Recovery system of mould corrosive wash solution, namely sodium hydroxide

A sodium hydroxide and recovery system technology, applied in the direction of alkali metal oxides/hydroxides, inorganic chemistry, alkali metal compounds, etc., can solve problems such as environmental pollution, reduce production costs, improve the environment, and improve corrosion cleaning efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

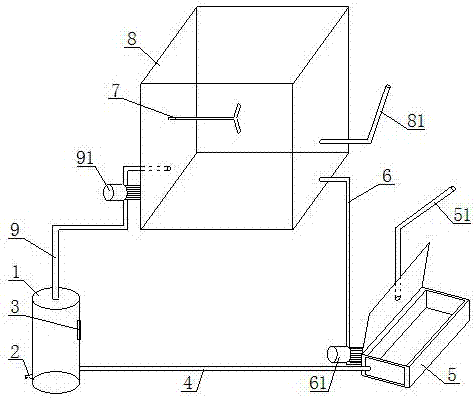

[0014] Such as figure 1 As shown, a recovery system for mold etching solution sodium hydroxide includes a storage container 1, a mold cooking container 5 and a reaction pool 8, the bottom of one side of the storage container 1 is provided with a drain valve 2, and the other side of the storage container 1 Be connected with the liquid inlet of mold boiling container 5 by pipeline I4, be provided with exhaust pipe 51 on the top cover of boiling mold container 5, reaction pool 8 is the hollow structure of top opening, is provided with stirring blade 7 in reaction pool 8, stirs The shaft end of the blade 7 passes through the reaction tank 8 and is driven by a motor. The liquid inlet on one side of the reaction tank 8 is connected to the liquid outlet of the mold cooking container 5 through the pipeline II6. The pipeline II6 is provided with a delivery pump I61, which is located in the pipeline II6 The upper reaction tank 8 is provided with an air intake pipe 81, and the liquid out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com