Etching liquid for copper molybdenum and alloy films as well as preparation method of etching liquid

A technology of alloy film and etching solution, which is applied in the field of etching solution of copper molybdenum and alloy film and its preparation, can solve the problems of increasing the manufacturing cost and manufacturing cycle of display products, and the negative impact on the resolution of display products, etc., achieving excellent Etching precision, environmental friendliness, effect of improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

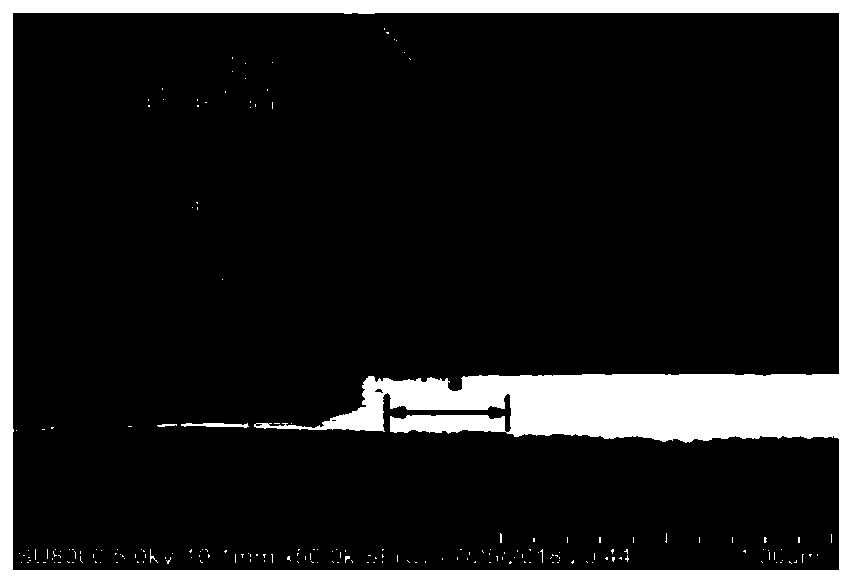

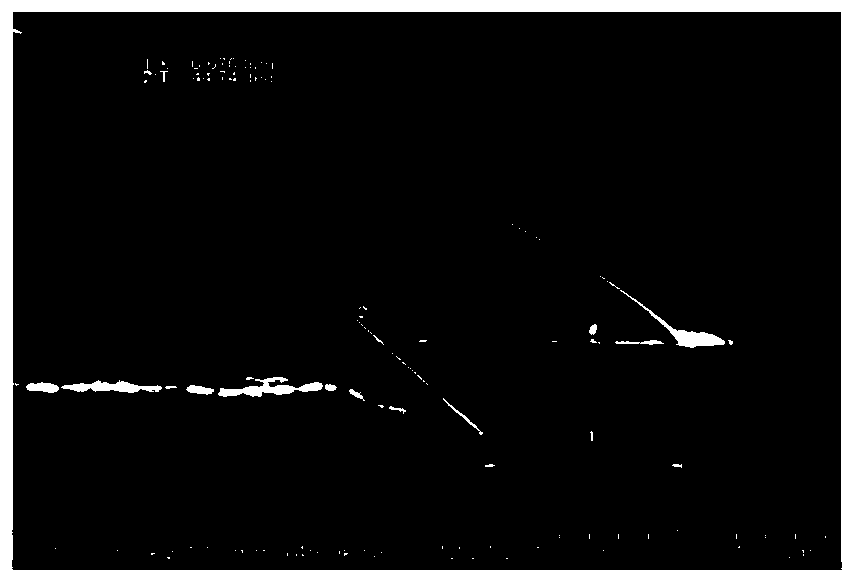

Image

Examples

preparation example Construction

[0052] The second aspect of the present invention is to provide the preparation method of the aforementioned etching solution, comprising: mixing and stirring hydrogen peroxide, hydrogen peroxide stabilizer, amine pH regulator, complexing agent, metal corrosion inhibitor, and water to obtain the method for use in the present invention. Copper molybdenum and alloy film etchant.

[0053] Wherein, the mass percent content of each component in the etching solution is the same as that described above, and will not be repeated here.

[0054] Specifically, hydrogen peroxide can be mixed with water first, and then hydrogen peroxide stabilizers, amine pH regulators, complexing agents, and metal corrosion inhibitors can be added to the mixing system. The order of adding the corrosion inhibitor, complexing agent and metal corrosion inhibitor is not limited.

[0055] The preparation method of the etching solution of the present invention has relatively low technological difficulty, and c...

Embodiment 1

[0061] The etchant of the present embodiment comprises the following components according to mass percentage:

[0062] Hydrogen peroxide 10%

[0063] Hydrogen peroxide stabilizer: malonic acid 1.5%, succinic acid 2.2%, phenylurea 0.2%

[0064] Amine pH regulator: N,N-Diaminoethylethylenediamine 2.8%

[0065] Complexing agent: glutamic acid 3.66%

[0066] Metal corrosion inhibitor: 2-aminopyrimidine 0.05%

[0067] Water: 79.59%

[0068] The above components were mixed and stirred at 32° C. to obtain the etching solution of this embodiment.

[0069] The additives of the etching solution in this embodiment include the following components according to the mass percentage:

[0070] Hydrogen peroxide stabilizer: malonic acid 4.88%, succinic acid 4.57%, phenylurea 0.2%

[0071] Amine pH regulator: N,N-Diaminoethylethylenediamine 6.53%

[0072] Complexing agent: glutamic acid 5.58%

[0073] Metal corrosion inhibitor: 2-aminopyrimidine 0.05%

[0074] Water: 78.19%

[0075] T...

Embodiment 2

[0077] The etchant of the present embodiment comprises the following components according to mass percentage:

[0078] Hydrogen peroxide 12%

[0079] Hydrogen peroxide stabilizer: p-hydroxybenzenesulfonic acid 0.3%, succinic acid 2.16%, phenylurea 0.15% Amine pH regulator: N, N-dihydroxyethylpropylenediamine 2.12%

[0080] Complexing agent: malonic acid 3.66%

[0081] Metal corrosion inhibitor: 3-amino-1,2,4 triazole 0.04%

[0082] Water: 79.57%

[0083] The above components were mixed and stirred at 32° C. to obtain the etching solution of this embodiment.

[0084] The additives of the etching solution in this embodiment include the following components according to the mass percentage:

[0085] Hydrogen peroxide stabilizer: 6.54% succinic acid, 0.2% phenylurea

[0086] Amine pH regulator: N,N-Dihydroxyethylpropylenediamine 7.24%

[0087] Complexing agent: glutamic acid 3.75%

[0088] Metal corrosion inhibitor: 3-amino-1,2,4 triazole 0.1%

[0089] Water: 82.17%

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com