Patents

Literature

45results about How to "Reduce etching costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Etching system and method for treating the etching solution thereof

InactiveUS20050263488A1Improve etch selectivityReduce etching costsDecorative surface effectsSemiconductor/solid-state device manufacturingPresent methodEngineering

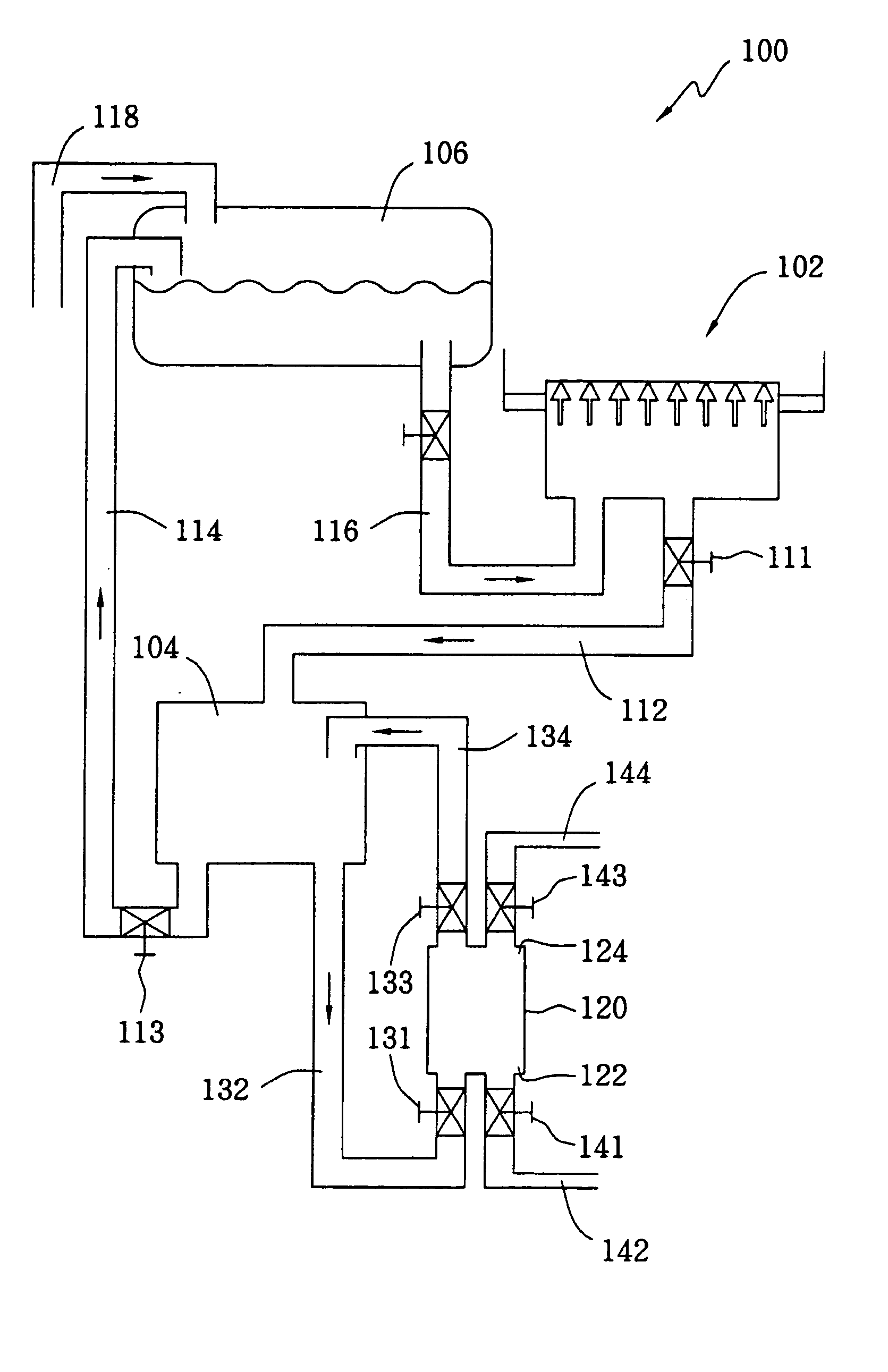

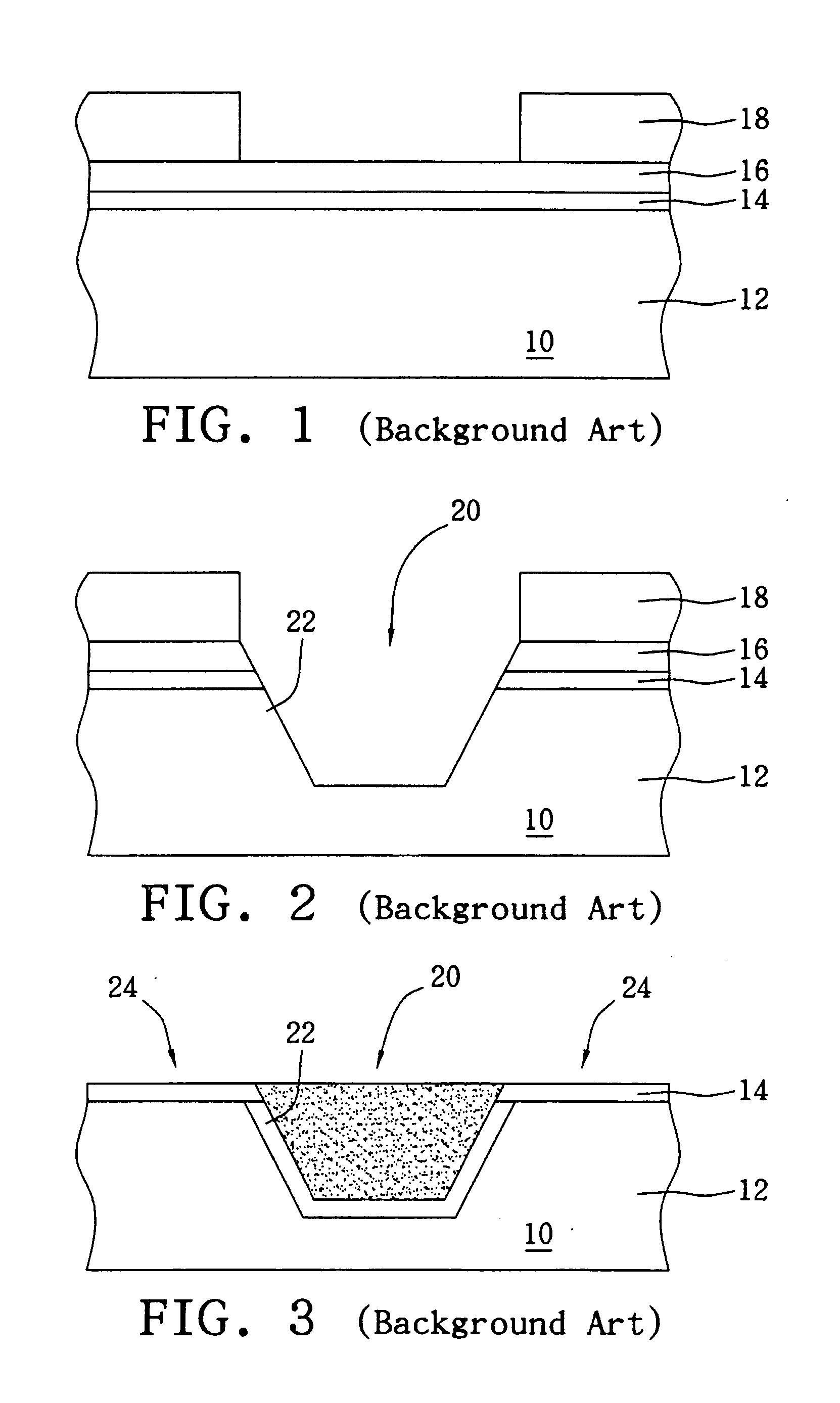

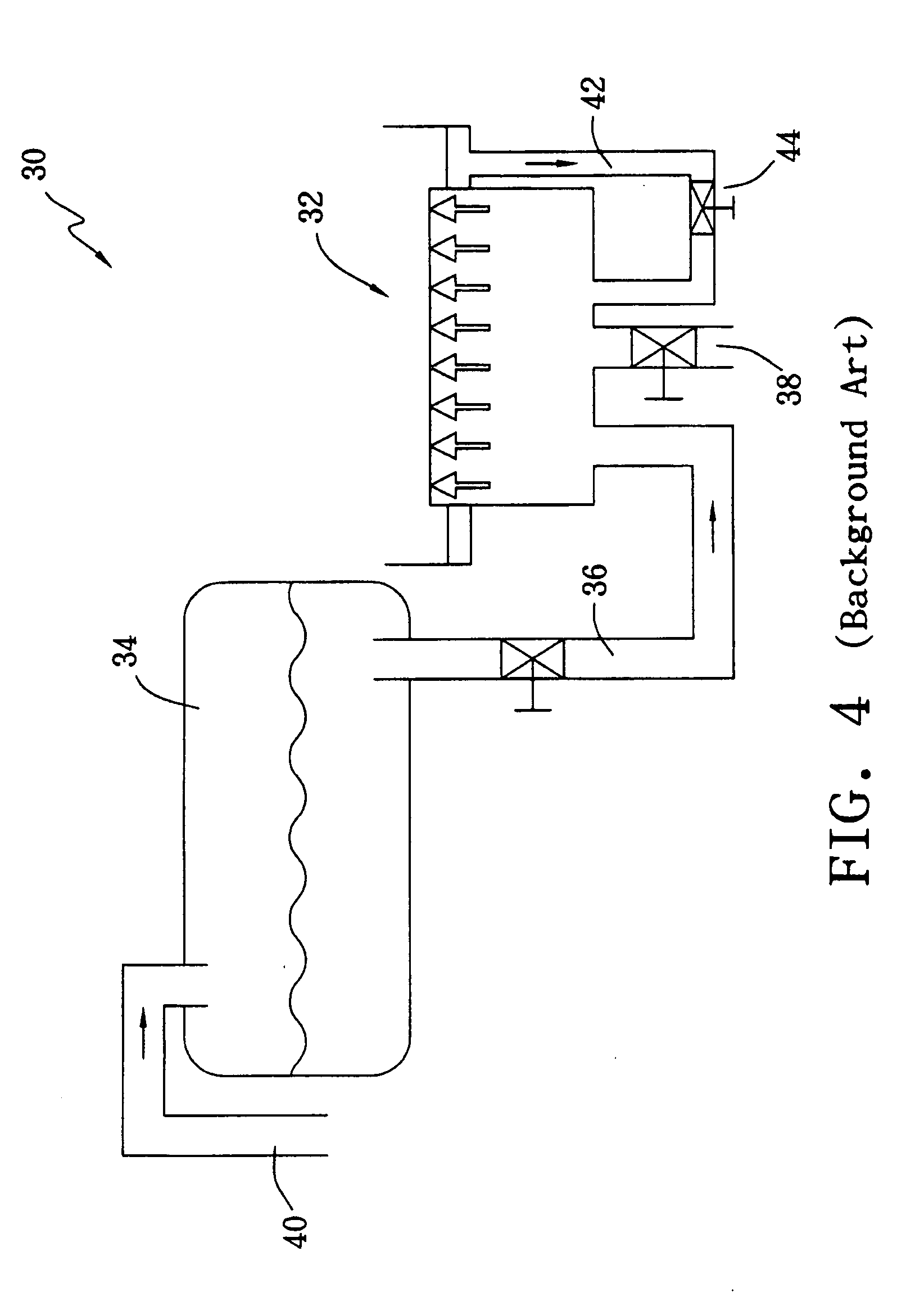

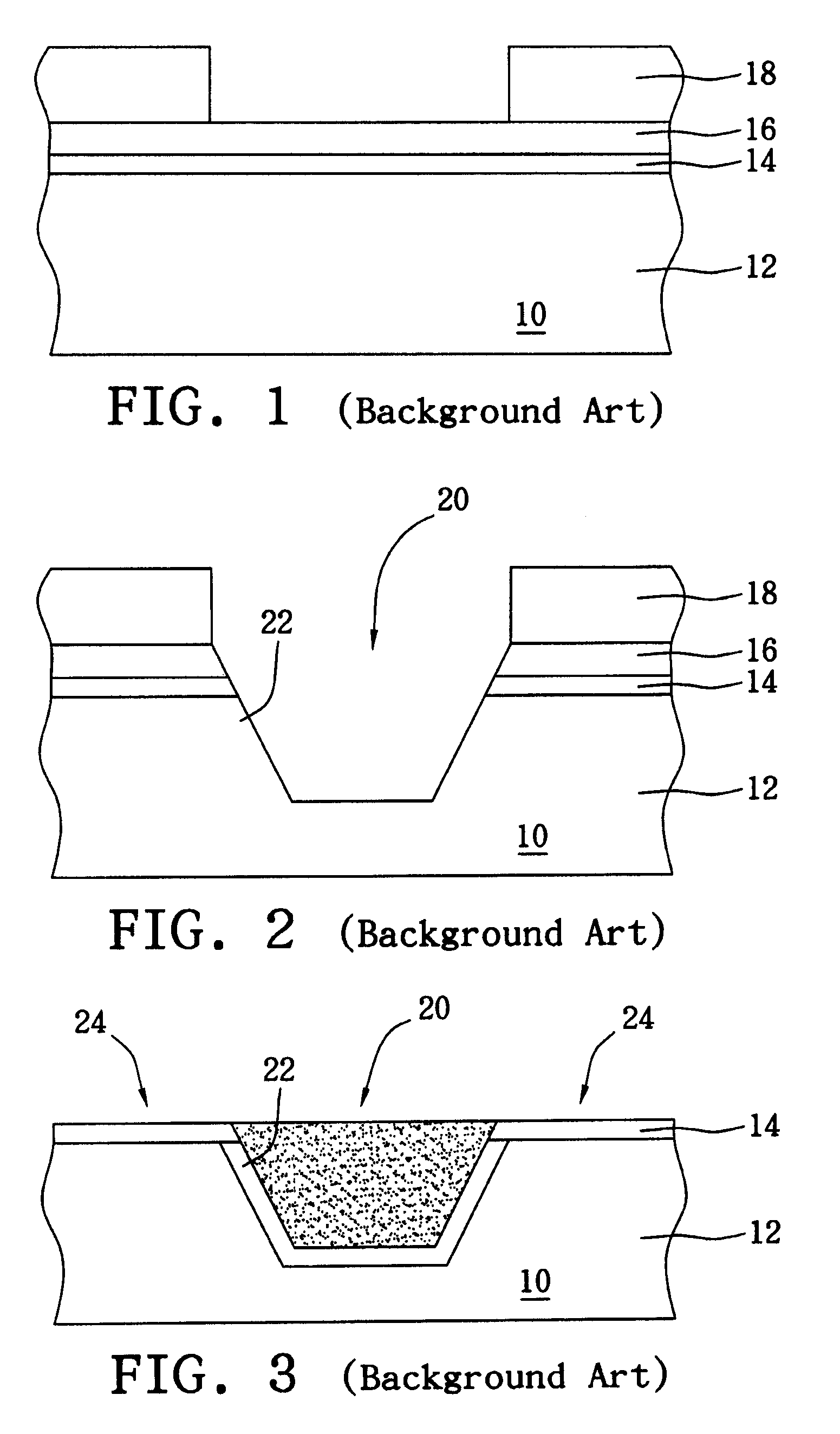

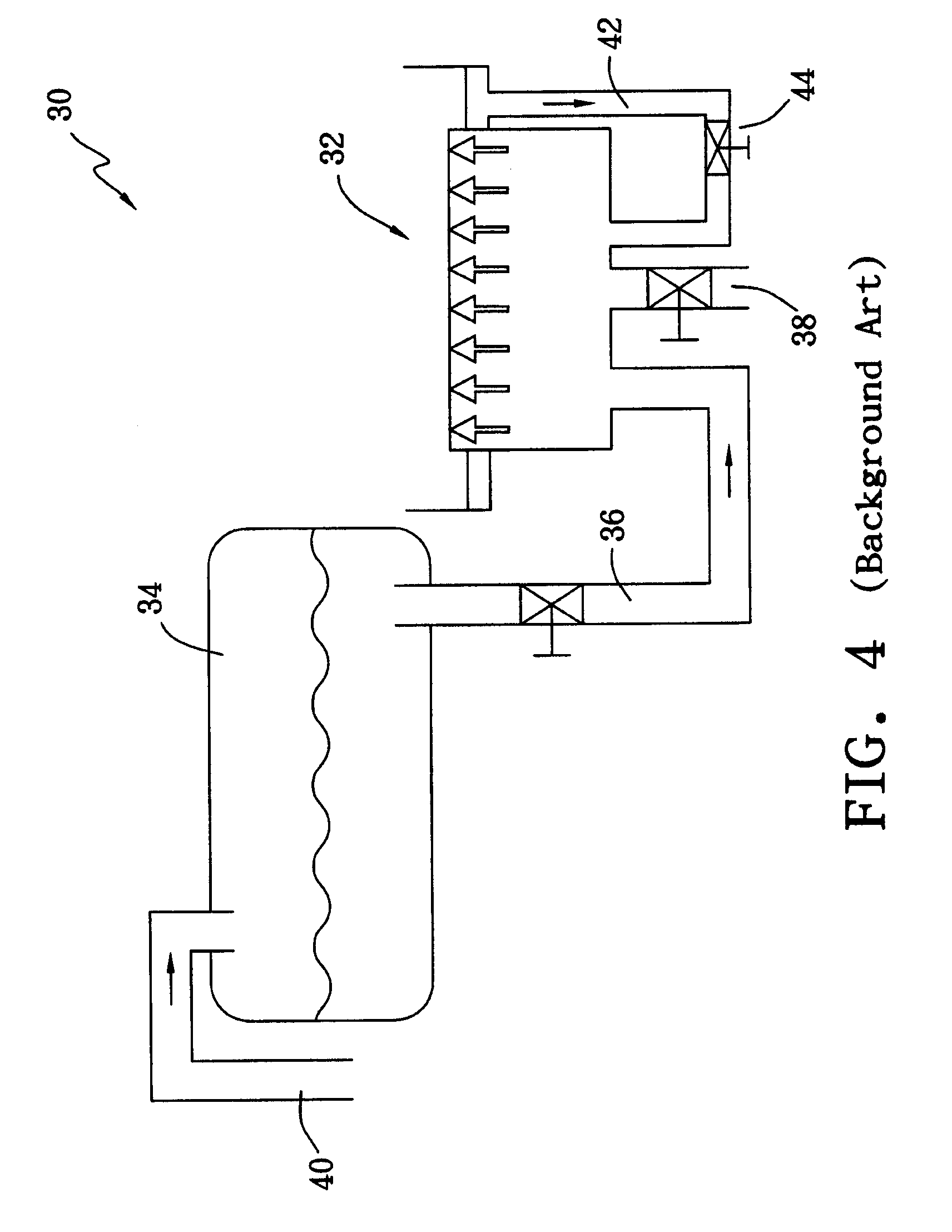

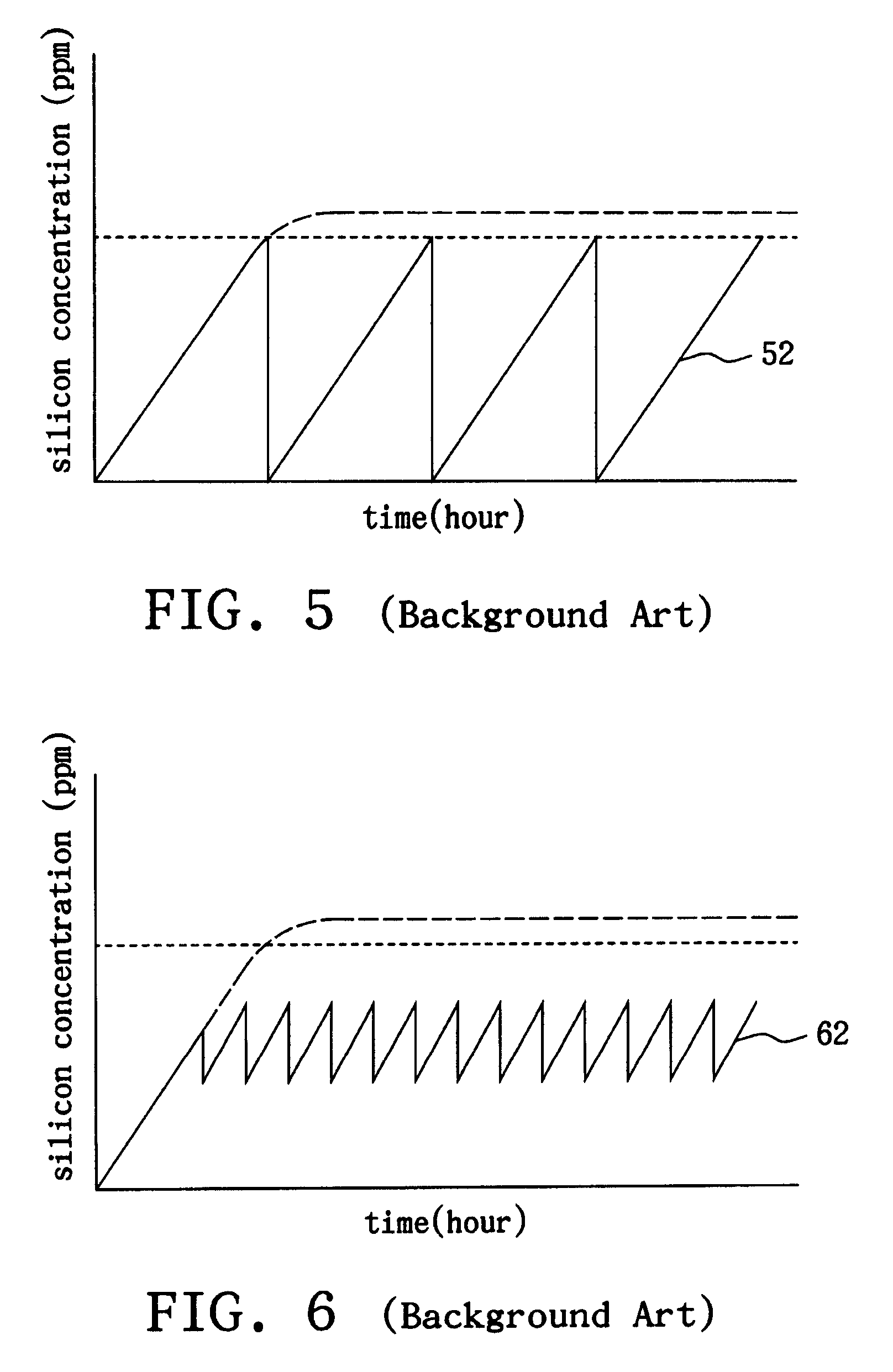

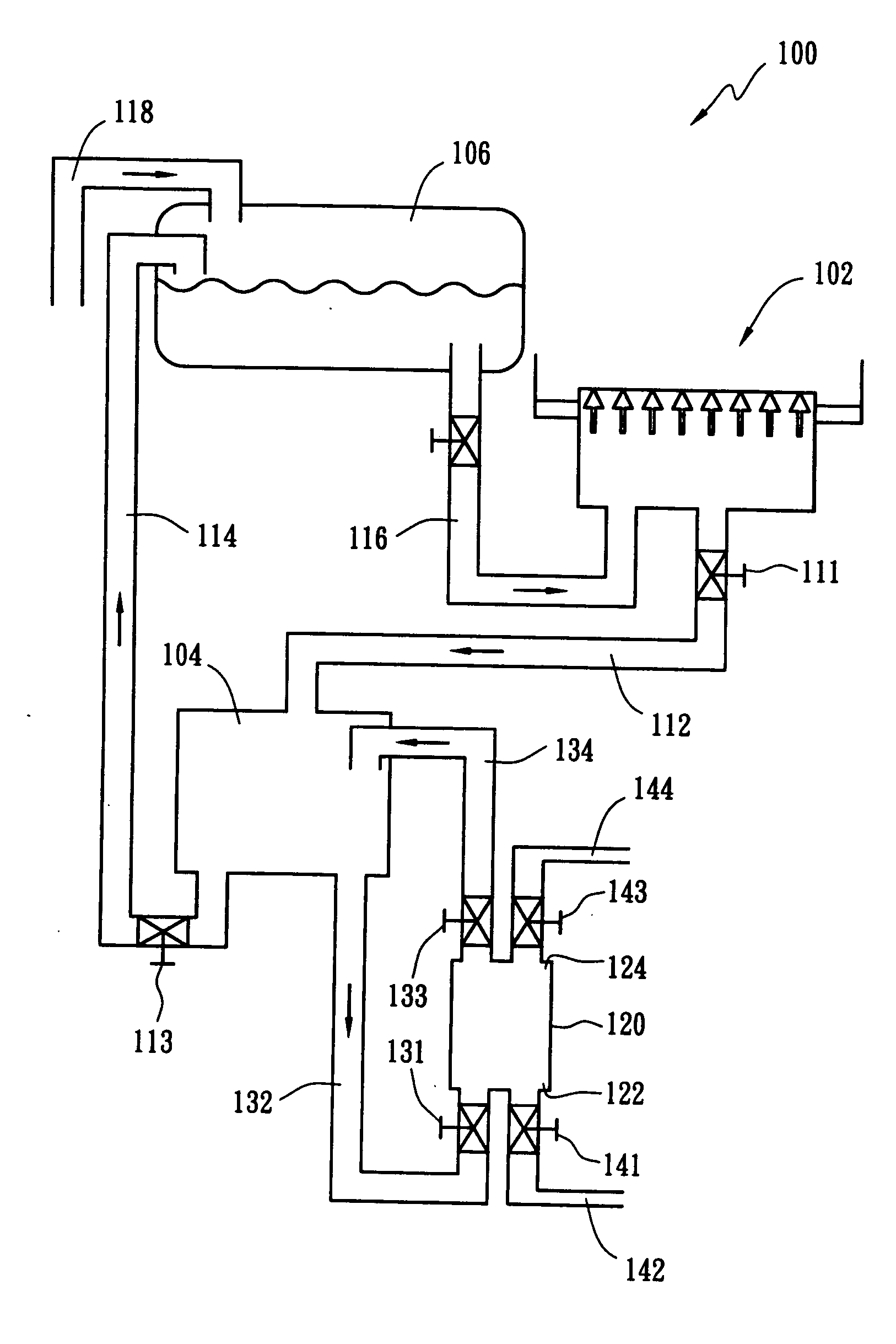

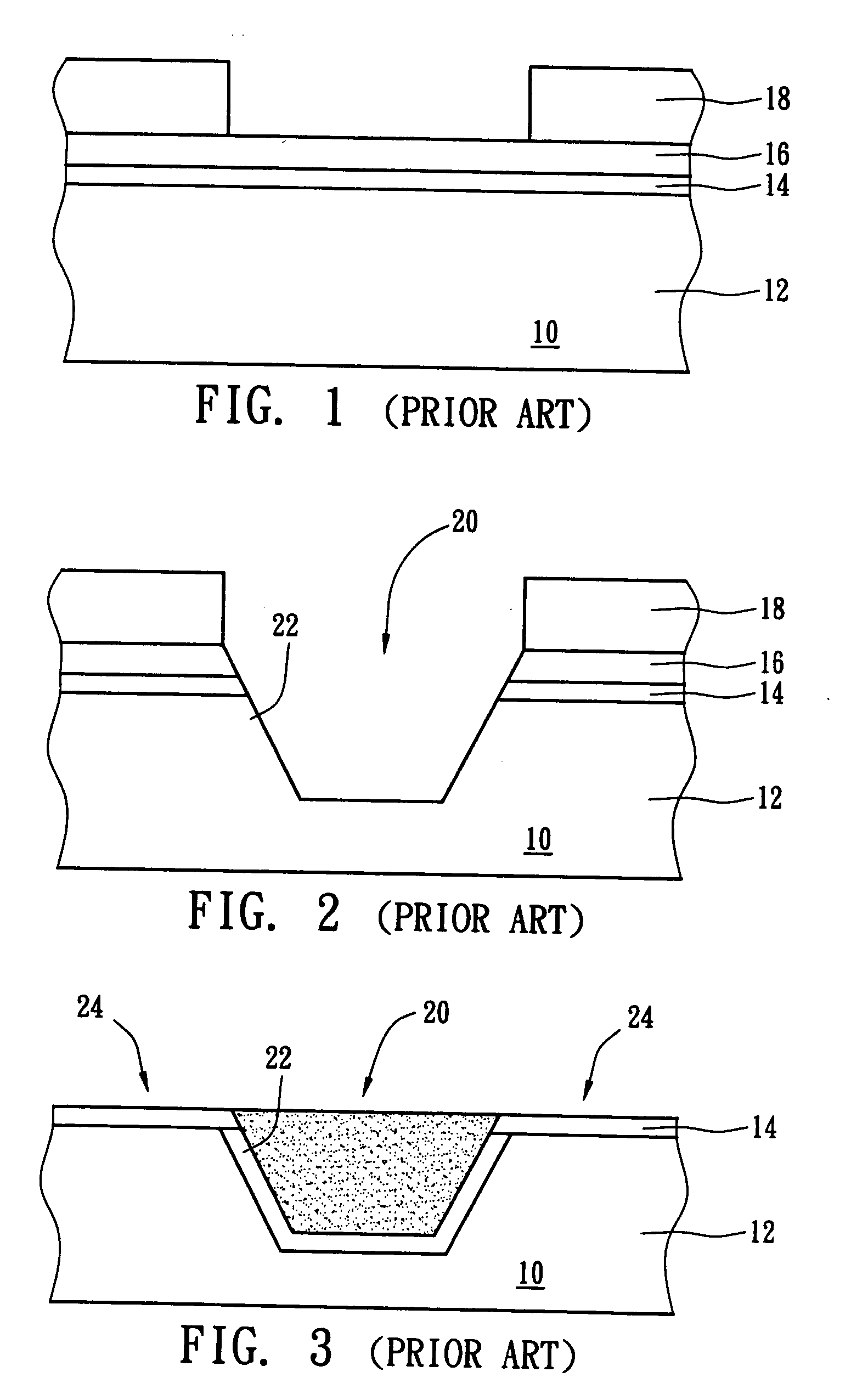

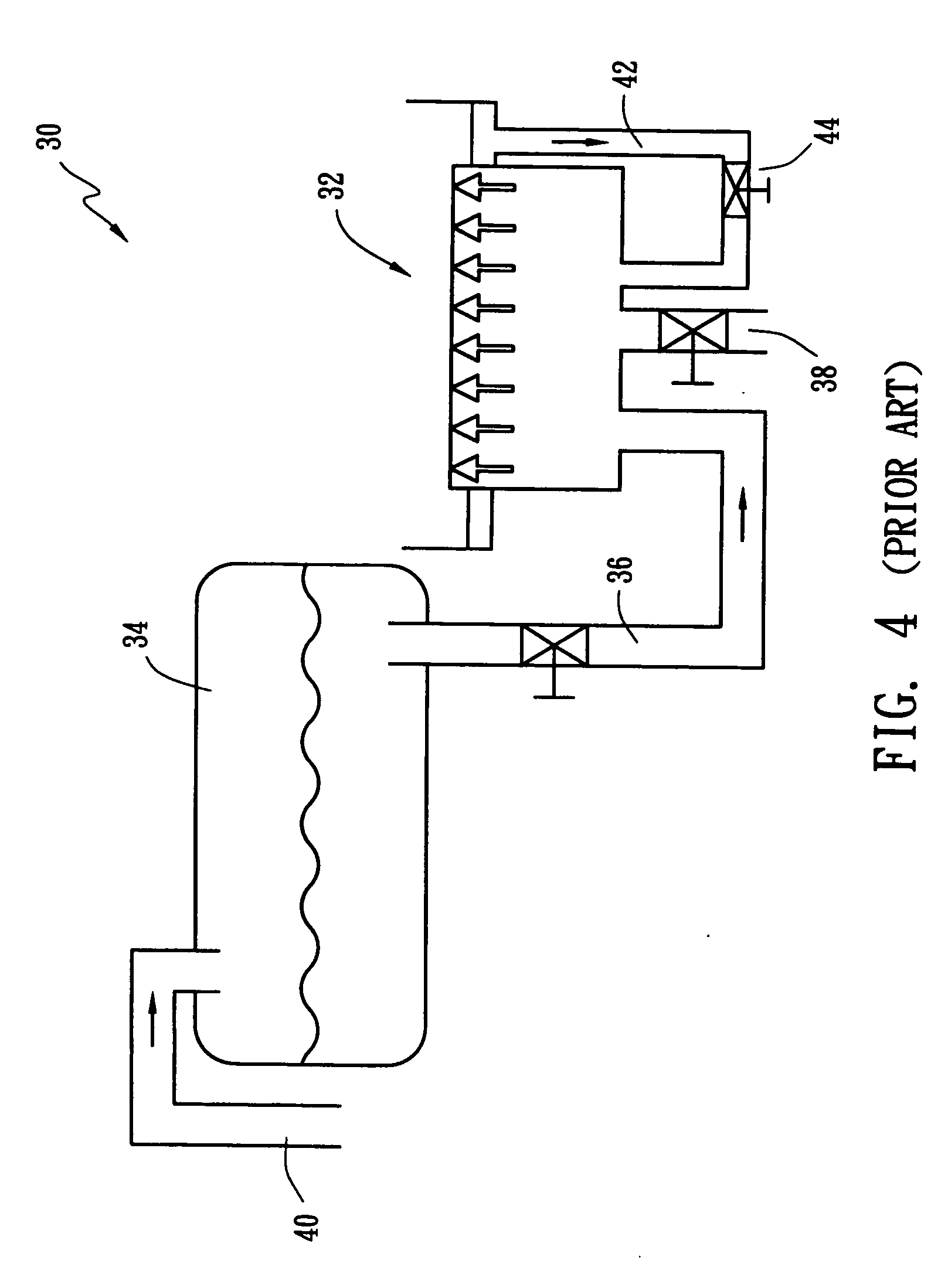

The present etching system includes a processing tank with an etching solution containing silicon, a cooling tank, a pre-heating tank, a first pipe for transferring the etching solution from the processing tank to the cooling tank, a second pipe for transferring the etching solution from the cooling tank to the pre-heating tank, and a third pipe for transferring the etching solution from the pre-heating tank to the processing tank. The present method for treating the etching solution first performs an etching process using the etching solution, which is then cooled to a first temperature to form a silicon-saturated etching solution. After silicon-containing particles larger than a predetermined size are filtered out, the silicon-saturated etching solution is heated to a second temperature to form a non-saturated etching solution for performing another etching process later. The second temperature is preferably at least 10° C. higher than the first temperature.

Owner:PROMOS TECH INC

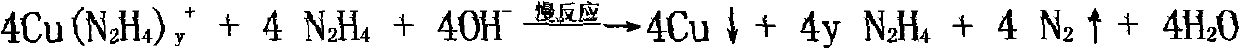

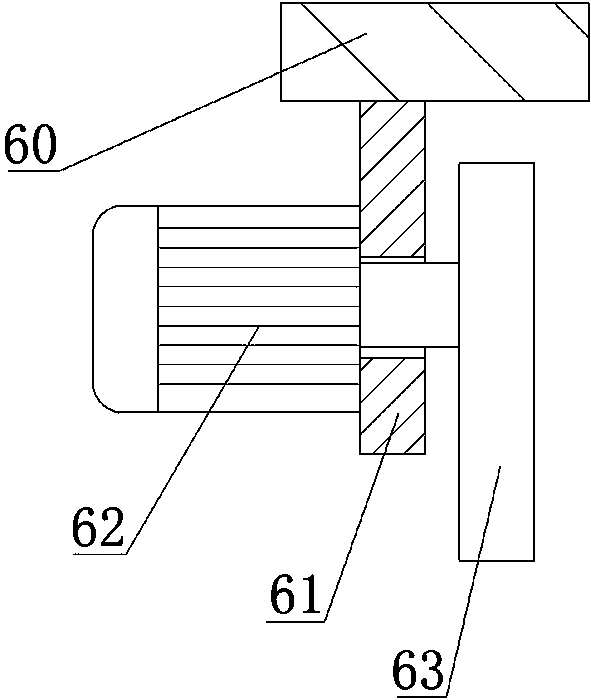

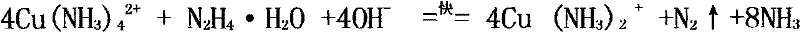

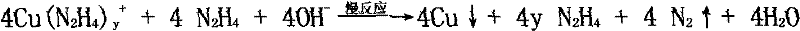

Method for recovering copper from alkaline etching waste liquid and recycling alkaline etching liquid

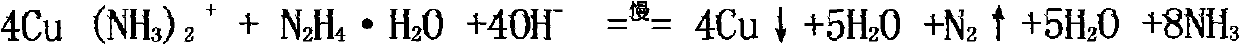

The invention discloses a method for recovering copper from alkaline etching waste liquid and recycling the alkaline etching liquid, comprising the step of adding a hydrazine hydrate reducing agent and a catalyst into the alkaline etching waste liquid to recover copper powder, wherein the alkaline etching waste liquid can be recycled after the copper powder is recovered. The invention has the optimum conditions of: placing the alkaline etching waste liquid into a reactor; adding hydrazine hydrate with mass percent concentration of 40 percent according to added quantity of 160-200mL / L; adding a solution of various salts of ruthenium, palladium, nickel and cobalt as the catalyst with added quantity of 0.01-0.2g / L (metered by the masses of the ruthenium, the palladium, the nickel and the cobalt), reacting for 30-35 minutes at temperature between 70DEG C and 100DEG C; and separating to obtain the copper powder. The invention has the beneficial effect that after the copper is recovered from the alkaline etching waste liquid, the alkaline etching waste liquid can be regenerated and recycled, therefore, various resources in the alkaline etching waste liquid can be used fully, and the etching cost of a printing plate and the discharge of pollutants can be reduced.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

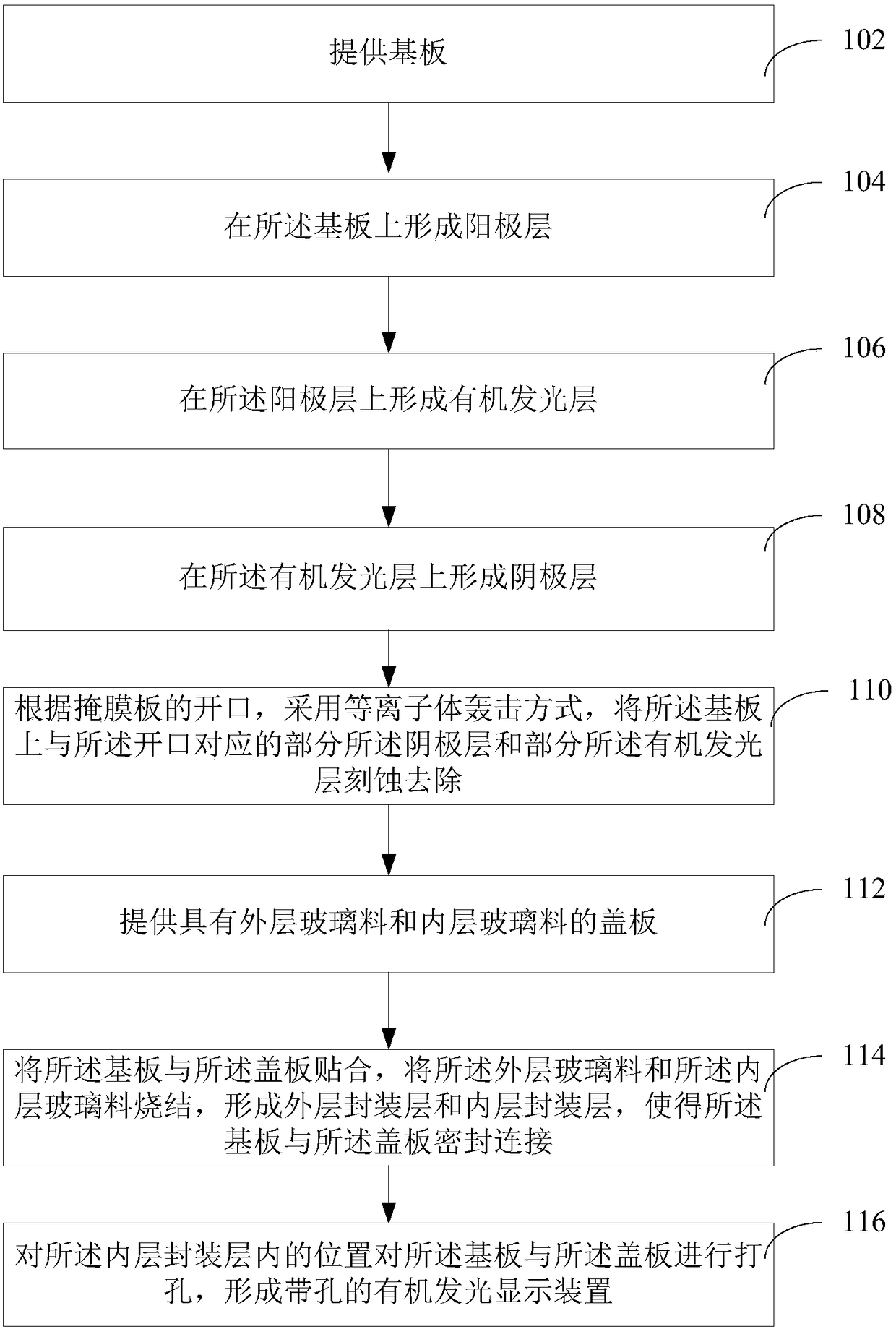

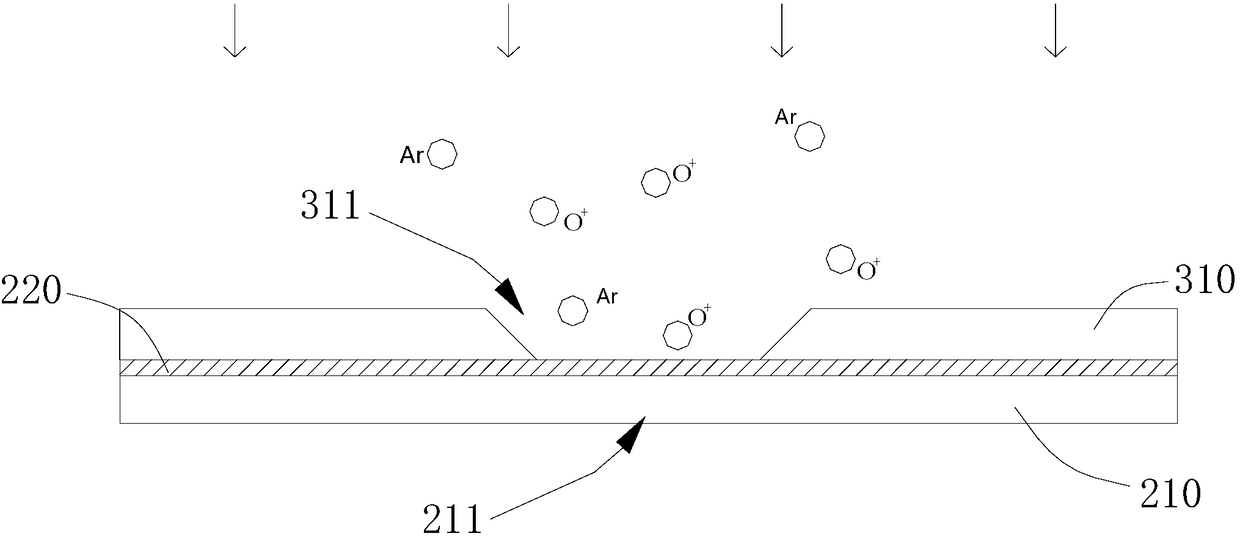

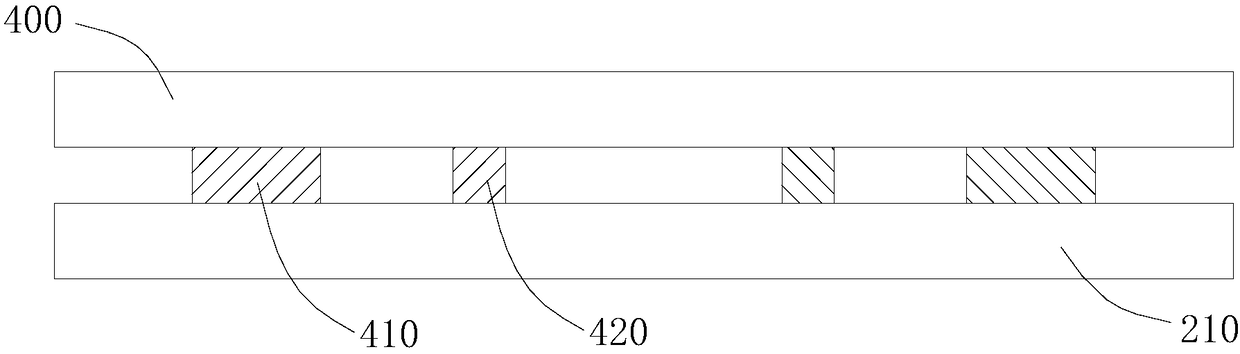

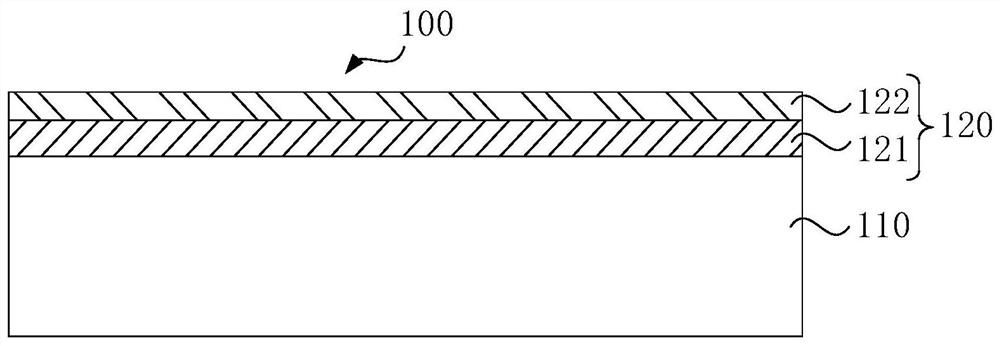

Organic light-emitting display apparatus and preparation method thereof

InactiveCN108206244AEfficient etchingWon't burnSolid-state devicesSemiconductor/solid-state device manufacturingEtchingChemistry

The invention relates to an organic light-emitting display apparatus and a preparation method thereof. The preparation method comprises the steps of providing a substrate; forming a positive electrodelayer on the substrate; forming an organic light-emitting layer on the positive electrode layer; forming a negative electrode layer on the organic light-emitting layer; removing a part of the negative electrode layer and a part of the organic light-emitting layer which are corresponding to an opening in the substrate through etching by adopting a plasma bombardment mode through the opening of a mask plate; providing a cover plate with an outer layer glass material and an inner layer glass material; enabling the substrate to be laminated with the cover plate, and performing sintering on the outer layer glass material and the inner layer glass material to form an outer layer packaging layer and an inner layer packaging layer, and enabling the substrate and the cover plate to be connected ina sealing manner; and performing hole punching on the substrate and the cover plate in the inner layer packaging layer to form the organic light-emitting display apparatus with holes. By virtue of the plasma bombardment mode, more efficient organic material etching can be realized, and higher production efficiency and higher etching precision are achieved; and in addition, scalding to a pixel region can be avoided, the etching cost can be lower and the production cost can be lowered effectively.

Owner:TRULY HUIZHOU SMART DISPLAY

Etching liquor and circular use method thereof

The invention discloses etching liquor and a circular use method thereof. The etching liquor comprises copper chloride, organic amine, an oxidizing agent, an additive agent and deionized water. In each liter of etching liquor, 10 to 150 g of copper chloride, 10 to 200 g of organic amine, 1 to 100 g of the oxidizing agent, 1 to 100 g of the additive agent and the balance deionized water are included; in the use process of the etching liquor, the solution is alkaline, and the requirement for a device is not high, the use cost is low, operation is safe and environment-friendly, and a detection control system is simple; low etching is achieved, the etching speed is high, and stability is high. A membrane separation technology and a deposition reduction technology are combined, circular recycling of the etching liquor can be well achieved, a product after the reaction is nitrogen and water, other impurities are not brought in, and filter liquor obtained after copper filter and depositing can be recycled to be used for preparing new etching liquor.

Owner:长沙利洁环保科技有限公司

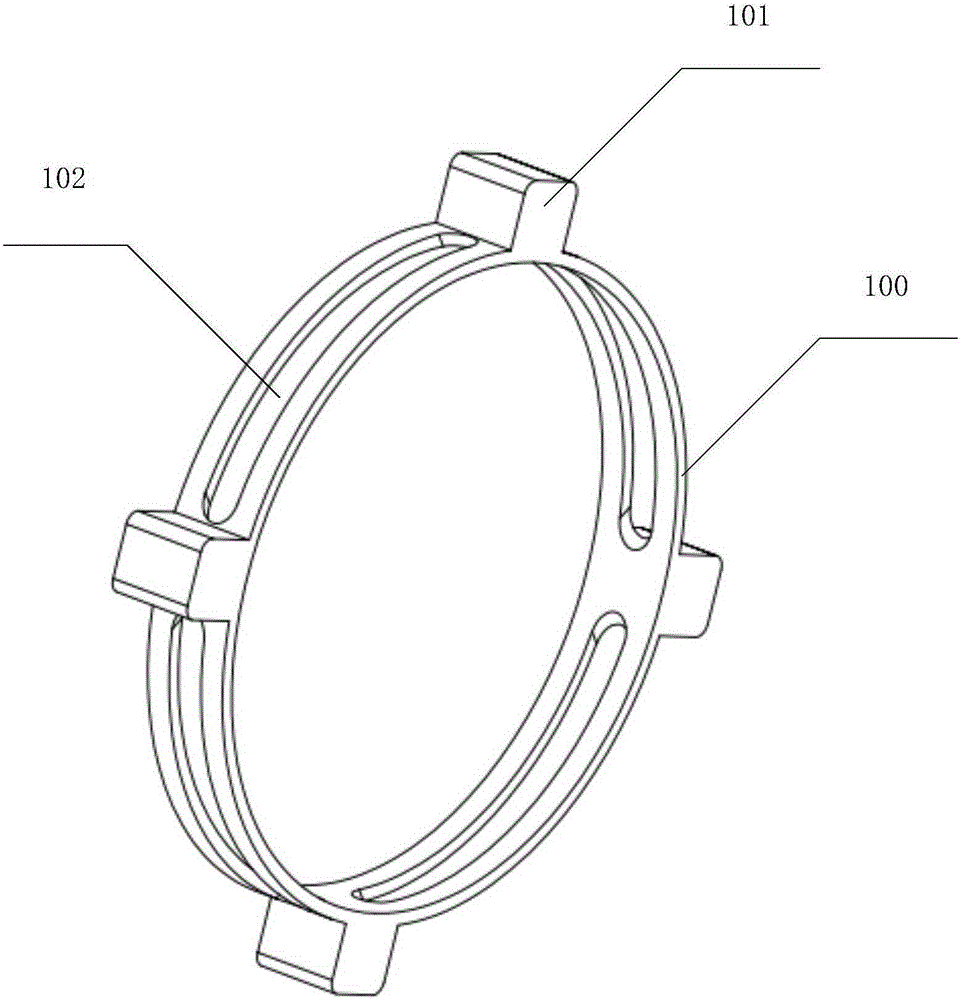

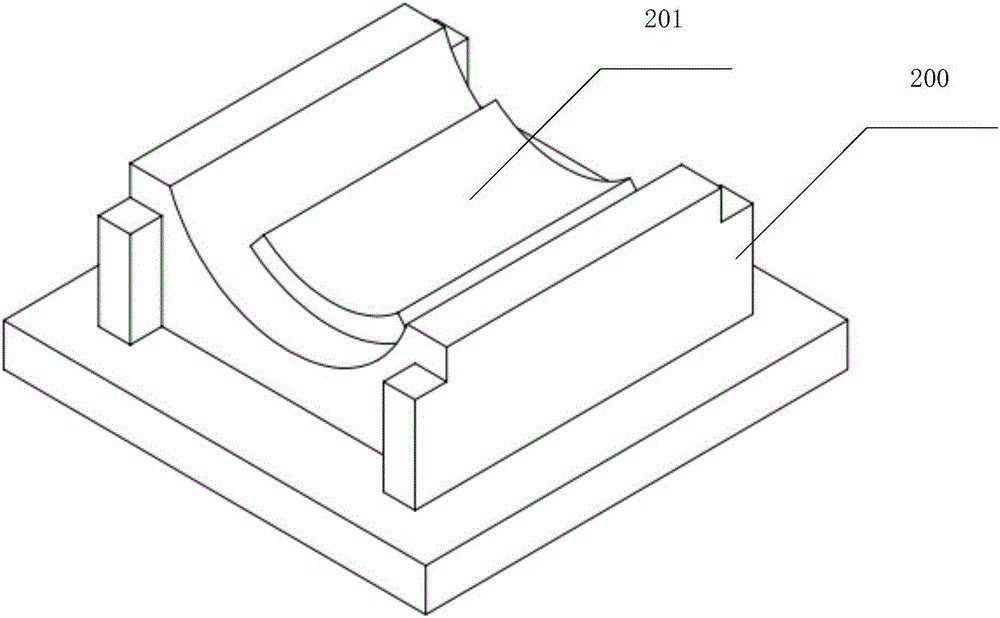

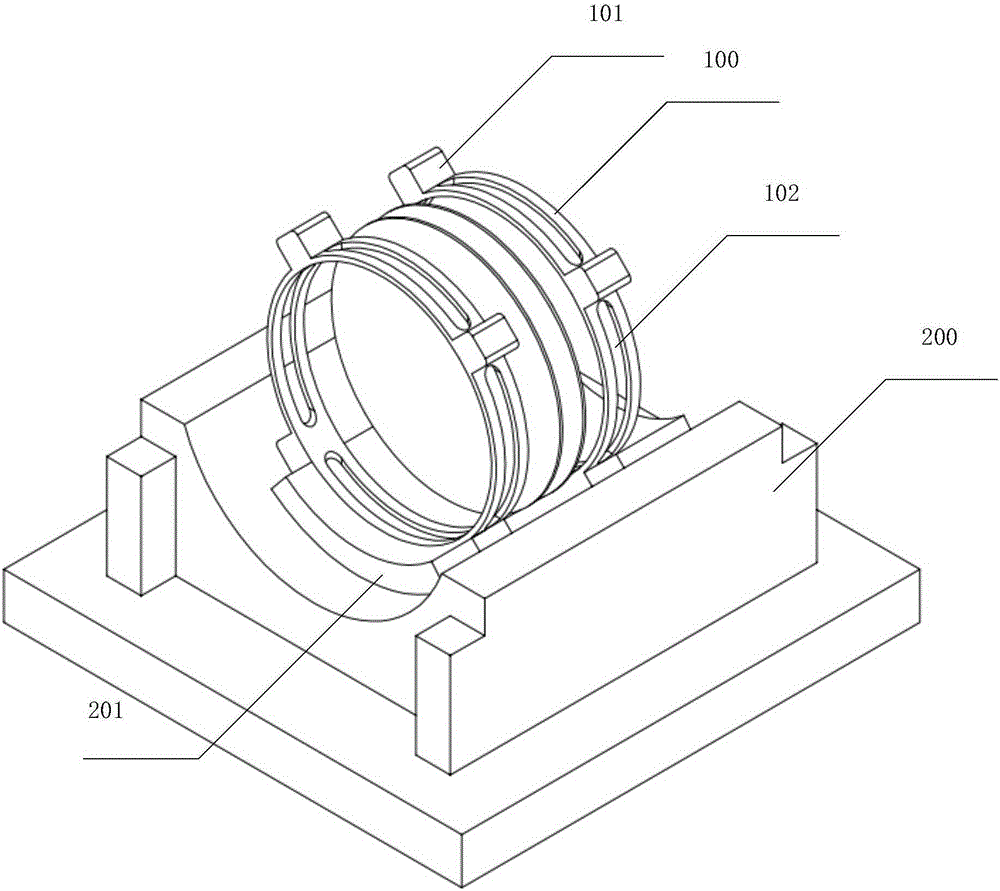

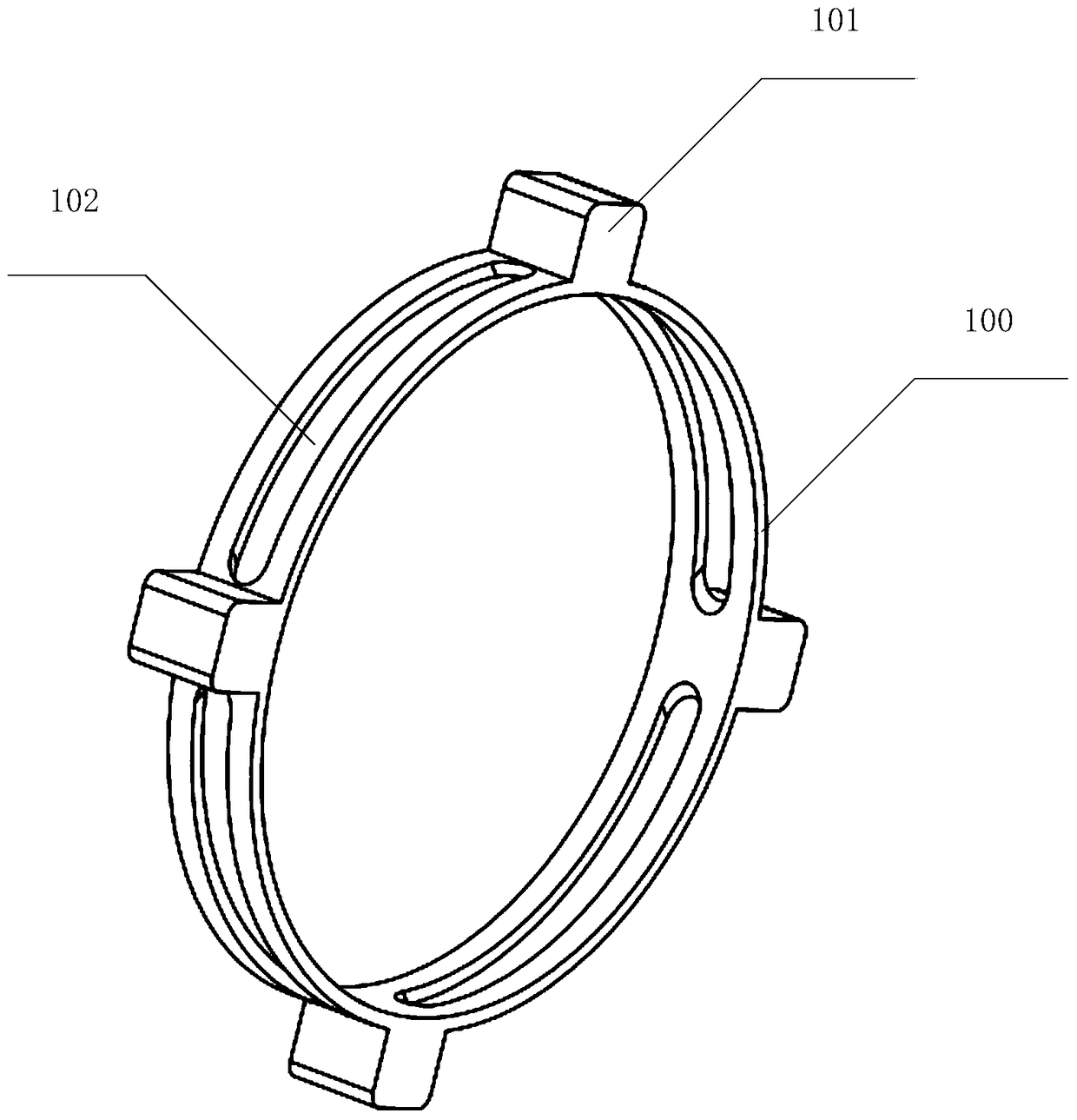

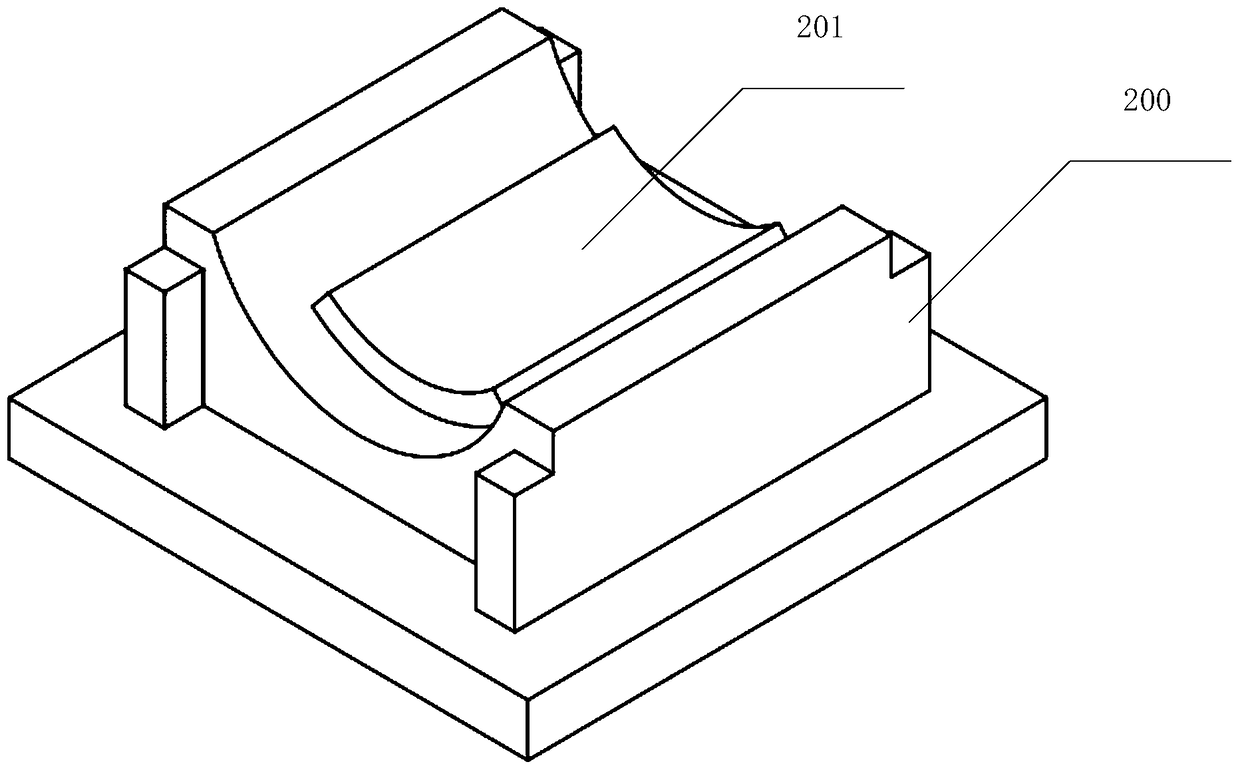

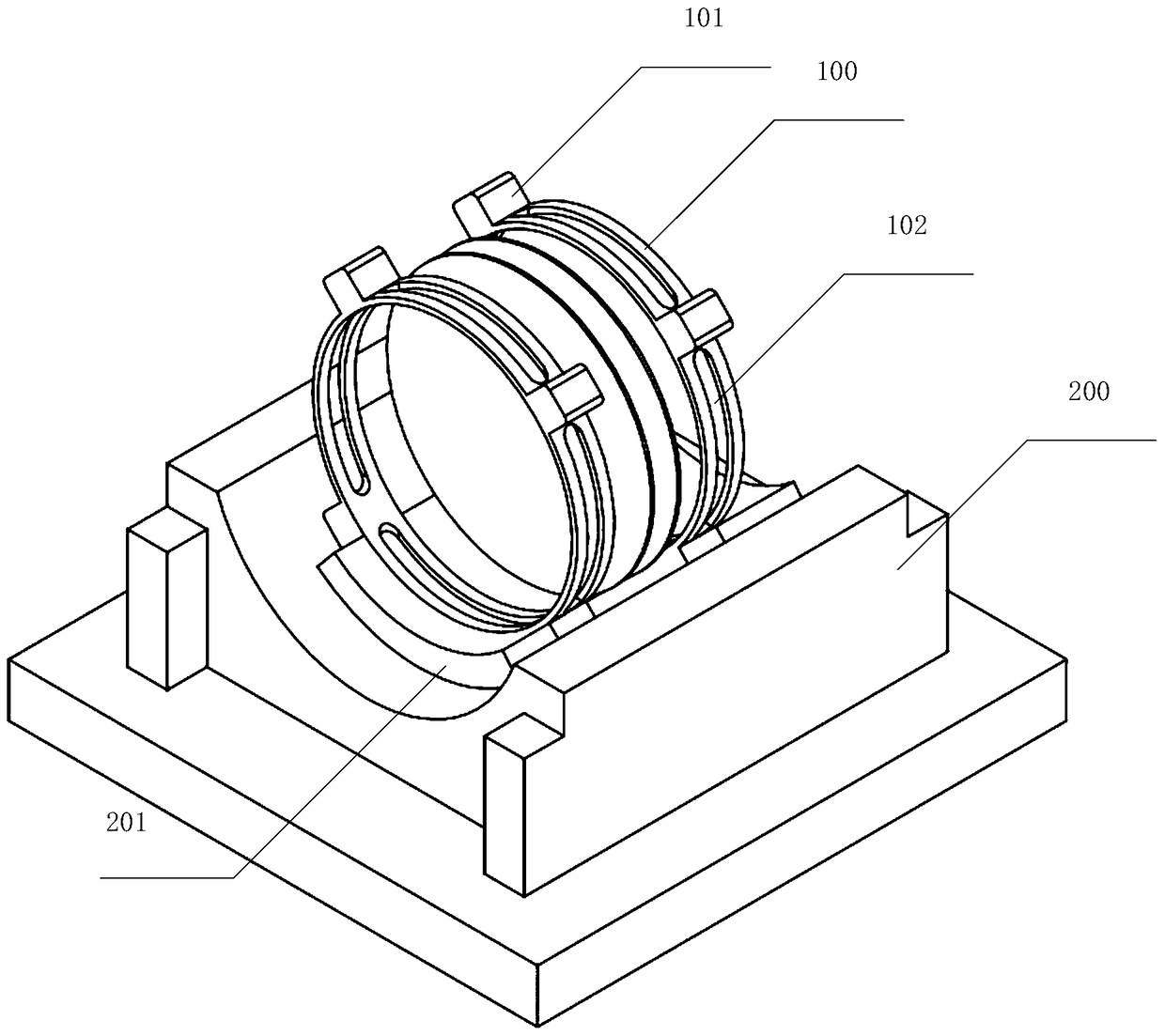

Etching device and wafer one side etching method

ActiveCN105225992ATo achieve the purpose of single-sided etchingImprove etching efficiencySemiconductor/solid-state device manufacturingEtchingElectrical and Electronics engineering

The application discloses an etching device and a wafer one side etching method. The base of the etching device is used for placing a plurality of clamping piece rings; at least two wafers are arranged between adjacent clamping piece rings; the water surfaces to be etched are towards adjacent clamping piece rings; the plurality of clamping piece rings and the plurality of wafers arranged on the base are clamped by a clamping device, and then corrosive liquids can be injected through the liquid inlet slots of the clamping piece rings to corrode the wafers. At least two wafers are closely attached, and only the water surfaces to be etched are towards adjacent clamping piece rings, and thereby after the corrosive liquids are injected through the liquid inlet slots of the clamping piece rings, the corrosive liquids can only touch the water surfaces to be etched, thereby etching one side of a wafer.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

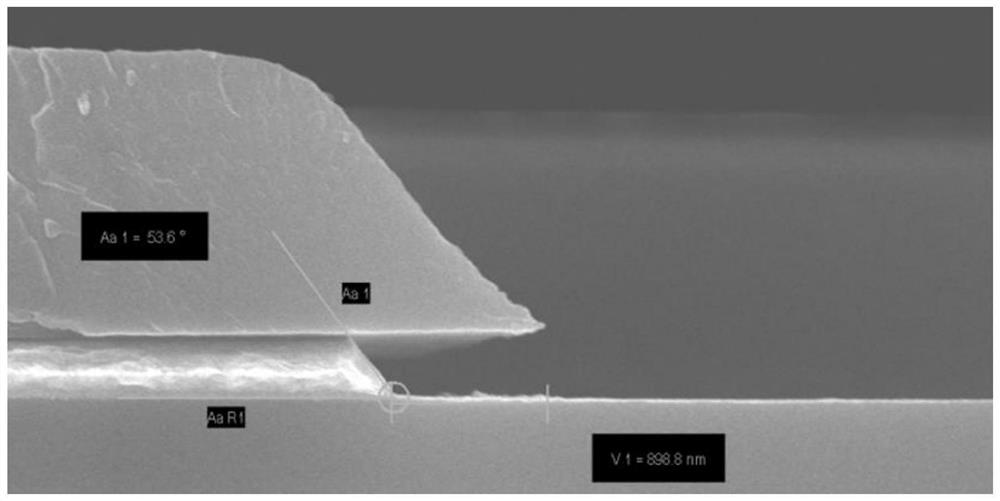

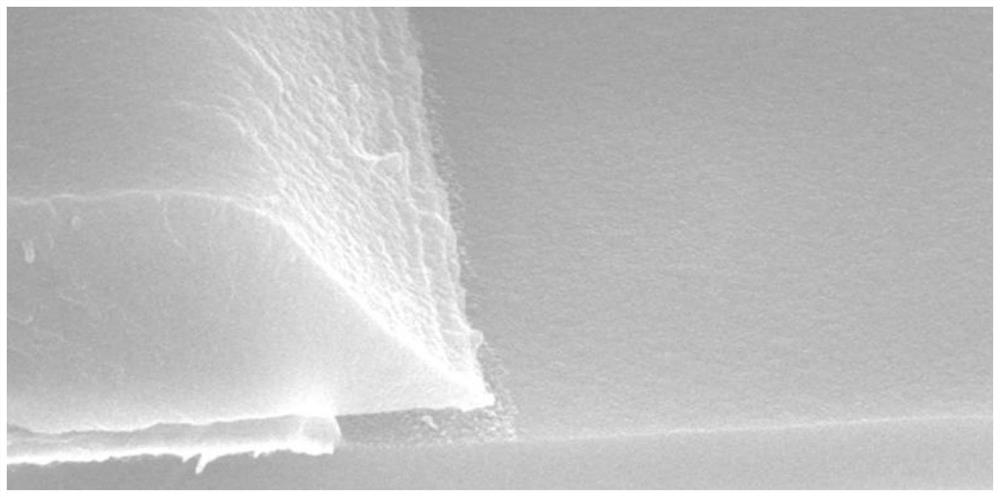

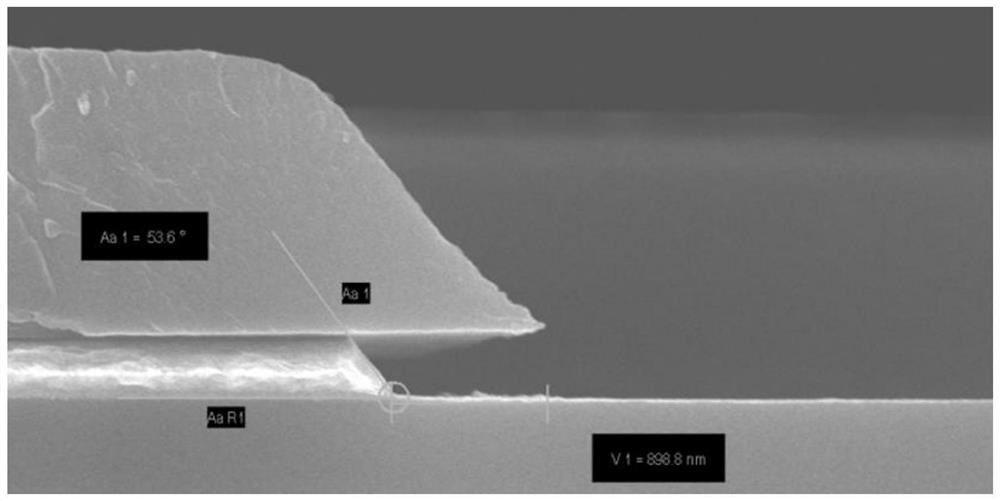

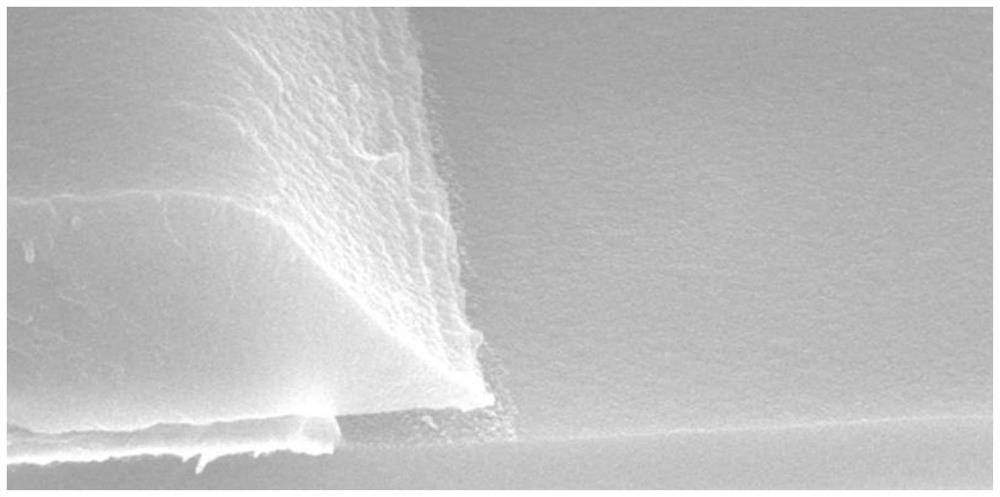

Wet etching method for ZnO-based transparent conductive film

ActiveCN102709156AControllable etch rateInhibit side etchSemiconductor/solid-state device manufacturingSemiconductor devicesThin membraneSolar battery

The invention discloses a wet etching method for a ZnO-based transparent conductive film The wet etching method comprises the following steps: coating photoresist on a substrate deposited with the ZnO-based transparent conductive film; carrying out exposure and development and removing part of the photoresist so that the substrate to be etched is exposed; baking the substrate; proportioning with weak acids and deionized water to form a weak acid solution; putting the substrate to be etched into the weak acid solution for etching for 1-10000 seconds; washing with deionized water; removing the photoresist with an organic solution; and measuring the etching depth and the profile of the etched pattern. A weak acid solution wet etching process is adopted in the method, and the method has the advantages of simple operation, low cost, controllable etching rate, high etching precision and the like, and can be applied to a pattern processing technology of ZnO-based transparent electrodes in the fields of solar batteries, panel display, LEDs (light-emitting diodes) and the like, so that the industrial applications of the ZnO-based transparent conductive films the above fields are promoted.

Owner:SUN YAT SEN UNIV

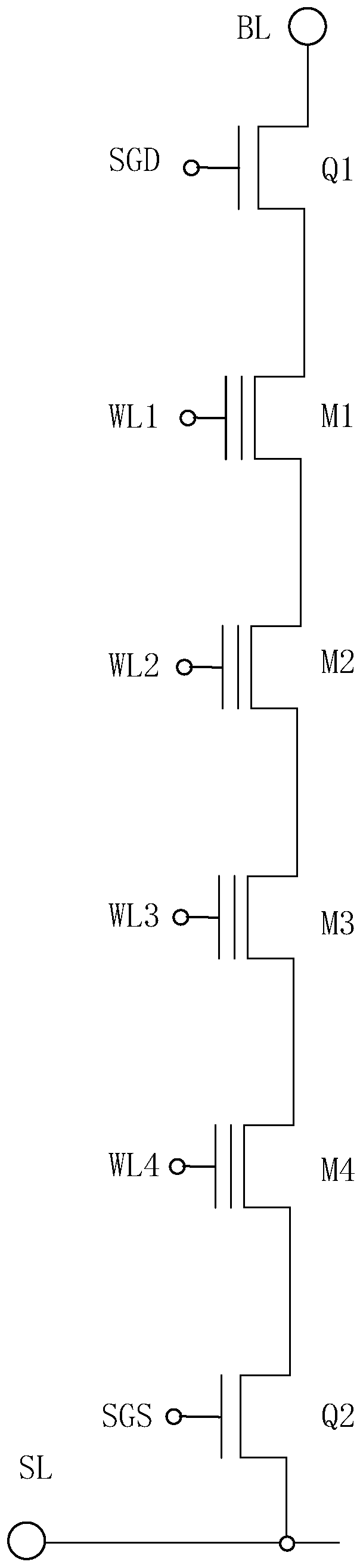

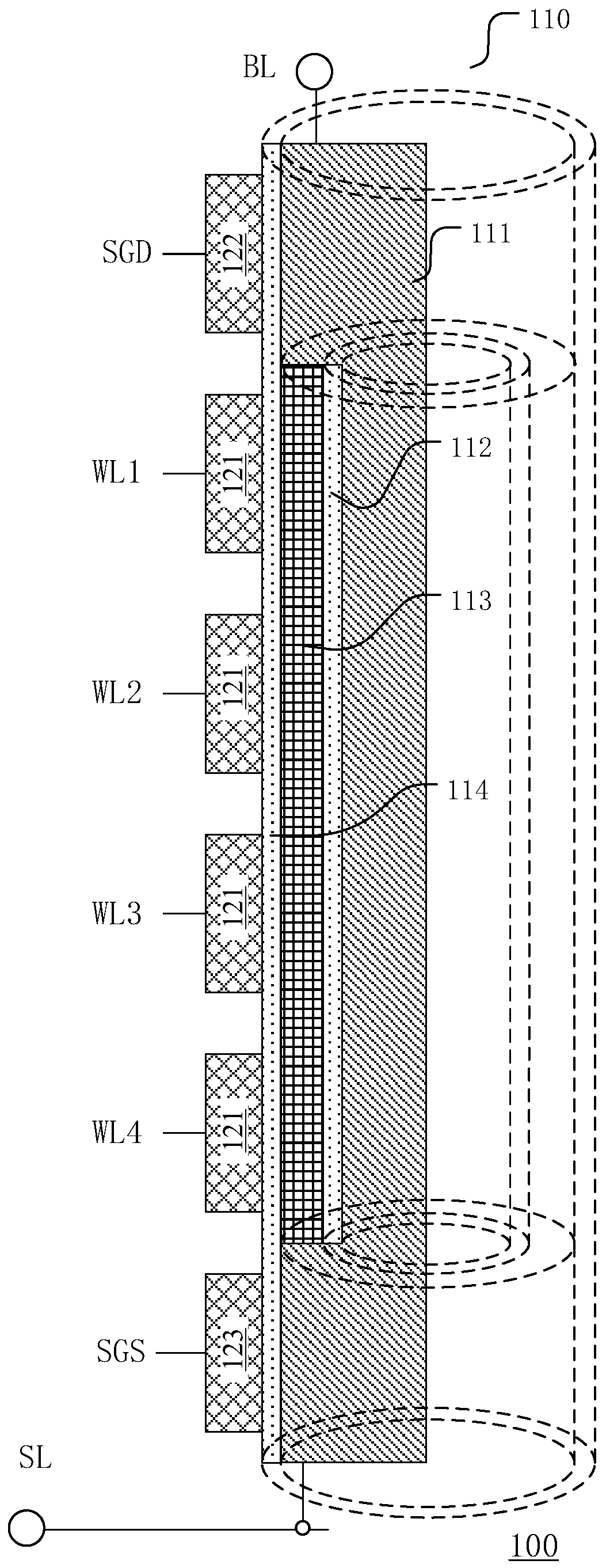

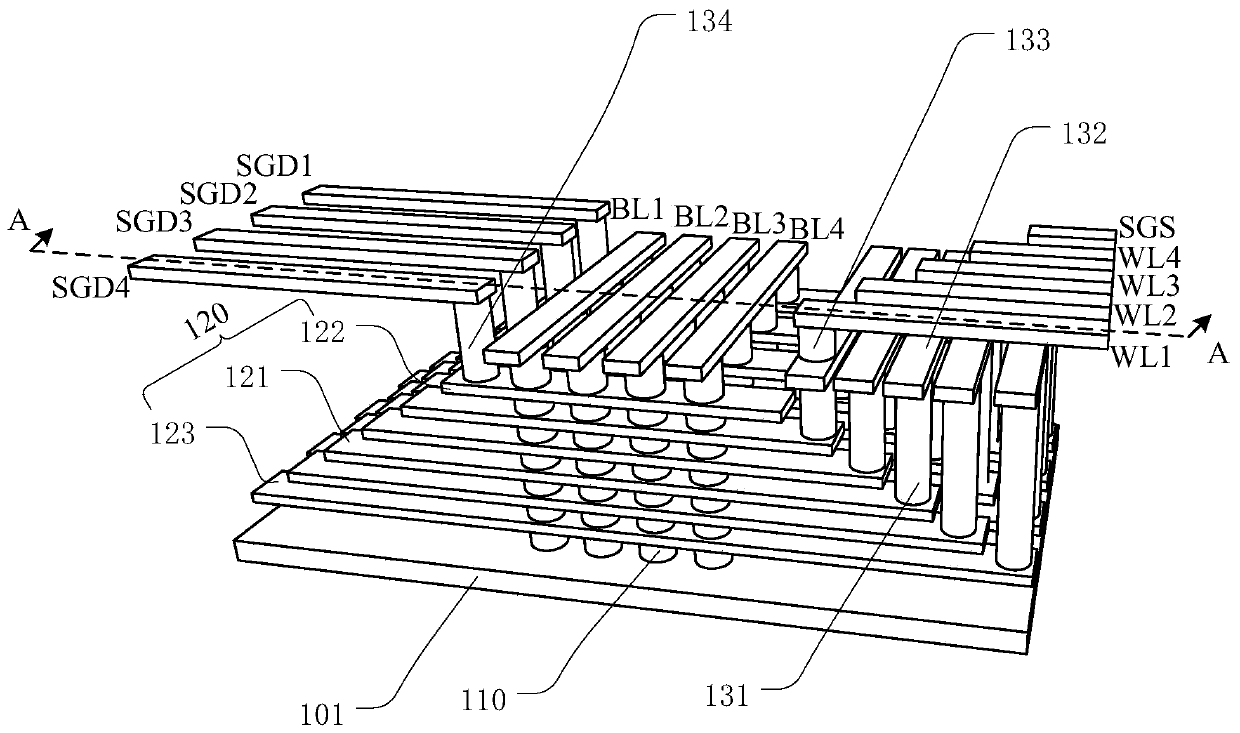

3D memory device and manufacturing method thereof

ActiveCN111180454AImprove flatnessComplete structureSolid-state devicesSemiconductor devicesEngineeringMechanical engineering

The invention discloses a 3D memory device and a manufacturing method thereof. The manufacturing method comprises the steps: forming a first laminated structure on a substrate, wherein the first laminated structure comprises a plurality of interlayer insulating layers and gate conductor layers which are stacked alternately, and the first laminated structure is provided with a first step structure;forming a first filling layer covering the first step structure and the substrate; forming a second laminated structure covering the first laminated structure, the second laminated structure comprising a plurality of interlayer insulating layers and gate conductor layers which are alternately stacked, the second laminated structure having a second step structure; and forming a plurality of firstvirtual channel columns, wherein at least a part of the first virtual channel columns are located in the second step structure, and the top surface of at least one first virtual channel column is thestep surface of the second step structure. According to the manufacturing method, the top surface of the virtual channel column and the step surface of the step structure are coplanar, so that the problem of poor flatness of the device is solved.

Owner:YANGTZE MEMORY TECH CO LTD

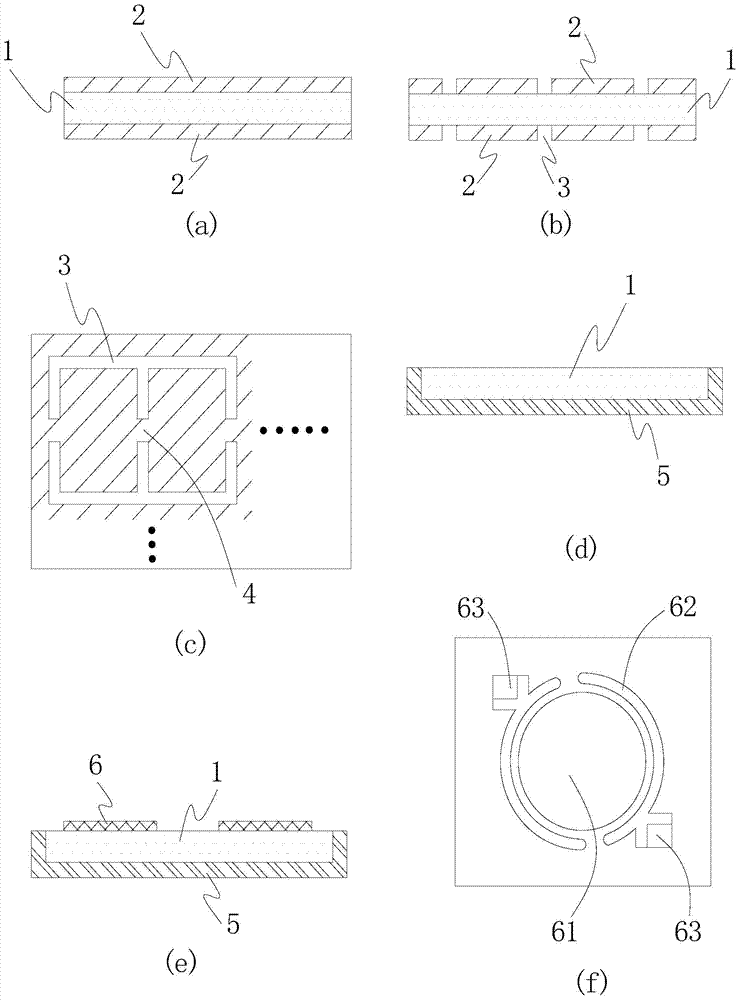

Method for manufacturing high-power high-reflectance COB substrate and light source

InactiveCN104282824AReduce etching costsEasy to implementSemiconductor devicesEnergy conservationReflectivity

The invention provides a method for manufacturing a high-power high-reflectance COB substrate and light source. The method comprises the following steps that a transparent substrate body is provided; light sensitive films are formed in the two sides of the transparent substrate body; exposure developing is carried out on the light sensitive films on the two sides of the transparent substrate body, and the appearance frame lines of a product on the transparent substrate body are exposed out; the penetrating step is carried out on the appearance frame lines of the product on the transparent substrate body; the light sensitive films are removed; mirror face reflecting layers are formed on the bottom face and the side faces of the transparent substrate body after the light sensitive films are removed; a circuit layer is printed and sintered on the front face of the transparent substrate body after the light sensitive films are removed and a crystal solidification area is arranged on the front face of the transparent substrate body; a weld line area and an electrode are formed on the circuit layer; insulation oil is printed on the other parts, except for the crystal solidification area, the weld line area and the electrode, of the front face of the transparent substrate body. The method for manufacturing the high-power high-reflectance COB substrate and light source can greatly improve the reflecting capacity of the COB substrate or light source, light efficiency is improved, and energy conservation and environment protection are achieved.

Owner:SHENZHEN ZHIJIN ELECTRONICS

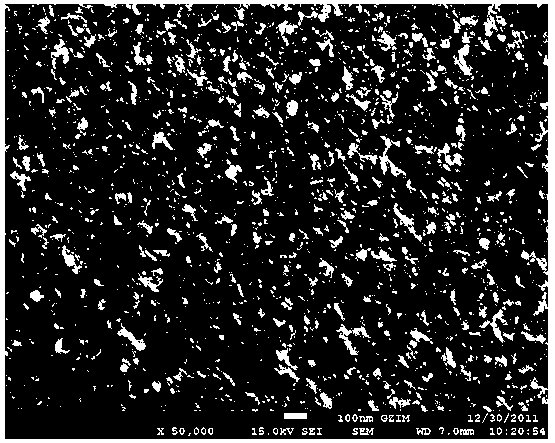

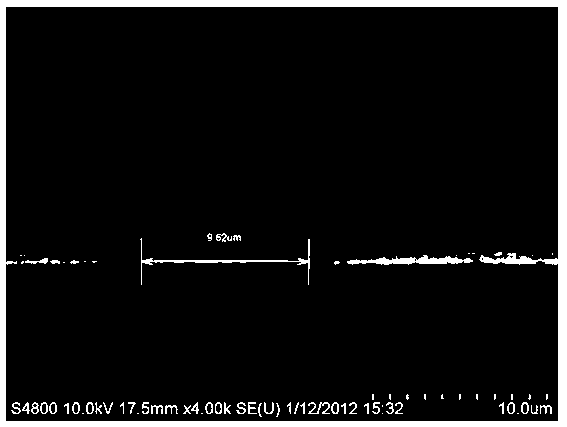

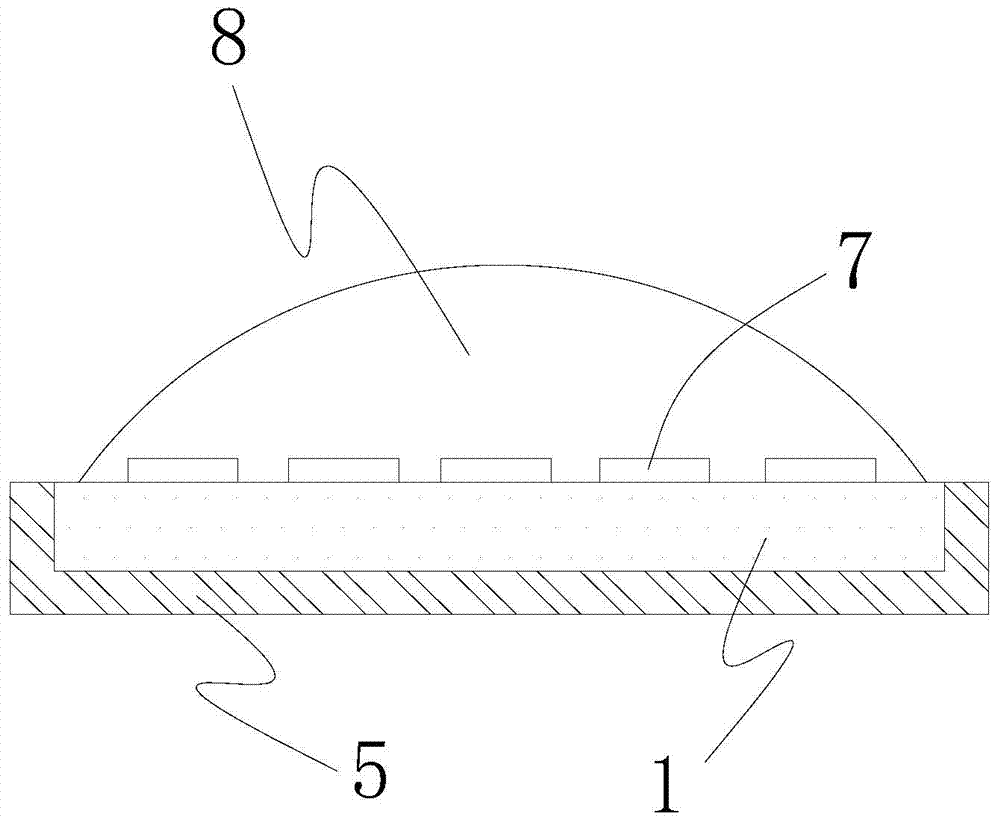

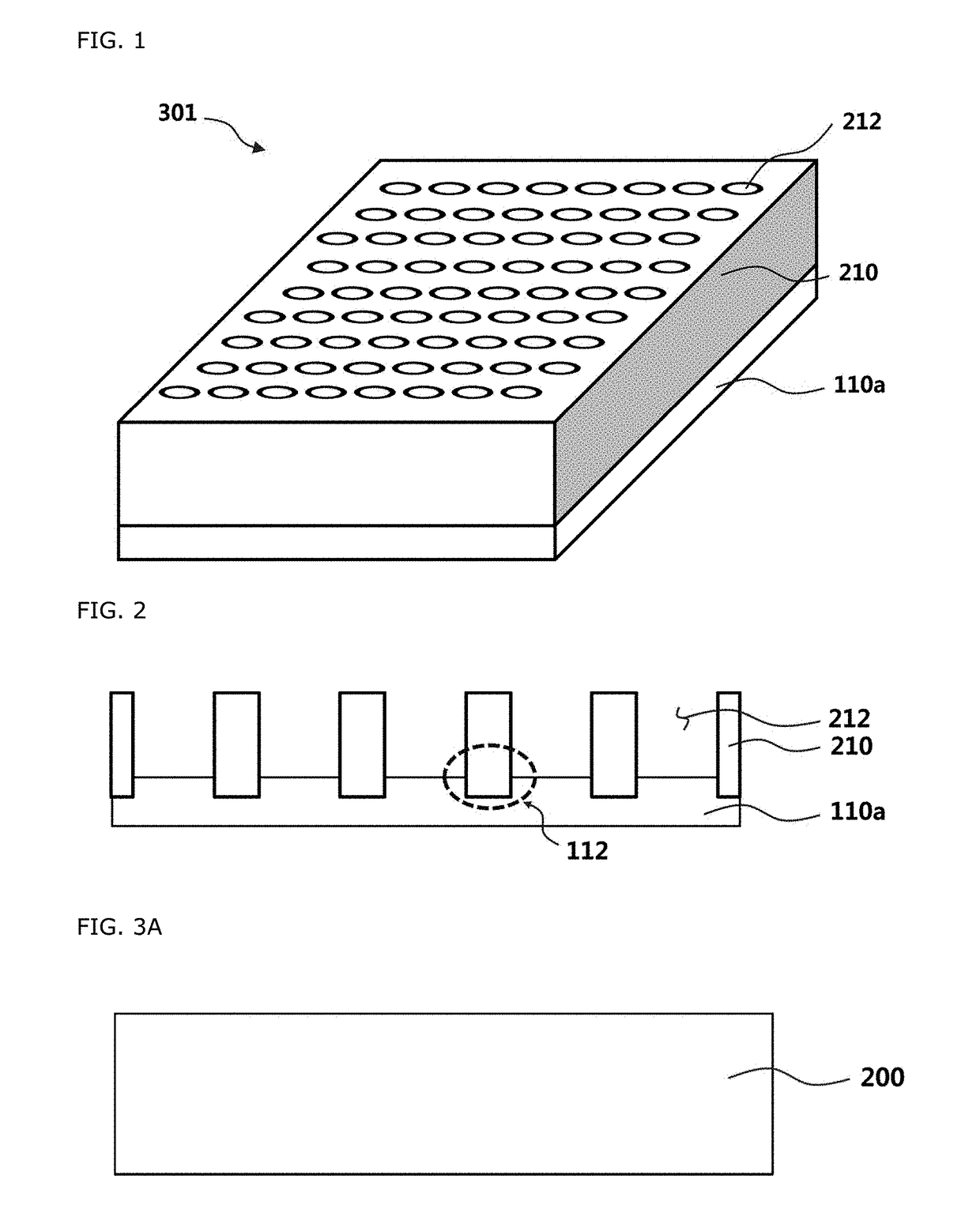

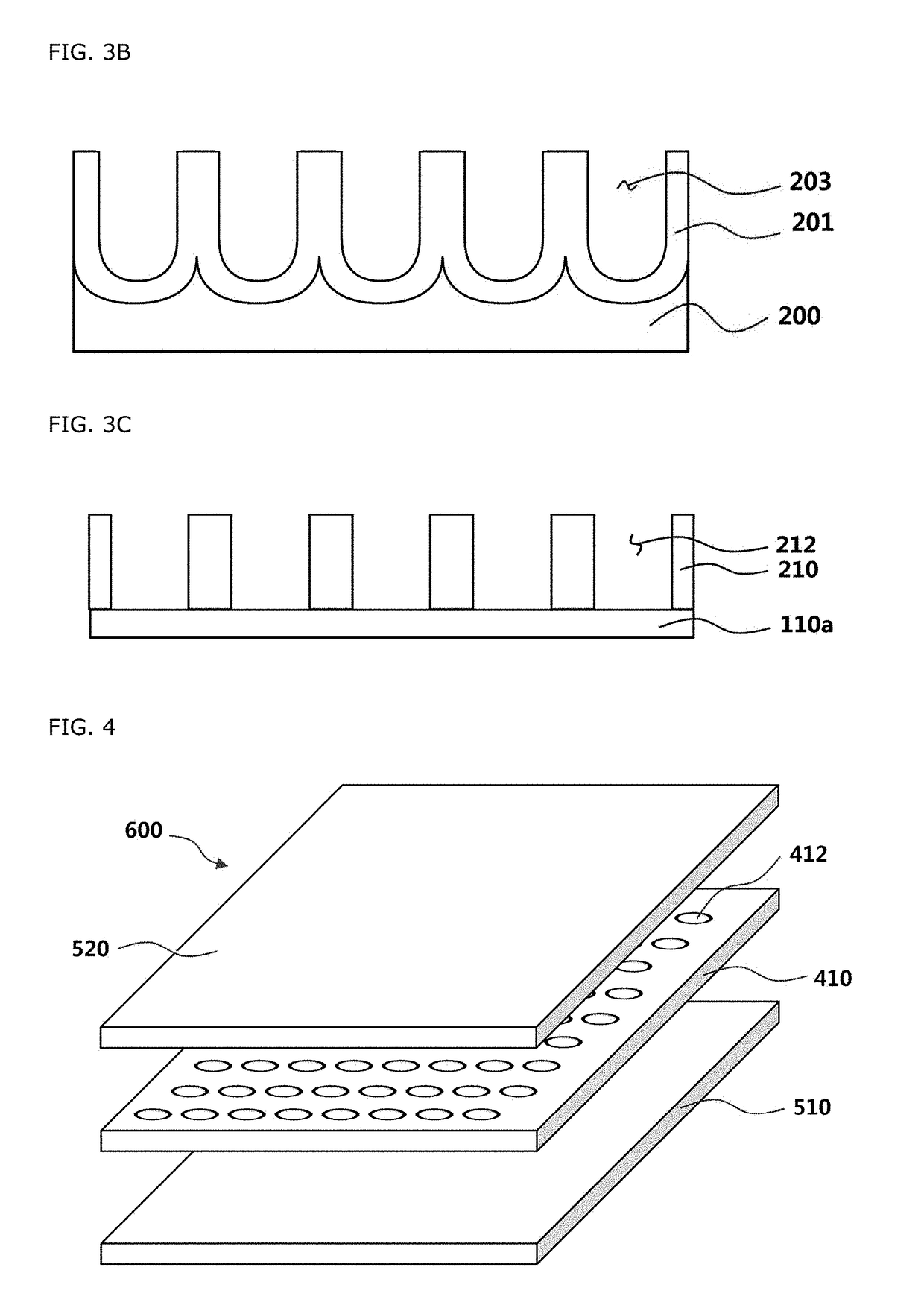

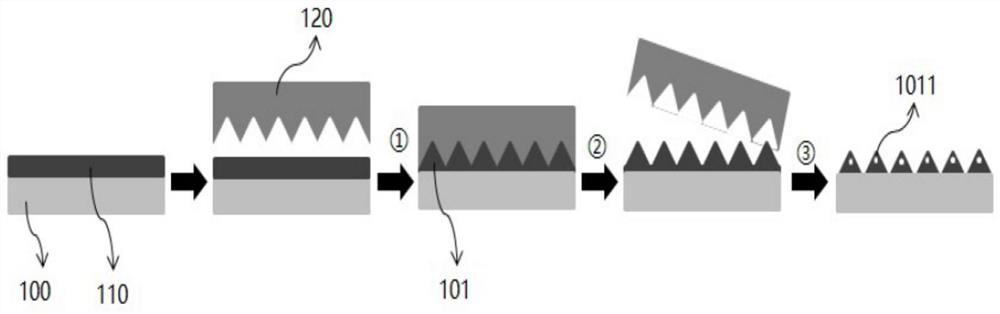

Etching mask, manufacturing method therefor, porous membrane manufacturing method using etching mask, porous membrane, fine dust-blocking mask including porous membrane, and manufacturing method for surface enhanced raman scattering active substrate

ActiveUS20170282127A1Simple methodReduce etching costsSemi-permeable membranesMembranesPorous membraneThin membrane

The present disclosure provides an etching mask, a method for manufacturing the same, a method for manufacturing a porous membrane using the same, a porous membrane, a fine dust blocking mask including the same, and a method for manufacturing a surface enhanced Raman scattering active substrate. In this connection, the etching mask includes an organic film; and a pattern layer disposed on the organic film, wherein the pattern layer has openings defined therein having a uniform size, wherein each of the openings includes a micro-scale or nano-scale hole.

Owner:PUSAN NAT UNIV IND UNIV COOPERATION FOUND

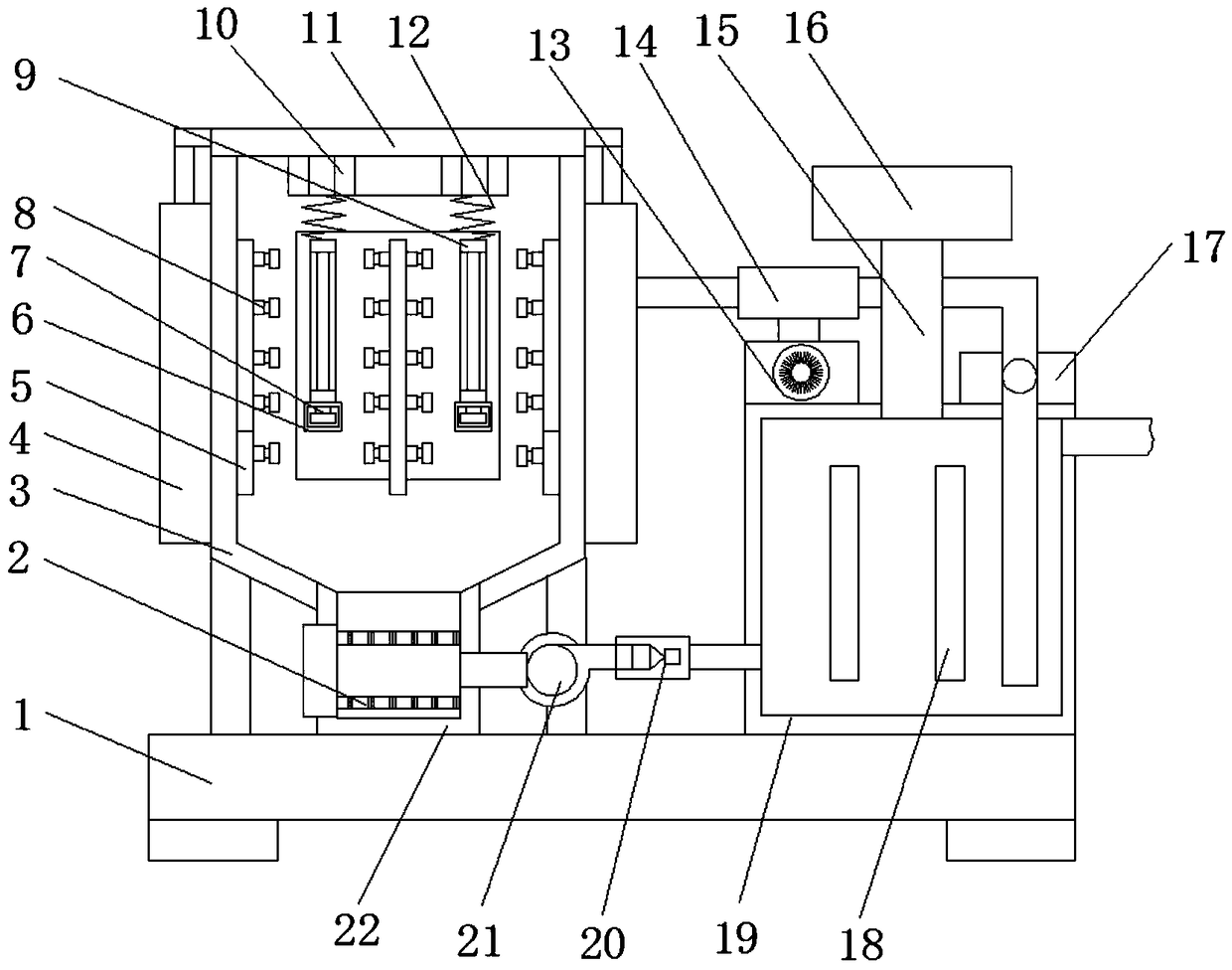

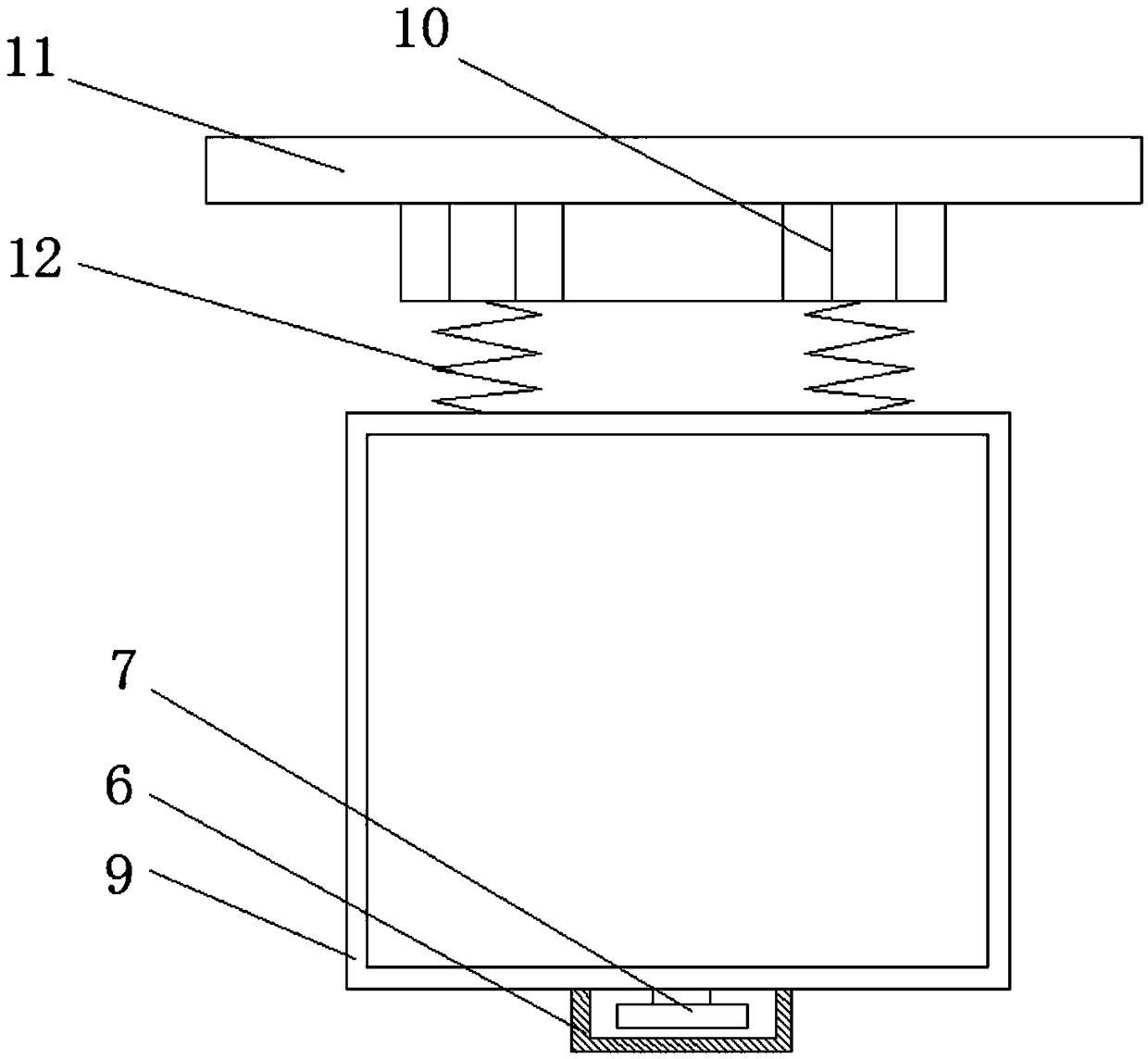

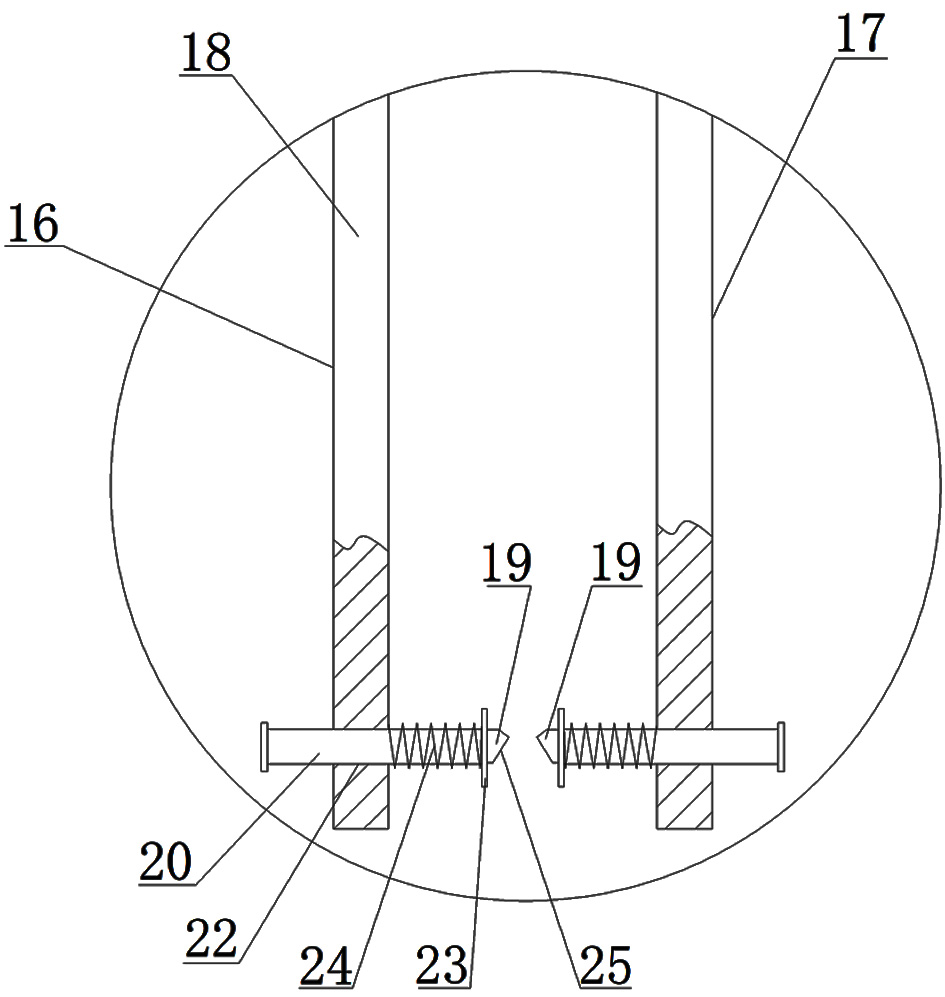

Liftable etching device based on LED lamp panel

ActiveCN109348622AAvoid depositionEtching speed is fastElectroluminescent light sourcesInsulating layers/substrates workingFixed frameLED lamp

The invention discloses a liftable etching device based on an LED lamp panel. The liftable etching device comprises a base, wherein the top of the base is connected with an etching box through bolts;two sides of the etching box are connected with vertically arranged linear electric push rods through bolts respectively; the tops of movable rods of the two linear electric push rods are connected with the same box cover through bolts; the bottom of the box cover is connected with connecting blocks in equally-spaced distribution through bolts; and two ends of the bottoms of the connecting blocksare connected with tension springs through bolts respectively. According to the liftable etching device, an etching solution is heated by a heater inside an etching solution storage tank, the etchingspeed can be improved, through circulating etching of the etching solution, impurities can be avoided from being deposited inside the etching box effectively to cause the occurrence of phenomenon thatthe machine halts for cleaning at regular intervals is needed, the etching efficiency is improved, a vibration motor drives a fixed frame to vibrate, the etching solution remaining in the fixed frameis recycled through vibration, the waste of resources is avoided, and the etching cost is reduced.

Owner:安徽迪思自动化设备有限公司

Method for Treating an Etching Solution

InactiveUS20070017903A1Selective stabilityReduce etching costsDecorative surface effectsSemiconductor/solid-state device manufacturingPresent methodEngineering

The present etching system includes a processing tank with an etching solution containing silicon, a cooling tank, a pre-heating tank, a first pipe for transferring the etching solution from the processing tank to the cooling tank, a second pipe for transferring the etching solution from the cooling tank to the pre-heating tank, and a third pipe for transferring the etching solution from the pre-heating tank to the processing tank. The present method for treating the etching solution first performs an etching process using the etching solution, which is then cooled to a first temperature to form a silicon-saturated etching solution. After silicon-containing particles larger than a predetermined size are filtered out, the silicon-saturated etching solution is heated to a second temperature to form a non-saturated etching solution for repeating the etching process later. The second temperature is preferably at least 10° C. higher than the first temperature.

Owner:PROMOS TECH INC

Fine high-efficiency etching technology in high-order high-density circuit board

ActiveCN108811351AReduce etching costsEasy to operateConductive material chemical/electrolytical removalHigh densityEtching

The invention discloses a fine high-efficiency etching technology in a high-order high-density circuit board. The technology has the following steps that S1) copper plates are welded to the top and bottom of a substrate respectively, adhesive tapes are pasted to the top of the upper copper plate and the bottom of the lower copper plate respectively, the shapes of the adhesive tapes are kept consistent with that of a required line layer, sealing strips are pasted to positions where the adhesive tapes make contact with the substrate, an etching solution is avoided from corroding copper materialsunder the adhesive tapes, and accurate etching is achieved; and S2) an etching machine is prepared by that a rotating shaft is installed at the two sides of an etching groove rotationally, one end ofthe rotating shaft is provided with a handwheel, a bearing table is welded to the rotating shaft, two blind holes are formed in the top of the bearing table, extension springs are welded into the blind holes respectively, a pressure plate is welded to the top of each spring, and an outlet duct is connected to a gas outlet of an air compressor. Thus, the etching cost can be reduced, inorganic acidcan be used in a cyclic way, and operation is simple.

Owner:SICHUAN HAIYING ELECTRONICS TECH

Method for treating the etching solution

InactiveUS20080093343A1Reduce etching costsLittle changeDecorative surface effectsSemiconductor/solid-state device manufacturingPresent methodEngineering

The present etching system includes a processing tank with an etching solution containing silicon, a cooling tank, a pre-heating tank, a first pipe for transferring the etching solution from the processing tank to the cooling tank, a second pipe for transferring the etching solution from the cooling tank to the pre-heating tank, and a third pipe for transferring the etching solution from the pre-heating tank to the processing tank. The present method for treating the etching solution first performs an etching process using the etching solution, which is then cooled to a first temperature to form a silicon-saturated etching solution. After silicon-containing particles larger than a predetermined size are filtered out, the silicon-saturated etching solution is heated to a second temperature to form a non-saturated etching solution for performing another etching process later. The second temperature is preferably at least 10° C. higher than the first temperature.

Owner:PROMOS TECH INC

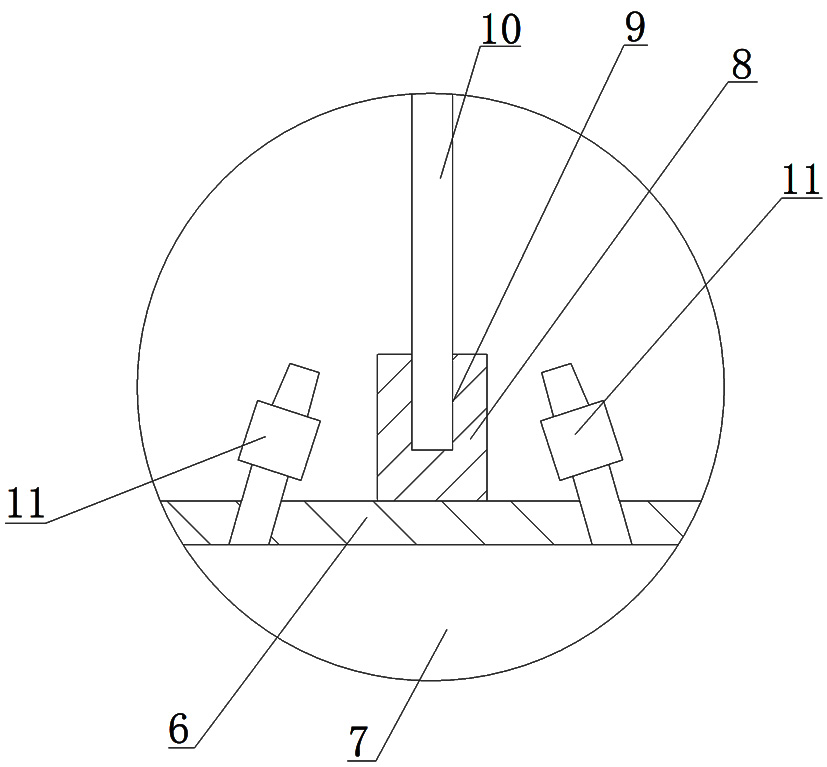

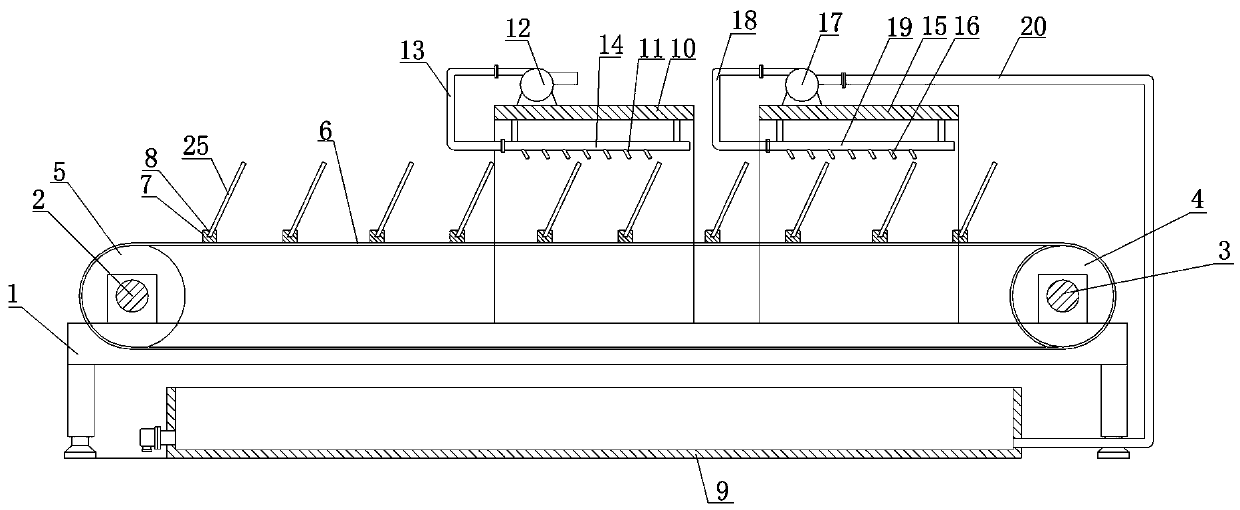

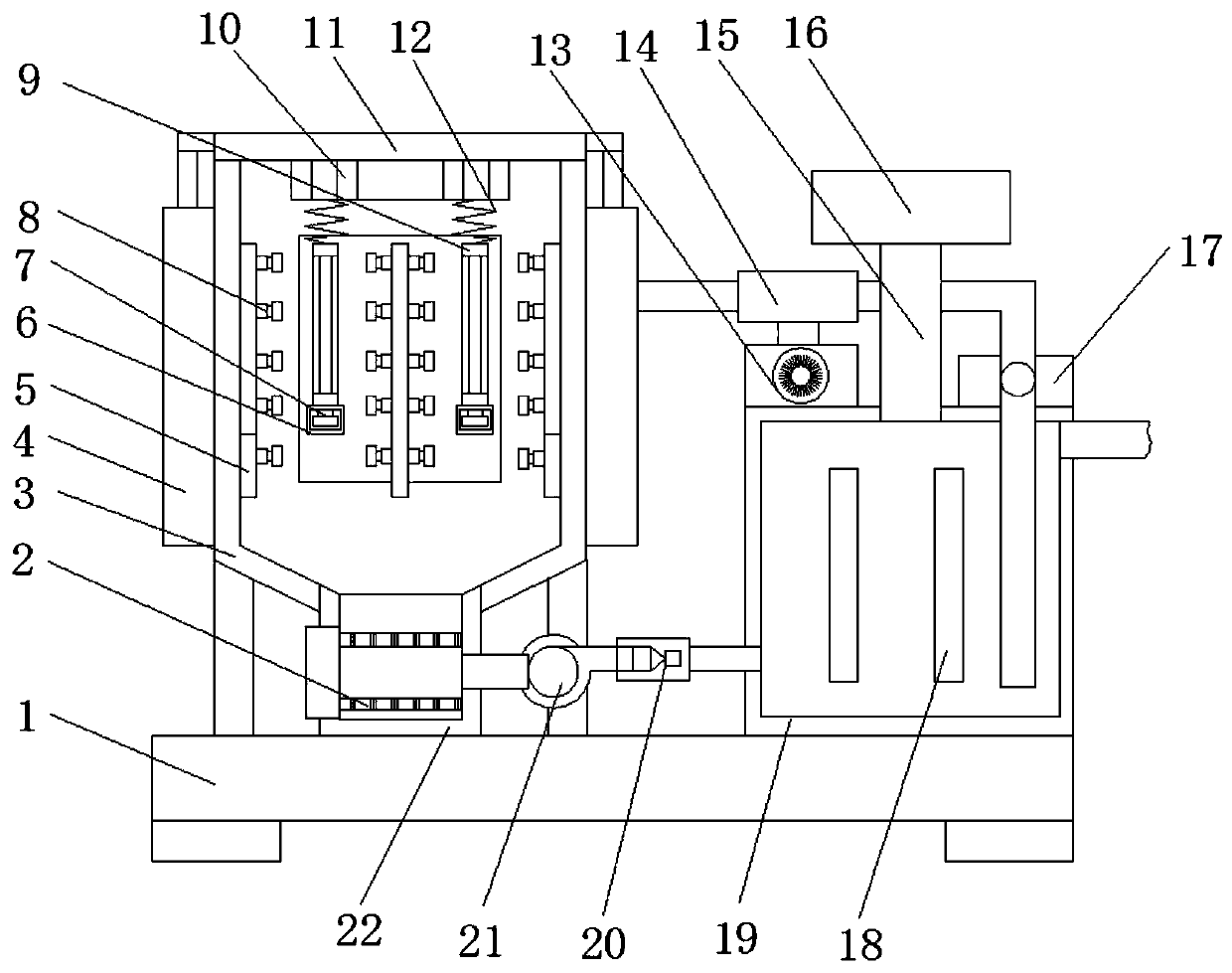

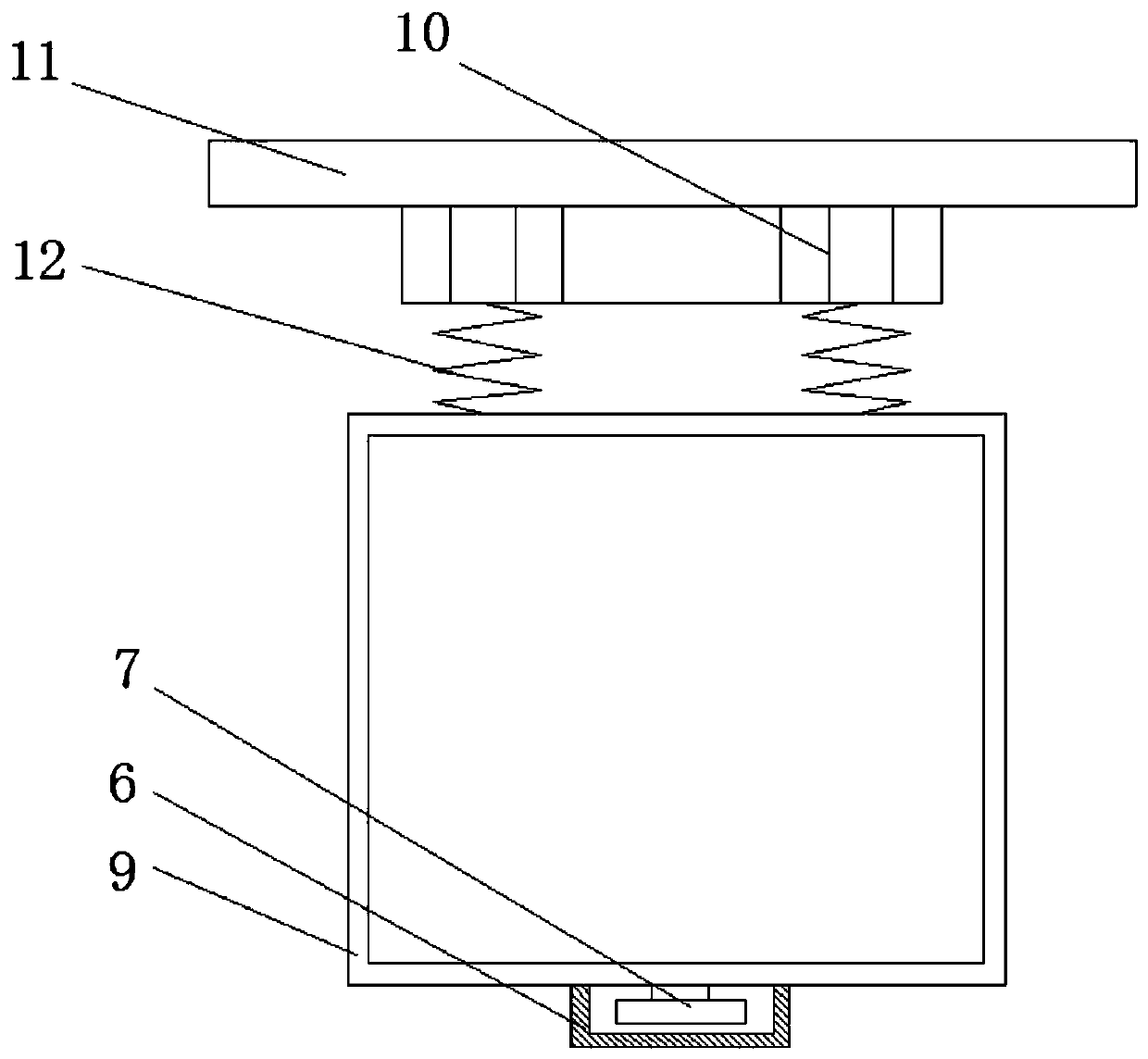

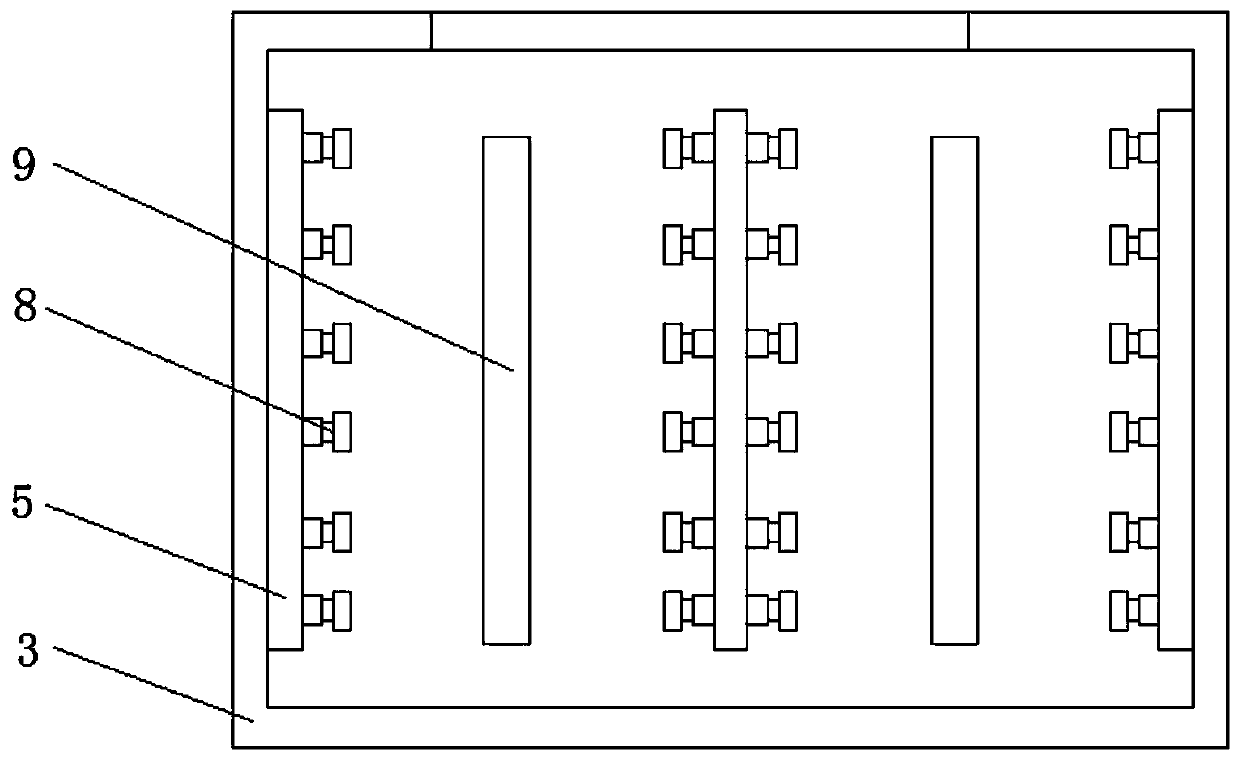

Etching solution recycling device and utilization method thereof

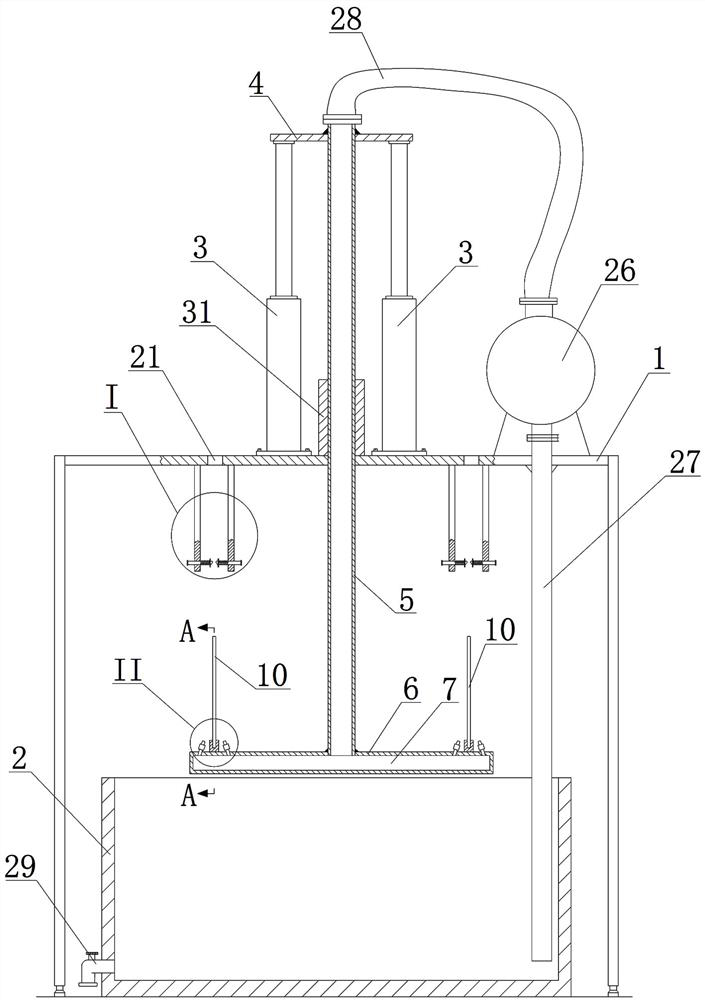

PendingCN112020230ARealize SupplementEtching speed upConductive material chemical/electrolytical removalStructural engineeringMechanical engineering

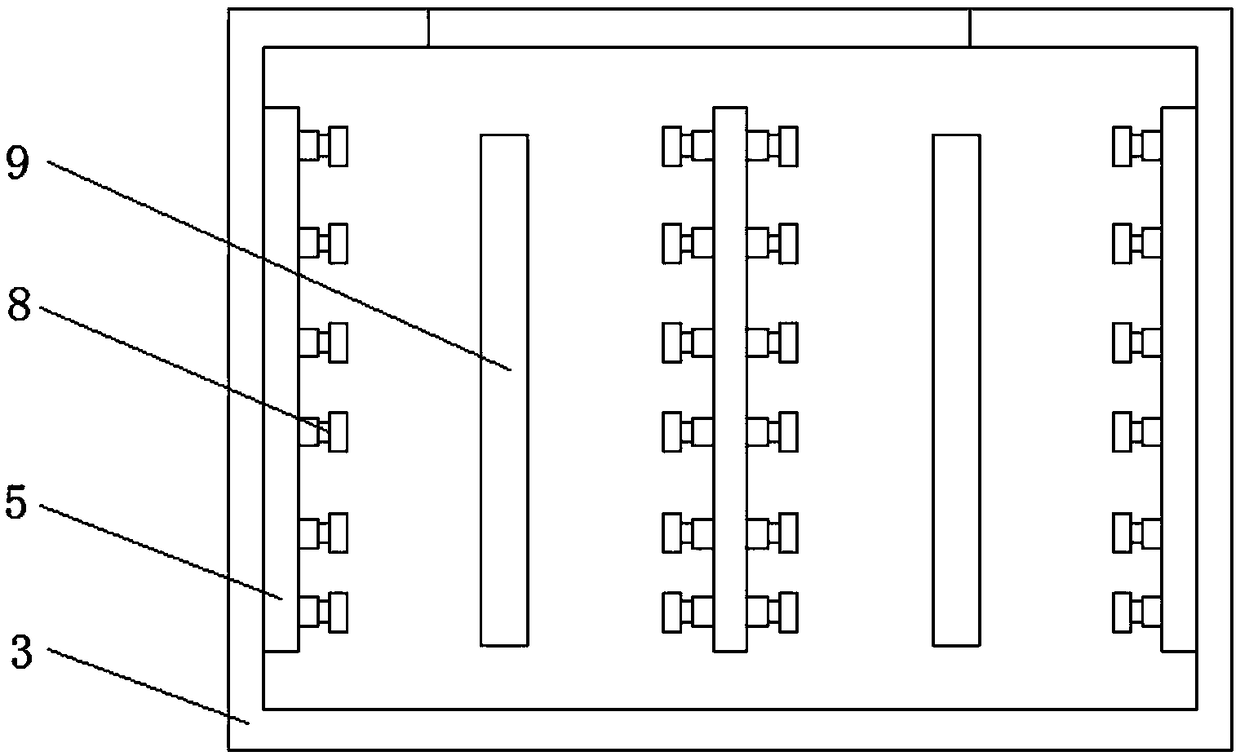

The invention discloses an etching solution recycling device, which comprises a gantry (1) and an etching tank (2) arranged below the cross beam of the gantry (1), wherein a lifting oil cylinder (3) is fixedly mounted at the top of the cross beam of the gantry (1), a lifting plate (4) is welded at the acting end of the piston rod of the lifting oil cylinder (3), the lower end portion of a hollow pipe (5) penetrates through the cross beam, a bearing disc (6) positioned right above the etching tank (2) is welded at the extending end, a plurality of bearing tables (8) distributed in an array modeare welded to the top of the bearing disc (6), a longitudinally-formed groove (9) is formed in the top of each bearing table (8), a circuit board (10) is inserted into each groove (9), and nozzles (11) located on the bearing disc (6) are arranged on the left side and the right side of each bearing table (8). The etching solution recycling device has the beneficial effects that the structure is compact, the etching efficiency is greatly improved, the etching cost is greatly reduced, and the operation is simple.

Owner:四川睿杰鑫电子股份有限公司

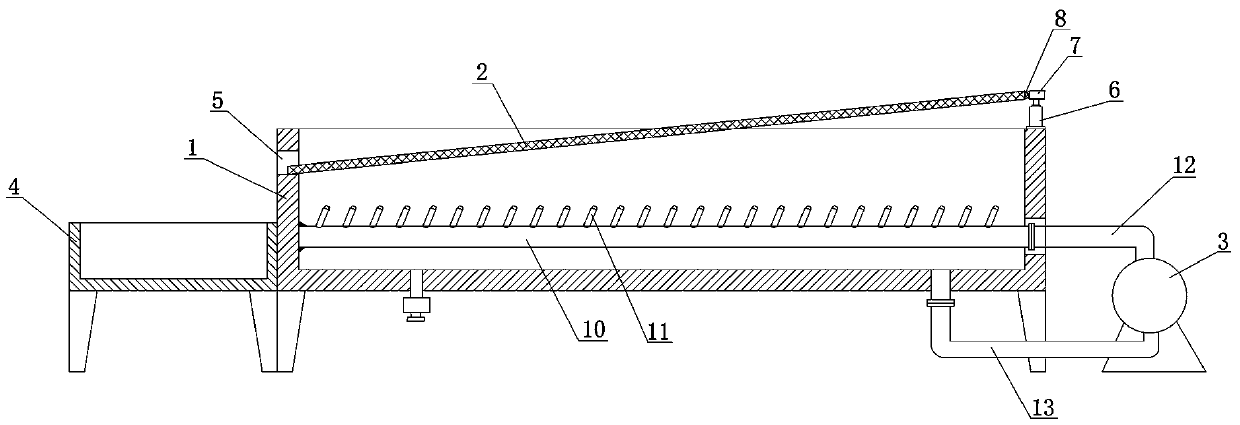

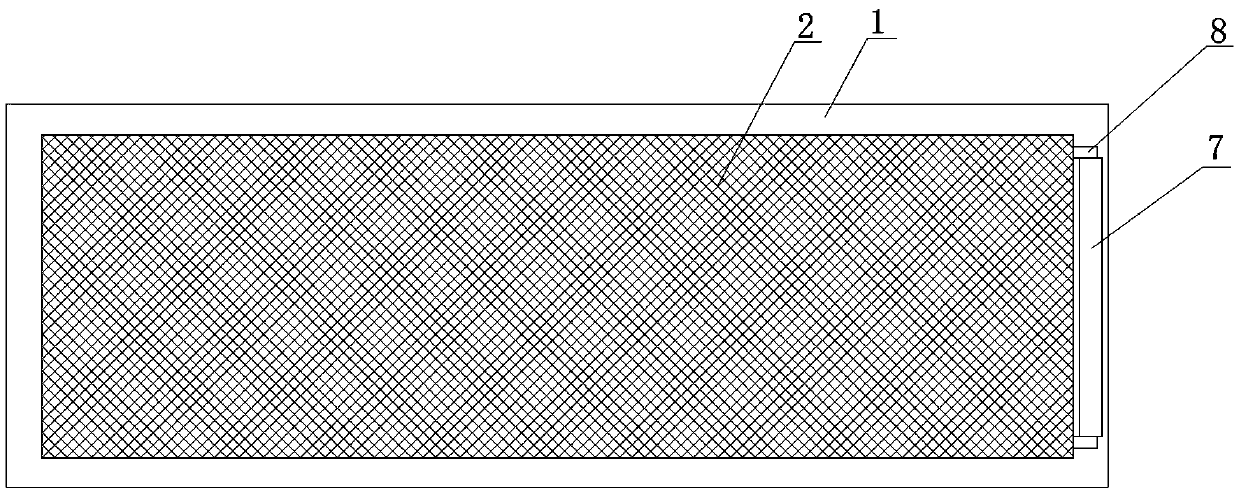

Rapid etching device and method for printed circuit board of new energy automobile

ActiveCN110113884ACompact structureImprove etching efficiencyConductive material chemical/electrolytical removalNew energyPrinted circuit board

The invention discloses a rapid etching device for a printed circuit board of a new energy automobile. The device comprises an etching groove (1), a filter screen (2), a water pump (3) and a circuit board collecting tank (4), and a through groove (5) is formed in the left side wall of the etching groove (1). A vertically arranged oil cylinder (6) is fixedly mounted at the top of the right side wall of the etching groove (1), and a supporting plate (7) is welded to the top of a piston rod of the oil cylinder (6). A hinge seat (8) is arranged on the supporting plate (7), and the filter screen (2) is obliquely arranged downwards leftwards and is arranged above the etching groove (1). The left edge of the filter screen (2) extends into the through groove (5), and the right edge of the filter screen (2) is hinged to the hinge seat (8) through a pin shaft. A water outlet pipe (10) is welded in the etching groove (1) and located on the left side wall. The beneficial effects of the invention are that the structure is compact, the etching efficiency is greatly improved, the etching cost is greatly saved, and the operation is simple.

Owner:SICHUAN HAIYING ELECTRONICS TECH

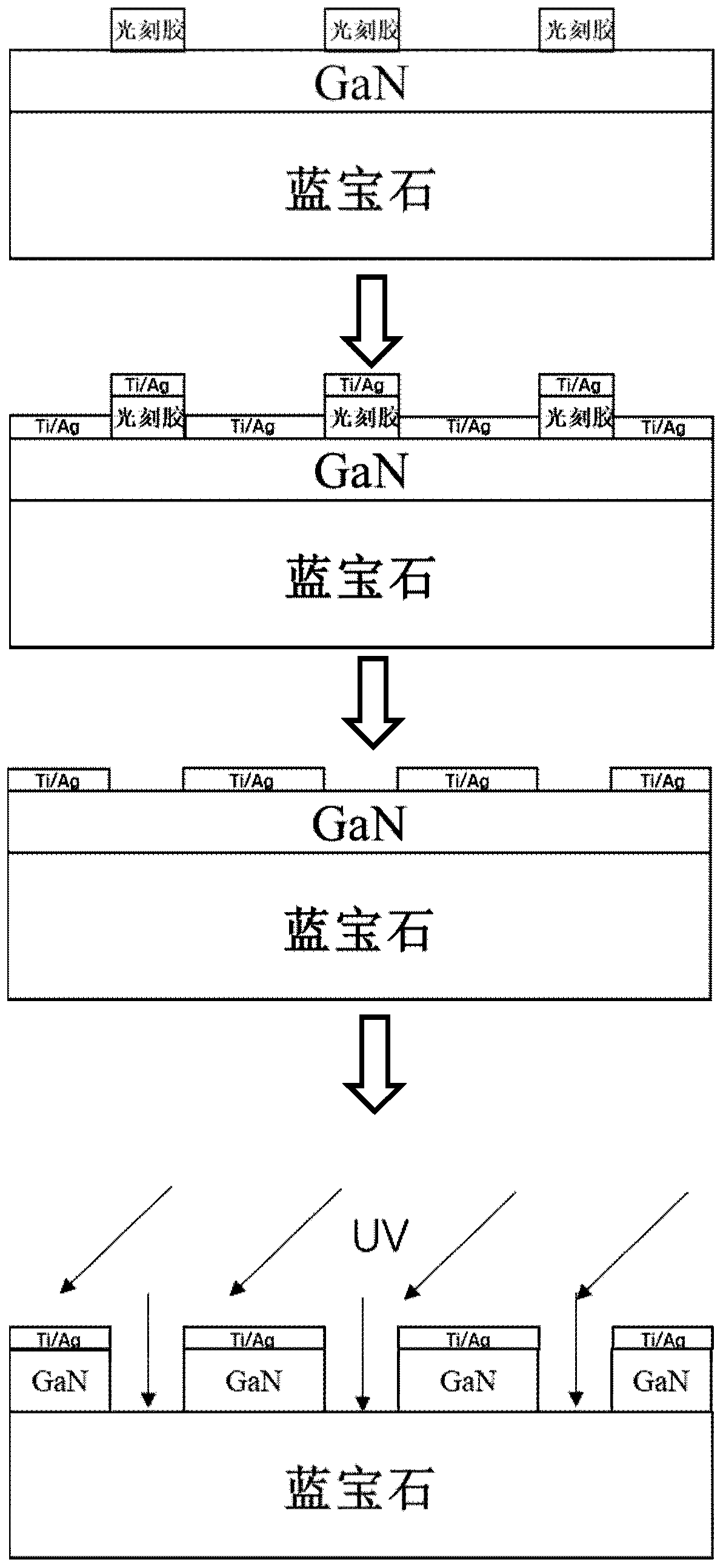

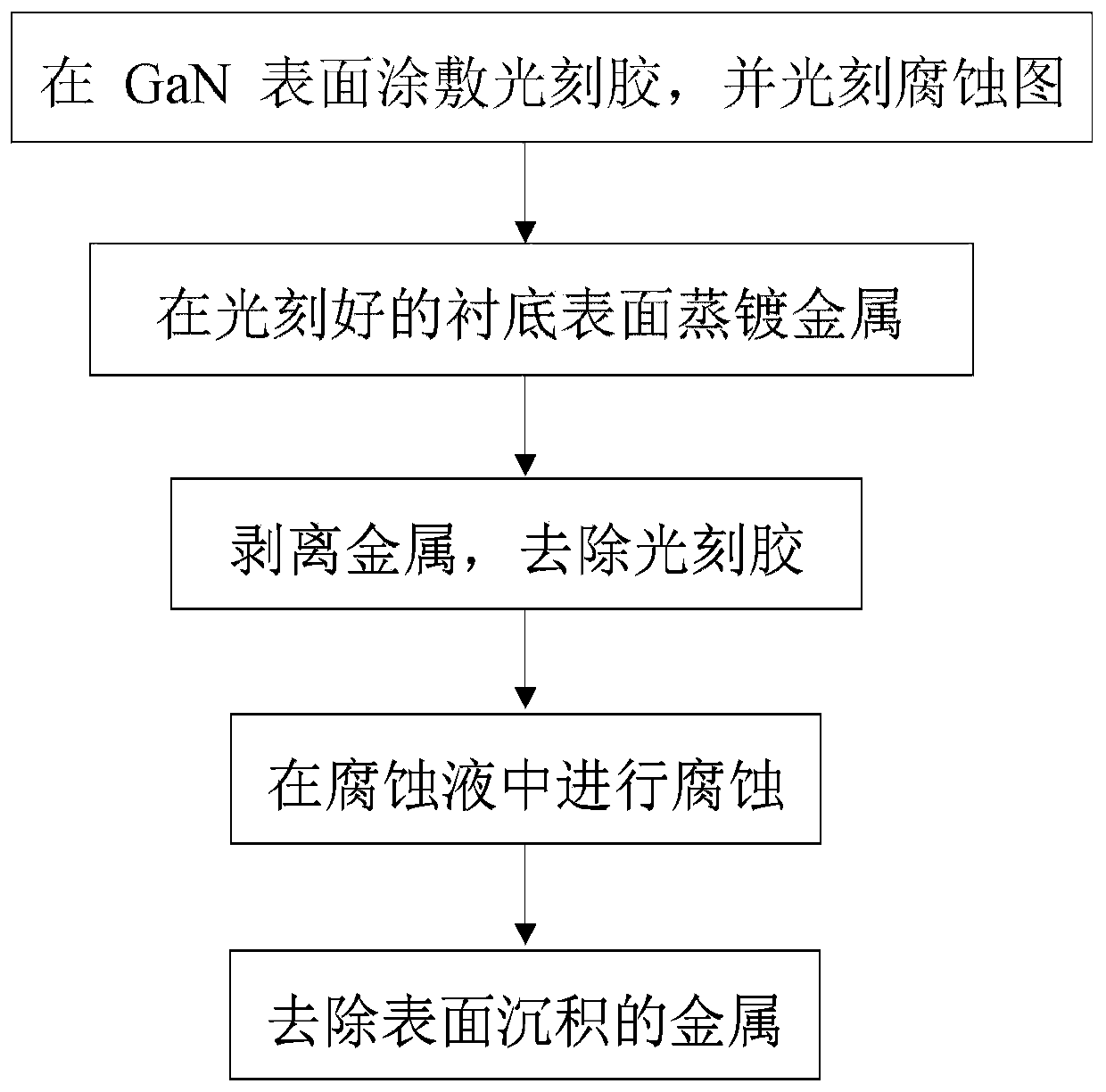

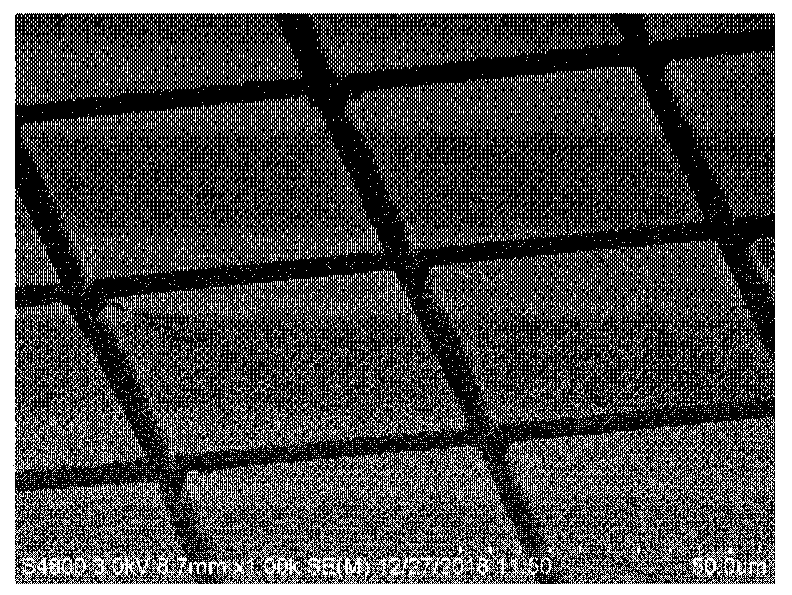

Wet etching method for nitride materials

InactiveCN110010461AFast etch rateThe method is simpleSemiconductor/solid-state device manufacturingEtchingPhotoresist

The invention relates to a wet etching method for isotropically etching nitride materials. The method comprises the steps of: coating a photoresist on the surface of GaN, and photoetching and etchinga pattern; evaporating a layer of metal on the photoetching substrate; performing metal stripping, and removing the residual photoresist; then putting the treated GaN into corrosive solution for corrosion; and finally, immersing the etched epitaxial wafer sample into a diluted nitric acid solution to remove surface metal. The method is high in etching speed, low in etching cost and simple in process, and the surface of the etched GaN is flat, the etched pattern can be automatically regulated and controlled according to the requirement.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

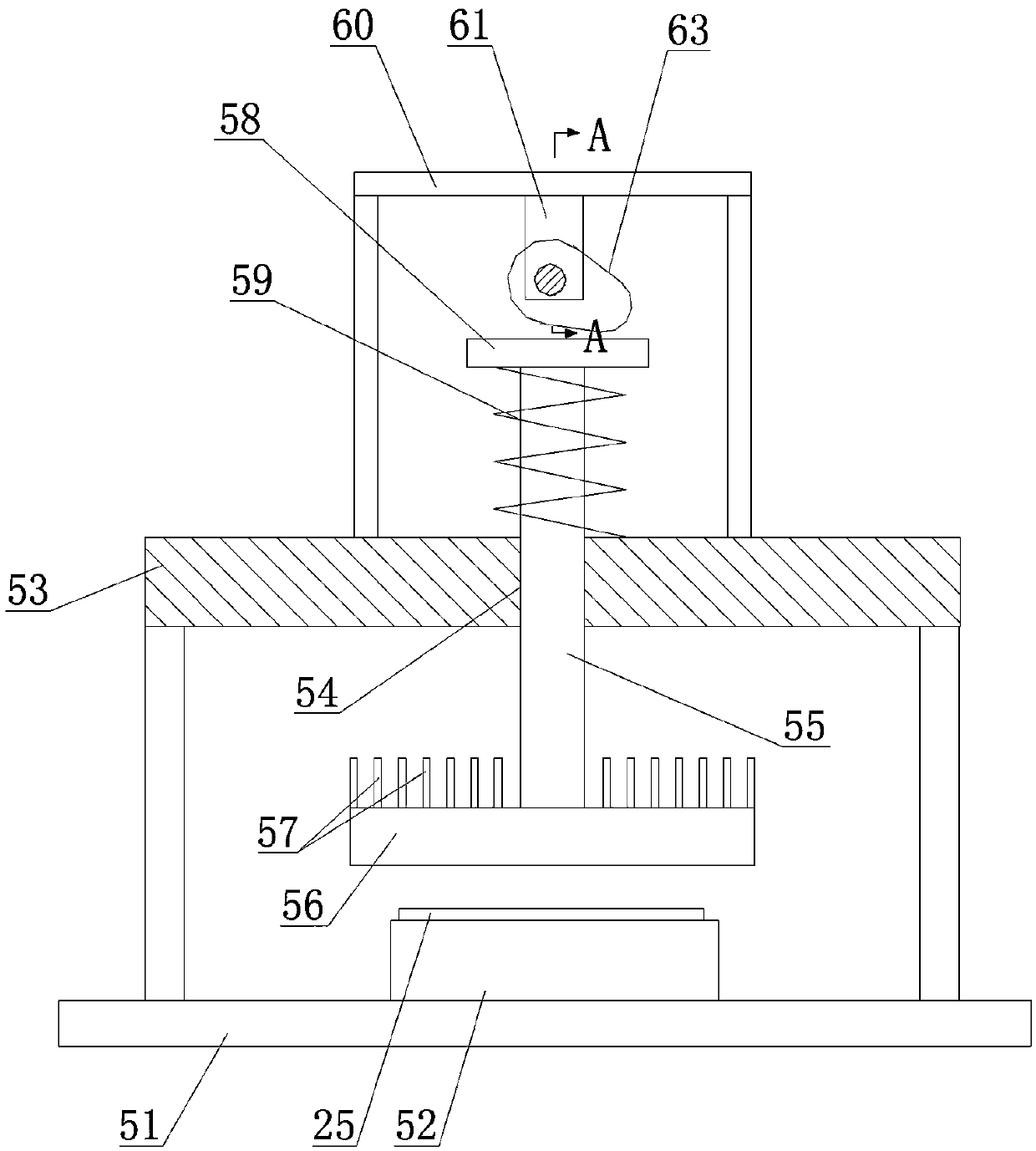

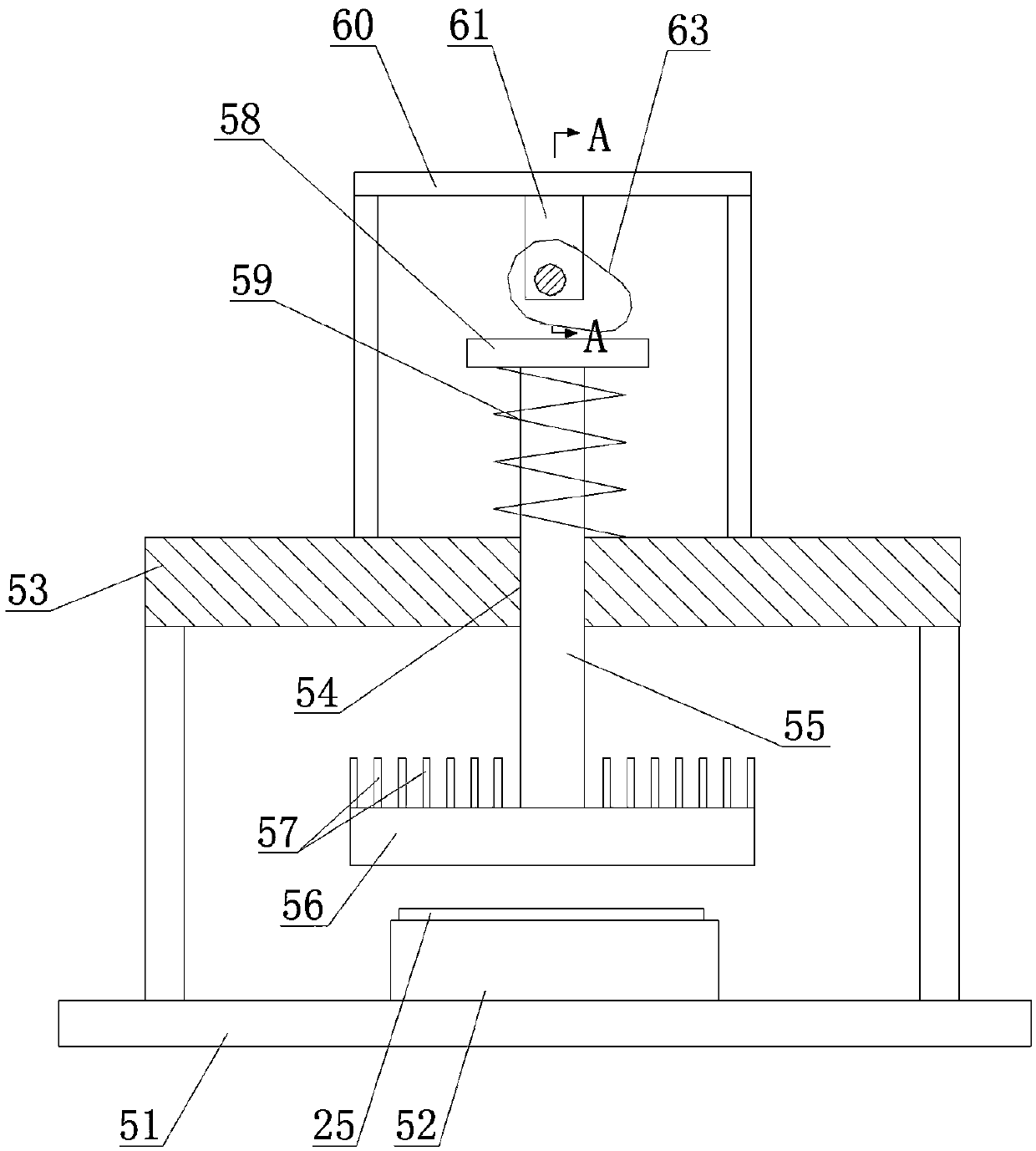

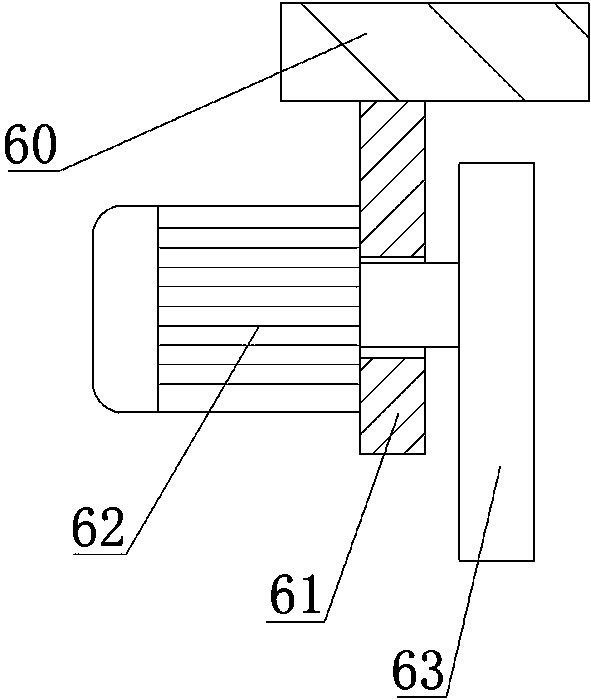

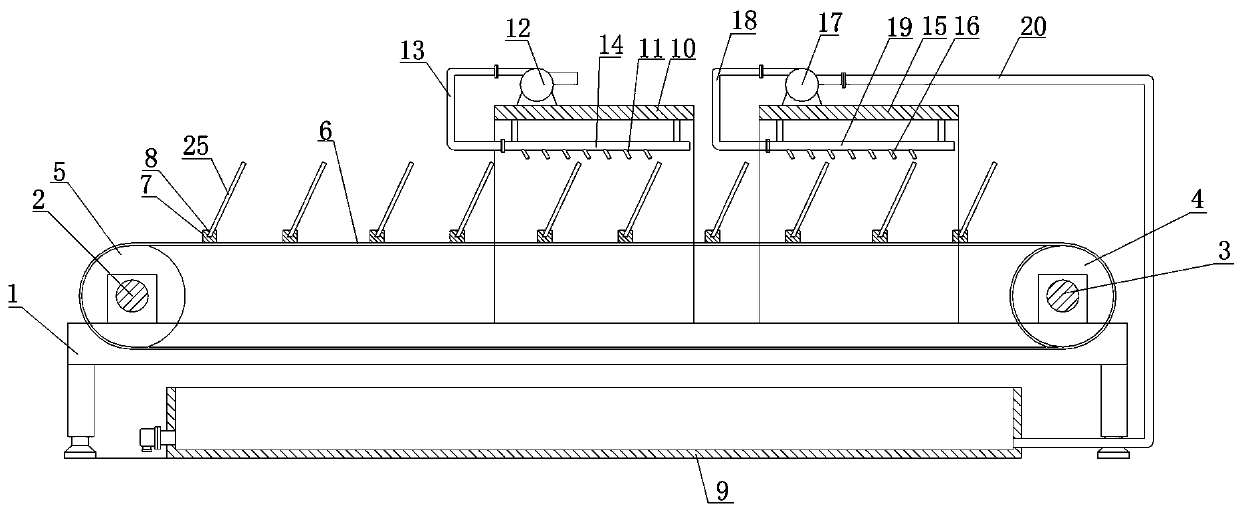

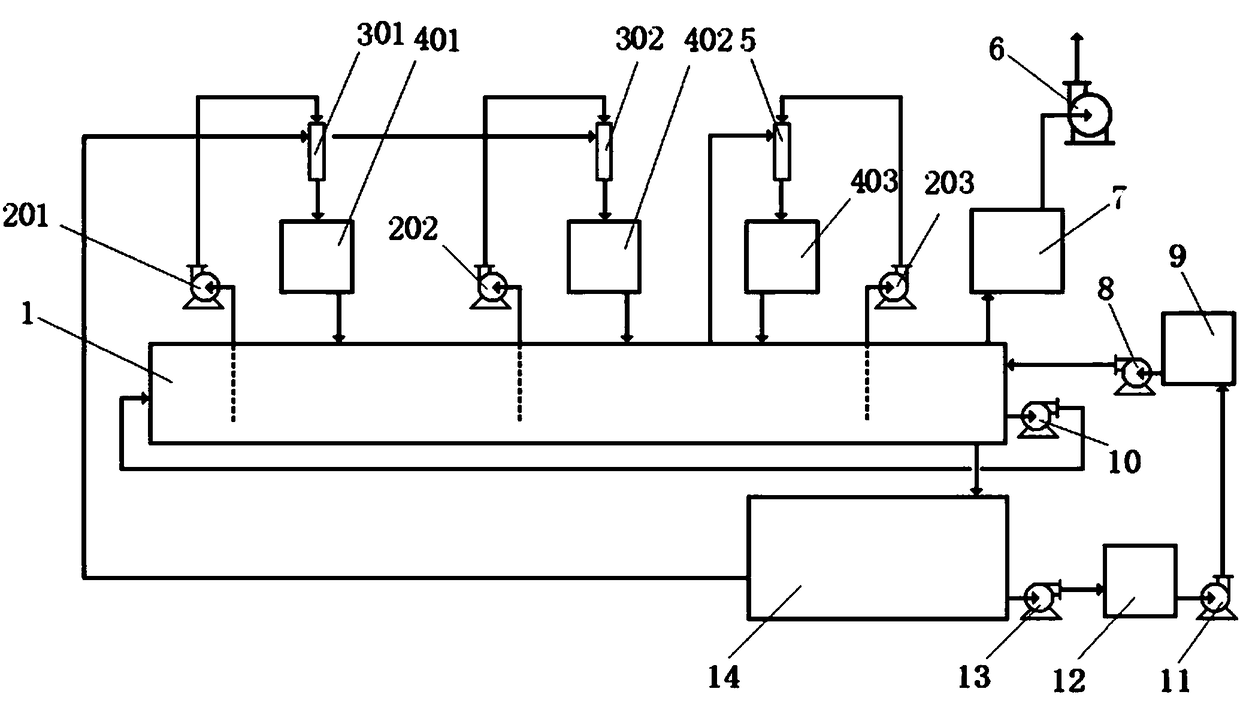

Production line and production process of printed circuit board for new energy automobile

ActiveCN110072343AReduce labor intensityIncrease productivityConductive material chemical/electrolytical removalProduction lineNew energy

The invention discloses a production line of a printed circuit board for a new energy automobile; the production line comprises an etching device and a leveling device, wherein the etching device comprises a rack (1), a power unit, and a purging device and a spraying device arranged on the rack (1); the leveling device comprises a working table (51) and a driving mechanism; a bearing table (52) isarranged on the top of the working table (51); and an arched frame A (53) which is fixedly arranged above the bearing table (52) is arranged on the top of the working table (51). The production linehas the beneficial effects that the structure is compact, the labor intensity of workers is reduced, the production efficiency of the printed board for the new energy automobile is improved, the etching liquid is repeatedly used, the heat deformation of the circuit board is prevented, and the etching cost is saved.

Owner:SICHUAN HAIYING ELECTRONICS TECH

Higher-order high-density circuit board copper plating technology

InactiveCN108823616AReduce etching costsImprove copper plating qualityPrinted circuit manufactureCopper platingHigh density

The invention discloses a higher-order high-density circuit board copper plating technology. According to a step of copper plating, a to-be-plated circuit board is placed in a coating bath, the temperature in the coating bath is controlled between 30-40 DEG C, the electroplating current is 1.2A / dm<2>-3A / dm<2>, and the electroplating time is 10-20 min; after the step of copper plating is completed,a blower fan blows a plating solution attach to the surface of the circuit board, the plating solution falls to the coating bath, and the plating solution is saved, after the above step, a brighteneris sprayed at the surface of the circuit board by workers, so that the surface of the circuit board is smooth and clean, and during a brightener sprinkling process, the surface of the circuit board is uniformly smeared with the brightener. The higher-order high-density circuit board copper plating technology has the beneficial effects that the etching cost is saved, the plating solution is recycled, and the copper plating quality is high.

Owner:SICHUAN HAIYING ELECTRONICS TECH

Method for recovering copper from alkaline etching waste liquid and recycling alkaline etching liquid

The invention discloses a method for recovering copper from alkaline etching waste liquid and recycling the alkaline etching liquid, comprising the step of adding a hydrazine hydrate reducing agent and a catalyst into the alkaline etching waste liquid to recover copper powder, wherein the alkaline etching waste liquid can be recycled after the copper powder is recovered. The invention has the optimum conditions of: placing the alkaline etching waste liquid into a reactor; adding hydrazine hydrate with mass percent concentration of 40 percent according to added quantity of 160-200mL / L; adding a solution of various salts of ruthenium, palladium, nickel and cobalt as the catalyst with added quantity of 0.01-0.2g / L (metered by the masses of the ruthenium, the palladium, the nickel and the cobalt), reacting for 30-35 minutes at temperature between 70DEG C and 100DEG C; and separating to obtain the copper powder. The invention has the beneficial effect that after the copper is recovered from the alkaline etching waste liquid, the alkaline etching waste liquid can be regenerated and recycled, therefore, various resources in the alkaline etching waste liquid can be used fully, and the etching cost of a printing plate and the discharge of pollutants can be reduced.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

Production line and production process of printed circuit boards for new energy vehicles

ActiveCN110072343BReduce labor intensityIncrease productivityConductive material chemical/electrolytical removalProduction lineNew energy

The invention discloses a production line of a printed circuit board for a new energy automobile; the production line comprises an etching device and a leveling device, wherein the etching device comprises a rack (1), a power unit, and a purging device and a spraying device arranged on the rack (1); the leveling device comprises a working table (51) and a driving mechanism; a bearing table (52) isarranged on the top of the working table (51); and an arched frame A (53) which is fixedly arranged above the bearing table (52) is arranged on the top of the working table (51). The production linehas the beneficial effects that the structure is compact, the labor intensity of workers is reduced, the production efficiency of the printed board for the new energy automobile is improved, the etching liquid is repeatedly used, the heat deformation of the circuit board is prevented, and the etching cost is saved.

Owner:SICHUAN HAIYING ELECTRONICS TECH

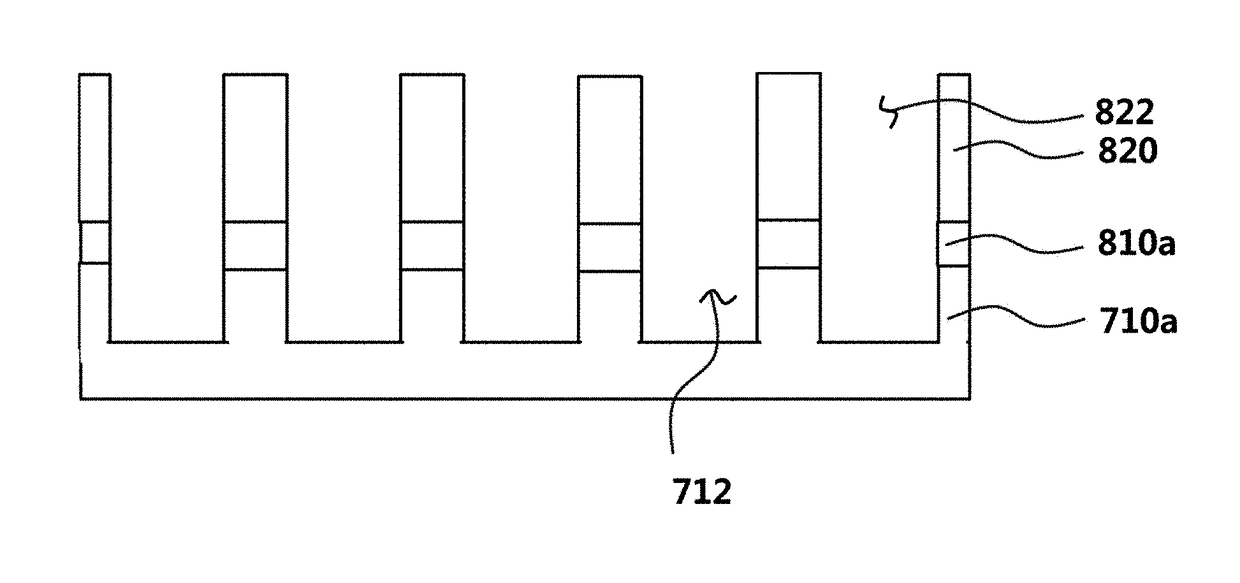

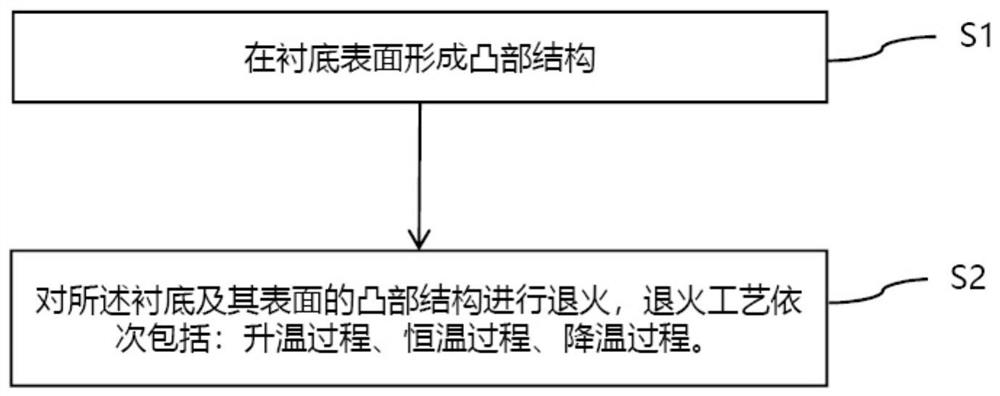

Patterned substrate, light -emitting diode and manufacturing method thereof

ActiveCN112993098ALow refractive indexImprove extraction efficiencySemiconductor devicesPatterned substrateLight-emitting diode

The invention provides a patterned substrate, a light-emitting diode and a manufacturing method of the patterned substrate, and the method comprises the following steps: forming a convex part structure on the surface of the substrate through the imprinting or reprinting of a nanometer mold, and carrying out the annealing treatment of the convex part structure on the surface of the substrate, and uniformly distributed pores are generated in the convex part structure by controlling parameters of an annealing process, so that the patterned substrate with high porosity inside is obtained. The patterned substrate, the light-emitting diode and the manufacturing method of the patterned substrate and the light-emitting diode are simple and economical, the light extraction efficiency can be remarkably improved through the manufactured patterned substrate and the manufactured light-emitting diode, and therefore the brightness of an LED is improved.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

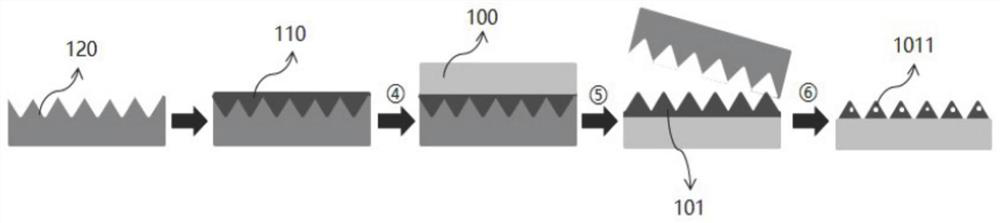

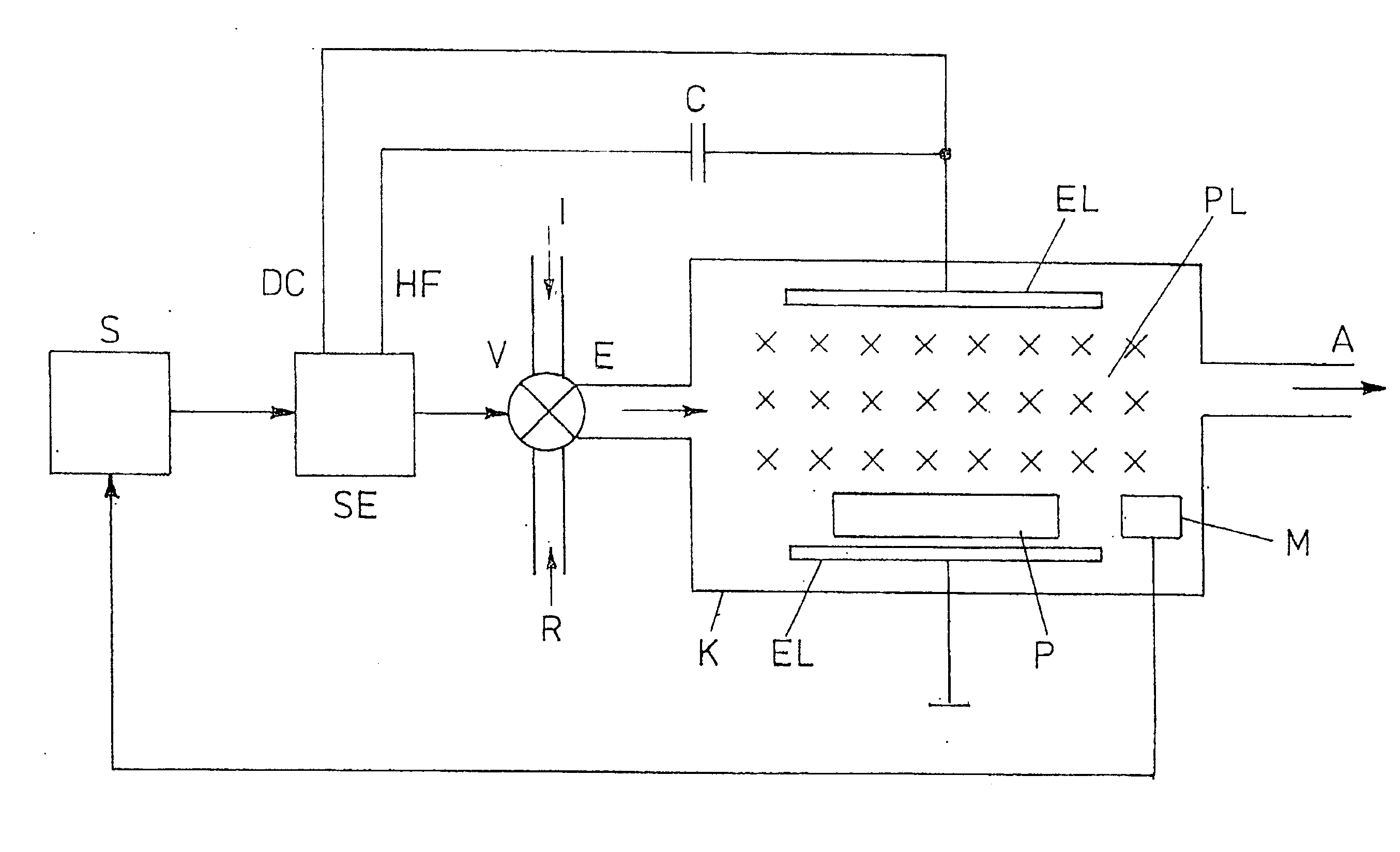

Method for etching a sample and etching system

InactiveUS20060169670A1Cost reductionReduce environmental pollutionElectric discharge tubesVacuum gauge using ionisation effectsChemistryStream flow

To reduce the use of expensive reactive gas, which is frequently also environmentally harmful, during etching by a plasma the reactive gas is first fed through a reaction chamber of an etching system for stabilization, until all the process parameters are adjusted to their setpoints. During this stabilization, all of the setting parameters of the etching system are stored in a memory. After storage, the gas flow rate of an inert gas, for example helium, that is fed through the reaction chamber instead of reactive gas is raised from an initial value until the reference gas flow rate is found that causes the same setting parameters as the reactive gas. This reference gas flow rate is also stored in the memory. In each subsequent etching process, the etching system is first adjusted by the inert gas flowing through the reaction chamber with the determined reference gas flow rate, and after stabilization is complete, the reactive gas is fed through the reaction chamber and the plasma is ignited for the actual etching process.

Owner:MICRONAS

A replenishing liquid capable of improving the service life of hydrogen peroxide-based etching liquid

Owner:武汉迪赛新材料有限公司

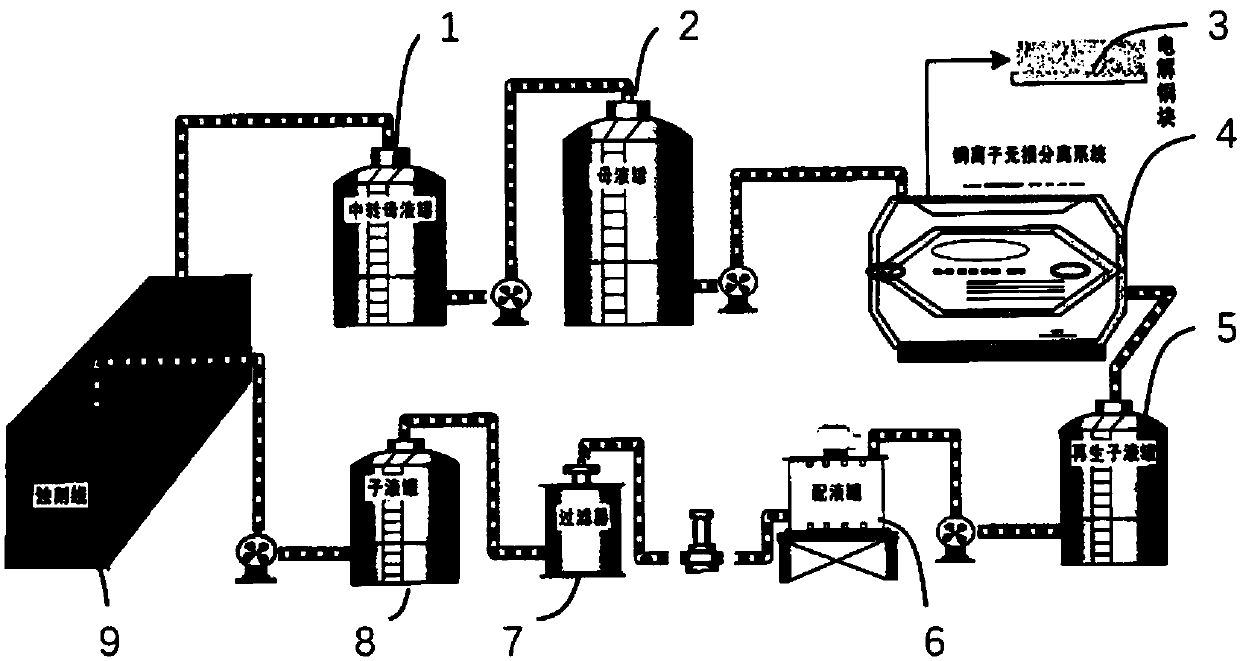

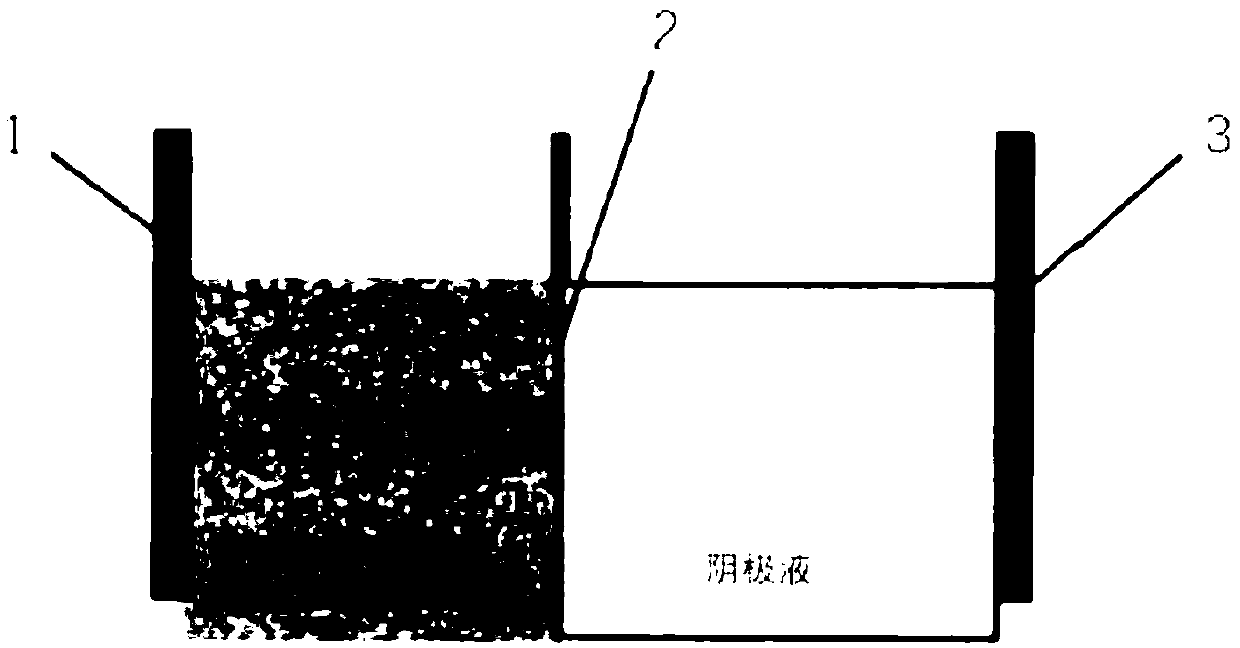

Copper extraction and cyclic regeneration technology of alkaline etching liquid

InactiveCN107858686AEmission reductionChemical composition balancePhotography auxillary processesProcess efficiency improvementLiquid wasteElectrolysis

The invention relates to a copper extraction and cyclic regeneration technology of alkaline etching waste liquid. The copper extraction and cyclic regeneration technology comprises the steps that (1)cupric ions in the alkaline etching waste liquid are converted into metal copper to be extracted through the damage-free separation direct electrolysis technology; (2) impurities in the etching liquidare filtered out through a filter; and (3) the alkaline etching waste liquid is adjusted to the qualified alkaline etching liquid through solution proportioning. According to the technology, a closedcycle is adopted, in the whole process, no other foreign substances are introduced, no hazardous substances are generated, solution compositions cannot be destroyed, the technical problems of accumulation of impurities in etching tanks and the like with which all kinds of regeneration cyclic etching liquid are faced during long-time operation are solved well, and the cyclically-regenerated etching liquid can compare favorably with newly-prepared etching liquid.

Owner:丰顺佳丰电子有限公司

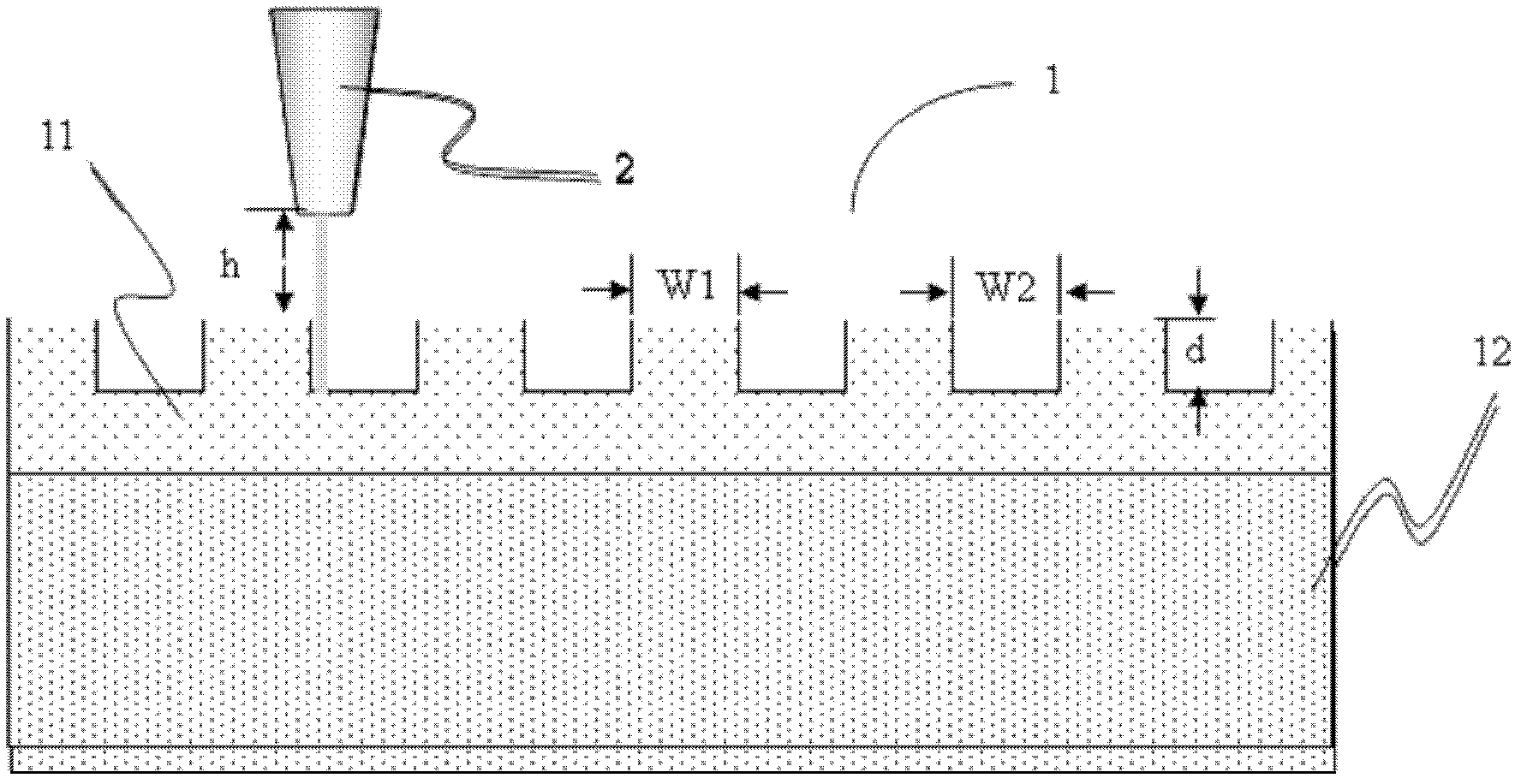

Manufacturing method for roughened transparent conducting base plate

InactiveCN103227232ASimple control processAccurately grasp the widthFinal product manufacturePhotovoltaic energy generationPower flowOptoelectronics

The invention discloses a manufacturing method for a roughened transparent conducting base plate, which mainly comprises the following steps: depositing a transparent conducting layer on a transparent base plate and covering the transparent conducting layer on one surface of the transparent base plate; and graving patterns through a laser source and roughening the surface of the transparent conducting layer. A thin film solar cell formed by the roughened transparent conducting base plate can effectively improve the current and efficiency.

Owner:ASIATREE TECH

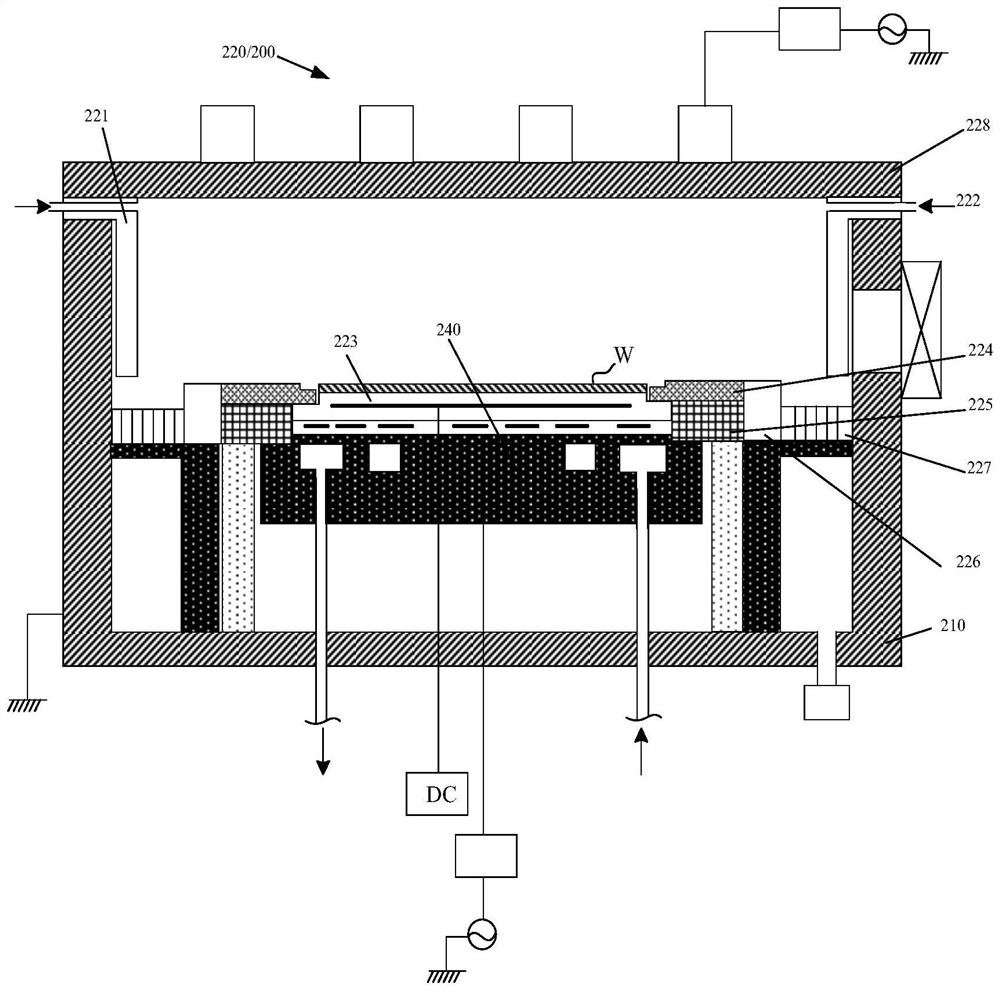

Semiconductor component, composite coating forming method and plasma reaction device

PendingCN114078679AAvoid corrosionReduce the risk of failureElectric discharge tubesSemiconductor/solid-state device manufacturingCoated surfacePlasma reaction

The invention relates to the technical field of plasma etching, and discloses a semiconductor component, a composite coating forming method and a plasma reaction device. The semiconductor component comprises a component body, the surface of the component body is provided with a composite coating, and the composite coating comprises a plasma corrosion-resistant coating and a waterproof sacrificial layer. The plasma corrosion-resistant coating is arranged on the surface of the component body. The waterproof sacrificial layer is arranged on the surface of the plasma corrosion-resistant coating. The surface of the plasma corrosion-resistant coating is coated with the waterproof sacrificial layer, so that the plasma corrosion-resistant coating is prevented from being in contact with water, the risk that the corrosion-resistant coating loses efficacy due to hydrolysis is greatly reduced, the time for cleaning, transportation, storage or putting into use can be shortened, the plasma etching production efficiency is greatly improved, and the etching cost is reduced.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

A liftable etching device based on LED light board

ActiveCN109348622BEtching speed is fastImprove etching efficiencyElectroluminescent light sourcesInsulating layers/substrates workingFixed frameLED lamp

The invention discloses a liftable etching device based on an LED lamp panel. The liftable etching device comprises a base, wherein the top of the base is connected with an etching box through bolts;two sides of the etching box are connected with vertically arranged linear electric push rods through bolts respectively; the tops of movable rods of the two linear electric push rods are connected with the same box cover through bolts; the bottom of the box cover is connected with connecting blocks in equally-spaced distribution through bolts; and two ends of the bottoms of the connecting blocksare connected with tension springs through bolts respectively. According to the liftable etching device, an etching solution is heated by a heater inside an etching solution storage tank, the etchingspeed can be improved, through circulating etching of the etching solution, impurities can be avoided from being deposited inside the etching box effectively to cause the occurrence of phenomenon thatthe machine halts for cleaning at regular intervals is needed, the etching efficiency is improved, a vibration motor drives a fixed frame to vibrate, the etching solution remaining in the fixed frameis recycled through vibration, the waste of resources is avoided, and the etching cost is reduced.

Owner:安徽迪思自动化设备有限公司

Three grade cyclic absorption treatment method and equipment in acid etching production lines

ActiveCN108425116ACarry out effectivelyEffective and stablePhotography auxillary processesProcess efficiency improvementAcid etchingProduction line

The invention discloses a three grade cyclic absorption treatment method and equipment in acid etching production lines. The three grade cyclic absorption treatment method comprises following steps: 1, electrolysis and regenerated liquid circulation; 2, chlorine gas absorption circulation; 3, etching solution circulation; 4, tail gas absorption circulation; and 5, tail gas treatment. According tothe three grade cyclic absorption treatment method, three grade cyclic absorption is adopted in acid etching production lines, so that absorption validity, rationality, and controllability are ensured, processing and recycling effect of Cl2 is ideal, absorption operation can be controlled based on ORP value, operation is convenient and stable, etching temperature is ensured to be stable, energy consumption is reduced, etching effect is improved, tail gas treatment load of the whole system is reduced, and secondary pollution is avoided.

Owner:SHENZHEN ZHONGKE OUTAIHUA ENVIRONMENTAL PROTECTION TECH

An etching device and a single-side etching method of a wafer

ActiveCN105225992BTo achieve the purpose of single-sided etchingImprove etching efficiencySemiconductor/solid-state device manufacturingEtchingEngineering

The application discloses an etching device and a wafer one side etching method. The base of the etching device is used for placing a plurality of clamping piece rings; at least two wafers are arranged between adjacent clamping piece rings; the water surfaces to be etched are towards adjacent clamping piece rings; the plurality of clamping piece rings and the plurality of wafers arranged on the base are clamped by a clamping device, and then corrosive liquids can be injected through the liquid inlet slots of the clamping piece rings to corrode the wafers. At least two wafers are closely attached, and only the water surfaces to be etched are towards adjacent clamping piece rings, and thereby after the corrosive liquids are injected through the liquid inlet slots of the clamping piece rings, the corrosive liquids can only touch the water surfaces to be etched, thereby etching one side of a wafer.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

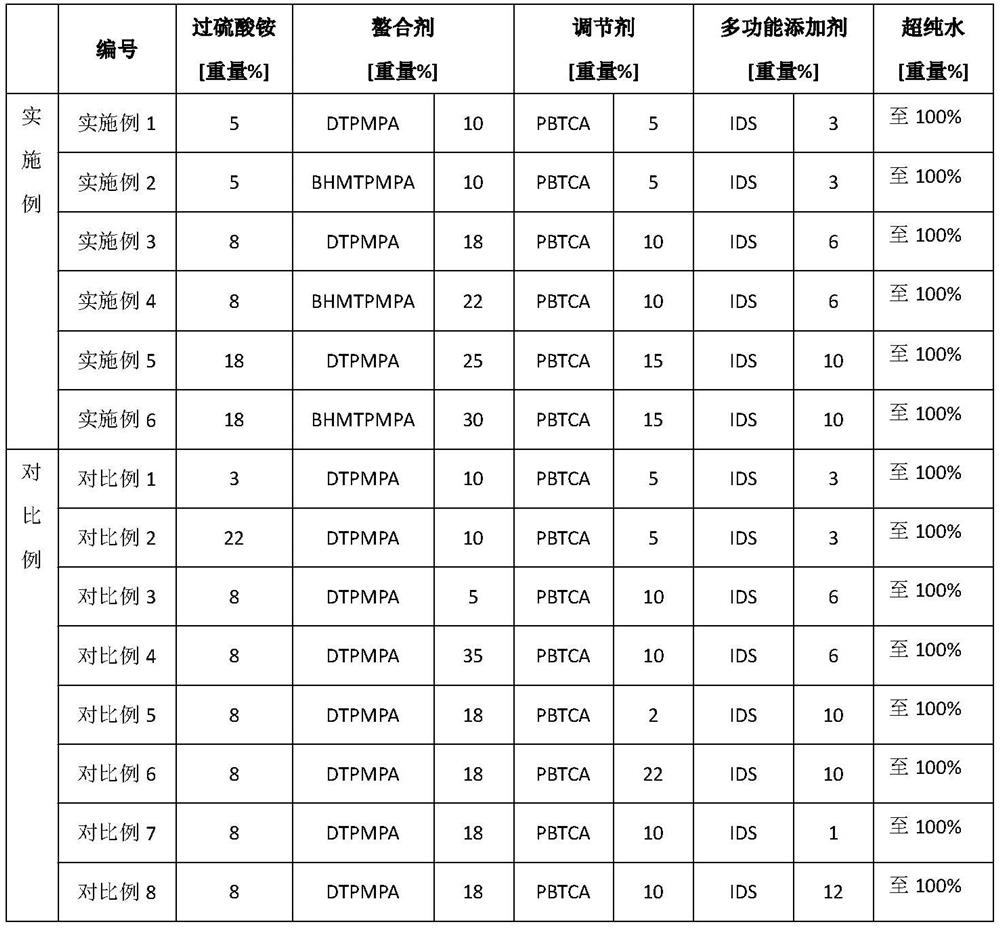

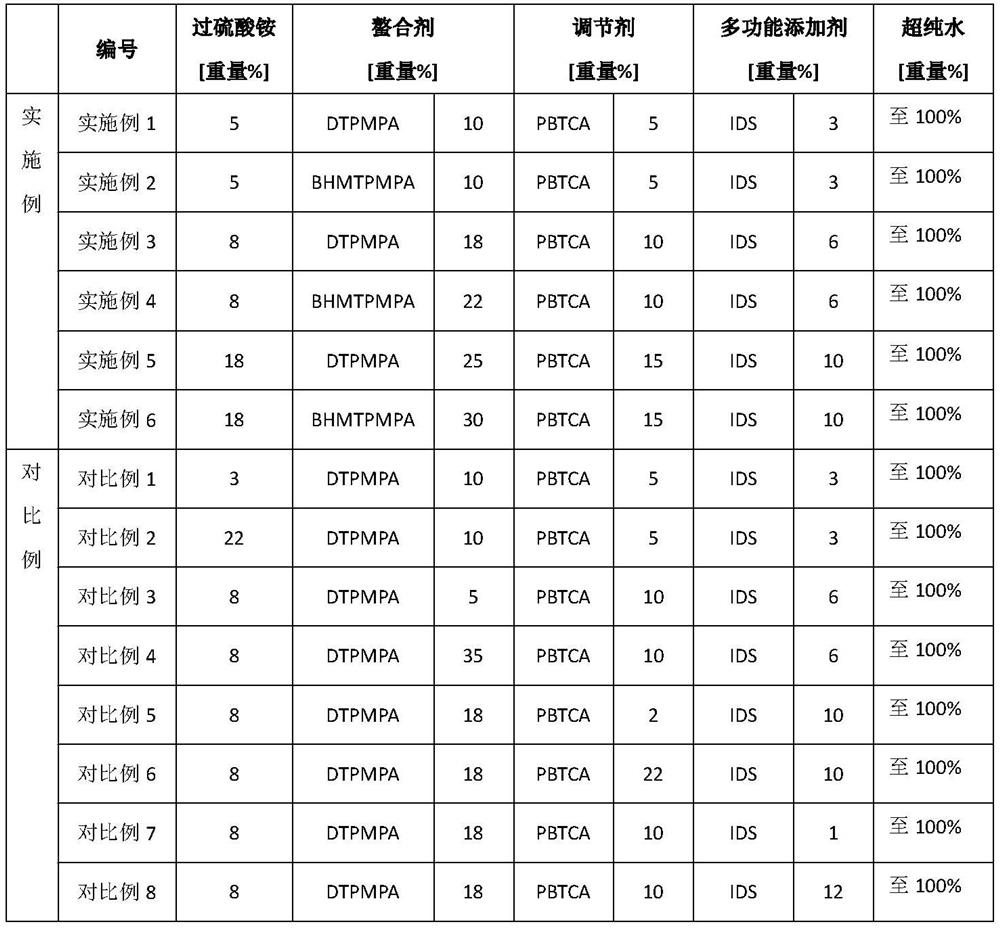

Replenishing liquid capable of prolonging service life of hydrogen peroxide etching liquid

The invention belongs to the technical field of materials for chemical etching of metal materials, and particularly relates to replenishing liquid capable of prolonging the service life of hydrogen peroxide etching liquid. Relative to the total weight of the whole composition, the replenishing liquid comprises the following components in percentage by weight: 4-20% of ammonium persulfate, 8-30% ofa chelating agent, 4-20% of a regulator, 2-10% of a multifunctional additive and ultrapure water for enabling the whole composition to reach 100%. After the replenishing liquid is added into the hydrogen peroxide etching liquid which is nearly invalid after continuous etching, the service life of the etching liquid can be obviously prolonged again, the purpose of reducing the use amount of the etching liquid can be achieved, the etching cost is obviously reduced, and the replenishing liquid has very high industrial popularization value.

Owner:武汉迪赛新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com