Etching liquid system and etching method of aluminum nitride substrate

A technology of etching solution and system, which is applied in chemical instruments and methods, surface etching compositions, semiconductor/solid-state device manufacturing, etc., can solve the problems of low practicability and few etching methods, and achieve strong etching ability and high High-precision etching and high-quality etching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 etching solution system

[0037] The formula of the first etching solution is as follows in Table 1.

[0038] Table 1 The mass percent of each component of the first etching solution

[0039]

[0040] The configuration raw material of the first etching solution:

[0041] The ammoniacal liquor selects the ammoniacal solution of 5%-15% mass fraction for use;

[0042] The strong oxidant is selected from 20%-40% mass fraction of hydrogen peroxide solution or potassium permanganate solution / potassium permanganate configuration to achieve the same effect;

[0043] The complexing agent is an amino hydroxy acid salt compound, including one or more of sodium nitrilotriacetate, ethylenediaminetetraacetic acid salt, and diethylenetriaminepentacarboxylate, and the complexing agent with a mass fraction >95% is selected. agent.

[0044] The first etching solution configuration steps are as follows:

[0045] Add pure water into the glass contain...

Embodiment 2

[0056] Embodiment 2 The etching method of aluminum nitride ceramic substrate

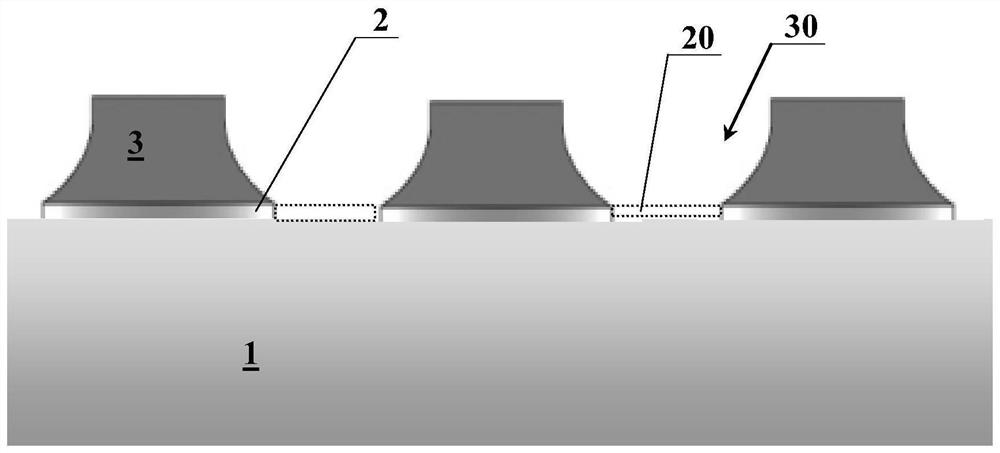

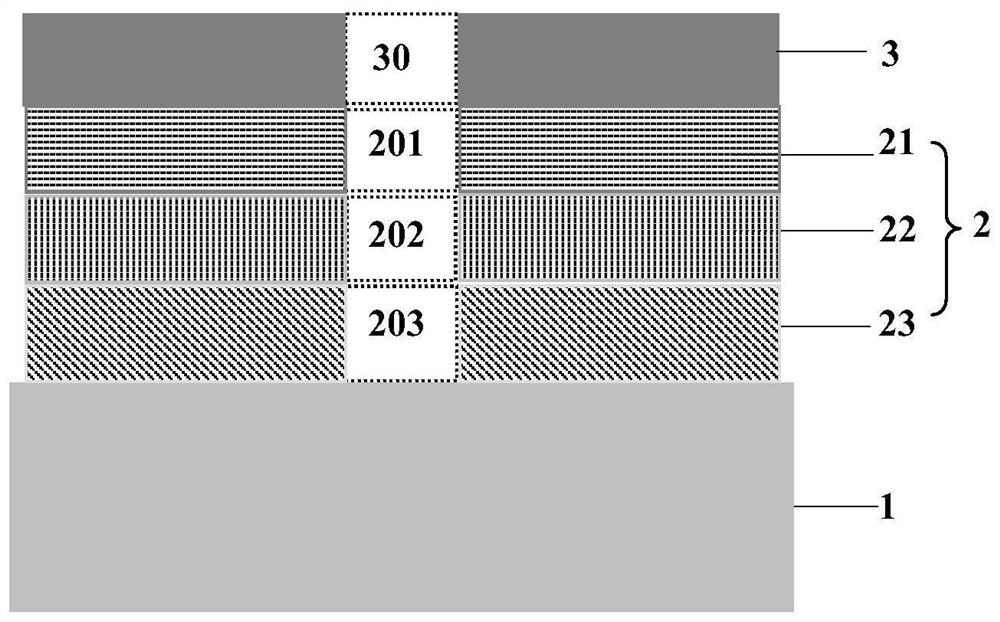

[0057] The structure of the etched aluminum nitride ceramic substrate is as follows: figure 1 As shown, the aluminum nitride substrate 1 is followed by a solder joint layer 2 and a copper foil 3 , and the solder joint layer 2 and copper foil 3 have a solder joint layer etched area 20 and a copper foil etched area 30 that need to be removed by etching. Such as figure 2 As shown, the solder bonding layer 2 includes a copper-silver eutectic layer 21 , a nitrogen-titanium reaction layer 22 and an aluminum-titanium intermetallic compound 23 , and the corresponding etching regions are 201 , 202 and 203 respectively.

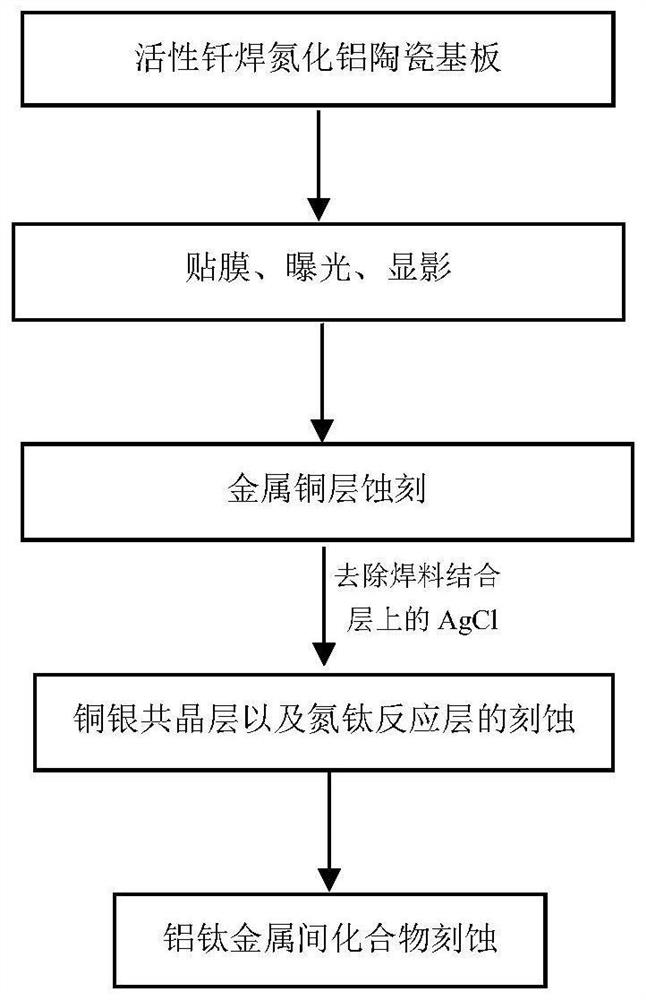

[0058] The etching process of aluminum nitride ceramic substrate is as follows: image 3 shown, including the following steps:

[0059] (a) metal copper layer etching

[0060] After the aluminum nitride ceramic substrate is pasted, exposed, and developed, the exposed metal copper layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com