Copper extraction and cyclic regeneration technology of alkaline etching liquid

A technology of recycling and etching solution, which is applied in the direction of photography technology, photography auxiliary technology, improvement of process efficiency, etc., can solve problems such as long time, waste of resources and environment, and difficulty in elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

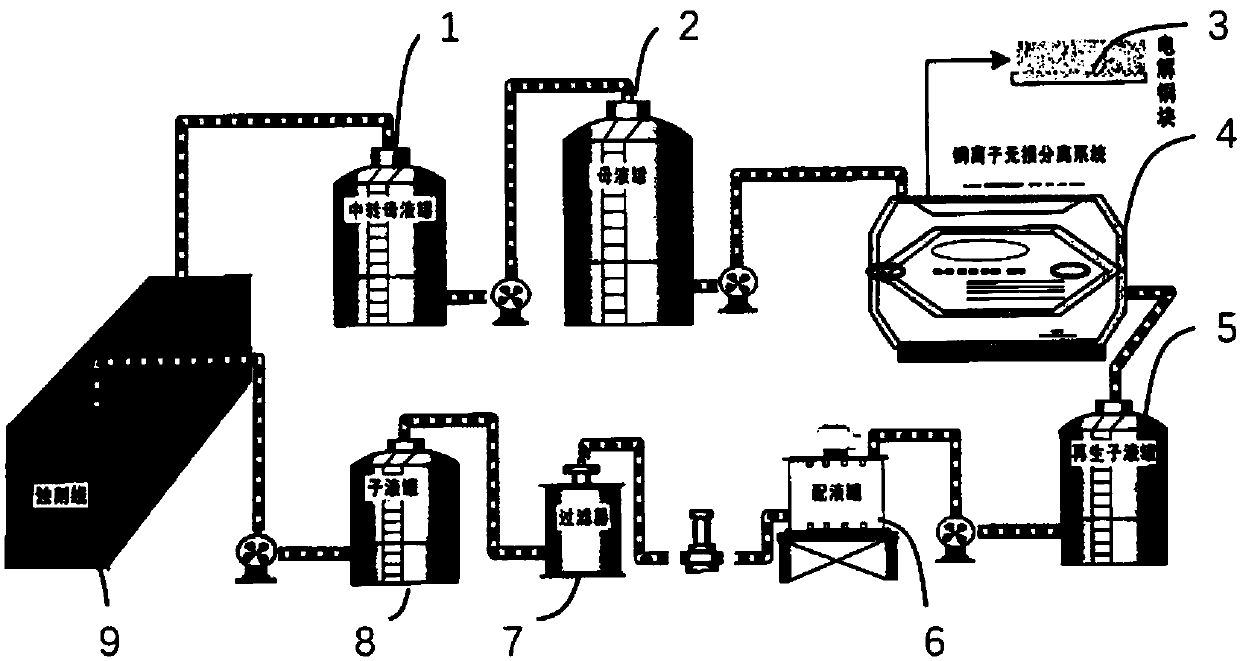

[0015] Such as figure 1 As shown, the alkaline etching waste liquid of the present invention extracts copper and recycles and regenerates process, comprises following recycle step:

[0016] Step (1): Alkaline etching waste liquid generated after etching in the alkaline etching production line (9) is pumped into the mother liquor tank (2) through the transfer mother liquor tank (1);

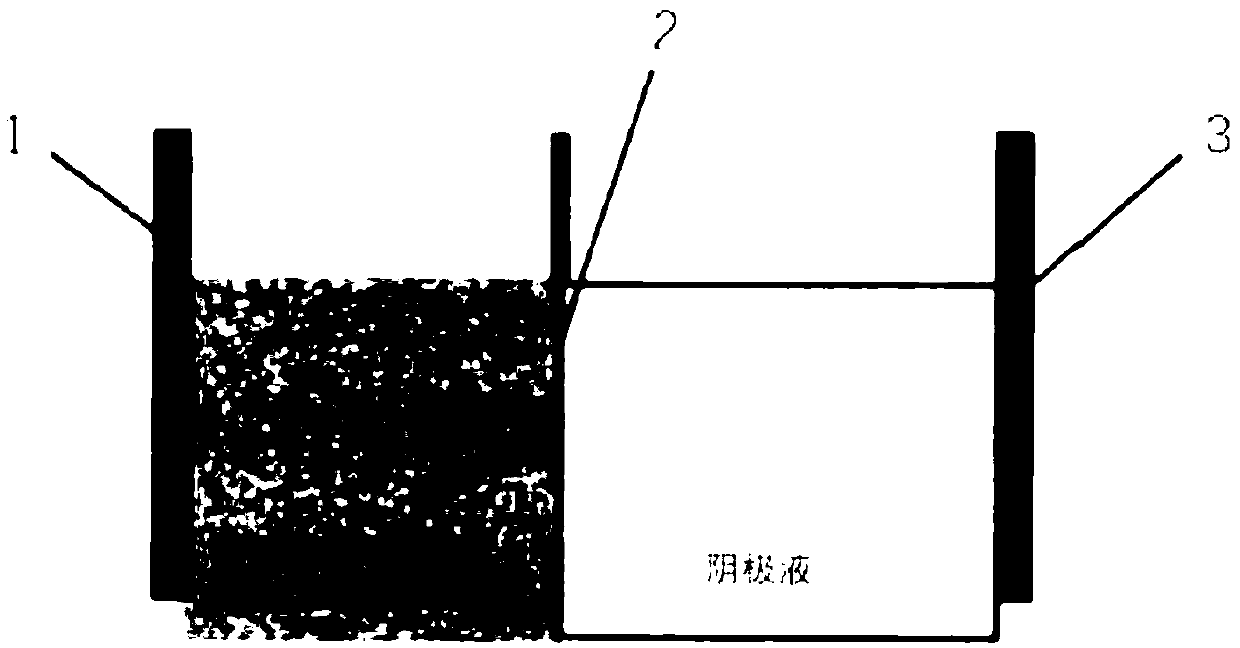

[0017] Step (2): The alkaline etching waste liquid in the mother liquor tank (2) is pumped into the copper ion non-destructive separation system (4), and the alkaline etching waste liquid is extracted by membrane separation technology in the copper ion non-destructive separation system (4). Copper extraction, the excess copper ions in the solution are electrolyzed into solid metal copper by electrolysis, and ammonium chloride and ammonia are released at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com