Patents

Literature

298results about How to "Improve etching efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

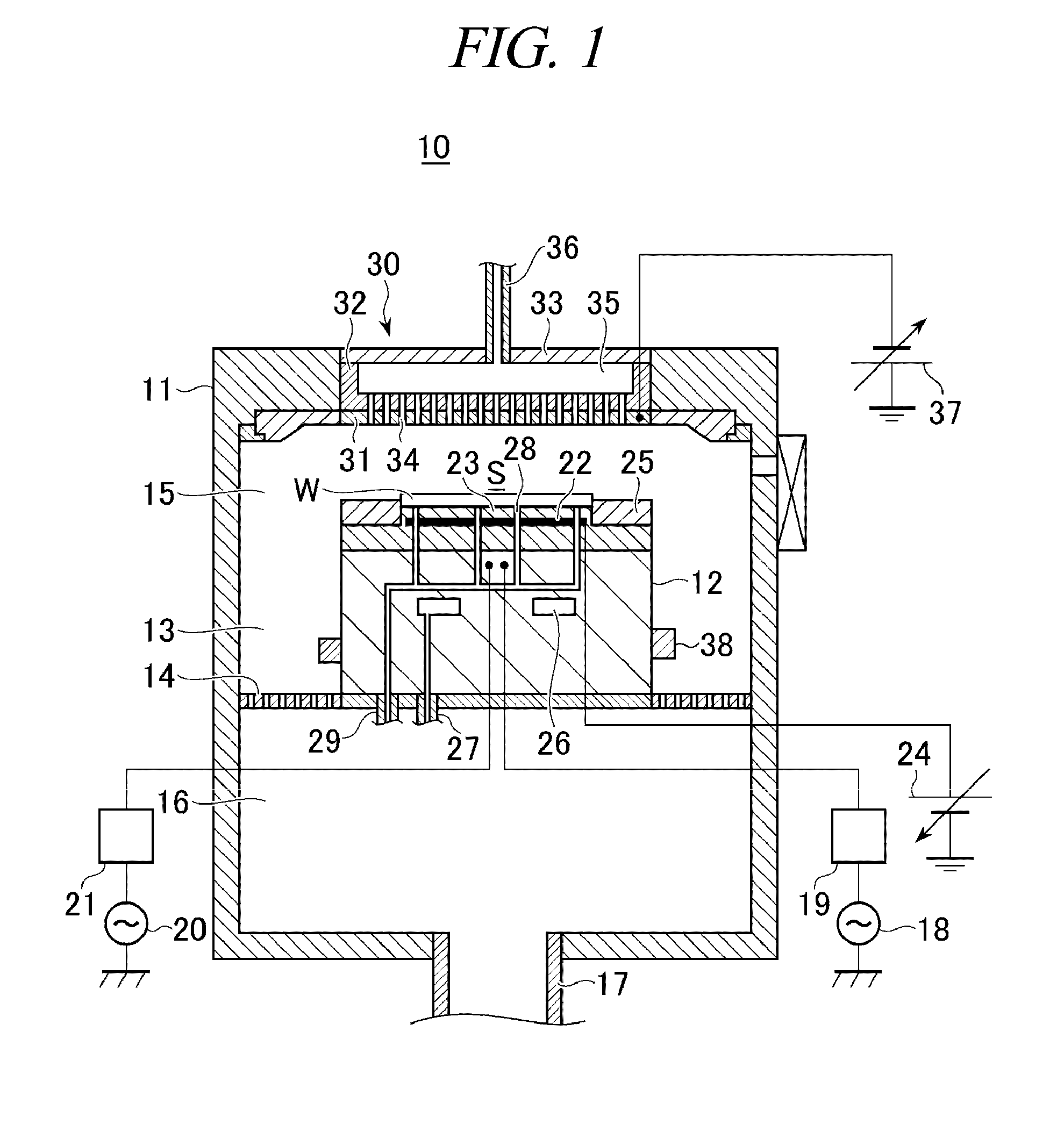

Apparatus and method for plasma etching

InactiveUS6239036B1Improve etching efficiencyLow costElectric discharge tubesDecorative surface effectsParallel plateProduct gas

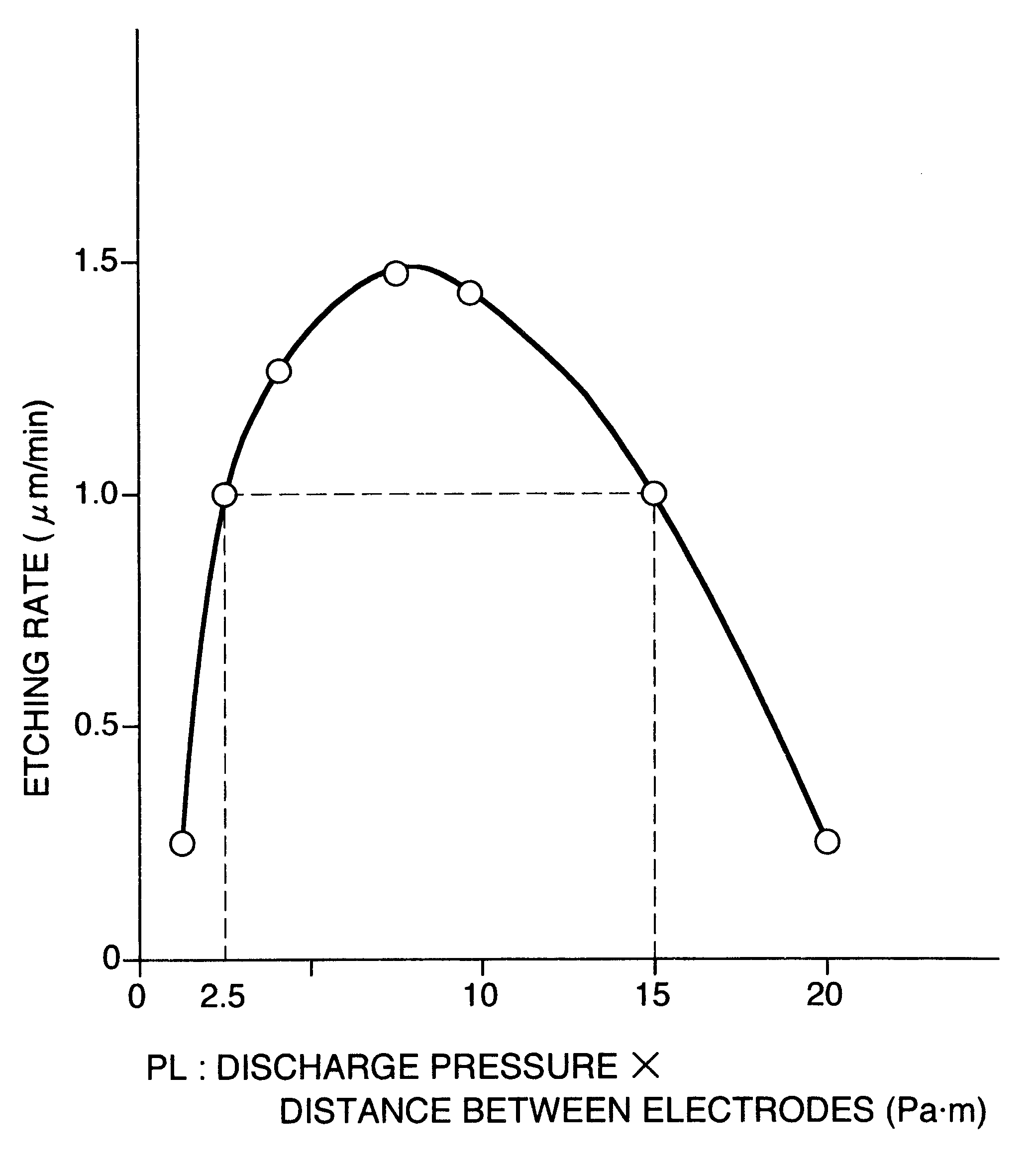

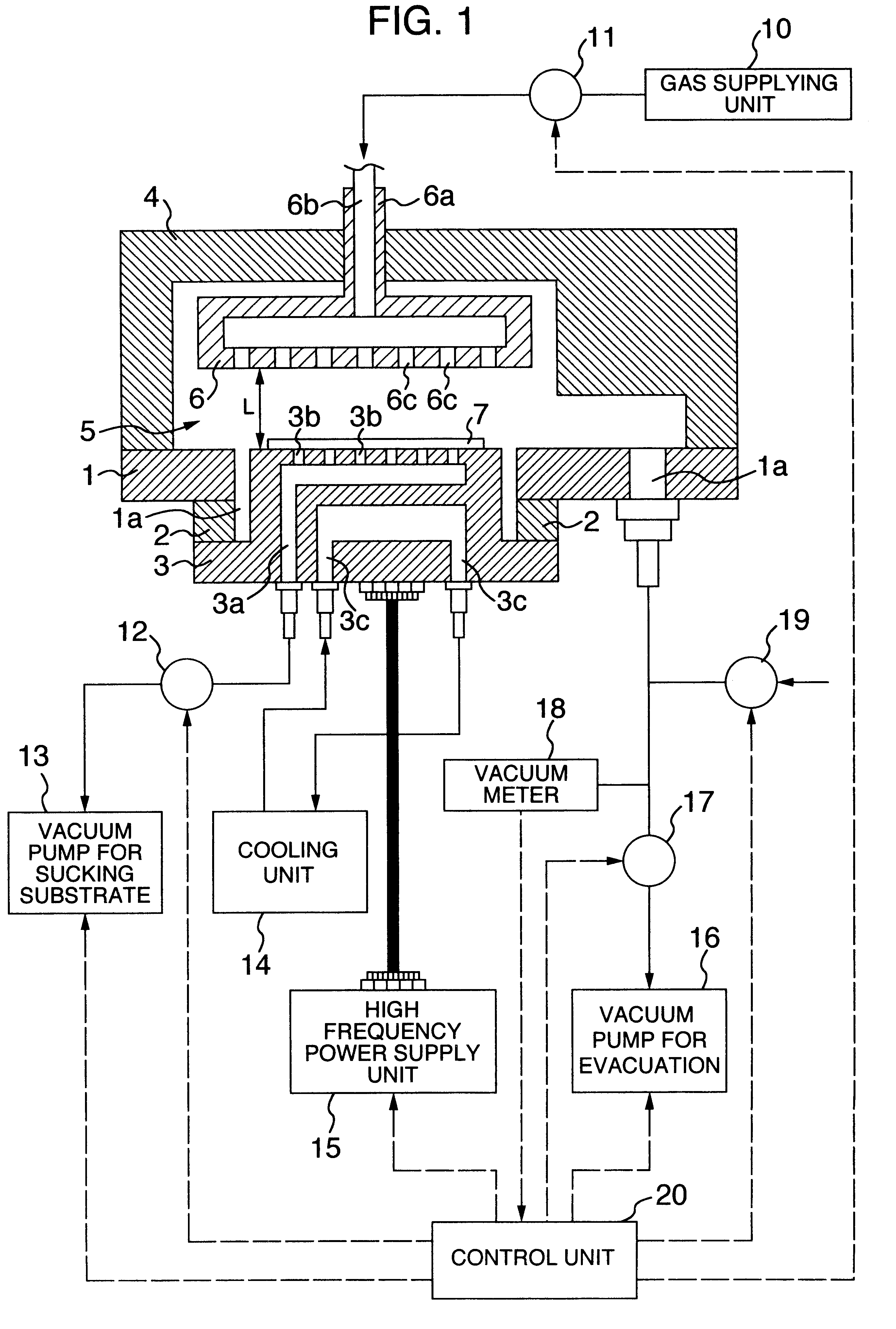

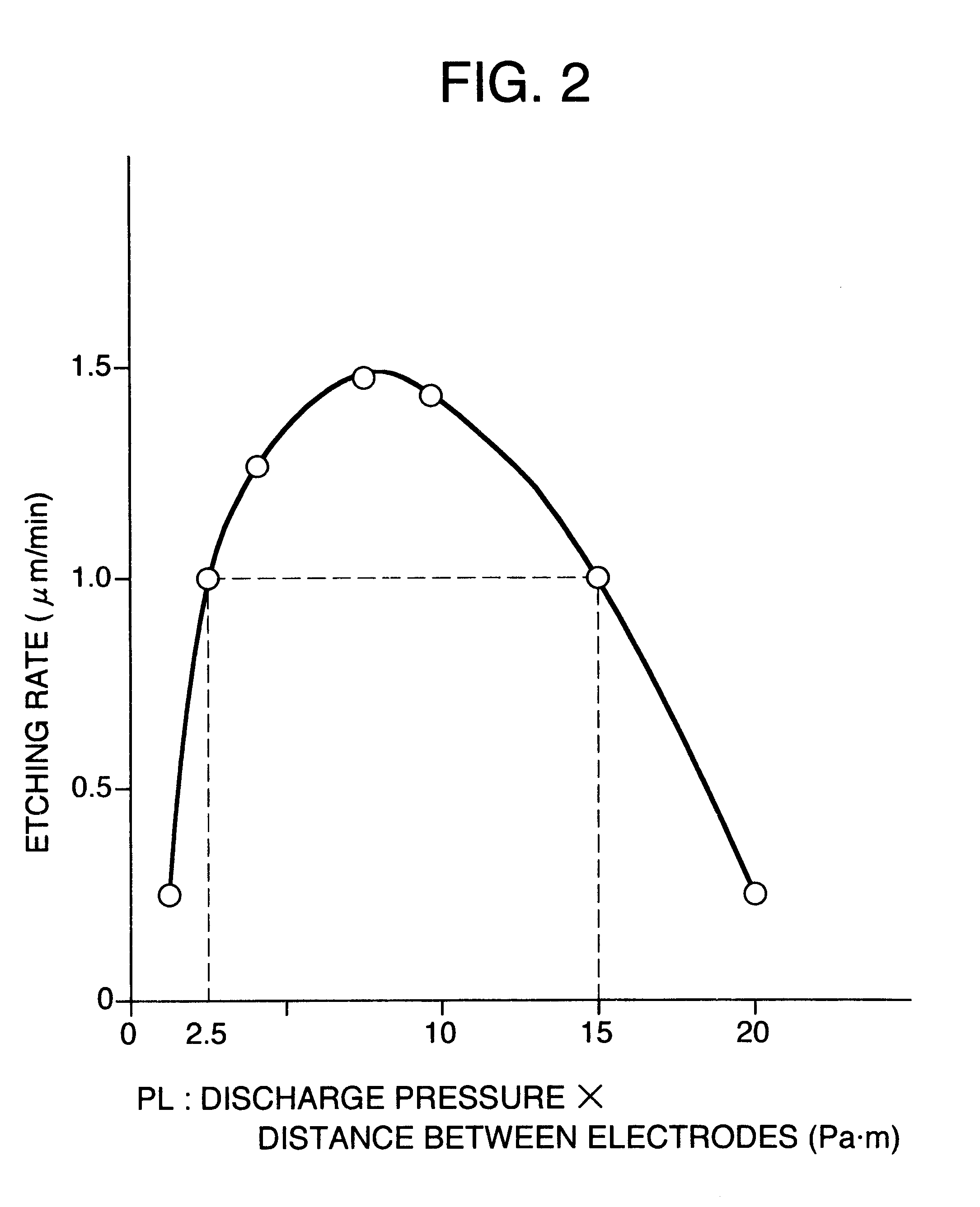

A plasma etching apparatus and a plasma etching method for conducting a plasma etching treatment for a substrate to be treated placed on one of parallel plate electrodes disposed oppositely to each other in a treatment chamber, wherein gas supplying device is used to supply a mixed gas including oxygen and a fluorine gas in the treatment chamber and the plasma discharge is conducted between the parallel plate electrodes under the condition that the product PL of a distance L[m] between the plate electrodes and the pressure P[Pa] of the mixed gas in the treatment chamber takes a value within 2.5[Pa.m] to 15[Pa.m] so as to efficiently perform an etching treatment, at a low cost, and in uniform.

Owner:PANASONIC CORP

Method for forming semiconductor structure

ActiveCN102737983AAvoid damageReduce rateSemiconductor/solid-state device manufacturingPhysicsPlasma etching

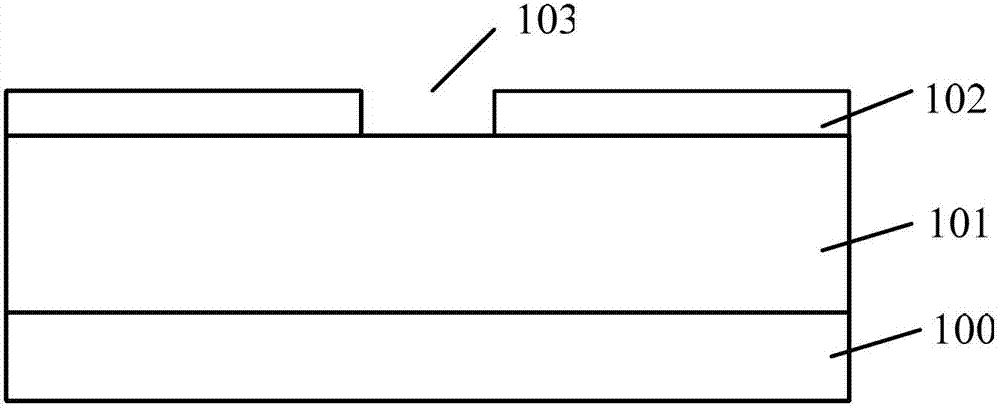

The invention discloses a method for forming a semiconductor structure, which comprises the following steps: providing a substrate and forming a dielectric layer on the substrate; forming a mask layer provided with an opening for exposing the surface of the dielectric layer on the dielectric layer; carrying out a plasma etching on the dielectric layer by taking the mask layer as a mask, wherein a bias power source outputs a bias power in pulse mode, when the bias power resource is switched on, etching part of the dielectric layer to form an etch-hole, when the bias power resource is switched off, forming a polymer on the surface of the mask layer, repeating the process of switching on the bias power resource and switching off the bias power resource till a through hole is formed. When forming the through hole, the etching step and the polymer forming step are repeated so that the polymer can keep a certain thickness, therefore, in the entire etching process, the mask layer is protected from damaging or the damage rate is reduced, and the etching ratio of the dielectric layer relative to the mask layer is increased.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

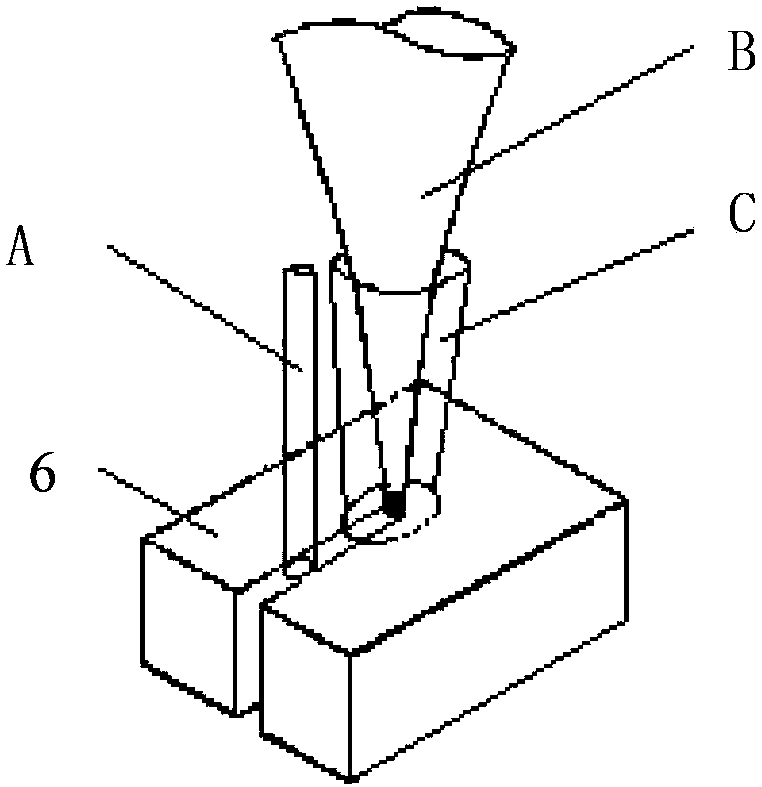

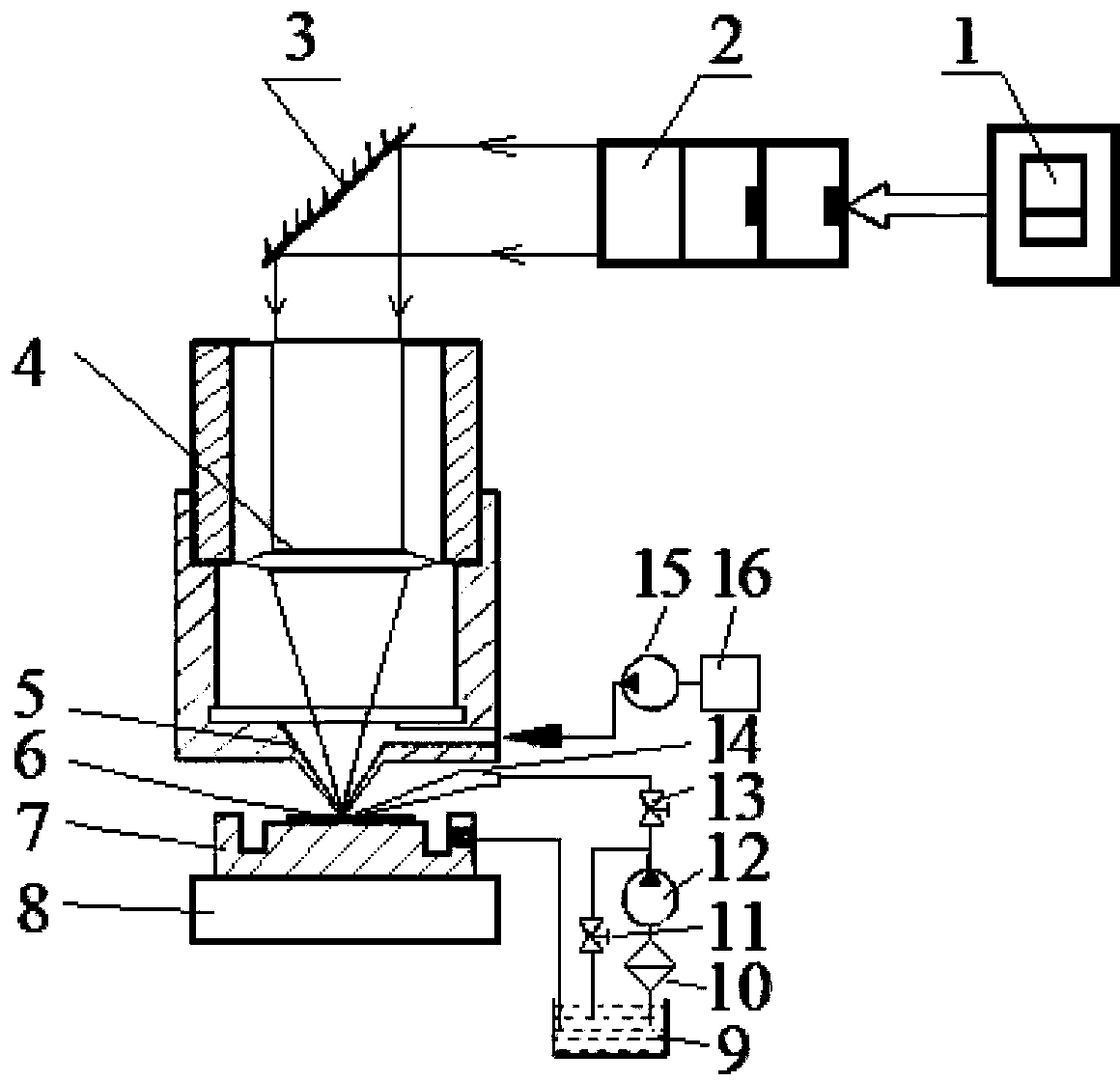

Laser processing method and system assisted by water jet and gas jet

InactiveCN103358027AFast power deliveryImproved Power Scouring ActionLaser beam welding apparatusPhysicsWater jet

The invention discloses a laser processing method and system assisted by a water jet and a gas jet. According to the laser processing method, a laser beam is focused on the surface of a workpiece; a gas jet beam of which the diameter is greater than that of the focus point of the laser beam is coaxial with the laser beam; after the gas jet beam enters a cut slot, a water jet beam behind the gas jet beam also enters the cut slot. The center line of the water jet beam is in a plane formed by the center line of the laser beam and the cut slot; the intersection point of the center line of the water jet beam and the surface of the workpiece is 1-2 mm from the focus point of the laser beam. The system comprises a laser generating mechanism, a gas jet nozzle and a workbench, wherein the longitudinal center line of the jet hole of a water jet nozzle behind the gas jet nozzle is in the plane formed by the center line of the laser beam and the cut slot; a gas pump and a water pump are respectively connected with the gas jet nozzle and the water jet nozzle; water circulates through the water pump, the water jet nozzle, a working cavity above the workbench and a water tank. According to the invention, the water jet beam restrains gas expansion, reduces the heat effect of laser, takes away deposits, and improves the efficiency and quality of laser ablation, so that the invention achieves remarkable effects particularly in processing plates with thicknesses above 15 mm.

Owner:GUILIN UNIV OF ELECTRONIC TECH +1

Etchant composition for glass of flat panel display

InactiveCN101481215AHigh transparencyQuality improvementSurface treatment compositionsNitrate saltsDisplay device

The invention relates to a glass etchant composition, more specifically, to a glass etchant composition forming a panel display. The glass etchant composition comprises 5-20 wt.% of HF; 10-50 wt.% of more than one inorganic acid selected from a group consisting of HSO, HPO, HCl, HCO, HNO and HClO; 0.5-10 wt.% of carboxylic acid; 0.01-5 wt.% of an inorganic nitrate salt as a first additive; and water residual. The glass etchant composition here provided brings high quality for transparency and surface roughness of glass processed, with stable etching capability, long service life and increased etching efficiency (etching sheet numbers).

Owner:EXAX INC

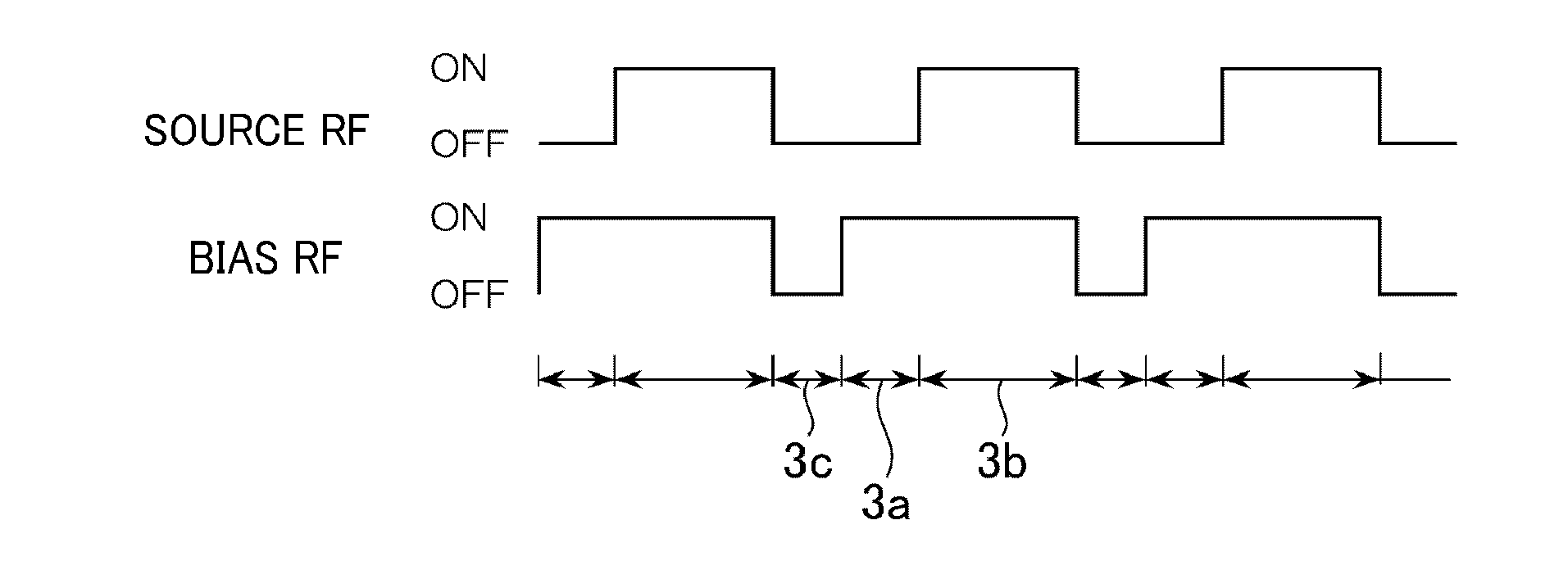

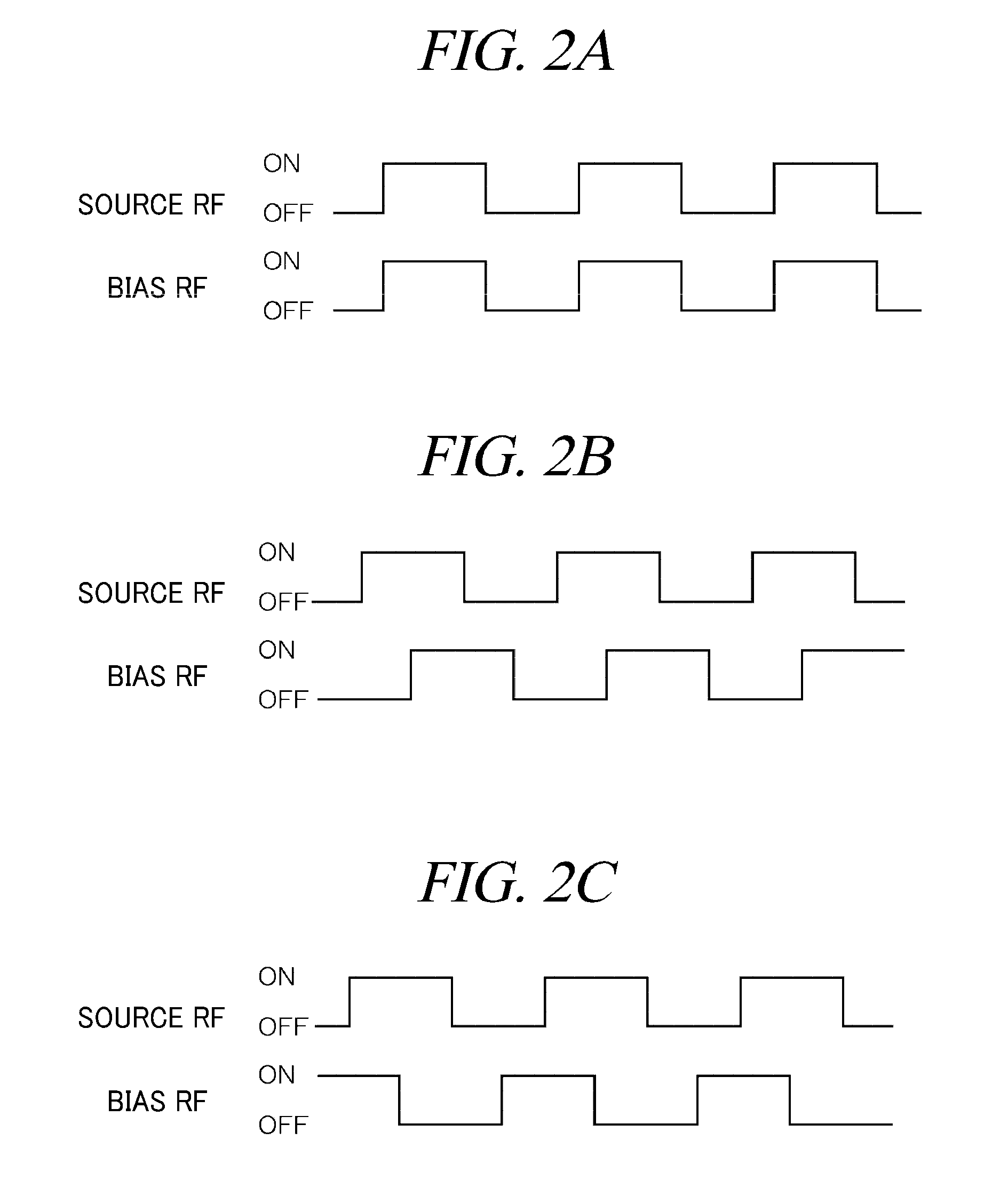

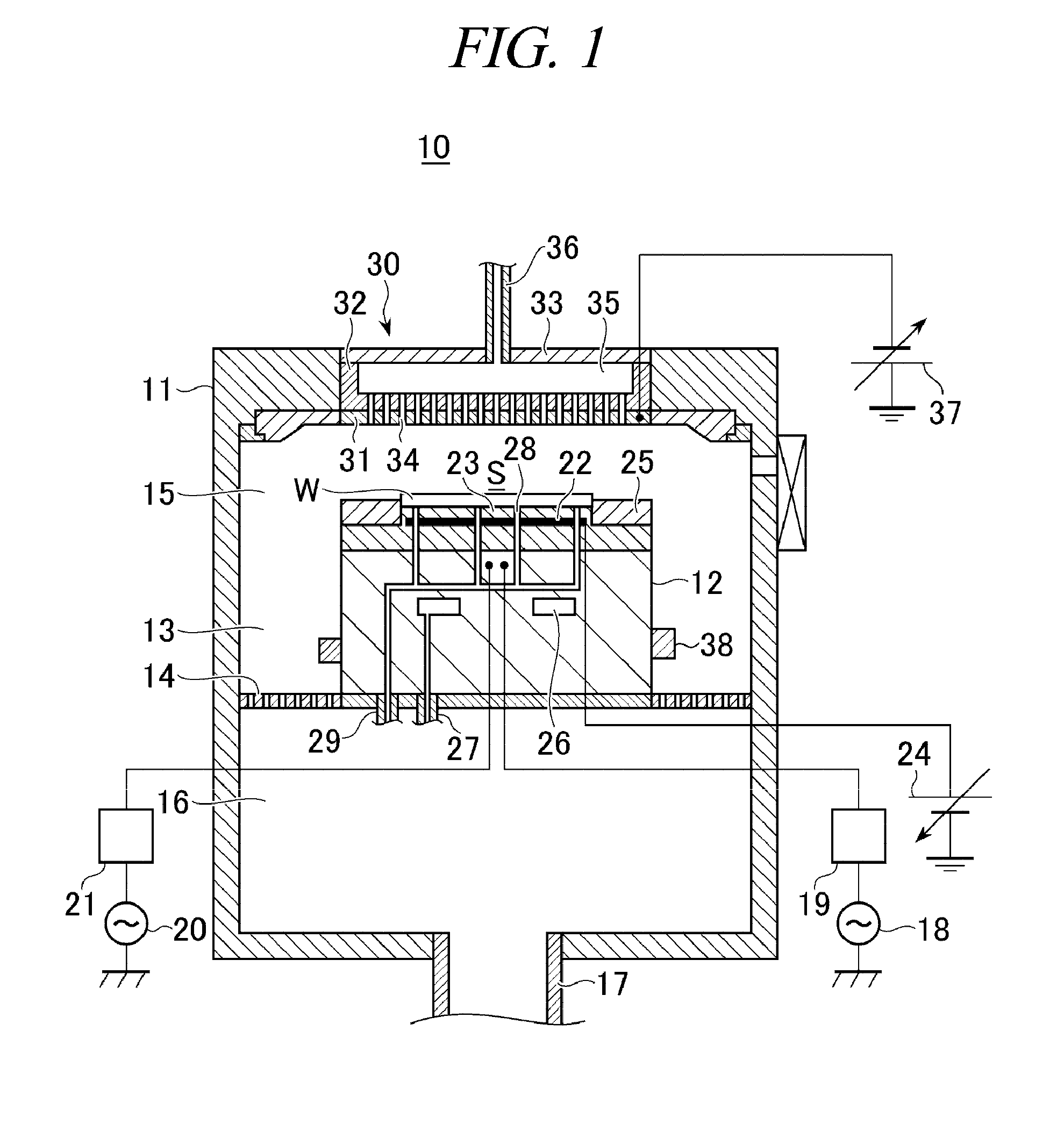

Substrate processing method

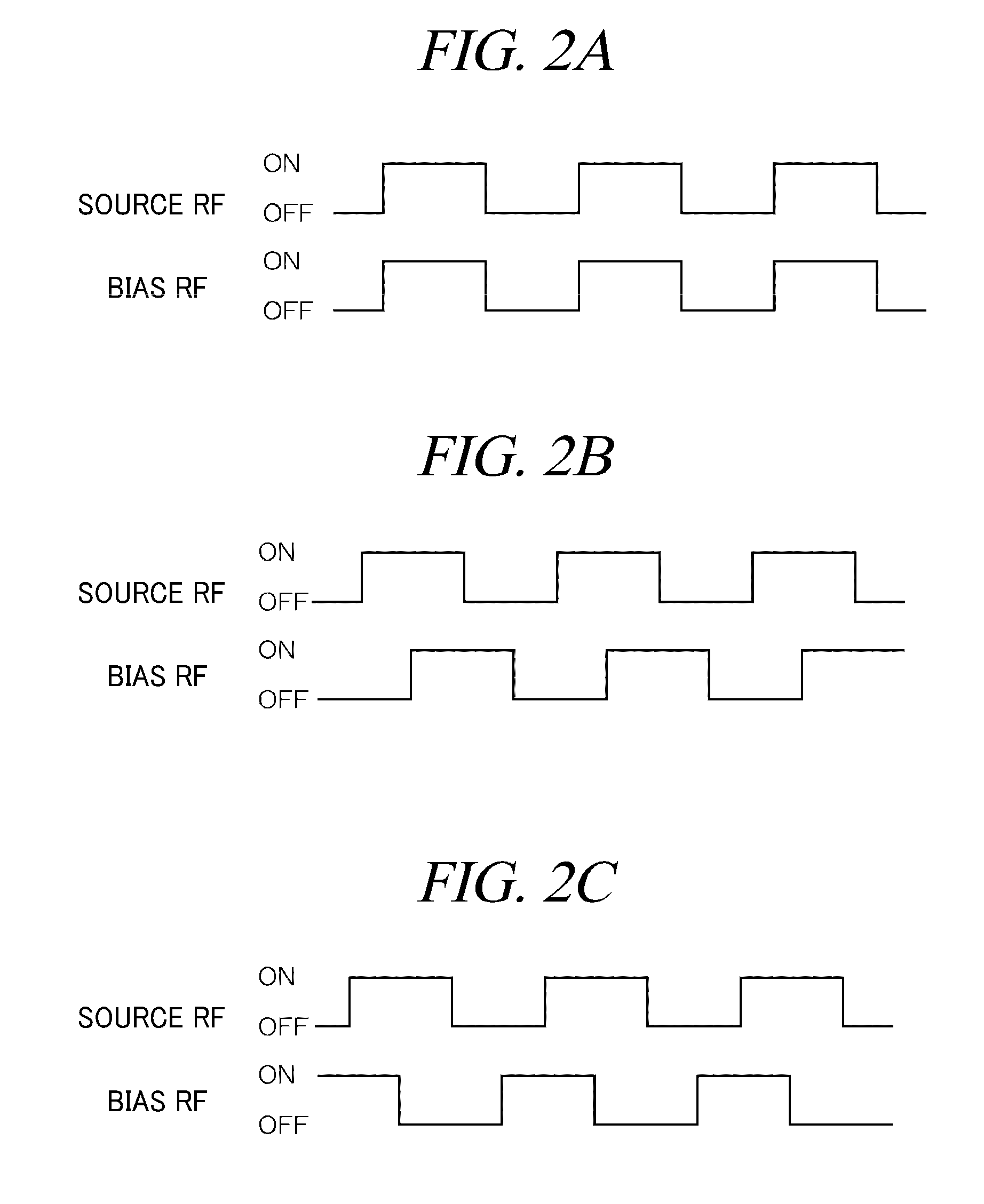

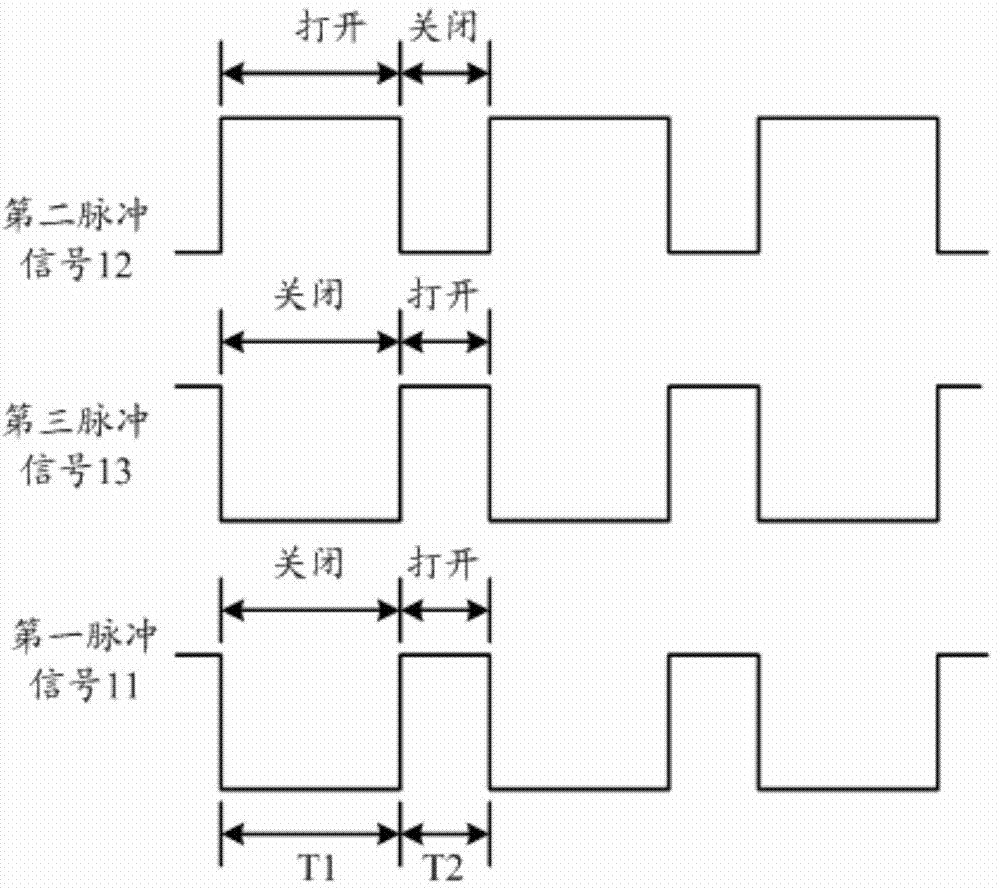

ActiveUS8685267B2Suppressing decrease in positive ion etching efficiencyImprove etching efficiencyElectric discharge tubesDecorative surface effectsPulsed waveAtomic physics

There is provided a substrate processing method capable of preventing the decrease in etching efficiency by positive ions and increasing the overall etching efficiency by using negative ions. The substrate processing method includes applying a plasma RF and a bias RF in the pattern of a pulse wave, respectively. The substrate processing method repeatedly performs the steps of: (3b) etching a substrate by positive ions in plasma by applying both the plasma RF and the bias RF; (3c) generating negative ions in a processing chamber by stopping the application of both the plasma RF and the bias RF; and (3a) attracting the negative ions to the substrate by applying the bias RF and stopping the application of the plasma RF. A duty ratio of the bias RF is set to be greater than a duty ratio of the plasma RF.

Owner:TOKYO ELECTRON LTD

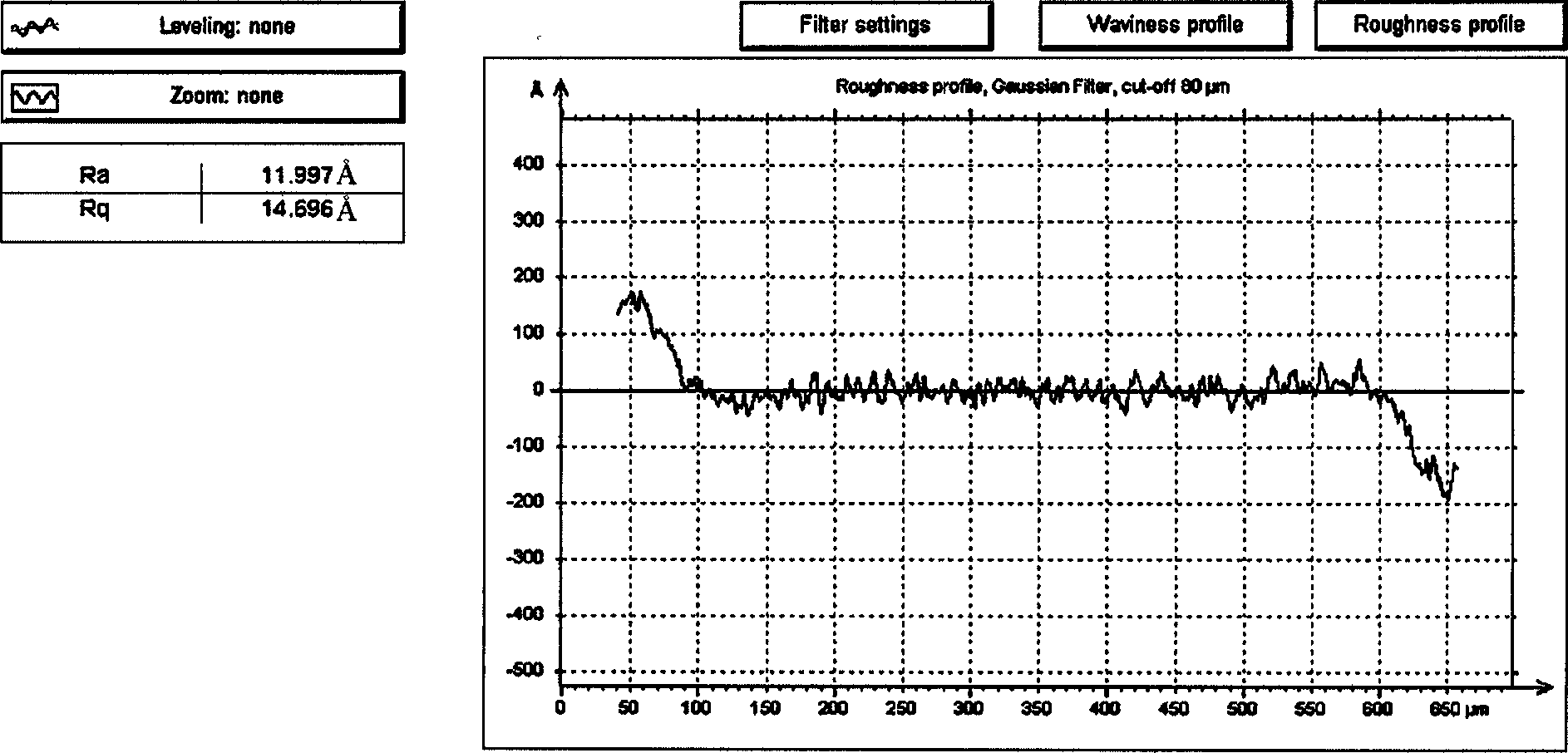

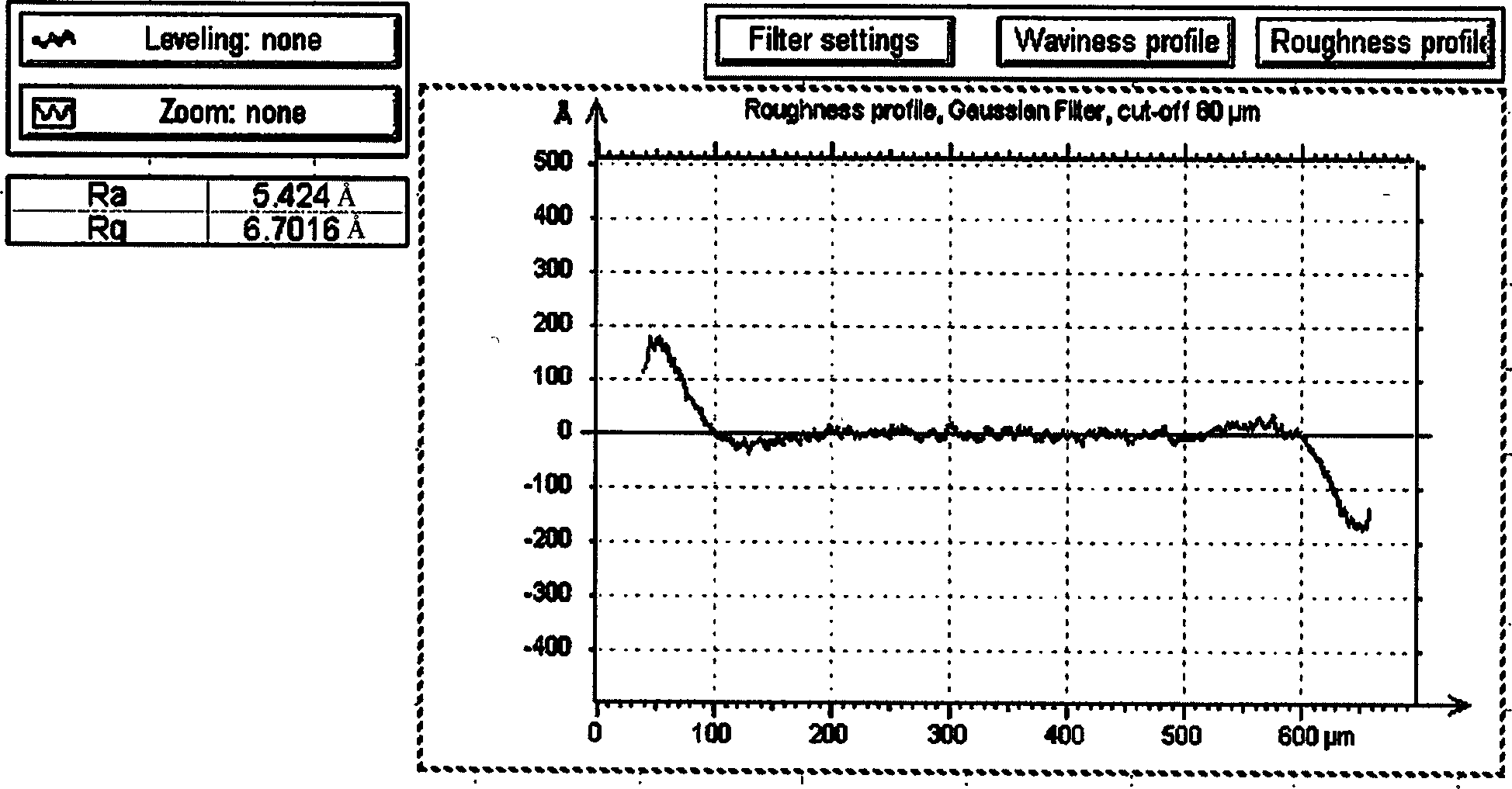

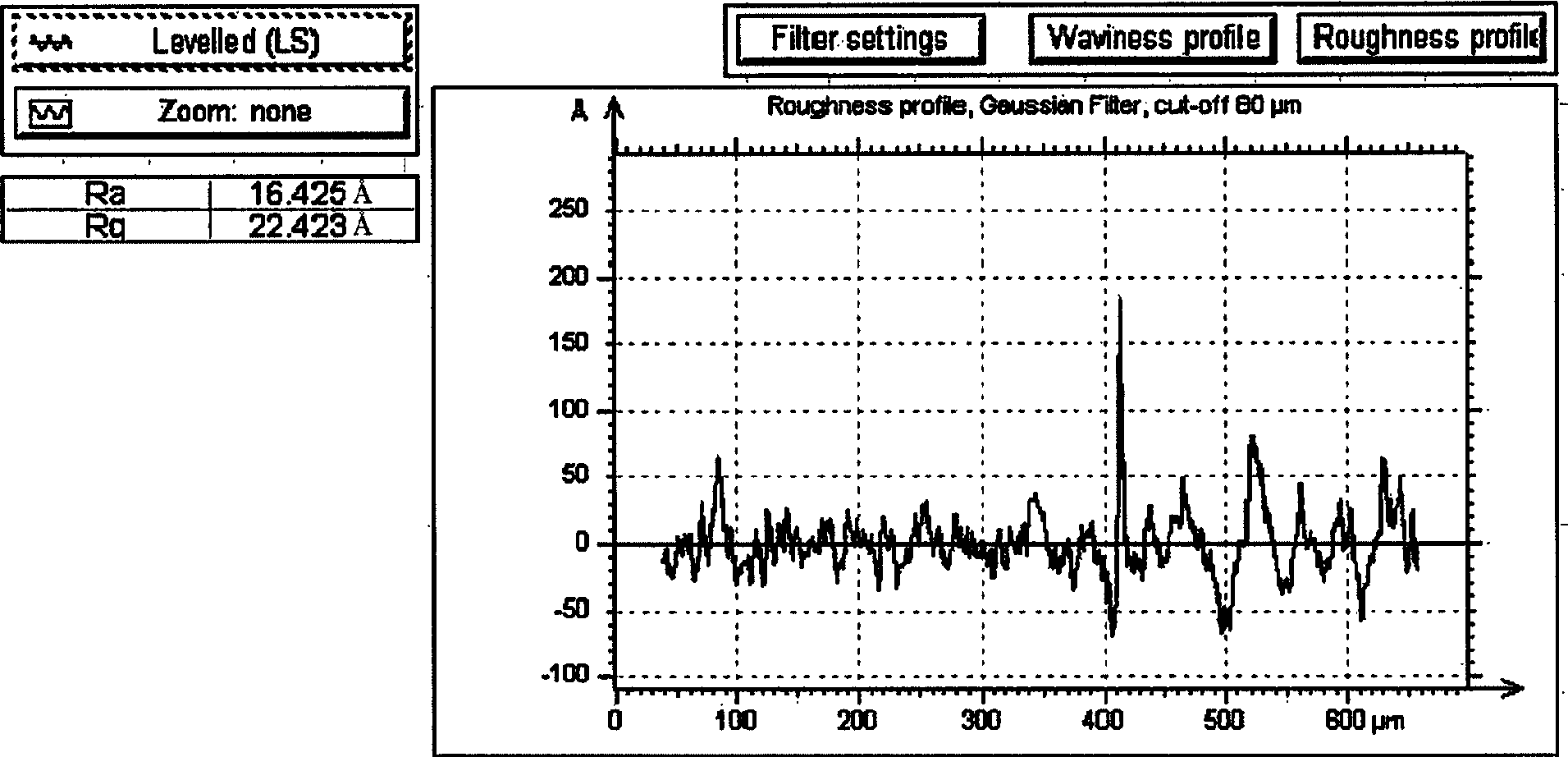

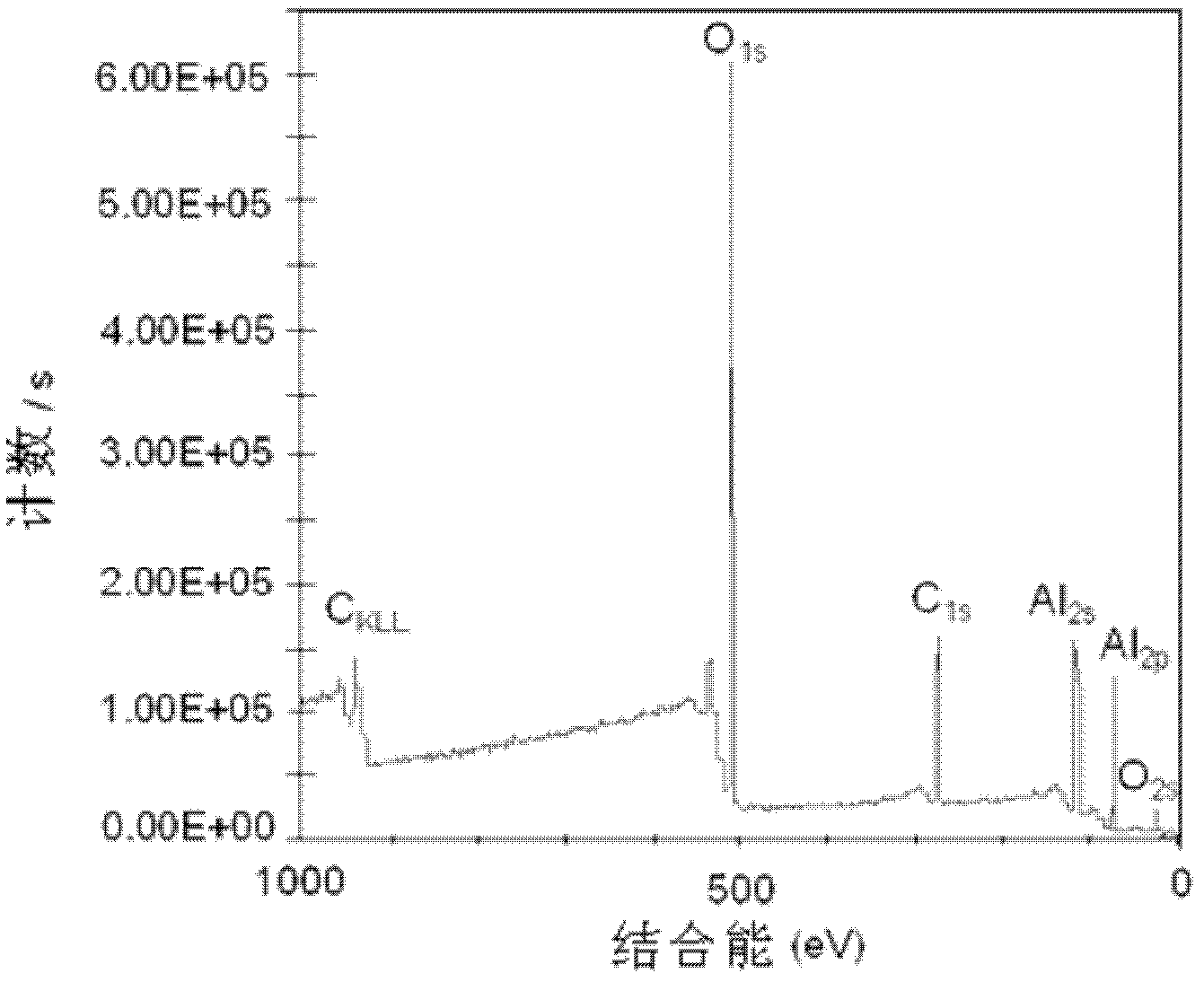

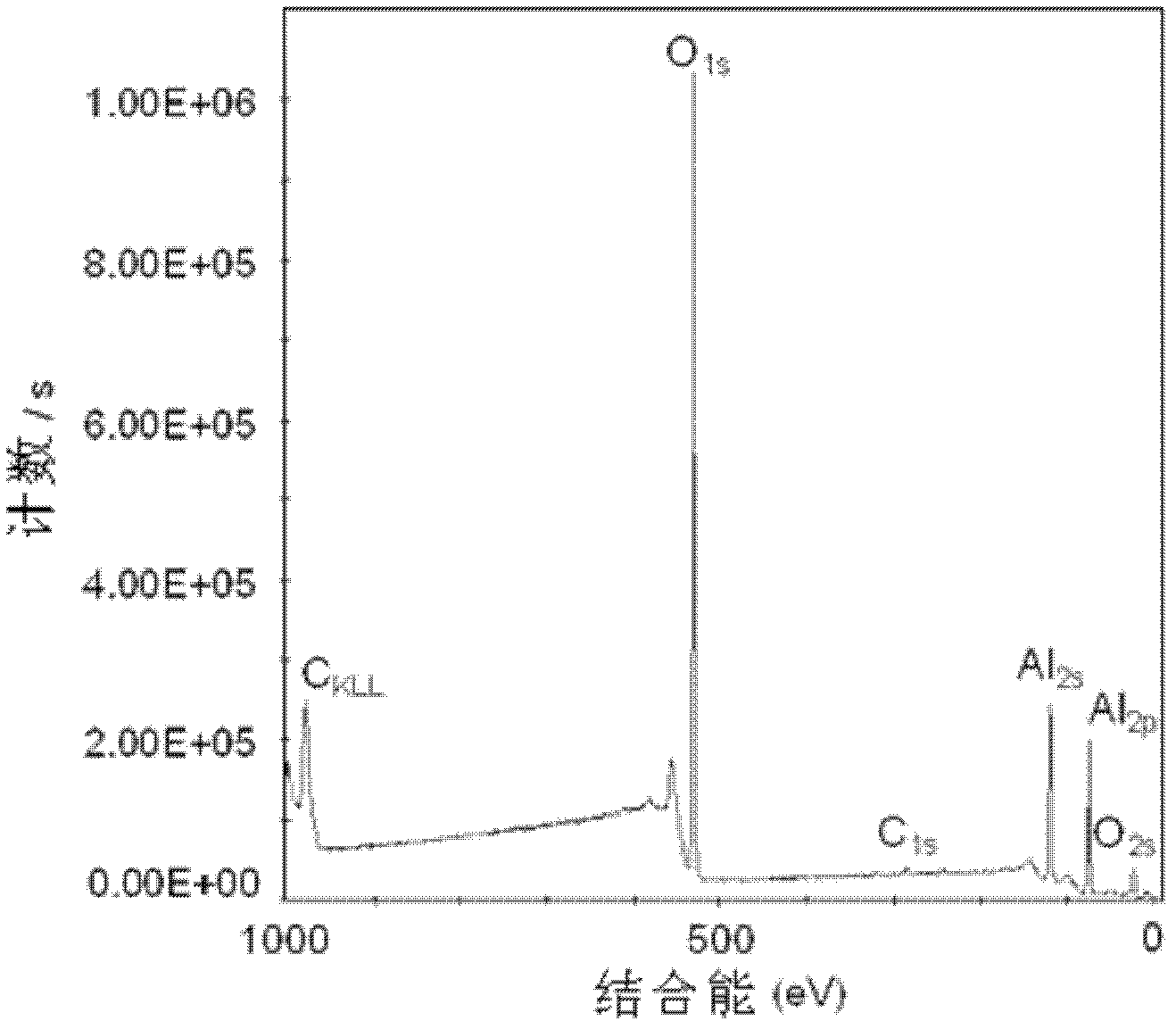

Method for cleaning alpha-Al2O3 monocrystal

ActiveCN102500573AImprove cleanlinessGood repeatabilityAfter-treatment detailsCleaning using liquidsSingle crystalPollution

The invention relates to a method for cleaning an alpha-Al2O3 monocrystal. According to the method, the problem that surface pollutants cannot be cleaned completely because the alpha-Al2O3 monocrystal has strong surface adsorbability and stable surface performance and is difficult to dissolve in the conventional method for cleaning the alpha-Al2O3 monocrystal is solved. The method for cleaning the alpha-Al2O3 monocrystal comprises the following steps of: soaking the alpha-Al2O3 monocrystal in ethanol and surfactant sequentially; and performing heat soaking treatment in a mixed solution of concentrated sulfuric acid and hydrogen peroxide, a mixed solution of ammonia water, hydrogen peroxide and water and a mixed solution of concentrated hydrochloric acid, hydrogen peroxide and water sequentially. The method for cleaning the alpha-Al2O3 monocrystal is a multi-step wet chemical cleaning method. By the method for cleaning the alpha-Al2O3 monocrystal, the pollutants on the surface of the alpha-Al2O3 monocrystal can be cleaned effectively and completely; the cleaned aluminum oxide monocrystal has high cleanliness; and the cleaning method is high in repeatability. Equipment for cleaning is simple, convenient to operate and easy to master; and the process is safe and pollution-free.

Owner:WUXI HAITE NEW MATERIAL RES INST

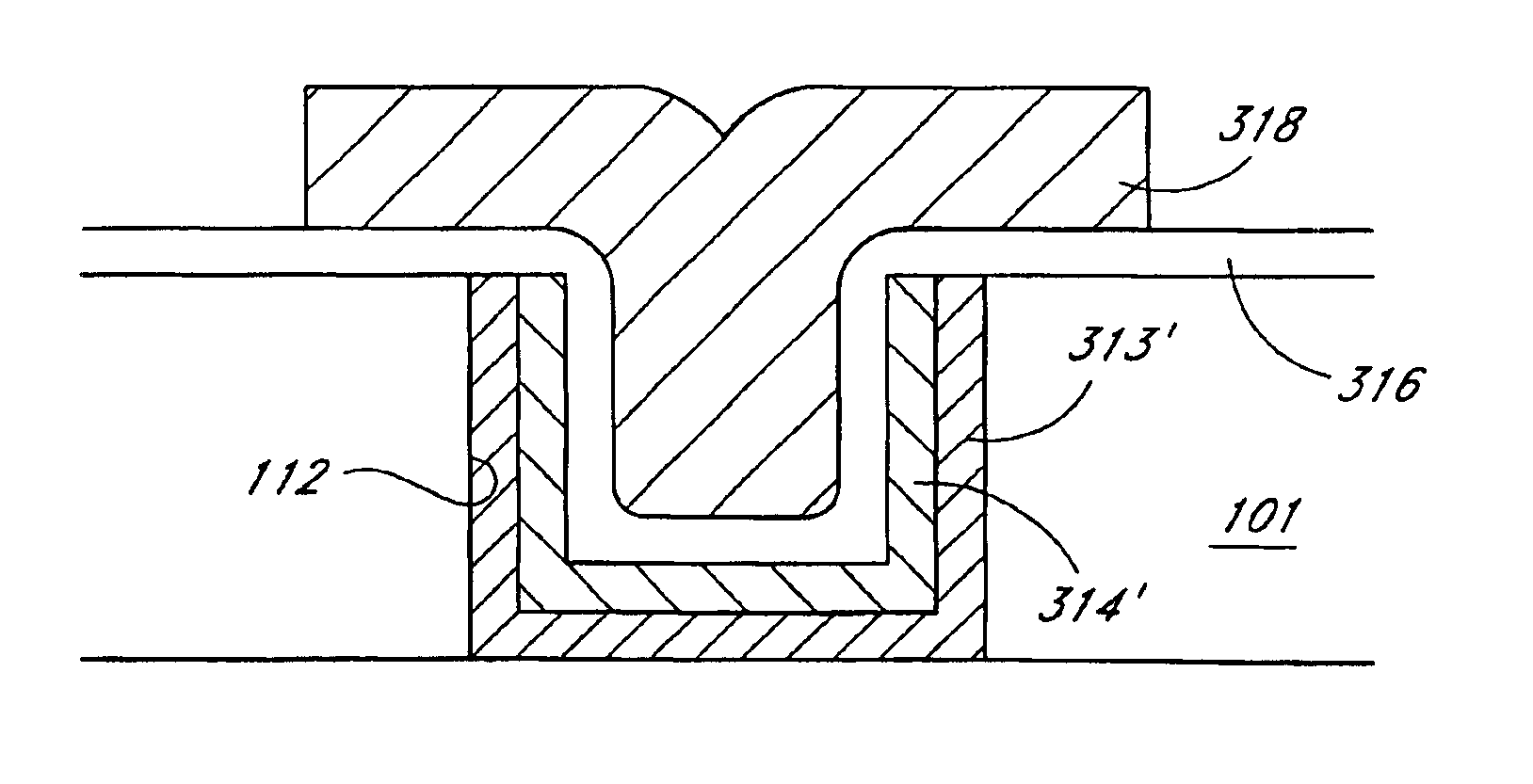

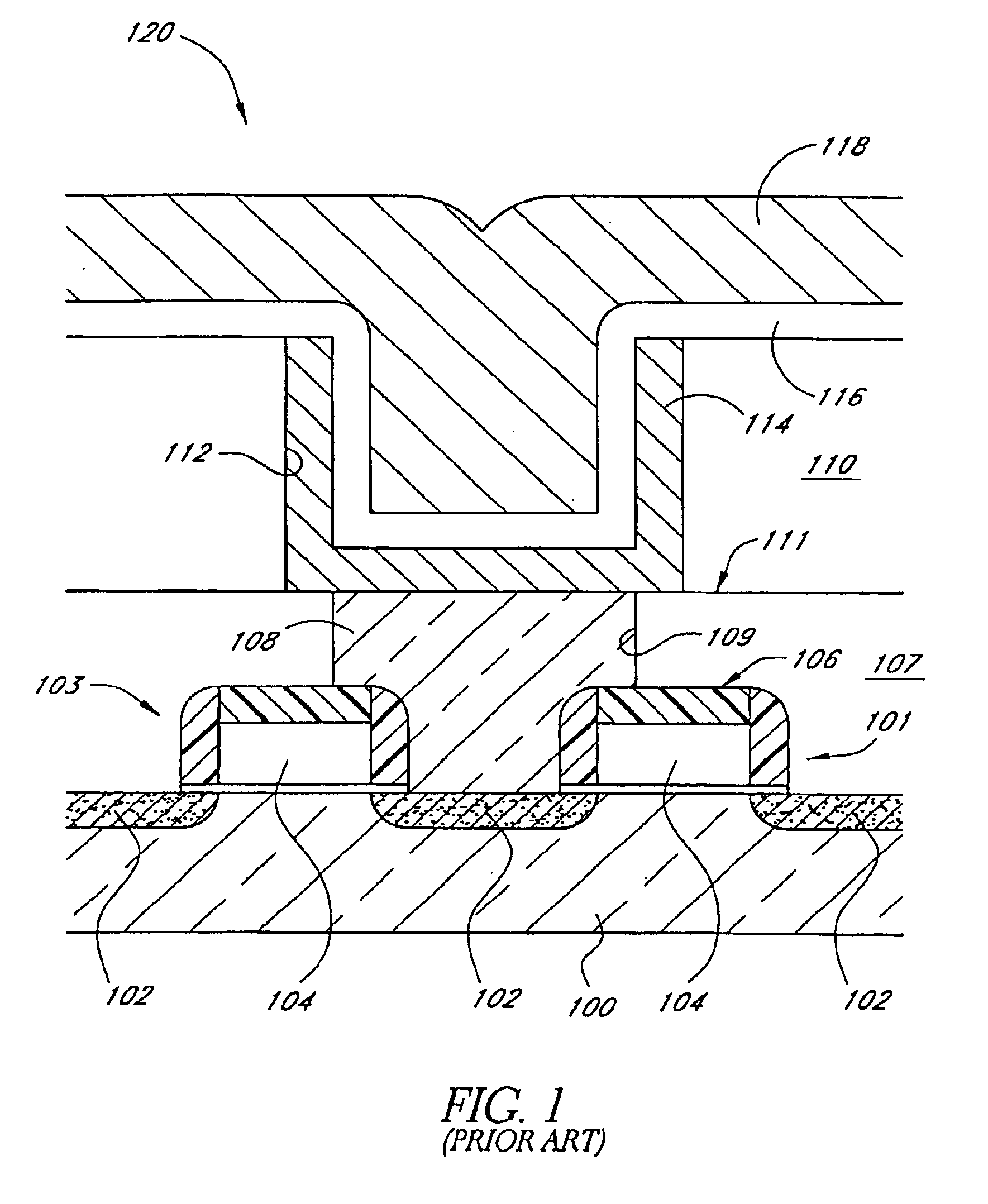

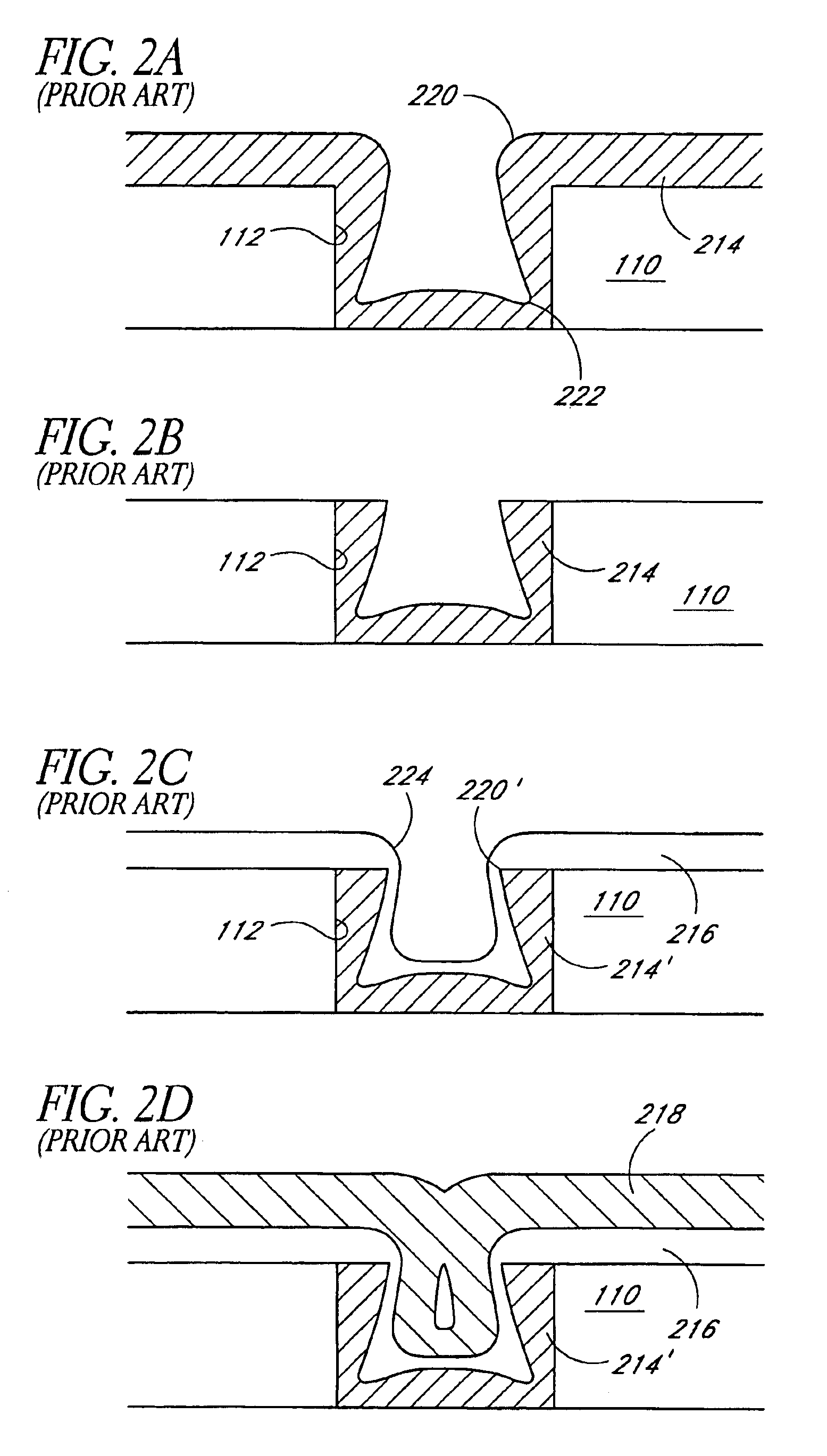

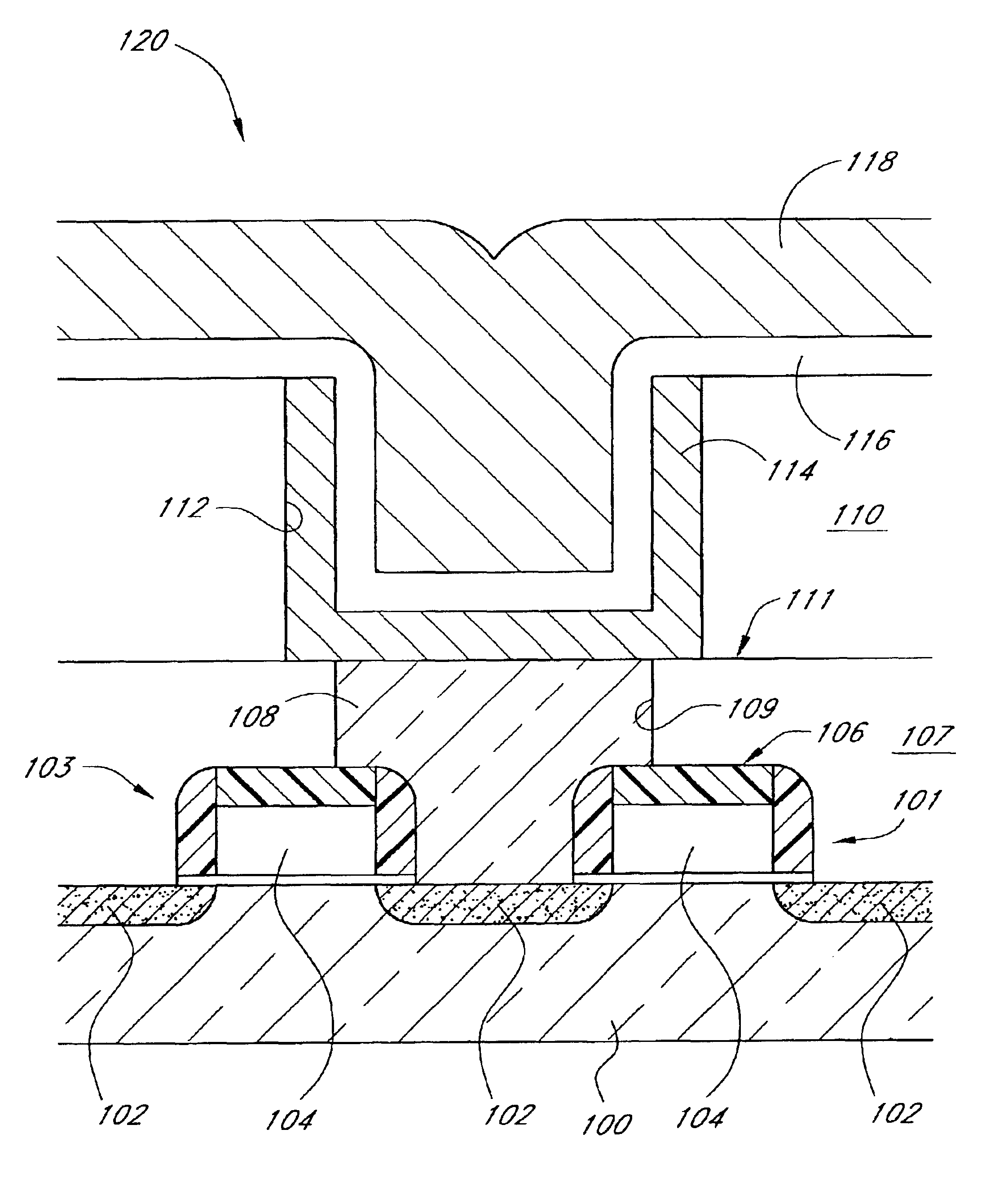

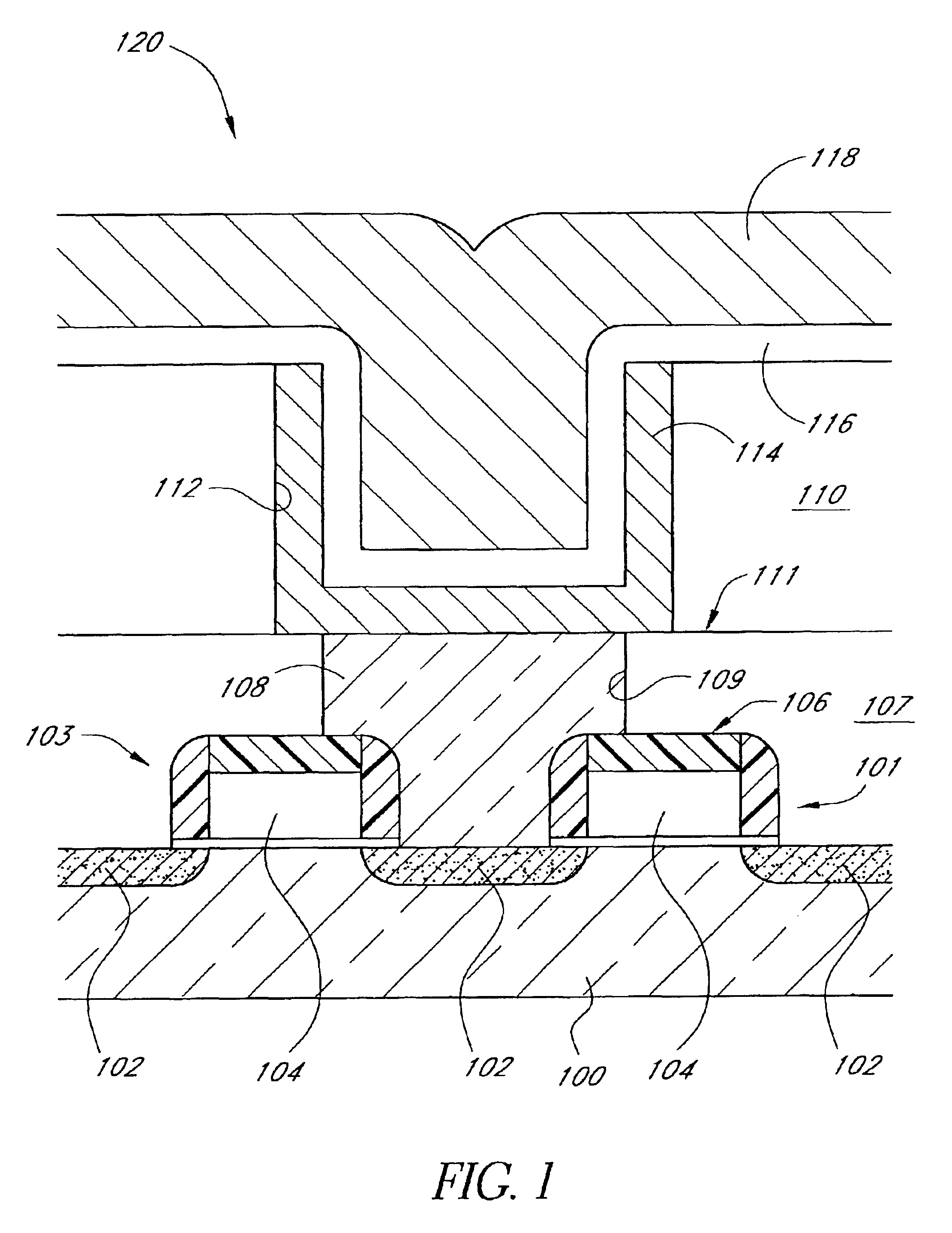

Integrated capacitors fabricated with conductive metal oxides

InactiveUS6869877B2Improve uniformityImprove reliabilitySemiconductor/solid-state device manufacturingCapacitorsOptoelectronicsCapacitor

A capacitor for a memory device is formed with a conductive oxide for a bottom electrode. The conductive oxide (RuOx) is deposited under low temperatures as an amorphous film. As a result, the film is conformally deposited over a three dimensional, folding structure. Furthermore, a subsequent polishing step is easily performed on the amorphous film, increasing wafer throughput. After deposition and polishing, the film is crystallized in a non-oxidizing ambient.

Owner:MICRON TECH INC

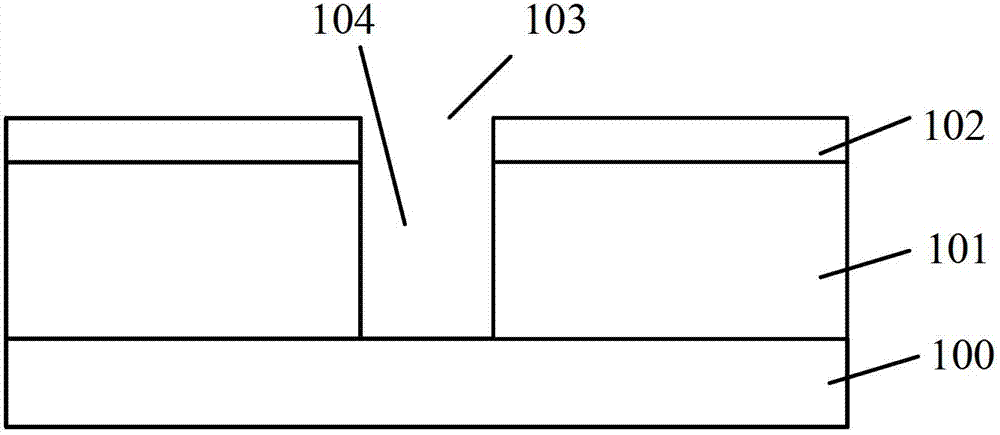

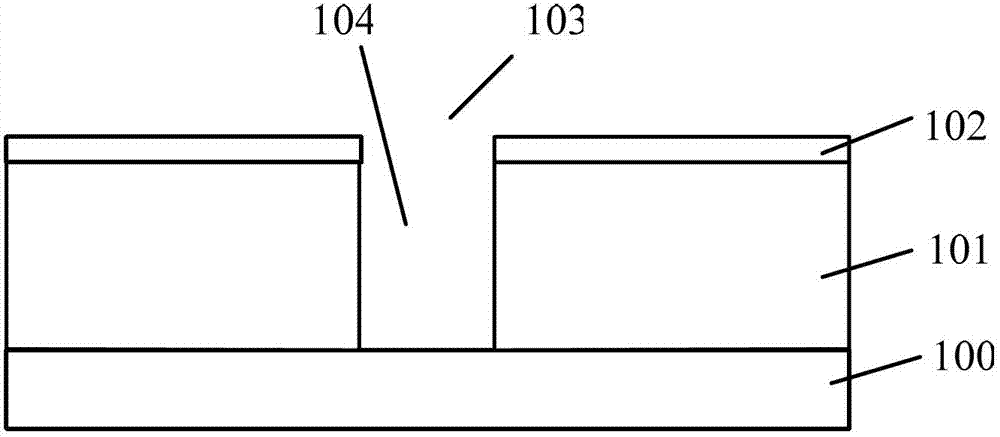

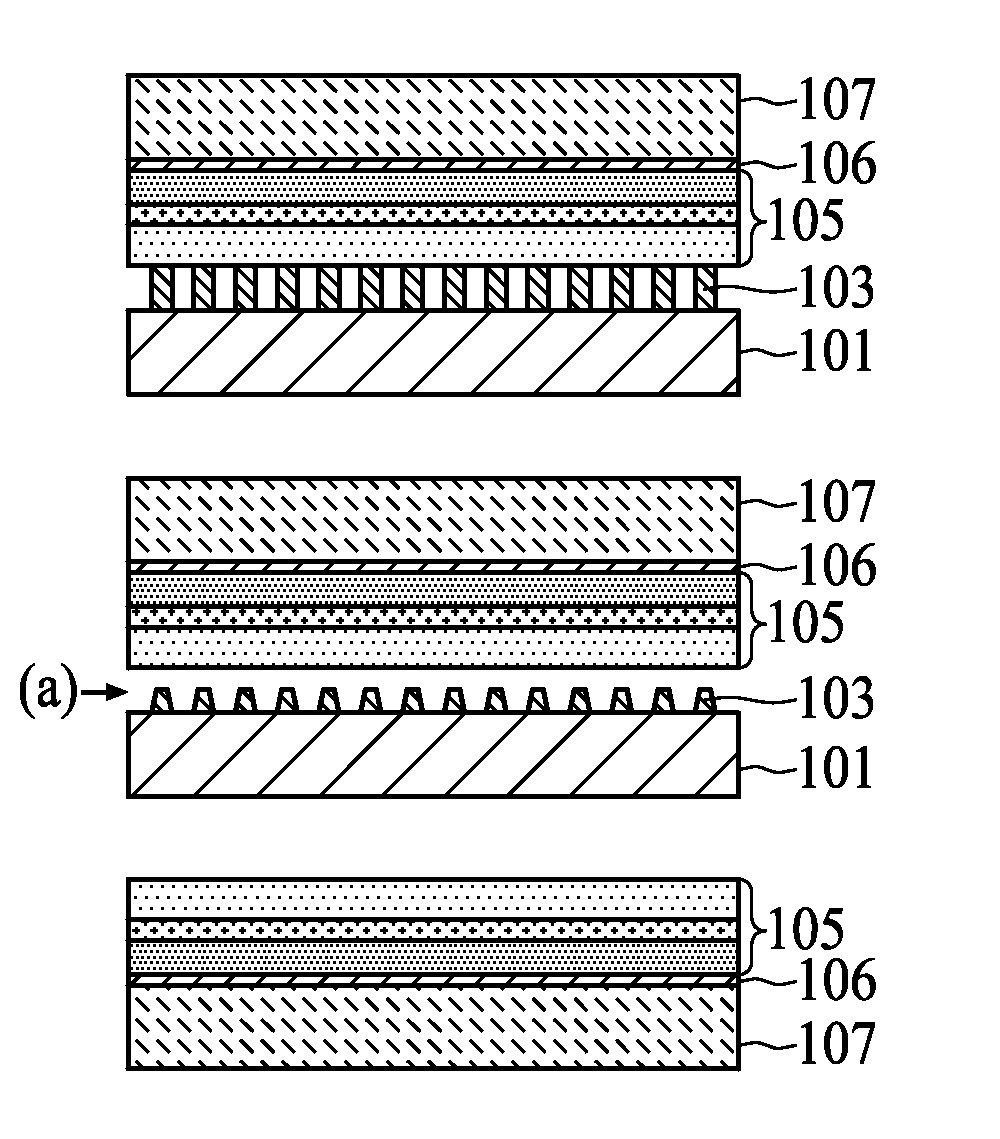

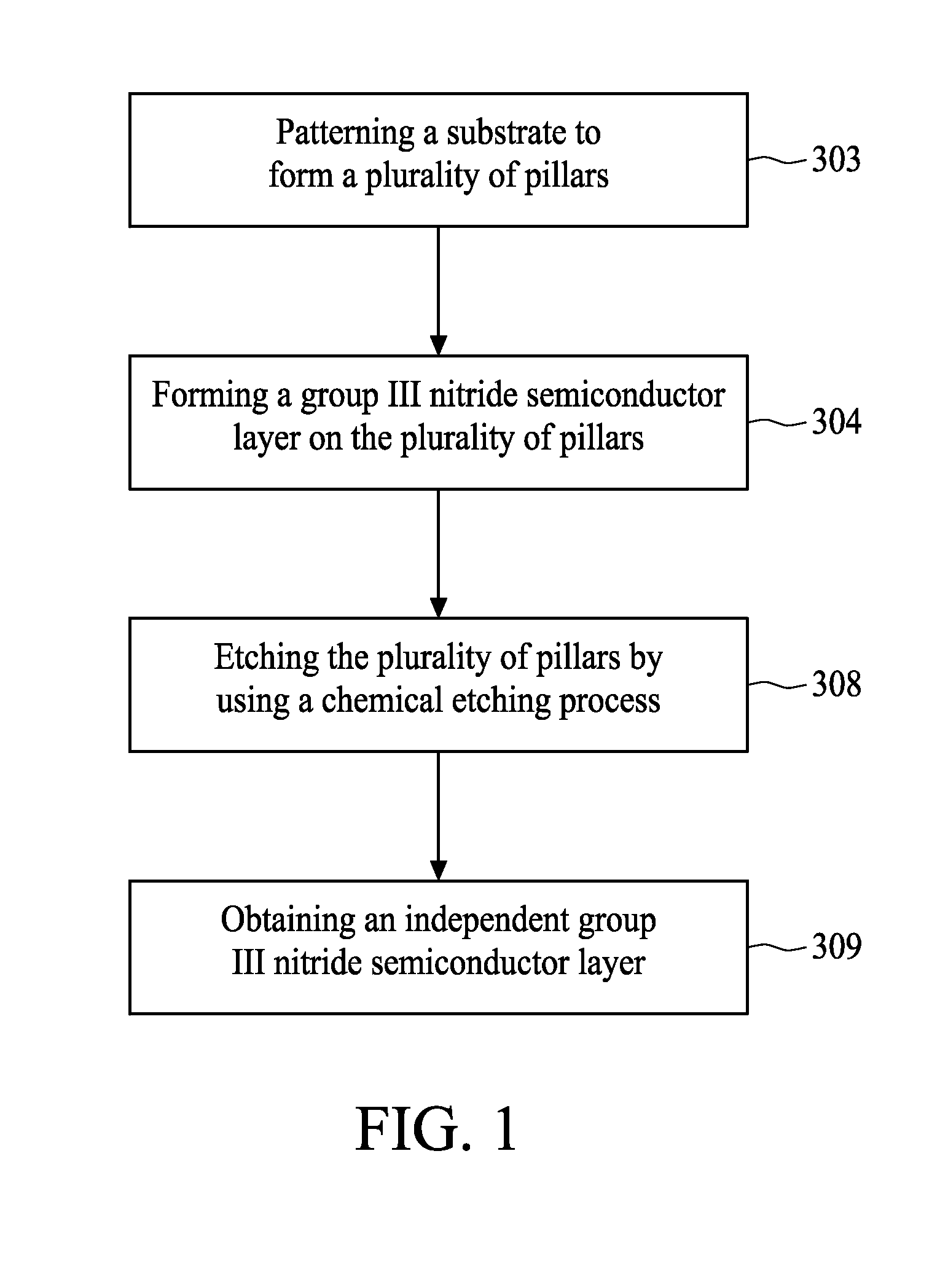

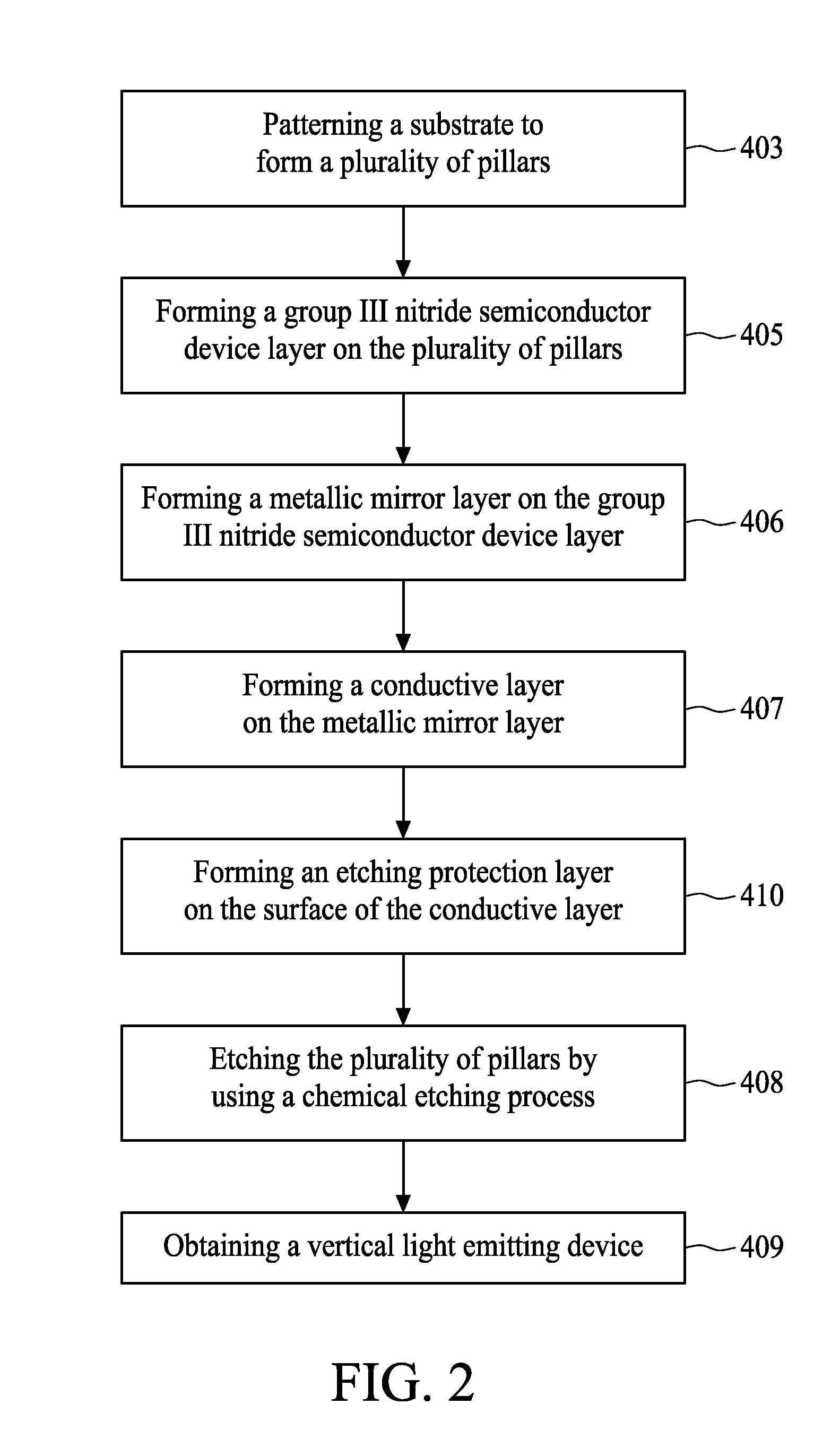

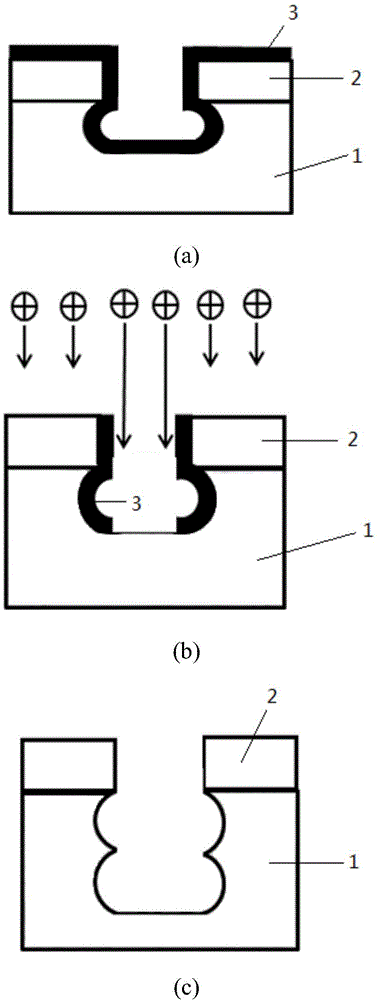

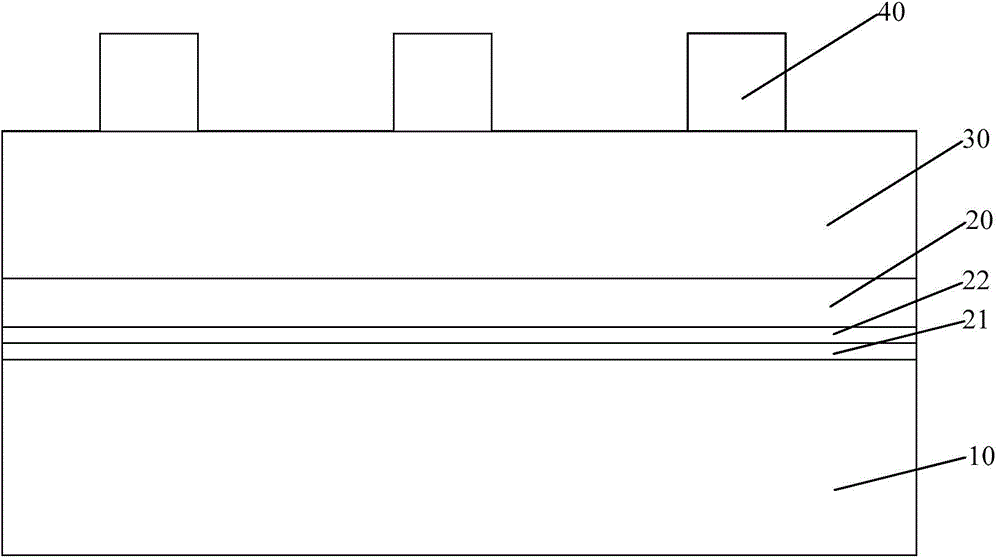

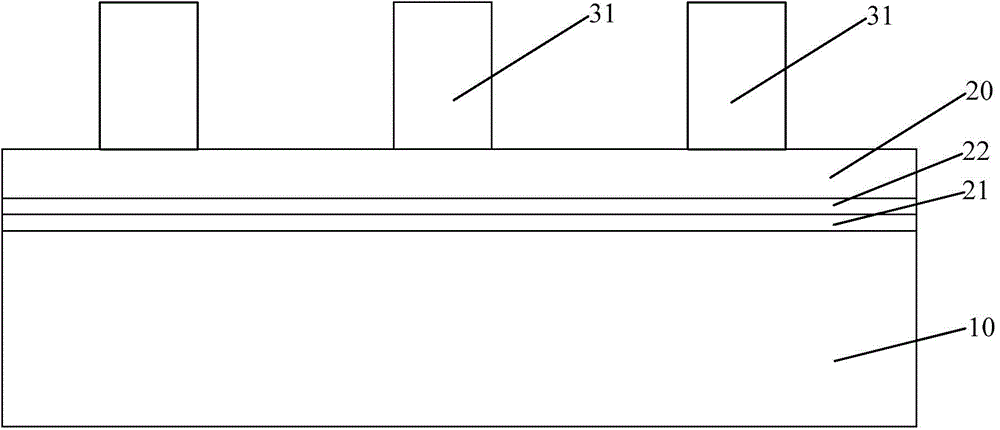

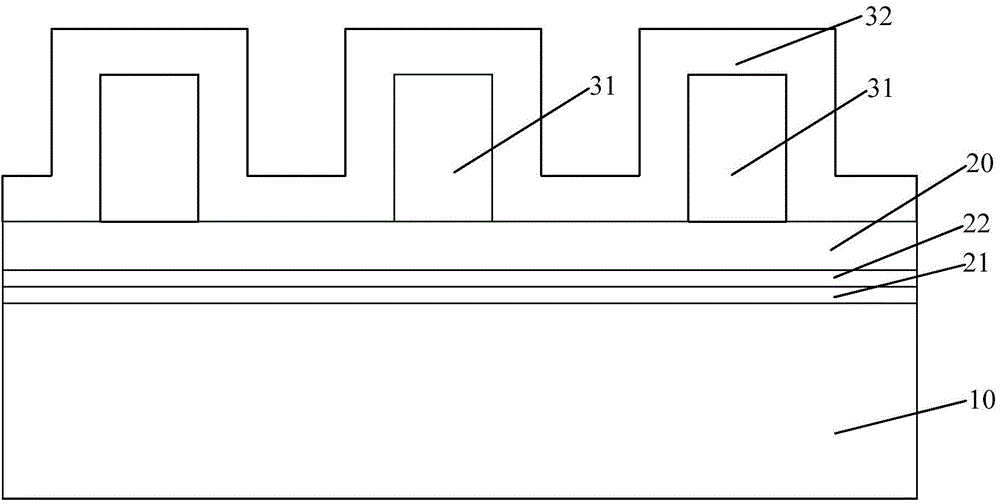

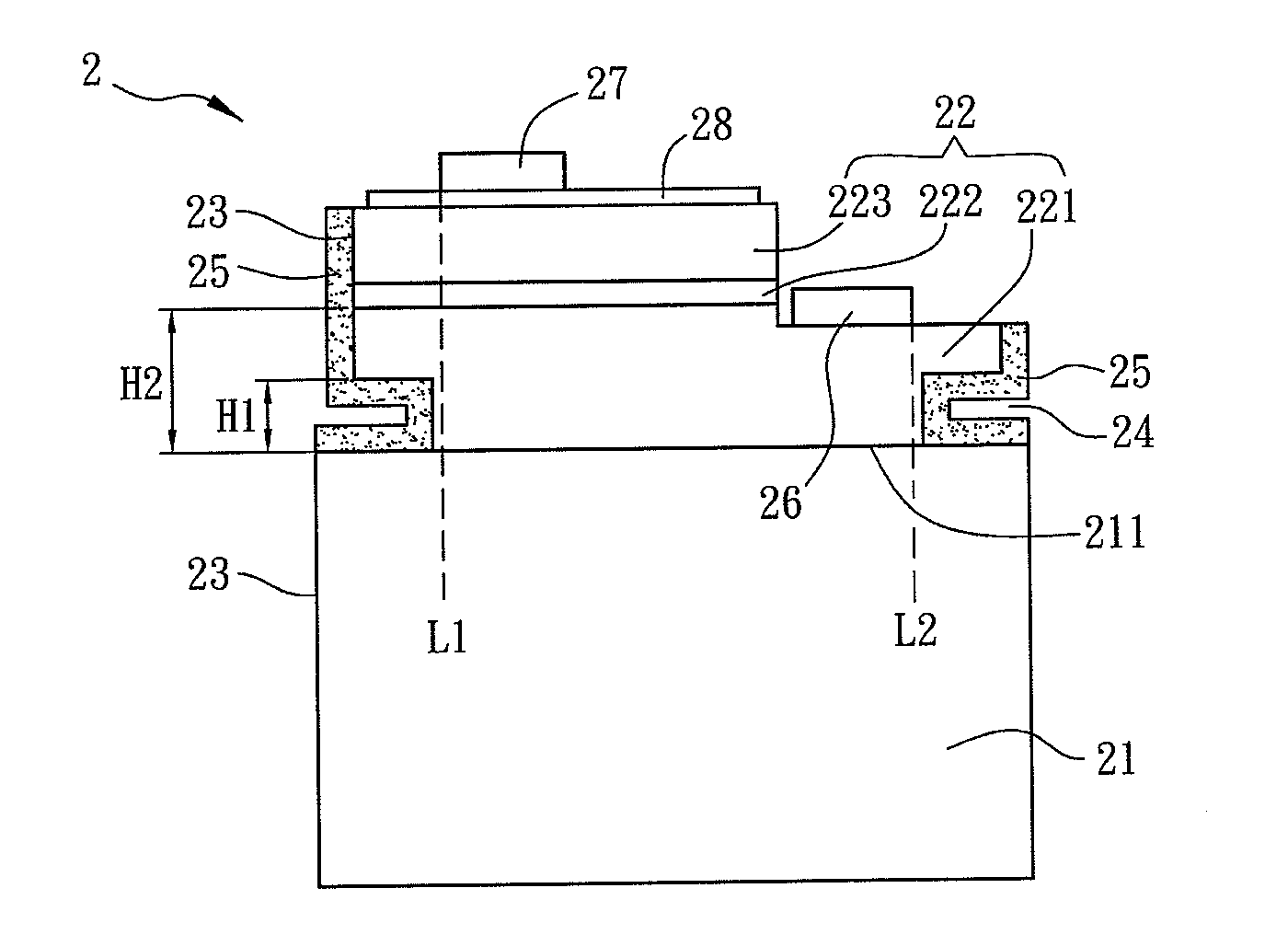

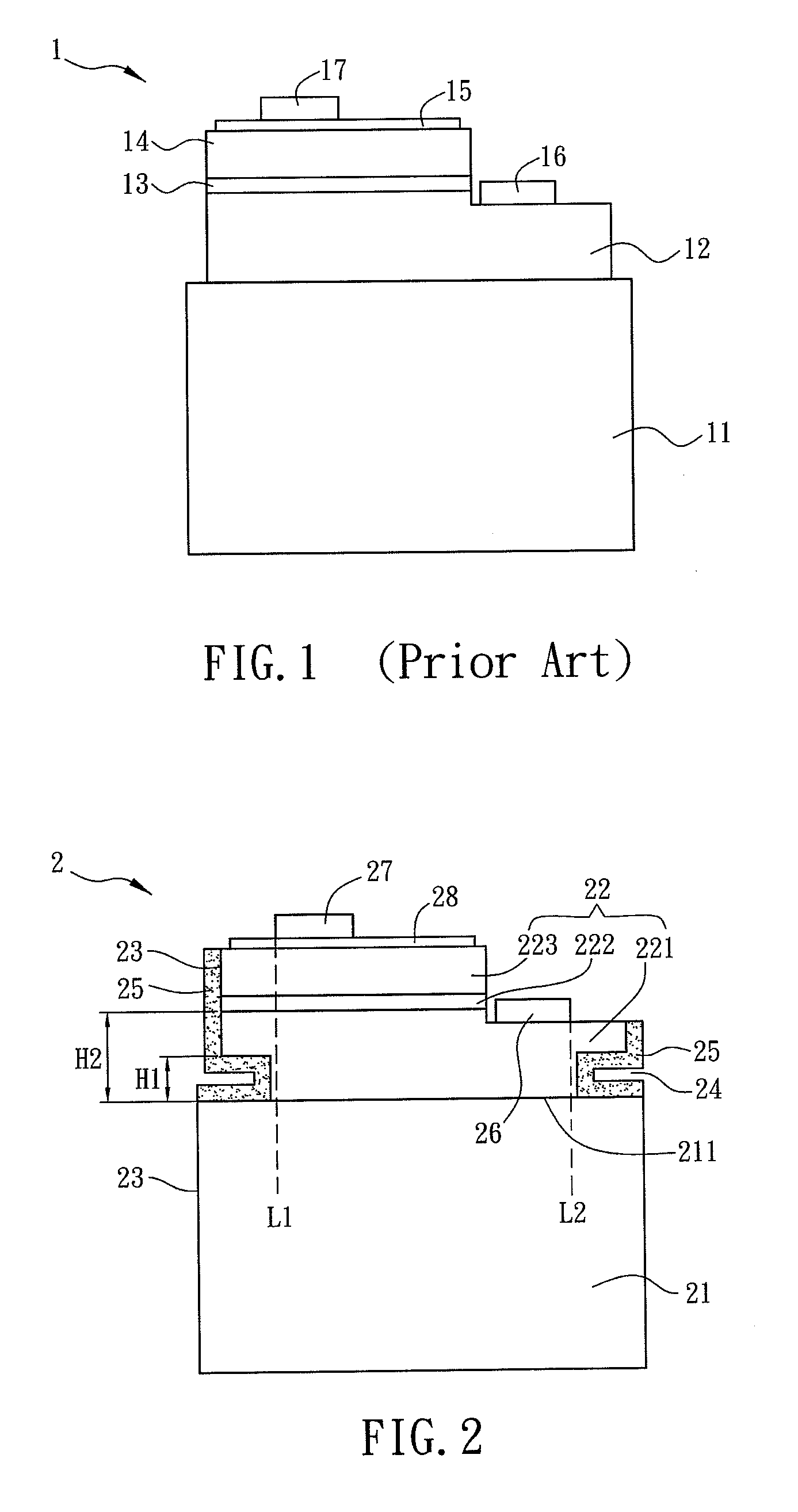

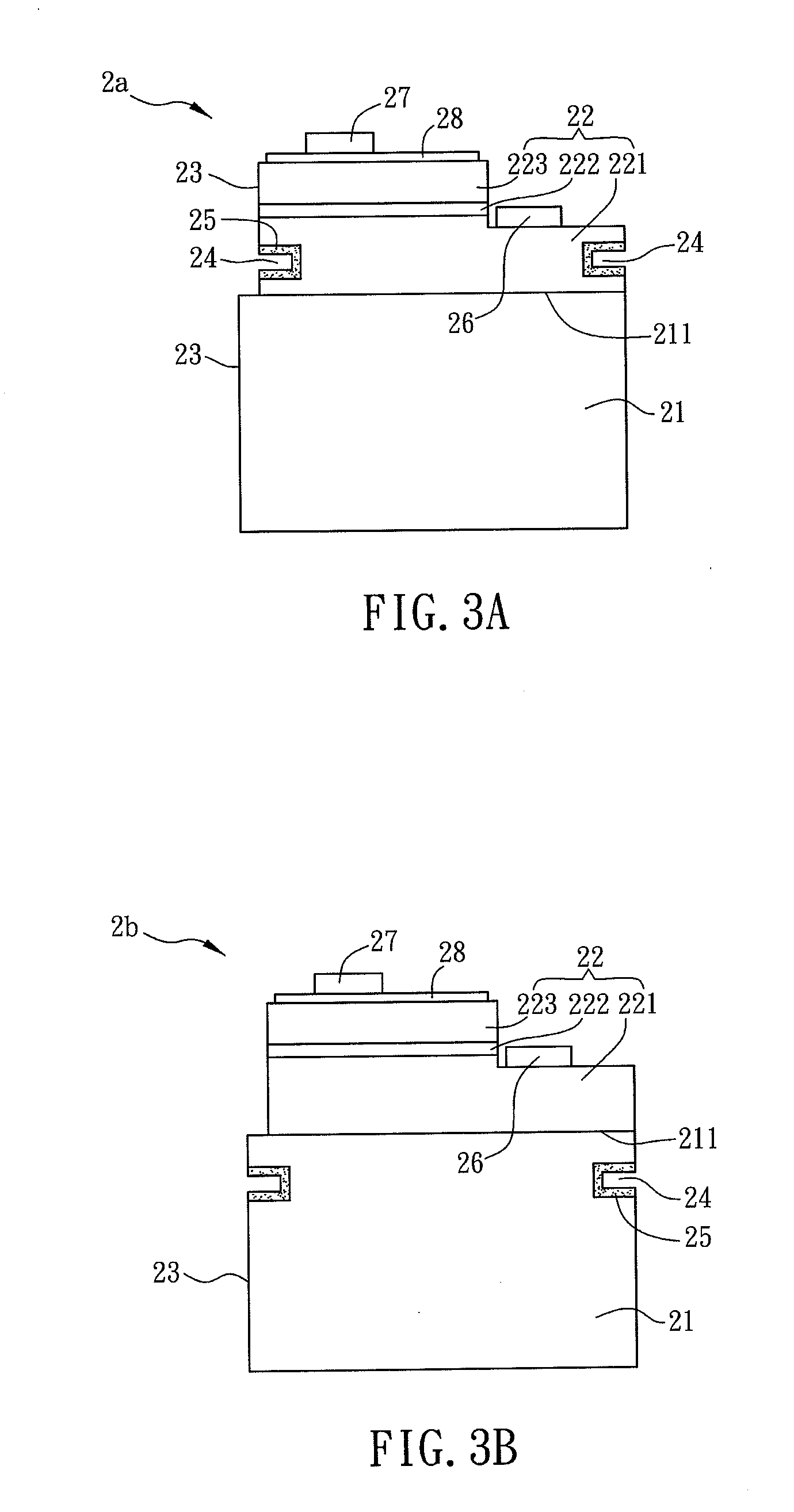

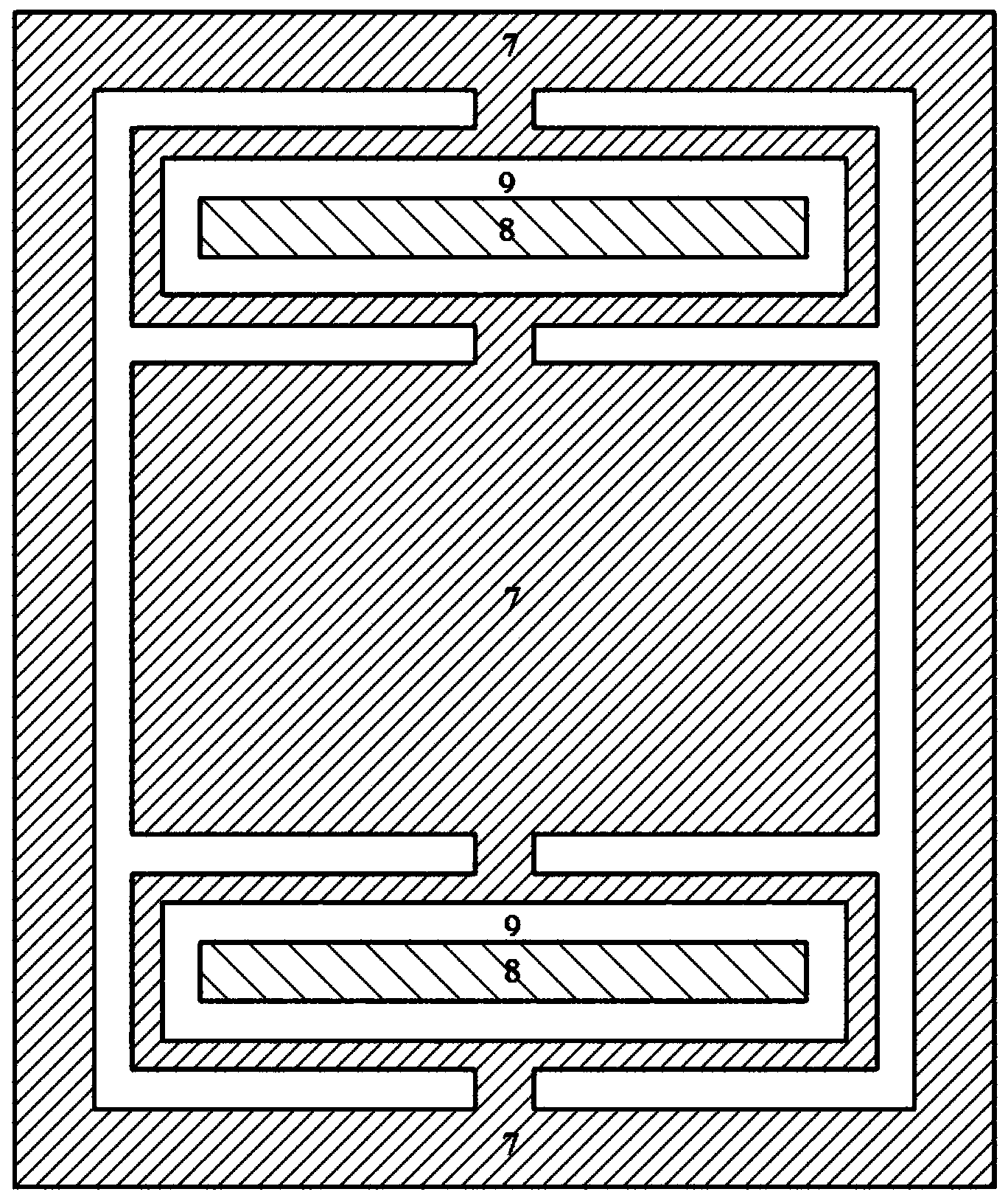

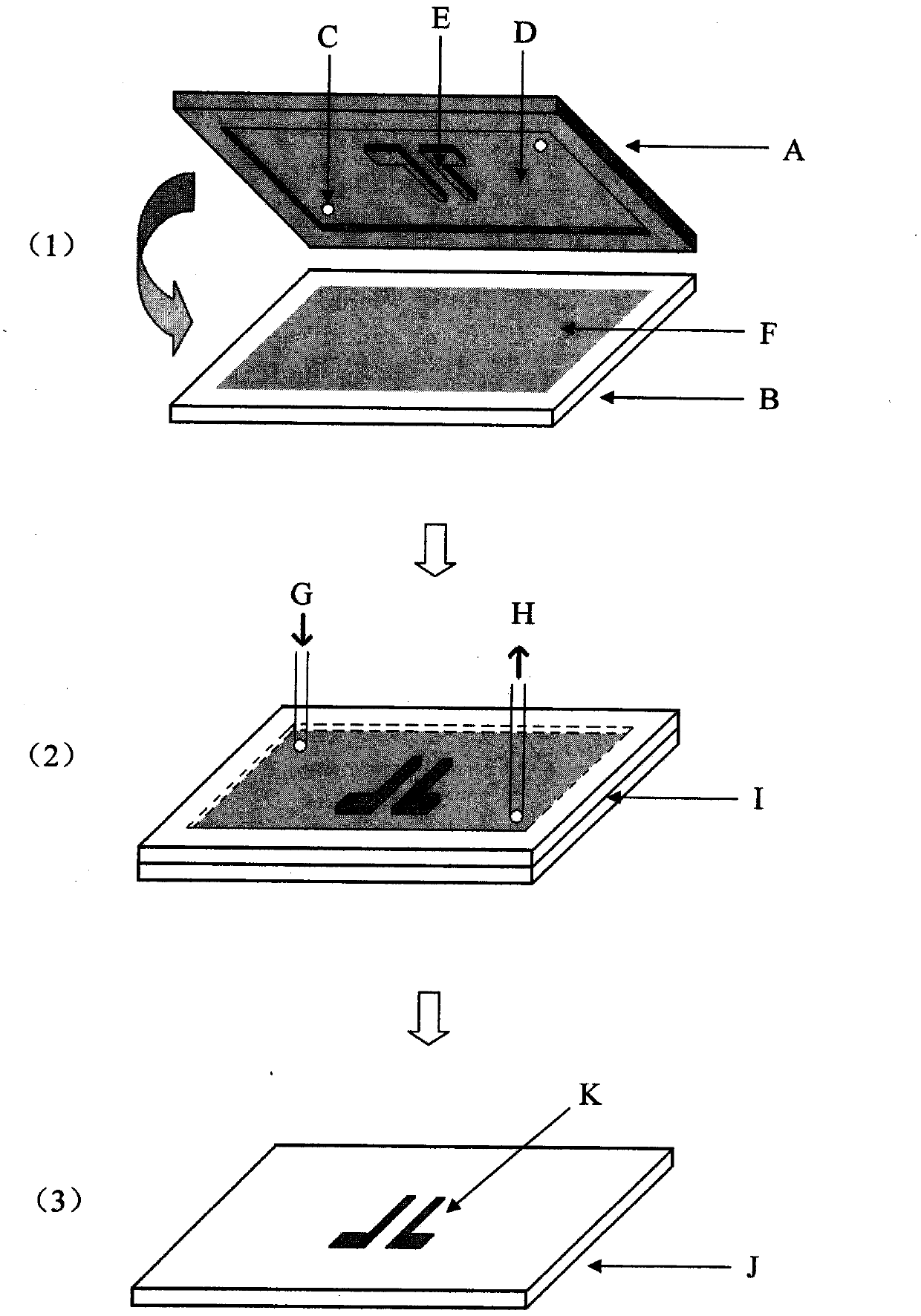

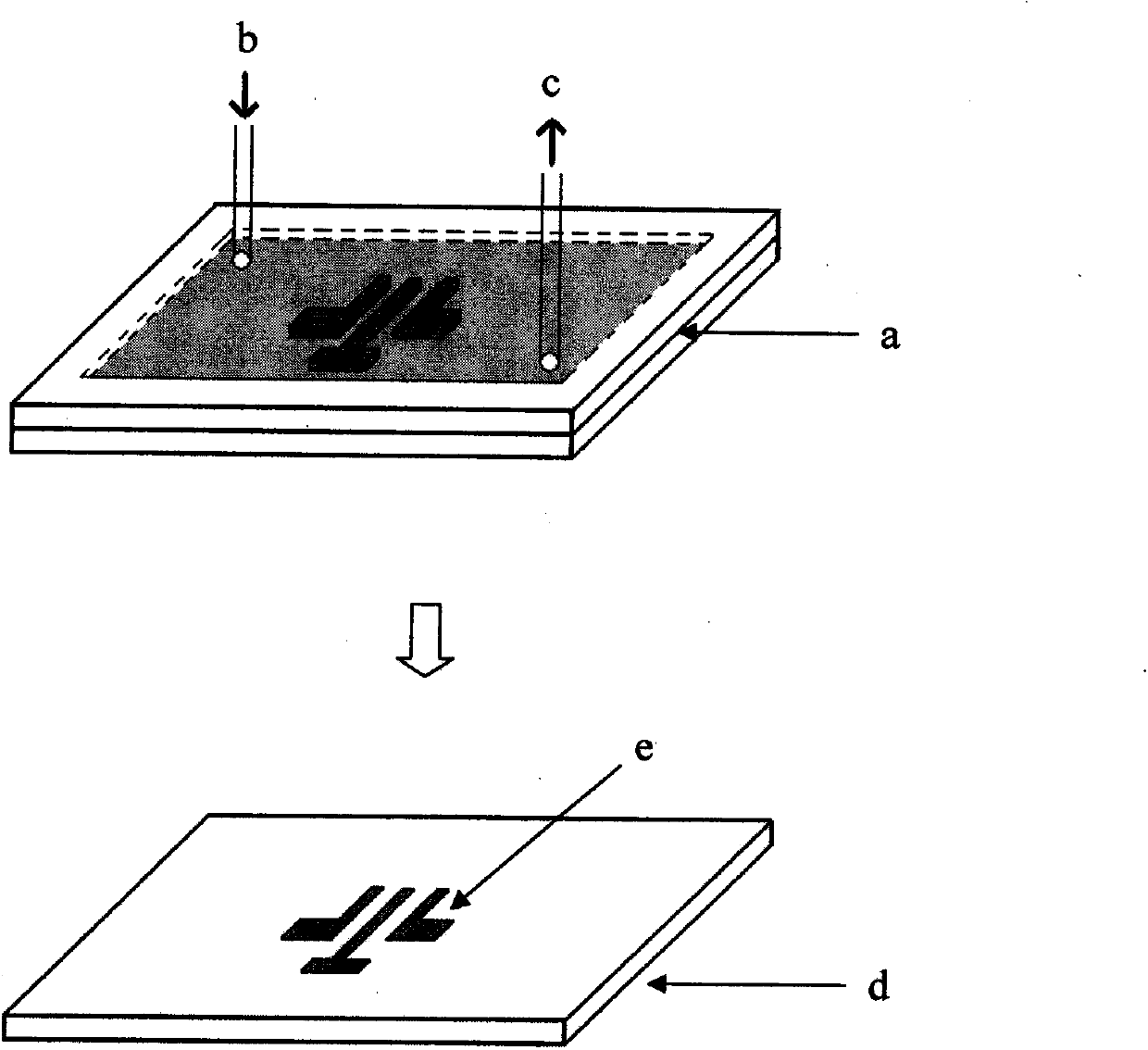

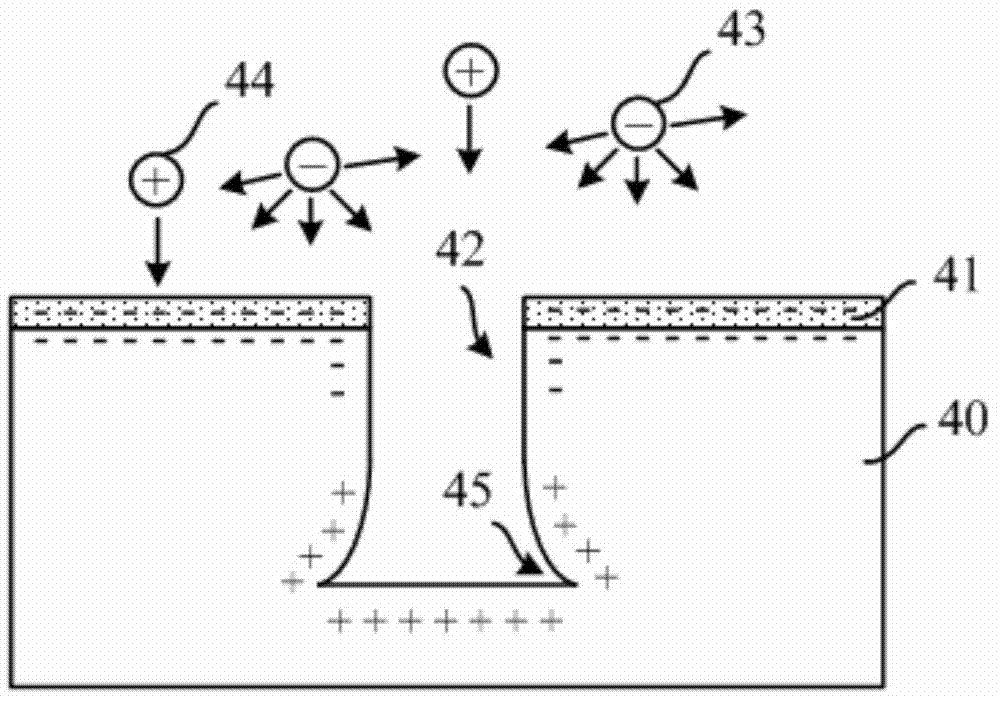

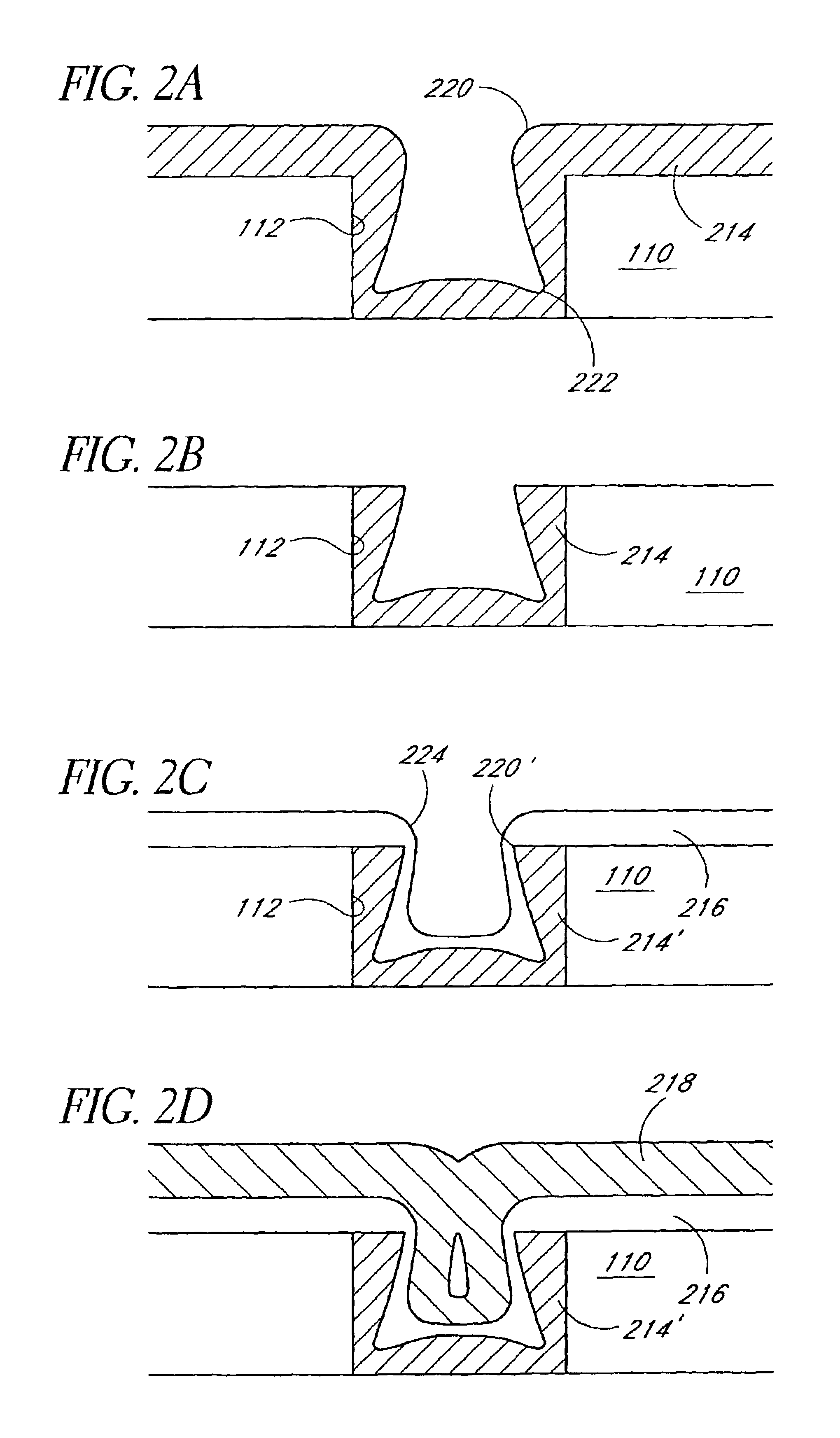

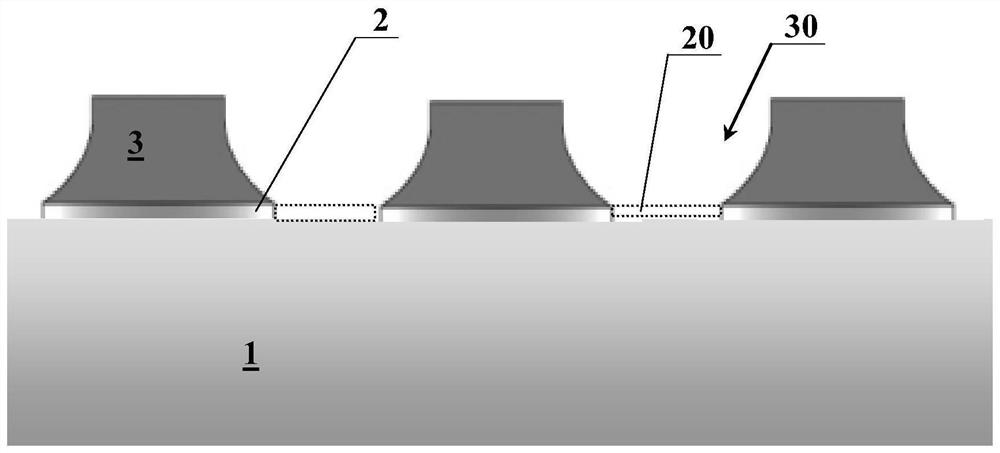

Substrate structure and method of removing the substrate structure

InactiveUS20100009476A1Increase the reaction areaImprove etching efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesPhotolithographyNitride semiconductors

A method of removing a substrate structure is described. A plurality of pillars is formed on a substrate by using a photolithography etching process. A group III nitride semiconductor layer is grown on the plurality of pillars. The plurality of pillars is etched to separate the group III nitride semiconductor layer from the substrate by using a chemical etching process.

Owner:ADVANCED OPTOELECTRONICS TECH

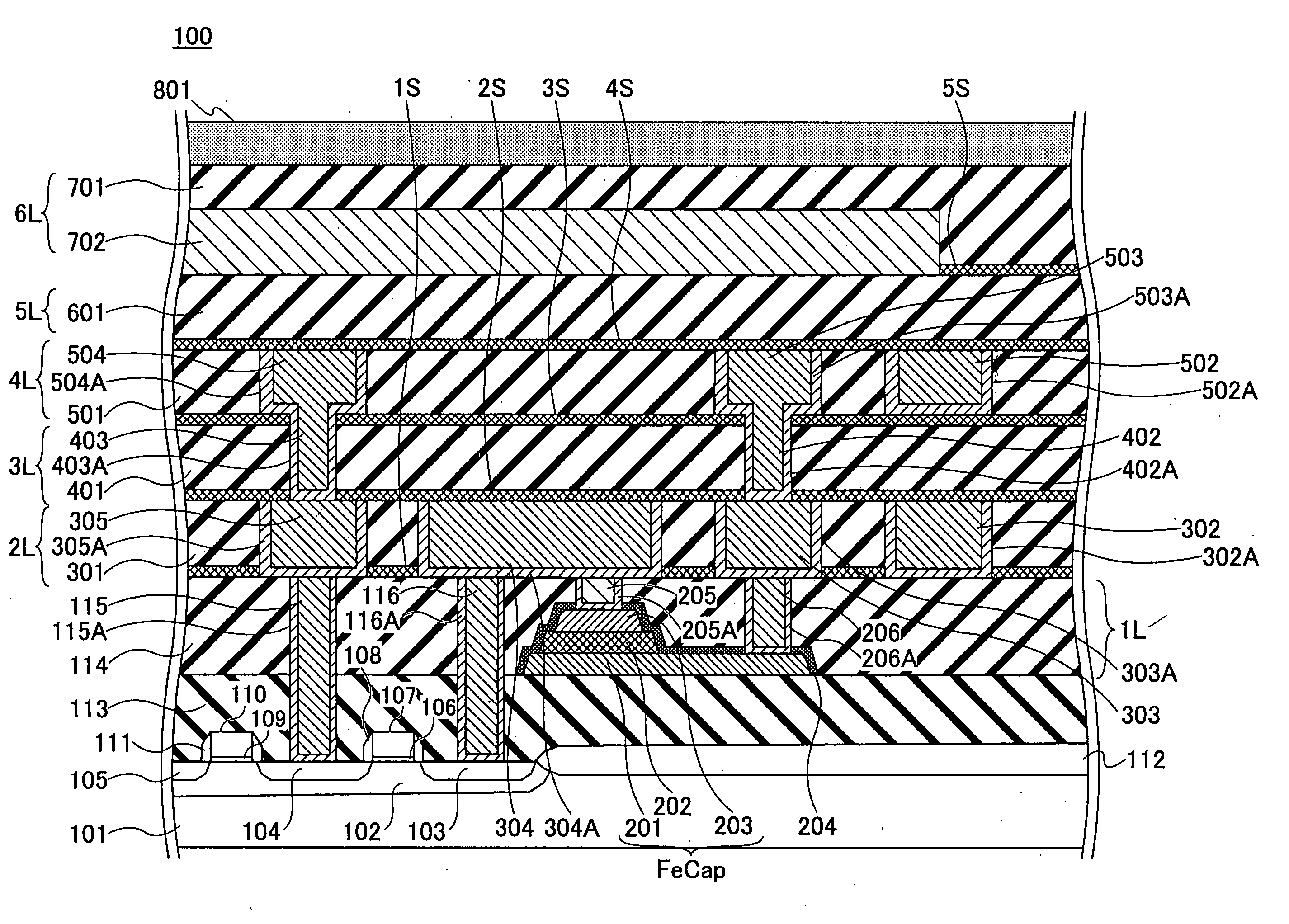

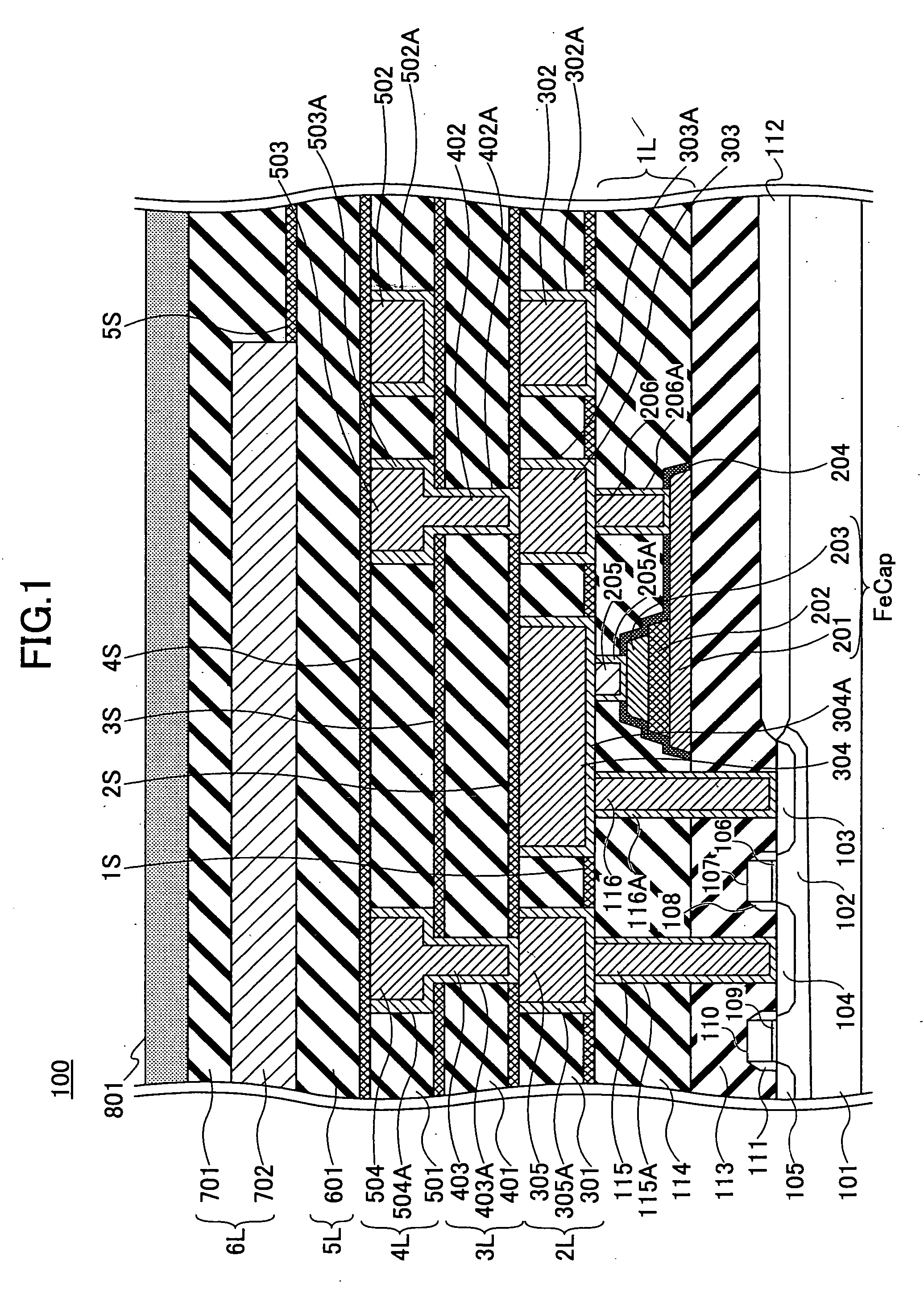

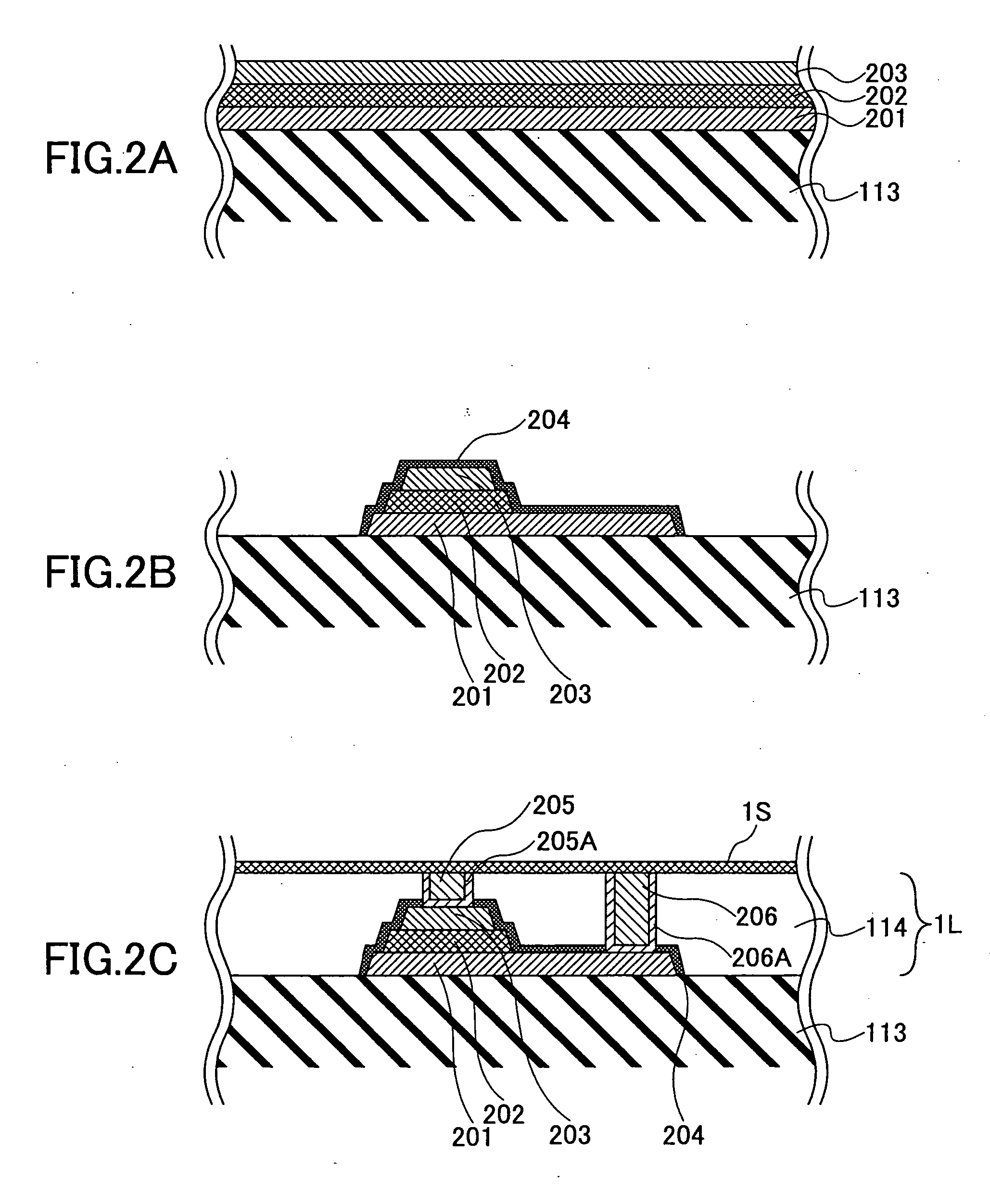

Semiconductor device and manufacturing method thereof

InactiveUS20060261387A1Improve etching efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDielectricInter layer

A semiconductor device is disclosed. The semiconductor device includes a ferroelectric capacitor formed on a substrate and a wiring structure formed on the ferroelectric capacitor. The wiring structure includes a dielectric inter layer and a Cu wiring section formed in the dielectric inter layer. In addition, an etching stopper layer including a hydrogen diffusion preventing layer is formed so as to face the dielectric inter layer.

Owner:FUJITSU SEMICON LTD

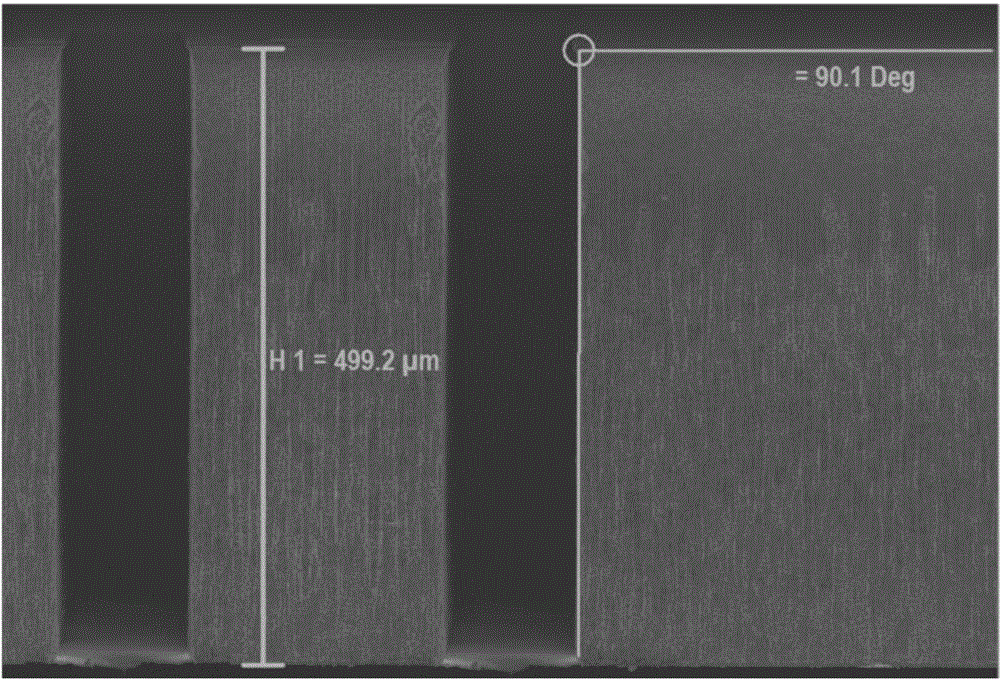

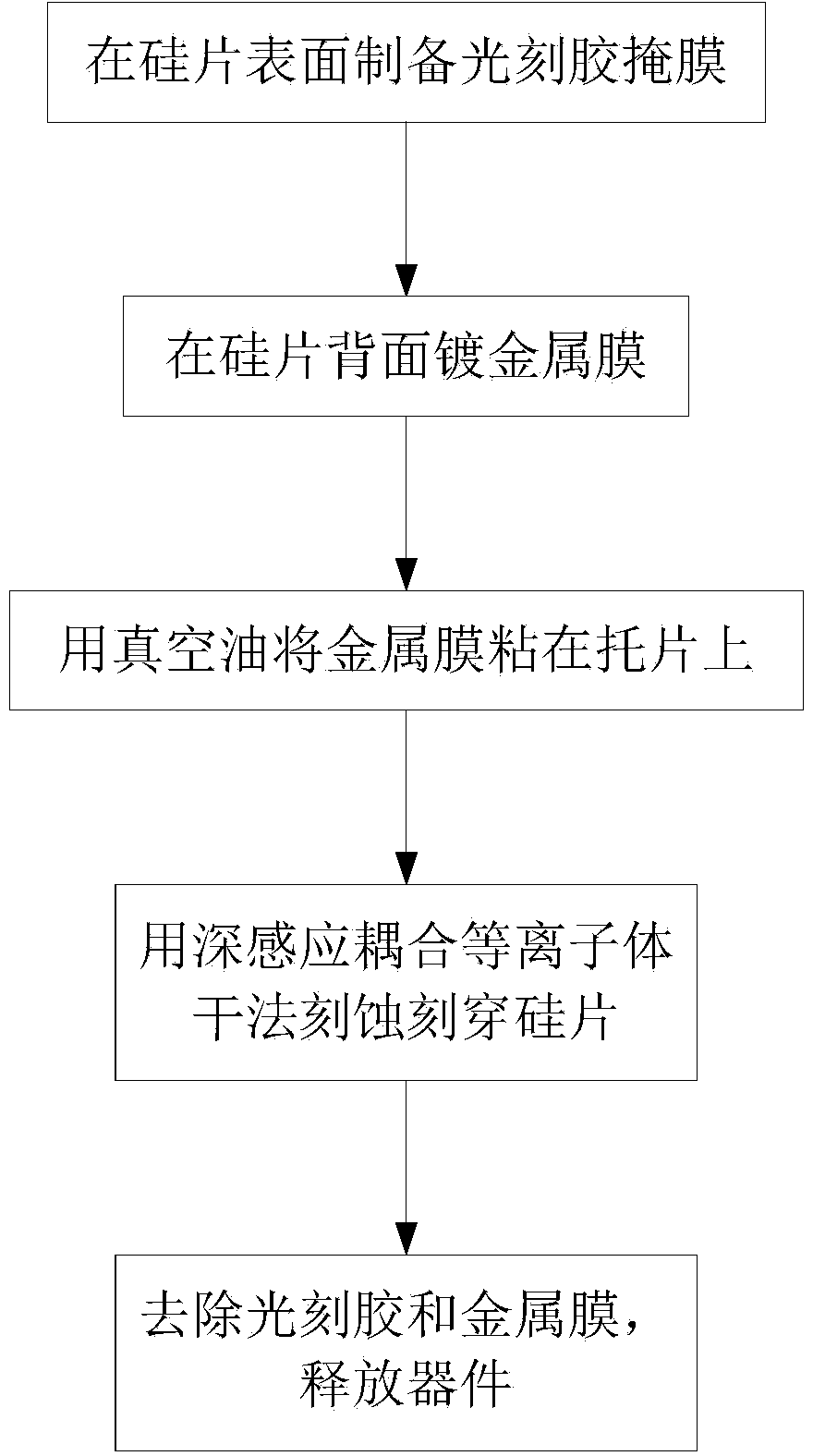

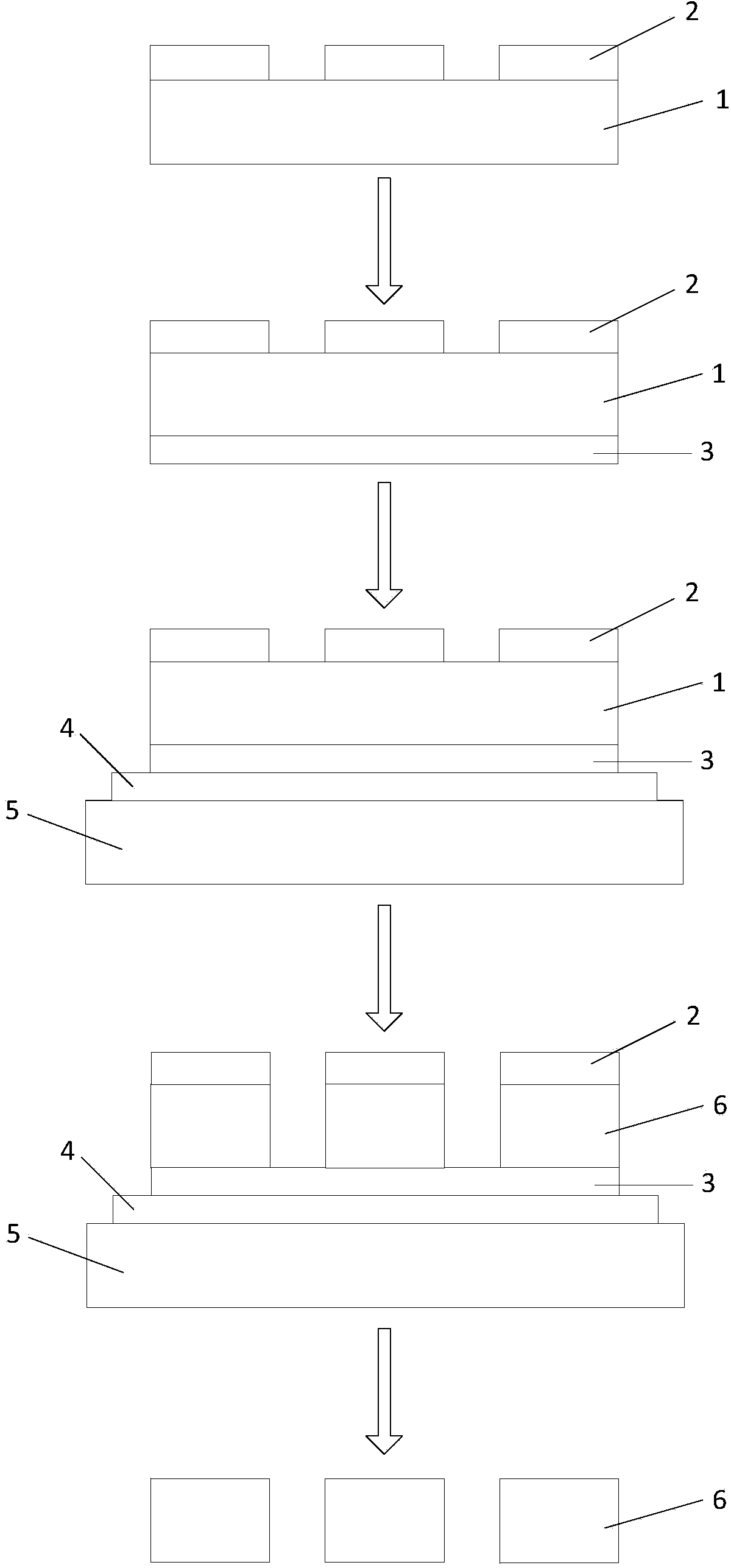

Deep silicon etching method

ActiveCN103950887AAchieve physical bombardmentReduce physical bombardmentDecorative surface effectsChemical vapor deposition coatingInductively coupled plasmaSilicon etching

The invention discloses a deep silicon etching method which comprises the following steps: (1) preparing a graphic photoresist mask on a silicon chip surface; (2) performing deep inductively coupled plasma dry etching of the silicon chip, wherein the etching is divided into several phases, each etching phase is completed in a inductively coupled plasma machine, and is completed through alternate circular processing of three steps of passivation, bombardment, and etching, and with the increase of the etching depth, the bombardment intensity in the bombardment step of each etching phase increases gradually. The method of the invention effectively solves the problems of difficult control of sidewall verticality and roughness, and difficult realization of large etching depth in the prior art, both improves the etching efficiency and increases the selection ratio or photoresist, and is high in etching groove sidewall verticality, low in roughness, and large in etching depth.

Owner:HUAZHONG UNIV OF SCI & TECH

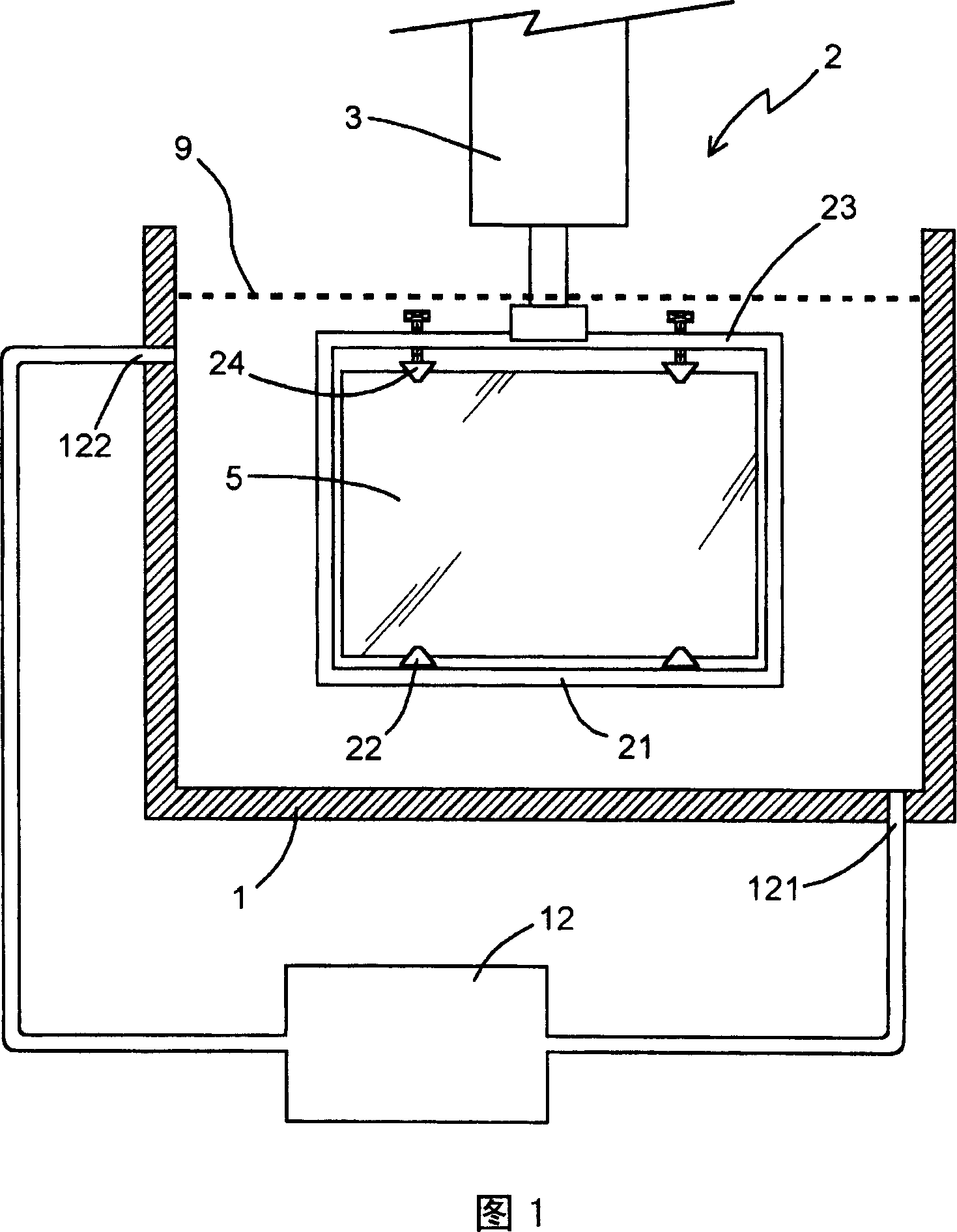

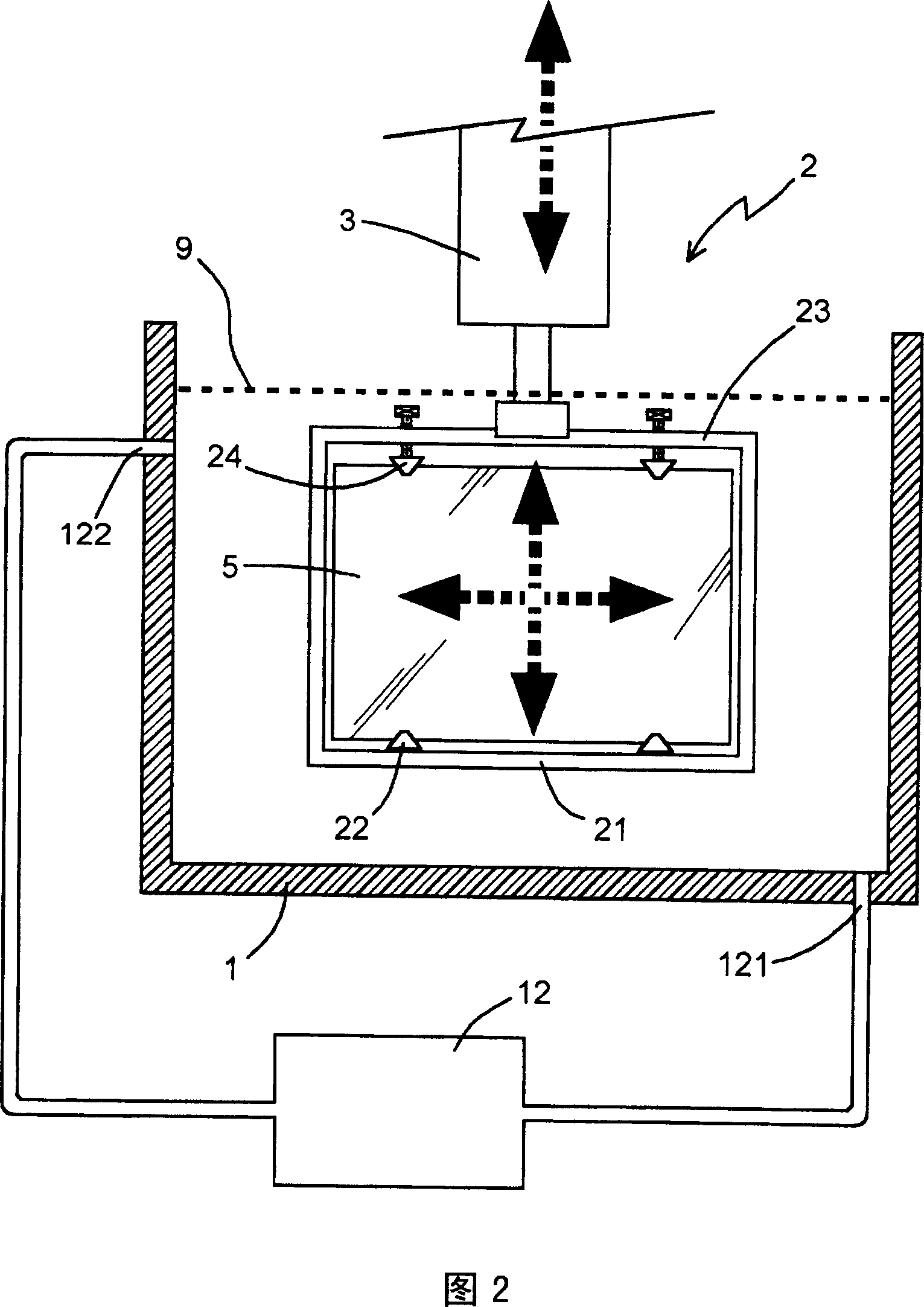

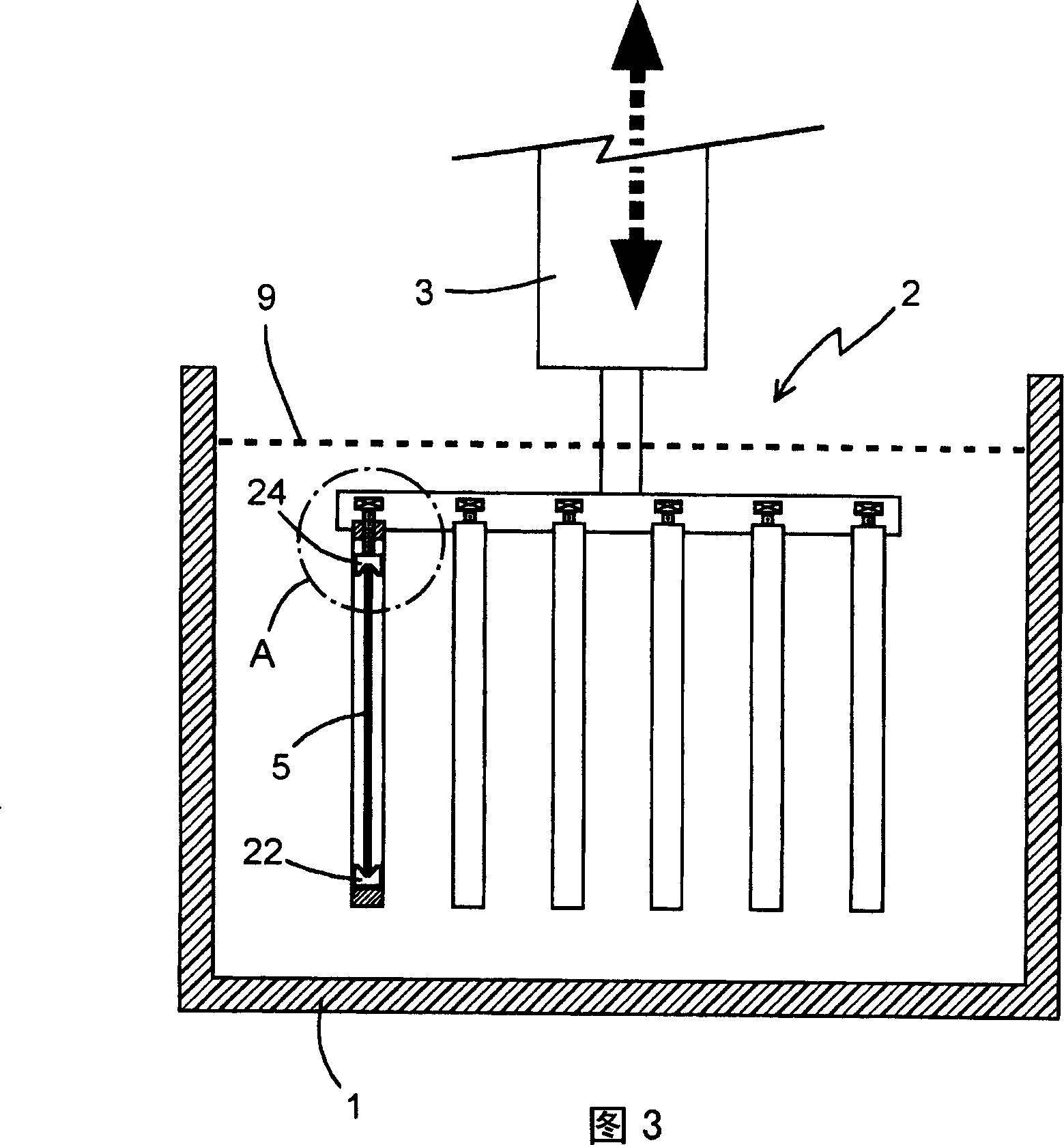

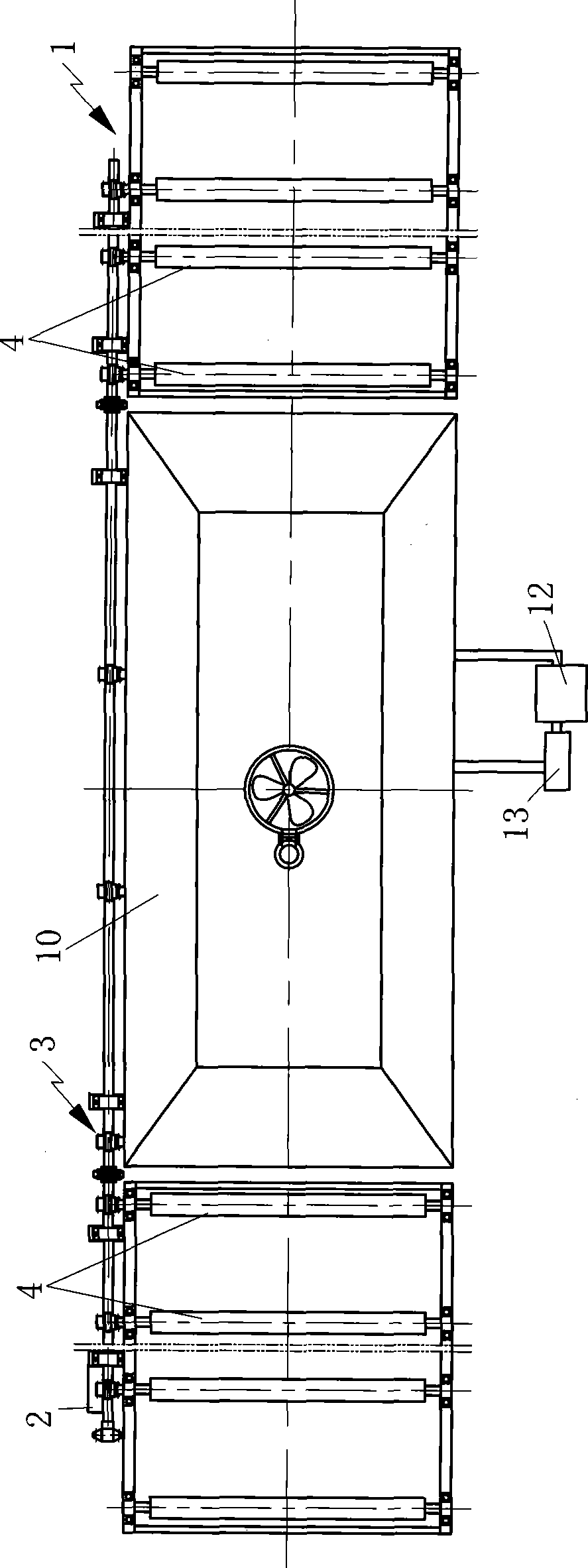

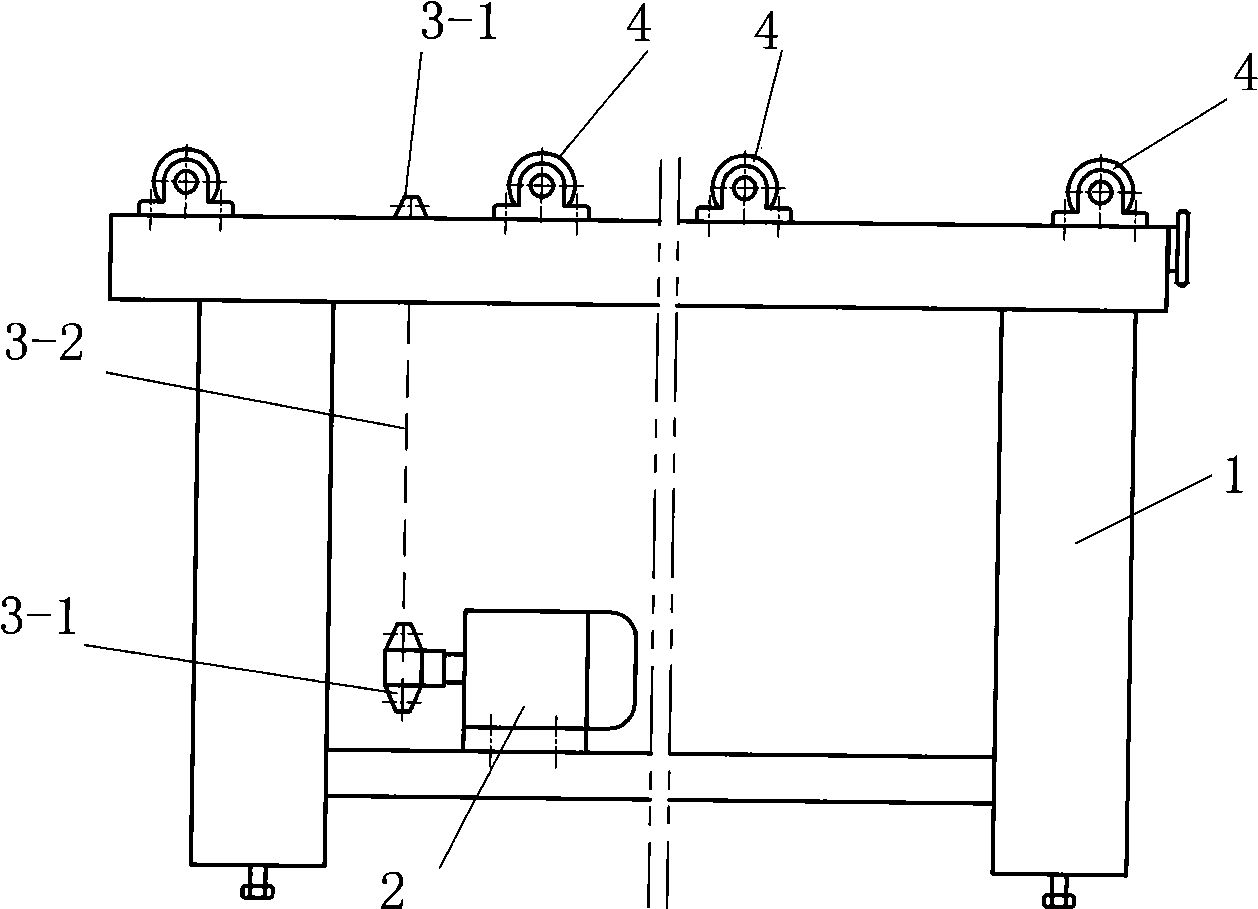

Method and device for panel etching process

InactiveCN101051603AEasy to separateUniform etching effectSemiconductor/solid-state device manufacturingNon-linear opticsRelative motionPhysics

The faceplate to be etched is immersed in the etching solution. In etching procedure, the faceplate makes reciprocating type displacement in up / down or left / right along direction parallel to the faceplate to let etching solution contact surface of faceplate evenly so as to obtain even etching effect. Moreover, relative motion between the faceplate and etching solution makes etched out art are separated from surface rapidly so as to reach purpose of raising etching effect.

Owner:ONANO INDAL CORP

Semiconductor structure and forming method thereof

ActiveCN106206307ASmall sizeConsistent widthSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

The invention provides a semiconductor structure and a forming method thereof. The forming method of the semiconductor structure comprises the steps that a semiconductor substrate is provided; a mask layer and a sacrificial material layer located on the surface of the mask layer are sequentially formed on the surface of the semiconductor substrate; the sacrificial material layer is etched to form a plurality of discrete sacrificial layers; side walls are formed on the side wall surfaces of the sacrificial layers; the sacrificial layers are removed; and supplement side walls are formed on the side wall surfaces of the side walls. By the method, improvement of the performance of the formed semiconductor structure is facilitated.

Owner:SEMICON MFG INT (SHANGHAI) CORP

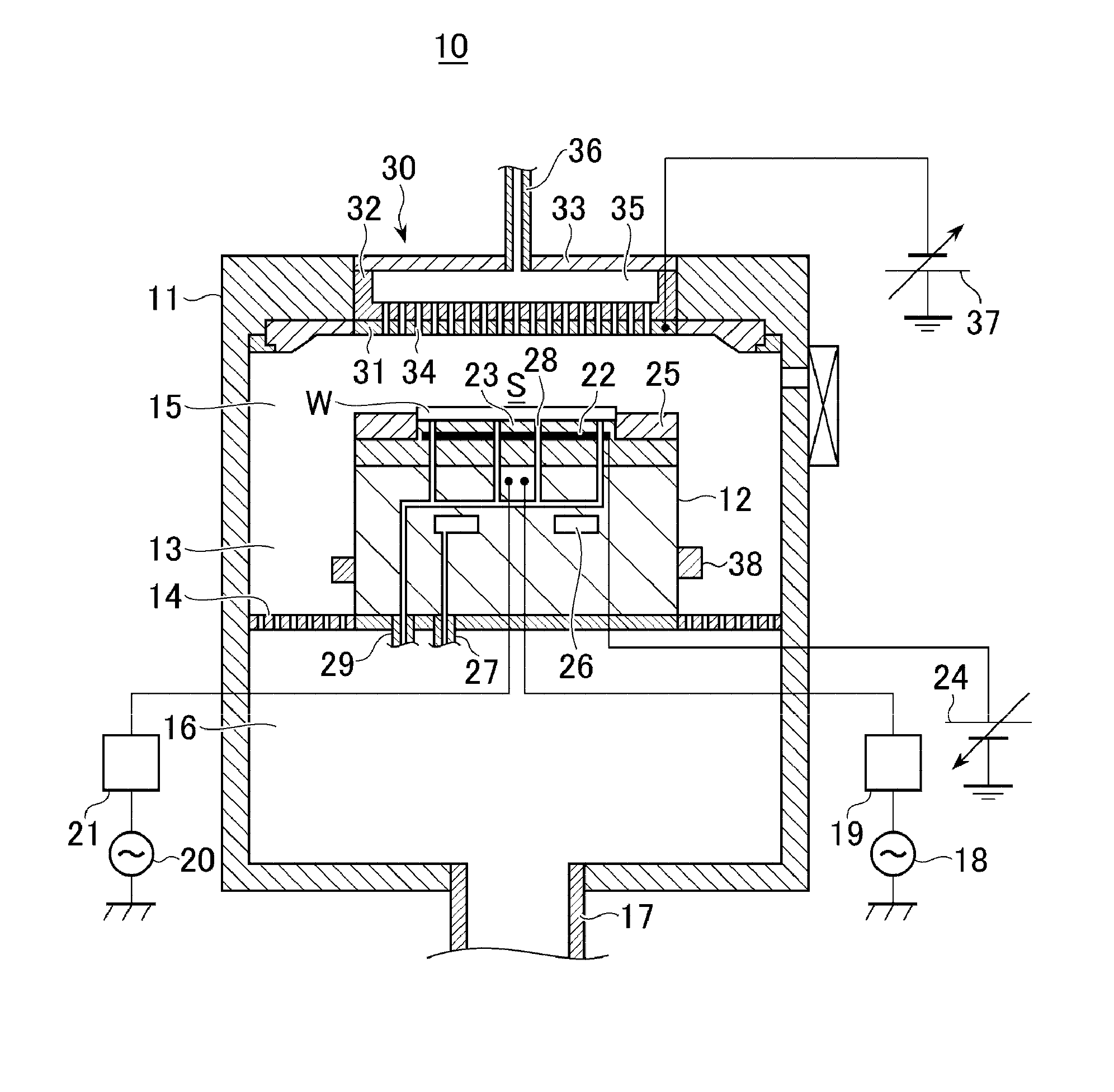

Substrate processing method

ActiveUS20110318933A1Improve etching efficiencySuppressing decrease in positive ion etching efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingPulsed waveAtomic physics

There is provided a substrate processing method capable of preventing the decrease in etching efficiency by positive ions and increasing the overall etching efficiency by using negative ions. The substrate processing method includes applying a plasma RF and a bias RF in the pattern of a pulse wave, respectively. The substrate processing method repeatedly performs the steps of: (3b) etching a substrate by positive ions in plasma by applying both the plasma RF and the bias RF; (3c) generating negative ions in a processing chamber by stopping the application of both the plasma RF and the bias RF; and (3a) attracting the negative ions to the substrate by applying the bias RF and stopping the application of the plasma RF. A duty ratio of the bias RF is set to be greater than a duty ratio of the plasma RF.

Owner:TOKYO ELECTRON LTD

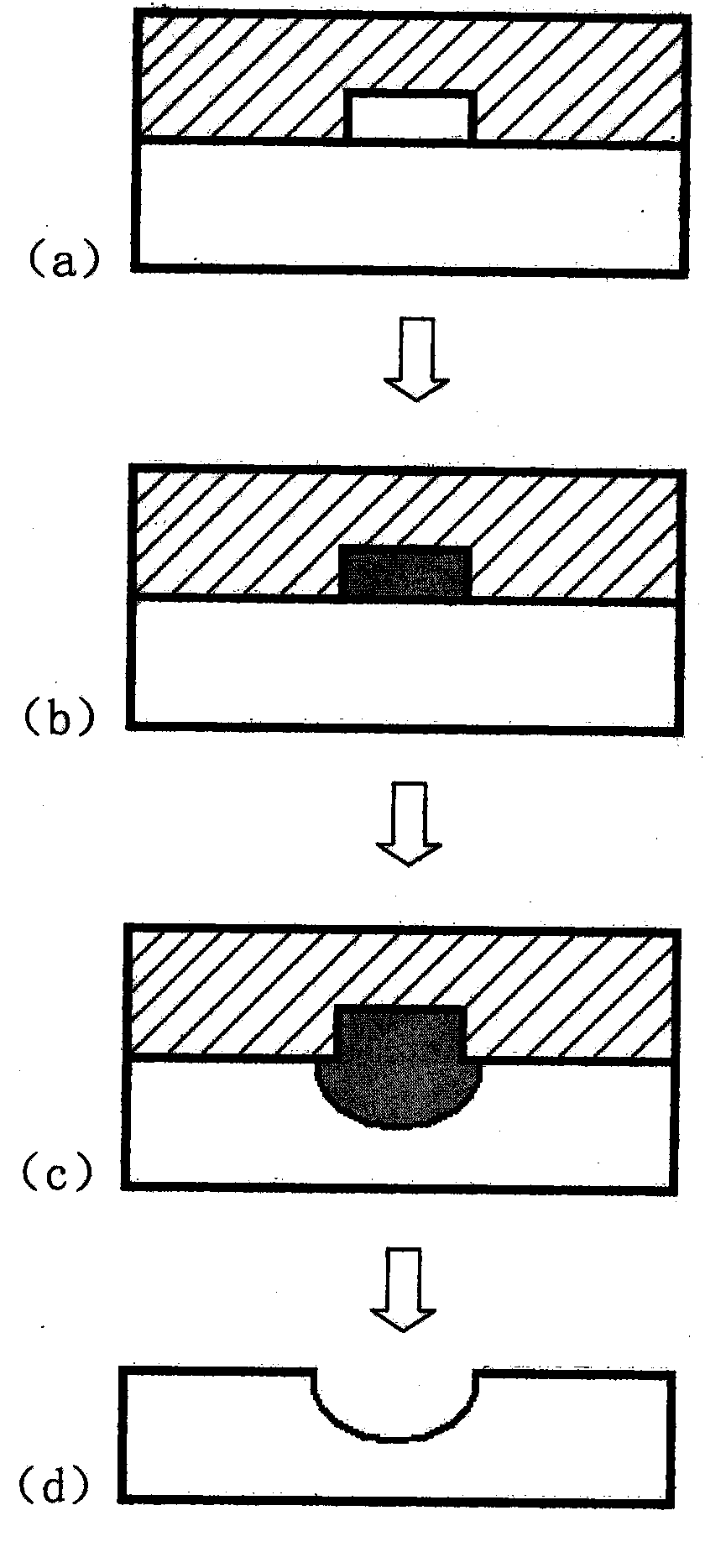

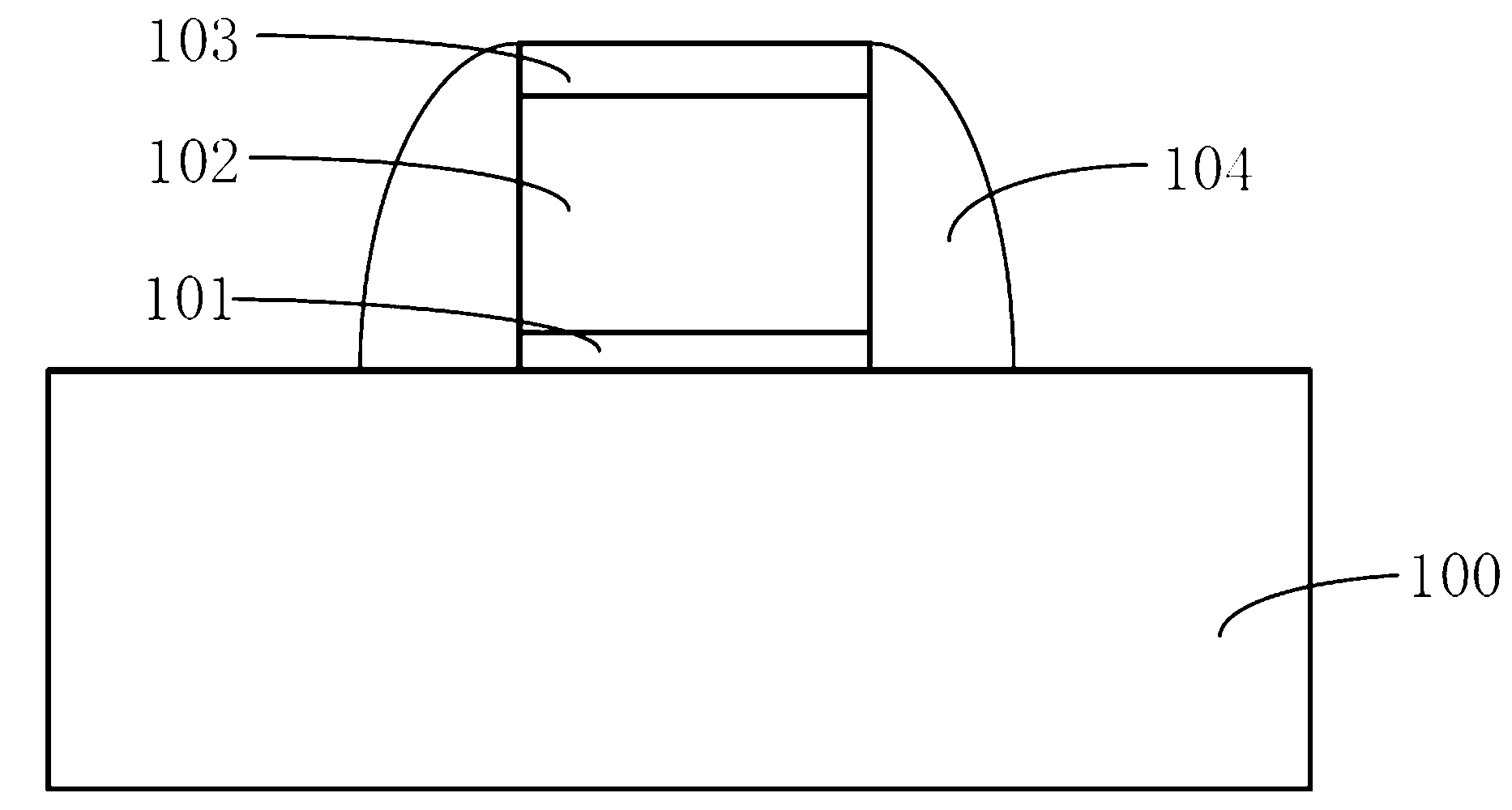

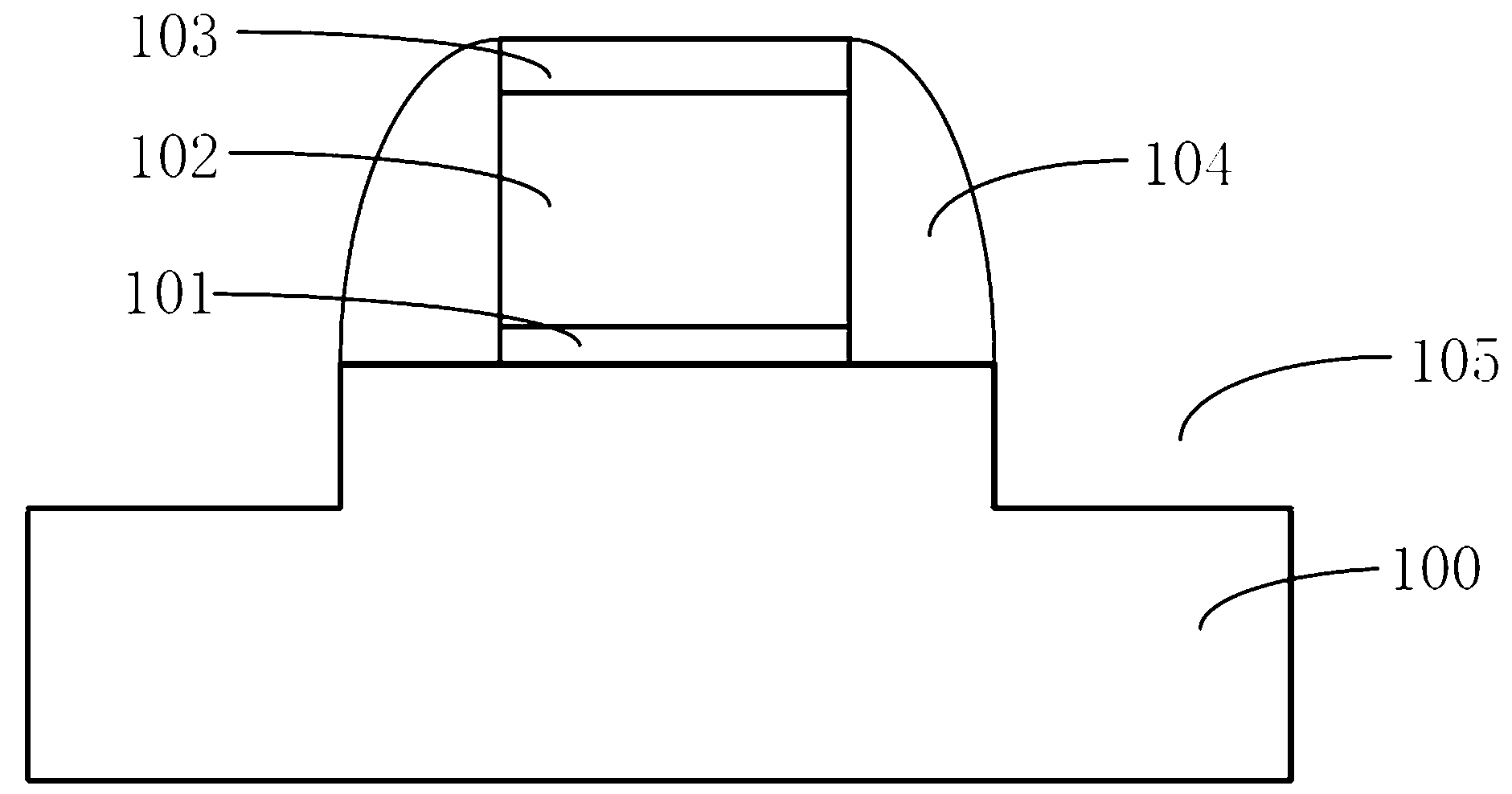

Light-emitting diode device and manufacturing method thereof

InactiveUS20120086029A1Improve etching efficiencyDecreasing light consumptionSemiconductor/solid-state device manufacturingSemiconductor devicesReflective layerLight-emitting diode

A light-emitting diode (LED) device includes a substrate and an epitaxial layer which is disposed on a surface of the substrate. A depression is disposed to a sidewall of the LED device, and a reflective layer is disposed to on least one portion of the depression. By the reflective layer disposed to the depression of the sidewall of the LED device, the light loss caused by the interface of the substrate and the epitaxial layer can be reduced, the light absorbed by the substrate can be decreased, and the angle of the light exiting from the LED device can be adjusted. A manufacturing method of the LED device is also disclosed.

Owner:CHI MEI LIGHTING TECH

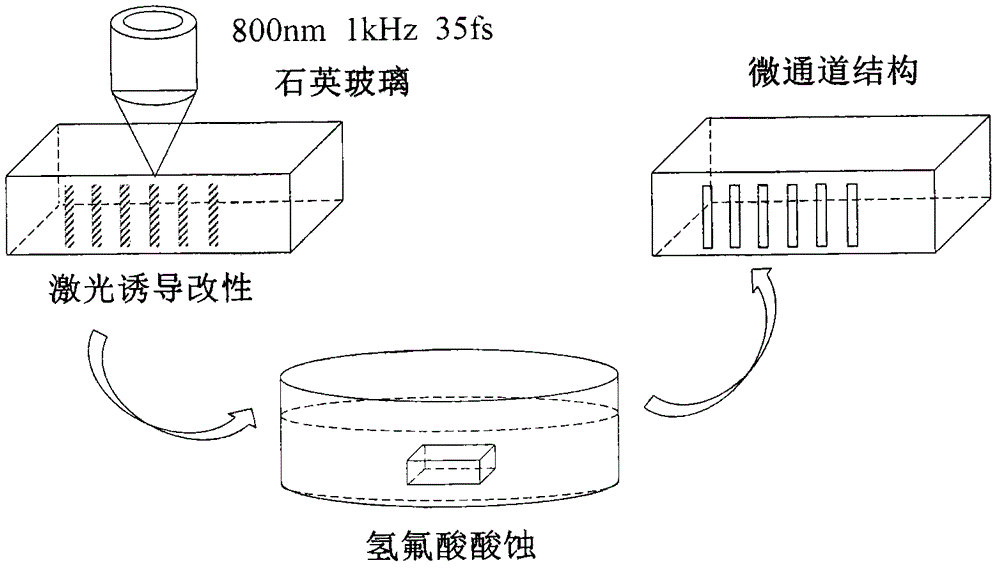

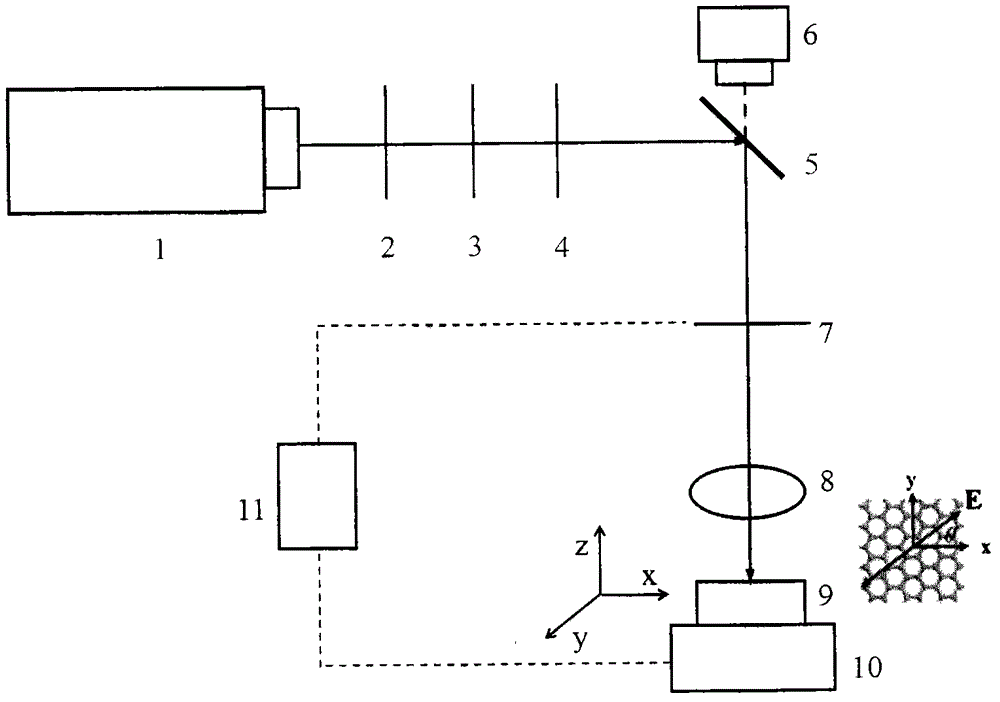

Method for manufacturing micro channel by combining laser polarization selective ablation with acid etching

InactiveCN104625438AImprove etching efficiencySignificant orientation dependenceLaser beam welding apparatusAcid etchingSelective ablation

The invention relates to a method for efficiently manufacturing a micro channel by combining femtosecond laser polarization selective ablation with chemical acid etching, and belongs to the technical field of femtosecond laser application. For the characteristics of crystalline state materials, the partial instant electronic dynamic state in the mutual action process of laser and the materials is adjusted by adjusting the laser polarization parameter and the included angle of the material crystal axis, materials in the laser machining area are triggered to be modified, and the machining efficiency and accuracy of the micro channel are improved with the assistance of chemical acid etching. The method is simple and efficient and has important study significance in the field of micro fluid machining.

Owner:EPHOTON

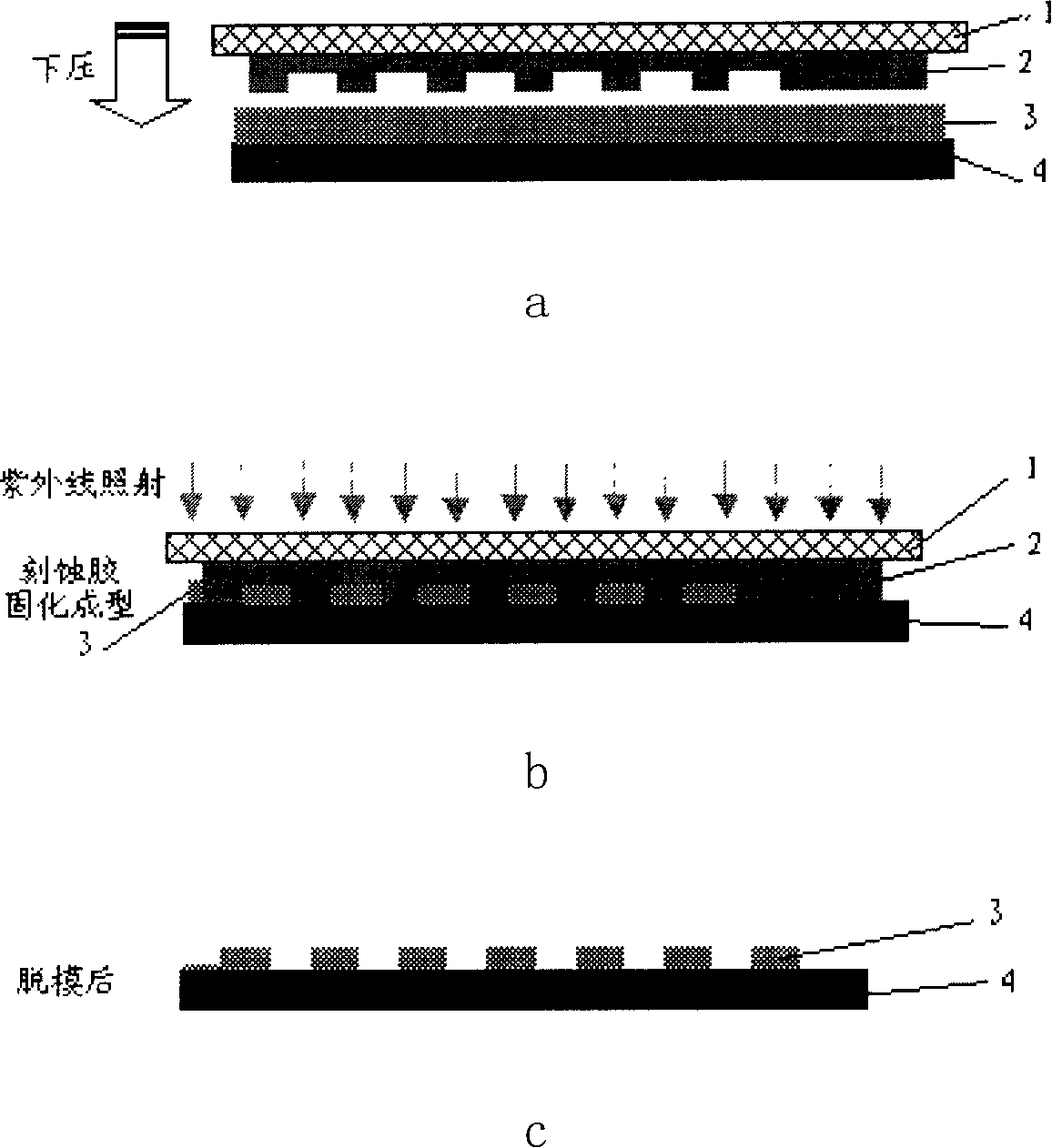

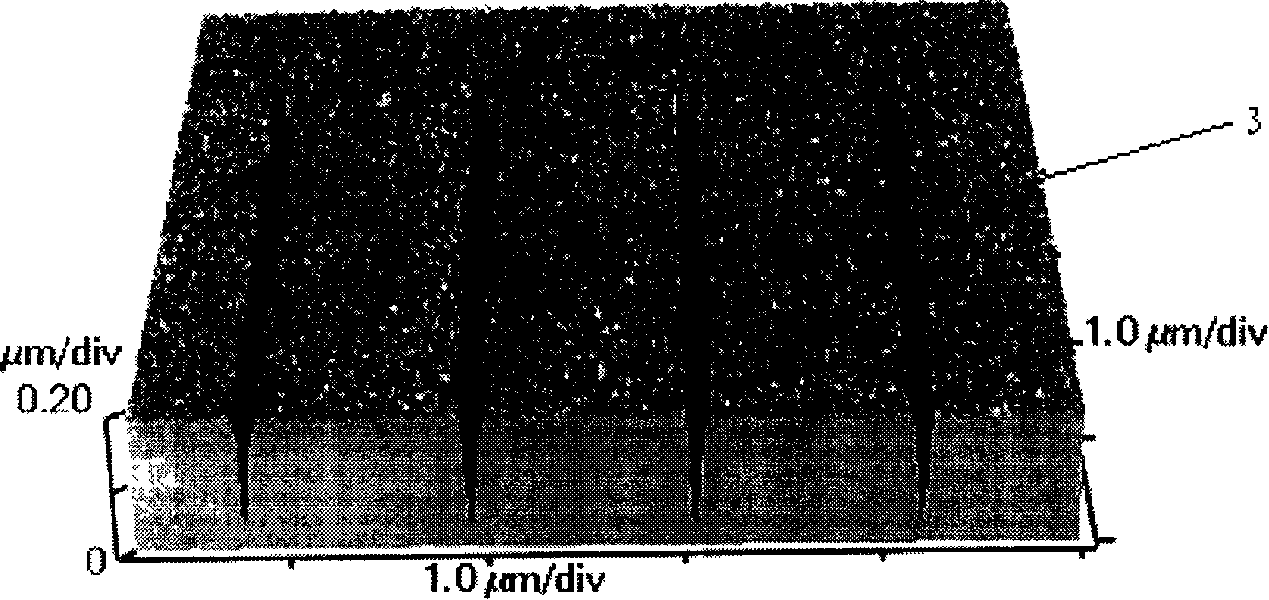

Ultraviolet ray solidification cation type etching glue for nano embessing

InactiveCN1719338ASmall amount of deformationHigh replica accuracyPhotosensitive materials for photomechanical apparatusEpoxyVinyl ether

The present invention discloses an UV photocuring cationic etchant for nano press-printing process. Its composition includes 10%-60% of fatty epoxide resin, 0%-30% of organic silicone epoxy resin, 10%-40% of vinyl ether, 0%-20% of polycaprolactone polyalcohol, 0%-15% of long-chain fatty epoxide resin, 1%-10% of photo-initiator and 0%-8% of adjuvant. The photo-initiator is one or more than one compounds selected from diaryl iodine onium phosphate, triaryl sulphur onium hexafluoroantimonate or triaryl sulphur onium hexafluoroarsenate, and the adjuvant includes organic silane coupling agent, organic silane flow agent and organic alcohols or polyether alkyl comodified silicone oil defoaming agent.

Owner:XI AN JIAOTONG UNIV

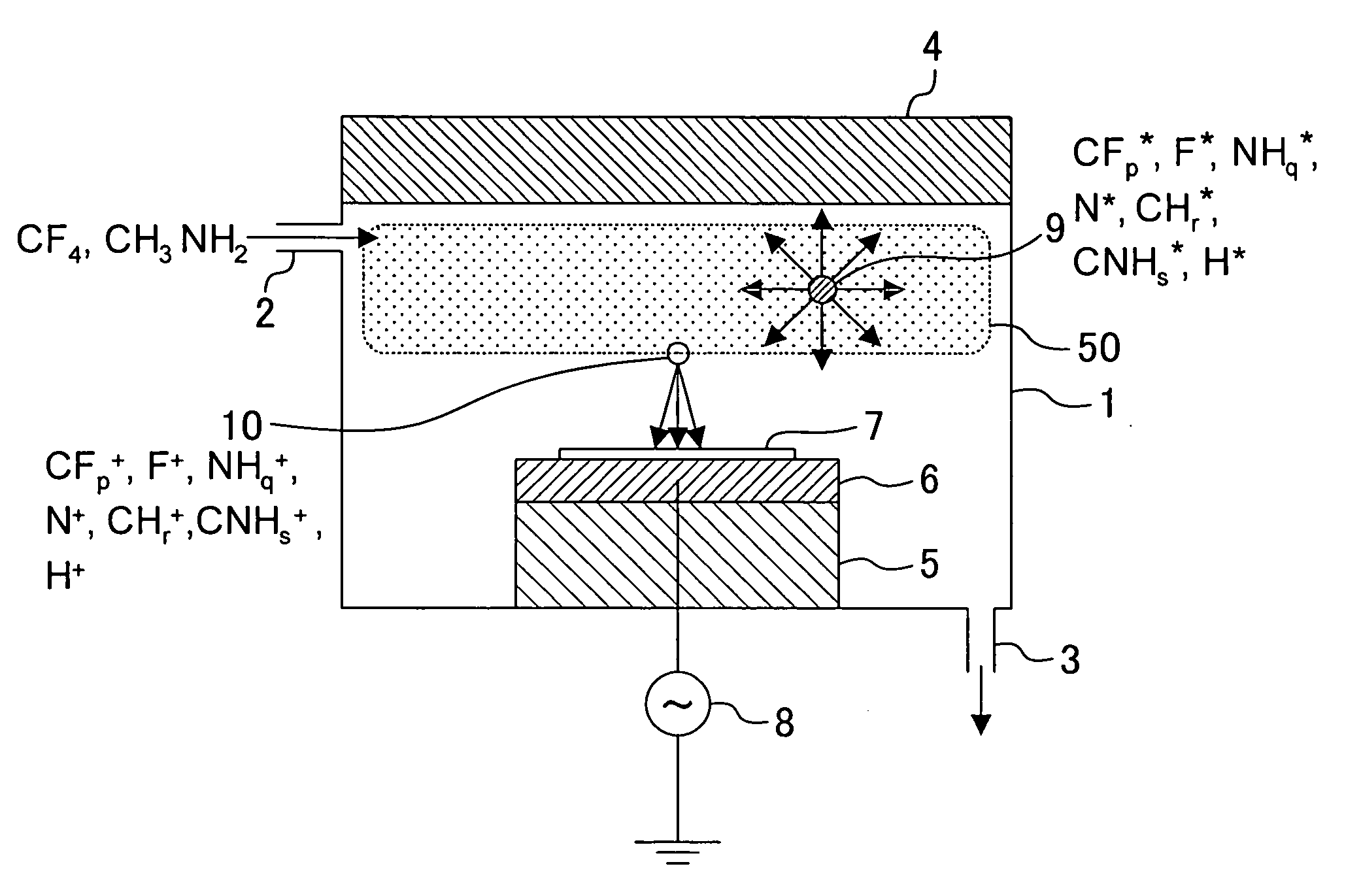

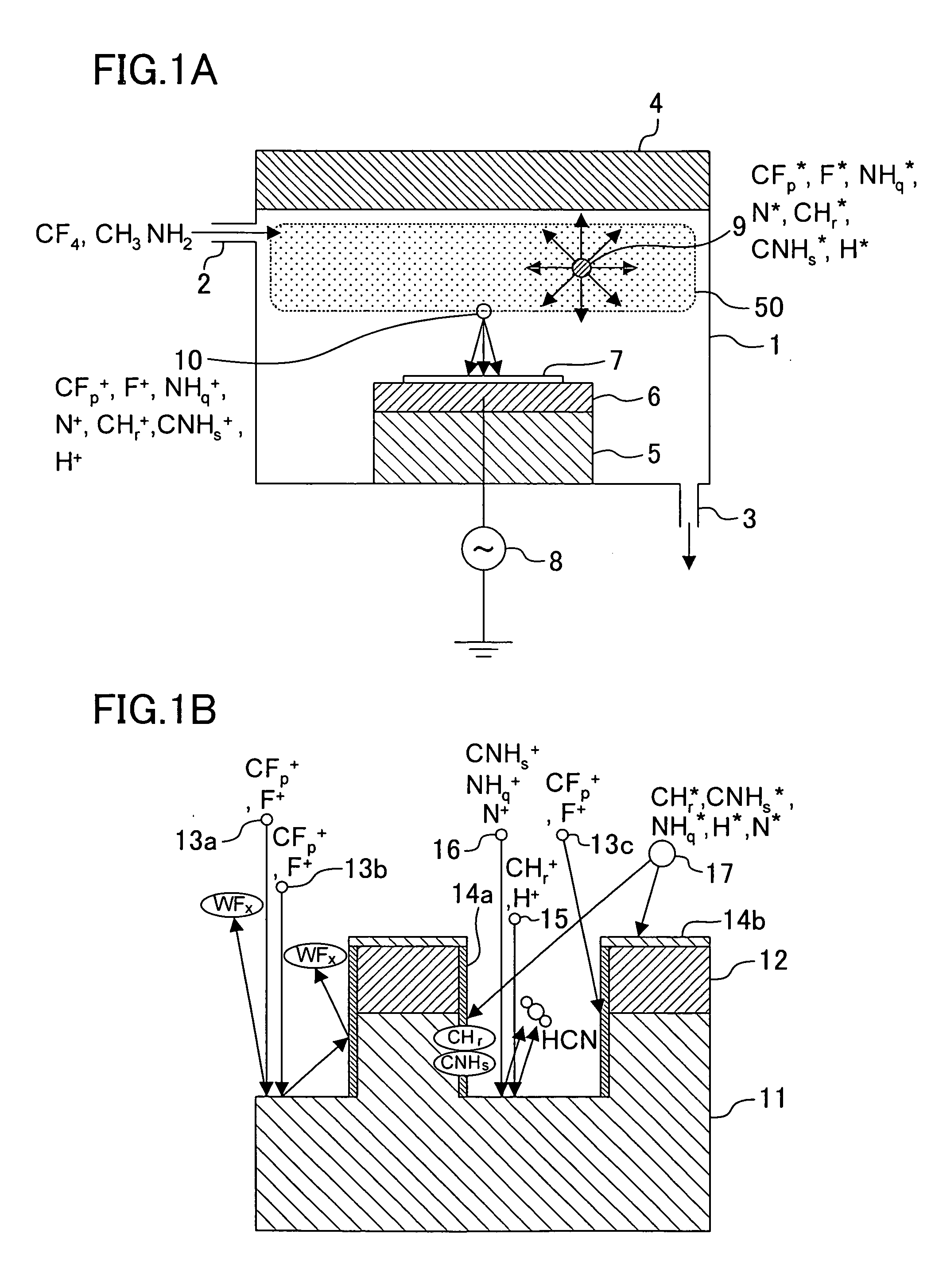

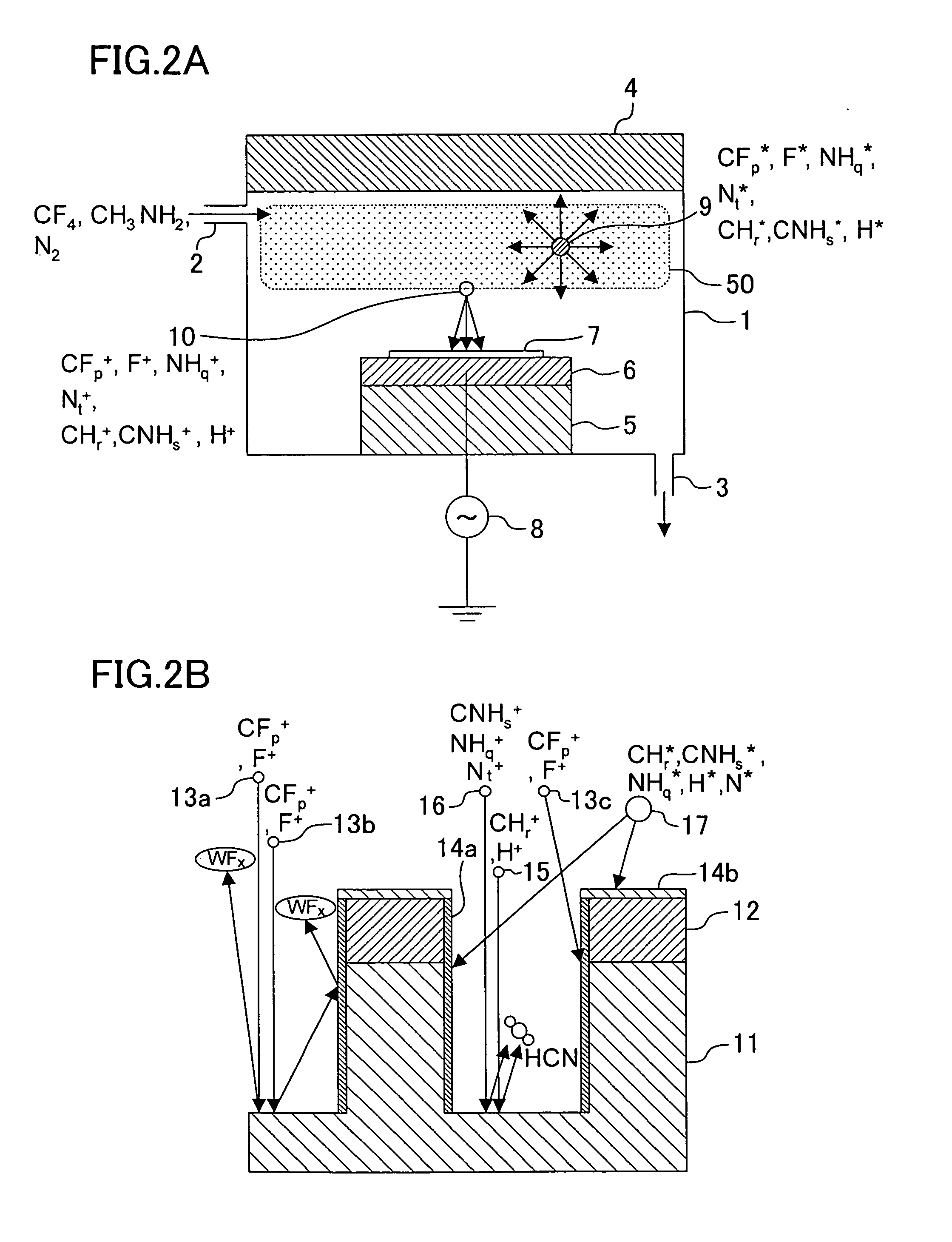

Dry etching method, fine structure formation method, mold and mold fabrication method

InactiveUS20070187359A1Efficient removalImprove etching efficiencyDecorative surface effectsOptical light guidesFine structureHydrogen atom

Owner:PANASONIC CORP

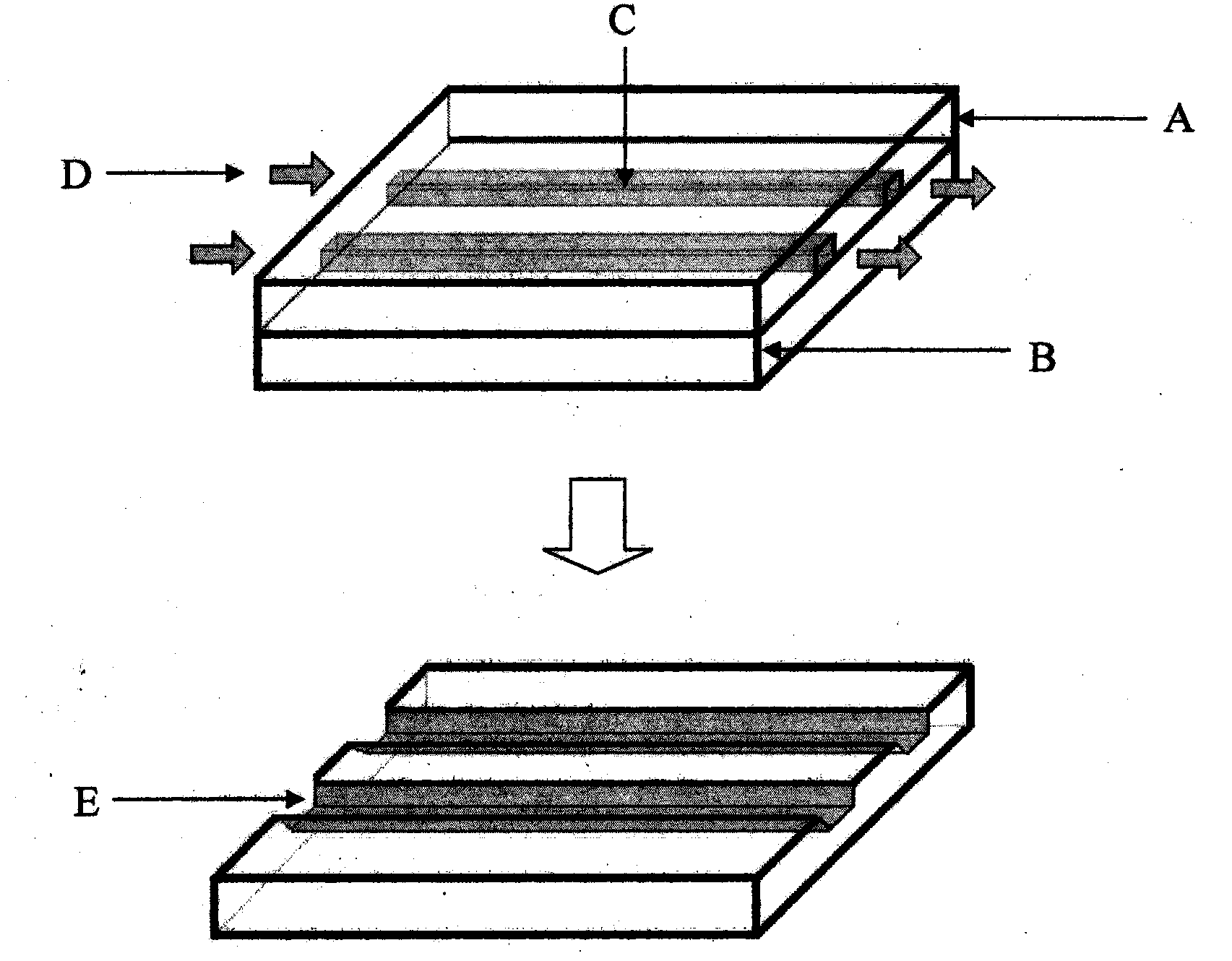

Manufacturing method of micro-fluid channel

InactiveCN103723676AReduce usageEasy to manufactureDecorative surface effectsChemical vapor deposition coatingRapid processingMicrofluidic channel

The invention provides a manufacturing method of a micro-fluid channel. According to an adopted technical scheme, the manufacturing method comprises the following steps of adhering a substrate with a micro-channel structure to a substrate surface to be processed; and then continuously introducing an etching solution to the substrate surface by virtue of an external pump valve system so as to realize rapid processing of the micro-fluid channel. By using the manufacturing method of the micro-fluid channel provided by the invention, a manufacturing process is rapid and simple, an etching sacrificial layer does not need to be prepared, the usage amount of the etching solution is greatly reduced, meanwhile the etching efficiency is remarkably improved; the manufacturing method is especially suitable for rapidly manufacturing micro-fluidic chips with low cost and slight pollution on a large scale.

Owner:XIAOSHAN BIOENG CENT OF YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG

Manufacturing method of semiconductor device

ActiveCN102832128AMinimize Microloading EffectsImprove etching efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesEtchingGreek letter sigma

The invention provides a manufacturing method of a semiconductor device. The manufacturing method comprises the following steps: providing a semiconductor substrate and forming a gate structure on the semiconductor substrate; forming a groove at a part which is prone to formation of a source region / drain region in the semiconductor substrate; performing pre-amorphization injection on the semiconductor substrate to form an amorphous layer at the bottom of the groove; performing anisotropic wet etching on the semiconductor substrate containing the amorphous layer so that the side wall of the groove is concave towards the direction of the ditch of the device to form a sigma-shaped groove; annealing to crystallize the amorphous layer, and further performing secondary anisotropic wet etching to remove the amorphous layer; and performing epitaxial growth of a germanium-silicon stress layer in the sigma-shaped groove. According to the manufacturing method, the sigma-shaped groove used for an embedded germanium-silicon strain MOS (metal oxide semiconductor) device is formed, an etching barrier layer is formed by anisotropic wet etching through adopting the pre-amorphization injection during the process of manufacturing the groove, the micro-loading effect can be reduced and the etching efficiency can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

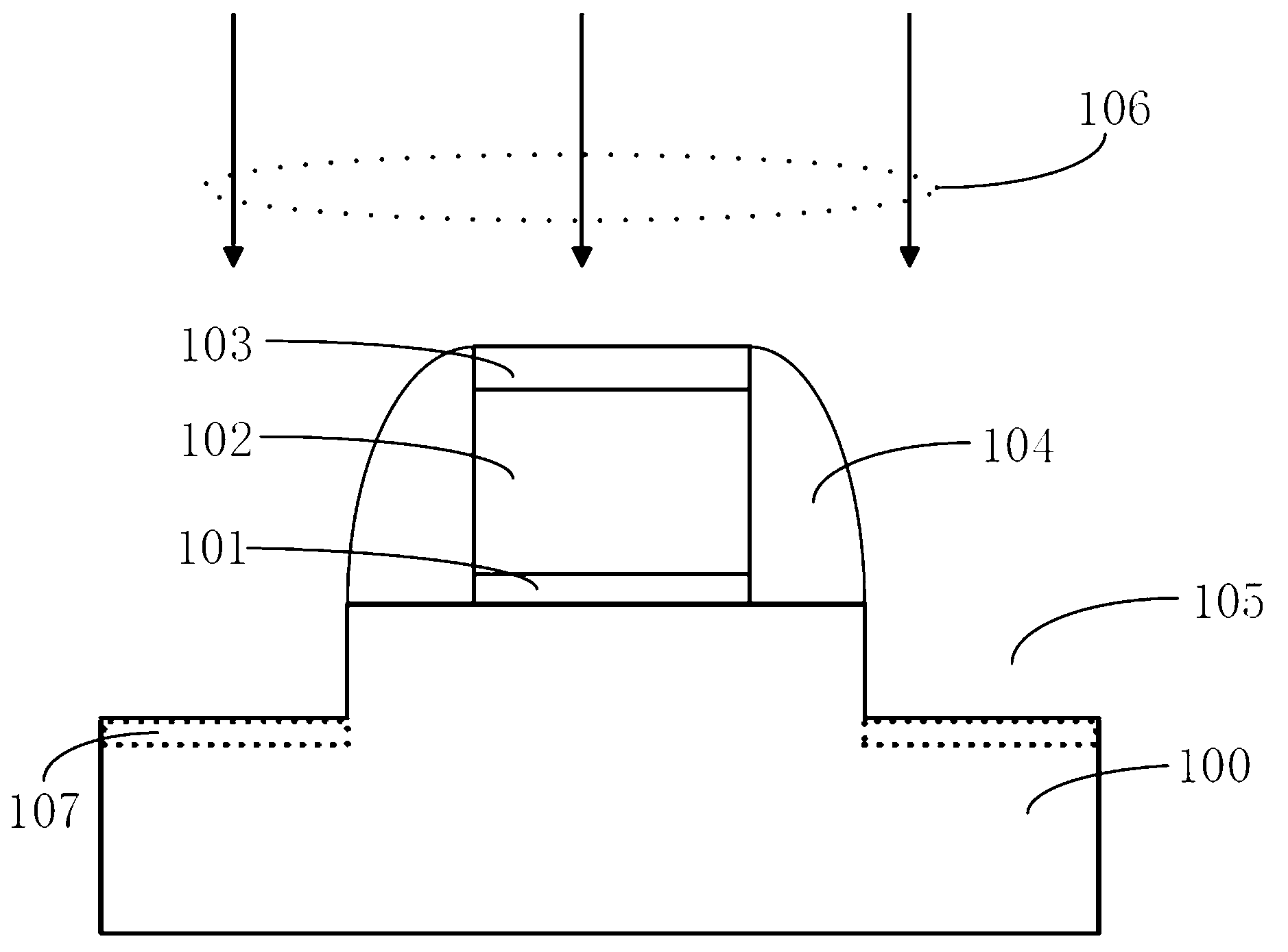

Bulk silicon machining process based on silicon chip etching and puncturing

ActiveCN103896206AAchieve physical bombardmentReduce physical bombardmentDecorative surface effectsChemical vapor deposition coatingInductively coupled plasmaMachining process

The invention discloses a bulk silicon machining process based on silicon chip etching and puncturing, which comprises the following steps of preparing a patterned photoresist mask on the surface of a silicon chip; putting a metal film on the back surface of the silicon chip; adhering the metal film to a supporting chip by using vacuum oil, wherein the supporting chip is a silicon chip with an oxide layer on the surface; etching and puncturing the silicon chip to obtain a bulk silicon microstructure by using an inductively coupled plasma dry-etching system, wherein a staged etching method is adopted for inductive coupled plasma dry-etching, and comprises a plurality of etching stages each of which is alternately and cyclically implemented by three steps of passivation, bombardment and etching in an inductive coupled plasma machine, and along with the increasing of the etching depth, the bombardment intensity of the bombardment step in each etching stage is gradually enhanced; removing the photoresist mask and the metal film, and releasing the bulk silicon microstructure. According to the process, the selection ratio of photoresist, the etching depth and the perpendicularity of the sidewall of an etching groove can be effectively increased.

Owner:HUAZHONG UNIV OF SCI & TECH

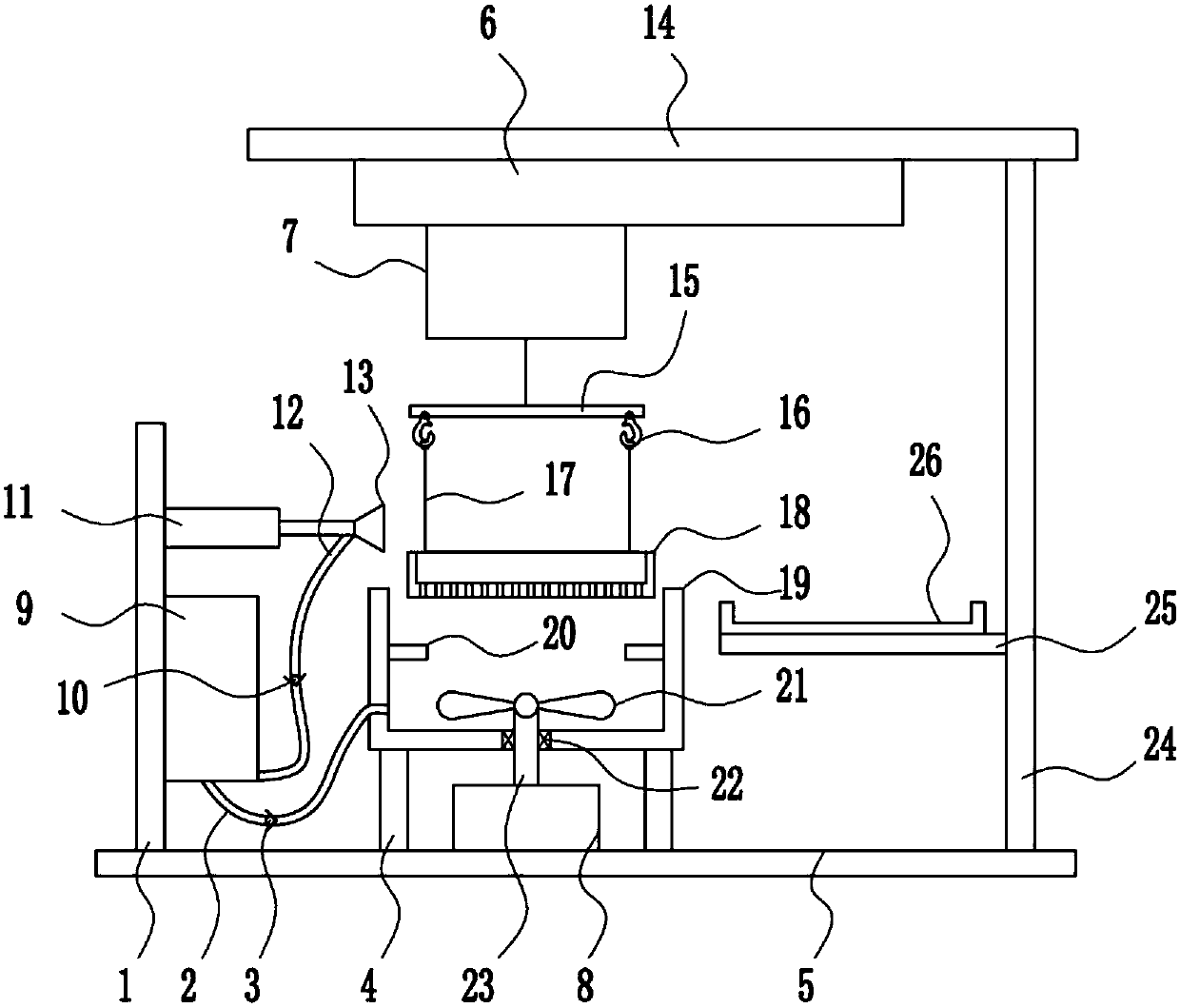

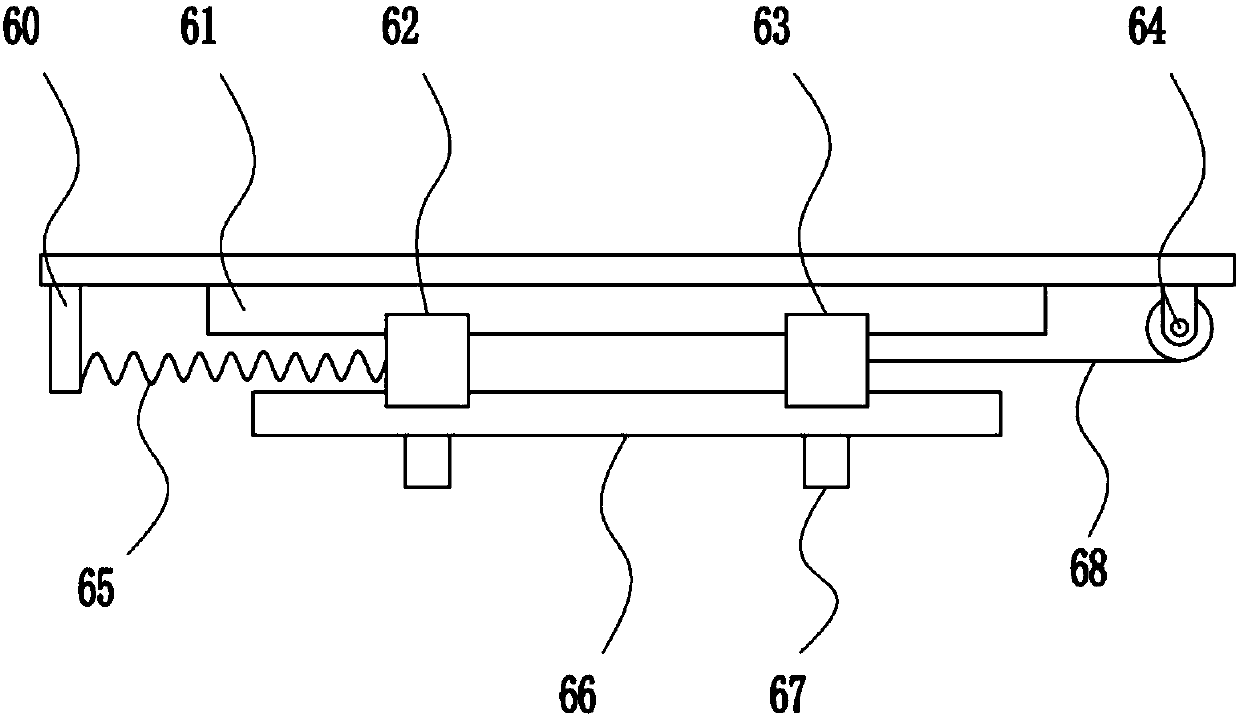

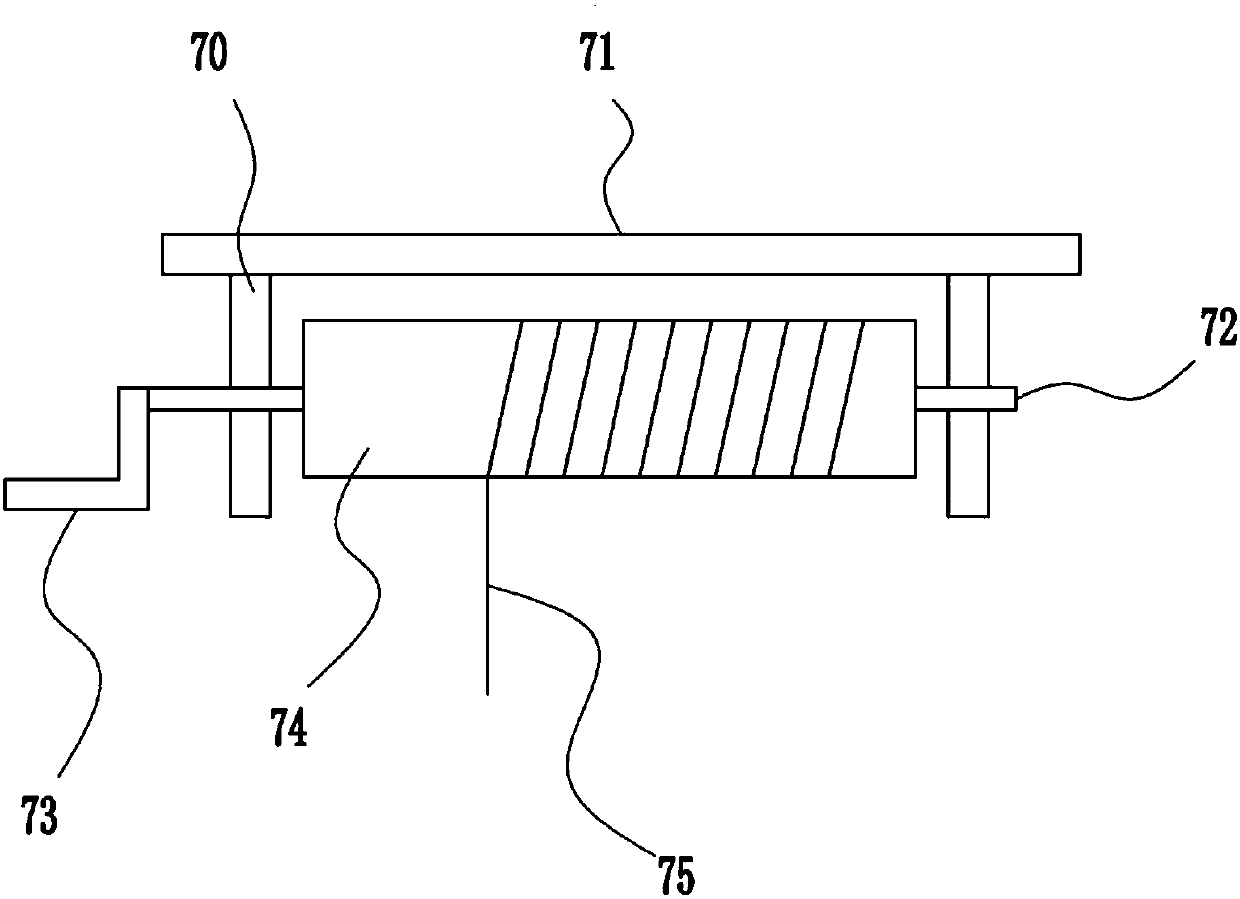

Printed circuit board (PCB) etching equipment for production of electronic display screen

InactiveCN107683026AQuick collectionQuick drop effectConductive material chemical/electrolytical removalEngineeringCam

The invention relates to etching equipment, in particular to printed circuit board (PCB) etching equipment for production of an electronic display screen. The PCB etching equipment, which can be usedfor reducing labor intensity of a worker, is high in etching efficiency and is convenient to operate, for the production of the electronic display screen is provided by the invention. In order to solve the technical problem, the PCB etching equipment for the production of the electronic display screen comprises a left rack, a first pipeline, a first one-way valve, a support rod, a bottom plate, amobile device, a lifting device, a rotation device, a liquid transmission device and a second one-way valve, wherein the left rack is welded at a left side of the top of the bottom plate, and the liquid transmission device is arranged at a lower part of a right side of the left rack. By the PCB etching equipment, the rotation direction of an electric winding wheel is controlled, the effects of rapidly collecting and placing a PCB is achieved by matching of the electric winding wheel and a first spring, a rotation motor is controlled to rotate, a cam and a second spring are matched with each other, an etching liquid is stirred by rotating rotation blades, so that the PCB and the etching liquid are in full contact, and the etching efficiency is improved.

Owner:郑诗青

Preparation method of electrochemical sensor

ActiveCN103808776AReduce consumptionImprove etching efficiencyMaterial electrochemical variablesElectrochemical gas sensorEtching

The invention provides a preparation method of an electrochemical sensor. The preparation method is characterized by covering the surface of a solid conductive film with a micro-fluidic chip, and continuously guiding etching fluid into the micro-fluidic chip so as to realize the rapid patterned etching of the conductive film. Since the etching liquid on the surface of the conductive film is continuously updated, the etching efficiency is remarkably improved; in addition, the volume of an etching cavity inside the micro-fluidic chip is small, so that the consumption of etching liquid is greatly reduced. The preparation method can be used for mass production of electrochemical sensors.

Owner:HANGZHOU TINKER BIOTECHNOLOGY CO LTD

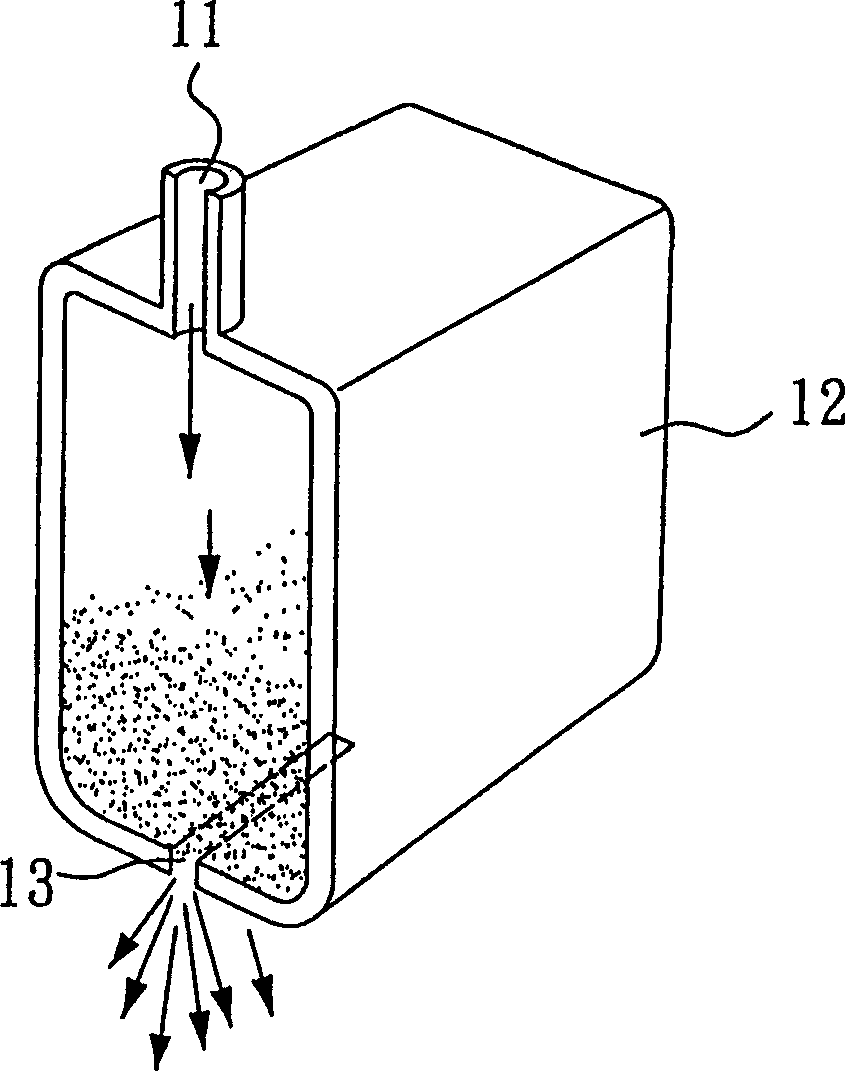

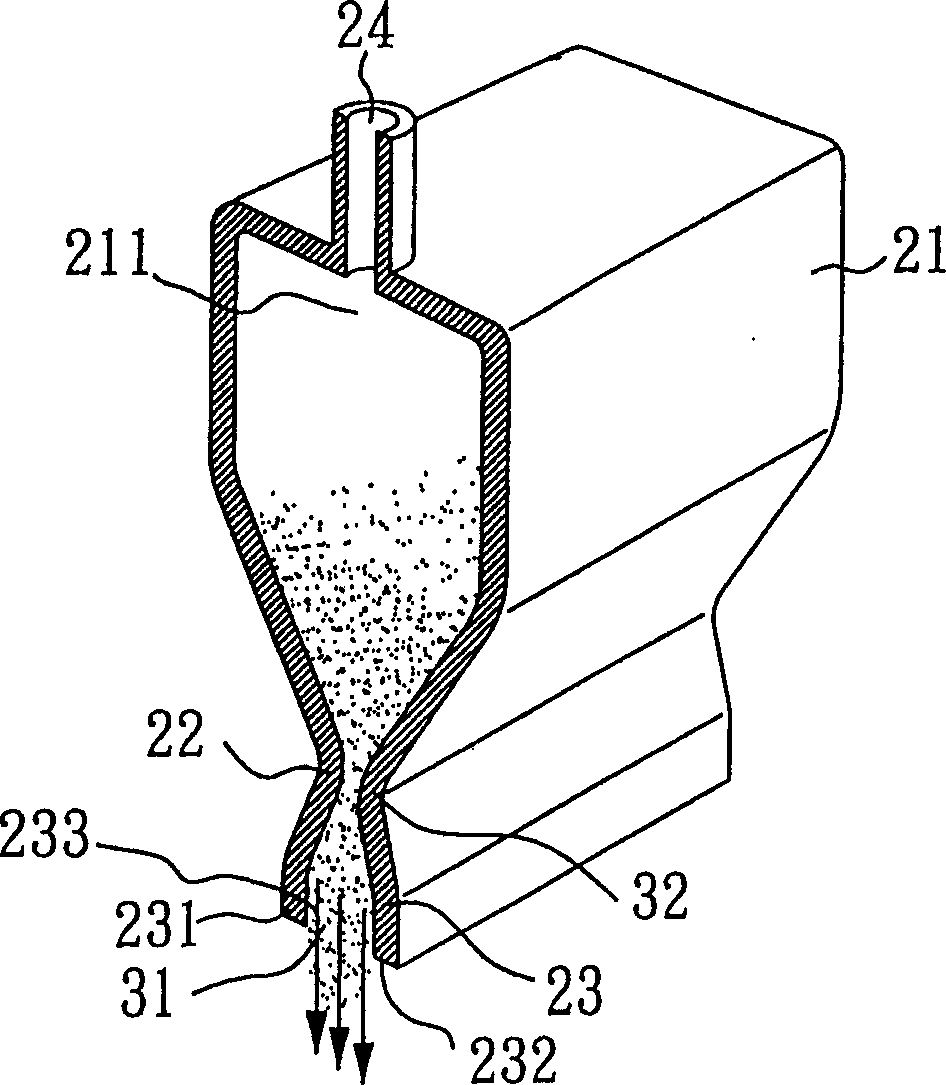

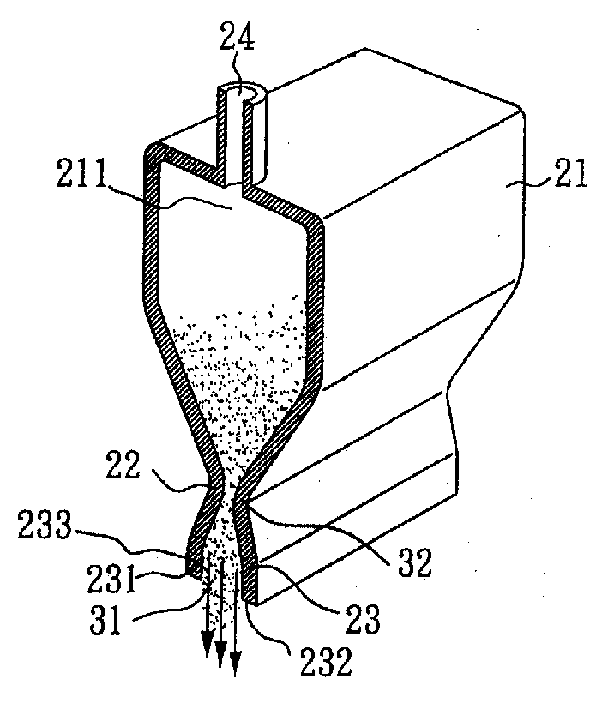

Jet nozzle structure of sand ejector

InactiveCN1565805AImprove etching efficiencyReduce the occurrence of lateral etchingBlast gunsSand blastingEngineering

The invention provides a jet nozzle for a sand blasting machine comprising an input part, a throat part, and an output part. The input part communicates with a delivery pipe and receives the grinding materials from the delivery pipe. The throat part is the extension part of the input part. The output part is the extension part from the throat part. The width of the input part is more than that of the output part and the width of the output part is more than that of the throat part, which can make the grinding materials transport through the output part.

Owner:AU OPTRONICS CORP

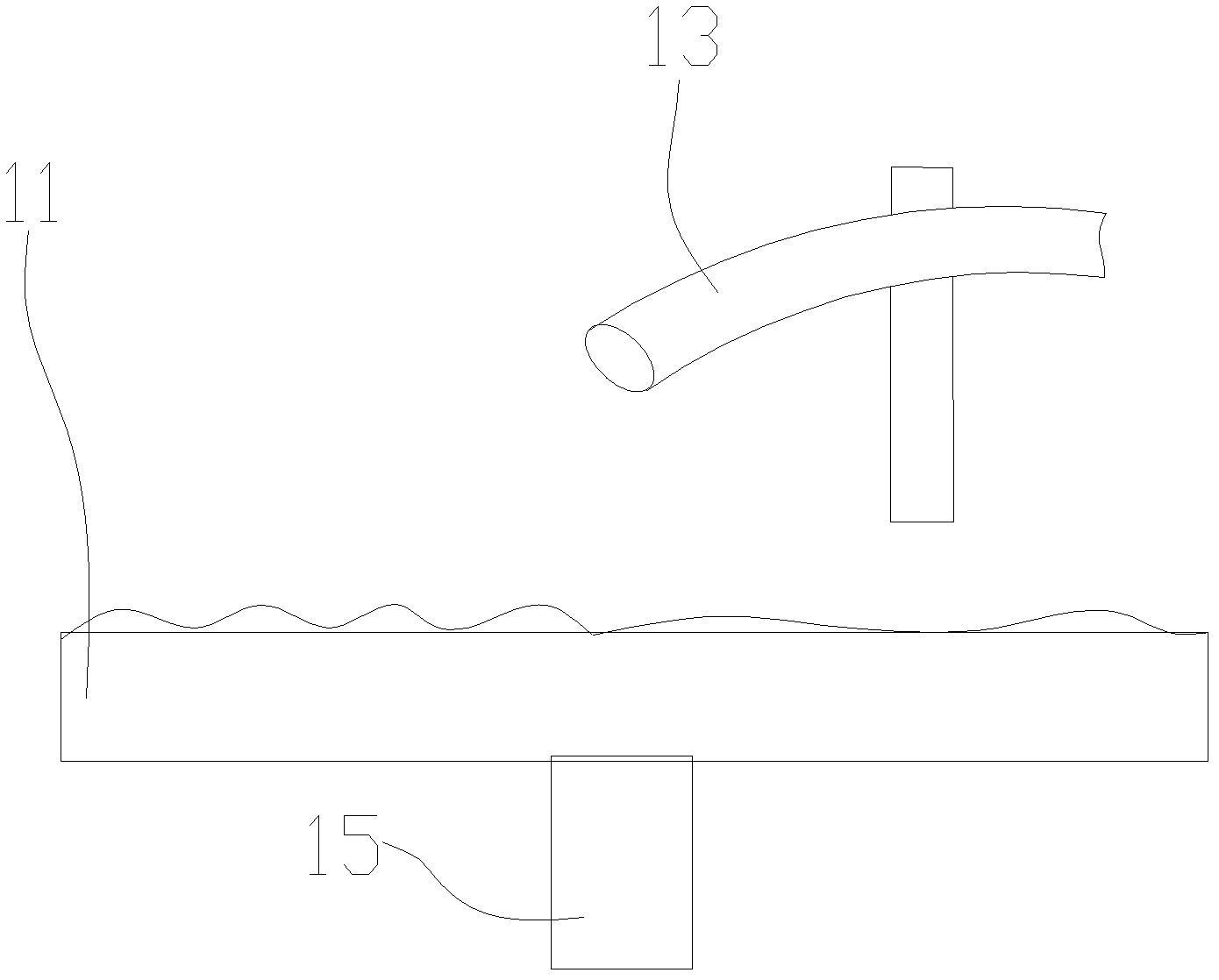

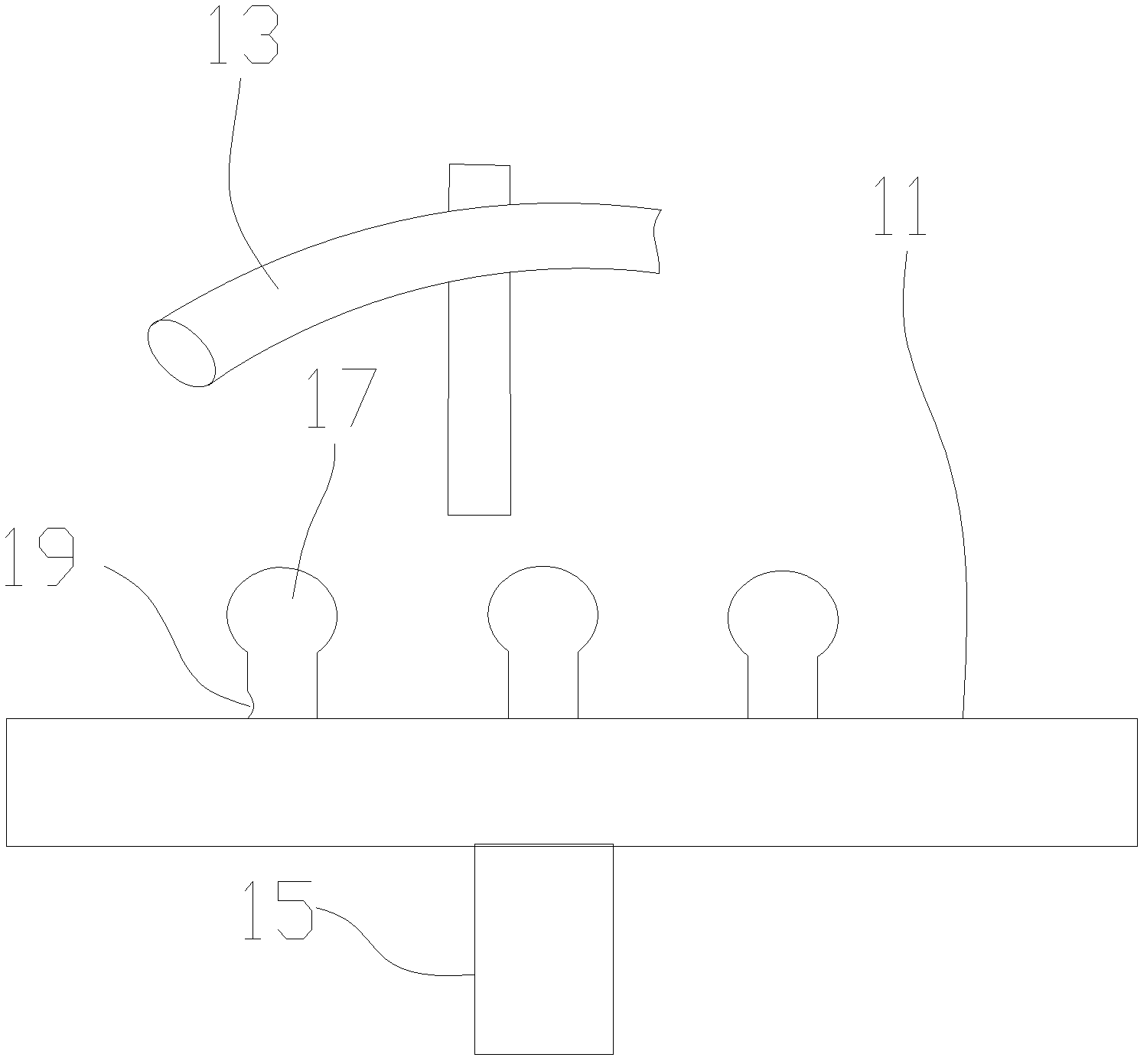

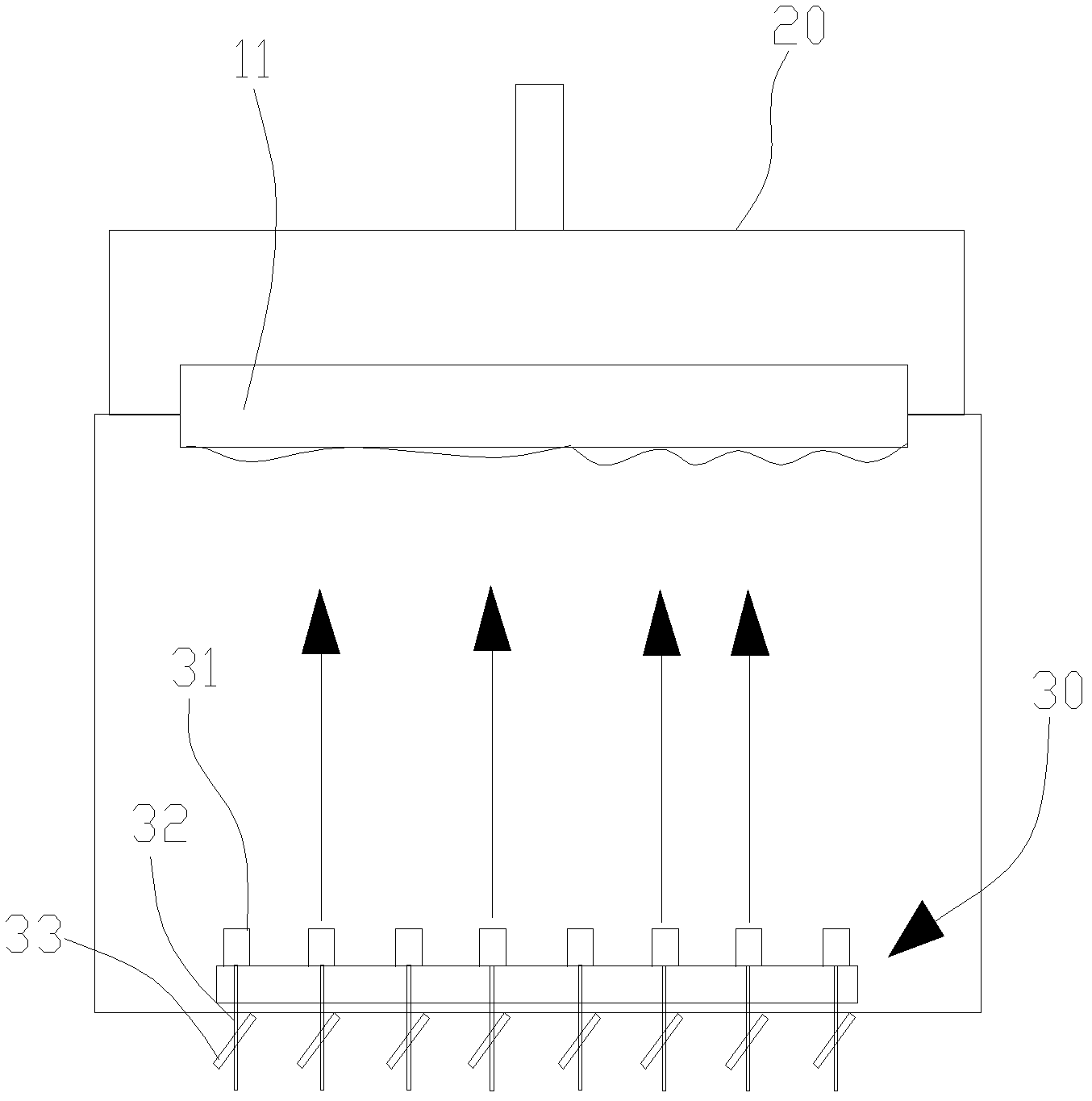

Semiconductor wafer liquid-spraying etching system and method

InactiveCN102623323AAvoiding Inscribed Corner ProblemsTraffic adjustment in timeSemiconductor/solid-state device manufacturingSpray nozzlesSpray nozzleSemiconductor

The invention relates to a liquid-spraying etching system and method of a semiconductor wafer. The semiconductor wafer liquid-spraying etching system comprises a carrying-platform device and a spraying device, wherein the carrying-platform device is used for fixing the semiconductor wafer when the surface to be etched of the semiconductor wafer faces downwards, and controlling rotation of the semiconductor wafer; the spraying device is placed below the carrying-platform device and comprises a plurality of spraying nozzles and a plurality of controlling pieces; all the spraying nozzles are used for spraying etching liquid on the corresponding positions of the surface to be etched on the semiconductor wafer upwards; the plurality of controlling pieces correspond to the plurality of spraying nozzles; and each controlling piece is used for controlling the spraying flow rate of the etching liquid of the spraying nozzle corresponding to the control piece. The liquid-spraying etching system and method have good etching uniformity and can improve the quality of products.

Owner:NANTONG FUJITSU MICROELECTRONICS

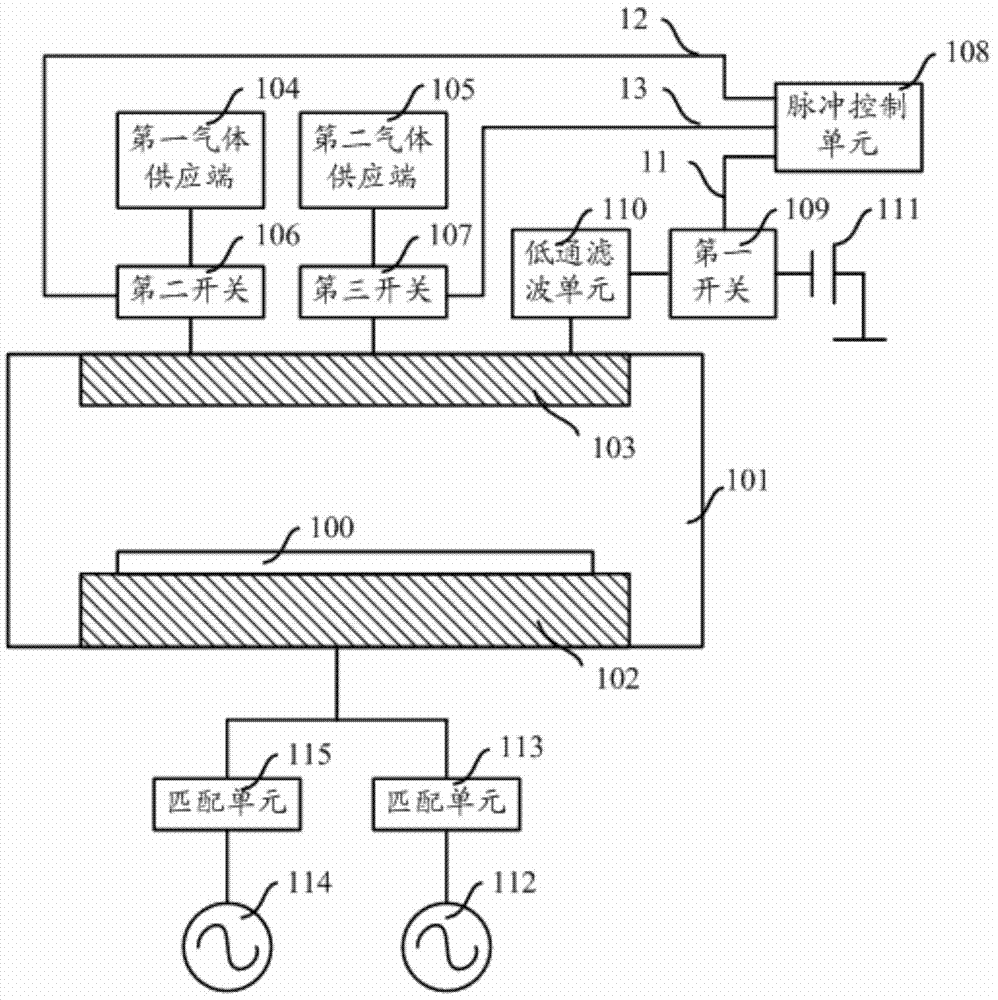

Plasma etching device and etching method thereof

ActiveCN103531429AAvoid accumulationImprove performanceElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityEngineering

The invention discloses a plasma etching device and an etching method thereof. The plasma etching device comprises a processing chamber, a first electrode, a second electrode, a first gas supply end, a second gas supply end and an impulse control unit, wherein the first electrode is located in the processing chamber, provided with a platform for placing a wafer and electrically connected with at least one radio-frequency power supply; the second electrode is located in the processing chamber, faces the first electrode and is electrically connected with a direct-current power supply, and a first switch is arranged between the second electrode and the direct-current power supply; the first gas supply end feeds first gas into the processing chamber, and a second switch is arranged between the first gas supply end and the processing chamber; the second gas supply end feeds second gas into the processing chamber, and a third switch is arranged between the second gas supply end and the processing chamber; and the impulse control unit synchronously generates a first impulse signal, a second impulse signal and a third impulse signal for controlling the first switch, the second switch and the third switch respectively. The plasma etching device prevents accumulation of electric charge in a to-be-etched material during etching.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Integrated capacitors fabricated with conductive metal oxides

InactiveUS6940112B2Improving uniformity and reliabilityEasy to integrateTransistorSolid-state devicesOptoelectronicsCapacitor

A capacitor for a memory device is formed with a conductive oxide for a bottom electrode. The conductive oxide (RuOx) is deposited under low temperatures as an amorphous film. As a result, the film is conformally deposited over a three dimensional, folding structure. Furthermore, a subsequent polishing step is easily performed on the amorphous film, increasing wafer throughput. After deposition and polishing, the film is crystallized in a non-oxidizing ambient.

Owner:MICRON TECH INC

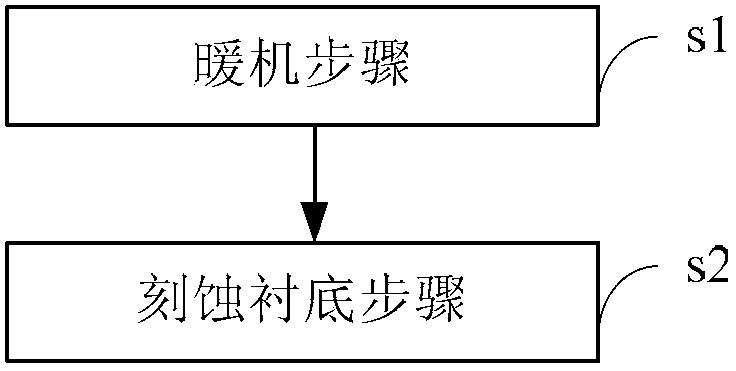

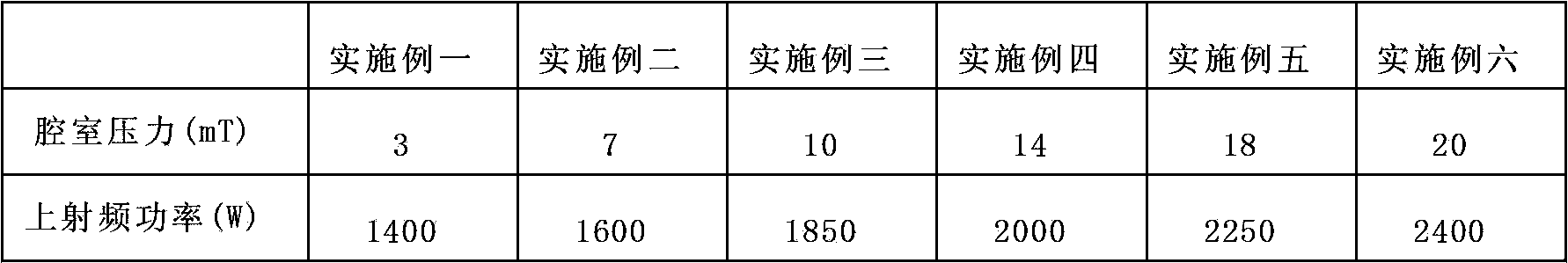

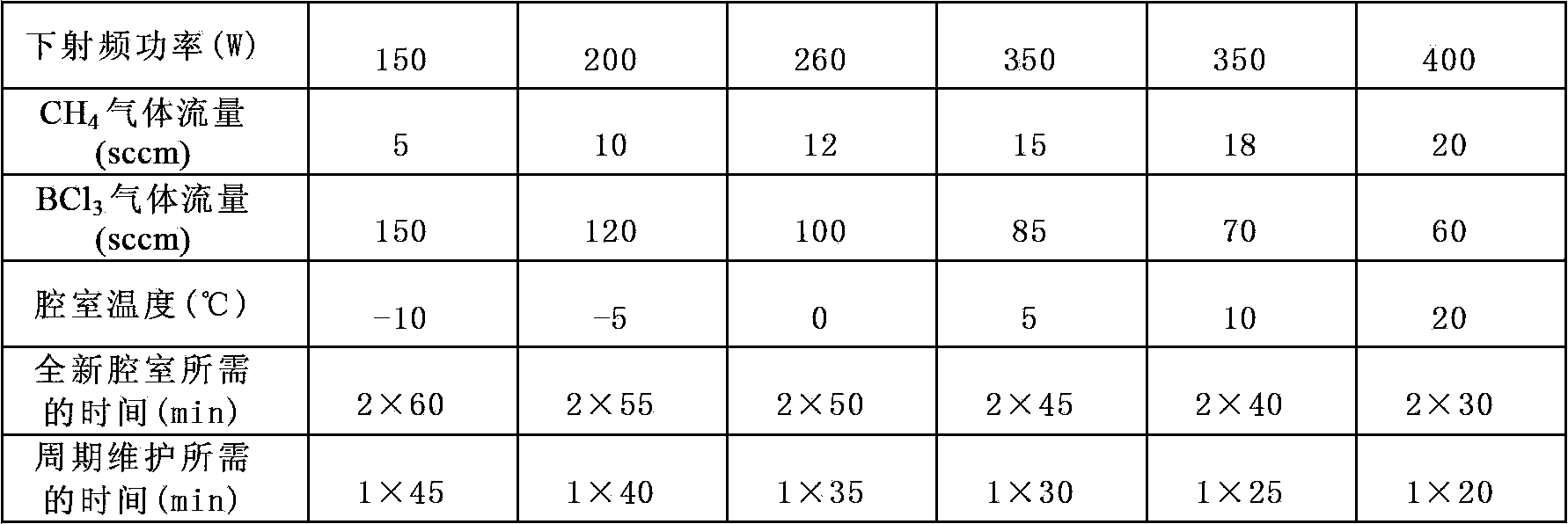

Seasoning method and etching method

InactiveCN103515176AShorten the timeImprove efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogenPolymer

The invention provides a seasoning method and an etching method. The seasoning method, which is used for forming a polymer on the inner wall of a chamber in a seasoning process so as to enable the chamber to reach a working state required by the process, comprises the following steps: filling gases containing carbon and hydrogen into the chamber; motivating the gases containing carbon and hydrogen into a plasma body; and depositing a polymer layer on the inner wall of the chamber by utilizing the plasma body containing carbon and hydrogen. With the seasoning method, the time of the seasoning process can be reduced, the efficiency of the seasoning process is improved; besides, the cost of the seasoning process can be reduced, and the production cost of the whole etching process can be reduced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

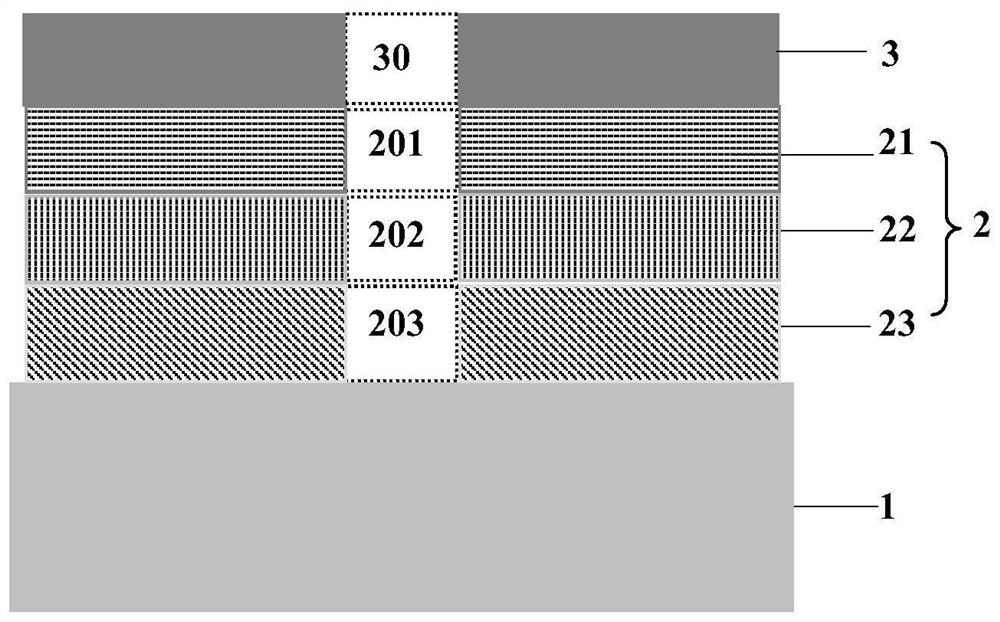

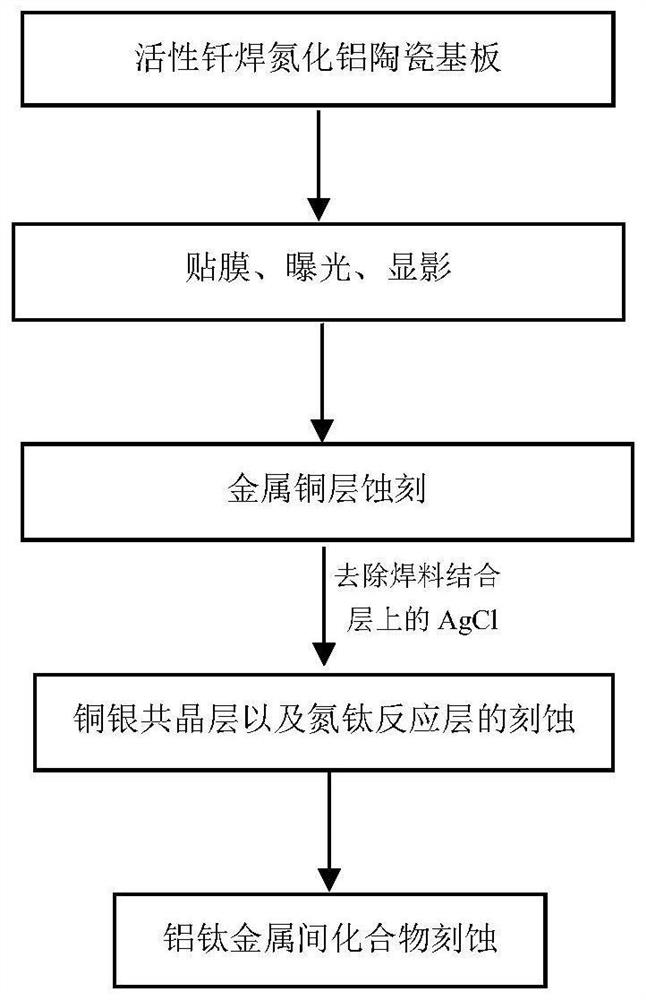

Etching liquid system and etching method of aluminum nitride substrate

ActiveCN111621787AImprove thermal conductivityImprove etching efficiencySemiconductor/solid-state device manufacturingSurface treatment compositionsReaction layerEtching

The invention discloses an etching liquid system and an etching method of an aluminum nitride substrate. The etching liquid system comprises first etching liquid and second etching liquid, wherein thefirst etching liquid comprises the following components according to mass percent: 1% to 5% of ammonium hydroxide, 3% to 8% of strong oxidant, 0.5% to 5% of complexing agents and the balance of water, and the second etching liquid comprises the following components according to mass percent: 1% to 5% of alkali, 2% to 8% of hydrogen peroxide and the balance of water. According to the etching method of the aluminum nitride substrate, a solder bonding layer is etched in two steps of etching a copper-silver eutectic layer and a nitrogen-titanium reaction layer by using the first etching liquid and etching aluminum-titanium intermetallic compounds by using the second etching liquid. The etching liquid system has the advantages of high selectivity and high etching power; the etching method hasthe advantages of high etching efficiency and good etching quality; and the efficient high-precision etching of the aluminum nitride ceramic substrate with high thermal conductivity is realized.

Owner:江苏富乐华半导体科技股份有限公司

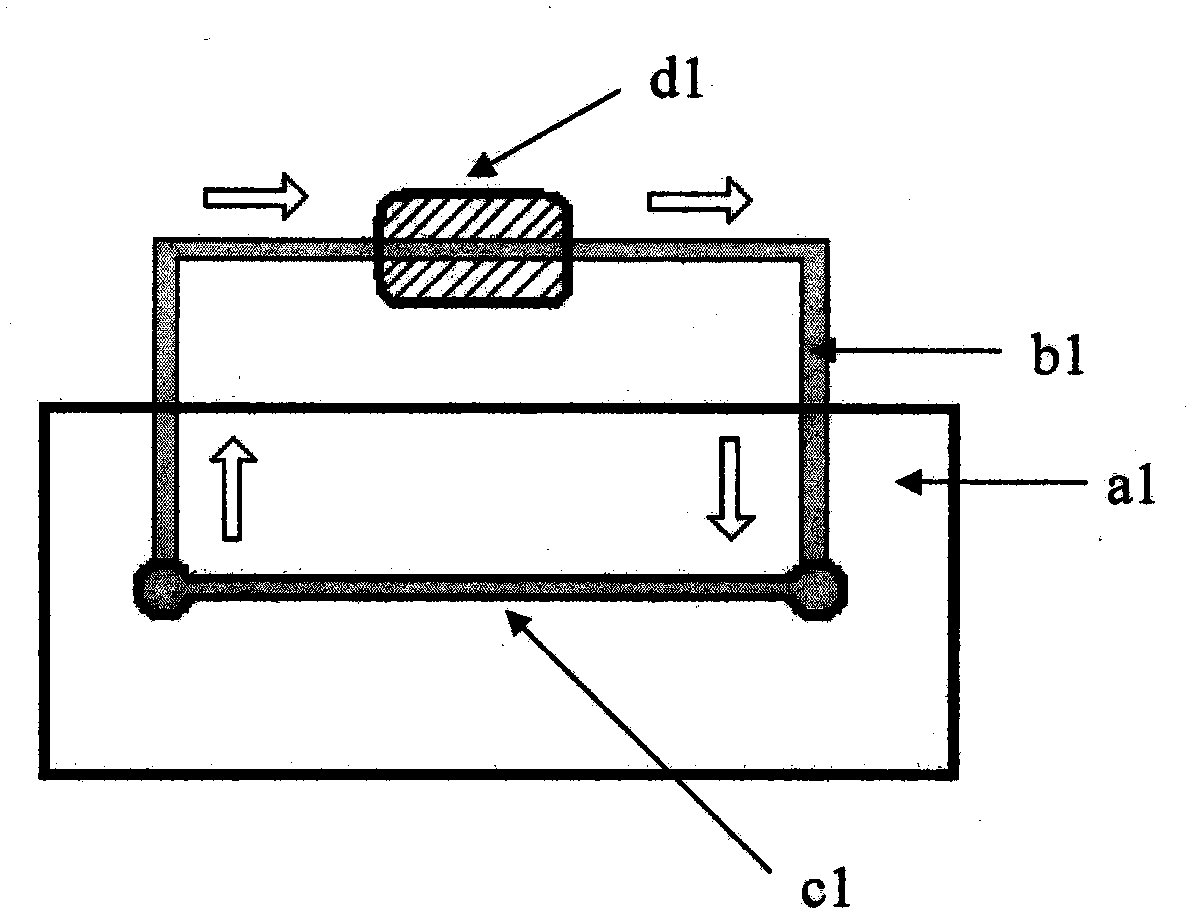

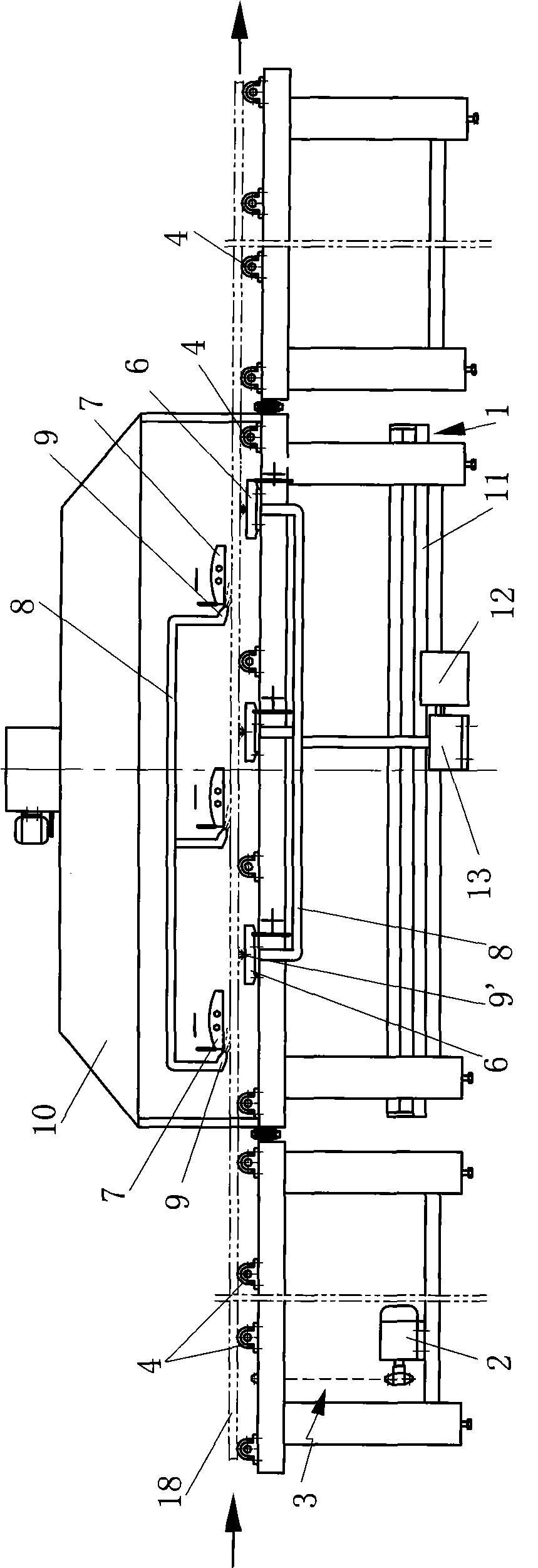

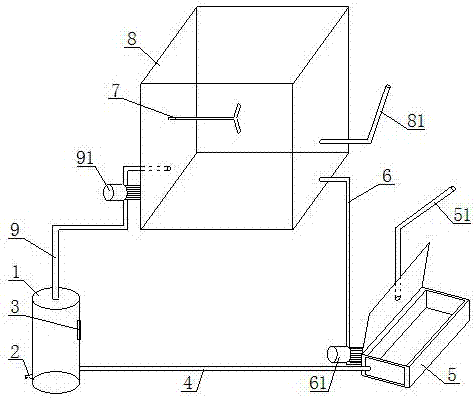

Method for electrolytically etching pictures and text on metal plate and device thereof

ActiveCN101545132AImprove production environmentReasonable structureElectrolysis componentsMetalElectrolyte

The invention discloses a method for electrolytically etching pictures and text on a metal plate and a device thereof. The method comprises the following steps: putting a metal plate with an electrolytically etched picture and text layer on the upper surface on a conveyer roller and moving to an electrolytic region with an upper negative electrode and a lower positive electrode which are arranged to be staggered in the vertical direction; simultaneously jetting electrolyte in a gap between the upper surface of the metal plate and the negative electrode along the moving direction of the metal plate and a gap between the lower surface of the metal plate and the positive electrode; and applying voltages on the positive electrode and the negative electrode so that the electrolytic etching region on the upper surface of the metal plate is electrolytically etched. The device comprises a stand, a motor, a transmission device, the conveyer roller, the positive electrode, the negative electrode, an electrolyte pipeline, an upper nozzle and a lower nozzle. The invention hardly generates short circuits and has high etching efficiency, high radiation speed and reasonable structure.

Owner:常州正成机电科技有限公司

Recovery system of mould corrosive wash solution, namely sodium hydroxide

InactiveCN107055573ALow production costImprove etching efficiencyAlkali metal oxides/hydroxidesBlowoff valveSludge

The invention discloses a recovery system of a mould corrosive wash solution, namely sodium hydroxide. The system comprises a storage container, a mould boiling container and a reaction tank. A blowoff valve is arranged on the bottom of one side of the storage container, the other side of the storage container is connected with a liquid inlet of the mould boiling container through a pipe line I, an air discharging pipe is arranged on a top cover of the mould boiling container, the reaction tank is of a hollow structure with an opening in the top, stirring blades are arranged in the reaction tank, a liquid inlet in one side of the reaction tank is connected with a liquid outlet of the mould boiling container through a pipeline II, a conveying pump I is arranged on the pipeline II, an air inlet pipe is located at the position, above the pipeline II, of the reaction tank, a liquid outlet in the other side of the reaction tank is connected with a liquid inlet in the top of the storage container through a pipeline III, and a conveying pump II is arranged on the pipeline III. According to the recovery system, the sodium hydroxide solution containing NaAlO2 is converted into a sodium hydroxide solution which can be utilized again and dry sludge obtained through aluminum hydroxide sedimentation, the system saves more energy and is more environmentally friendly, and the corrosive wash efficiency of an extrusion mould is effectively improved.

Owner:JIANGSU JIALV IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com