Method for electrolytically etching pictures and text on metal plate and device thereof

An electrolytic etching, metal plate technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of waste, unfavorable etching interface update, unfavorable circuit board walking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

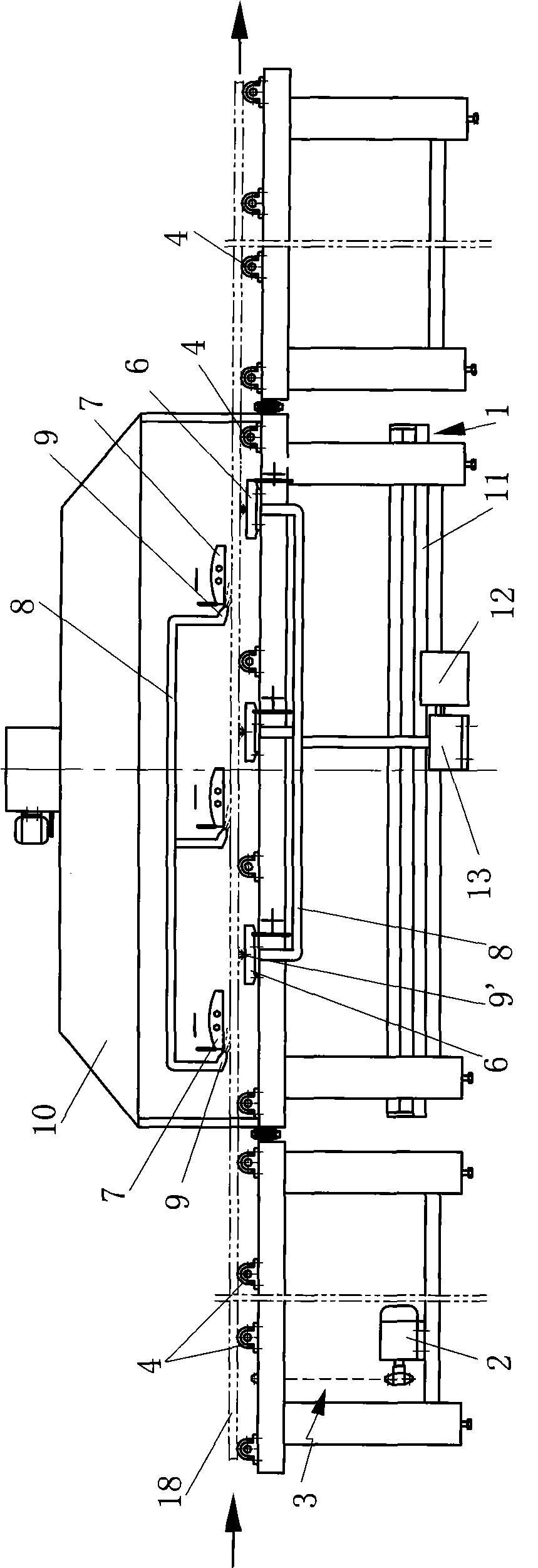

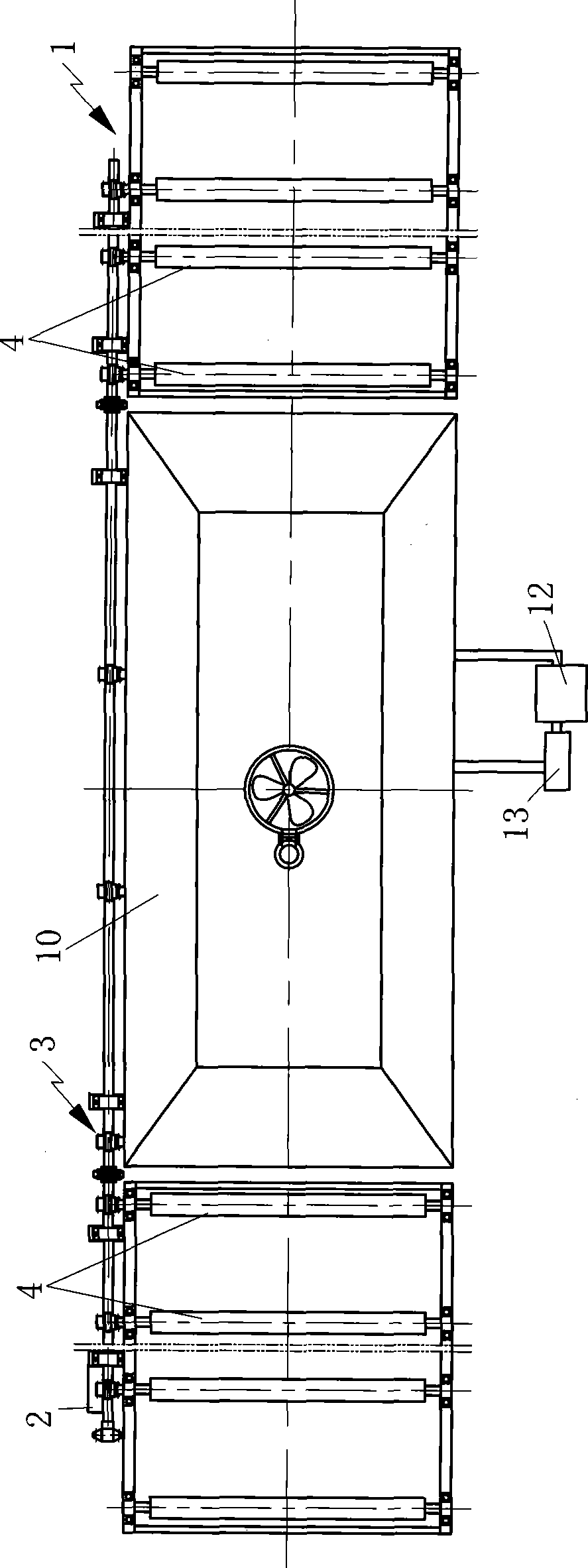

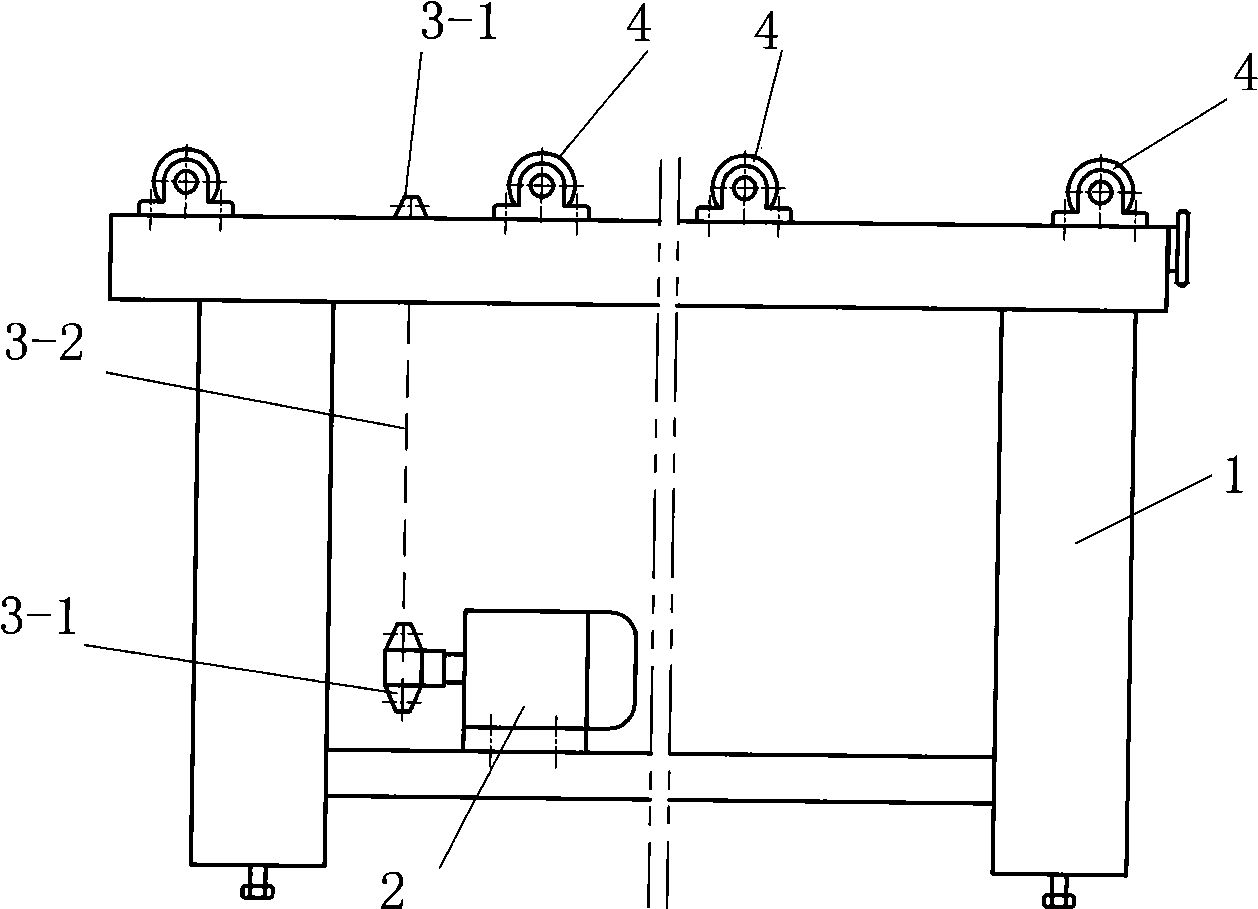

[0026] Such as figure 1 , 2 , 5, and 7, the method for electrolytically etching a metal plate of the present invention includes a method for electrolytically etching a metal plate, including step a. Plate 18 is placed on conveying roller 4 or conveyer belt, b, metal plate 18 is moved to electrolysis zone by conveying roller 4 or conveyer belt, negative electrode 7 of c, electrolysis zone is on, positive electrode 6 is below, and vertical The direction is dislocated, and the metal plate 18 is moved so that the upper surface of the metal plate 18 faces the negative electrode 7 and maintains a certain gap with the negative electrode 7; the lower surface of the metal plate 18 faces the positive electrode 6 and has a gap with the positive electrode 6 Keep a certain gap; d, spray electrolyte solution in the gap between the upper surface of the metal plate 18 and the negative electrode 7 along the moving direction of the metal plate 18; e, simultaneously move toward the gap between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com