Wet etching method for ZnO-based transparent conductive film

A transparent conductive thin film, wet etching technology, used in circuits, electrical components, semiconductor devices, etc., can solve the problems of fast etching rate and difficult control, achieve low etching cost, inhibit lateral etching, select wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

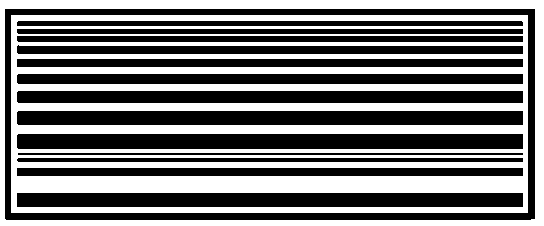

[0021] The Ga-doped ZnO-based transparent conductive film grown by the MOCVD method is glued and glued. use figure 1 The photoresist shown in the photoetching plate performs photolithography and development on the Ga-doped ZnO transparent conductive film, removes unnecessary photoresist, and obtains pattern structures with different line widths.

[0022] Mix glacial acetic acid and water at a ratio of 1:1, etch the above-mentioned Ga-doped ZnO-based transparent conductive film for 4 minutes, etch away the ZnO exposed from the glue, and then remove the glue.

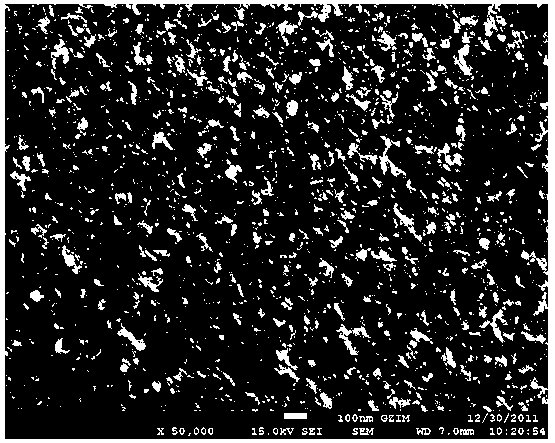

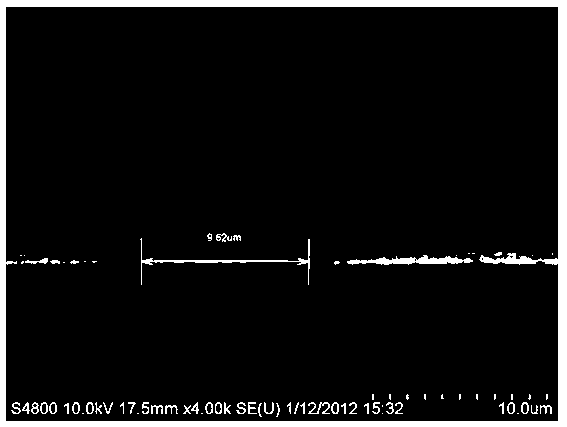

[0023] Scanning electron microscope (SEM) image of Ga-doped ZnO transparent conductive film grown by MOCVD before etching figure 2 Shown; the partial side scanning electron microscope (SEM) image formed by etching the ZnO-based thin film with acetic acid solution is shown in image 3 Shown; The scanning electron microscope (SEM) image of the partial cross-section formed by etching the ZnO-based film with acetic acid s...

Embodiment 2

[0025] The Al-doped ZnO-based transparent conductive film grown by MOCVD method has a film thickness of about 250nm, which is coated with glue and shaken off. use figure 1 The photoresist plate shown in the photolithography and development of the Al-doped ZnO transparent conductive film removes the unnecessary photoresist to obtain the pattern of the desired structure.

[0026] Mix glacial acetic acid and water at a ratio of 1:1 to etch the above-mentioned Al-doped ZnO-based transparent conductive film for 5 minutes to etch the ZnO-TCL exposed from the glue.

Embodiment 3

[0028] The Ga-doped ZnO-based transparent conductive film grown by MOCVD method has a film thickness of about 250nm, which is coated with glue and shaken off. use figure 1 The photoresist shown in the photoetching plate performs photolithography and development on the Ga-doped ZnO-based transparent conductive film, removes unnecessary photoresist, and obtains the desired etched structure pattern. The above-mentioned Ga-doped ZnO transparent conductive film was etched with ammonium chloride with a mass concentration of 15%, and the ZnO-TCL exposed from the glue could be etched away for 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com