Mechanical characteristic monitoring device for substructure of G-series high-speed train as well as application method and production method thereof

A high-speed railway foundation and monitoring device technology, which is applied in the direction of measuring devices, railway signals and safety, and the measurement of the change force of optical properties of materials when they are stressed, can solve the problem of high environmental requirements, susceptibility to electromagnetic radiation, inability to Use and other problems to achieve the effect of effective and reliable experimental data and small overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

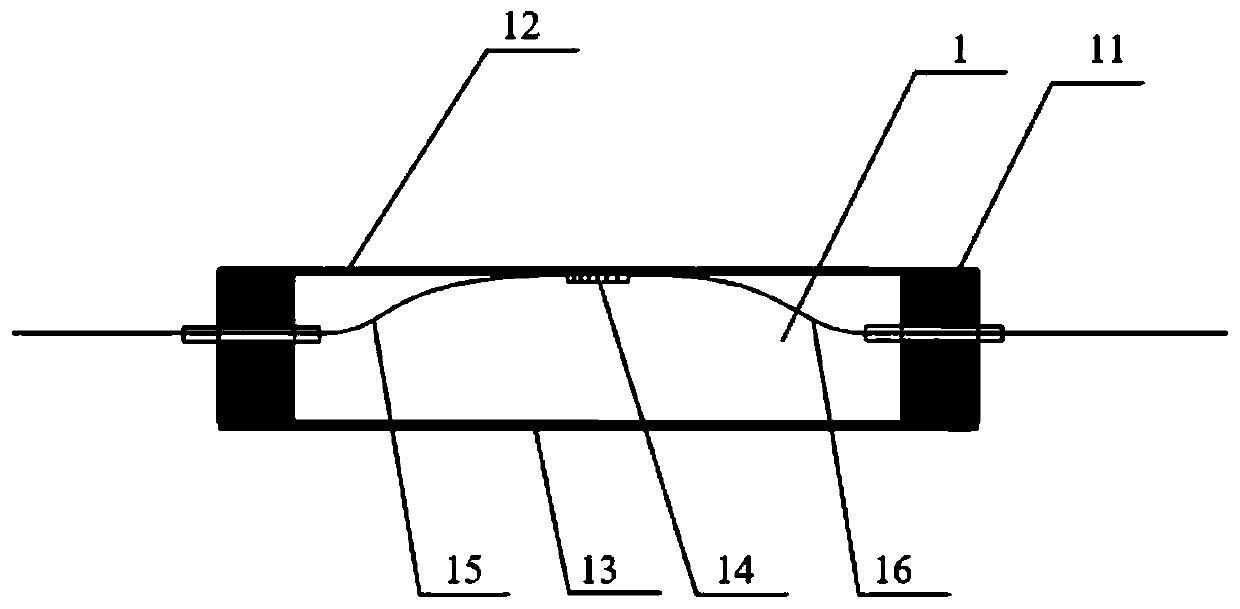

[0043] The high-speed railway subgrade force characteristic monitoring device of the present invention includes a miniature FBG earth pressure sensor 1, a monitoring device, and a carrier 2;

[0044] The miniature FBG earth pressure sensor 1 comprises a hollow cylindrical bushing 11, the upper and lower end surfaces of the bushing 11 are respectively sealed with an upper circular diaphragm 12 and a lower round diaphragm 13, which seals the inner chamber of the bushing 11, A FBG gate region 14 is bonded to the center of the lower surface of the upper circular diaphragm 11 , and the FBG gate region 14 is connected to the first optical fiber 15 , and the first optical fiber 15 passes through the wall of the casing 11 .

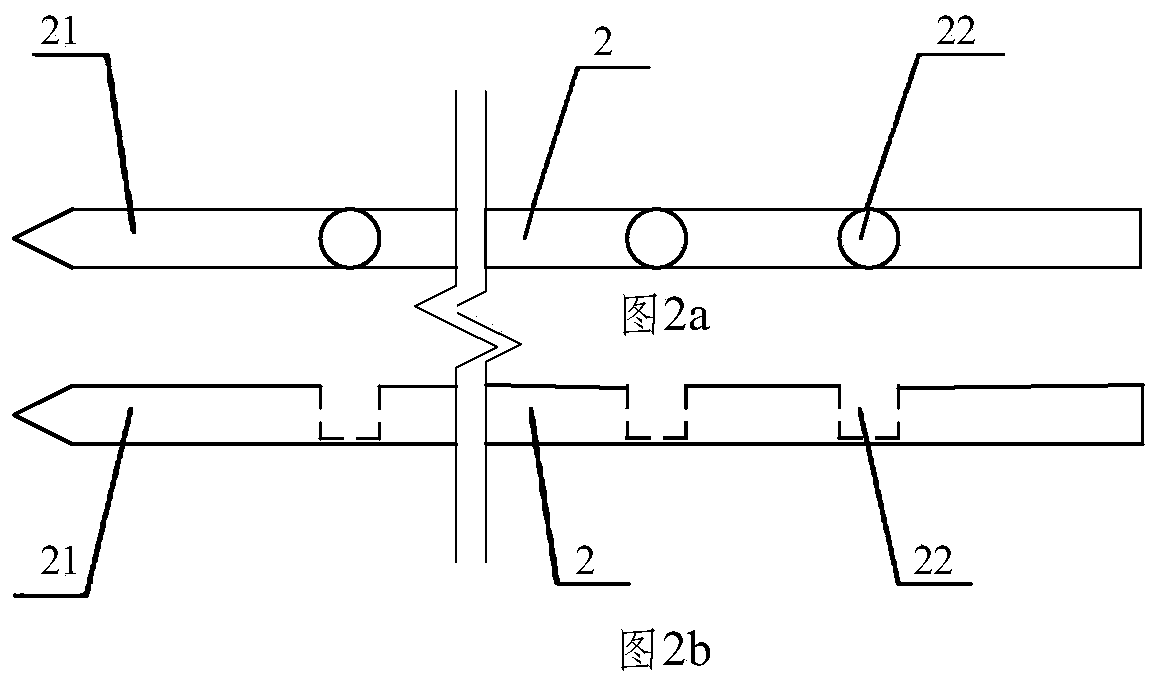

[0045] The carrier 2 includes a strip-shaped body 21 with a sharp front end and a square cross-section. A plurality of grooves 22 for placing miniature FBG earth pressure sensors are reserved on the body 21 .

[0046] The monitoring device includes a demodulator,...

Embodiment 2

[0052] The manufacturing method of miniature FBG earth pressure sensor of the present invention comprises the following steps:

[0053] 1) Clean the lower surface of the circular diaphragm: wipe the lower surface of the circular diaphragm with 99% absolute ethanol. Stainless steel materials will be covered with a lot of oil during the delivery and storage process. These oils will affect the effect of the adhesive on the lower surface of the circular diaphragm and the FBG, and then affect the entire measurement result;

[0054] 2) Determine the center of the lower surface: In order to ensure that the gate area of the FBG is pasted to the center of the circular diaphragm, it is necessary to fix the center of the circular diaphragm by drawing two diameter lines on the lower surface of the circular diaphragm with a pencil. Determine the position of the center of the circle;

[0055] 3) Fix the grid area of FBG at the center of the lower surface of the circular diaphragm with ...

Embodiment 3

[0060] The test method for monitoring the stress characteristics of the high-speed railway foundation using the monitoring device for the stress characteristics of the high-speed railway foundation of the present invention comprises the following steps:

[0061] 1) Determine the monitoring point for the mechanical characteristics of the high-speed railway foundation, and make a corresponding length of miniature FBG earth pressure sensor carrier for the measuring point and open a hole.

[0062] 2) Use the drilling device to drill at the height of the monitoring point of the high-speed railway foundation: ensure that the drilling speed is not too fast during the entire drilling process, so as to avoid excessive damage to the high-speed railway foundation.

[0063] 3) Install the miniature FBG earth pressure sensor: place the miniature FBG earth pressure sensor on the carrier, open a hole through the bolt drilling machine, and send the miniature fiber grating sensor carrier into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com