Jet nozzle structure of sand ejector

A sandblasting machine and nozzle technology, applied in the direction of spray guns, explosion generating devices, abrasives, etc., can solve problems such as inconsistent directions, reduced effect of etching PDP panels, and lateral etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

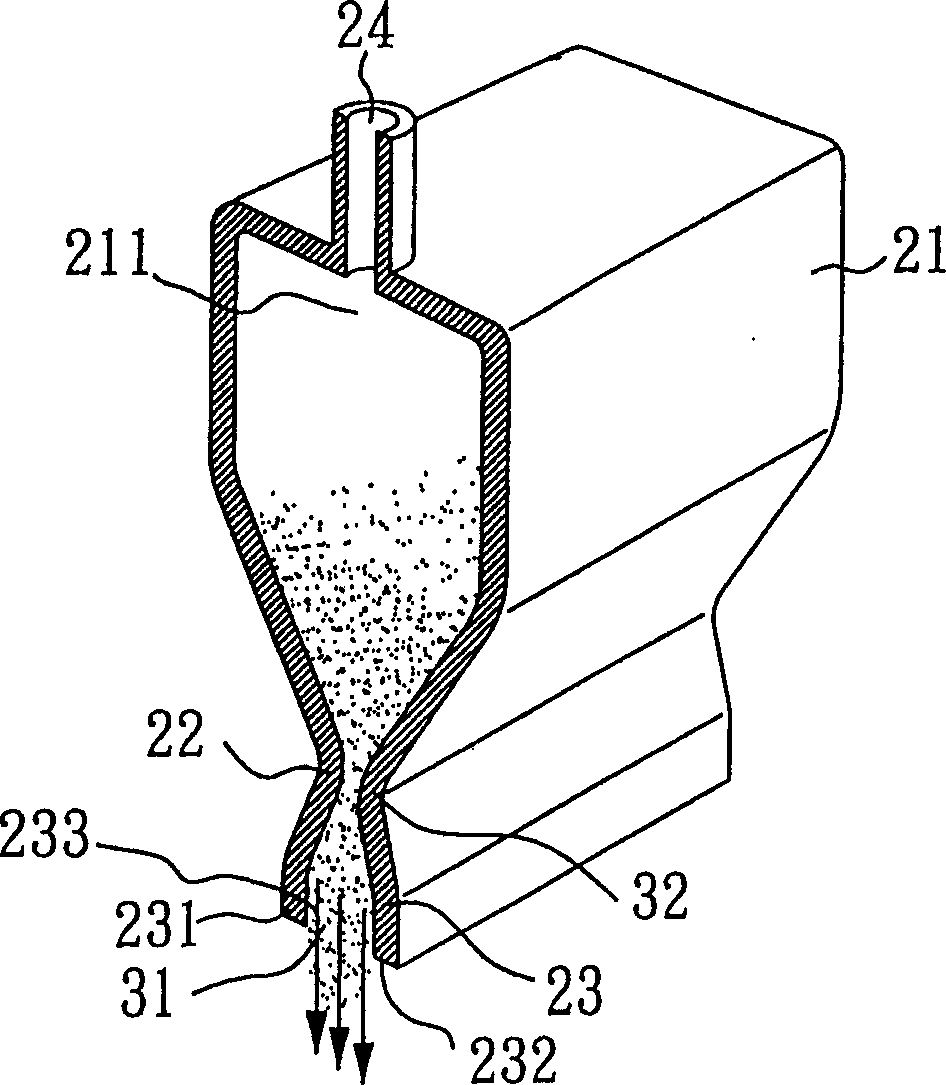

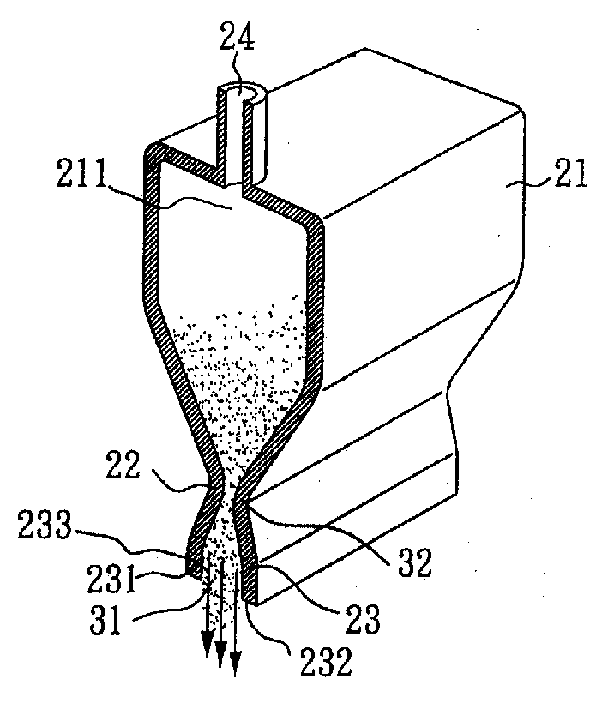

[0010] For preferred embodiments of the present invention, please refer to figure 2 The schematic diagram of the nozzle structure shown mainly includes an input part 21, a throat part 22 and an output part 23, wherein the throat part 22 is formed by extending the bottom end of the input part 21, and the output end 23 is formed by extending the bottom end of the throat part 22. The output end 23 includes a first output wall 231 and a second output wall 232, the first output wall 231 and the second output wall 232 are flat, and there is an output channel 31 between the first output wall 231 and the second output wall 232 . In this embodiment, the shape of the input portion 21 is wide at the top and narrow at the bottom, so that the throat 22 extending from the bottom of the input portion 21 has a narrow channel 32 .

[0011] The above-mentioned input part 21 is connected with a conveying pipe 24 with an input port 211, so that the grinding material (sand material) provided by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com