Patents

Literature

62 results about "Antimony trisulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimony trisulfide (Sb₂S₃) is found in nature as the crystalline mineral stibnite and the amorphous red mineral metastibnite. It is manufactured for use in safety matches, military ammunition, explosives and fireworks. It also is used in the production of ruby-colored glass and in plastics as a flame retardant. Historically the stibnite form was used as a grey pigment in paintings produced in the 16th century. It is a semiconductor with a direct band gap of 1.8-2.5 eV. With suitable doping, p and n type materials can be produced.

Method for preparing photonic crystal with inverse opal structure through ultraviolet radiation

InactiveCN106381520AWide selection of materialsEasy to prepareFrom gel stateMaterial nanotechnologyMicrosphereRefractive index

The invention discloses a method for preparing photonic crystal with an inverse opal structure through ultraviolet radiation. The method comprises: mixing mono-dispersed colloid microspheres with deionized water, and performing ultrasonic dispersion to form a uniform colloid microsphere dispersion liquid; pre-arranging a substrate in a plastic colorimetric ware, soaking the surface of the substrate with the colloid microsphere dispersion liquid for vertical deposition self-assembly, and obtaining a template of the photonic crystal with an opal structure; adding a refractive index material or a precursor material thereof, such as silica, zinc sulfide, zinc oxide, silver sulfide, titanium dioxide, antimony trisulfide, and alumina dropwise on the template, carrying out natural penetration, and performing drying at the room temperature; and removing the initial template of the photonic crystal with an opal structure in an ultraviolet radiation manner to obtain the photonic crystal with an inverse opal structure on the substrate. The method is simple and is low in cost and wide in material selection range.

Owner:ZHEJIANG SCI-TECH UNIV

Clutch facing piece for automobile and production method thereof

InactiveCN101655128AHigh strengthHigh modulusMixing operation control apparatusCeramic shaping apparatusConductor CoilAntimony trisulfide

The invention discloses a clutch facing piece for an automobile and a production method thereof. The production method comprises the following steps: stirring 10-20% of water soluble phenolic resin, 0.5-1.5% of alumina, 4-8% of crystalline flake graphite, 0.6-1.2% of antimony trisulfide, 6-10% of ground calcium carbonate, 8-12% of chalcopyrite powder, 6-10% of magnetite powder, 3-8% of vermiculitepowder, 12-18% of barium sulfate, 6-15% of powder nitrile-butadiene rubber and water according to parts by weight of each component, preparing suspension, then dipping 15-25% of basalt fibre and obtaining a product by drying, winding, pressing, heat treatment and mechanical processing. By using the invention, the temperature resistance and the wear resistance of the clutch facing piece for the automobile are enhanced, a phenomenon of dust raising in the production and use process is reduced, and the product is more affinitive to the environment.

Owner:十堰法雷诺动力科技有限公司

Mixing fireworks and producing method thereof

A mixed 'firecracker-fireworks' having the effects of firecracker and fireworks and generating 5 colors is prepared from potassium perchlorate, Mg-Al alloy powder, strontium carbonate, phenolic resin, polyvinyl chloride, strontium nitrate, sulfur, glutinous rice flour, etc. Its advantages are simple preparing process, dual effect, multiple color and long perdurability.

Owner:黄远清 +1

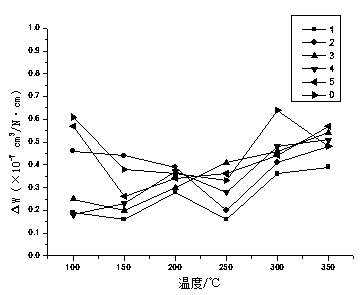

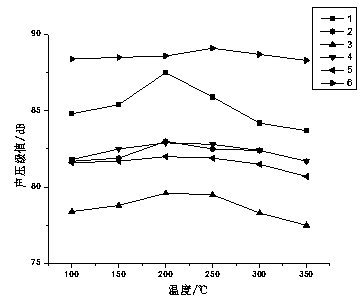

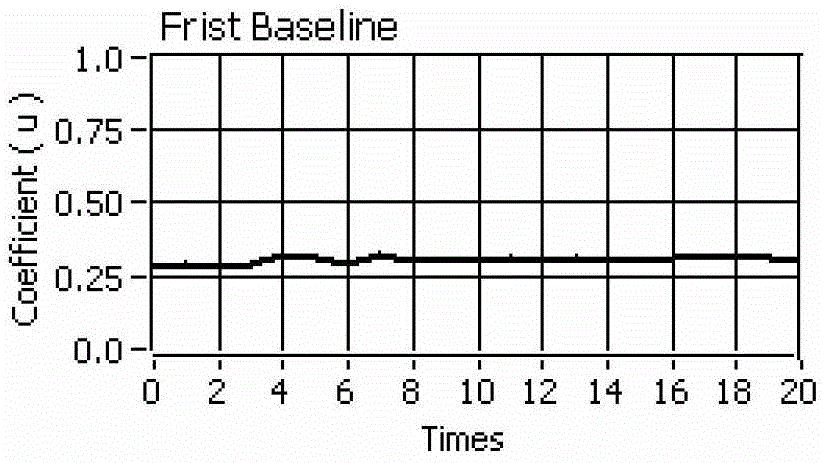

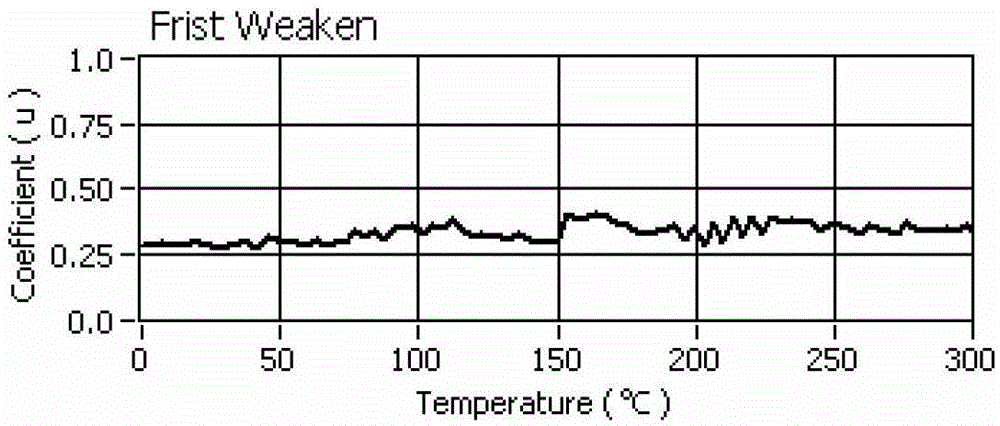

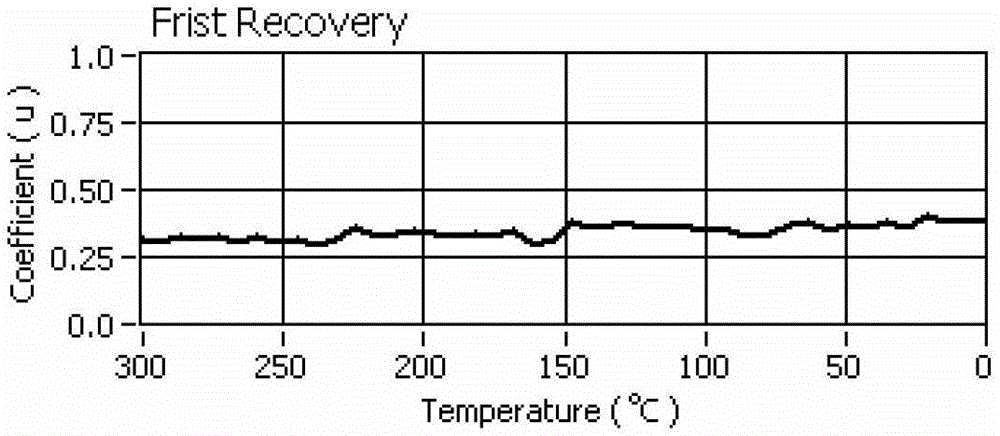

Low-noise heat-fade-resistant resin-base friction material

InactiveCN104109342AStable coefficient of frictionReduce noiseOther chemical processesLow noisePolymer science

The invention discloses a l-noise heat-fade-resistant resin-base friction material which is prepared from the following components in percentage by mass: 10-15% of nano aluminum oxide modified phenol aldehyde resin, 3-6% of aramid fiber pulp, 12-18% of mineral fiber, 5-7% of graphite, 3-5% of antimony trisulfide, 5-7% of coke, 0.5-1.5% of aluminum oxide, 3-5% of ferric oxide, 5-7% of cashew oil friction powder, 3-9% of expanded vermiculite, 2-6% of kieselguhr, 3-9% of nitrile-butadiene rubber and the balance of barium sulfate. The material has the advantages of appropriate and stable friction factor, favorable heat fade resistance, low abrasion ratio, low braking noise, high plastic deformation resistance, high shock resistance and the like, and conforms to the operating requirements.

Owner:YANCHENG INST OF TECH

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

Zirconium oxide modified novel high temperature resistant ceramic car disc brake pad and preparation method thereof

ActiveCN103335044AReduce conductionImprove cooling effectOther chemical processesFriction liningAntimony trisulfideAramid

The invention provides a zirconium oxide modified novel high temperature resistant ceramic car disc brake pad and a preparation method of the brake pad. The brake pad is prepared by the following steps: mixing barium sulfate, red copper fiber, ceramic fiber, zirconium oxide, synthetic graphite, antimony trisulfide, aramid fiber, mica powder, frictional powder, phenolic resin, light calcium carbonate and rubber powder, and putting the mixture into an oven with 70 DEG C to form mixed surface material; preparing steel fiber, synthetic graphite, flake graphite, petroleum coke powder, blanc fixe, porous iron powder, phenolic resin, light magnesium oxide, rubber powder and wollastonite into mixed backing material in the same way; pre-pressing and molding the mixed backing material, the mixed surface material and steel backing on a cold-pressing molding machine, then putting the product into a hot-pressing molding mould, and carrying out hot-pressing molding; after that, putting the product into a heat treatment oven, and carrying out heat treatment; and grinding the surface of the product, processing by other existing steps, and packaging. The zirconium oxide modified novel high temperature resistant ceramic car disc brake pad is free from heat fade, stable in friction coefficient, good in friction performance, stable in brake, sensitive and reliable, low in hardness and low in wear rate.

Owner:武汉市祥龙摩擦材料有限责任公司

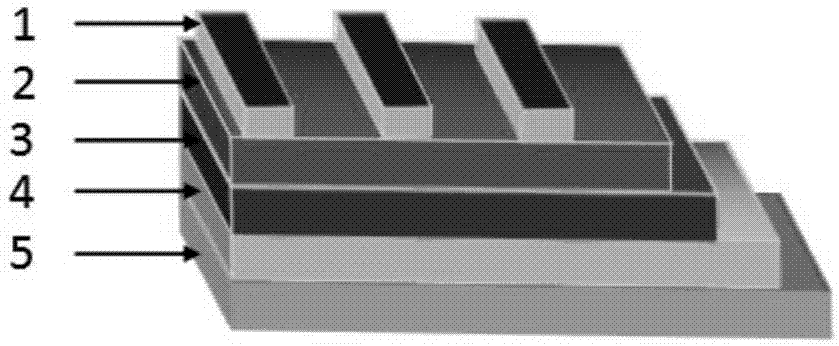

Plane structure hybrid solar cell based on antimony trisulfide compact film

InactiveCN107302057AHigh crystallinityLess miscellaneousSolid-state devicesSemiconductor/solid-state device manufacturingThioureaHole transport layer

The invention discloses a plane structure hybrid solar cell based on an antimony trisulfide compact film, belonging to the field of film materials and devices. The solar cell comprises a transparent conductive substrate, an electron transport layer, a light absorption layer, a hole transport layer and a metal electrode. According to the light absorption layer, SbCl3 and thiourea with the ratio of 1 to 1.5 to 2.5 is used as a precursor, a compact Sb2S3 film is prepared through spin coating, and the thickness range is from 360 nanometers to 1 micron. The compact Sb2S3 film is used as the light absorption layer to form the plane structure hybrid solar cell, the cost is low, the process simple, the mass production is easy, and compared with a mesoporous structure solar cell, the plane structure solar cell based on the Sb2S3 compact film has the advantages of high repeatability and easy improvement of cell efficiency.

Owner:FUZHOU UNIV

Lithium ion battery, cathode material thereof and preparation method

ActiveCN106299316AImprove uniformityGood dispersionCell electrodesSecondary cellsDispersityMass ratio

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a cathode material for a lithium ion battery. The cathode material comprises a nuclear-shell structure with a nuclear layer and a shell layer, the nuclear layer is antimonous oxide, the shell layer is antimony trisulfide, and the mass ratio of the nuclear layer to the shell layer is (0.4-5):1. Compared with the prior art, prepared material powder has good uniformity and dispersity, is simple in preparation process, low in manufacturing cost, short in experimental time, low in environmental pollution and high in yield, and has an excellent industrial application prospect. The lithium ion battery cathode material is high in initial charge-discharge efficiency and specific capacity (reaching 900mAh / g for the first time and current commercial graphite theoretical specific capacity is 372mAh / g) and good in cycle performance, and effectively solves the problems of low initial efficiency and low specific capacity of a current lithium ion battery cathode material.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

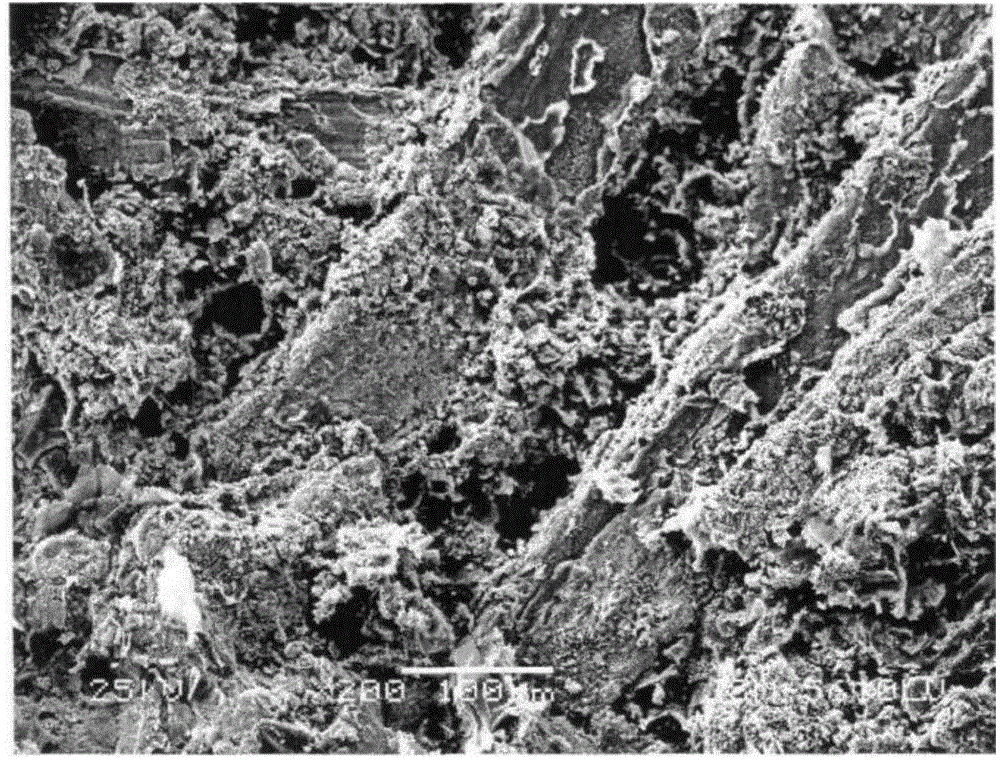

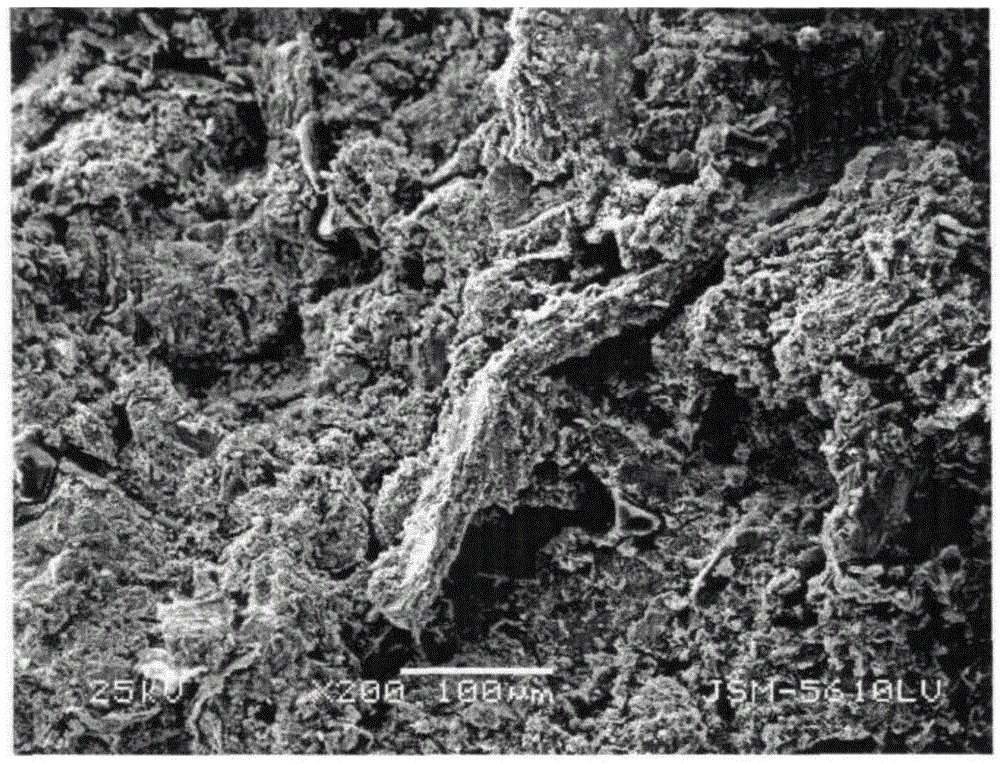

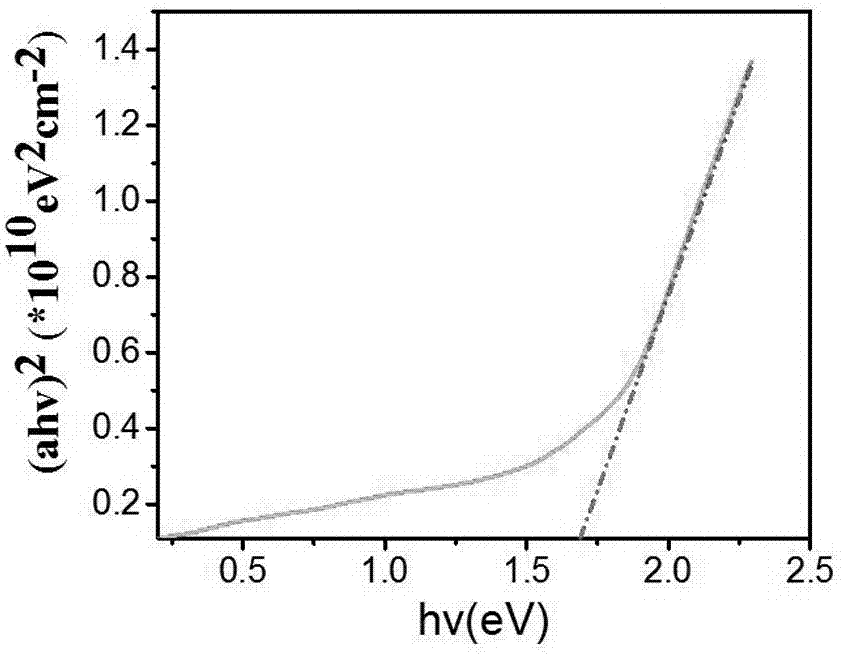

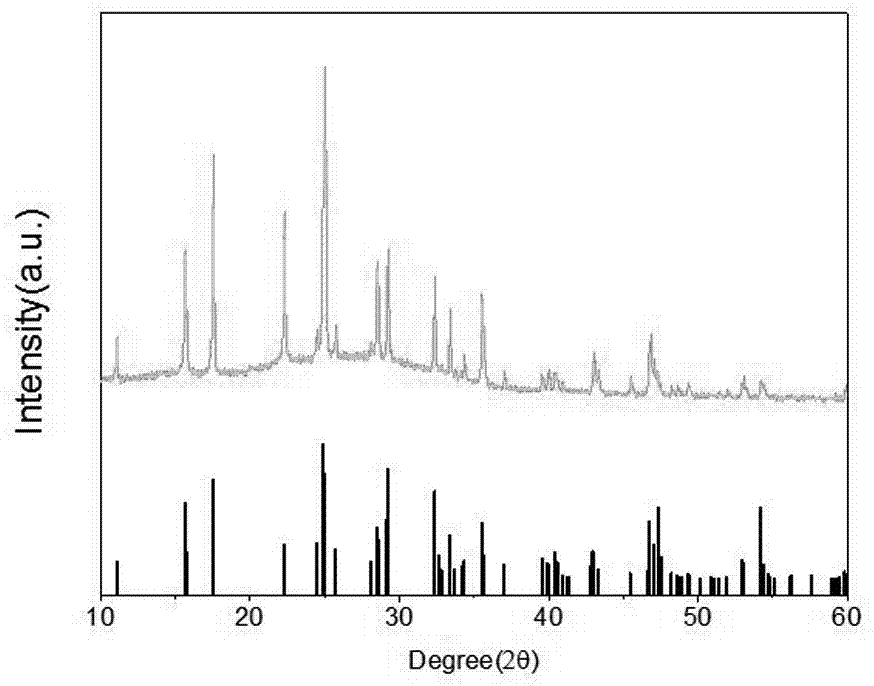

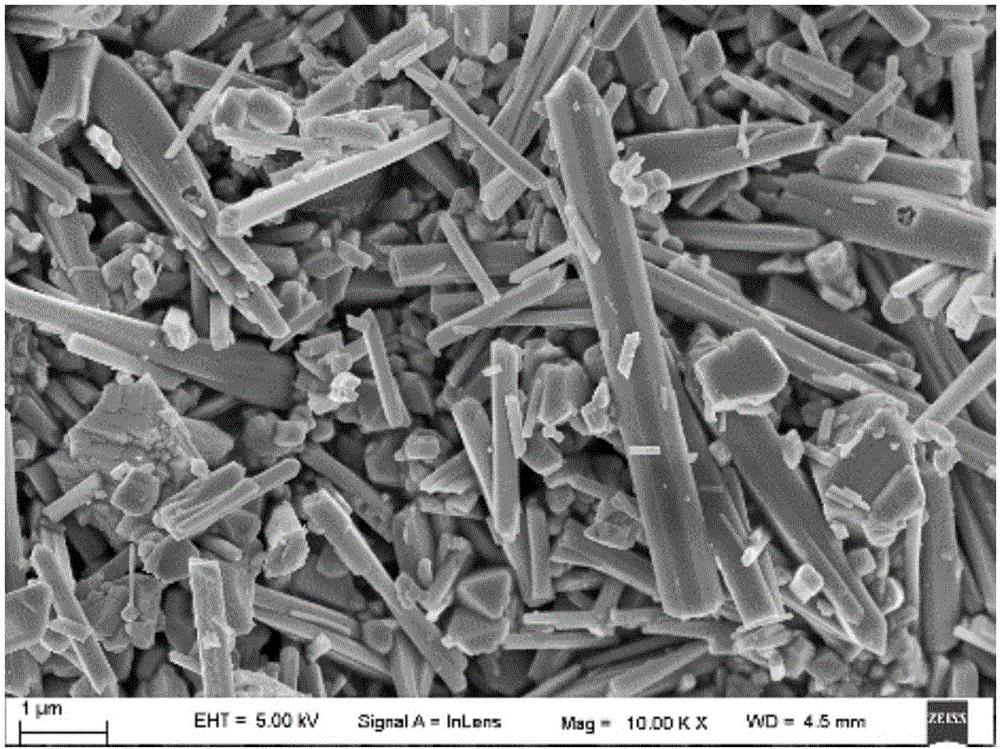

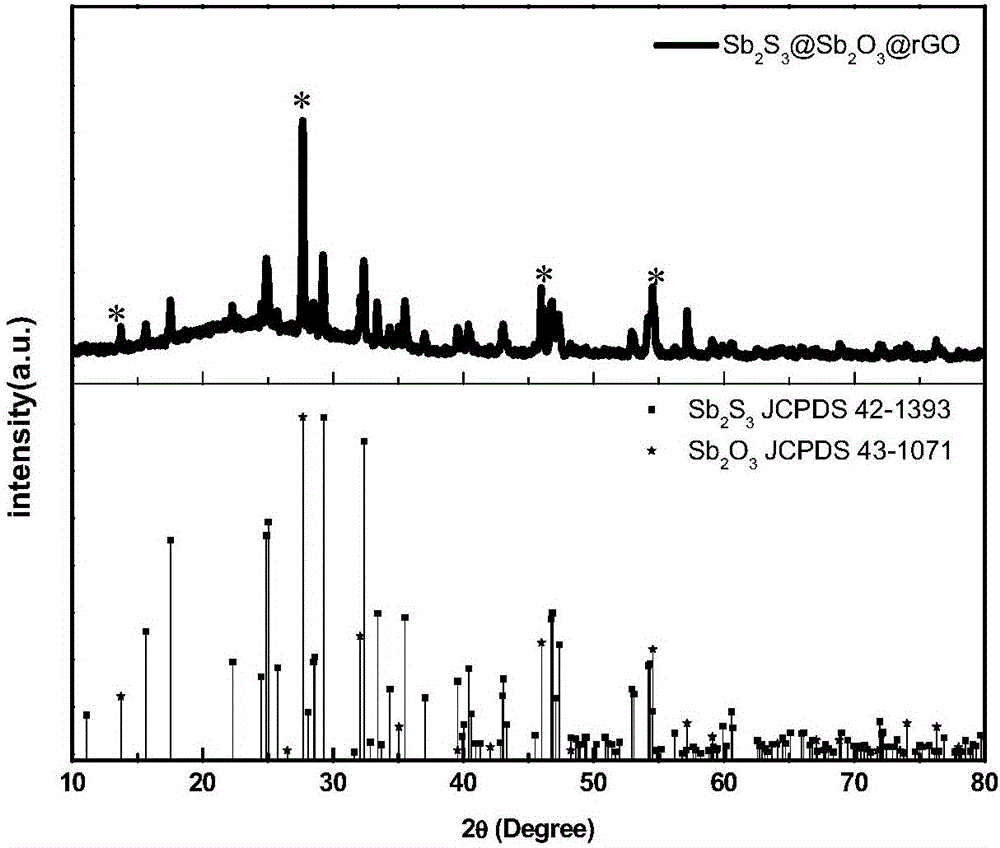

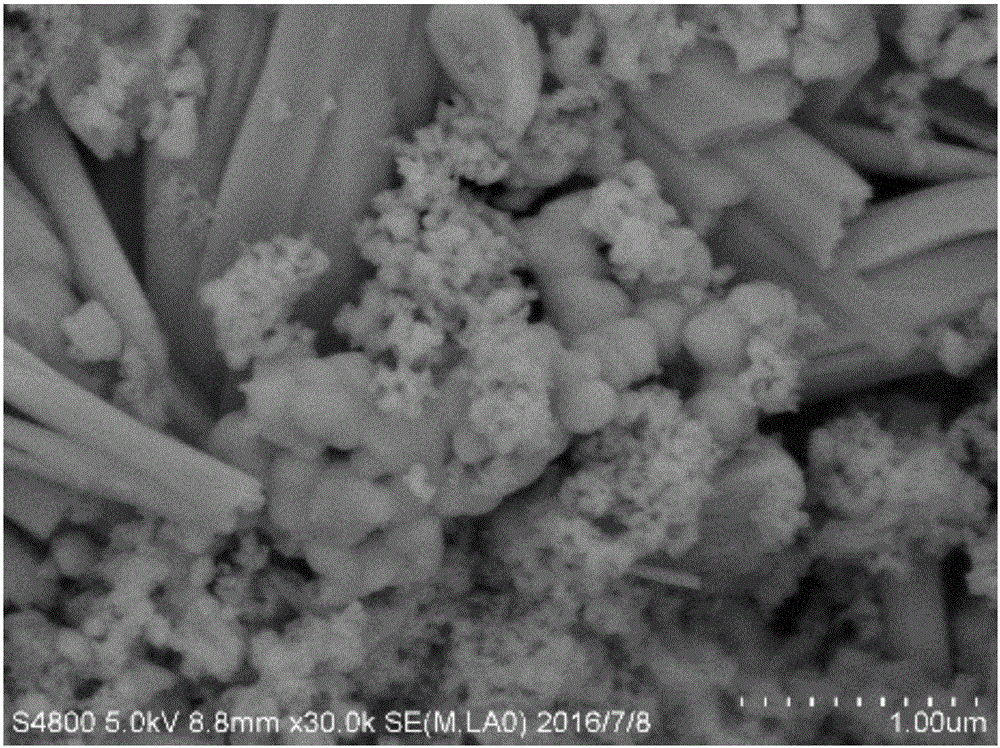

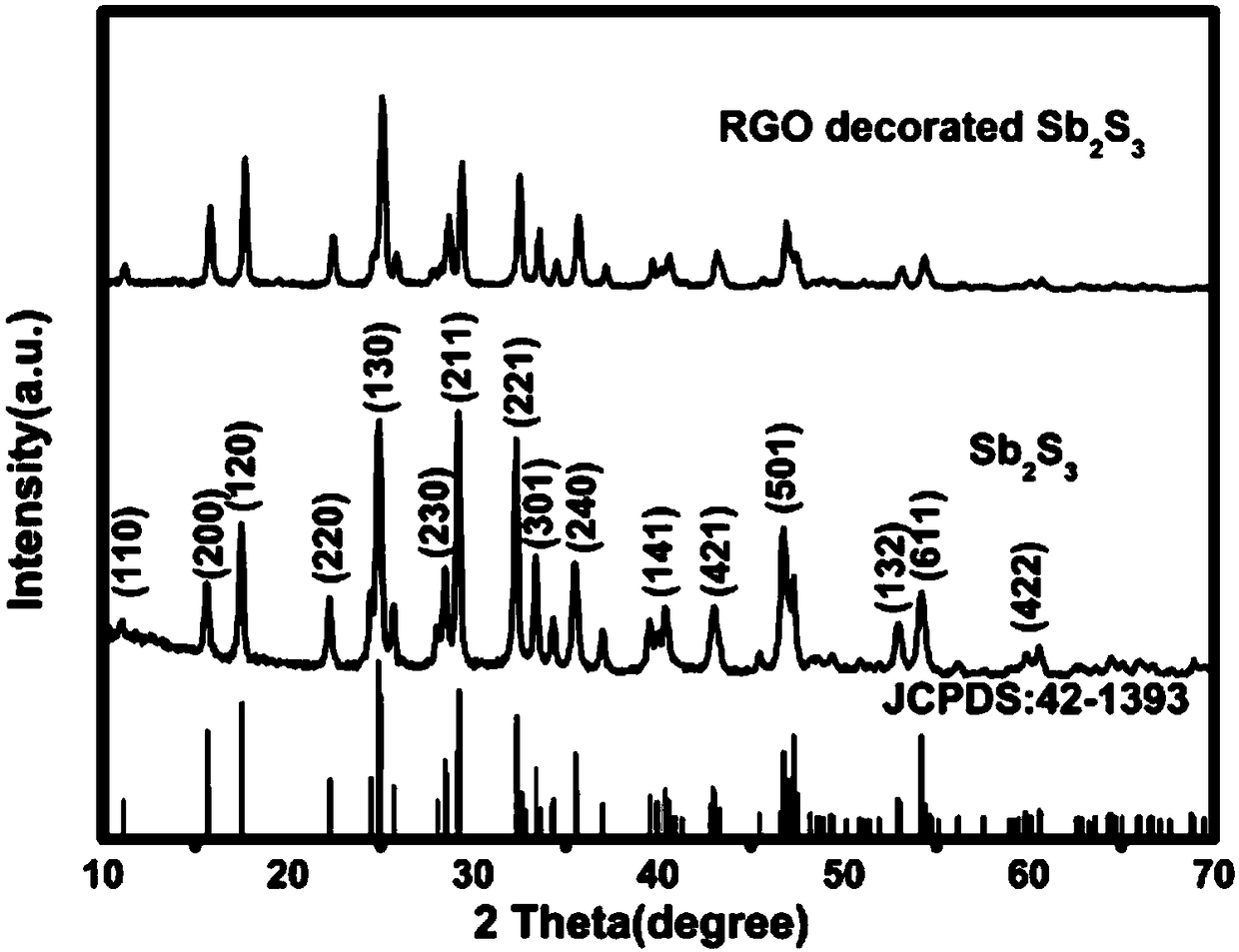

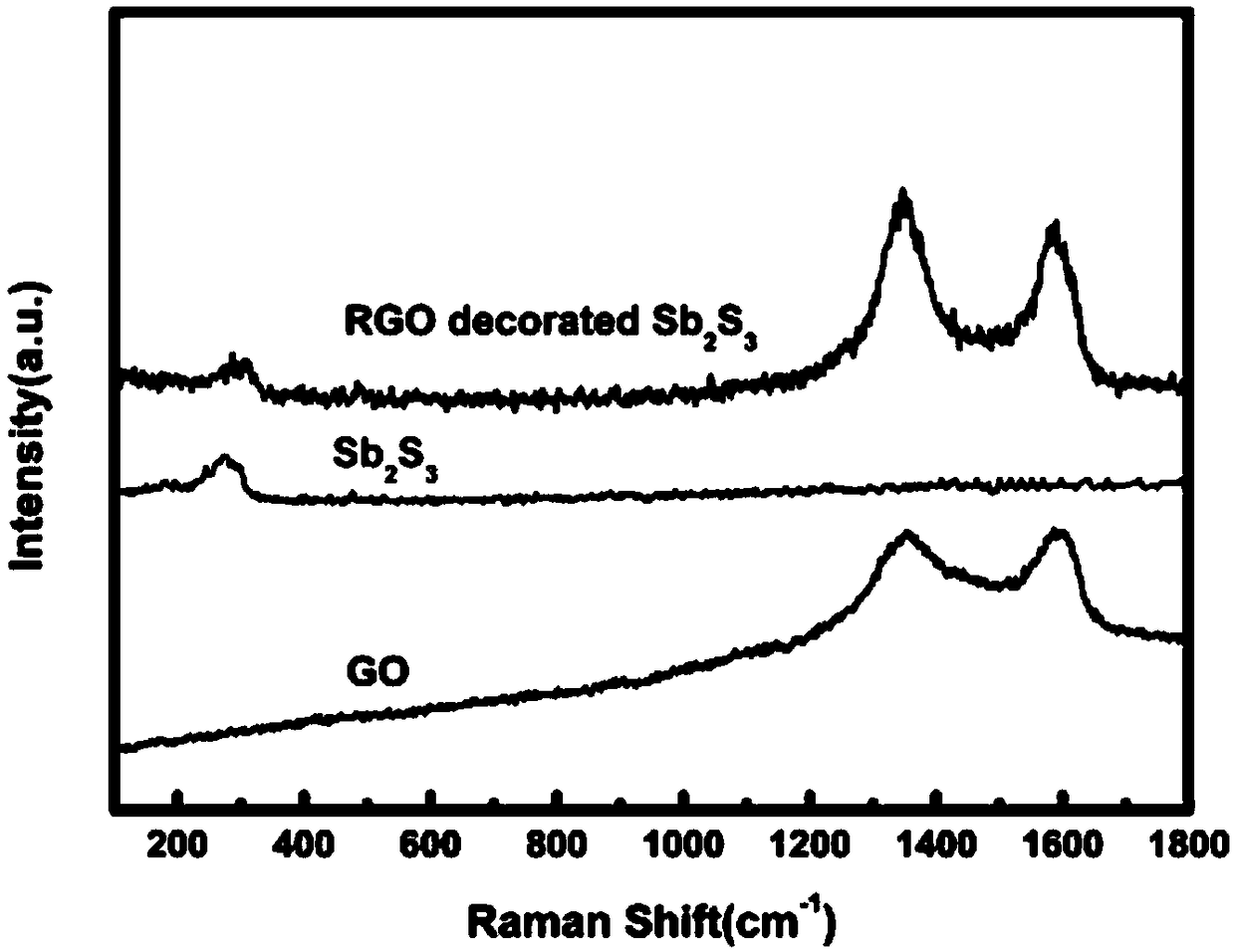

Reduced graphene oxide modified antimony trisulfide battery anode material

ActiveCN108695495AImprove cycle performanceImprove conductivityCell electrodesSecondary cellsRoom temperatureSodium-ion battery

The invention relates to a reduced graphene oxide modified antimony trisulfide battery anode material. The battery anode material is prepared by following steps: (1) adding Sb2S3 powder into anhydrousethanol, then dispersing the solution into a graphene oxide solution, and stirring the mixed solution until the mixed solution becomes uniform and stable to obtain a precursor solution; (2) transferring the precursor solution obtained in the step (1) to a hydrothermal reactor, heating the hydrothermal reactor to carry out reactions, and cooling the reactor to the room temperature to obtain suspension; and (3) filtering the suspension obtained in the step (2), washing, and drying to obtain the target product. Compared with the prior art, an Sb2S3 nano rod is prepared by a hydrothermal method,the preparation method is simple, the process is easy to control, the raw materials are easily available, and the cost is low. The prepared reduced graphene oxide modified Sb2S3 nano composite structure has an excellent electrochemical sodium storage performance and is a good sodium ion battery anode material.

Owner:SHANGHAI UNIV OF ENG SCI

Non-asbestos friction material composition

ActiveUS20160265612A1Great abrasionSuppress generationFriction liningActuatorsMetal fibersAntimony trisulfide

Provided by the present invention are: a non-asbestos frictional material composition containing a binder, an organic filler, an inorganic filler, and a fiber substrate, wherein, in the non-asbestos frictional material composition, content of a copper is 5% or less by mass as a copper element, content of a metal fiber other than a copper fiber and a copper alloy fiber is 0.5% or less by mass, and a titanate salt is contained therein with antimony trisulfide or zinc powders, with content of the titanate salt being in the range of 10 to 35% by mass; and a frictional material and a friction member that use the said non-asbestos frictional material composition.

Owner:RESONAC CORPORATION

Reinforced organic ceramic friction material and preparation method thereof

InactiveCN107502292AStable coefficient of frictionLow friction lossOther chemical processesFriction liningAntimony trisulfideAramid

The invention relates to a reinforced organic ceramic friction material which is prepared from 25.6-27% of polysulfonamide, 5.6-9% of potassium titanate whiskers, 9-12.6% of aramid fiber, 5-7% of copper fiber, 3.4-4% of ceramic fiber, 4-4.6% of zirconite, 3.4-4% of vermiculite, 15-16.4% of graphite, 2.2-3% of carbon black, 2.2-3% of antimony trisulfide, 2.2-3% of magnesium oxide, 1.2-2% of mica, 3.6-4% of nitrile rubber powder and 8-10% of nitrile rubber modified phenolic resin. During preparation, a preparation method comprises the steps: firstly grinding polysulfonamide, the potassium titanate whiskers, the aramid fiber, the copper fiber and the ceramic fiber to form powder; then, grinding zirconite, vermiculite, graphite, carbon black, antimony trisulfide, magnesium oxide and mica to form particles; and finally, mixing the nitrile rubber powder and the nitrile rubber modified phenolic resin with the powder and the particles, and carrying out hot pressing on the mixture to obtain the reinforced organic ceramic friction material. The reinforced organic ceramic friction material is stable in friction performance, low in wear rate, long in service life and free of noise.

Owner:甘肃澜驰汽车配件有限公司

Preparation method of environment-friendly porous rock granular material

ActiveCN104261688ALower the foaming temperatureImprove water absorptionGlass shaping apparatusGlass productionPorosityManganese

The invention relates to a preparation method of an environment-friendly porous rock granular material, which comprises the following steps: carrying out crushing and ball milling on screen glass to obtain CRT (cathode ray tube) screen glass powder; putting the CRT screen glass powder, manganese peroxide, sodium nitrate, lithium nitrate and antimony trisulfide in a ball mill, and carrying out ball milling to form a mixture; adding the mixture into a mold, sending into a roller hearth kiln, keeping the temperature for 5-10 minutes, and heating to 770-780 DEG C at the rate of 4-8 DEG C / minute; heating to 780-790 DEG C at the rate of 0.2-1 DEG C / minute; and cooling to 50-80 DEG C below at the rate of 80-200 DEG C / minute, crushing and screening to obtain the environment-friendly porous rock granular material. The environment-friendly porous rock granular material has the advantages of high strength, high water absorptivity, high aeration porosity, low foaming temperature and low use cost, and can not generate environment pollution in the production and use process. The environment-friendly porous rock granular material can be stored underground as excellent rain water, is a water purification material of rivers, lakes, reservoirs, fish ponds and the like, and can also be used as a heat-insulation fireproof construction material and other novel materials.

Owner:天津仁新玻璃材料有限公司

Ceramic brake pad

InactiveCN106641050AAvoid it happening againGuaranteed cleanlinessOther chemical processesFriction liningAdhesiveNoise reduction

The invention relates to the technical field of automobile parts, in particular to a ceramic brake pad. The ceramic brake pad is prepared from following materials including, by weight, 5-15 parts of adhesive, 23.5-33.5 parts of reinforcing agent, 1-7 parts of friction increasing agent, 11.3-21.3 parts of anti-wear lubricant, 5.7-15.7 parts of elastic flexibilizer, 27.5-37.5 parts of filling agent, wherein the reinforcing agent is formed by mixing the following materials including aramid fiber, ceramic fiber, potassium titanate whisker and calcium carbonate whisker at the weight ratio of 1:8:8:2; the anti-wear lubricant is formed by mixing the following materials including molybdenum disulfide, antimony trisulfide, graphite and calcined petroleum coke at the weight ratio of 1:3.5:1.9:1.75; the adhesive is formed by mixing the following materials including nano-rubber powder and butadiene-arylonitrile modified phenolic resin at the weight ratio of 4:6.5. The unit cost of products is lowered, the effect of noise reduction is achieved, and the impact strength of products is improved.

Owner:福建安翔汽车配件有限公司

Locomotive flame retardant and heat resistant cable material and preparation method thereof

InactiveCN104804281AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsLow-density polyethyleneHexafluoropropylene

The invention discloses a locomotive flame retardant and heat resistant cable material and a preparation method thereof. The locomotive flame retardant and heat resistant cable material is prepared from the following raw materials in parts by weight: 78-94 parts of LDPE, 33-51 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 11-17 parts of 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, 16-22 parts of waste glass powder, 10-15 parts of brucite powder, 3-6 parts of diglycolamide oleate borate, 4-8 parts of antimony trisulfide, 3.5-5 parts of erucyl amide, 2-4 parts of oxidized polyethlene wax, 1.5-2.5 parts of TMPTO, 17-23 parts of a composite flame retardant, 2-3 parts of lead oxide phosphite hydrate, 1-2 parts of cerium isooctanoate, 1-2 parts of pentachlorodiphenyl and 2-3 parts of methyl 4-tert-butylbenzoate. The prepared cable material is highly flame retardant and heat resistant, has the flame retardant effect during the use, can work for a long time under a high temperature condition, is prevented from softening and deforming, is good in use effect and long in service life, and meets the demand of high performance of locomotive cables.

Owner:ANHUI KANGLIYA CO LTD

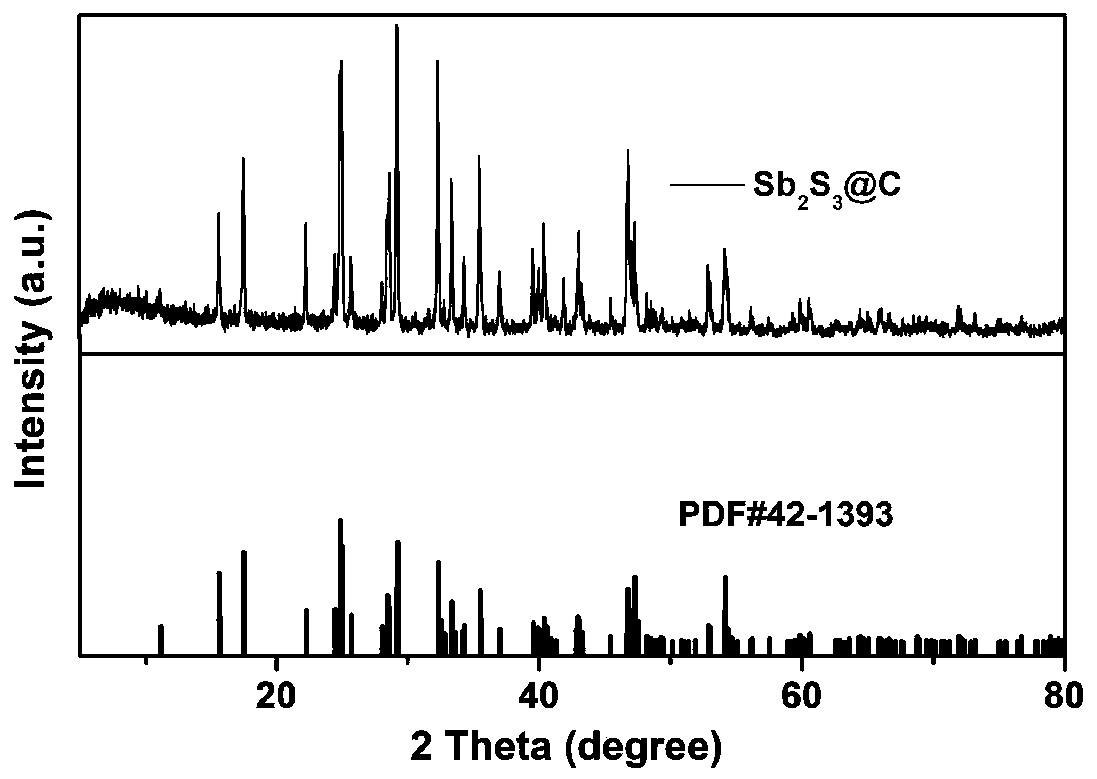

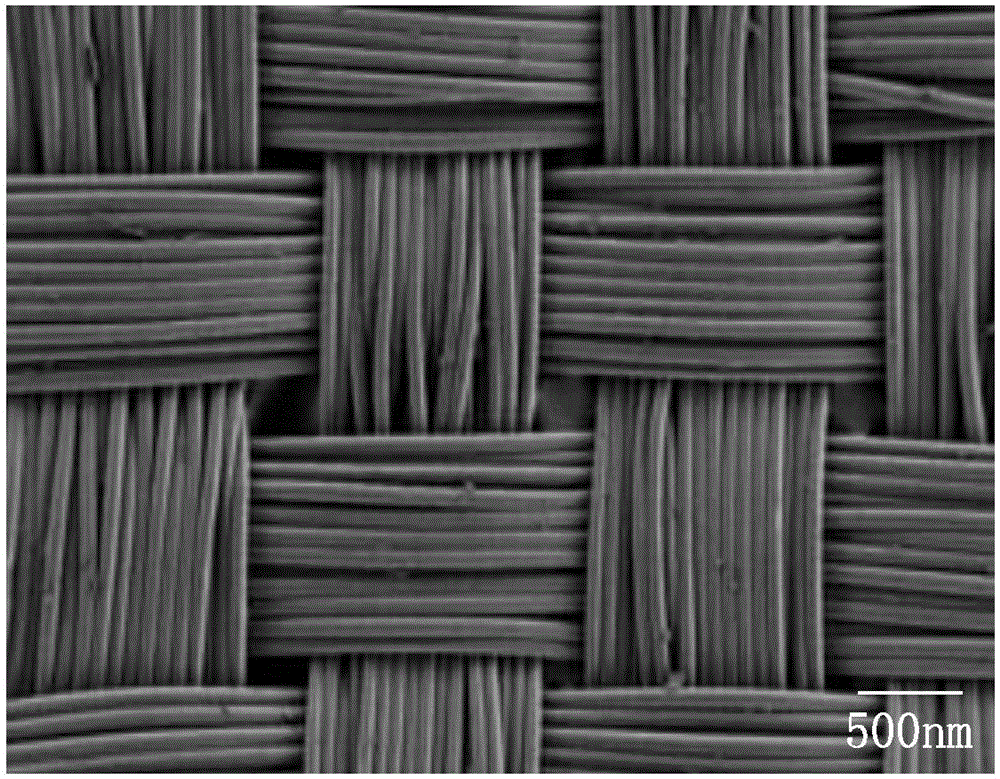

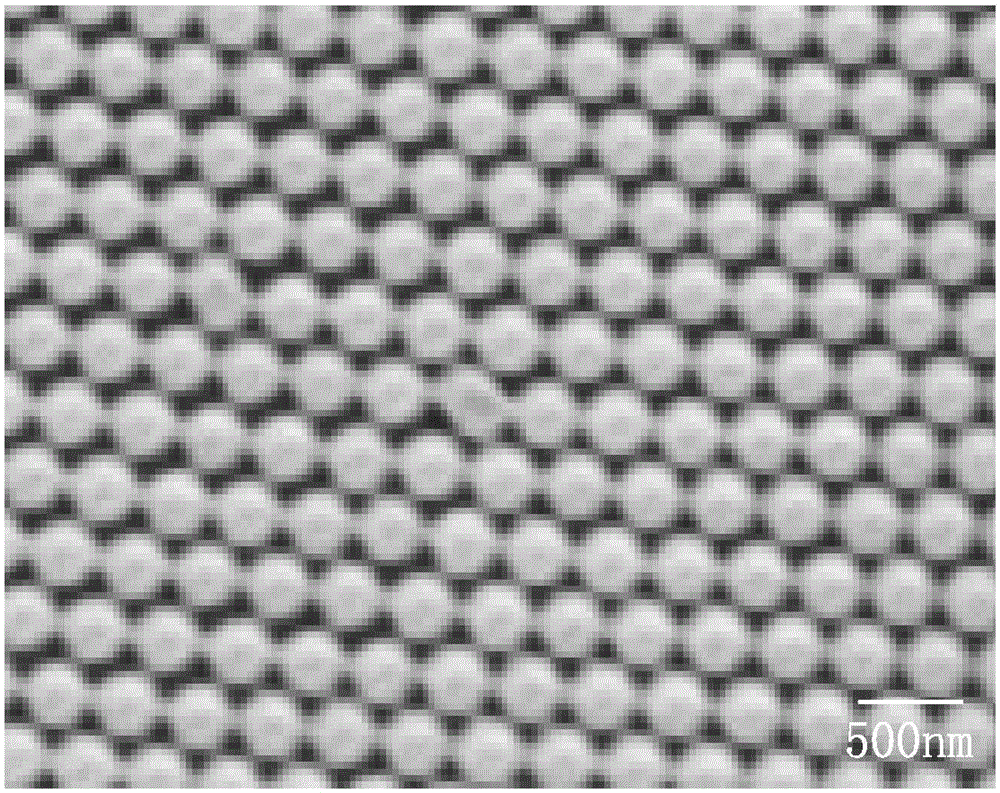

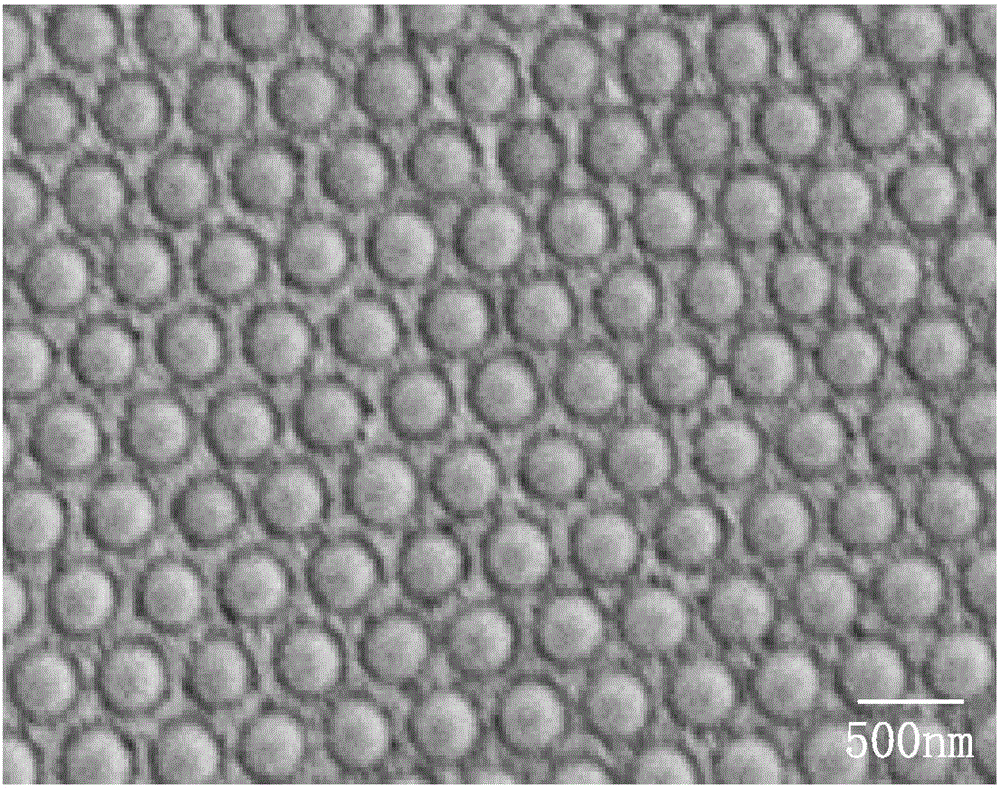

ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof

ActiveCN110931739AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyTin compoundsHydrogen atmosphereArgon atmosphere

The invention belongs to the technical field of batteries, and discloses a ZnS / SnS / antimony trisulfide [at] C hollow nanocube structure composite material, and a preparation method and application thereof. The composite material is prepared by the following steps: mixing water, tin tetrachloride, sodium citrate, zinc chloride and sodium hydroxide, washing with water, and drying to obtain H-ZHS; ultrasonically dispersing H-ZHS in an aqueous solution, adding sodium hydroxide or potassium hydroxide for etching, adding dopamine, stirring, washing with water and drying to obtain H-ZHS[at]PDA; adding H-ZHS[at]PDA and thiourea; vulcanizing in a hydrogen atmosphere at the temperature of 300-350 DEG C; cooling to room temperature, mixing the obtained H-SnS<2> / ZnS[at]PDA, antimony trichloride and absolute ethyl alcohol, carrying out hydrothermal reaction at 90-120 DEG C, washing with water, drying, carbonizing the obtained H-ZnS / SnS<2> / Sb<2>S<3>[at]PDA in an argon atmosphere at 500-530 DEG C, and cooling to room temperature, so as to obtain the H-SnS<2> / Sb<2>S<3>[at]PDA.

Owner:GUANGDONG UNIV OF TECH +1

Antimony trisulfide nanodot/sulfur-doped carbon composite material, preparation method thereof and application of antimony trisulfide nanodot/sulfur-doped carbon composite material to sodium/potassium ion battery

ActiveCN110729478AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCarbon compositesNanodot

The invention discloses an antimony trisulfide nanodot / sulfur-doped carbon composite material, a preparation method thereof and application of the antimony trisulfide nanodot / sulfur-doped carbon composite material to a sodium / potassium ion battery. Sb2S3 nanodots are uniformly distributed in pores and on the surface of sulfur-doped carbon, so that the composite material can be formed. According tothe preparation method, an organic antimony salt is placed in a reducing atmosphere so as to be subjected to reduction treatment, so that an antimony nanodot / carbon composite material can be obtained; the antimony nanodot / carbon composite material and a sulfur source are arranged in a protective atmosphere so as to undergo a solid-phase reaction, so that the antimony trisulfide nanodot / sulfur-doped carbon composite material can be formed. The Sb2S3 of the composite material is a nano point material; the nano point material has a unique volume effect, a surface effect, a quantum size effect, amacroscopic quantum tunnel effect and the like and can effectively enhance the electrochemical properties of the composite material; the sulfur-doped carbon carrier can enhance the conductivity of the composite material and can relieve the large volume expansion of the antimony trisulfide material in a charging / discharging process. The antimony trisulfide nanodot / sulfur-doped carbon composite material presents characteristics such as high capacity and favorable cycle stability when being used for sodium-ion and potassium-ion batteries.

Owner:CENT SOUTH UNIV

All-solid sodium secondary battery electrolyte and preparation method and application thereof

The invention provides an all-solid sodium secondary battery electrolyte and a method and application thereof. The all-solid sodium secondary battery electrolyte is prepared from a first component anda second component, wherein the first component is selected from Na2S (sodium sulfide) and / or Na2Se (disodium selenide); the second component is selected from one or multiple of Sb2S3 (antimony trisulfide), Sb2Se3 (antimony triselenide), Sb2S5 (antimony pentasulfide), Sb2Se5 (antimony pentaselenide), P2S5 (phosphorus pentasulfide), P2S3 (phosphorus trisulfide), As2S3 (arsenic trisulfide), As2S5 (arsenic pentasulfide), S (sulfur), Se (selenide), SnS2 (selenide disulfide), SiS2 (silicon disulfide), SnS (selenide sulfur), GeS2 (germanium disulfide) and GeS (germanium sulfide); the granularity ofthe all-solid sodium secondary battery electrolyte is 10nm to 10mum; the raw materials also comprise doping matters, and the doping matters are selected from one or multiple of a third component, oxide and halide; the third component and the second component are different. The all-solid sodium secondary battery electrolyte has the advantages that the sodium ion conductivity is higher in an all-solid sodium secondary battery; the electrochemical window is broader; the all-solid sodium secondary battery prepared by the electrolyte has good rate and cycle properties.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Production method of multi-copper-wire non-asbestos clutch panel

InactiveCN108679129ANo wear rateNon-irritatingOther chemical processesFriction liningIrritationCopper wire

The invention discloses a production method of a multi-copper-wire non-asbestos clutch panel. The production method comprises the following raw materials in parts by weight, 15-25 parts of copper wirereinforcing bodies, 2-4 parts of thickening agents, 3-4 parts of tackifying resins, 16-35 parts of adhesives and 40-60 parts of fillers, wherein the mixed specific gravity of monopotassium phosphate,calcium sulfate, magnesium sulfate, zinc sulfate, aluminum oxide, flake graphite, antimony trioxide, heavy calcium carbonate, chalcopyrite powder, magnetite powder, vermiculite powder and barium sulfate in the fillers is 3:2:1:2:1:1:3:2:1:4:2:3. According to the production method, the specific gravity of each component is strictly controlled, a traditional clutch panel formula is changed, and thecomprehensive performance of the clutch panel is greatly improved; the manufacturing process is simple, and the temperature environment is ensured; the heat resistance is good and can reach more than350 DEG C, the high temperature friction coefficient is stable and the wear rate is low; and the product-related production process has no irritation to a human body.

Owner:来安县隆华摩擦材料有限公司

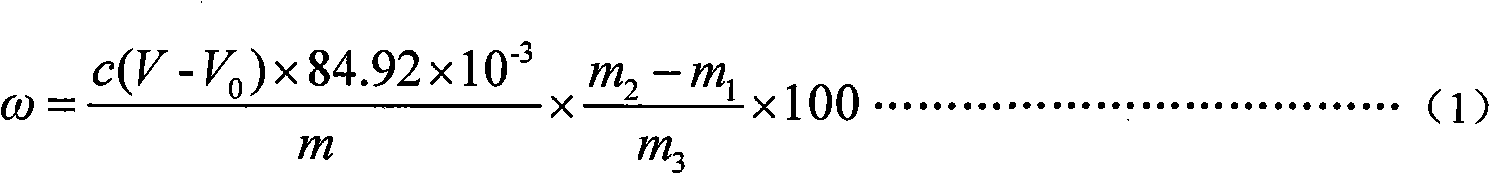

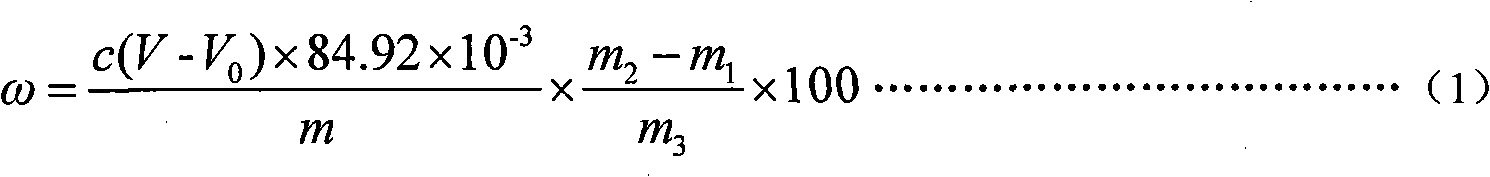

Analysis method of antimony trisulfide in mixed agent for firecracker

InactiveCN102072905ASimple methodEasy to operateMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationPhosphoric acidAntimony trisulfide

The invention discloses an analysis method for measuring Sb2S3 in a mixed agent for firecracker. The analysis method comprises the steps of: with civil firecracker as a raw material, forming the best measuring conditions by detaching the firecracker for sampling in a dry environment, grinding, screening with a sieve of 120 meshes, and drying; weighing a sample, washing potassium perchlorate, sulphur and organic binder components in the sample by respectively using hot water, carbon bisulfide and acetone, and drying for later use; weighing a sample, adding 12ml of hydrochloric acid and 5ml of phosphoric acid, covering a watch glass, slowly heating the sample on an electric furnace by shaking simultaneously until the solution boils slightly, removing the watch glass, and keeping the solution boiling slightly until the color of the solution becomes yellowish and transparent; adding 30-35ml of boiling water, shaking uniformly, dripping two drops of methyl orange indicator, titrating the solution with a potassium bromate standard solution until the solution becomes reddish, adding one drop of the indicator, and titrating until the solution fades. The method has the advantages of less interference and high accuracy, and can meet the requirements in industrial production. The method can also be used for measuring the content of chemical agents, stibnite, and antimony trisulfide used as an additive in industry, thereby having a broad application prospect.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

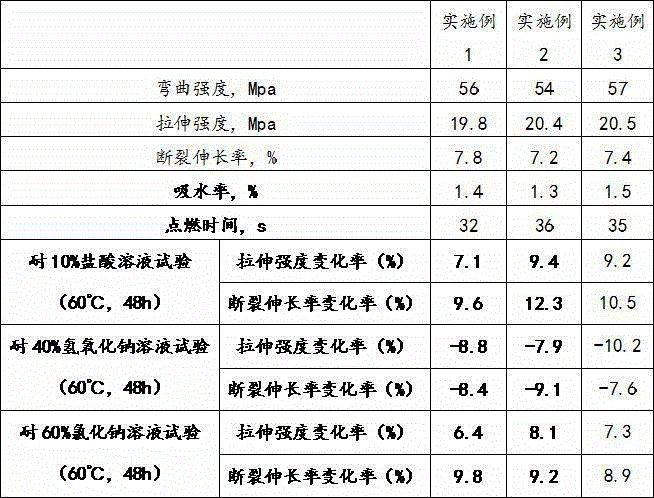

High-strength corrosion-resistant wood-plastic composite material for plates and preparation method thereof

InactiveCN104817852AImprove flame retardant performanceImprove stabilityCalcium silicateAntimony trisulfide

The invention discloses a high-strength corrosion-resistant wood-plastic composite material for plates and a preparation method thereof. The high-strength corrosion-resistant wood-plastic composite material for plates is prepared from the following raw materials in parts by weight: 100-120 parts of wood meal, 20-30 parts of chlorinated polyethylene, 8-10 parts of polybutadiene rubber, 2-4 parts of bis(2-(2-butoxyethoxy)ethyl)adipate, 3-5 parts of magnesium powder, 5-10 parts of antimony trisulfide, 10-15 parts of nano boehmite, 3-5 parts of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 5-8 parts of methylacryloyloxy silane, 14-18 parts of hollow microbead, 6-7 parts of high-boron calcium borate, 3-4 parts of 4-hydroxymethyl-2,6-di-tert-butyl phenol, 8-10 parts of calcium laurate, 10-12 parts of dimethyl terephthalate, 5-7 parts of ethylene-octylene copolymer, 6-8 parts of triphenyl phosphite, 40-50 parts of activated calcium carbonate, 4-6 parts of gypsum whisker, 12-14 parts of ammonium polyphosphate, 5-9 parts of sugarcane wax and 7-8 parts of dimethyl silicone oil. The wood-plastic composite material has the advantages of excellent flame retardancy, excellent mechanical properties, excellent corrosion resistance, excellent aging resistance and longer service life.

Owner:罗满清

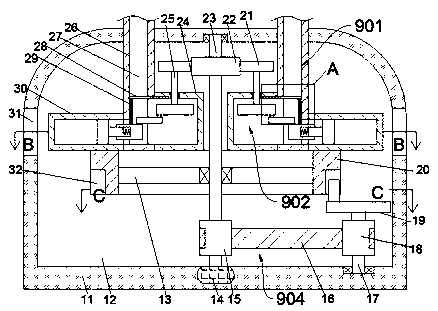

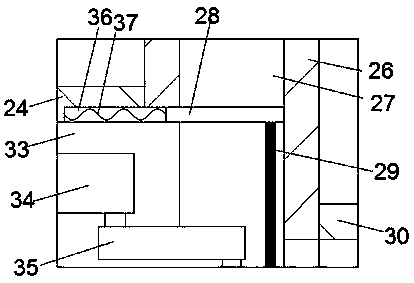

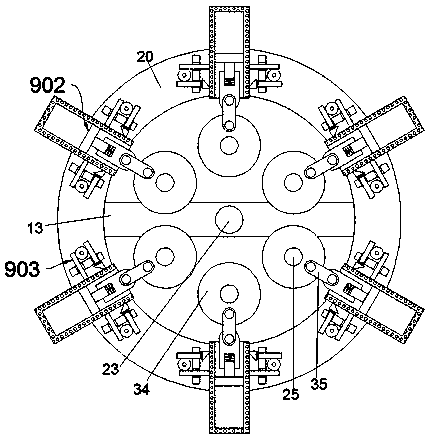

Pushing device for filling internal fuel in fireworks production

The invention discloses a pushing device for filling internal fuel in fireworks production. The pushing device comprises a filling box, wherein the filling box is internally provided with a working cavity; the inner wall of the top end of the working cavity is communicated with the outer part and is provided with six centrosymmetric storage pipes; the storage pipes are internally provided with sinking boxes; and unloading systems located in the working cavity are arranged on the storage pipes. According to the pushing device, round table type station rotation switching is adopted to carry outordered and automatic arrangement on the fuel filling process, by utilizing the fact that the fuels in the vertical pipelines move down due to the own gravity and the pipelines are showed and closed in the pushing process, the filling of quantitative fuels at each time is realized, so that the filling process of the fuels such as black powder, metal salt, dextrin and antimony trisulfide in the fireworks is highly automatic, thereby satisfying the mechanical machining demand, avoiding the squib problem of the artificial manufacturing and ensuring the quality and safety of the fireworks.

Owner:上栗县金信出口烟花制造有限公司

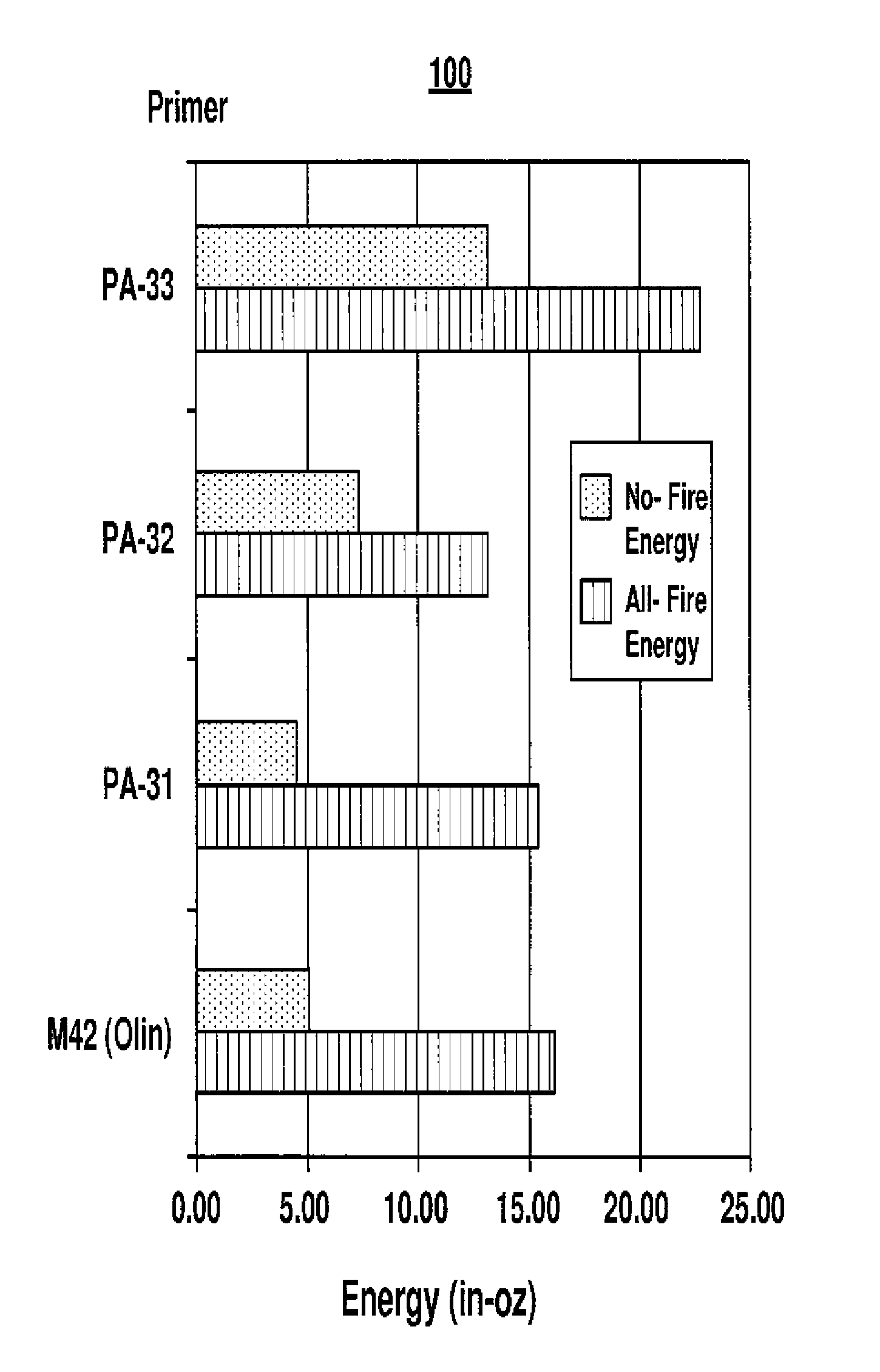

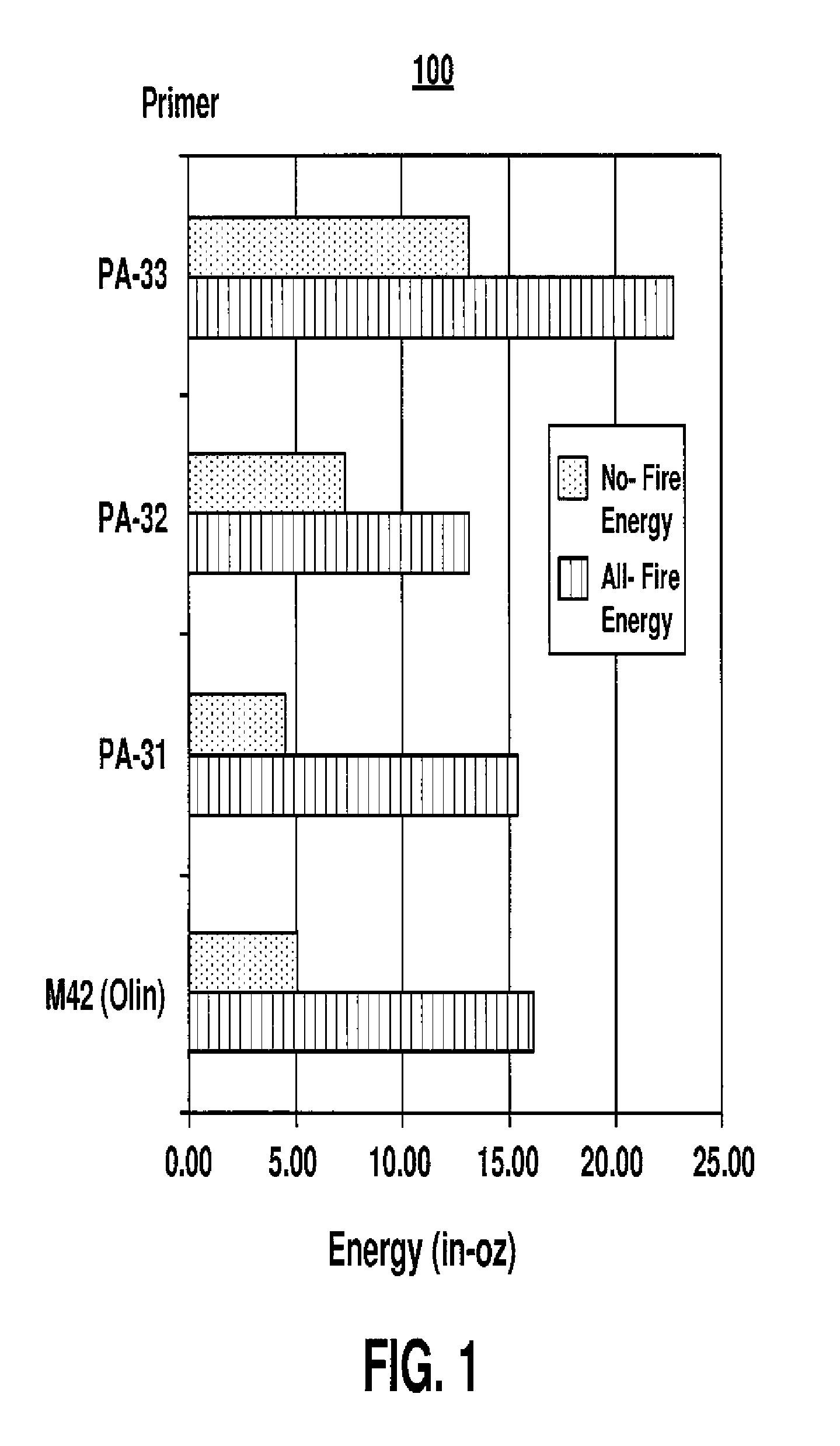

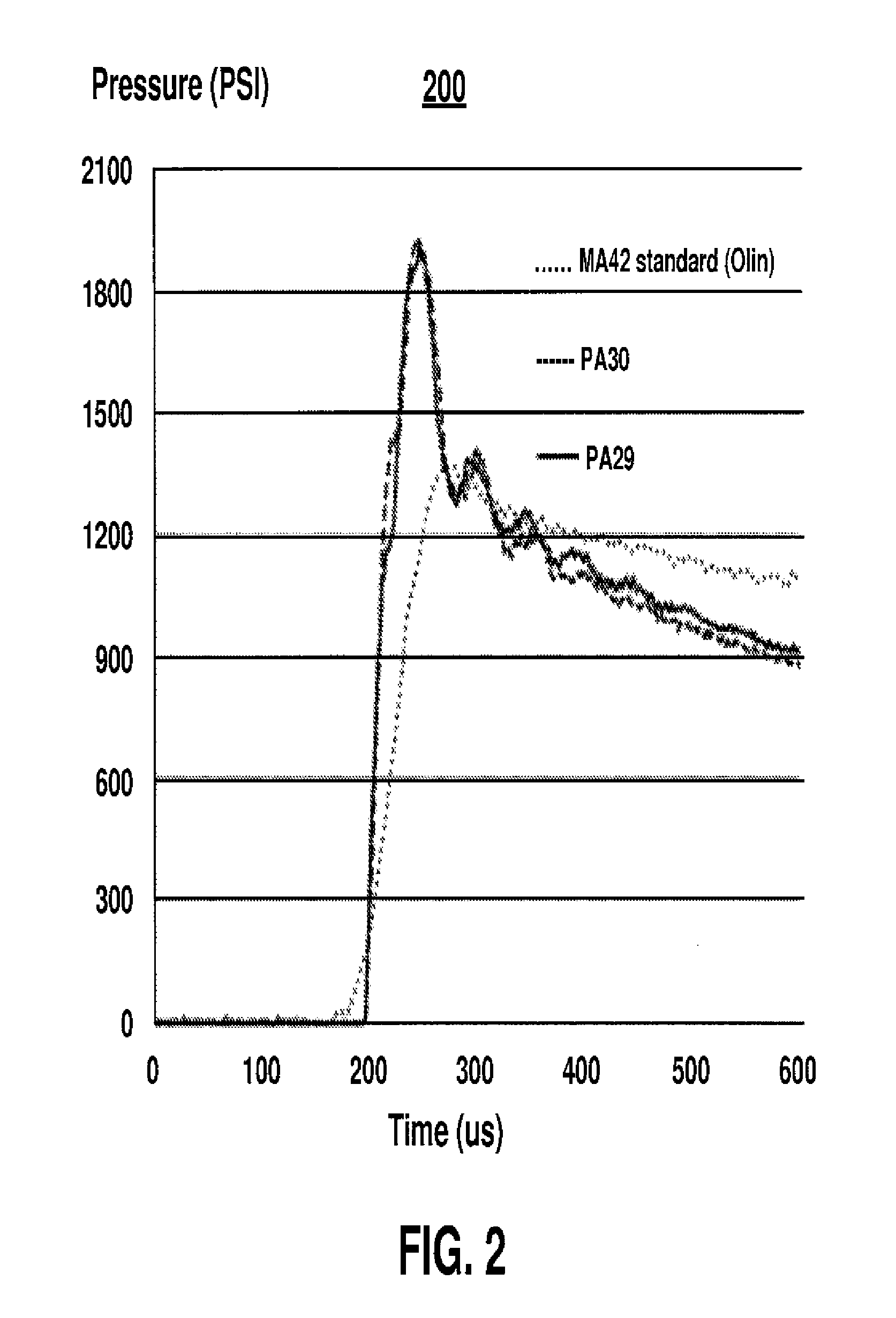

Non-toxic primer mix

ActiveUS9409830B1Stringent performance requirementEnhancing impact and friction sensitivityLoomsWoven fabricsPotassium nitrateBarium nitrate

A non-toxic primer mix in which DBX-1 (copper(I) 5-nitrotetrazole) acts as the primary explosive portion of the primer. Furthermore, in this mix, boron carbide (B4C) replaces the traditional frictionator / fuel, toxic antimony trisulfide. In addition, potassium nitrate replaces the toxic barium nitrate (BaNO3)2) as the oxidizer, providing an ignition flame from the primer in a pyrotechnic reaction. The non-toxic primer therefore embodies a lead-free, barium-free, antimony-free explosive material that can include added fuels, sensitizers, explosives and / or binders.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Friction material composition, and friction material and friction member each obtained using friction material composition

ActiveUS20200308461A1Stable coefficient of frictionIncrease coefficient of frictionOther chemical processesFriction liningGraphiteAntimony trisulfide

A friction material composition containing a binder, an organic filler, an inorganic filler and a fibrous base material, wherein the friction material composition either contains no copper as an element or has a content of copper as an element that does not exceed 0.5% by mass, contains α-alumina and γ-alumina in a mass ratio within a range from 1:20 to 1:5, contains a silicone-containing phenol resin, contains 20 to 35% by mass of a titanate salt, contains 3 to 7% by mass of a graphite having a median diameter of 1 to 30 μm, and contains antimony trisulfide.

Owner:NISSAN MOTOR CO LTD +1

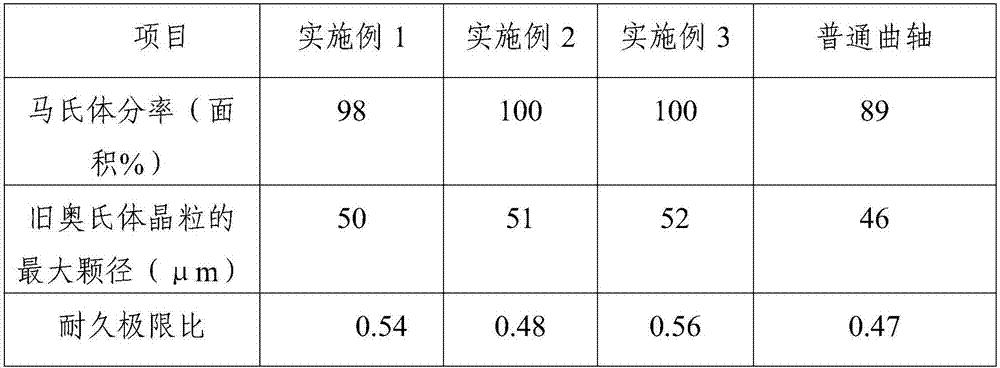

Manufacturing method of compressor crankshaft

InactiveCN107876780ACrystal clearGood yield resistanceTurbinesOther manufacturing equipments/toolsNiobiumManganese

The invention provides a manufacturing method of a compressor crankshaft and relates to the field of powder metallurgy. The preparation method comprises the following steps that iron powder, aluminumpowder, copper powder, tin powder, niobium powder, vanadium powder, manganese, chromium and nanosized titania powder are evenly mixed and stirred under the temperature of 80-100 DEG C for 60-80 min, then heating is conducted till the temperature is 180-200 DEG C, then boron, silicon nitride, copper thiocyanate, antimonous sulfide powder and carbon powder are added, cooling is conducted till the temperature is 100-120 DEG C, then a mixed material is loaded into a mould and pressed into a blank, and then natural cooling is conducted till the temperature is the room temperature, wherein the pressing pressure is 100-200 MPa; and the obtained pressed blank is placed into a closed sintering furnace to be sintered, in the sintering temperature-increasing process, the temperature increasing speedbetween the room temperature and 900 DEG C is 14 DEG C / min, and heat preservation is conducted for 30 min under the temperature of 900 DEG C. The metal crystalline phase is clear, the tensile strength, the yield strength and abrasion resistance are all very good, processing cannot change the characteristics of original materials, and processing complexity caused due to the fact that for meeting performance requirements, the processed material is subjected to other treatment is avoided.

Owner:ANHUI BOGUTE ELECTRICAL & MECHANICAL TECH CO LTD

Preparation method of antimonous sulfide/AgI/Ag/BON photocatalyst for soil remediation

PendingCN111282591AEasy to separateImprove performancePhysical/chemical process catalystsOrganic fertilisersFiltrationWater chlorination

The invention relates to a preparation method of a Sb2S3 / AgI / Ag / BON photocatalyst for soil remediation. The preparation method comprises the steps: adding Bi5O7I into a 0.5-1 M NaOH solution, stirringfor a period of time, collecting a product A, adding the product A into a stable dispersion solution containing antimony trichloride and L-cysteine, carrying out hydrothermal reaction at the temperature of 140 DEG C-160 DEG C for 10-16 h, cooling, carrying out suction filtration, washing and drying to obtain a composite product B; and adding the product B into a silver nitrate solution, carryingout ultrasonic treatment for 10-30 min, stirring for 2-4 h, filtering, drying, illuminating for 30-60 min under a 100 W xenon lamp, and drying to obtain the Sb2S3 / AgI / Ag / BON photocatalytic material. The method is simple to operate, and the reaction process is easy to control. The method is suitable for industrial production, and has green, clean and environment-friendly effects.

Owner:GUILIN UNIV OF ELECTRONIC TECH

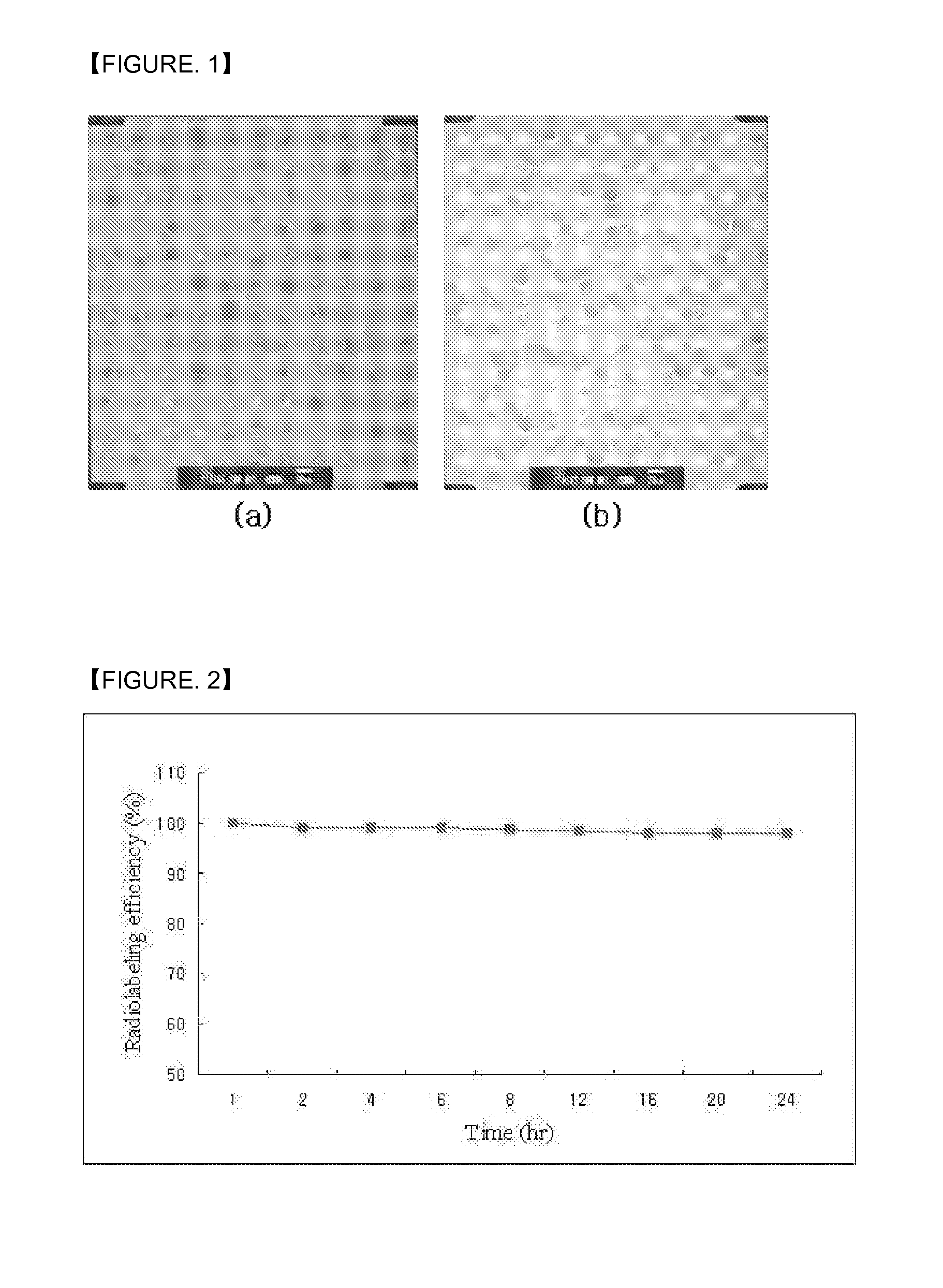

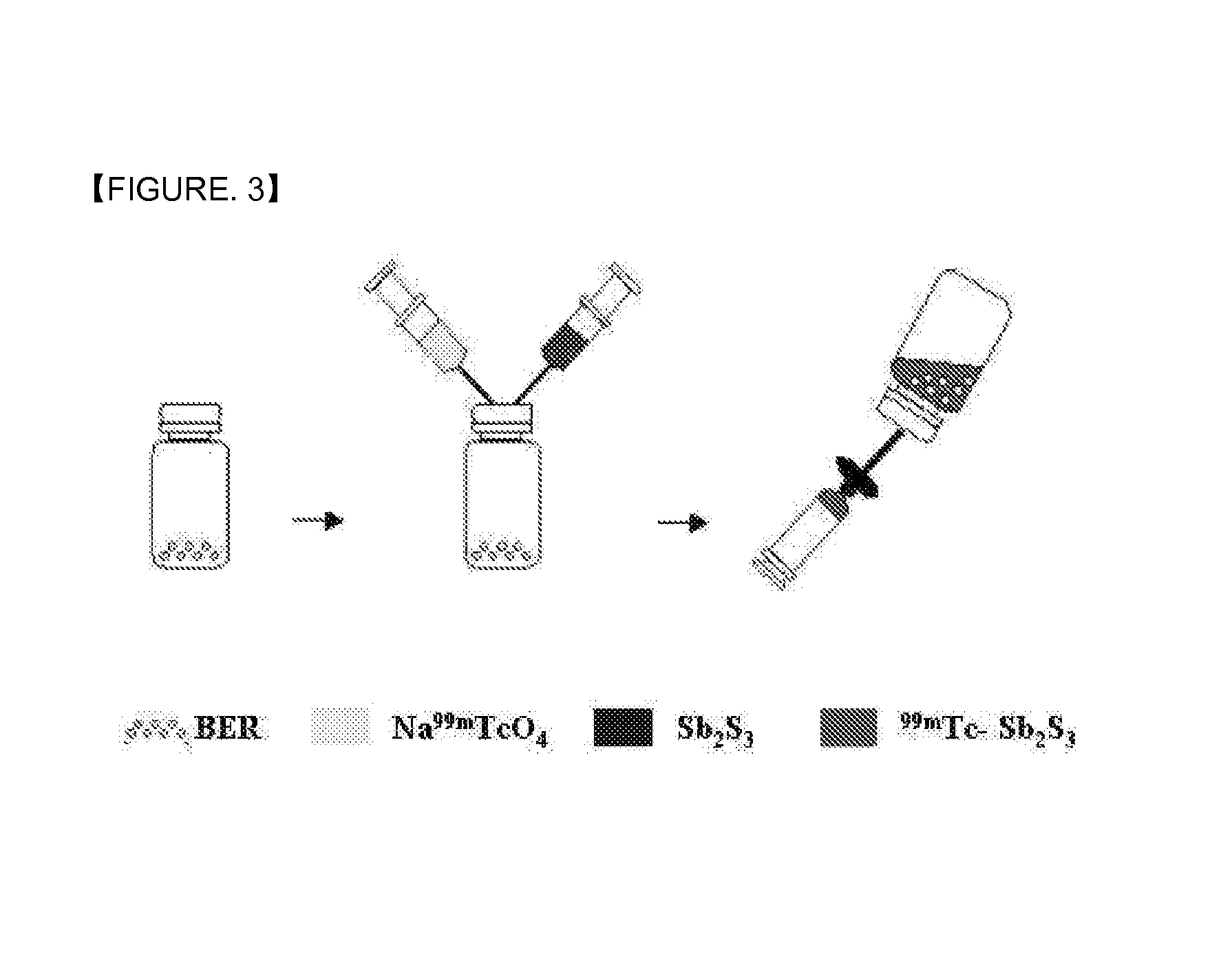

Method for preparing technetium-labeled antimony sulfide nanocolloid

ActiveUS7264791B2Easier and much economical preparation methodDelayed reaction timePowder deliveryDispersion deliveryTechnetiumPertechnetate

The present invention relates to a preparation method for technetium-antimony trisulfide nanocolloid, more precisely, a preparation method for technetium-antimony trisulfide nanocolloid which is characterized by the processes of mixing and stirring or irradiating of pertechnetate and antimony sulfide nanocolloid in the presence of borohydride exchange resin to obtain the technetium-antimony trisulfide nanocolloid radioactive complex.

Owner:KOREA ATOMIC ENERGY RES INST

Method for dissolving antimonous sulfide into stibious

The invention discloses a method for dissolving antimonous sulfide, which utilizes the acidity and coordinating capability of hydrochloric acid and phosphoric acid to dissolve through a chemical dissolving method. In the method, a chemical product antimonous sulfide, the chemical purity of which is 97.0%, is utilized as a dissolving object, the content of antimonous sulfide can be measured after antimonous sulfide is dissolved under the optimum condition, and the measured result data can be used to illustrate the soluble completeness; the optimum condition of dissolving is as follows: adding 12ml of hydrochloric acid and 5ml of phosphoric acid; covering a watch glass, shaking the watch glass on an electric stove while slowly heating until the solution is boiling slightly, removing the watch glass, and maintaining slight boiling until the color of the solution is light yellow and transparent and is completely dissolved. Oxidation-reduction titration is used to measure the content of antimonous sulfide, therefore, the dissolved antimonous sulfide exists in the solution in the form of antimony (III), instead of in form of antimony (V). By using the dissolving method of antimonous sulfide in the invention, the measured result after a sample is dissolved reaches 96.82, which differs 0.18% to the actual value. In the method, the sample can be completely dissolved, and the solvent is non-toxic and safe and has low price, thereby meeting the requirements of environment protection and industrial production. The established dissolving method is also applied to dissolve antimonous sulfide in an antimonite and antimonous sulfide used as an additive in the industry and has wide application prospect.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

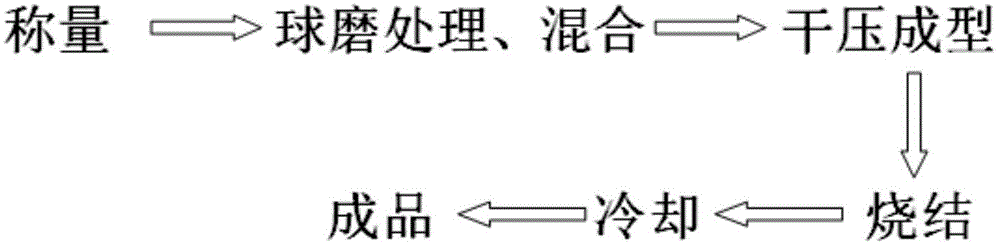

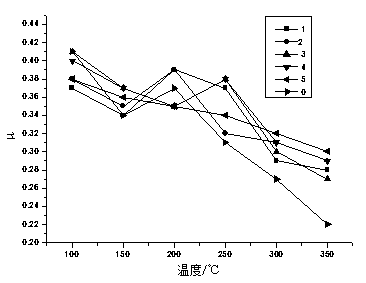

Metal sulfide ceramic friction material and preparation method thereof

The invention discloses a metal sulfide ceramic friction material. The metal sulfide ceramic friction material is prepared from, by weight, sulfur powder, tin powder, antimony trisulfide, alumina powder, iron and aluminum powder, steel fibers, molybdenum disulfide and graphite. The invention further discloses a preparation method of the metal sulfide ceramic friction material. The preparation method specifically comprises the steps that the needed raw materials are weighed, part of the raw materials are processed through ball milling, all the raw materials are mixed to be uniform and then processed through dry pressing molding, normal pressure sintering is performed, and then the metal sulfide ceramic friction material is prepared. The metal sulfide ceramic friction material has the larger heat capacity and has the high enough mechanical strength and the good running-in performance at high temperature. According to the metal sulfide ceramic friction material and the preparation method thereof, the preparation technology is simple, the raw material sources are wide, operation is convenient, and industrial production is easy to achieve.

Owner:西安艾菲尔德复合材料科技有限公司

Fireproof flame-retardant plastic flooring and manufacture method thereof

The invention discloses fireproof flame-retardant plastic flooring and a manufacture method thereof. The fireproof flame-retardant plastic flooring comprises, by weight part, 78-91 of polyphenylene sulfide, 42-56 of vinyl chloride-acrylonitrile copolymer, 22-34 of polypentabromobenzyl acrylate, 8-14 of antimony trisulfide, 10-15 of magnesium hexasilicate, 15-25 of polysulfonyl diphenylene phenylphosphonate, 13-19 of methyl pentachlorooctadecanoate, 10-15 of expandable graphite, 4-9 of tri(2,3-dibromopropyl) isocyanurate, 7-13 of triisooctyl borate, 5-10 of zirconium oxychloride, 9-16 of sodiumtungstate, 14-19 of dicyclohexyl phthalate, 8-14 of tetrachloro dioctyl phthalate, 5-10 of chlorinated paraffin, and 13-17 of high aluminum fine powder. The manufactured plastic flooring is fireproof, is high in oxygen index, low in smoking amount and excellent in flame retardance, has no drop burning, and is greatly improved in safety coefficient.

Owner:JIANGYIN ZHIYUAN AUTOMOBILE DECORATION PARTS CO LTD

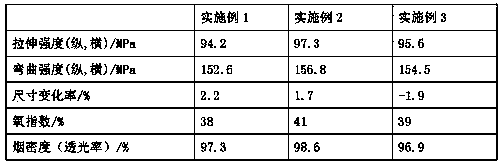

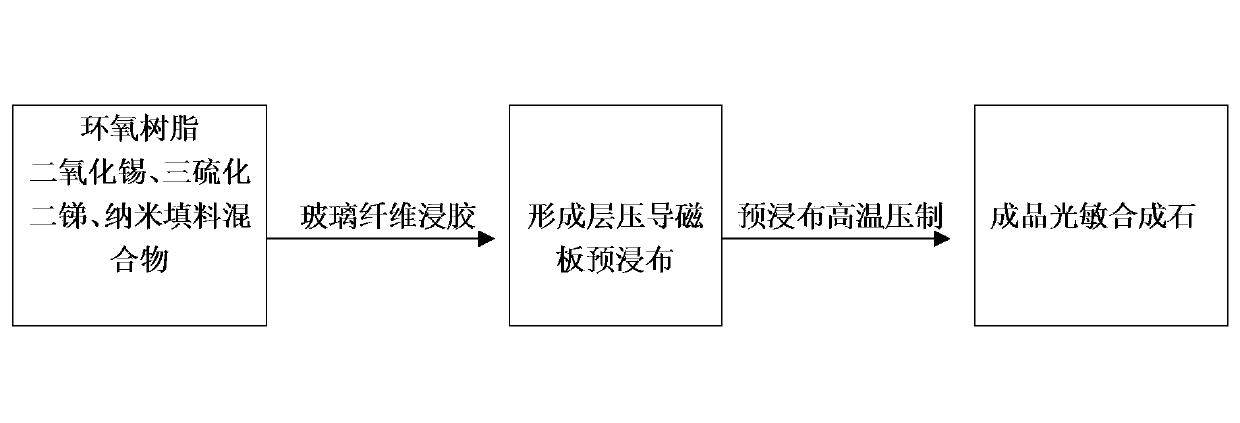

Photosensitive synthetic stone raw material composition and production method of photosensitive synthetic stone

The invention discloses a photosensitive synthetic stone raw material composition and a production method of a photosensitive synthetic stone. The synthetic stone which not only has a photosensitive function but also is antistatic is successfully manufactured by means of addition of a certain percentage of tin dioxide and antimony trisulphide into raw materials. The invention provides a production process which is low in cost and stable in performance. The production process comprises the following steps: (1) mixing the raw materials of nano-silica and nano calcium carbonate in a ratio of 1:1 and manufacturing into nanofillers; (2) pouring the raw materials of epoxy resin, tin dioxide, antimony trisulphide and the nanofillers in the step (1) in a weight ratio of 10:1.25:1.25:1 into a preparation container to mix uniformly; (3) getting the mixture in the preparation container, and forming a laminated magnetic conductive board prepreg through glass fiber impregnation; and (4) getting the laminated magnetic conductive board prepreg in the step (3), and pressing to form the finished photosensitive synthetic stone at the temperature of 270 DEG C. The production method of the photosensitive synthetic stone has the advantages of enhancing competitiveness of products in a market, being favorable for market sales of the products and worthy of promotion.

Owner:焦作市天益科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/523d5043-e134-42d5-a959-7bd75fe40c59/HDA0002283133150000011.png)

![ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/523d5043-e134-42d5-a959-7bd75fe40c59/HDA0002283133150000012.png)

![ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/523d5043-e134-42d5-a959-7bd75fe40c59/HDA0002283133150000021.png)