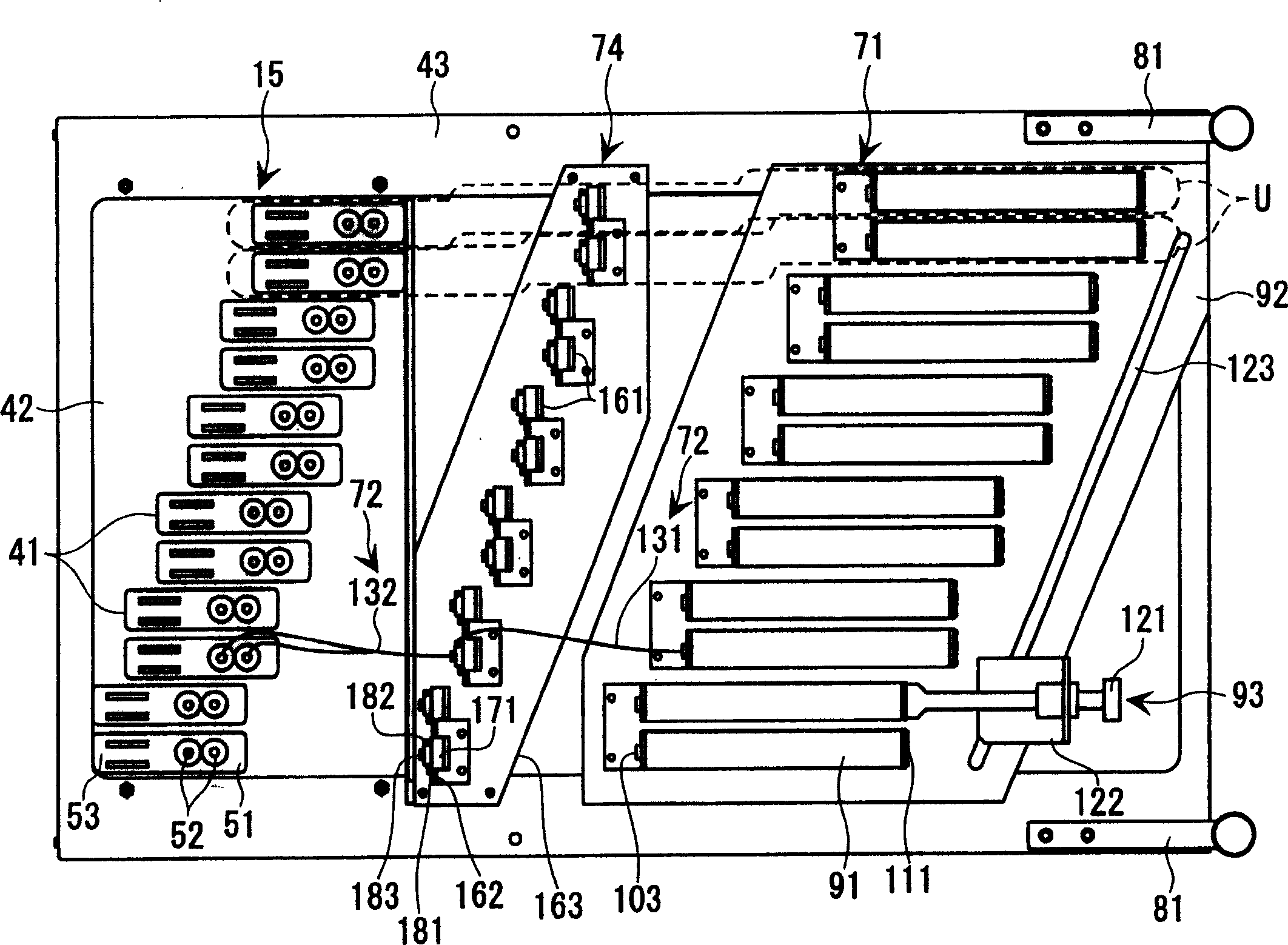

Function liquid supply apparatus, imaging apparatus, method of manufacturing electro-optical device, electro-optical device, and electronic device

Owner:SEIKO EPSON CORP

Sound reproduction systems and method for arranging transducers therein

InactiveUS8422721B2Single transducer incorporationPiezoelectric/electrostrictive microphonesTransducerEngineering

Loudspeaker system including a housing and at least four transducers arranged therein. Each transducer includes a substantially circular diaphragm and the diaphragms are constructed with specific sizes such that the ratio of a diameter of each diaphragm to the diameter of an immediately larger diaphragm is between 1:1 and 1: Phi2(Phi=(1+√5) / 2), preferably 1:Phi, and the ratio of the diameter of each diaphragm to an immediately smaller diaphragm, is between 1:1 and 1:(1 / Phi), preferably 1:1 / Phi. Moreover, the diaphragms are arranged such that centers thereof lie on a spiral, clockwise or counterclockwise, in ascending size order with the center of the smallest diaphragm being closest to the pole of the spiral. A microphone and single-diaphragm loudspeaker in which the diaphragm has a spiral shape are also disclosed.

Owner:RIZZELLO FRANK

Mechanical characteristic monitoring device for substructure of G-series high-speed train as well as application method and production method thereof

InactiveCN110375898AReduce volumeEasy to makeForce measurement by measuring optical property variationThermometers using physical/chemical changesData acquisitionEngineering

A mechanical characteristic monitoring device for a substructure of a G-series high-speed train comprises micro FBG soil pressure sensors, a monitoring device and a vehicle; each micro FBG soil pressure sensor comprises a hollow cylindrical sleeve, an upper circular diaphragm and a lower circular diaphragm are sealed and pasted on the upper end surface and the lower end surface of each sleeve respectively and seal the inner cavity of the corresponding sleeve, a gate region of an FBG is bonded at the circle center of the lower surface of each upper circular diaphragm, the gate region of each FBG is connected with an optical fiber, and each optical fiber passes through the wall surface of the corresponding sleeve; the vehicle comprises a strip-shaped body, the front end of the body is sharp,the cross section of the body is a square, and multiple grooves used for placing the micro FBG soil pressure sensors are reserved in the body; and the monitoring device comprises an interrogator anddata acquisition and storage equipment, the input terminal of the interrogator is connected with each micro FBG soil pressure sensor by virtue of the corresponding optical fiber, and the output terminal of the interrogator is connected with the data acquisition and storage equipment. The invention also comprises a production method of the micro FBG soil pressure sensors of the mechanical characteristic monitoring device for the substructure of the G-series high-speed train and a test method for monitoring mechanical characteristics of the substructure of the G-series high-speed train.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com