Patents

Literature

150results about How to "Improve etching precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

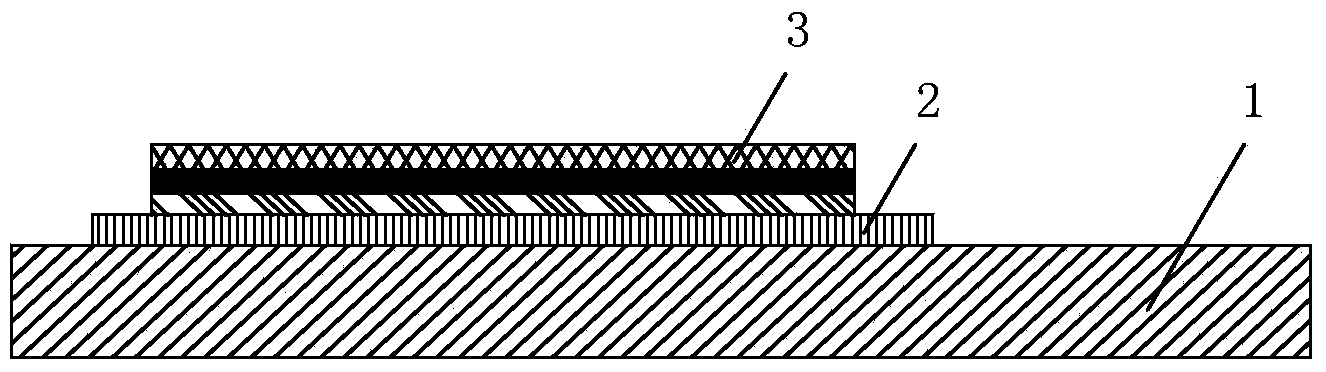

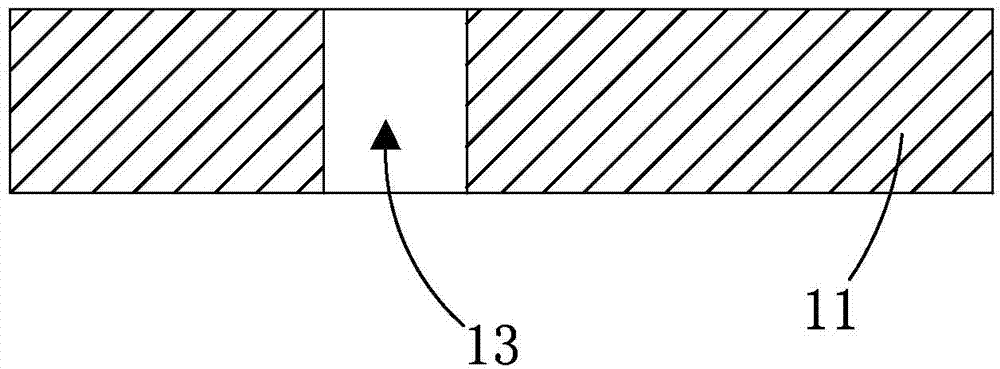

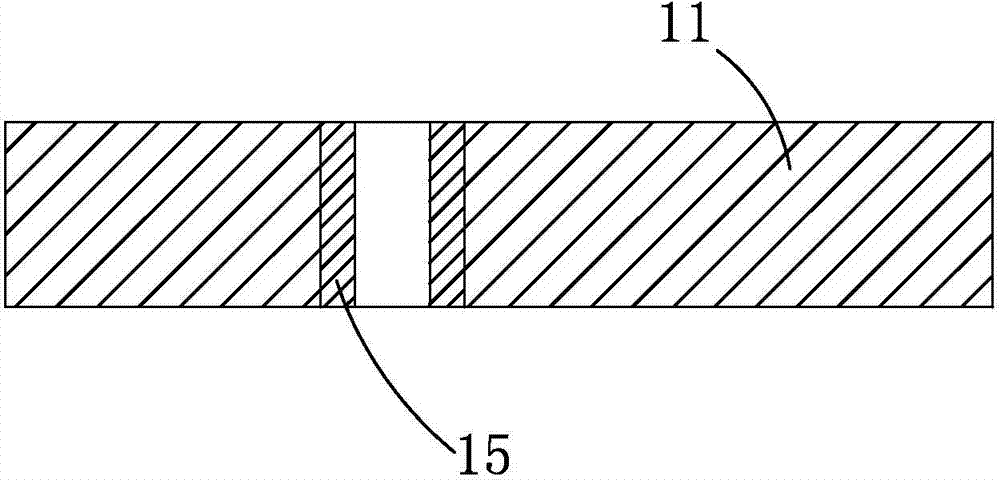

Miniature light emitting diode lamp panel, manufacturing method thereof, backlight module and display device

ActiveCN109449259AEasy maintenanceReduce manufacturing costSolid-state devicesNon-linear opticsIntegrated circuitPrinted circuit board

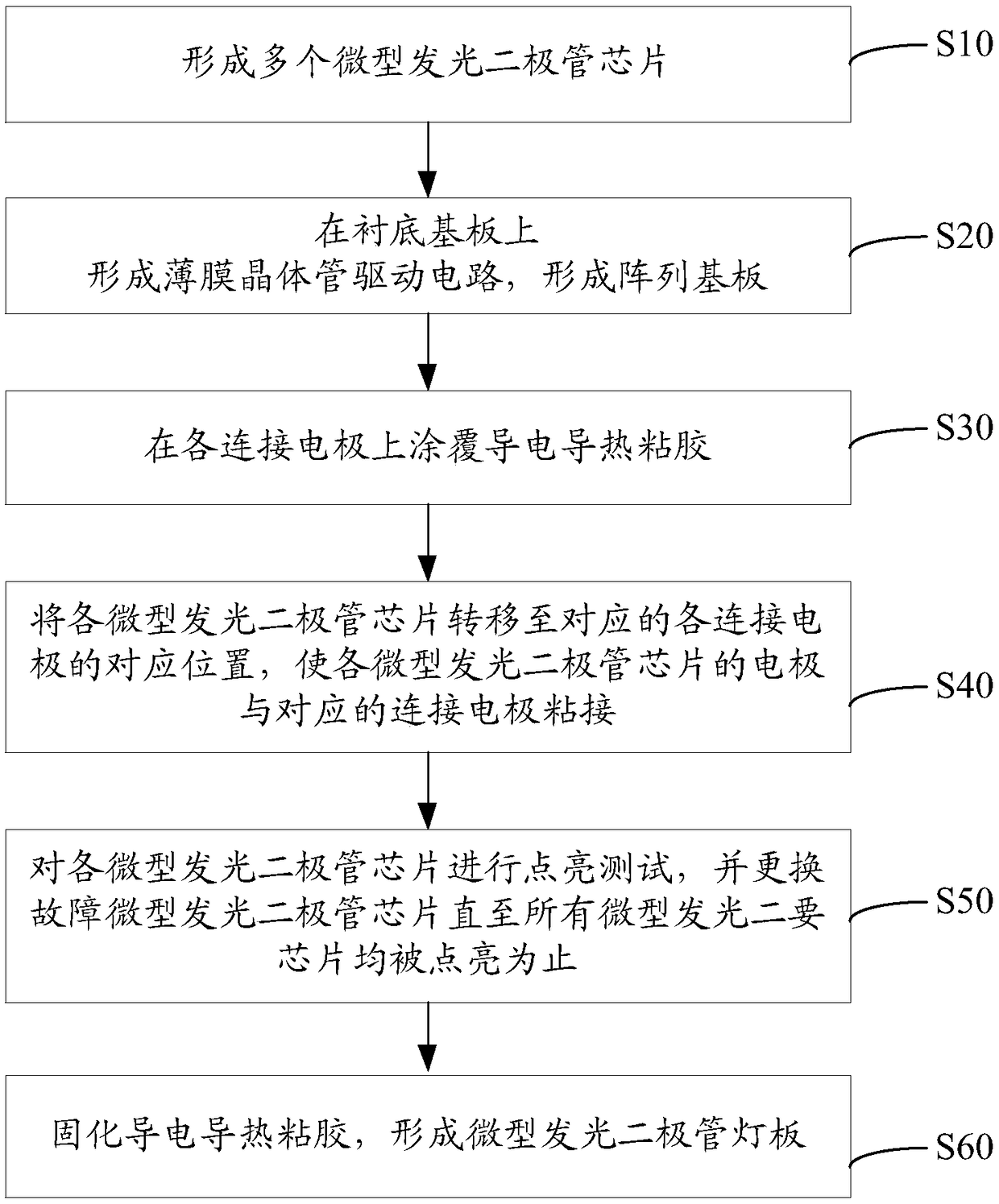

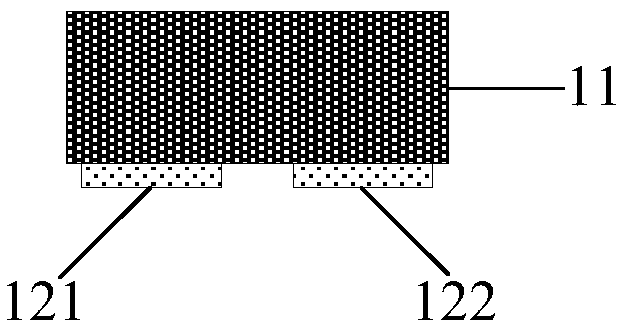

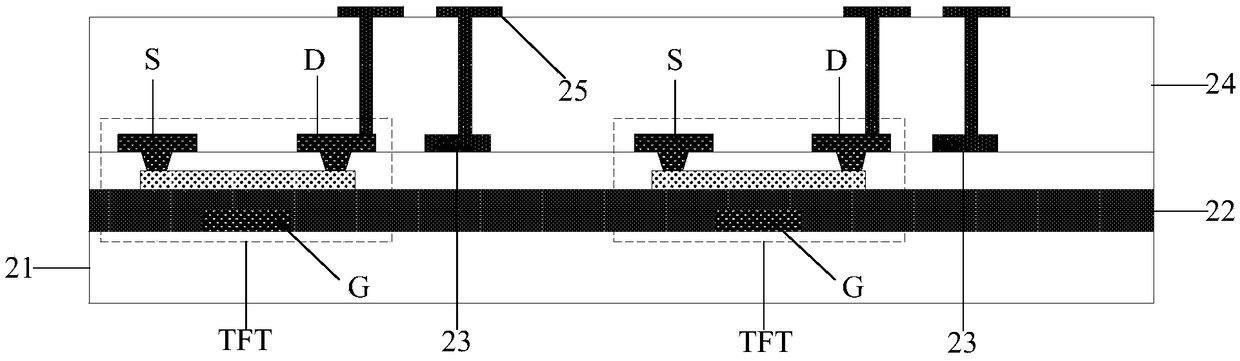

The invention discloses a miniature light emitting diode lamp panel, a manufacturing method thereof, a backlight module and a display device. A thin film transistor array substrate is used to replacea PCB (Printed Circuit Board) in the prior art. The thin film transistor is characterized in that a large scale semiconductor integrated circuit is manufactured on a glass substrate, and film layers of a generation circuit are formed by sputtering, chemical vapor deposition and other processes, so that the manufacturing cost is lowered, and the etching accuracy is much higher than that of the PCB.During manufacturing of the lamp panel through combination of the thin film transistor array substrate and a miniature light emitting diode chip, the miniature light emitting diode chip is bonded with a current-conducting and heat-conducting adhesive, so that the chip with a poor light emitting effect can be replaced; maintenance of lamp panel is facilitated; and the difficulty of maintenance islowered.

Owner:HISENSE VISUAL TECH CO LTD

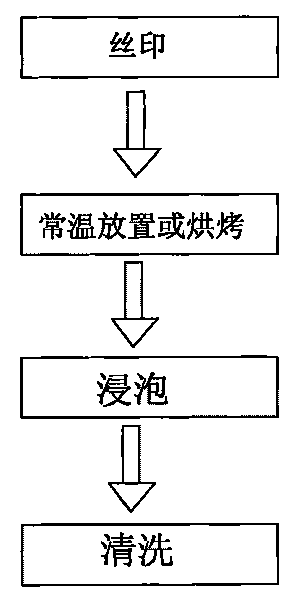

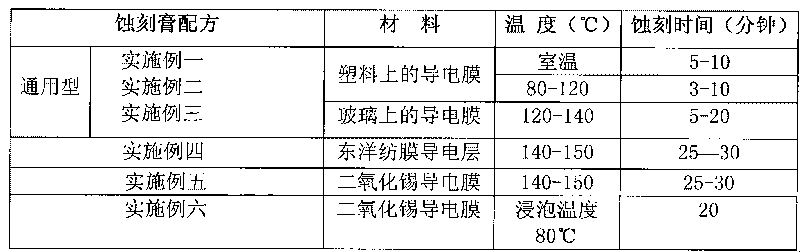

Etching plaster for metal and metal oxide transparent conducting layer and etching process

InactiveCN101717645AEliminate acid and alkali soaking processEliminate the soaking processSurface treatment compositionsEtchingDefoaming Agents

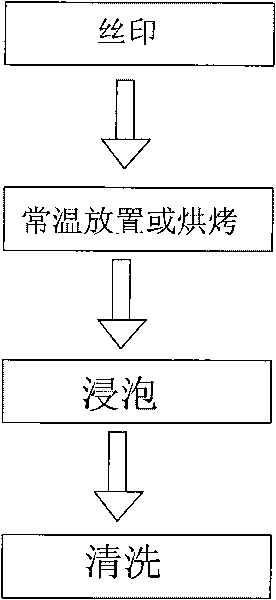

The invention discloses an etching plaster for metal and metal oxide transparent conducting layers and an etching process, in the invention, lagging production processes, such as the use of organic solvents, strong acid etching and strong alkaline cleaning and the like, are not used any longer, instead, the etching plaster and the etching process which do not pollute the environment are used. The etching plaster comprises the following components in parts by weight: 0.1-20 parts of salt substance, 2-50 parts of non-volatile acid, 10-30 parts of aqueous high molecular polymer, 0.1-10 parts of dilute wetting dispersant, 0.1-5 parts of defoamer, 10-40 parts of thickening agent, 0.1-10 parts of bacteriostat and 2-30 parts of water. The invention simplifies the process flow, cancels acid and alkali soaking and the use of organic solvents, lowers the environmental protection cost, improves the etching quality of products, and has the effects of high efficiency, energy saving and environmental protection. The invention is widely applied to the fields of electron, semiconductors, fine chemistry industry and the like.

Owner:张林

Plasma etching process

ActiveUS20150228495A1Easy to controlImprove etching precisionSemiconductor/solid-state device manufacturingReactive gasGas plasma

A method and system are provided for etching a layer to be etched in a plasma etching reactor, including: forming a reactive layer by injection of at least one reactive gas to form a reactive gas plasma, which forms, together with the layer to be etched, a reactive layer which goes into the layer to be etched during etching of said layer to be etched, wherein the reactive layer reaches a steady state thickness upon completion of a determined duration of said injection; said injection being interrupted before said determined duration has elapsed so that, upon completion of the forming of the reactive layer, the thickness of the reactive layer is smaller than said steady state thickness; and removing the reactive layer by injection of at least one inert gas to form an inert gas plasma, which makes it possible to remove only the reactive layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

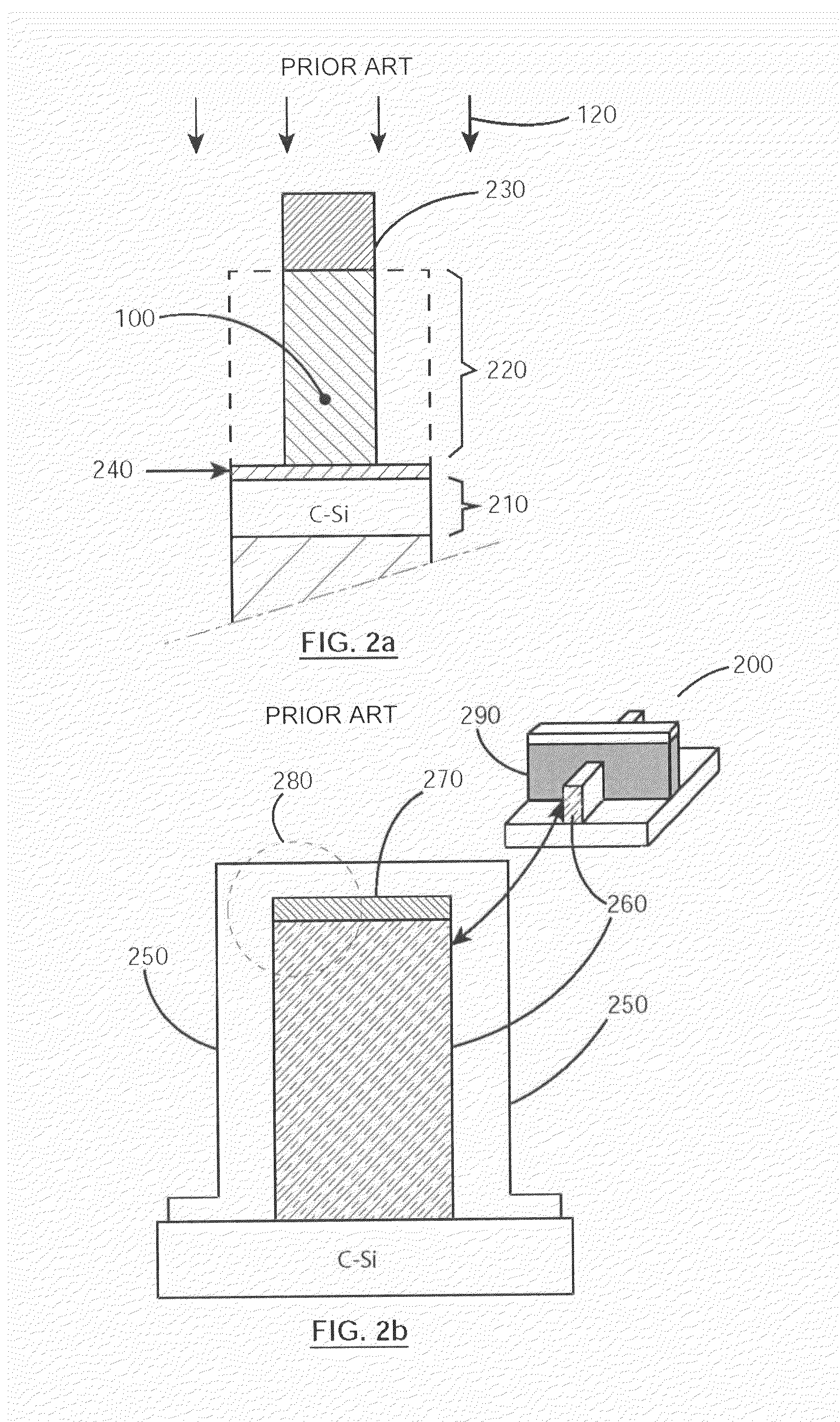

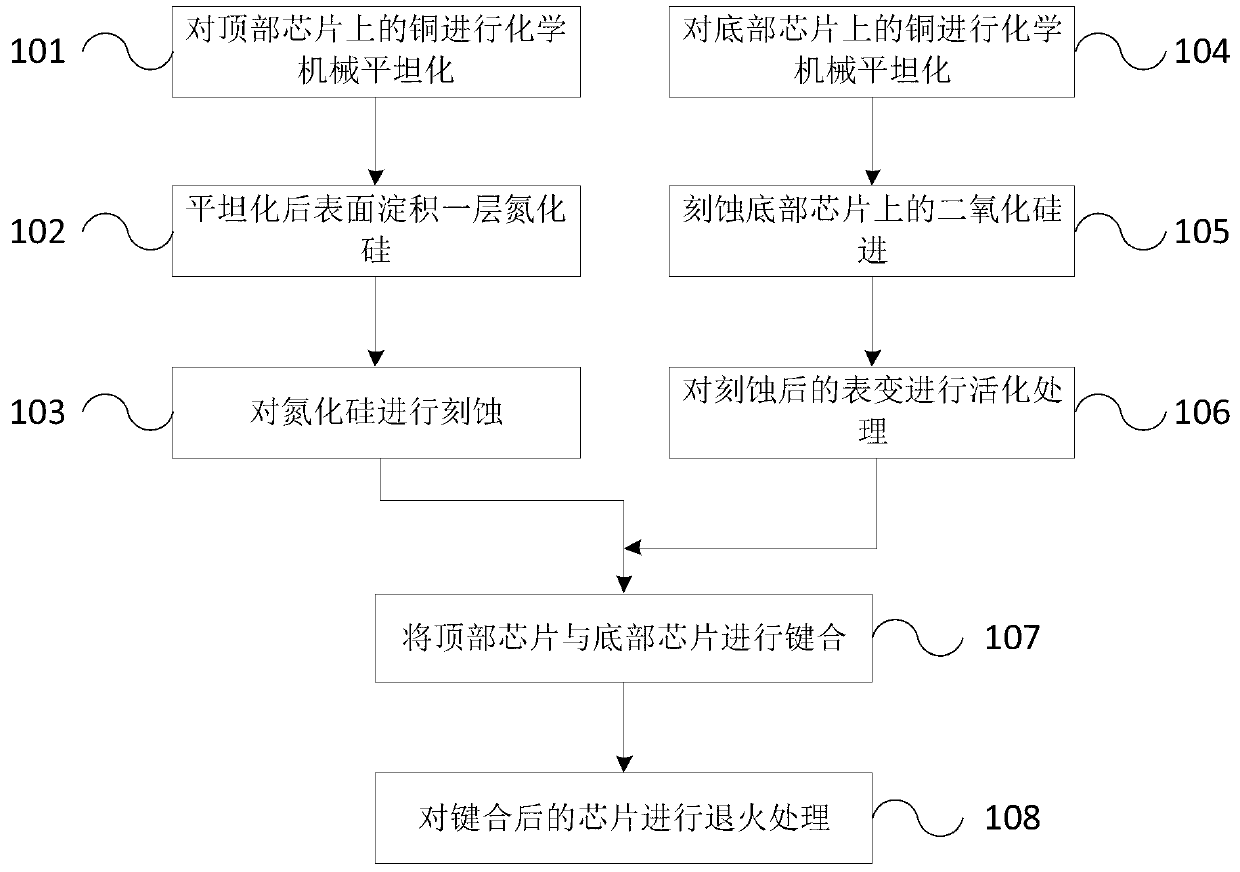

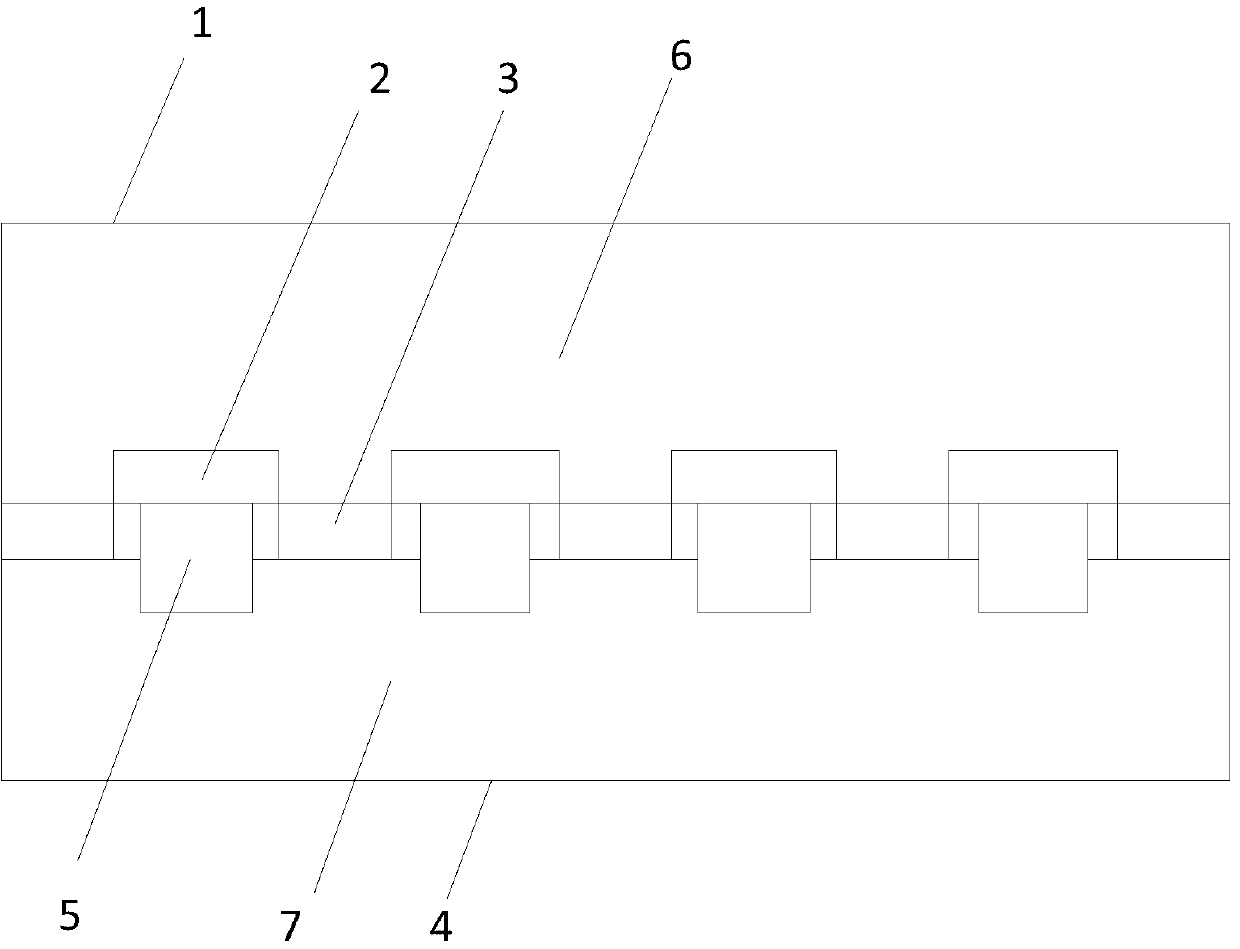

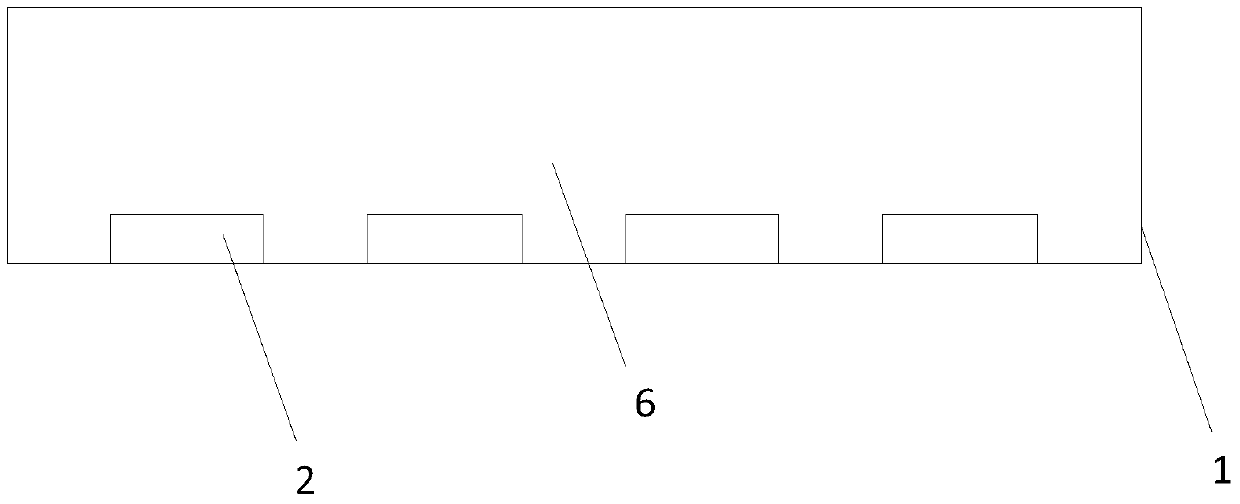

Metal bonding method of three-dimensional chip structure and bonding structure

ActiveCN103107128AStop the spreadImprove bonding qualitySemiconductor/solid-state device detailsSolid-state devicesBond qualityThin layer

The invention relates to the field of semiconductor fabrication, in particular to a metal bonding method of a three-dimensional chip structure and a bonding structure. The method comprises that copper of a top chip is processed in a chemical machinery planarization mode, a silicon nitride layer is deposited on the surface after being processed in a chemical machinery planarization mode, the silicon nitride layer attached to the copper of the top chip is etched, a groove is formed, the bottom of the groove is the copper of the top chip, copper of a bottom chip is processed in a chemical machinery planarization mode, a bottom silica layer is etched, the copper is enabled to be protruded, activating treatment is carried out to the surface after etch of the copper of the bottom chip is achieved, the copper of the top chip and the copper of the bottom chip are aligned and bonded, and annealing treatment is carried out to the chips after being bonded. According to the metal bonding method of the three-dimensional chip structure and the bonding structure, silicon oxide and silicon nitride are used for being matched with metal and metal bonding, bonding quality is enabled to be better, a silicon nitride layer thin layer can prevent the metal from diffusing into around materials, and goals that a technology process is simplified, temperature needed by bonding is reduced, bonding reliability is improved, bonding efficiency is improved, and bonding cost is reduced can be achieved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

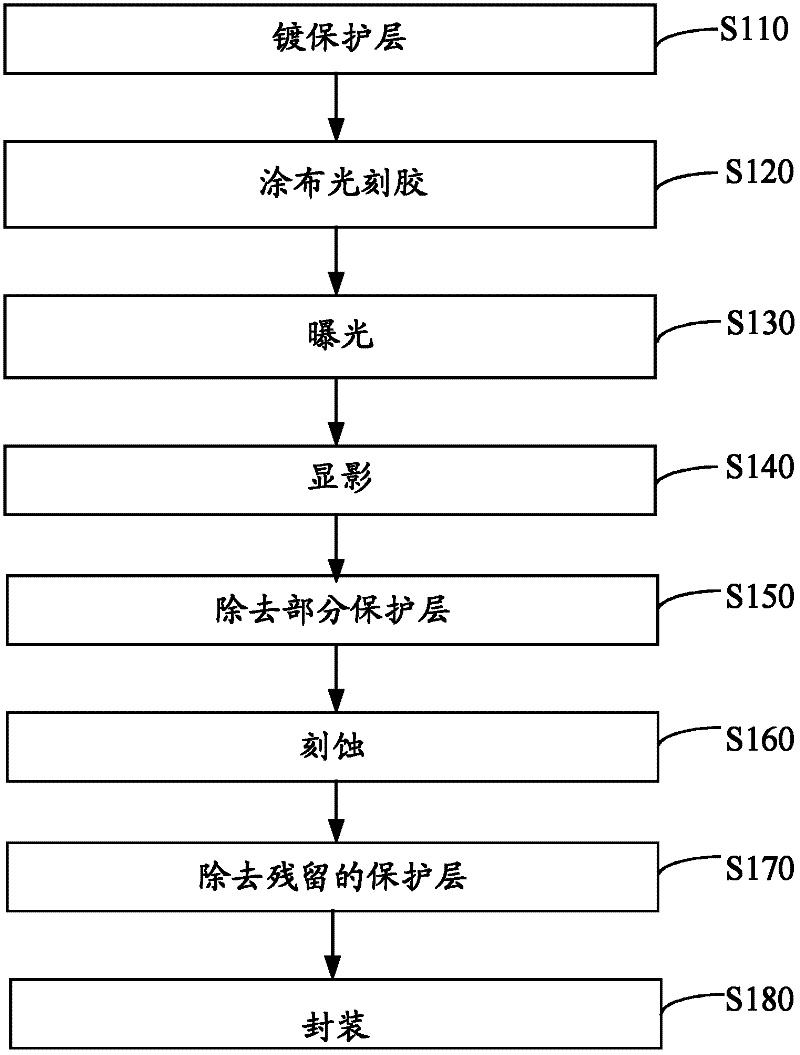

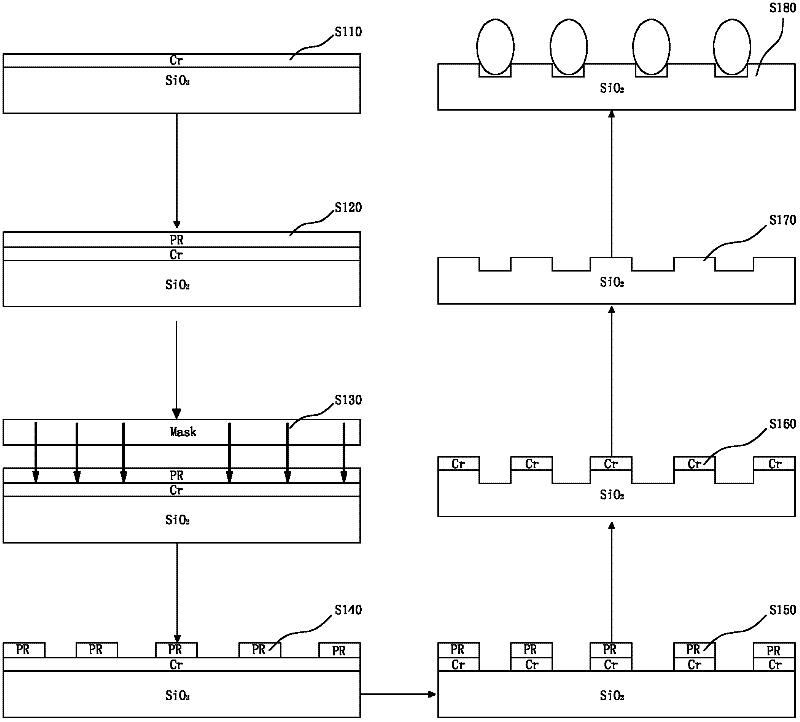

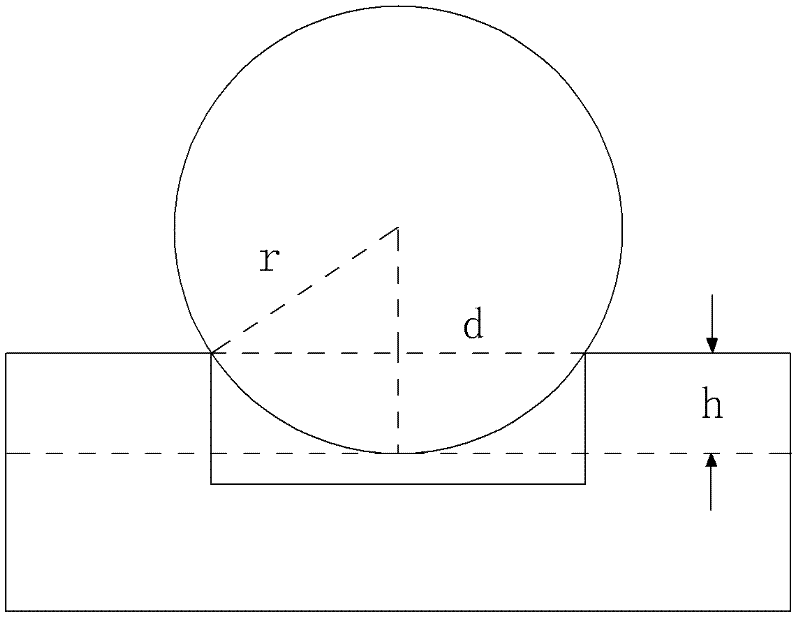

Critical method for manufacturing fiber array by semiconductor technology

InactiveCN102520482AOvercome the same sexImprove uniformityPhotomechanical apparatusOptical light guidesPhotoresistResist

The invention discloses a critical method for manufacturing a fiber array by a semiconductor technology. The method comprises the following steps of: plating a protective layer on a base plate; coating optical resist on the protective layer; exposing the optical resist; developing to remove a light-transmittable part in the optical resist; removing the part, which is not covered by the optical resist, in the protective layer; etching a U-shaped groove on the base plate by a dry etching technology; removing the protective layer remained on the base plate to get a fiber array location base plate; arranging fibers on the fiber array location base plate to form a fiber ribbon, and packaging the fiber ribbon to get the fiber array. By the dry etching technology, the high-precision U-shaped groove can be etched, and the fibers are located by the U-shaped groove, so that location precision of the fibers is improved, mean error of displacement is reduced greatly, and precision of the manufactured fiber array reaches 0.1 micrometer, thus, loss of optical signals is reduced, and the uniformity of the optical signals is improved.

Owner:SHENZHEN GIGALIGHT TECH

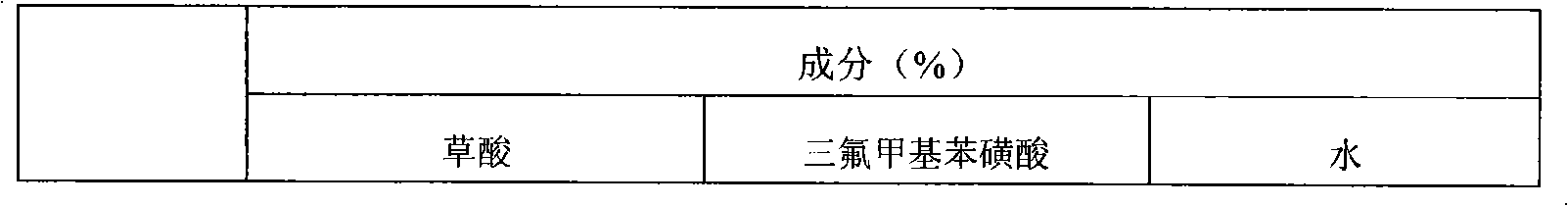

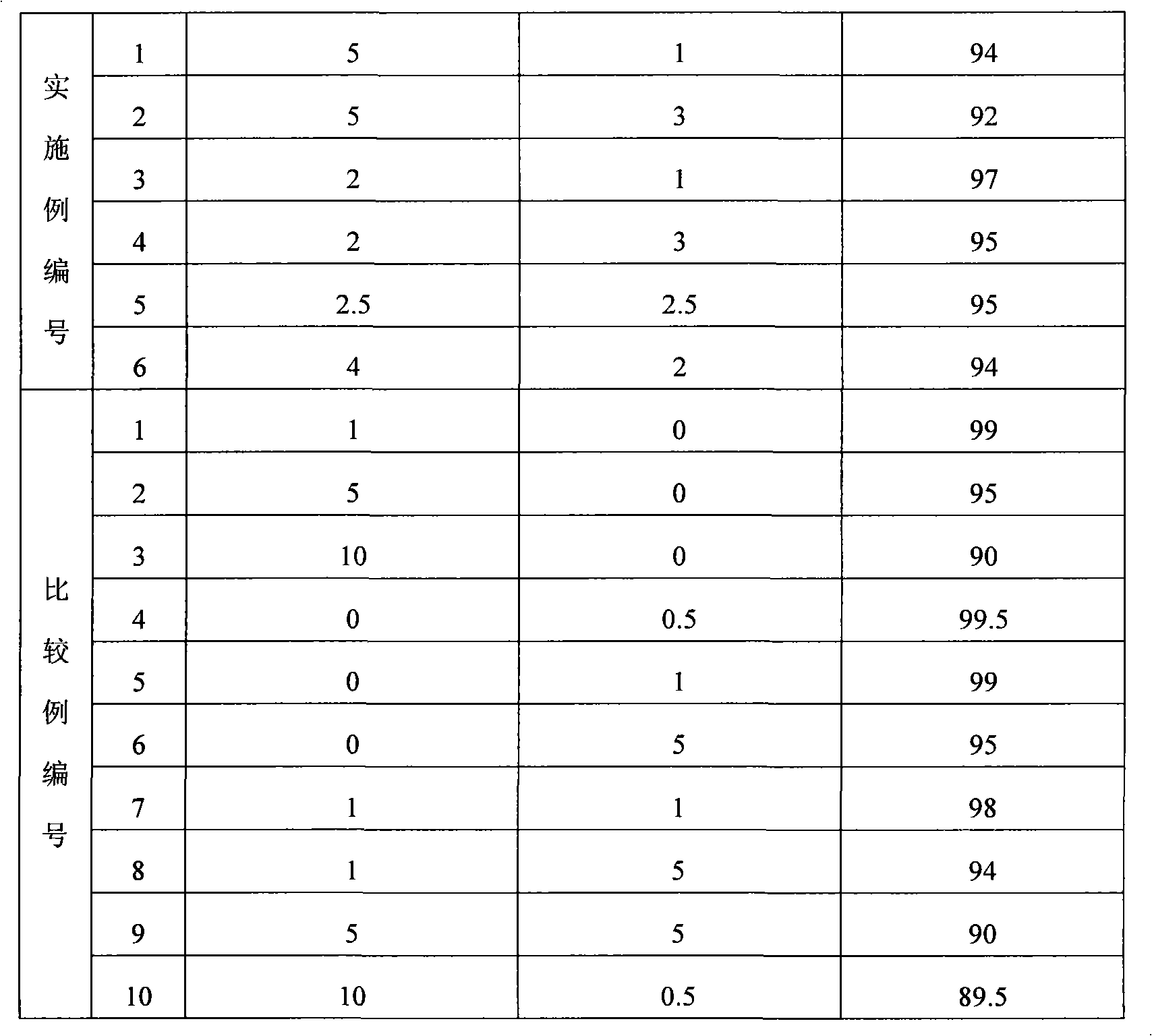

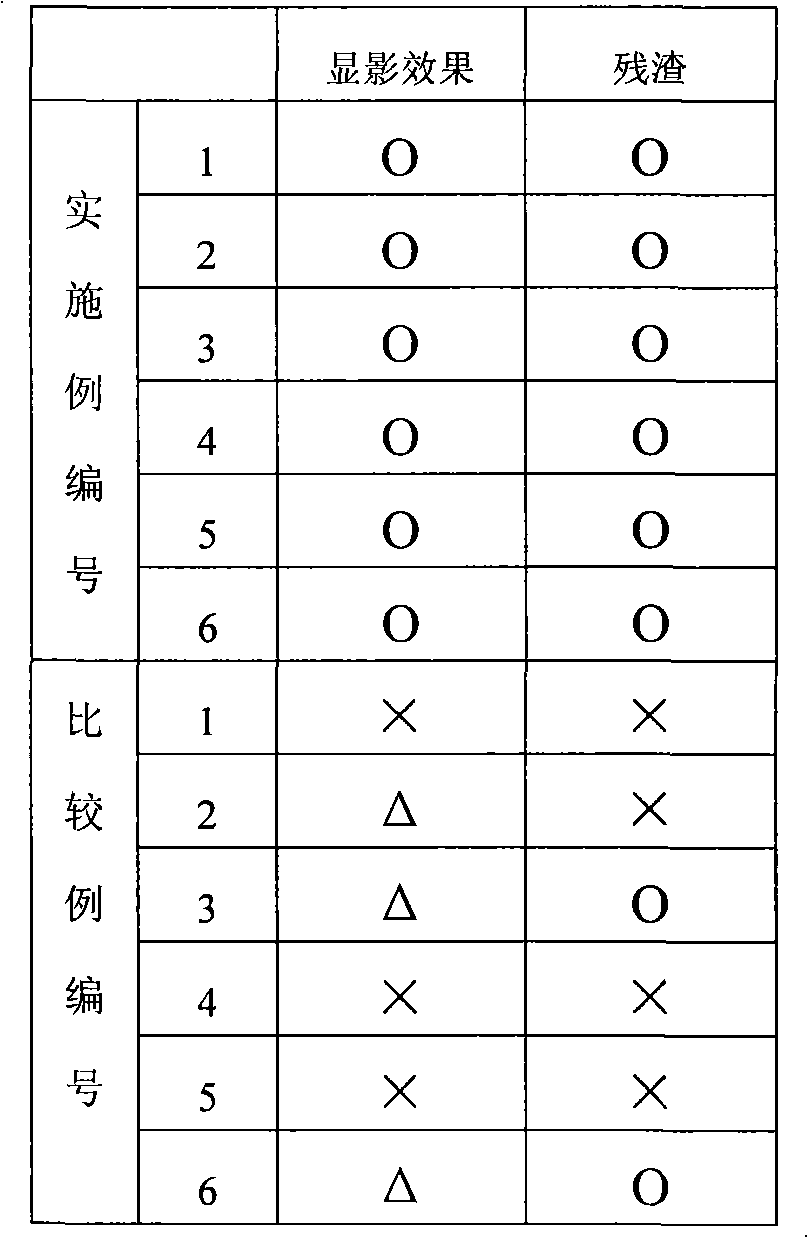

Etching liquid for flat panel display

The present invention discloses an etching liquid for the flat panel display. The etching liquid comprises oxalic acid, trifluoromethyl benzenesulfonic acid and water. The using amount of the oxalic acid is 1-10% of the total weight of the etching liquid. The using amount of the trifluoromethyl benzenesulfonic acid is 0.5-5% of the total weight of the etching liquid, and the balance is water. The invention provides the etching liquid for the flat panel display, which has the advantages of high efficiency, high etching precision and no pungent odour. The etching liquid is used for etching the ITO transparent conductive film. The adopted oxalic acid and the trifluoromethyl benzenesulfonic acid are organic acids. The compound composed of the two organic acids is not easily volatilized and has excellent wetting quality. When used as the ITO conductive film etching liquid, the etching liquid compound has the characteristics of excellent etching performance, no residue, less environmental pollution, etc.

Owner:HEFEI MAOTENG ENVIRONMENTAL PROTECTION TECH CO LTD

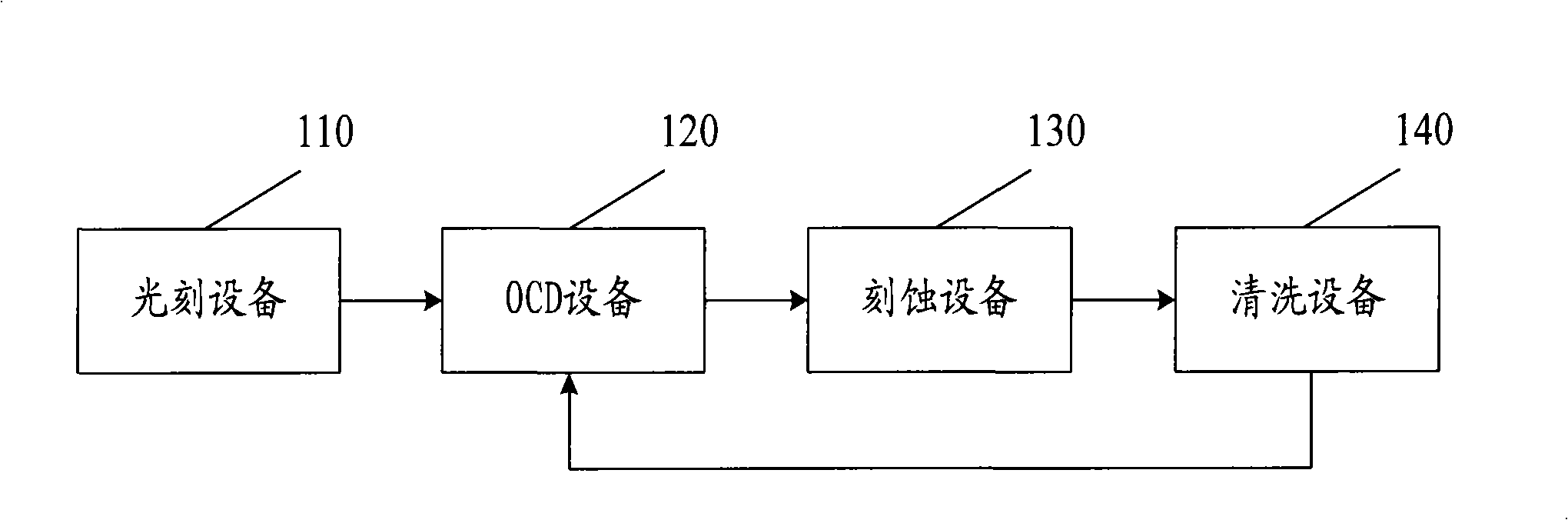

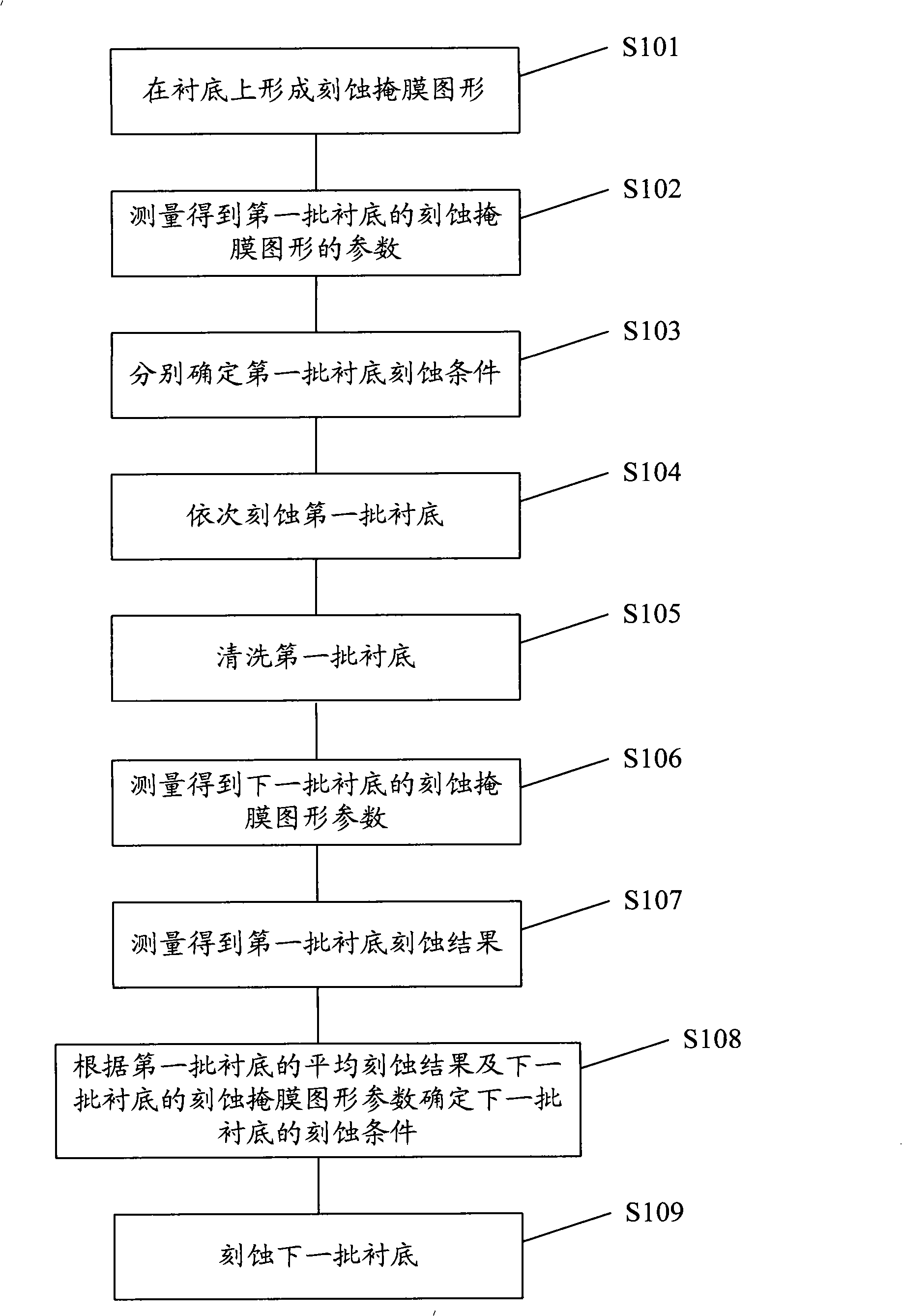

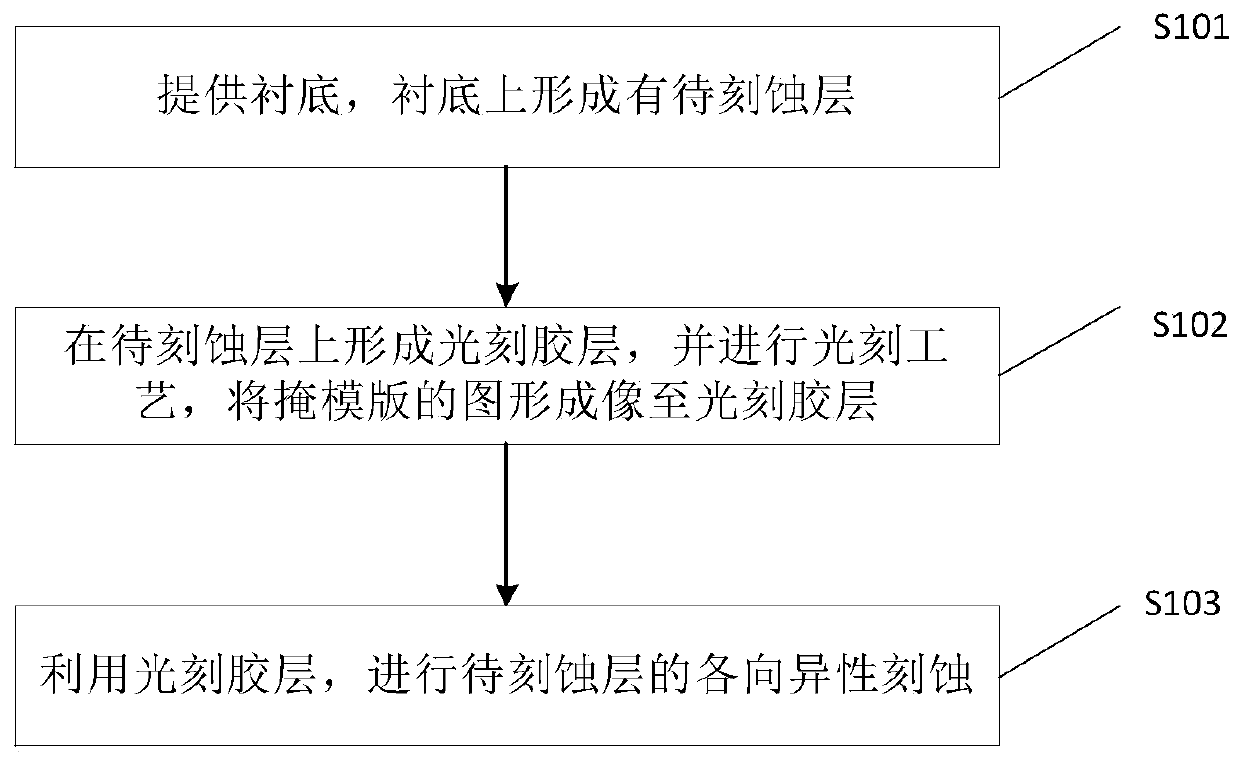

Etching method

ActiveCN101329986APrevent deviationEasy to controlSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEtchingControl force

The invention discloses an etching method which includes the steps that a former substrate is etched; the etching mask pattern of a latter substrate is detected; the etching pattern of the former substrate is detected; according to the detection results of the etching pattern of the former substrate and the etching mask pattern of the latter substrate, the etching condition of the next substrate is determined; based on the etching condition of the latter substrate, the latter substrate is etched. The etching method of the invention can further improve the controlling force of an etching technology and the precision of etching.

Owner:SEMICON MFG INT (SHANGHAI) CORP

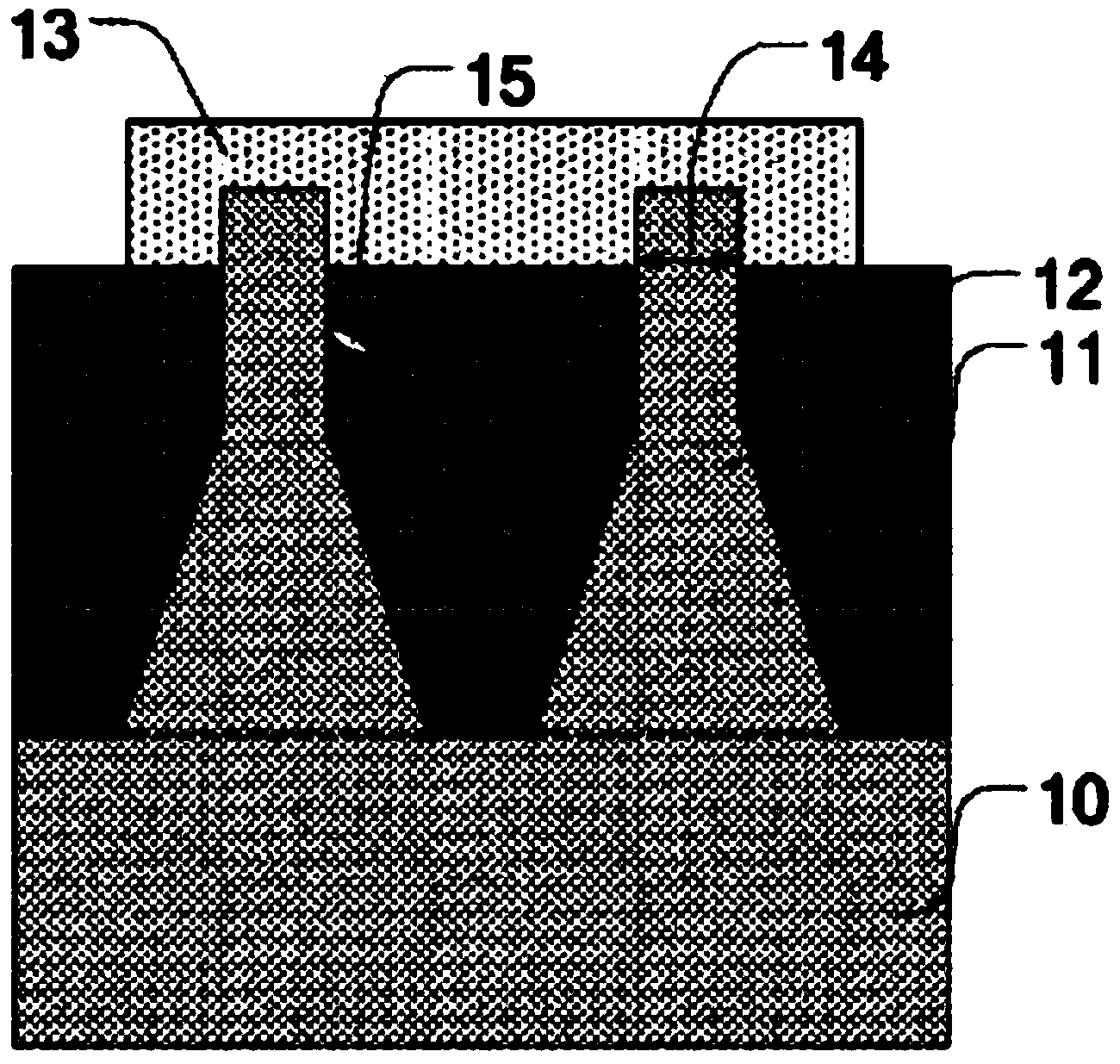

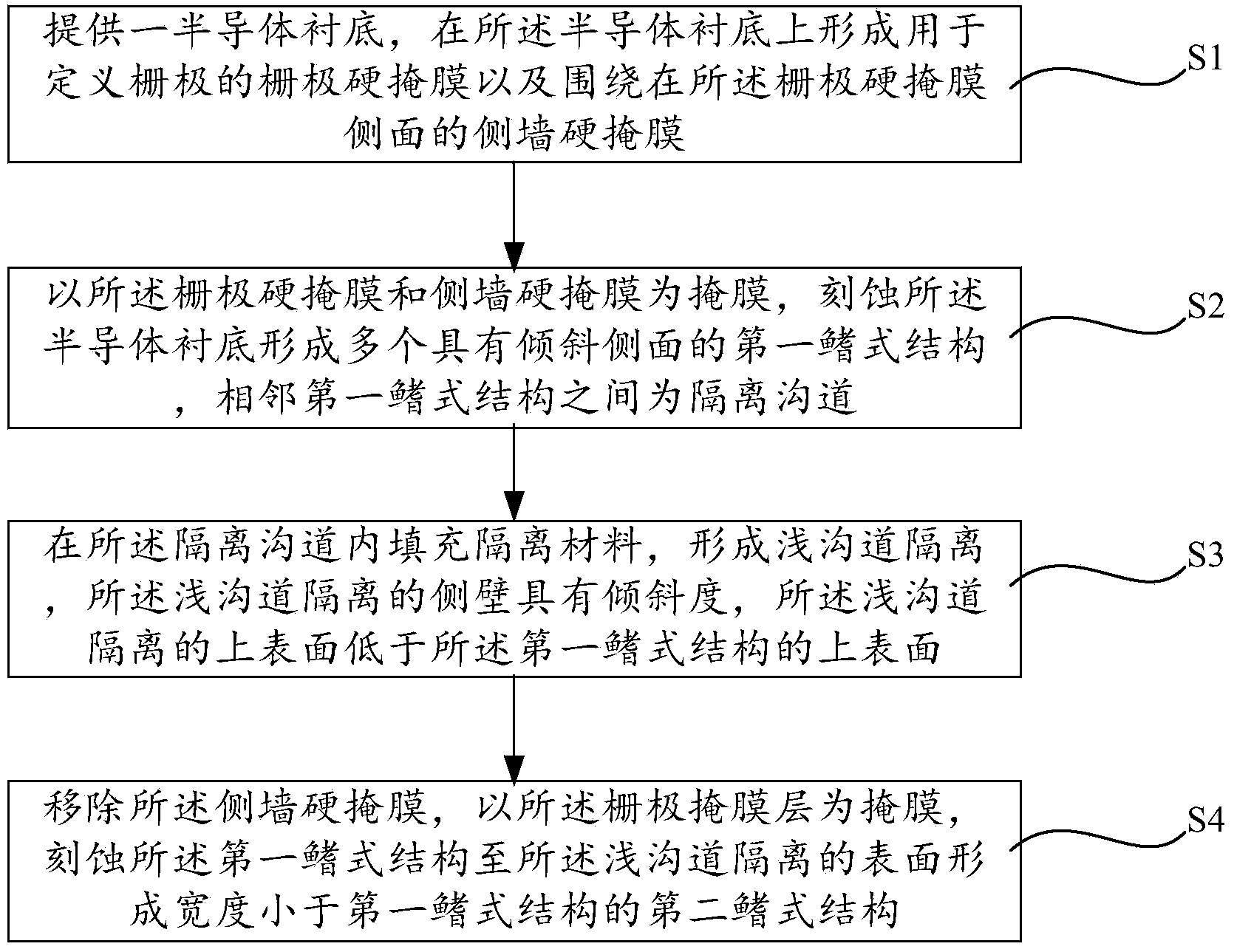

Method for manufacturing fin field effect transistor

InactiveCN104037088AReduce gapGap problemSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorEngineering

The invention provides a method for manufacturing a fin field effect transistor. The method includes forming a grid hard mask used for positioning a grid and a side wall hard mask surrounding the side face of the grid hard mask on a semiconductor substrate; by utilizing the side wall hard mask as a self-aligning hard mask, enabling the semiconductor substrate to form first fin structures with inclined side faces, forming shallow groove isolators among the first fin structures , removing the side wall hard mask, performing second-time etching, and finally acquiring the fin field effect transistor where the upper portion and the lower portion are different in width. The side faces of the fin structures are inclined when the shallow groove isolators are formed in a filling oxidation layer, so that filling process windows are increased, filling gaps are reduced, and device performance is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

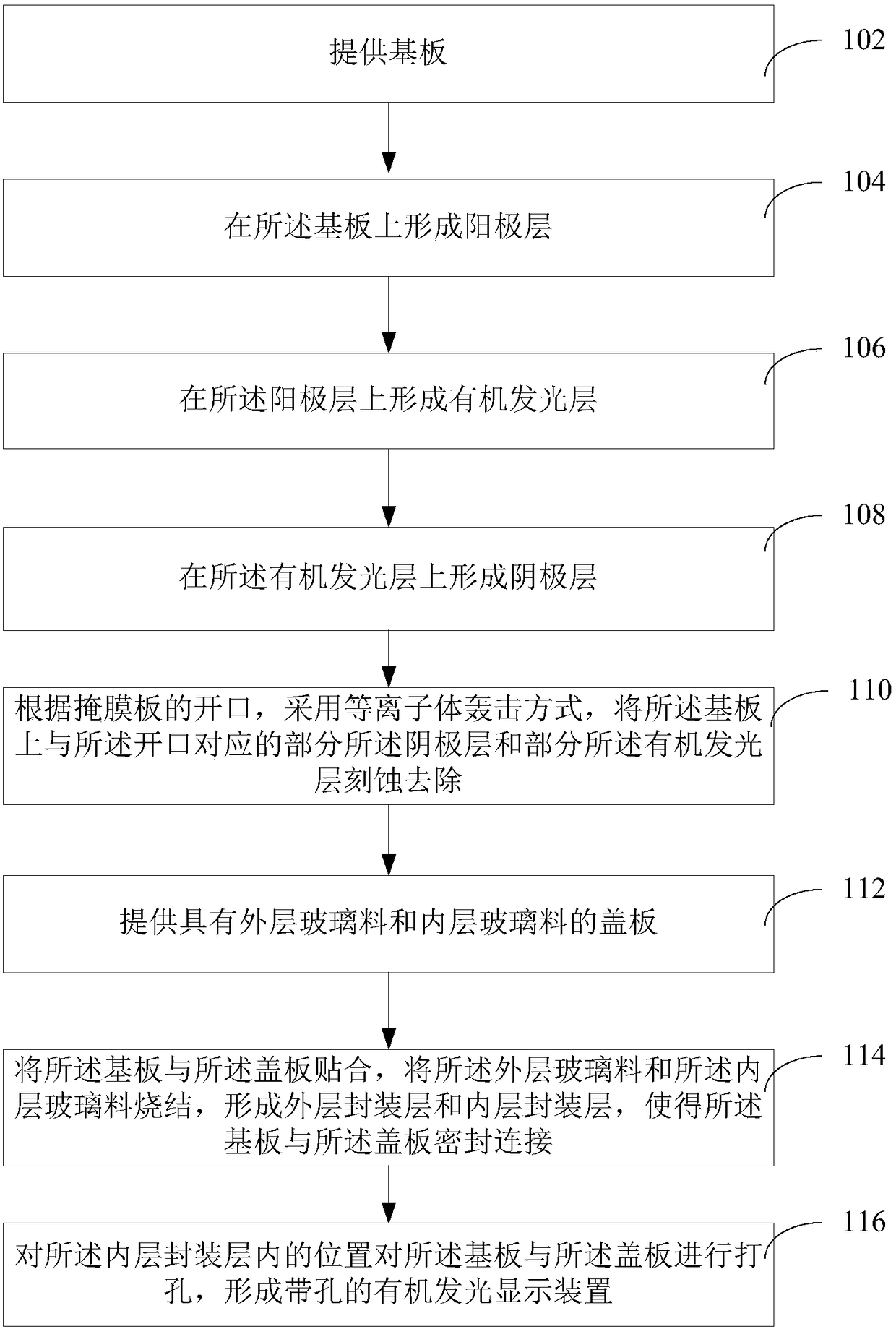

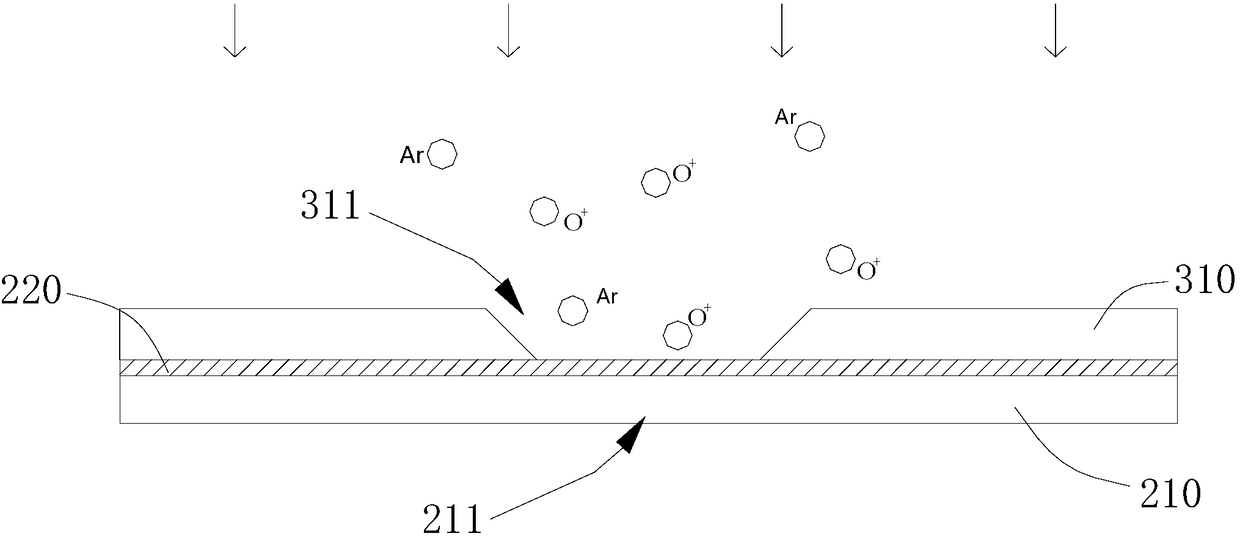

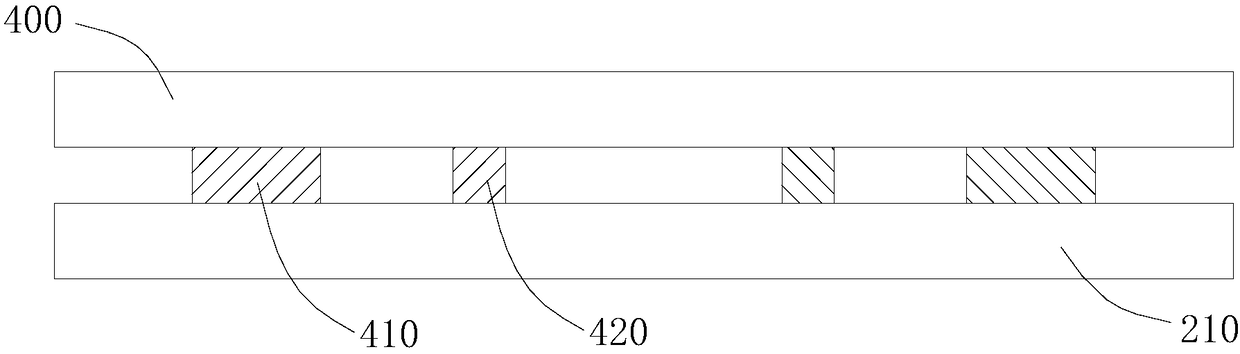

Organic light-emitting display apparatus and preparation method thereof

InactiveCN108206244AEfficient etchingWon't burnSolid-state devicesSemiconductor/solid-state device manufacturingEtchingChemistry

The invention relates to an organic light-emitting display apparatus and a preparation method thereof. The preparation method comprises the steps of providing a substrate; forming a positive electrodelayer on the substrate; forming an organic light-emitting layer on the positive electrode layer; forming a negative electrode layer on the organic light-emitting layer; removing a part of the negative electrode layer and a part of the organic light-emitting layer which are corresponding to an opening in the substrate through etching by adopting a plasma bombardment mode through the opening of a mask plate; providing a cover plate with an outer layer glass material and an inner layer glass material; enabling the substrate to be laminated with the cover plate, and performing sintering on the outer layer glass material and the inner layer glass material to form an outer layer packaging layer and an inner layer packaging layer, and enabling the substrate and the cover plate to be connected ina sealing manner; and performing hole punching on the substrate and the cover plate in the inner layer packaging layer to form the organic light-emitting display apparatus with holes. By virtue of the plasma bombardment mode, more efficient organic material etching can be realized, and higher production efficiency and higher etching precision are achieved; and in addition, scalding to a pixel region can be avoided, the etching cost can be lower and the production cost can be lowered effectively.

Owner:TRULY HUIZHOU SMART DISPLAY

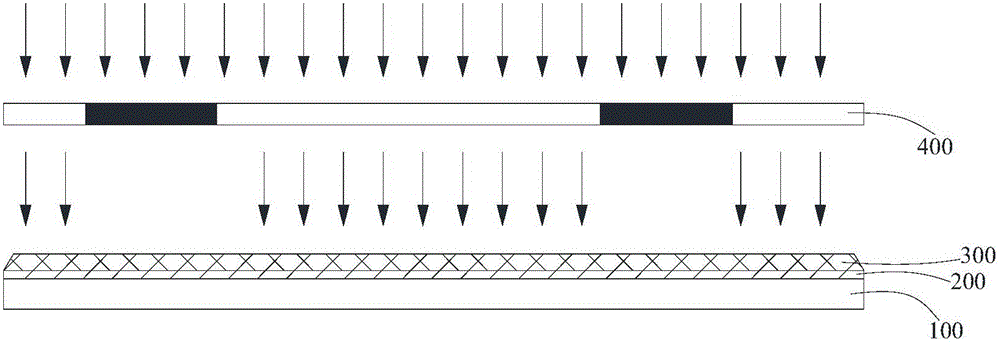

Flexible display panel and manufacturing method thereof

ActiveCN107910349AImprove yield rateAffect displaySolid-state devicesSemiconductor/solid-state device manufacturingEtchingEngineering

The invention discloses a flexible display panel and a manufacturing method thereof so that the possibility of excessive etching in groove hole etching in a non-display area of a flexible display panel can be reduced and thus the etching precision is improved and the yield of the flexible display panel is enhanced. The flexible display panel is composed of a flexible substrate, a buffer layer, a gate insulating layer, an interlayer dielectric layer, a thin-film transistor, an organic electroluminescence element, and an encapsulation layer. The flexible substrate consists of a display area anda non-display area. An etching stop layer is arranged at the display area of the flexible substrate; and the buffer layer, the gate insulating layer, and the interlayer dielectric layer are arranged on the flexible substrate and the etching stop layer successively. At least one etched groove hole is formed in a region, corresponding to the etching stop layer, of each of the buffer layer, the gateinsulating layer, and the interlayer dielectric layer in the non-display area respectively. And the thin-film transistor, the organic electroluminescence element, and the encapsulation layer are arranged on the interlayer dielectric layer in the display area successively.

Owner:BOE TECH GRP CO LTD

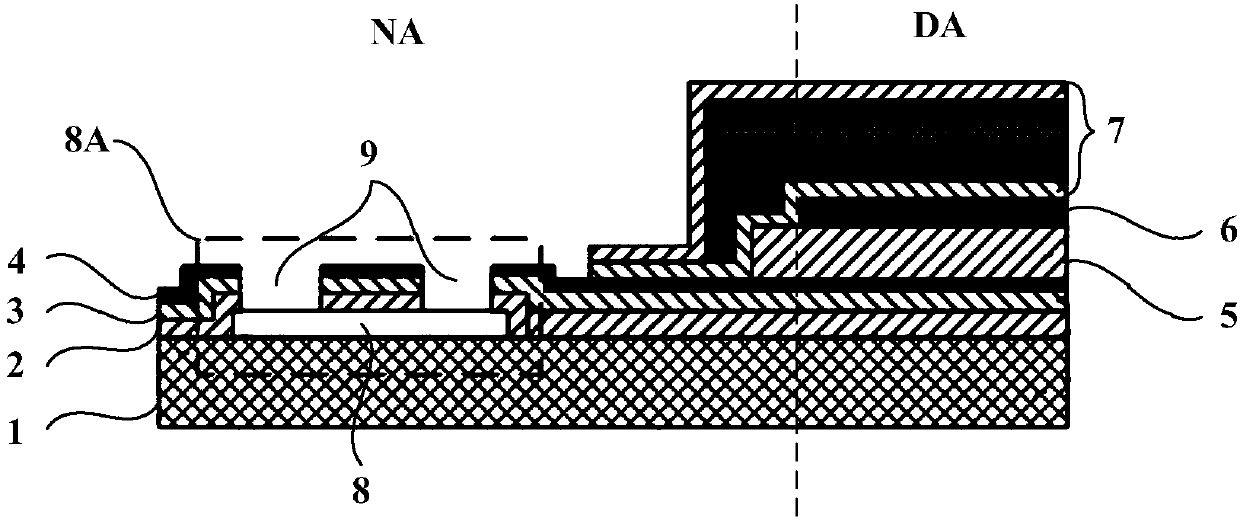

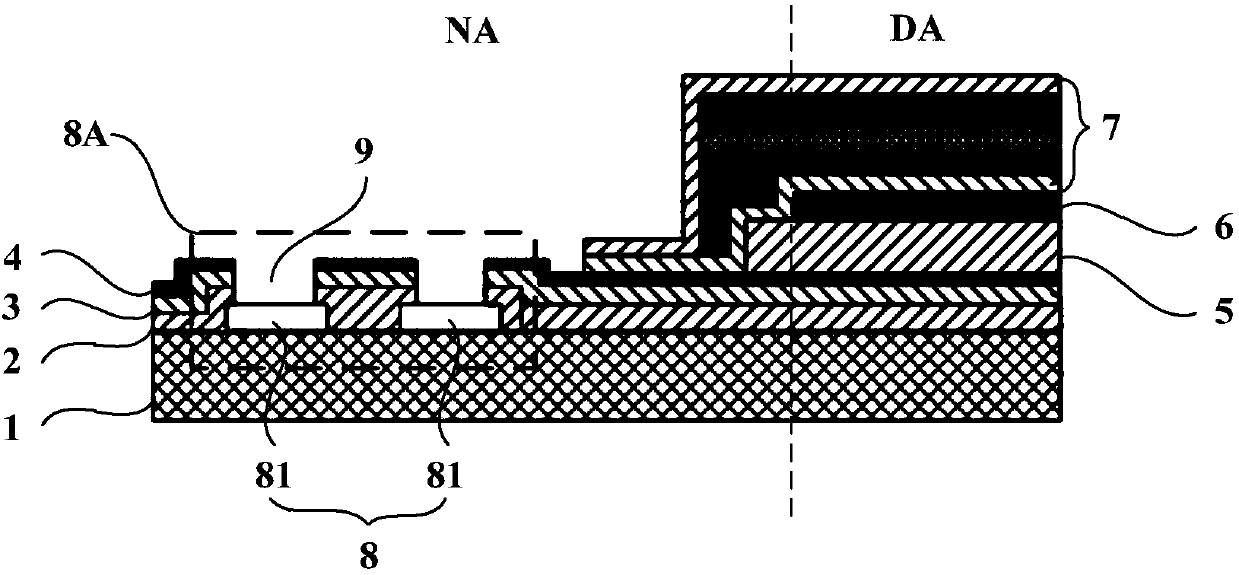

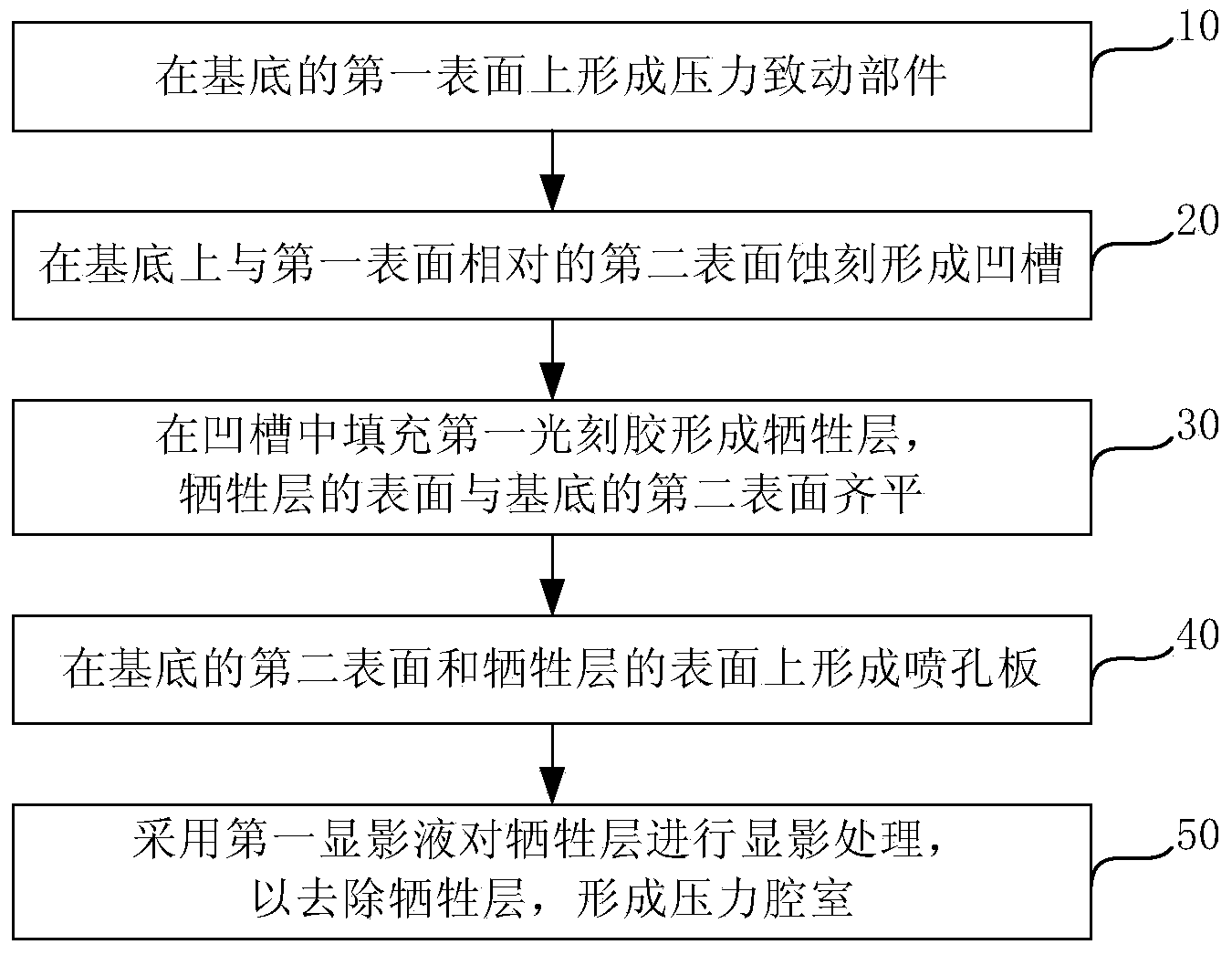

Liquid ejection head manufacturing method, liquid ejection head and printing device

The invention provides a liquid ejection head manufacturing method, a liquid ejection head and a printing device. The method comprises the steps that a pressure actuating part is formed on a first surface of a substrate; a groove is etched on a second surface opposite to the first surface on the substrate; the groove is filled with a first photoresist to form a sacrificial layer; the surface of the sacrificial layer is flush with the second surface of the substrate; orifice plates are formed on the second surface of the substrate and the surface of the sacrificial layer; and a first developer is used to develop the sacrificial layer to remove the sacrificial layer and form a pressure chamber. According to the liquid ejection head manufacturing method, the liquid ejection head and the printing device, which are provided by the invention, the problems that the manufacturing process of the existing liquid ejection head is complex, and the use of an adhesive easily reduces the printing quality are solved.

Owner:DALIAN UNIV OF TECH +1

Method for replacing backdrill copper removal process

InactiveCN104519669AQuality assuranceEasy to control etching depthPrinted circuit manufactureCopper platingEngineering

The invention provides a method for replacing a backdrill copper removal process. The method includes providing a printed circuit board, and drilling the printed circuit board to form a through hole; electroplating the through hole of the printed circuit board after the through hole is drilled to form a metal layer; filling the through hole of the printed circuit board where the metal layer is formed with ink; utilizing a plate grinding machine for grinding to grind off the ink protruding out of a through hole port; pasting a dry film in a copper plated surface area, needless of copper removal, of the printed circuit board with the through hole and after being electroplated, and exposing an area of 3-6mil larger than a single side of the through hole by the dry film; providing an etching line to etch the printed circuit board; repeating the etching step to remove metal filings left in the through hole. The method is high in copper removal efficiency, working process is easy to control, and quality of the printed circuit board is guaranteed.

Owner:SHENZHEN WUZHU TECH

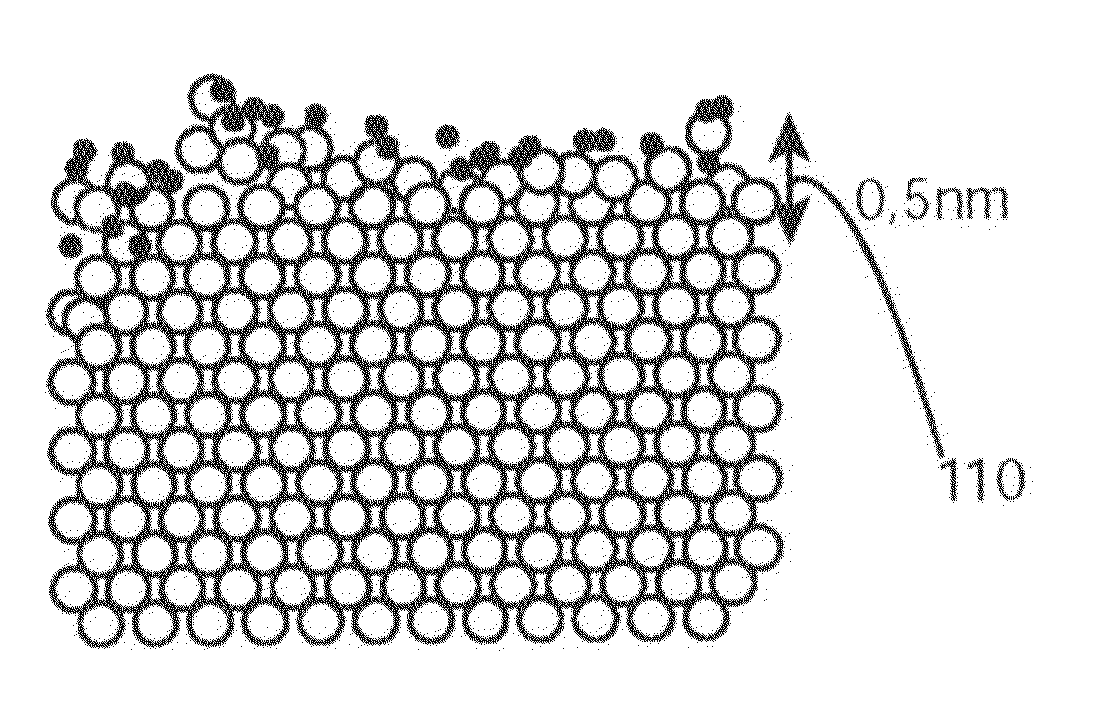

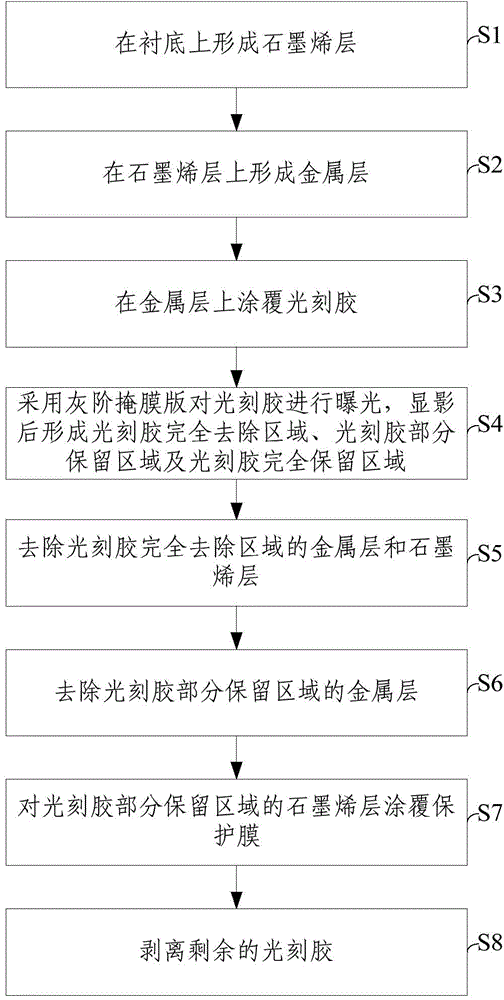

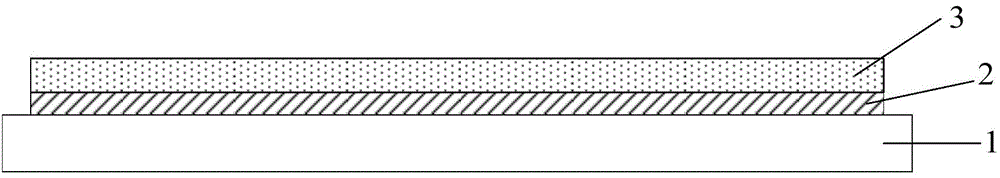

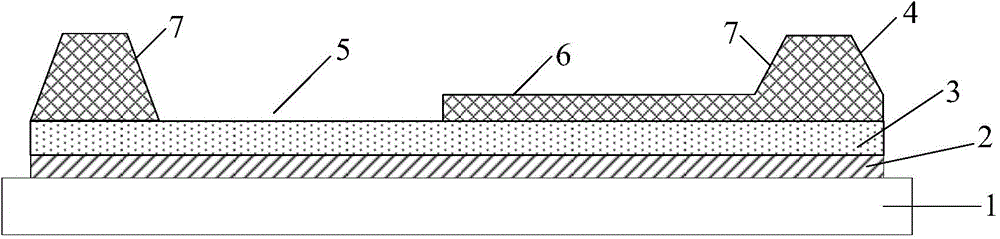

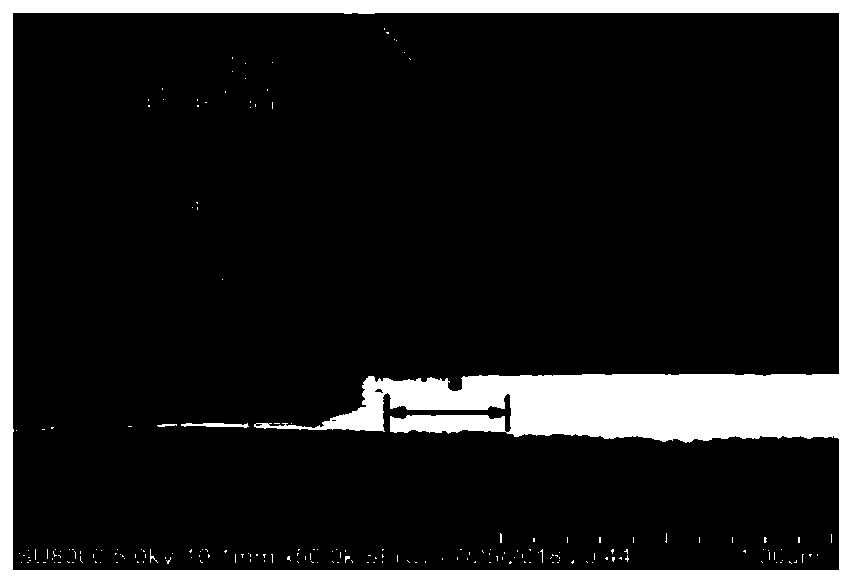

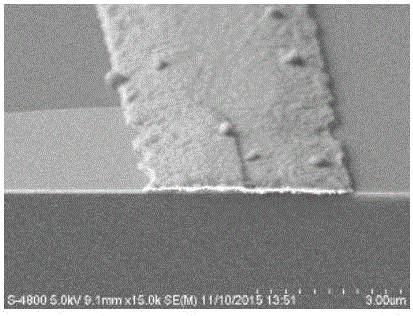

Graphene sensor, manufacturing method thereof and touch display device

InactiveCN104536614AReduce in quantityImprove etching precisionPhotomechanical coating apparatusPhotomechanical exposure apparatusDisplay deviceCvd graphene

The invention provides a manufacturing method for a graphene touch sensor. The manufacturing method includes the steps that a graphene layer is formed on a substrate; a metal layer is formed on the graphene layer; the metal layer is coated with photoresist; the photoresist is exposed by adopting a gray scale mask plate, and a complete photoresist removing region, a partial photoresist reserving region and a complete photoresist reserving region are formed after development is carried out; the portions, in the complete photoresist removing region, of the metal layer and the graphene layer are removed; the portion, in the partial photoresist reserving region, of the metal layer is removed; the portion, in the partial photoresist reserving region, of the graphene layer is coated with a protective film; the remaining photoresist is peeled off. The invention further provides a graphene sensor obtained by adopting the manufacturing method and a touch display device comprising the graphene sensor. The problem that the electrical conductivity of a graphene thin film becomes poor as an alkaline developing solution and an alkaline peeling solution make contact with the graphene thin film in the photolithography technology is solved, the yield is increased, and cost is reduced.

Owner:BOE TECH GRP CO LTD

Etching liquid for copper molybdenum and alloy films as well as preparation method of etching liquid

The invention provides an etching liquid for copper molybdenum and alloy films as well as a preparation method of the etching liquid. The etching liquid is prepared from the components including hydrogen peroxide, a hydrogen peroxide stabilizer, an amine pH regulator, a complexing agent, a metal corrosion inhibitor and the balance water; the amine pH regulator is a compound shown in formula 1 and / or formula 2, R1 and R4 are independently selected from C1-4 alkylene, and R2, R3, R5 and R6 are independently selected from single bonds or C2-4 alkylene. By the aid of the etching liquid, the excellent etching precision can be realized, no damage to metallic oxide IGZO films can be avoided further, the 6Mask technology of IGZO products can be upgraded to the 5Mask technology, the manufacturing cost of the display products can be reduced, and the resolution ratio of the display products can be increased.

Owner:CHENGDU ZHONGDIAN PANDA DISPLAY TECH CO LTD

Laser ablation processing method for quartz crystal

ActiveCN105522281AAddress mechanical strength requirementsAddressing Accuracy RequirementsLaser beam welding apparatusMicrometerBase frequency

The invention discloses a laser ablation processing method for quartz crystal. The laser ablation processing method specifically comprises the steps of selecting lasers, preparing control software, designing processing drawings, carrying out laser ablation, carrying out post-processing treatment and carrying out detection. The method for processing the quartz crystal is designed on the basis of limitation to the condition of each step, the quartz crystal can be effectively processed for forming various shapes and can be thinned through the processing method, the thickness of the thinned quartz crystal is small, the corresponding base frequency is high, and the strength of the processed quartz crystal is high. In addition, the processing method is simple, the processing accuracy is high, and the processing dimensional accuracy of the quartz crystal can be controlled to be within the range of + / - 5 micrometers.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

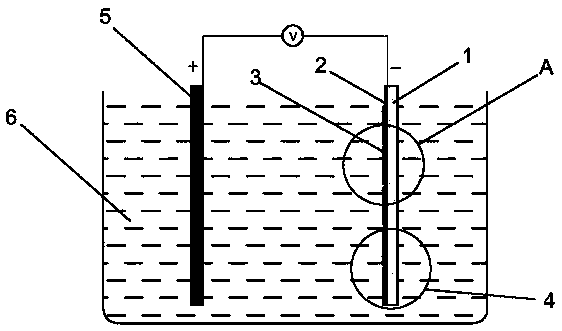

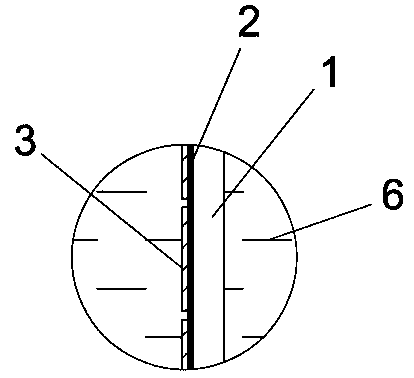

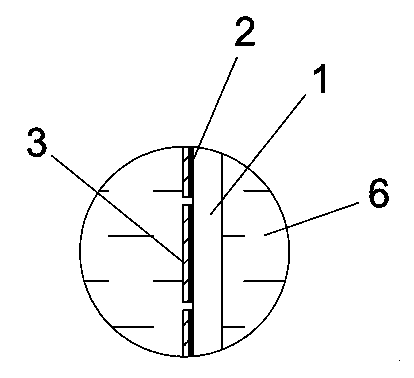

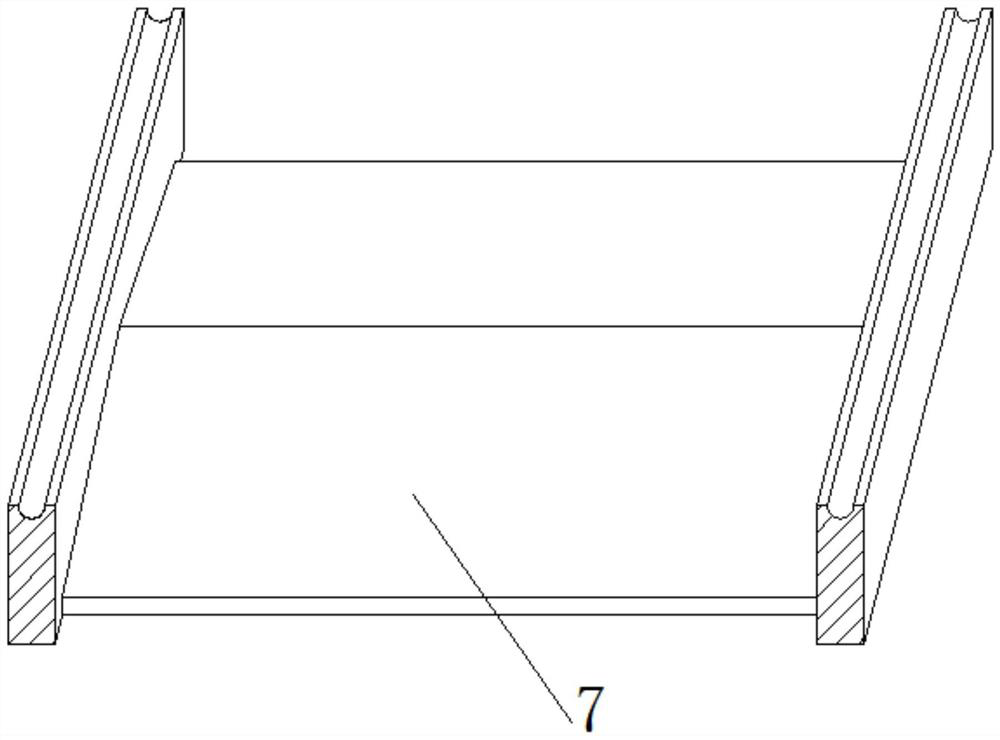

Method for etching FTO (fluorine-doped tin oxide) conductive thin film

InactiveCN103422153AImprove etching precisionIncrease productivityElectrolysis componentsOptoelectronicsAcid electrolyte

The invention provides a method for etching an FTO (fluorine-doped tin oxide) conductive thin film. The method includes steps of depositing the FTO conductive thin film on a substrate, covering an insulating etching-resistant layer on one side of the FTO conductive thin film according to preset patterns and further acquiring a cathode; placing the cathode and an inert anode into acid electrolyte, applying a constant voltage between the cathode and the anode, and etching and removing parts, which are not covered by the insulating etching-resistant layer, of the FTO conductive thin film. The method for etching the FTO conductive thin film has the advantages that the method is scientific and reasonable, various shortcomings in the prior art are overcome, and the etching production efficiency and the etching precision are high.

Owner:DALIAN HEPTACHROMA SOLAR TECH CO LTD

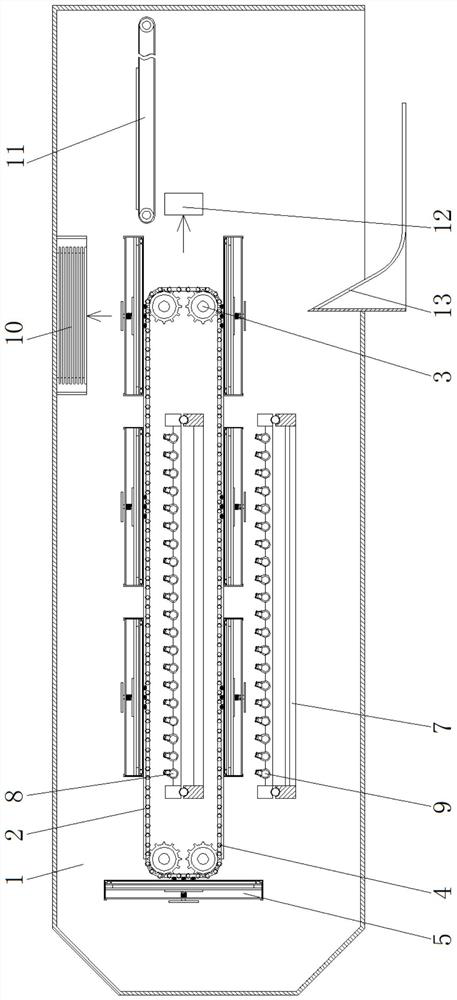

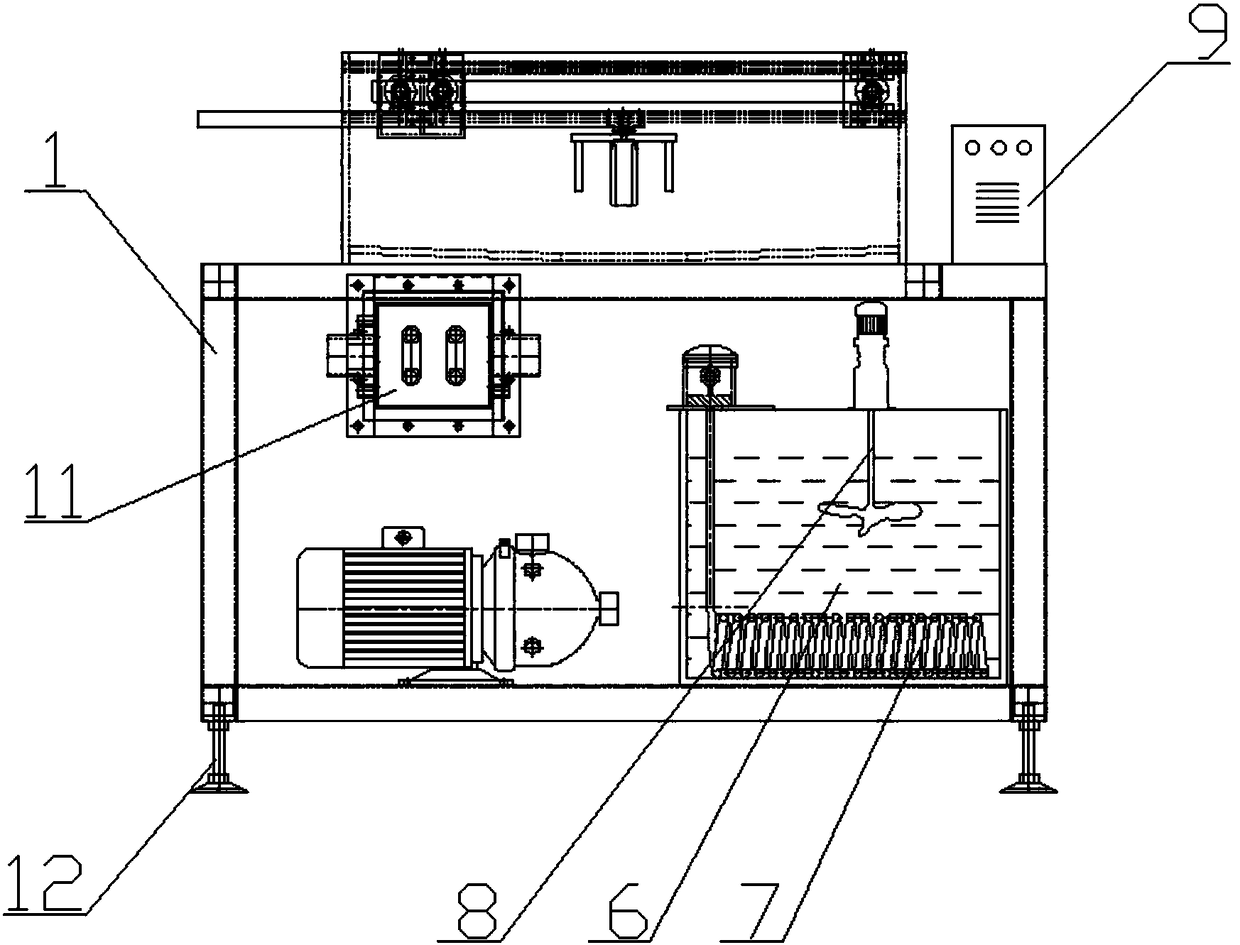

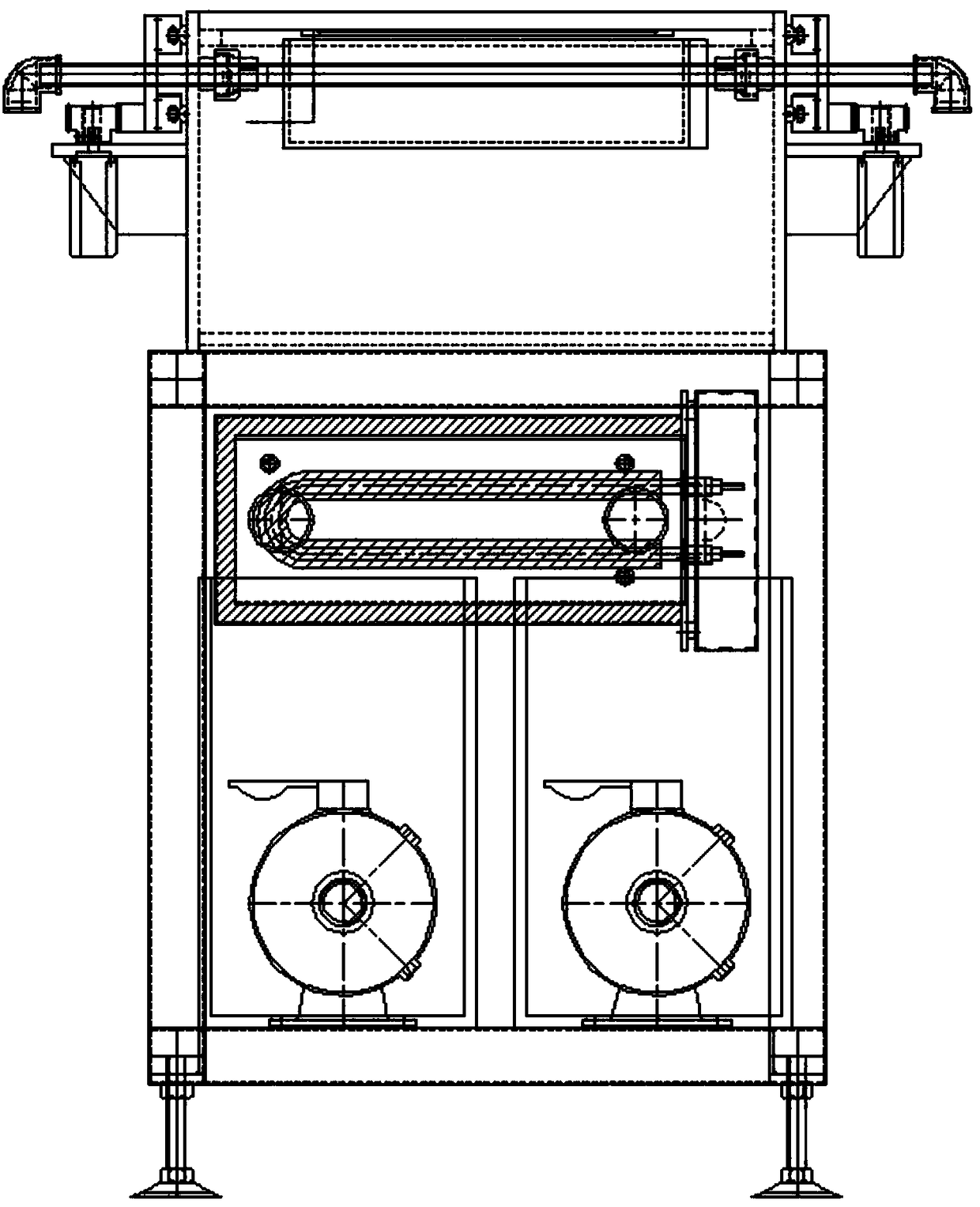

PCB circuit spraying etching machine

InactiveCN111669899AAvoid the "pool effect"Improve etching precisionConductive material chemical/electrolytical removalEtchingEngineering

The invention relates to the technical field of etching machines, and discloses a PCB circuit spraying etching machine. The PCB circuit spraying etching machine comprises a fixed box, a PCB and a booster pump, wherein fixed bases are fixedly installed in the fixed box, the interior of each fixed base is movably connected with a gear shaft in a sleeving manner, a chain is movably installed on the gear shaft, the chain is fixedly connected with a clamping device, and supporting frames are fixedly installed in an inner cavity of the fixed box and located between the fixed bases and below the fixed bases respectively. Through the arrangement of an upper spraying device and a lower spraying device, a liquid medicine is jetted upwards; Meanwhile, through the arrangement of the chain and the clamping device, the PCB passes through the area where the upper spraying device sprays the liquid medicine at a constant speed, gap etching is carried out on the bottom surface of the PCB, then the PCB is turned over and passes through the area where the lower spraying device sprays the liquid medicine so as to carry out gap etching on the other surface of the PCB, the pool effect is effectively prevented from being formed on the PCB, and thus the etching precision and uniformity are improved.

Owner:龚明瀚

Photoresist composition and preparation method and composition method thereof

ActiveCN105807563AImprove bindingImprove etching precisionPhotosensitive materials for photomechanical apparatusWavelengthPhotoresist

The invention provides a photoresist composition, which comprises first photosensitive resin, second photosensitive resin and film-forming resin, wherein the first photosensitive resin is photosensitive to light with a first wavelength; the second photosensitive resin is photosensitive to the light with a second wavelength; the second wavelength is different from the first wavelength; the second photosensitive resin comprises diphenylamine diazonium photosensitive resin; and the mass proportion of the second photosensitive resin in the photoresist composition is smaller than that of the first photosensitive resin in the photoresist composition. The invention further provides a composition method and a preparation method of the photoresist composition. When the composition method is carried out by the photoresist composition, a photoresist is not easily stripped from a metal film layer.

Owner:BOE TECH GRP CO LTD

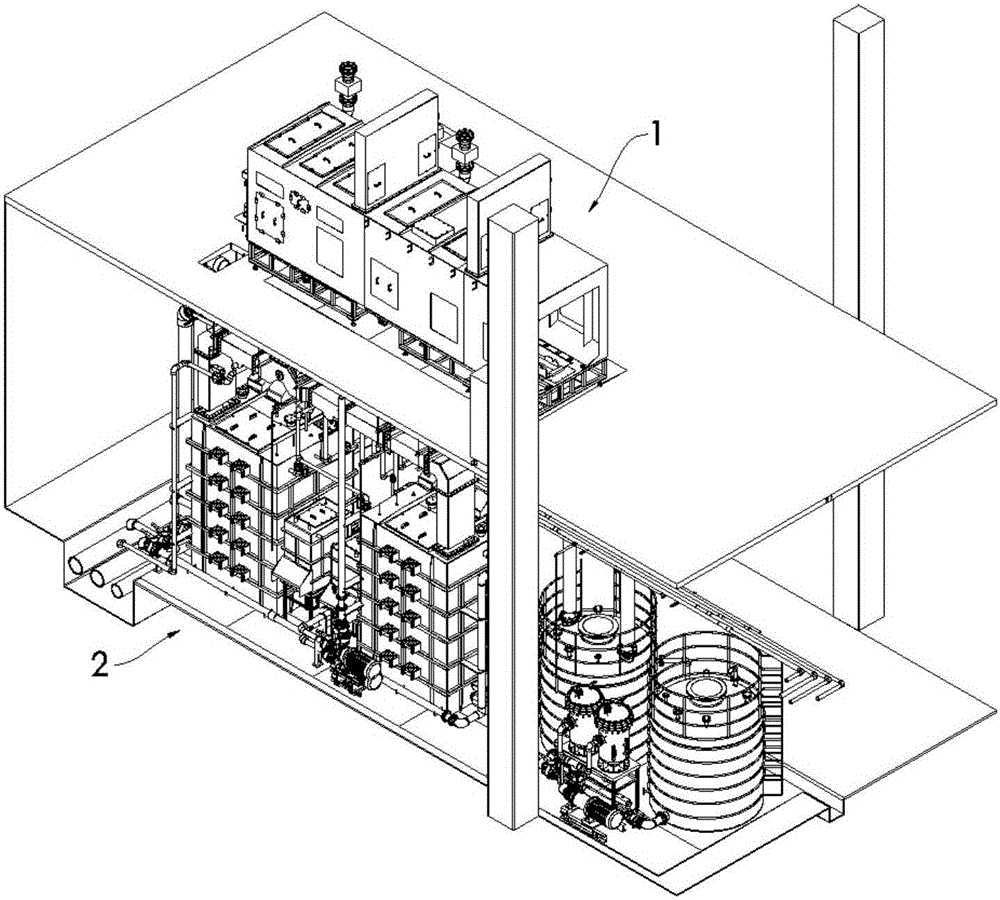

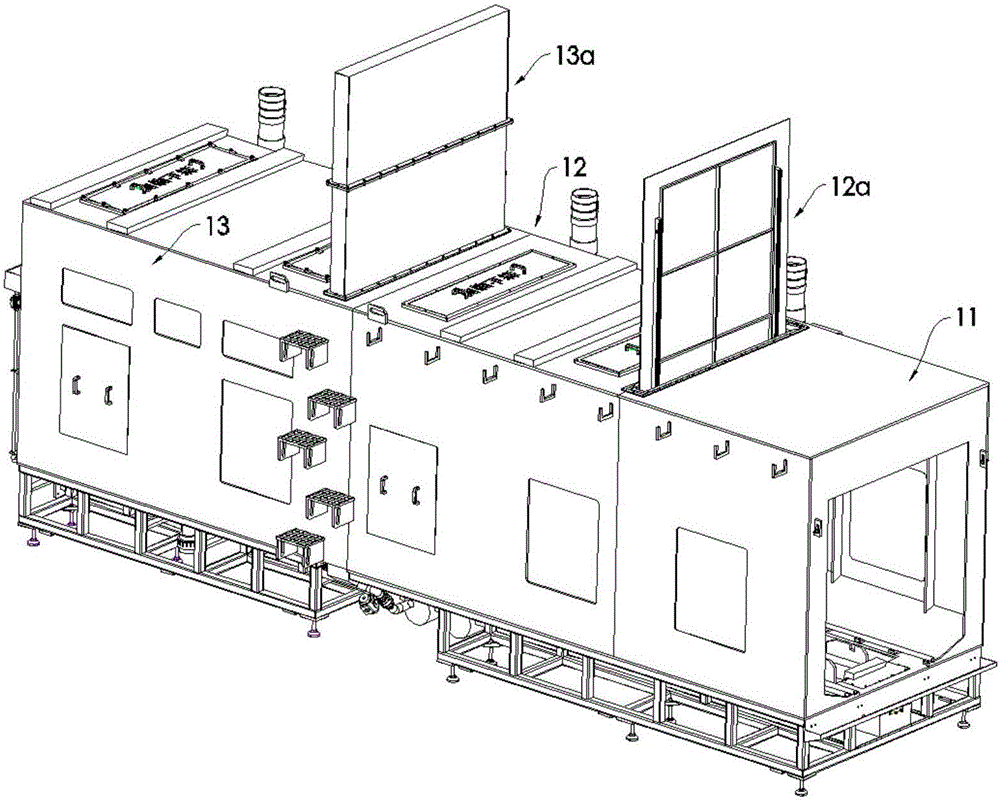

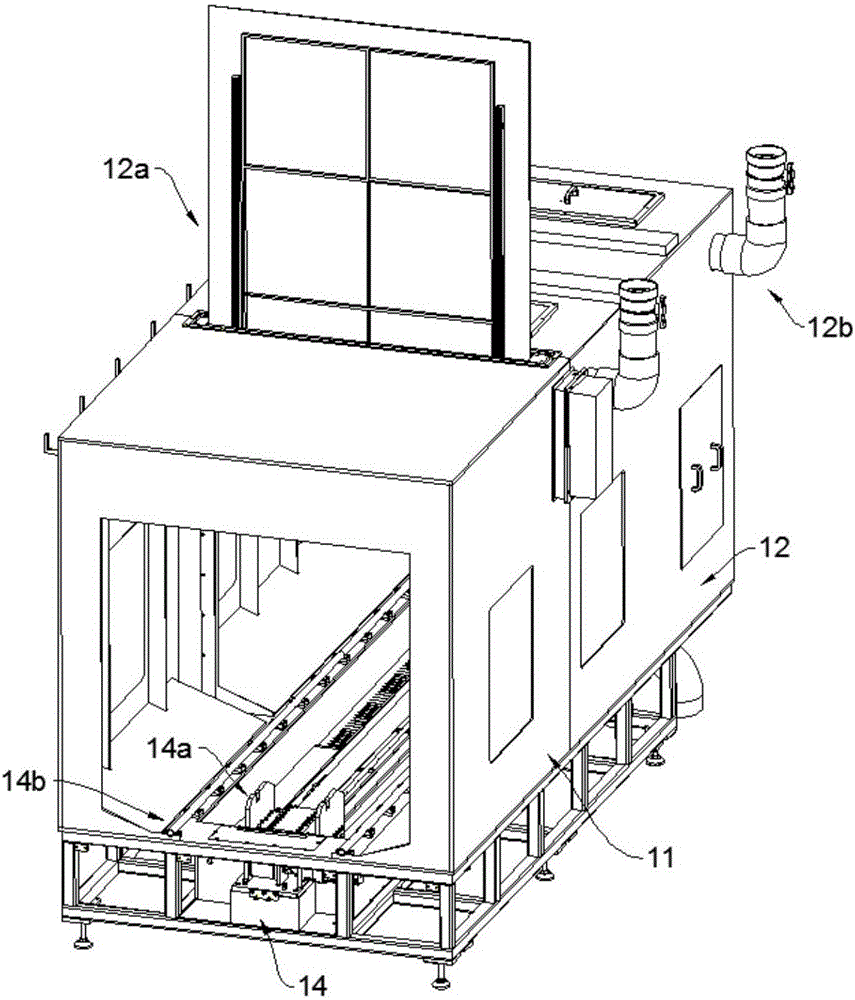

Top-jet type spray etching machine

A top-jet type spray etching machine comprises an etching machine body and a liquid medicine circulating system, wherein the etching machine body is mainly composed of a transition area, a cleaning area and an etching area, spraying devices are arranged on the cleaning area and the etching area respectively, synchronous belt conveying devices are arranged below the transition area and the cleaning area, a servo drive motor is arranged below the transition area, a slide rail penetrating through the transition area, the cleaning area and the etching area is arranged below the etching machine body, etching basket tools are placed on the slide rail, the synchronous belt conveying devices are connected and linked through push rods, and the liquid medicine circulating system is mainly composed of a DI water tank body, a chemical liquid medicine tank body, a heating tank, corresponding pipelines, corresponding valves and a circulating pump. In the glass panel etching process, the temperature, pressure, flow and the like of liquid medicine can be controlled in a full-automatic mode, double-sided waterfall etching is conducted on glass panel, no manual operation is needed in the whole working process, cleaning and etching are both completed automatically, and the etching precision and efficiency are remarkably improved.

Owner:CHENGDU IND INVESTMENT ELECTRONICS EQUIP

Wet etching method for ZnO-based transparent conductive film

ActiveCN102709156AControllable etch rateInhibit side etchSemiconductor/solid-state device manufacturingSemiconductor devicesThin membraneSolar battery

The invention discloses a wet etching method for a ZnO-based transparent conductive film The wet etching method comprises the following steps: coating photoresist on a substrate deposited with the ZnO-based transparent conductive film; carrying out exposure and development and removing part of the photoresist so that the substrate to be etched is exposed; baking the substrate; proportioning with weak acids and deionized water to form a weak acid solution; putting the substrate to be etched into the weak acid solution for etching for 1-10000 seconds; washing with deionized water; removing the photoresist with an organic solution; and measuring the etching depth and the profile of the etched pattern. A weak acid solution wet etching process is adopted in the method, and the method has the advantages of simple operation, low cost, controllable etching rate, high etching precision and the like, and can be applied to a pattern processing technology of ZnO-based transparent electrodes in the fields of solar batteries, panel display, LEDs (light-emitting diodes) and the like, so that the industrial applications of the ZnO-based transparent conductive films the above fields are promoted.

Owner:SUN YAT SEN UNIV

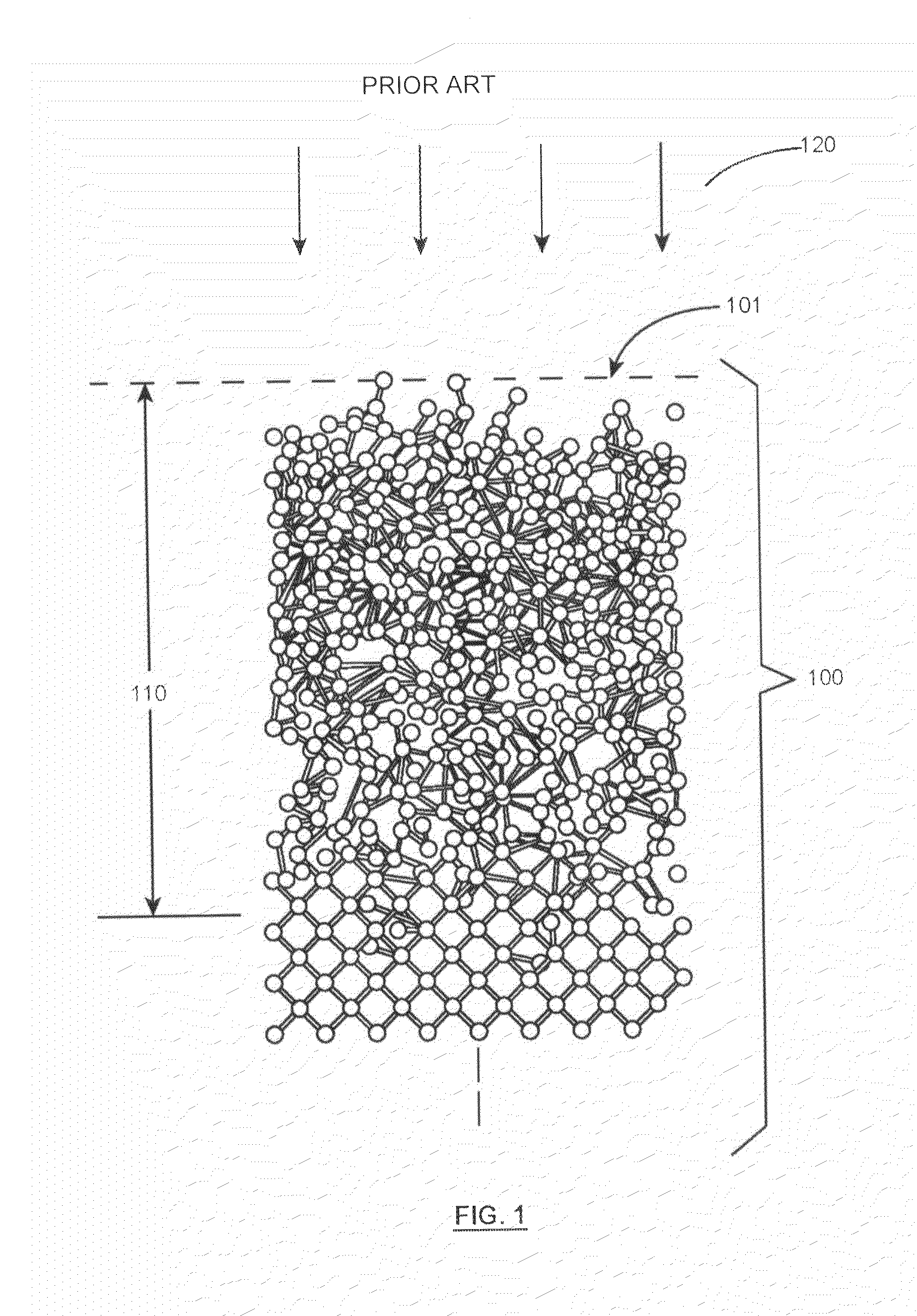

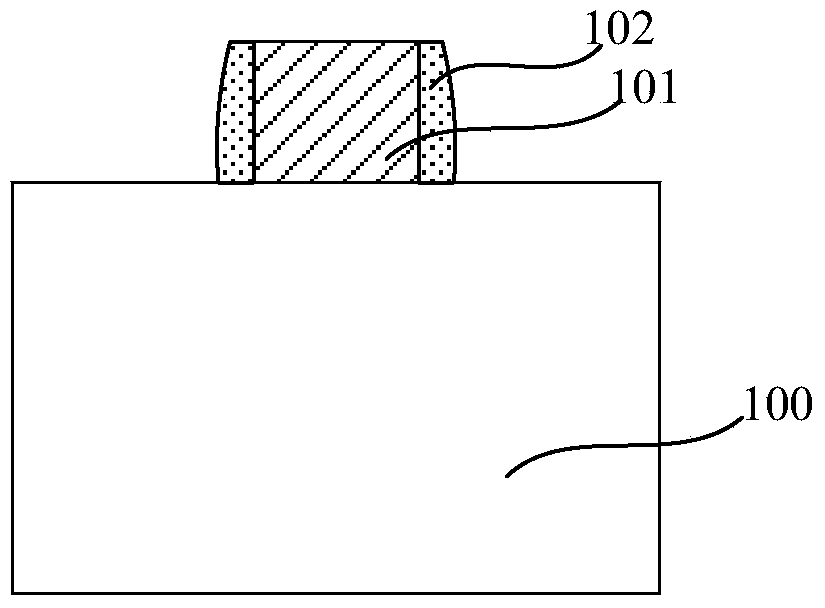

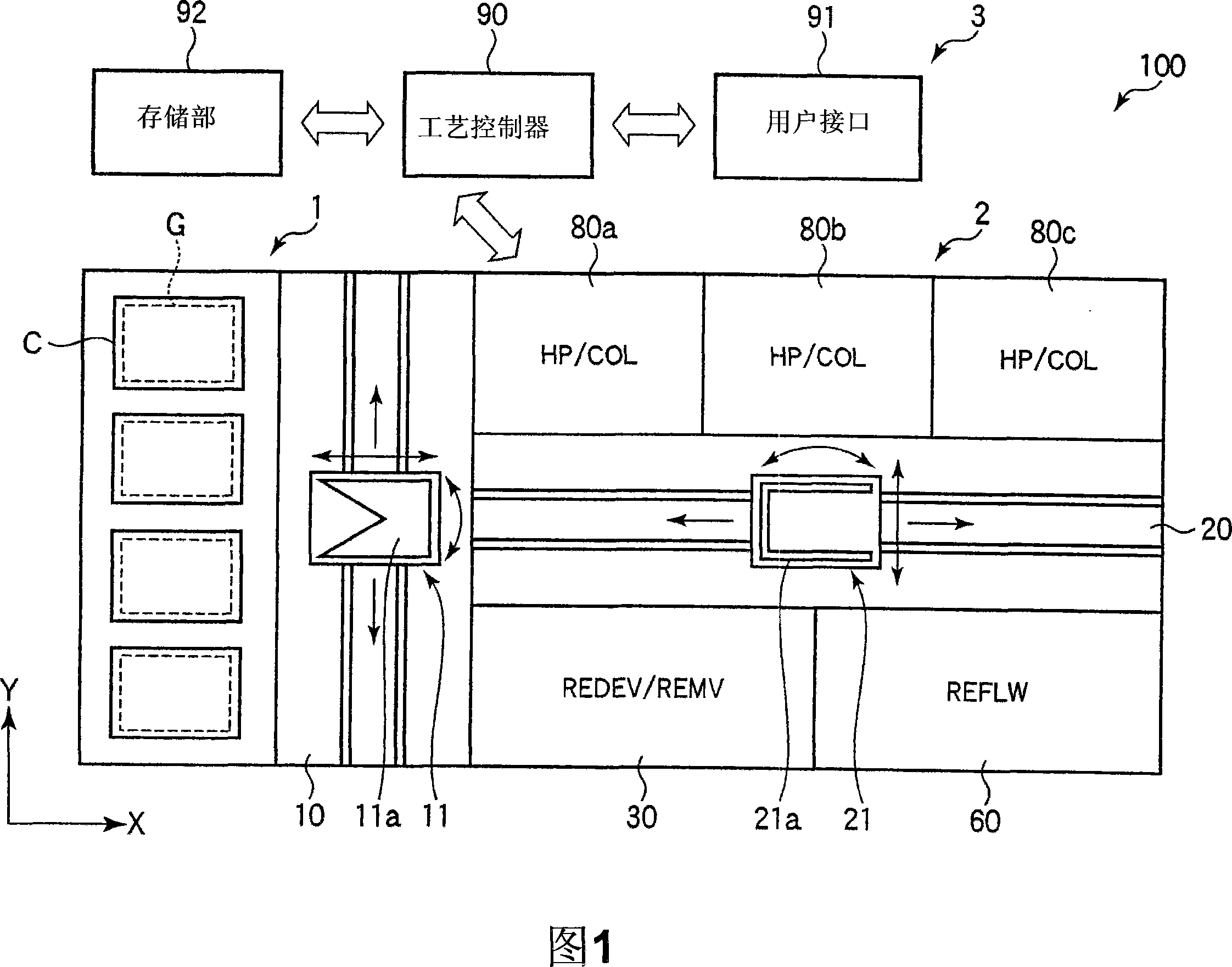

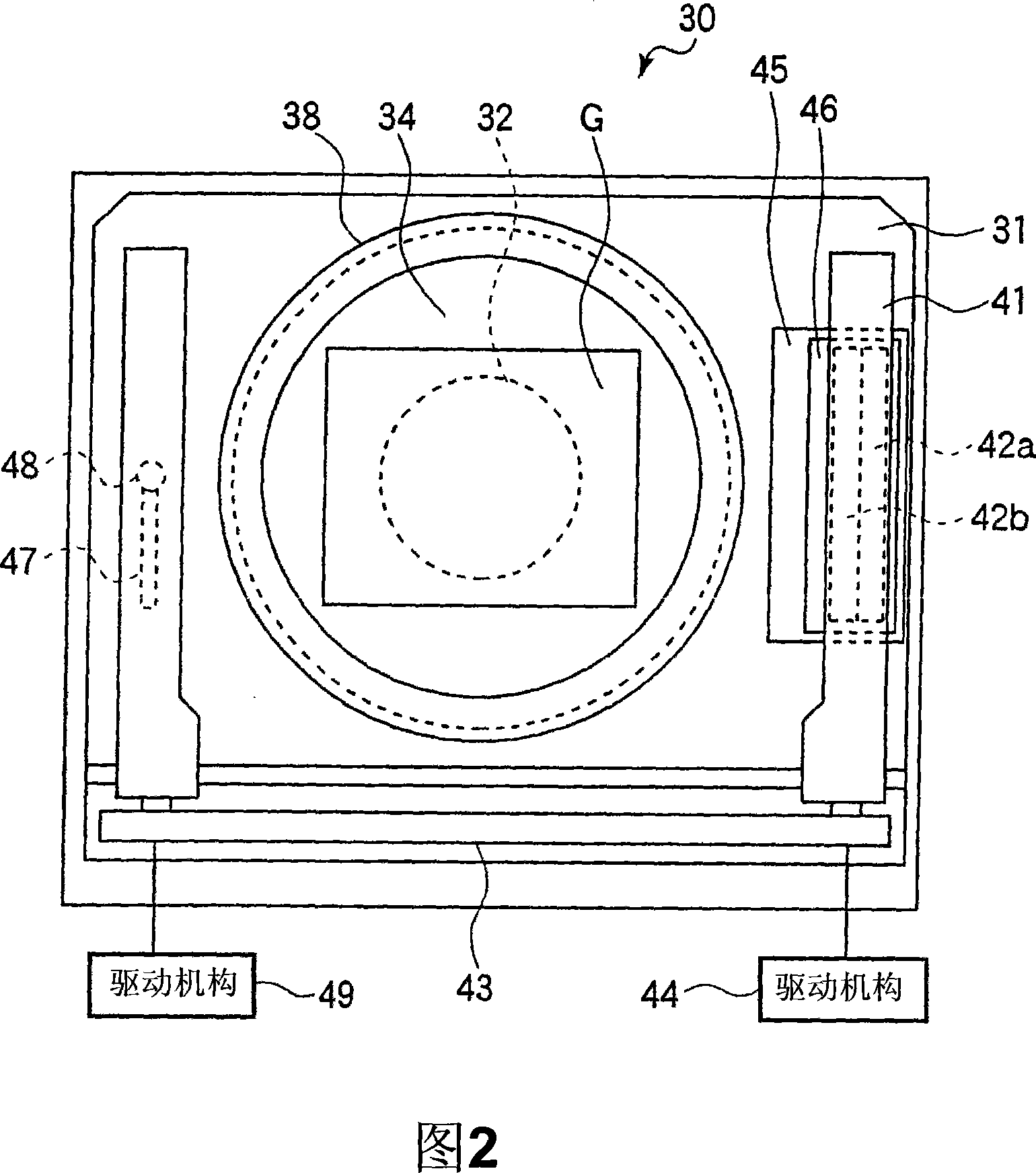

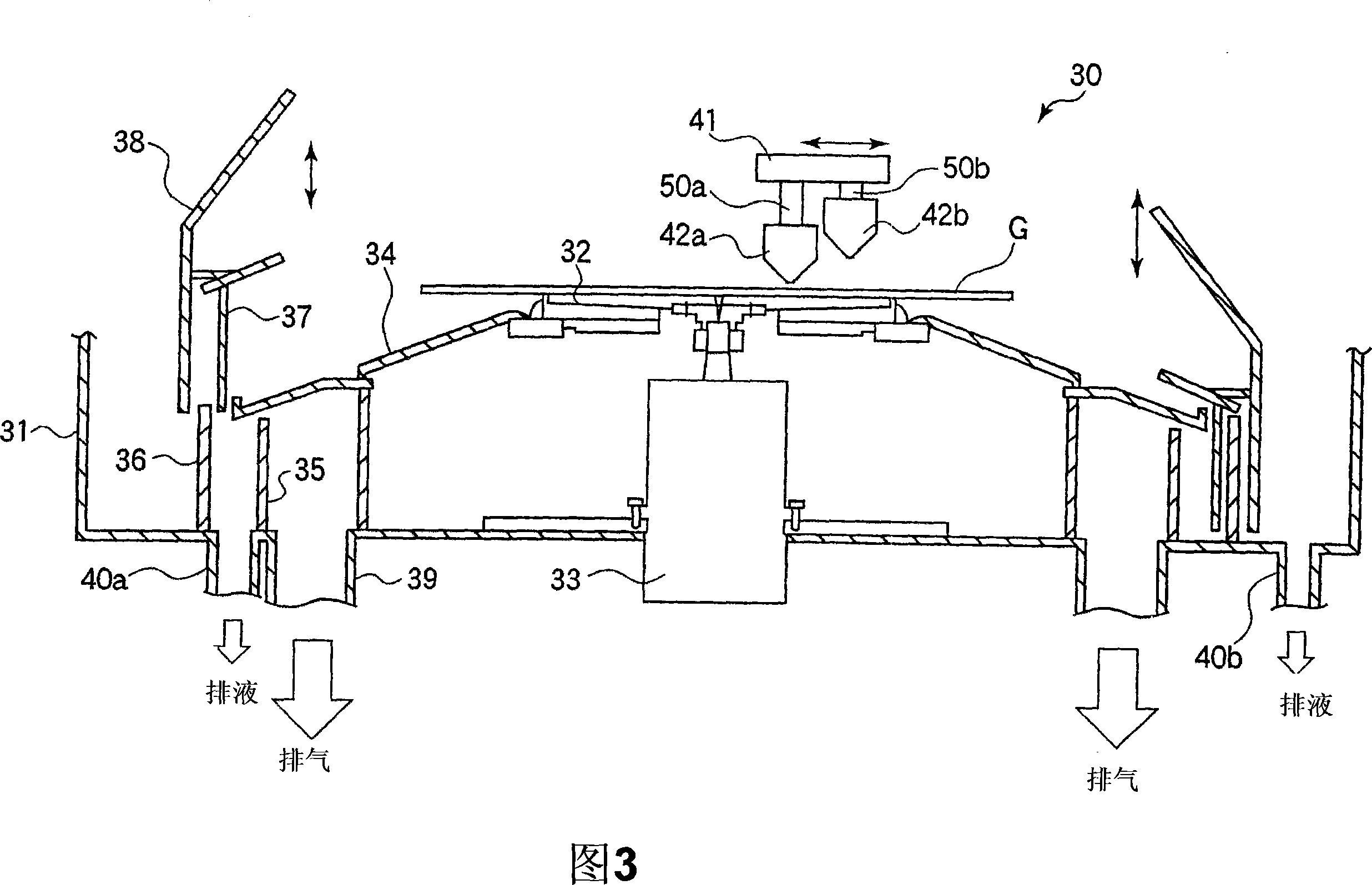

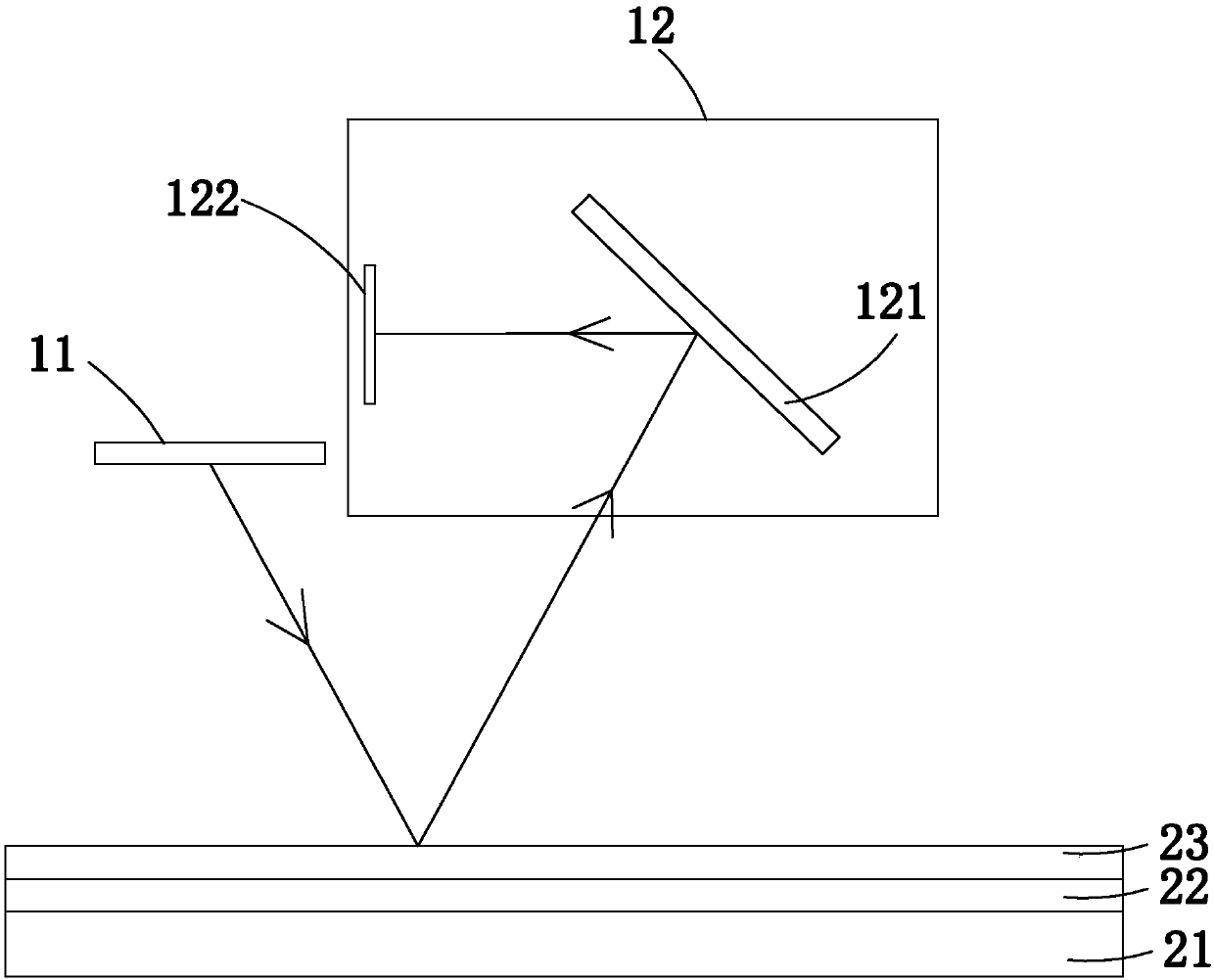

Reflow method, pattern generating method, and fabrication method for TFT element for LCD

InactiveCN101047120AReduce processing timeAvoid stagnationSemiconductor/solid-state device manufacturingNon-linear opticsResistLiquid-crystal display

To provide a technology that can precisely control the flow direction and area of a softened resist, and thereby can be utilized for forming a pattern and manufacturing a TFT element for liquid crystal displays in the reflow treatment of the resist. A resist 103 subjected to reflow treatment is formed in an overhang shape while a lower edge J at a side facing a target region S1overhangs to the side of the target region S1as compared with the edge of a lower-layer film 102. By allowing the lower edge J of the resist 103 to project from the lower-layer film 102, the resist 103 does not stagnate, thus allowing a softened resist to flow toward the target region S1rapidly. The flow of the resist 103 toward the prohibited area S2is suppressed as a reaction for accelerating the flow of the resist 103 toward the target region S1, thus stopping deformation without reaching the prohibited area S2.

Owner:TOKYO ELECTRON LTD

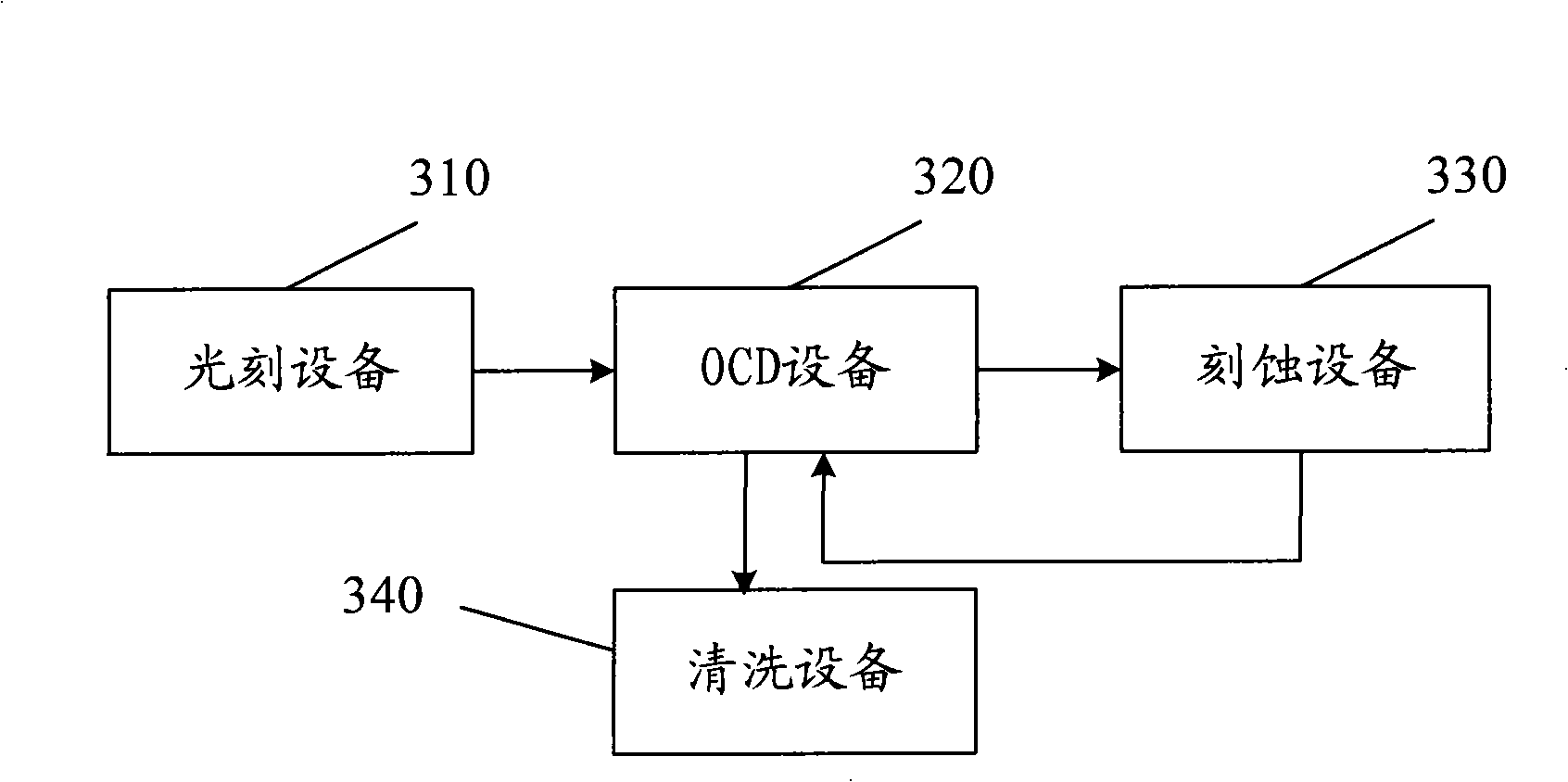

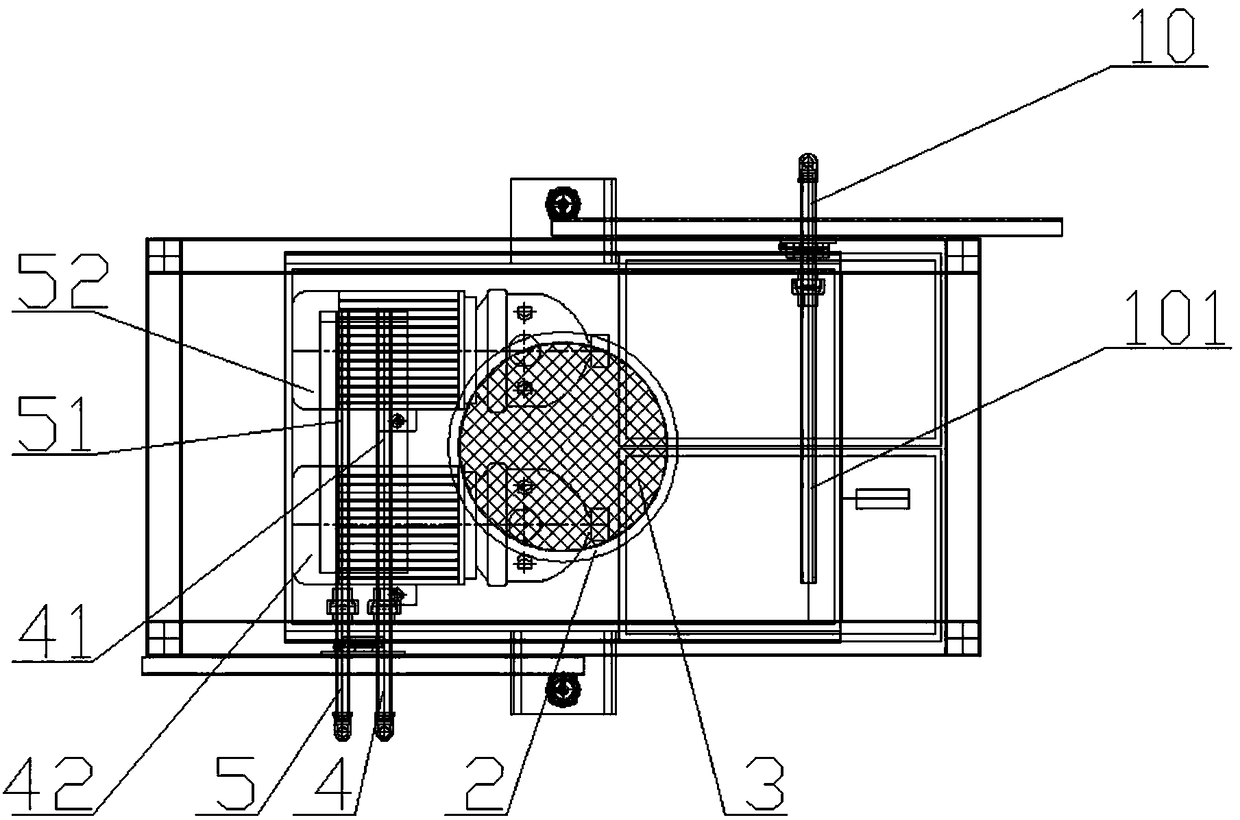

Etching equipment

PendingCN108109946AGuarantee processing qualityReduce usageSemiconductor/solid-state device manufacturingEngineeringResidence time

The invention relates to etching equipment. The etching equipment is characterized by comprising a rack, wherein a bearing device is arranged on the rack and is used for bearing a wafer or a printed circuit board, an etching device and a cleaning device are arranged below the bearing device, both can move leftwards and rightwards and are in synchronous linkage, the etching device comprises an etching cutter and an etching liquid pump, the cleaning device comprises a cleaning cutter and a cleaning liquid pump, the etching cutter and the cleaning cutter completely skim over a lower surface of the wafer or the printed circuit board, and a first narrow gap and a second narrow gap are respectively formed in the tops of the etching cutter and the cleaning cutter. A cleaning liquid is sprayed from bottom to top, the residence time of an etching liquid on a pre-processed surface of the wafer or the printed circuit board can be effectively shortened, a pool effect is reduced to a great extent,so that circuit etching precision and accuracy are ensured; and moreover, etching operation and cleaning operation can be sequentially performed on the wafer or the printed circuit board at the same station by the etching equipment, and the process continuousness is ensured.

Owner:成功环保科技(南通)有限公司

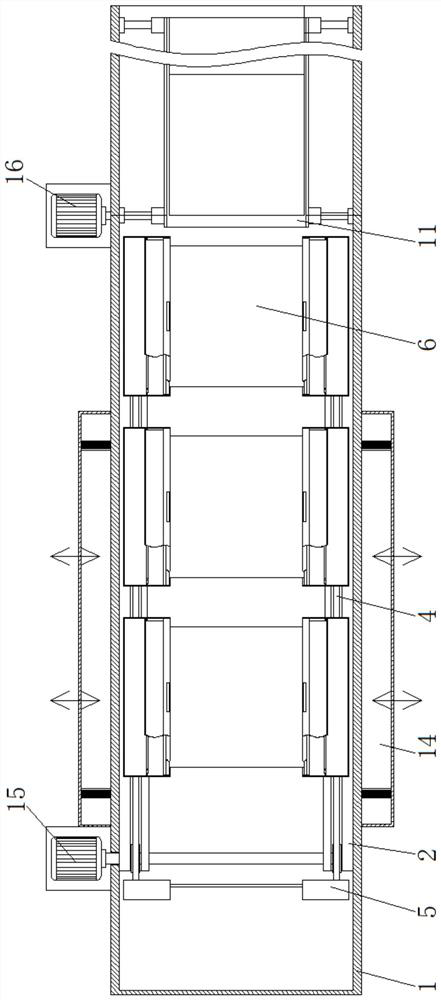

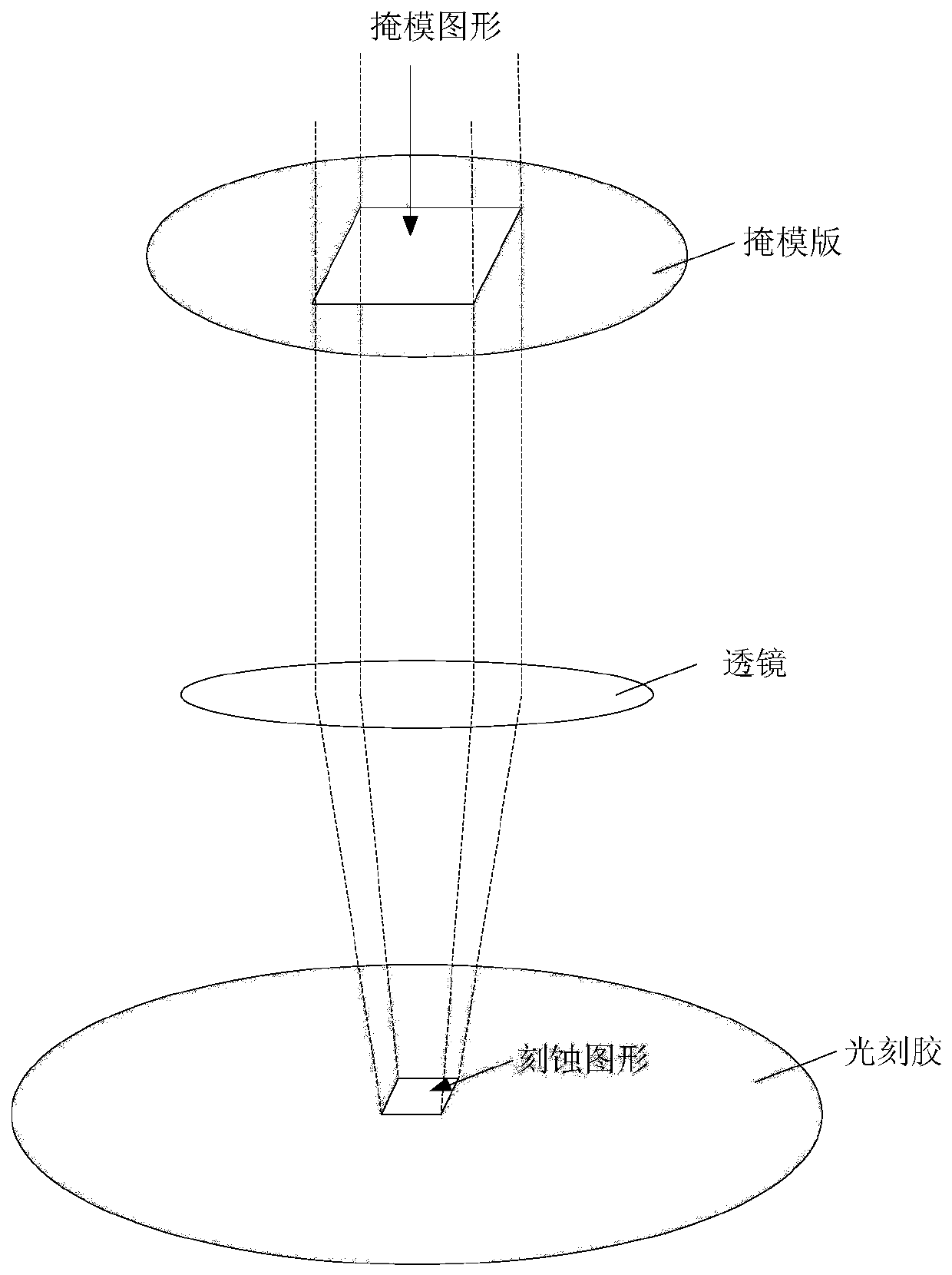

Mask plate and manufacturing method of semiconductor device

InactiveCN110491776APrevent heat deformationImprove etching precisionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPhotoresistPower semiconductor device

The invention provides a mask plate and a manufacturing method of a semiconductor device. Patterns of the mask plate comprise a first pattern capable of being exposed and a second pattern which is a sub-resolution auxiliary pattern, the ratio of the area of the first pattern to the total area of the mask plate is smaller than or equal to a preset ratio, and the ratio of the sum of the area of thesecond pattern and the area of the first pattern to the total area of the mask plate is within a preset range. Since the second graph is a sub-resolution auxiliary graph, the photoresist layer cannotbe imaged, so that etching of the to-be-etched layer cannot be affected; meanwhile, due to the existence of the second pattern, the density of the pattern in the mask plate is increased, the problem that the mask plate is heated and deformed due to the fact that light intensity is excessively concentrated when photoresist is patterned is solved, and the etching precision of the to-be-etched layerin the semiconductor device is improved.

Owner:YANGTZE MEMORY TECH CO LTD

Preparation technology of high-density interconnecting printed circuit board

InactiveCN104135822AImprove qualityAvoid the effects of thickness uniformityMultilayer circuit manufactureNon-metallic protective coating applicationTectorial membraneHigh density

The invention discloses a preparation technology of a high-density interconnecting printed circuit board. The preparation technology is characterized by comprising the steps of providing a first substrate which comprises a first conducting layer, a second conducting circuit and first insulating layers, etching the first conducting layer to form a first conducting circuit and a first window, drilling one first insulating layer to form a through hole, performing chemical copper deposition treatment on the first substrate, arranging a protective film on the surface of metallic copper covering the upper surface of the first substrate, forming a second window corresponding to the first window in the protective film, performing electroplating treatment on the first substrate provided with the protective film to allow the through hole and the first window to be filled with metallic copper, removing the protective film, and removing the metallic copper covering the upper surface of one first insulating layer, wherein the first conducting layer is located on the surface of one first insulating layer. The preparation technology of the high-density interconnecting printed circuit board saves a procedure of etching to reduce the thickness of the conducting circuits, improves the accuracy and the thickness uniformity of the conducting circuits, and improves the quality of the high-density interconnecting circuit board.

Owner:SHANGHAI MEADVILLE ELECTRONICS +1

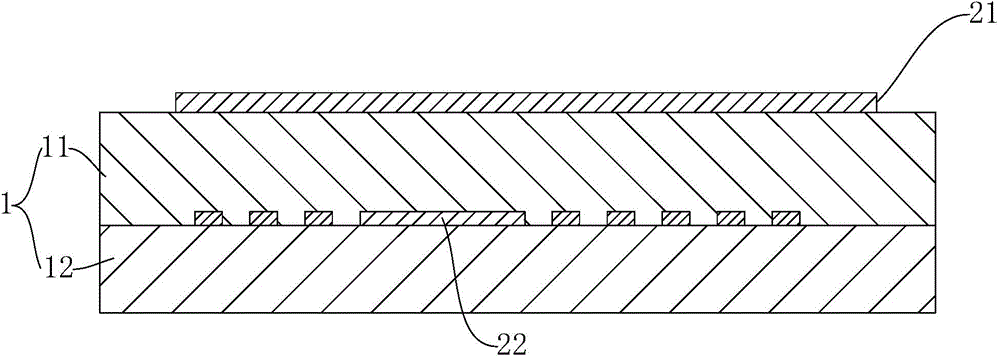

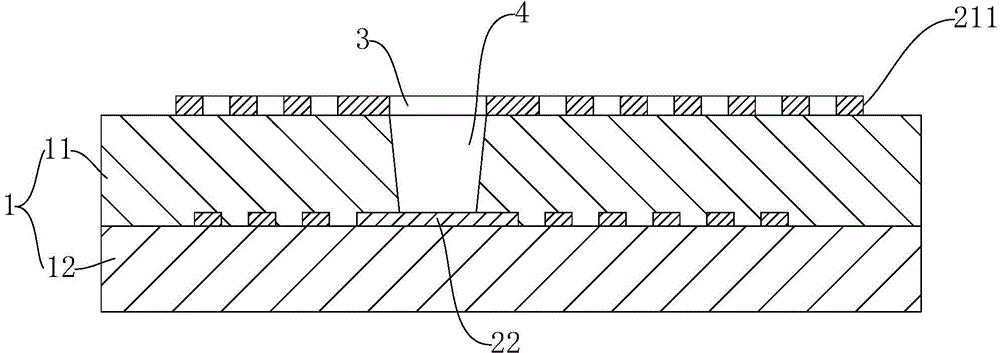

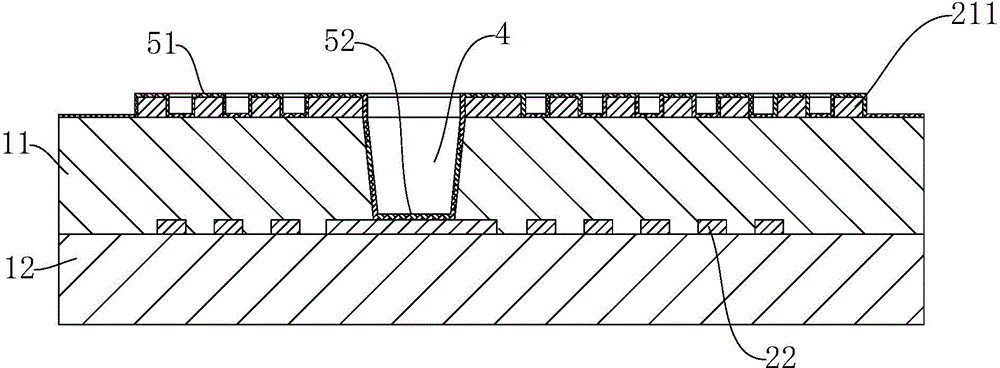

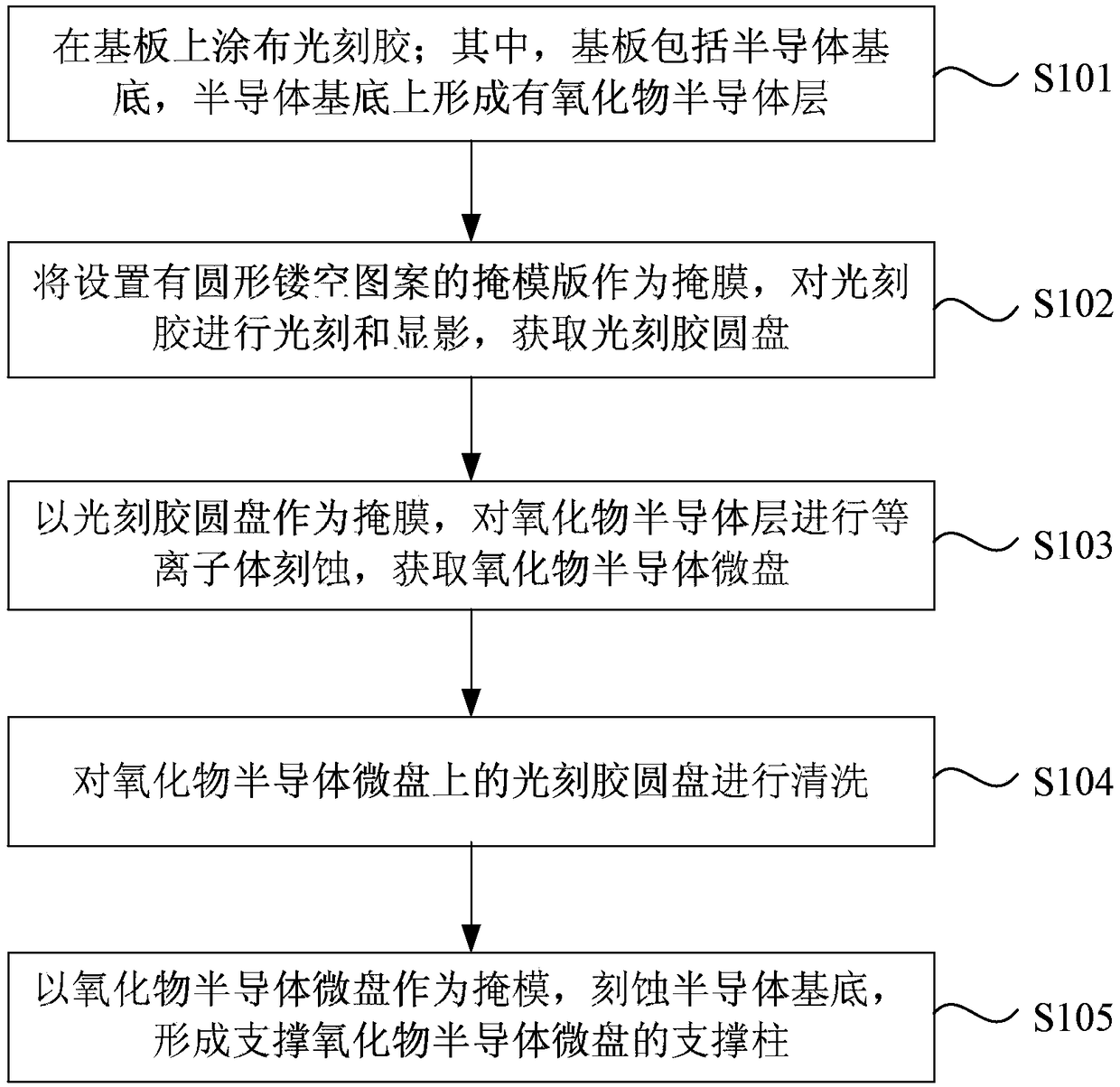

Micro-disk Raman laser device and manufacturing method thereof

ActiveCN108923245AFlexible control of etching speedImprove etching precisionSemiconductor laser structural detailsOptoelectronicsRaman laser

The embodiment of the invention discloses a micro-disk Raman laser device and a manufacturing method thereof. The micro-disk Raman laser device comprises a base plate coated with a photoresist, wherein the base plate comprises a semiconductor substrate; an oxide semiconductor layer is formed on the semiconductor substrate; a mask plate provided with a circular hollow pattern is used as a mask to photoetch and develop the photoresist to obtain a photoresist disk; the photoresist disk is used as a mask to perform plasma etching on the oxide semiconductor layer to obtain an oxide semiconductor micro-disk; the photoresist disk on the oxide semiconductor micro-disk is cleaned; and the oxide semiconductor micro-disk is used as a mask to etch the semiconductor substrate to form a supporting column which supports the oxide semiconductor micro-disk. The technical scheme provided by the embodiment of the invention can solve the problems of low etching precision and low repetitiveness of an existing micro-cavity Raman laser device.

Owner:NANJING UNIV

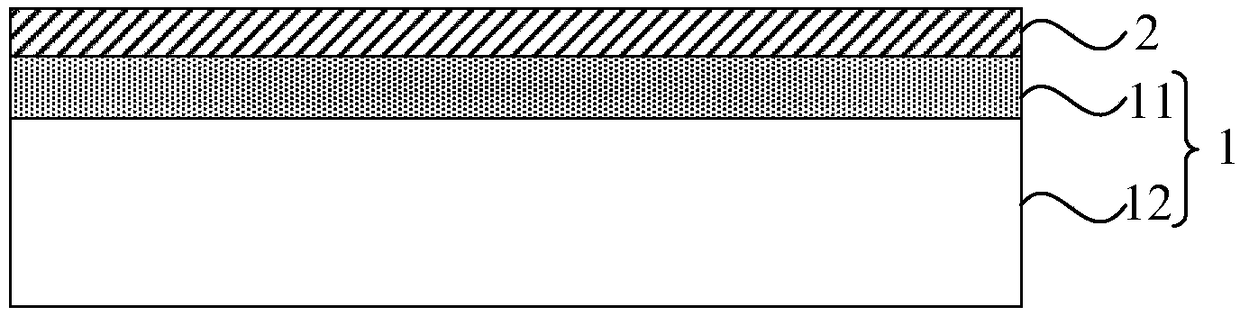

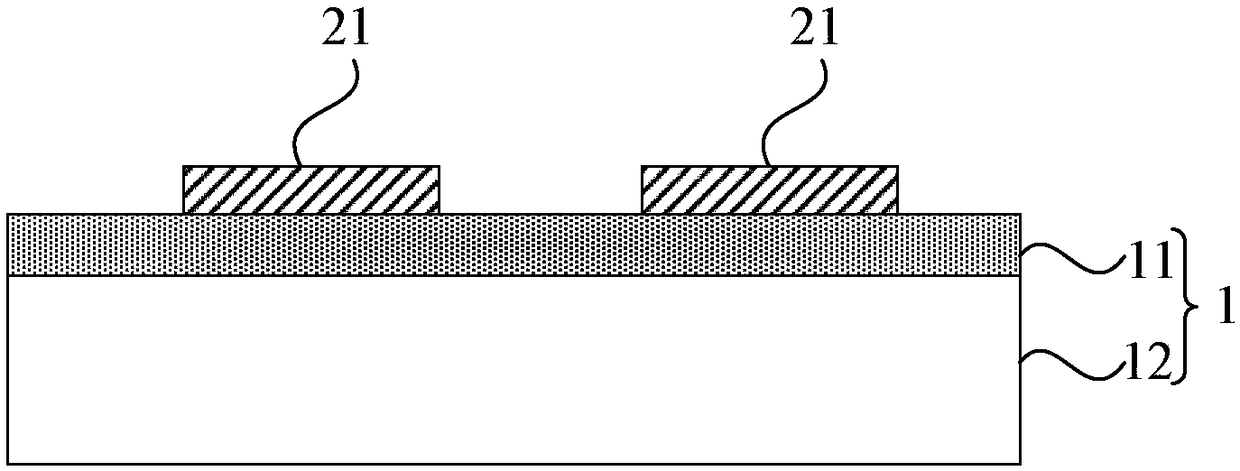

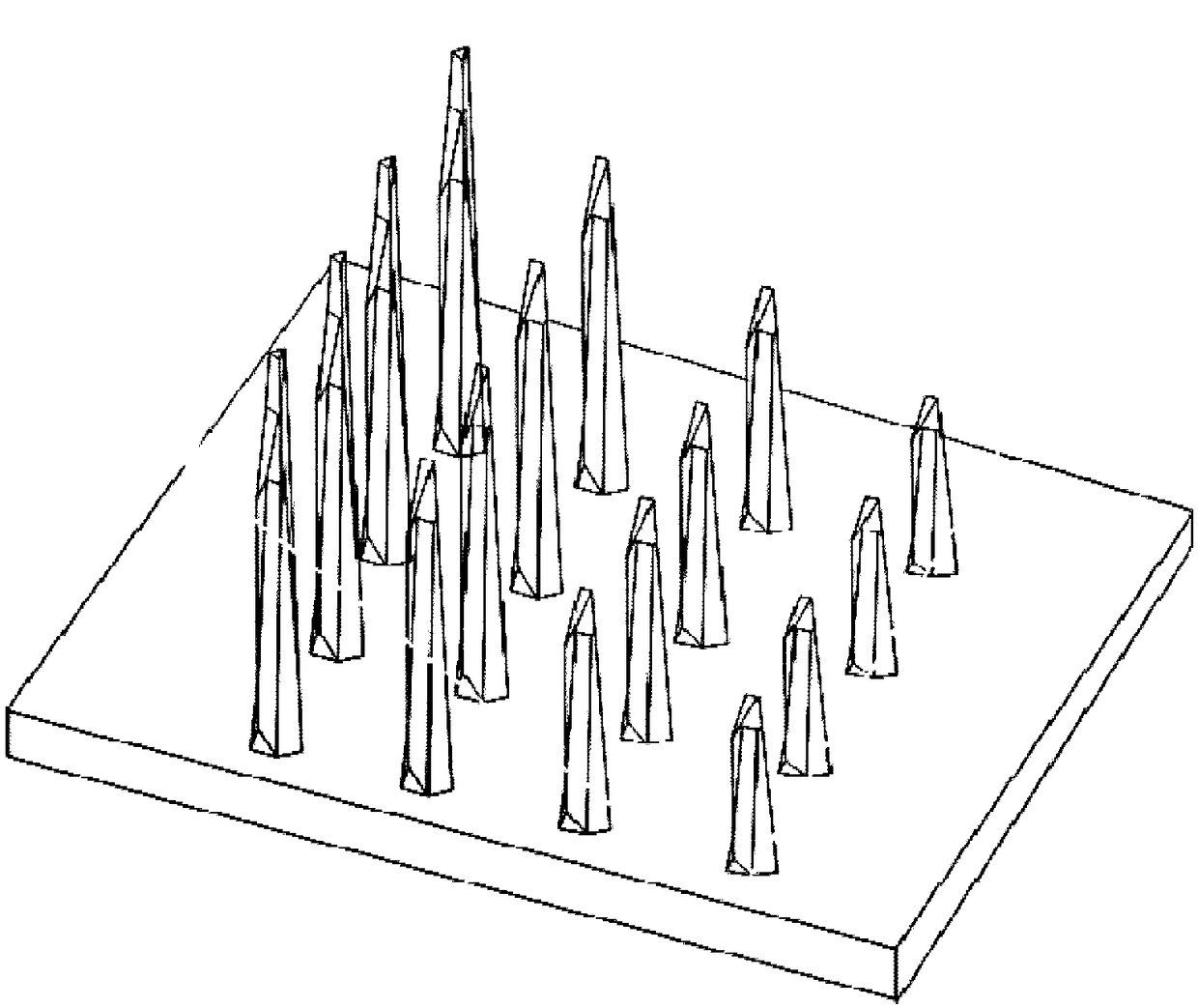

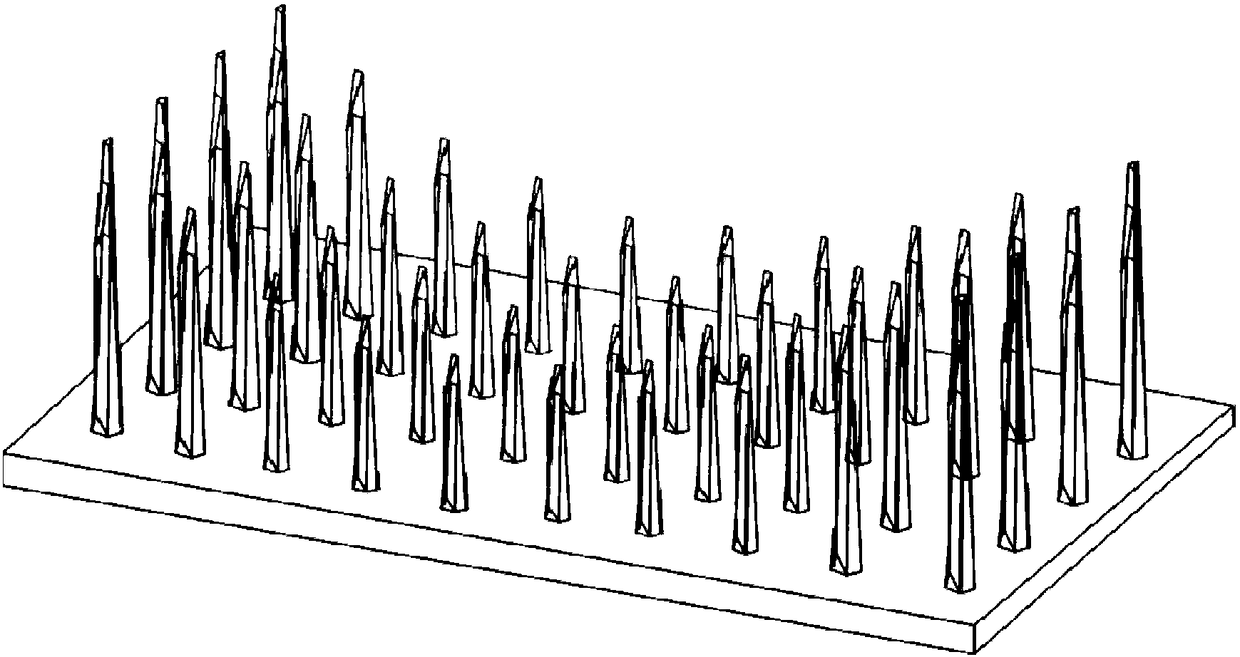

Method for obtaining high-density unequal height crystal microneedle array

ActiveCN108328567AAccurate shapeImprove etching precisionDecorative surface effectsMicroneedlesHigh densityComputer science

The invention discloses a method for obtaining a high-density curved surface or a beveled microneedle array. According to the method, the beveled or curved surface microneedle array is generated by changing the shapes and sizes of masks to generate needle-shaped quartz bosses with different heights. The shapes of the masks in the method can be circles or triangles, and different calculation modesare provided for different mask shapes and different mask sizes. By adoption of the method, the high-density microneedle array can be obtained, and the shape of the array can be accurately controlled.

Owner:SOUTHEAST UNIV

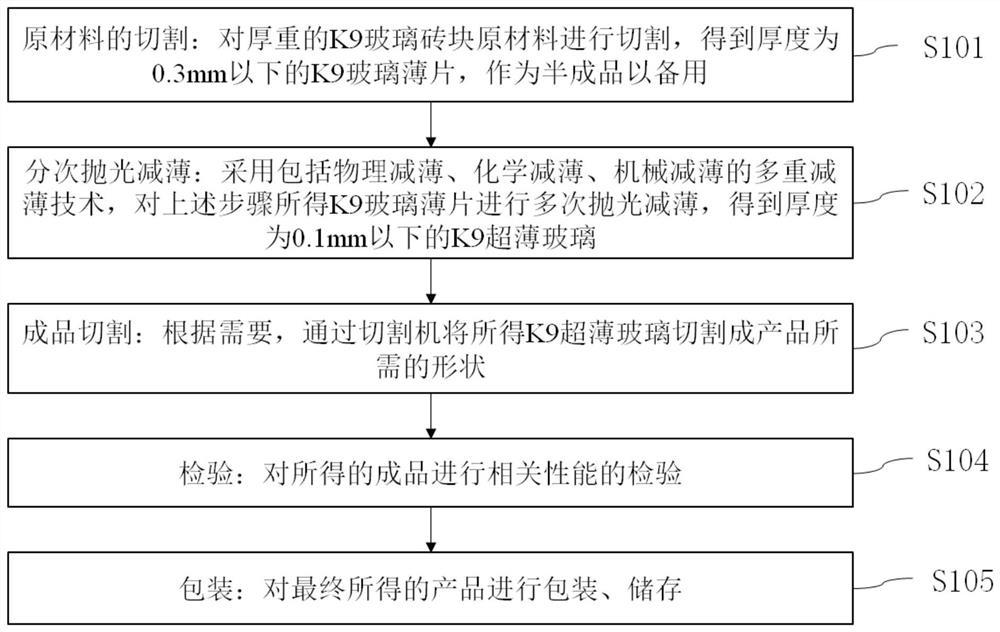

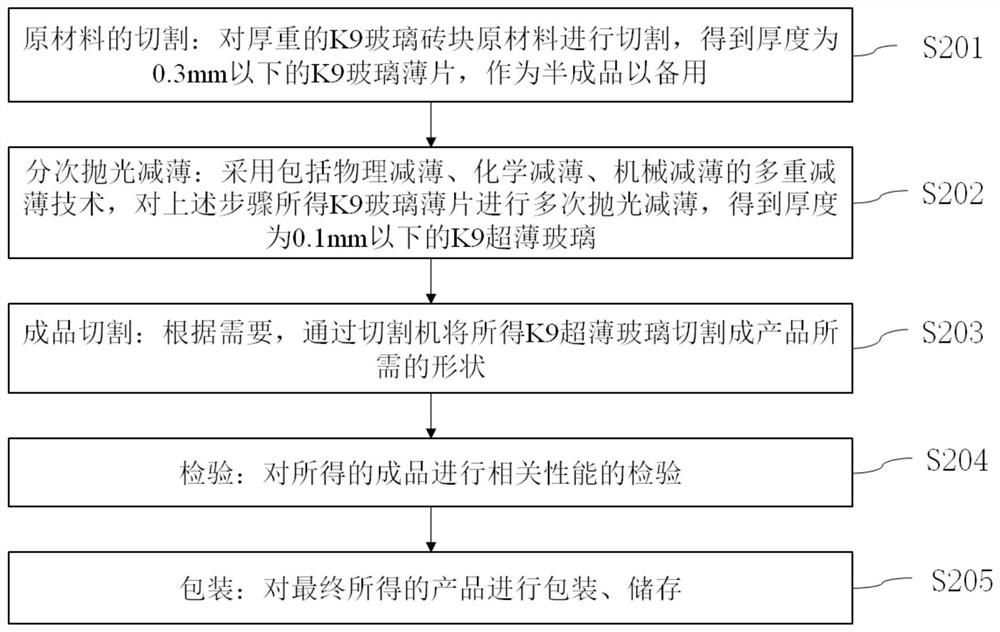

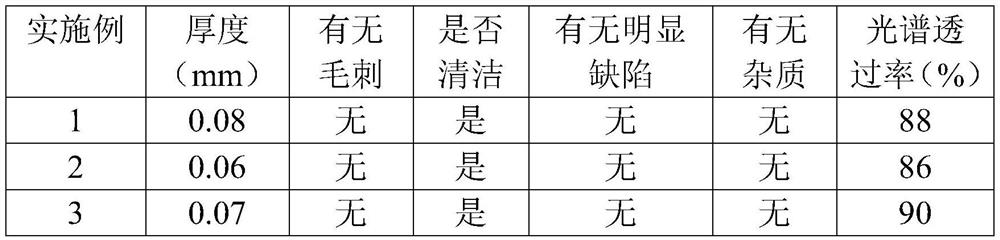

Processing method of K9 ultrathin glass

InactiveCN112408806AIncrease speedControllable thicknessGlass severing apparatusGlass tileSmooth surface

The invention relates to the technical field of optical glass processing, in particular to a processing method of K9 ultrathin glass, which comprises the following steps: cutting a thick and heavy K9glass brick raw material to obtain a K9 glass sheet as a semi-finished product for later use; then, subjecting the obtained K9 glass sheet to polishing and thinning for multiple times to obtain K9 ultrathin glass, wherein the process specifically comprises the steps of physical thinning, attaching and fixing, chemical thinning, cleaning, mechanical thinning and peptizing; cutting and inspecting afinished product; and finally, packaging and storing the finally obtained product. The advantages of physical thinning, chemical thinning and mechanical thinning are brought into full play, the thinning speed is high, the thinning thickness is controllable, and the K9 ultrathin glass with the ideal thickness and the flat and smooth surface is obtained; and by the adoption of a top-spraying waterfall flow type chemical thinning method, an etching solution can be recycled, energy and cost are saved, the automation degree of industrial production is improved, and application and popularization are facilitated.

Owner:TRIUMPH SCI & TECH GRP CO LTD +1

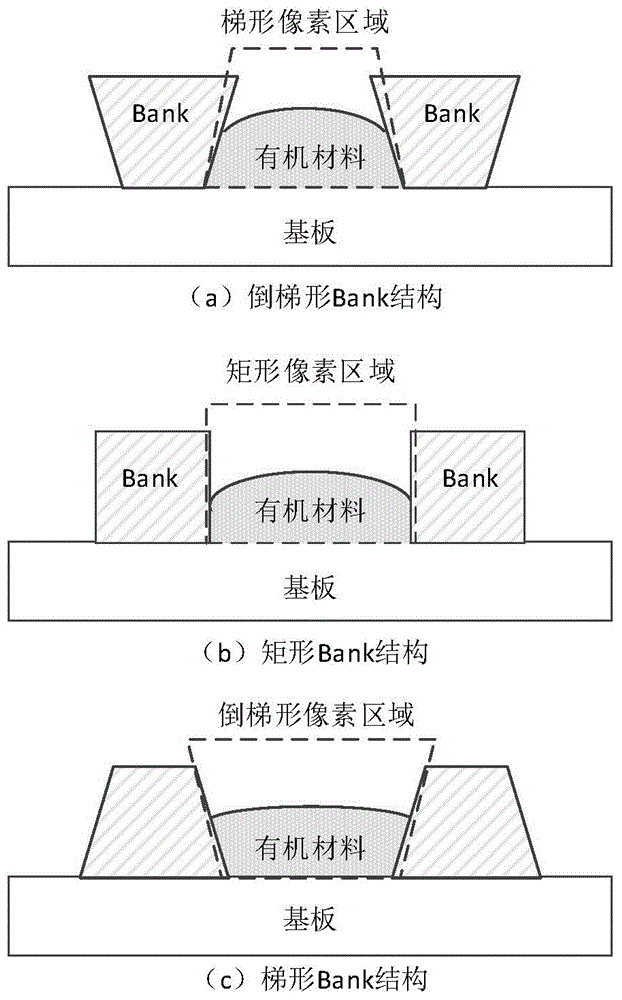

Preparation method for trapezoid pixel Bank structure and OLED device

ActiveCN105070685AImprove etching precisionImprove Pixel AccuracySolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionEngineering

The invention is applicable to the printing and displaying technology field and provides a preparation method for a trapezoid pixel Bank structure and an OLED device. The preparation method for the trapezoid pixel Bank structure comprises steps of providing a TFT backboard, preparing a Bank layer on the electrode of the TFT backboard, performing two times of exposure, development and etching on the Bank layer to form an inverted trapezoid pixel area, and obtaining a trapezoid pixel Bank structure having the trapezoid Bank. The preparation method for the trapezoid pixel Bank can effectively compensate the transverse corrosion for the pixel Bank by the developing liquid and corrosive liquid and can overcome the affect on the uniformity of the member pixel caused by the over-etching on the bottom of the Bank. In the meantime, the invention adopts the exposure mode of concentrating light first and scanning then to perform exposure processing on the positive Bank material, which improves the pixel accuracy of the display member and thus improves the resolution of the printing display member.

Owner:TCL CORPORATION

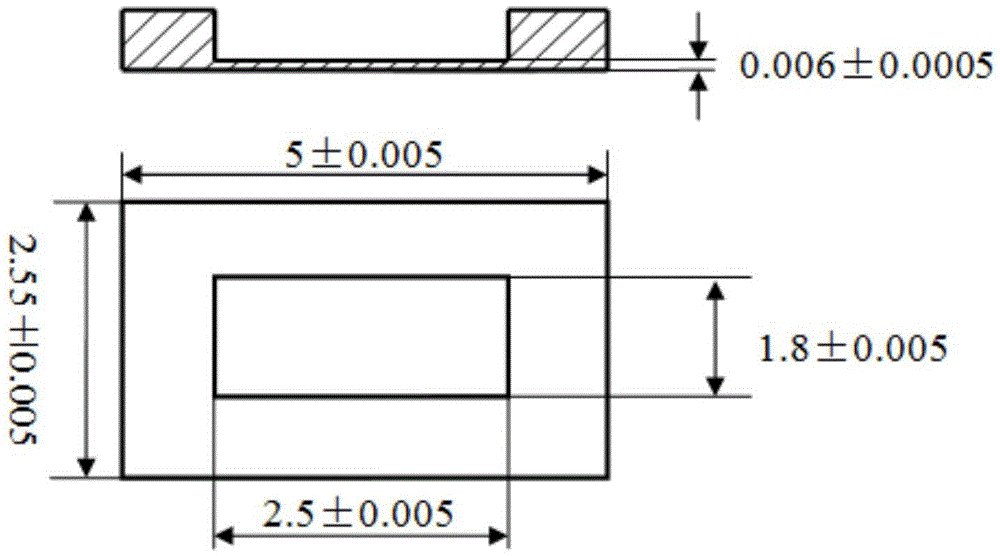

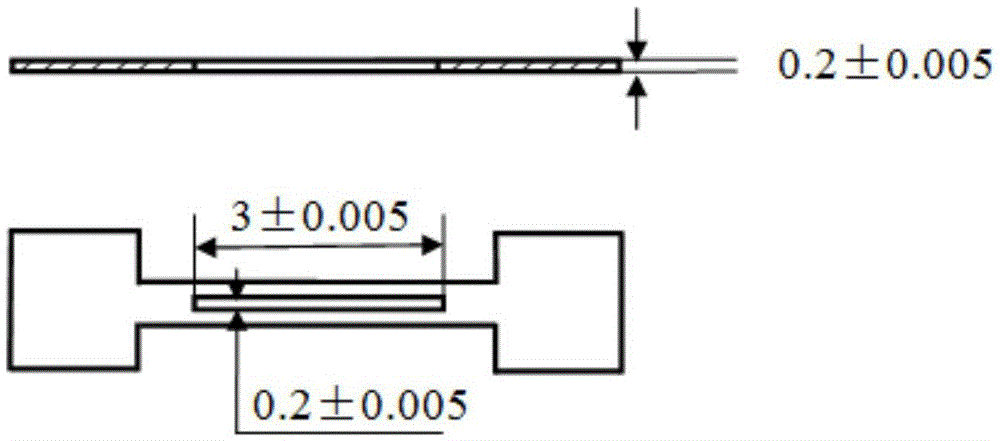

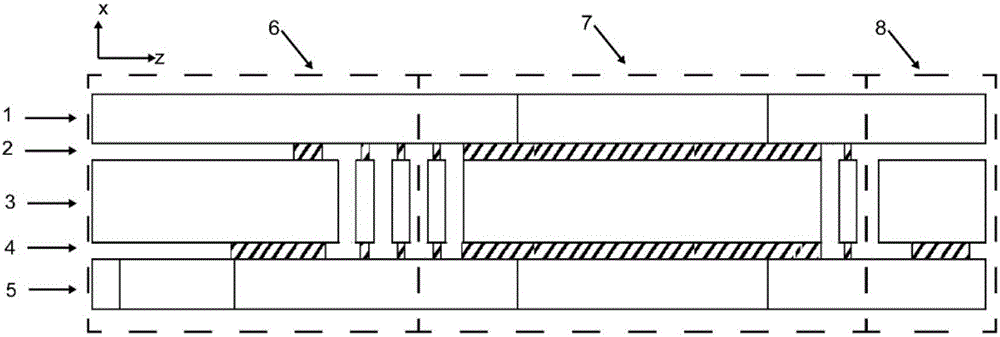

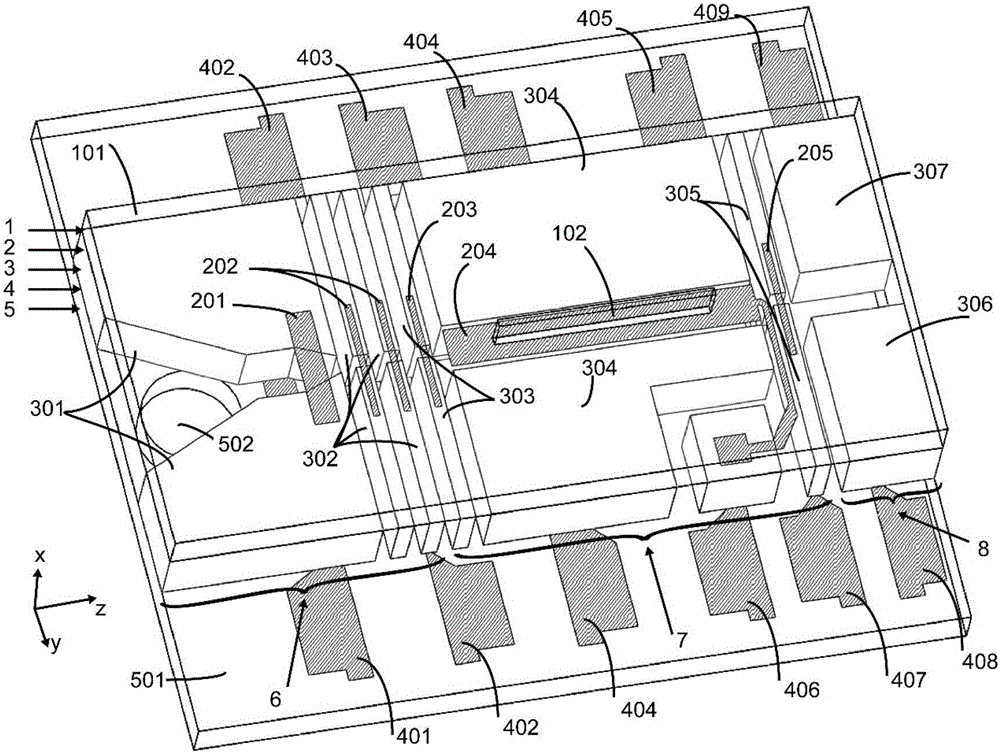

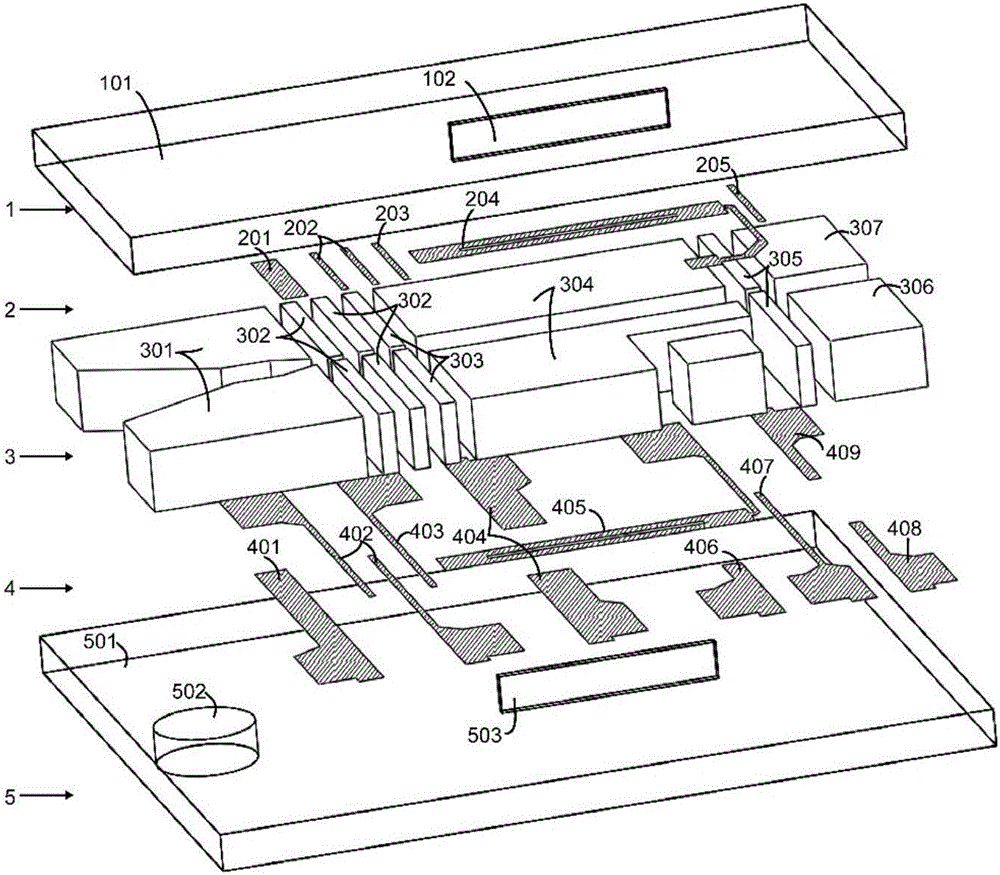

MEMS technology based multilayer structured rectangular ion trap and preparation method thereof

ActiveCN106024575AReduce volumeReduce weightStability-of-path spectrometersMicrominiaturised spectromotorsIon currentMass Spectrometry-Mass Spectrometry

The invention provides an MEMS technology based multilayer structured rectangular ion trap and preparation method thereof. The rectangular ion trap comprises an upper glass layer, a lower glass layer, an upper electrode layer grown on the lower surface of the upper glass layer, a lower electrode layer grown on the upper surface of the lower glass layer, as well as a silicon layer bonded between the lower surface of the upper glass layer and the upper surface of the lower glass layer. With such a design, a multilayer bonding structure featuring glass-metal-silicon-metal-glass is formed wherein the upper electrode layer, the silicon layer and the lower electrode layer are enclosed to form an ion flow channel. The ion flow channel is successively divided into an ion focal area and an ion analyzing area in the direction of ion current. The preparation method of the invention adopts MEMS technology, has low energy consumption, high processing precision, high yield, strong bonding strength and good long-term stability; in addition, the rectangular ion trap is advantageous in that its size is small and its weight is light. It has wide application prospects in the field of micro-mass spectrometry analysis and detection.

Owner:TSINGHUA UNIV

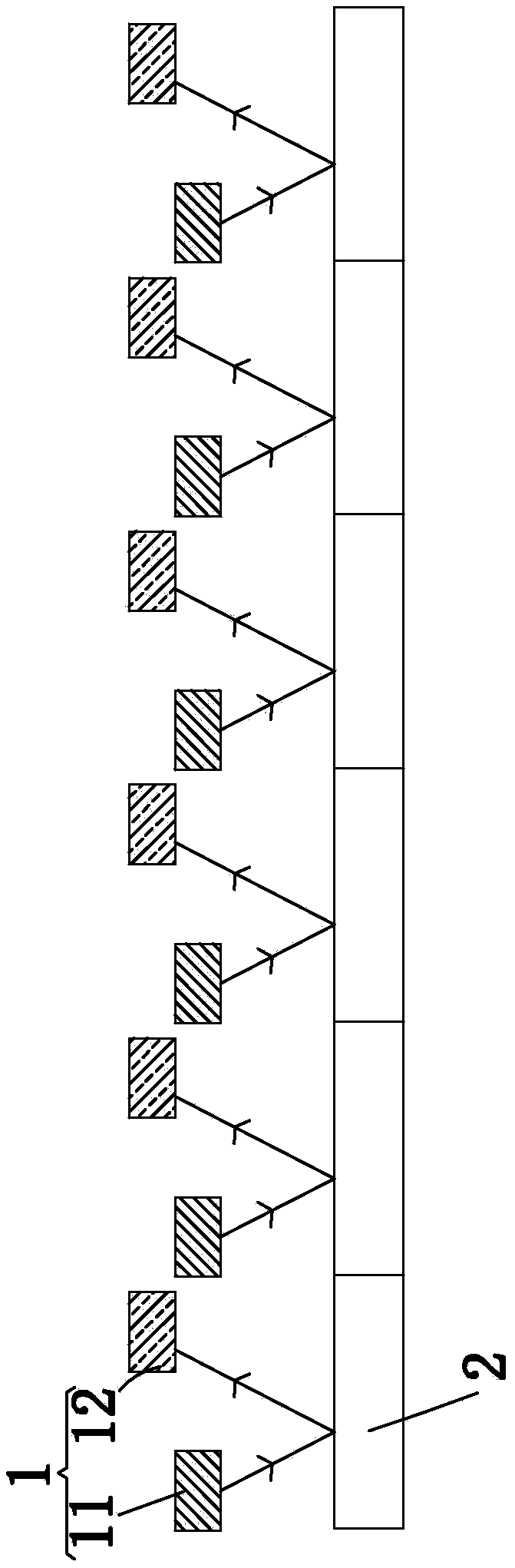

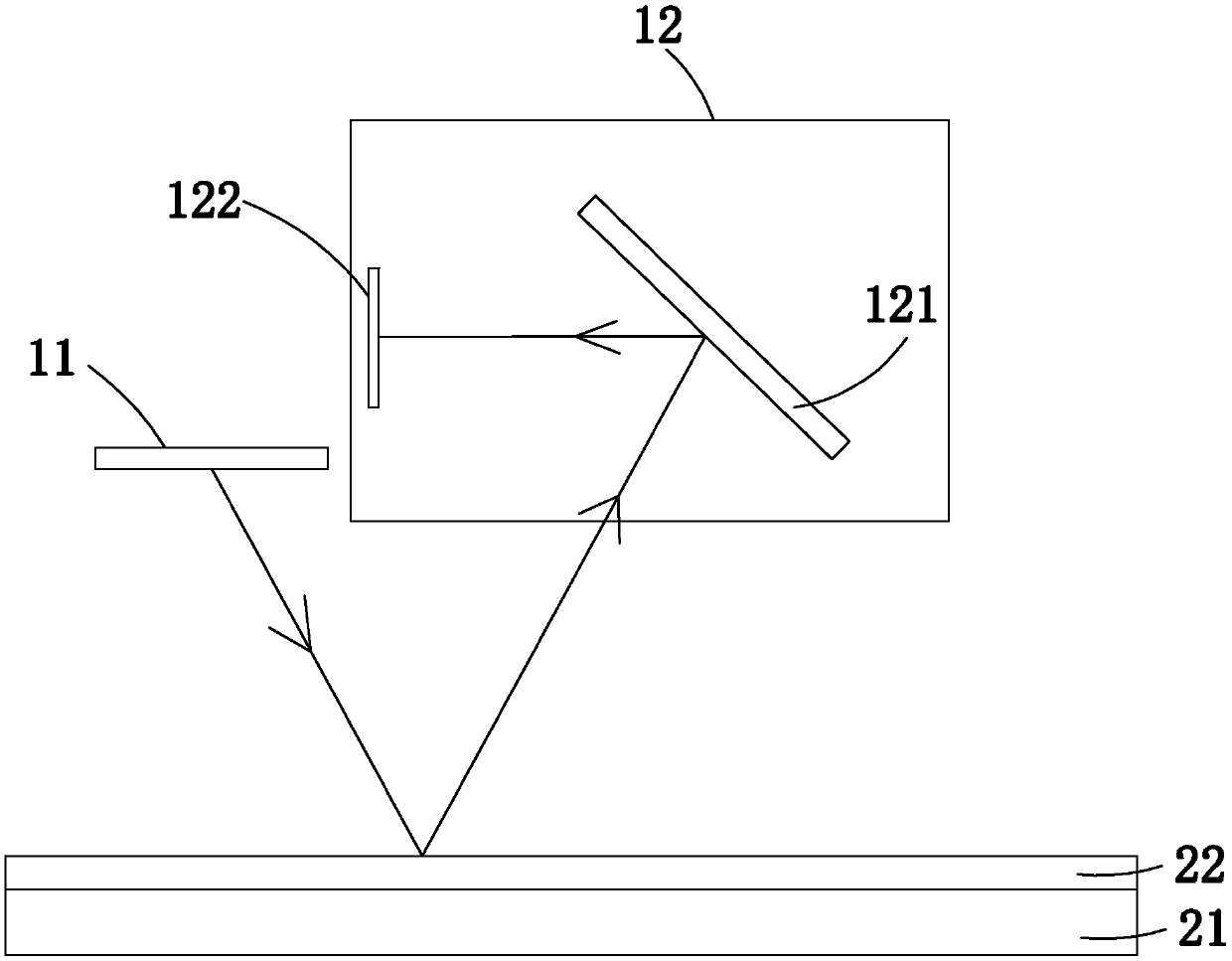

Etching monitoring device and etching monitoring method

ActiveCN109659262AImprove etching precisionMonitoring the etch processSemiconductor/solid-state device manufacturingNon-linear opticsComputer moduleOptoelectronics

The invention provides an etching monitoring device and an etching monitoring method. The etching monitoring device includes a plurality of monitoring units. Each of the monitoring units includes an incident light source and a signal processing module corresponding to the incident light source. Each incident light source is disposed corresponding to an etched region on the substrate to be etched.Different incident light sources correspond to different etched regions. The incident light sources are used for emitting incident light to the corresponding etched regions. The signal processing module is used for receiving reflected light, and converting the reflected light into a corresponding electrical signal according to the intensity of the reflected light. The etching stats of the substrate to be etched are determined by monitoring the change of the obtained electrical signal through the conversion of each signal processing module; the etching process can be effectively monitored; accurate data is provided for etching quality analysis; and development of etching processes and improvement of etching precision are promoted.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com