Patents

Literature

54results about How to "Less miscellaneous" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of Maotai-flavor liquor

ActiveCN101602991ARemove Lao ChenEliminate pesticide residuesAlcoholic beverage preparationBiologyBrewing

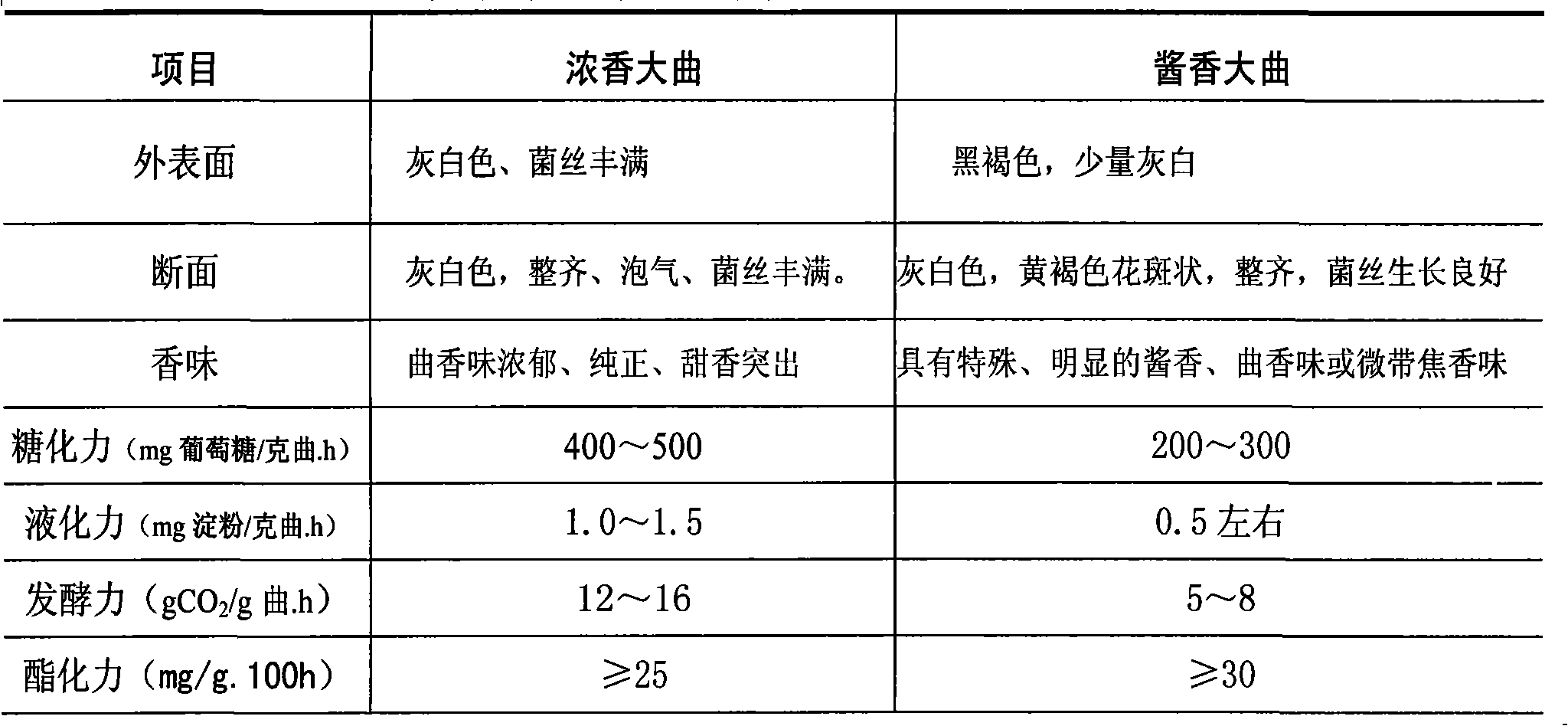

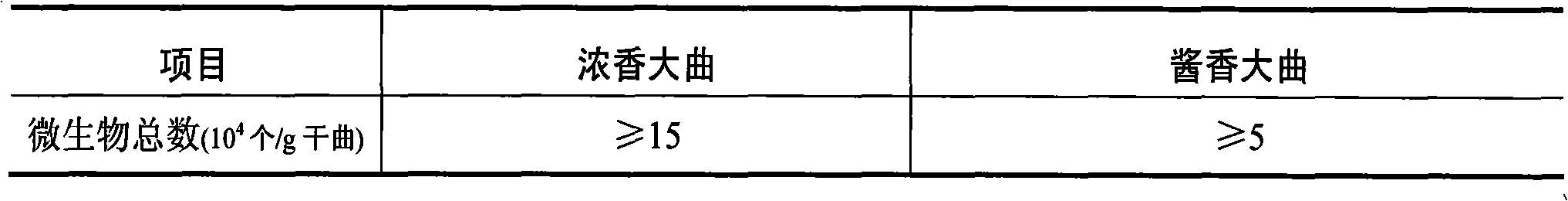

The invention discloses a production method of Maotai-flavor liquor. Compared with conventional process, the invention replaces sorghum and wheat with rice, sticky rice, corn, wheat and sorghum which serve as brewing materials, replaces the process of only taking Maotai-flavor daqu as a ferment with the fermentation process of combining two daqu: Luzhou-flavor daqu and Maotai-flavor daqu for preparation, and replaces the convenient process of twice of grain addition, eight rounds of fermentation and seven rounds of liquor taking with the process of one-time grain addition, nine times of fermentation and eight times of liquor taking. The invention has the following advantages: the quality of each round of liquor and combined mixed body of each round of liquor is superior the quality of the existing method, thus obviously reducing the yield of liquor of inferior quality rounds, obviously improving the yield of liquor of superior quality rounds and improving the total yield, and the Maotai-flavor style of the product and aftertaste thereof are both superior to Maotai-flavor style and aftertaste of the Maotai-flavor liquor prepared by the existing method, and the product has elegant multi-grain compound flavor.

Owner:SICHUAN TUOPAI SHEDE WINE

Method for preparing superfine groundnut oil

ActiveCN101433244AThe preparation process conditions are simpleAroma production is easy to controlEdible oils/fatsNeutral proteaseHydrolysate

The invention discloses a method for preparing fragrant peanut oil, which comprises the following steps: 1) a raw material is pretreated, wherein a peanut raw material is selected, is mixed with water, then is soaked, and then is subjected to coarse grinding and fine grinding; 2) complex enzyme is hydrolyzed, wherein the complex enzyme with neutral protease or alkali protease and flavor enzyme is selected to perform hydrolysis on the pretreated peanut raw material; 3) auxiliary materials are added, wherein reducing sugar, amino acid and peanut oil are added into a hydrolysate of the peanut raw material obtained through the treatment in step 2); 4) fragrance is generated through a thermal reaction, wherein the hydrolysate of the peanut raw material and the auxiliary materials are stirred evenly, then are transferred into a high pressure reaction kettle to be heated, and then are cooled to room temperature; and 5) the fragrant peanut oil is prepared, wherein a reaction liquid obtained after the treatment in step 4) is added with refined peanut oil, is quickly stirred first, and then is slowly stirred under certain temperature conditions, and water and impurities are removed through centrifugal separation to obtain the fragrant peanut oil product. The method can obtain flavor precursors of the fragrant peanut oil, namely amino acid and small peptide through the hydrolysis of the peanut raw material by the complex enzyme, and form the peanut oil with peanut fragrance flavor through the heating.

Owner:嘉里特种油脂(上海)有限公司

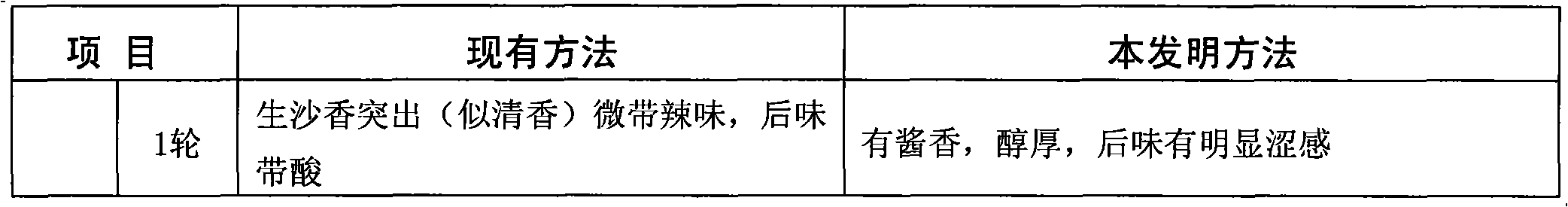

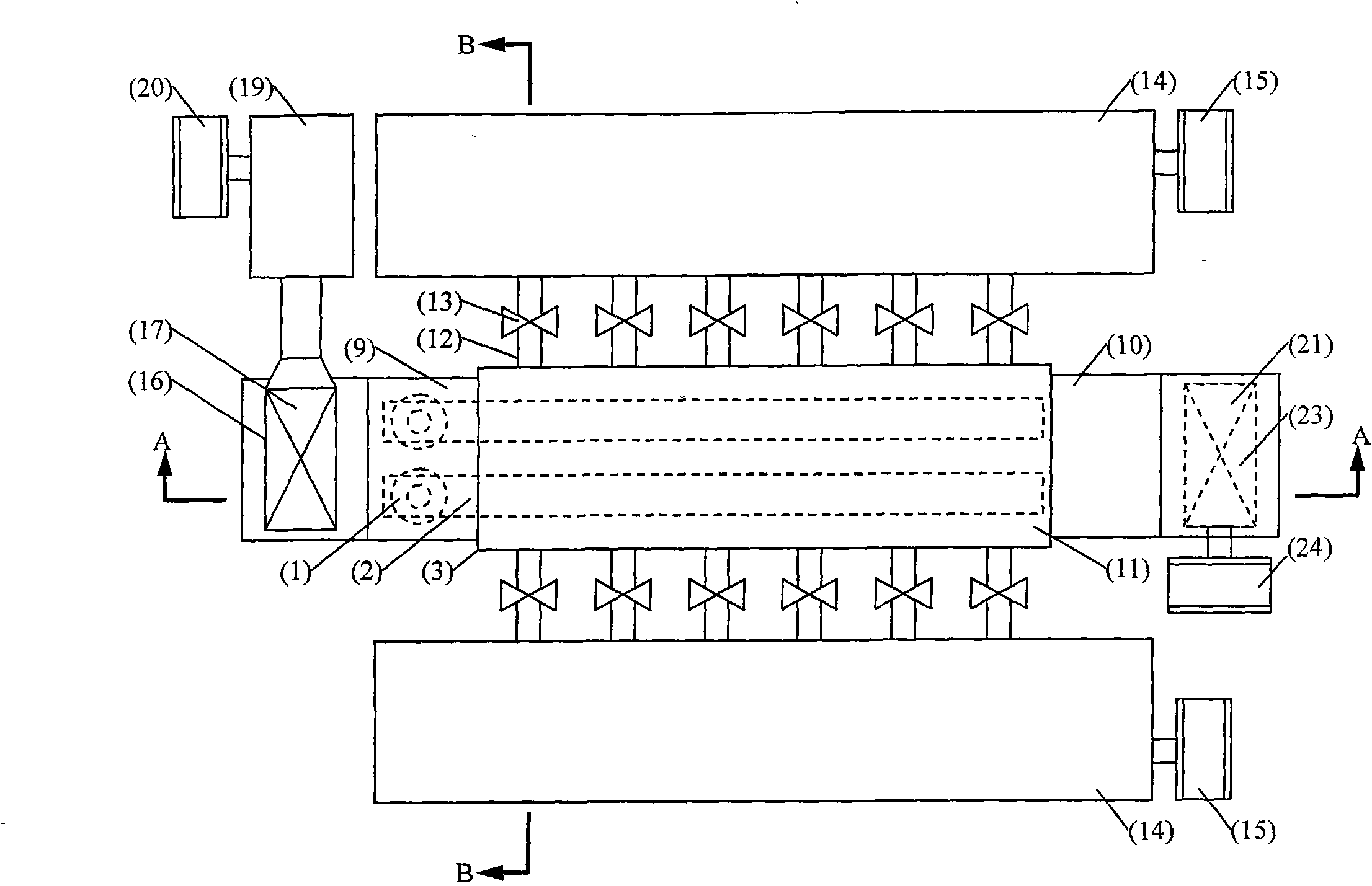

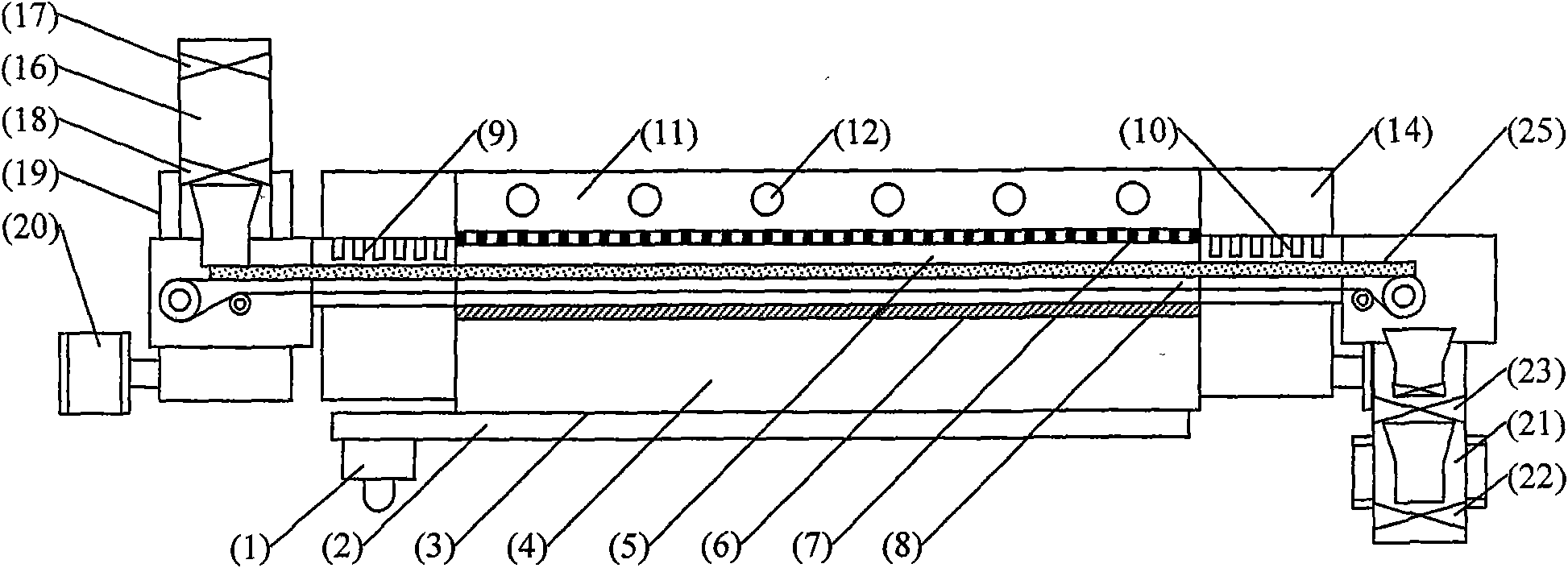

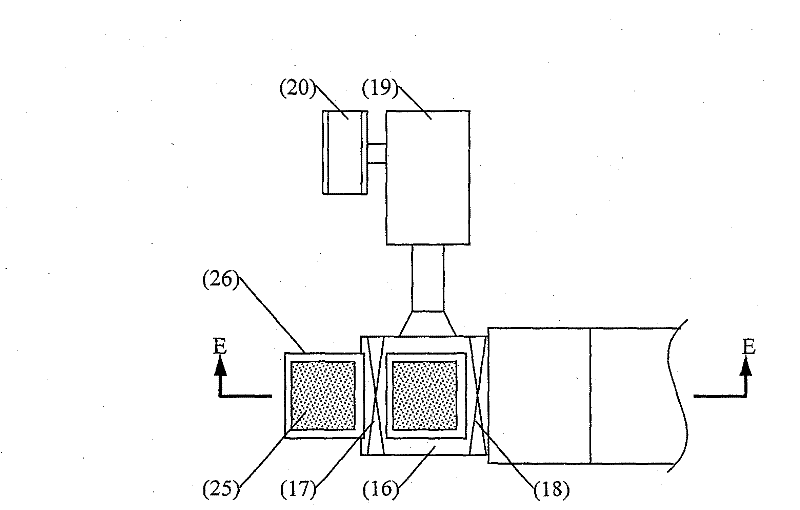

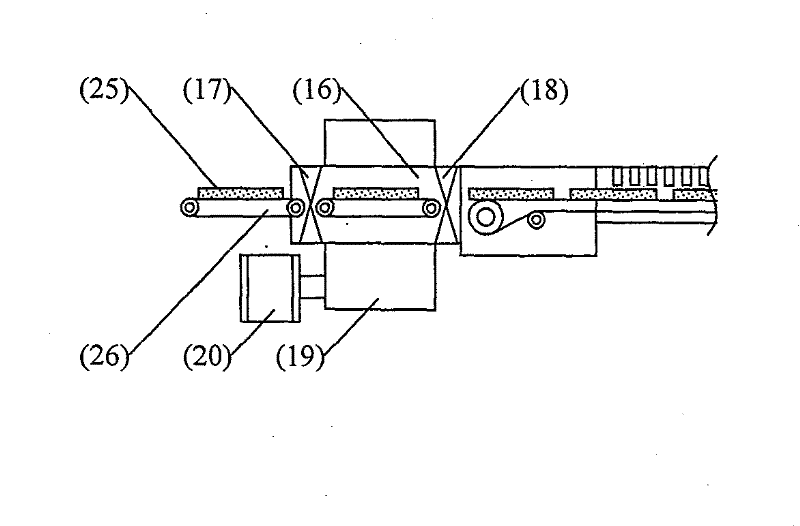

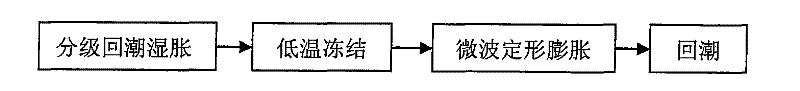

Low-temperature microwave expansion process of cut tobacco

The invention relates to a low-temperature microwave expansion process of cut tobacco. The process comprises the following steps of: putting expanded cut tobacco with the water content of 40-70 percent by rating resurgence in a die; then, freezing into blocks at a temperature of 55 DEG C below zero to 35 DEG C below zero; conveying the cut tobacco blocks into a microwave continuous freeze-dried system to sublimate and dry until the water content is 3-8 percent; and finally resurging to the water content of 12-13 percent to obtain a finished product of expanded cut tobacco. The cut tobacco is expanded by the process of the invention has the advantages of remarkable aroma and fragrance, lower breakage rate, remarkably lessened odor and controllable expansion degree.

Owner:周川

Technique of preparing superfine groundnut oil from peanut rough material

InactiveCN101176489AThe preparation process conditions are simpleAroma production is easy to controlEdible oils/fatsFood preparationFlavorNeutral protease

The invention relates to an aromatic peanut oil preparation craft with peanuts as the materials, comprising the following steps that: firstly, pretreatment of the materials: peanut materials are chosen, mixed and immersed into water successively and then are grinded roughly, and then the materials are grinded finely; secondly, hydrolysis of the compound enzyme: after the pretreatment, the peanut materials are hydrolyzed by the compound enzyme of the neutral protease and the flavor enzyme; thirdly, addition of accessories: after the treatments of the procedures, reduction sugar, amino acid and peanut oil are added into the hydrolysate of the peanut materials; fourthly, thermal reaction to produce an aromatic smell: the hydrolysate of the peanut materials and the accessories are moved into a high pressure reaction kettle to be heated and then be cooled to an ambient temperature; fifthly, prepartion of the aromatic peanut oil: refined peanut oil is added into the reaction liquid after the treatment of the fourth step, the mixture is agitated quickly and then is agitated slowly at a certain temperature, water and impurities are removed by centrifugal separation, and at last the aromatic peanut oil is obtained. The invention has the advantages that: the amino acid and small peptides which are the flavor precursor of the aromatic peanut oil can be obtained by compound enzyme hydrolyzing the peanut materials and then are heated to produce the peanut oil with peanut aromatic flavor.

Owner:嘉里特种油脂(上海)有限公司

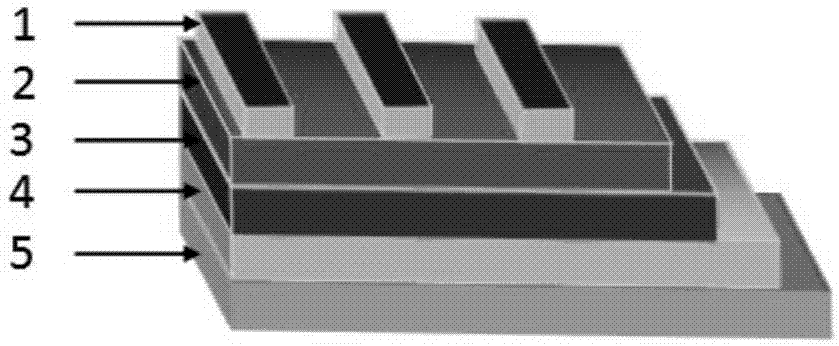

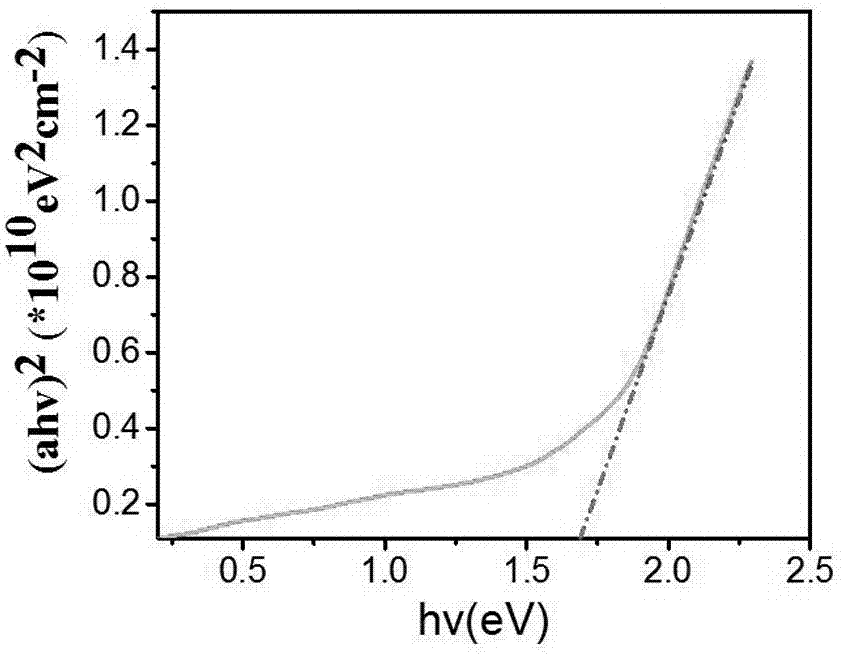

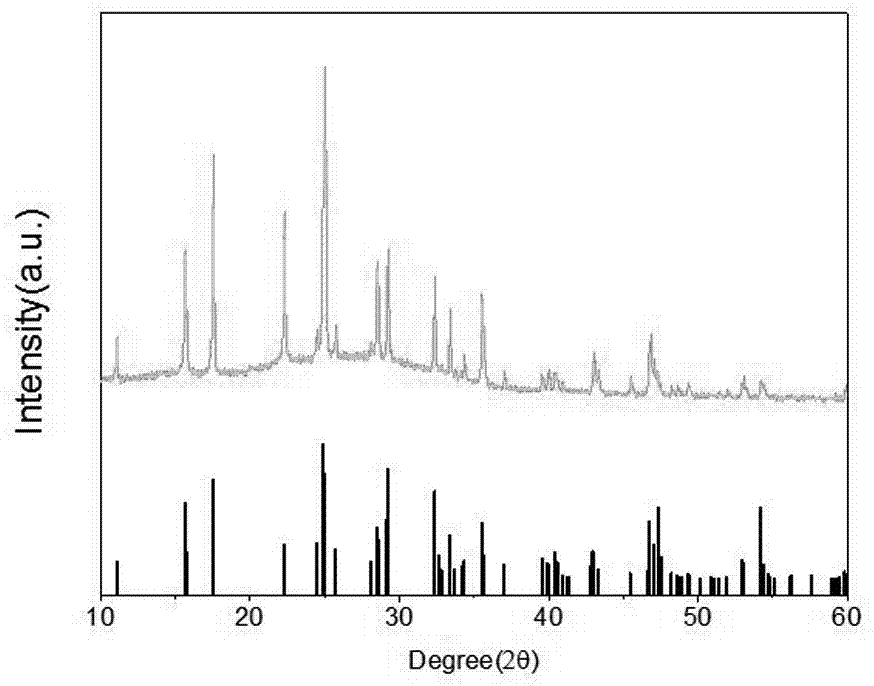

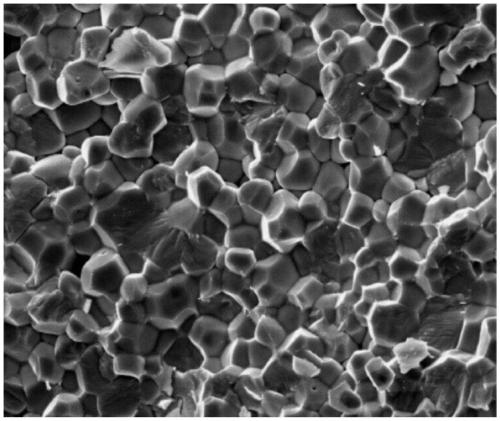

Plane structure hybrid solar cell based on antimony trisulfide compact film

InactiveCN107302057AHigh crystallinityLess miscellaneousSolid-state devicesSemiconductor/solid-state device manufacturingThioureaHole transport layer

The invention discloses a plane structure hybrid solar cell based on an antimony trisulfide compact film, belonging to the field of film materials and devices. The solar cell comprises a transparent conductive substrate, an electron transport layer, a light absorption layer, a hole transport layer and a metal electrode. According to the light absorption layer, SbCl3 and thiourea with the ratio of 1 to 1.5 to 2.5 is used as a precursor, a compact Sb2S3 film is prepared through spin coating, and the thickness range is from 360 nanometers to 1 micron. The compact Sb2S3 film is used as the light absorption layer to form the plane structure hybrid solar cell, the cost is low, the process simple, the mass production is easy, and compared with a mesoporous structure solar cell, the plane structure solar cell based on the Sb2S3 compact film has the advantages of high repeatability and easy improvement of cell efficiency.

Owner:FUZHOU UNIV

Low-temperature Microwave Vacuum Drying Technology of Shredded Tobacco

The invention relates to a low-temperature microwave vacuum drying process for tobacco shreds and belongs to the field of processing of the tobacco shreds. The process comprises the following step of: after carrying out moisture regaining, moisture balancing and low-temperature treatment on the tobacco shreds, feeding the tobacco shreds into vacuum drying equipment to be dried so as to obtain tobacco shred finished products with the moisture content of 11.5 percent to 13.5 percent. The drying process is carried out under the conditions of a vacuum pressure of 200Pa to 30kPa, a temperature of 0 DEG C to 70 DEG C and higher moisture content of 30 percent to 70 percent of the tobacco shreds, so that not only color, aroma and taste of the tobacco shreds are maintained, but also a certain filling value is improved. Moreover, the low-temperature microwave vacuum drying process for the tobacco shreds has low tobacco damage ratio and processing resistance performance. Odor and foreign flavor are obviously decreased.

Owner:康琪

Sour flavoring wine produced by using smaller lumped koji solid white spirit waste lees

ActiveCN101805680AImprove qualityLess miscellaneousAlcoholic beverage preparationMicroorganism based processesWhite spiritChemistry

The invention relates to a sour flavoring wine produced by using smaller lumped koji solid white spirit waste lees, which is prepared by saccharifying, fermenting and distilling the smaller lumped koji solid white spirit waste lees. The sour flavoring wine produced by using the smaller lumped koji solid white spirit waste lees is used for adjusting the acidity in blending a smaller lumped koji white spirit, which not only saves grains and reduces the production cost of the smaller lumped koji white spirit, but also improves the quality of the white spirit.

Owner:CHONGQING JIANGJIN WINERY GROUP

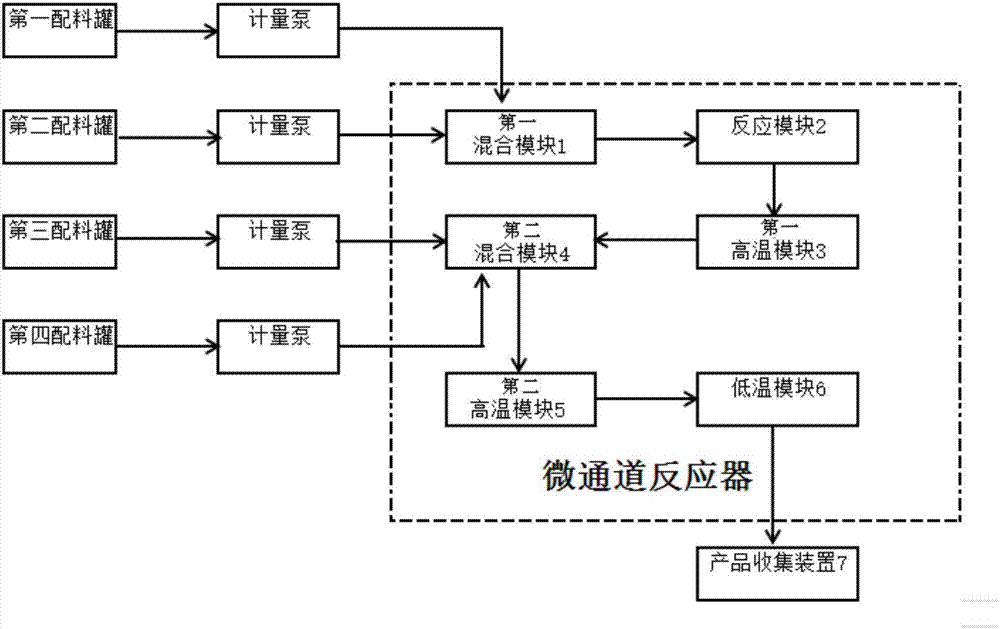

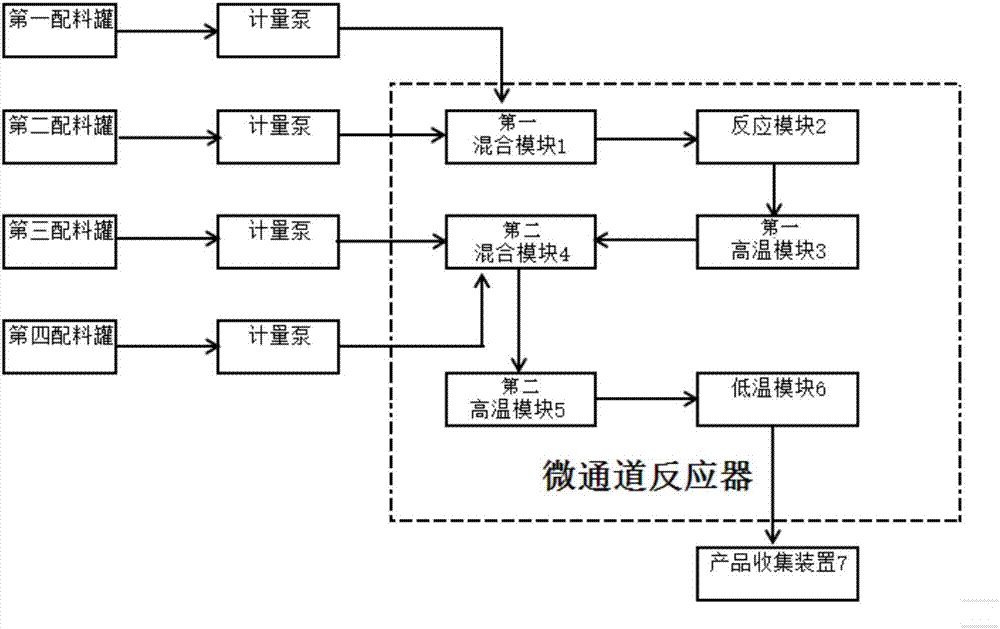

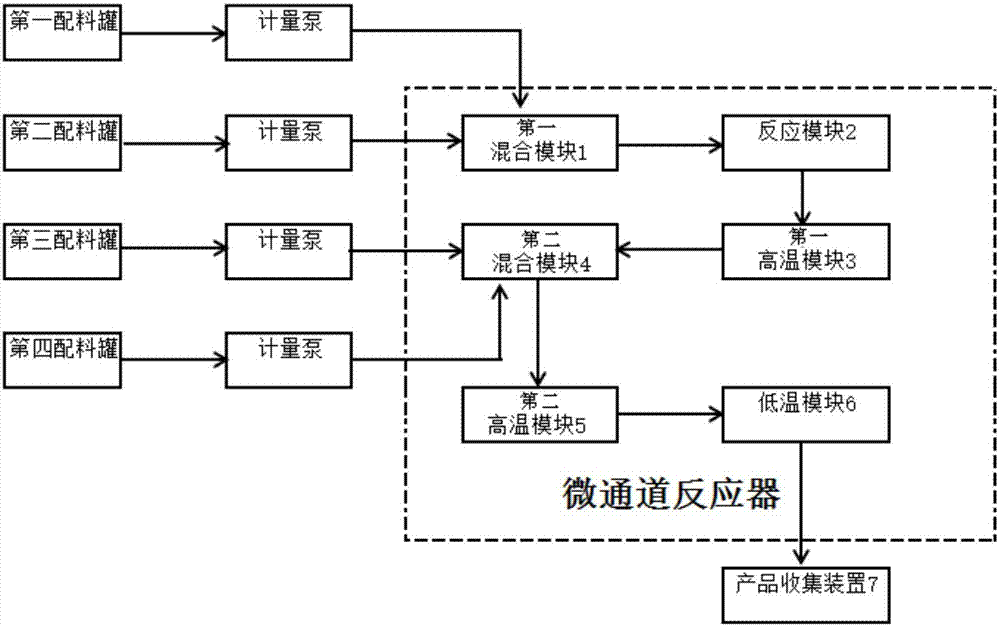

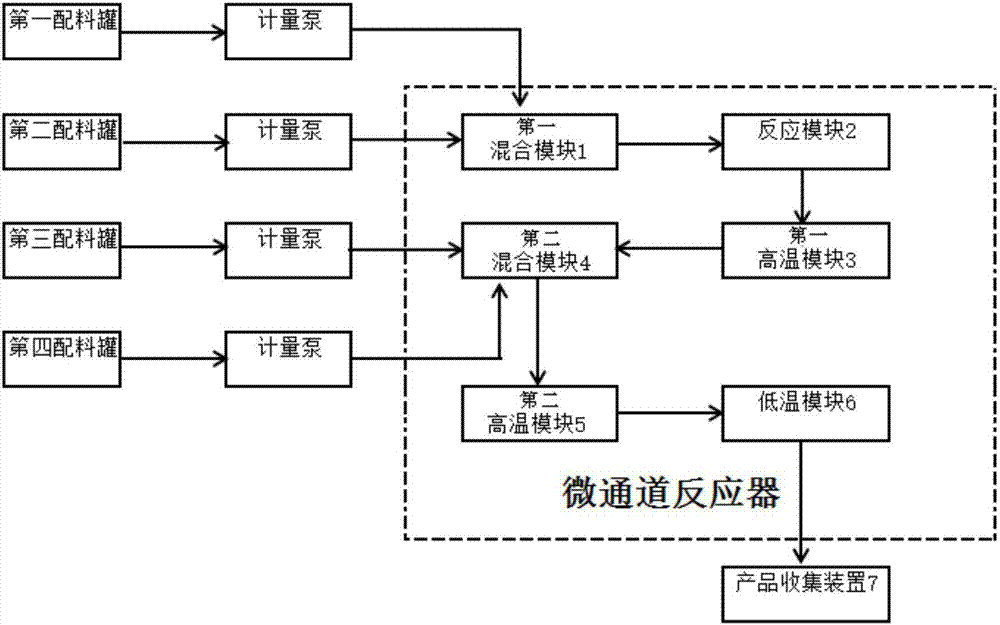

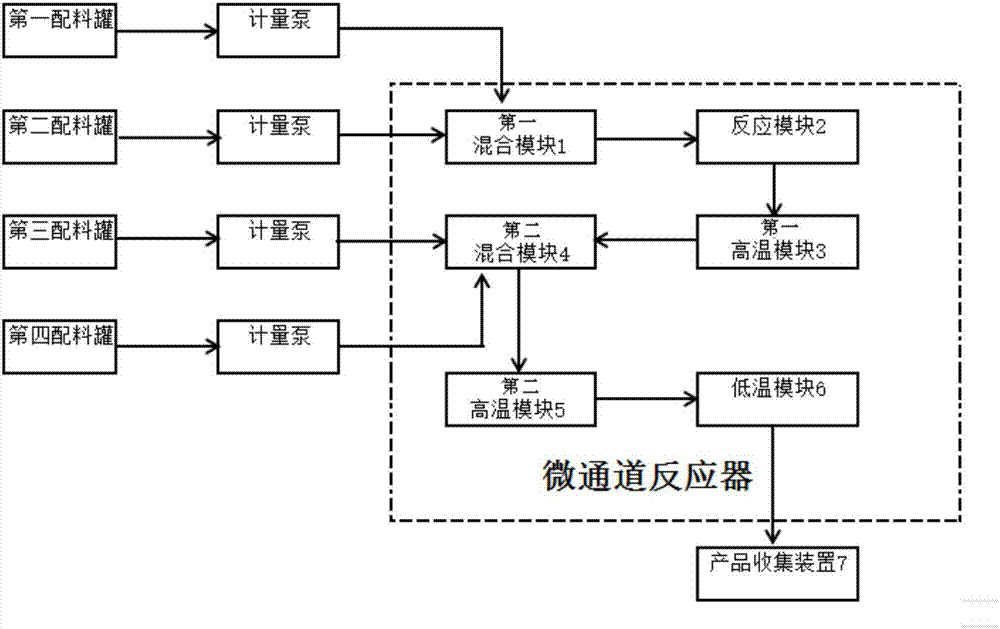

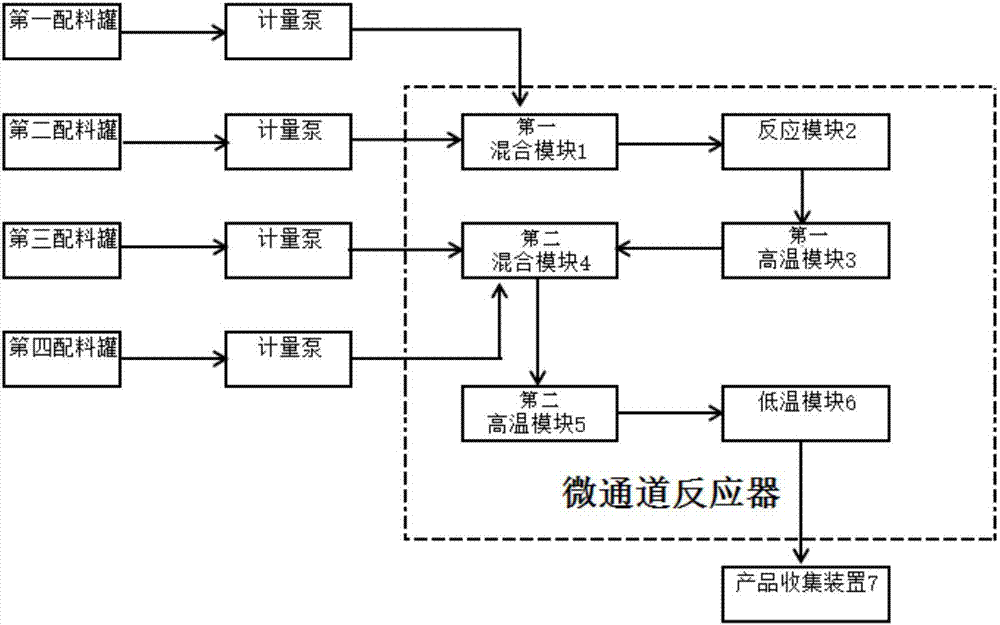

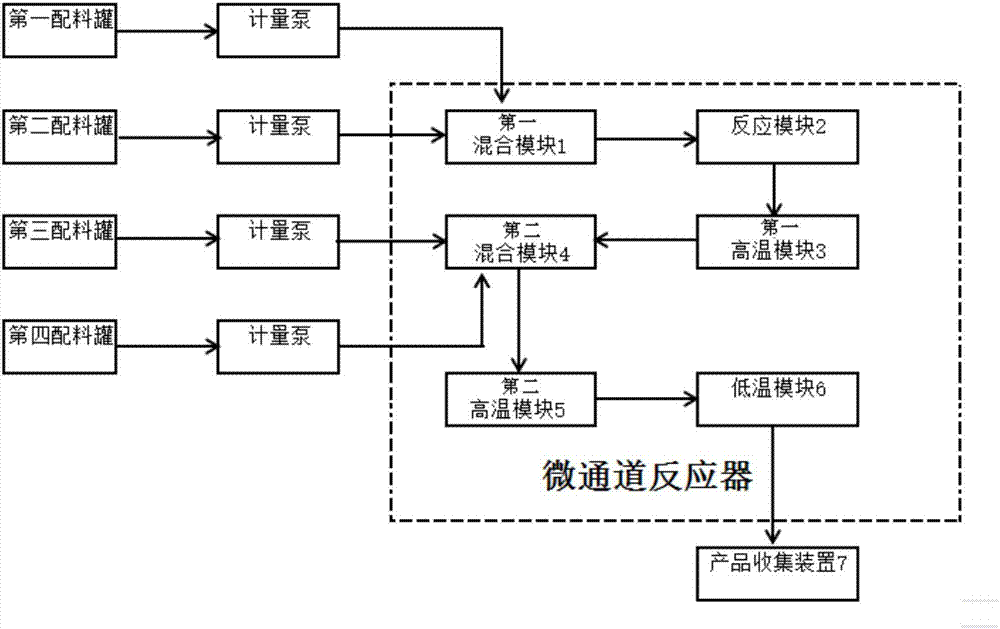

Method for preparing strong-fragrance peanut oil through microchannel reactor

ActiveCN107079999AShort reaction timeImprove catalytic reaction efficiencyChemical/physical/physico-chemical microreactorsFatty-oils/fats productionMaillard reactionReaction system

The invention relates to a method for preparing strong-fragrance peanut oil through a microchannel reactor. The method comprises the following steps of step I, pumping peanut enzymolysis reaction fluid and an enzyme solution into the microchannel reactor, performing mixing in a first mixing module to obtain a mixture, enabling the mixture to enter a reaction module, and performing an enzymolysis reaction; step II, performing high-temperature enzyme activity inactivation, and ending the enzymolysis reaction; step III, thoroughly mixing a reaction system with reducing sugar and peanut oil so as to obtain a mixed reaction system; step IV, enabling the mixed reaction system to enter a second high-temperature module, rapidly raising the temperature to reach the temperature required by a technology, and performing a Maillard reaction; and step V, enabling the reaction system to flow across a low-temperature module and flow out of the microchannel reactor so as to obtain crude products of the strong-fragrance peanut oil. Through the adoption of the method disclosed by the invention, the enzymolysis process can be accurately controlled, and the thermal reaction temperature and the post-treatment temperature can be quickly and accurately controlled; and through the usage of the microchannel reactor, amplification effects are not generated, upgrading and amplification are easy, and seamless amplification from research and development to production can be realized.

Owner:ENZYMECODE BIOTECHNOLOGY CO LTD

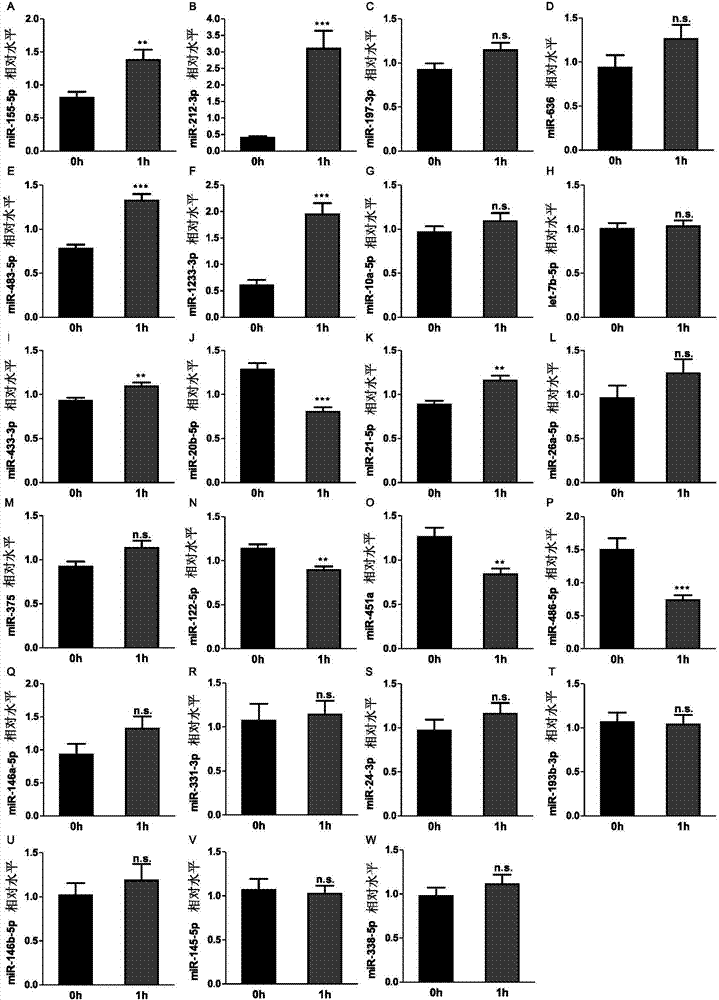

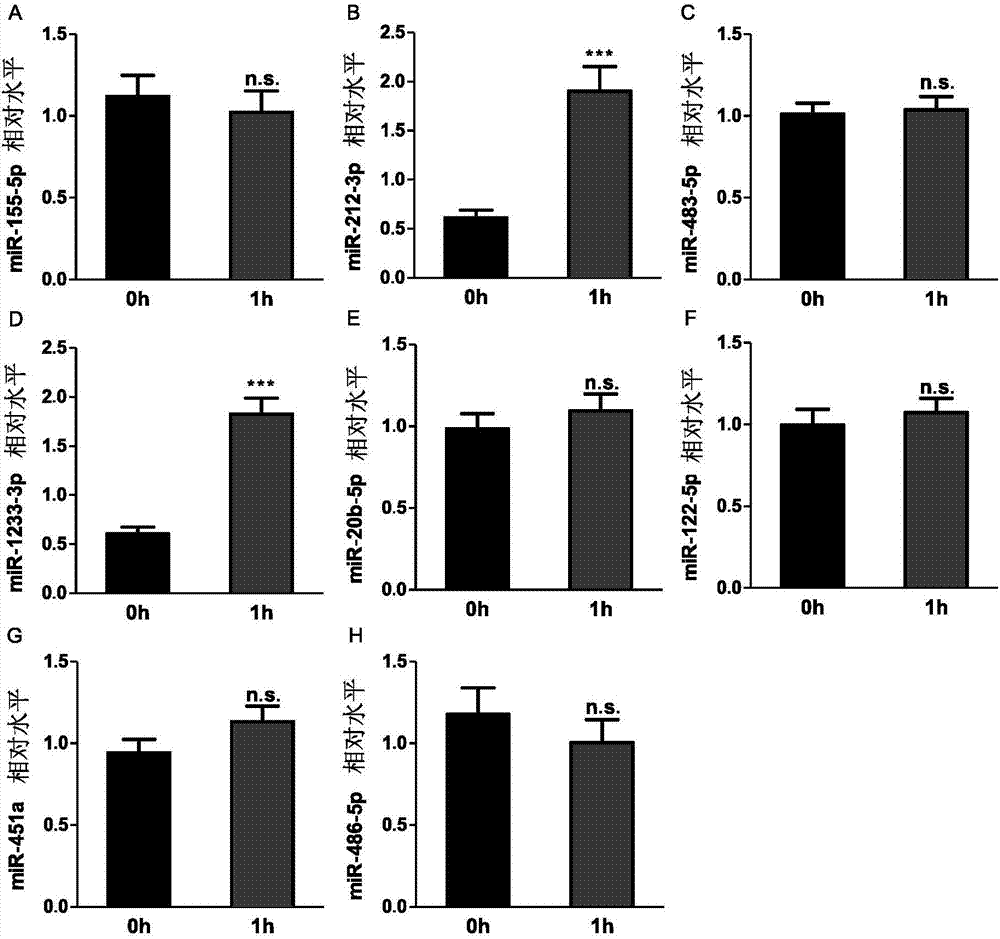

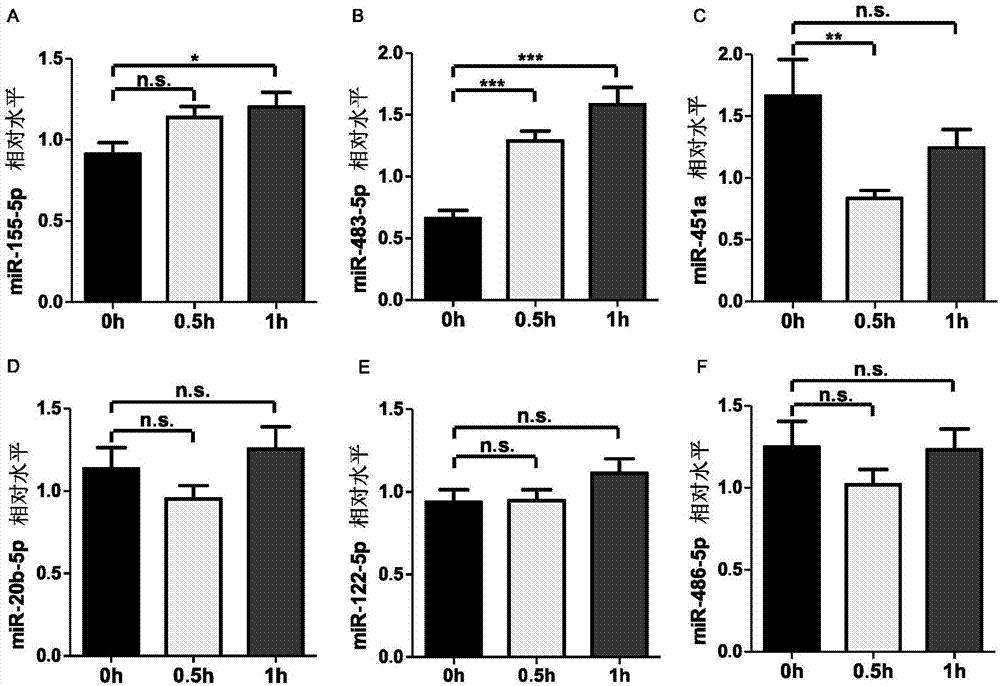

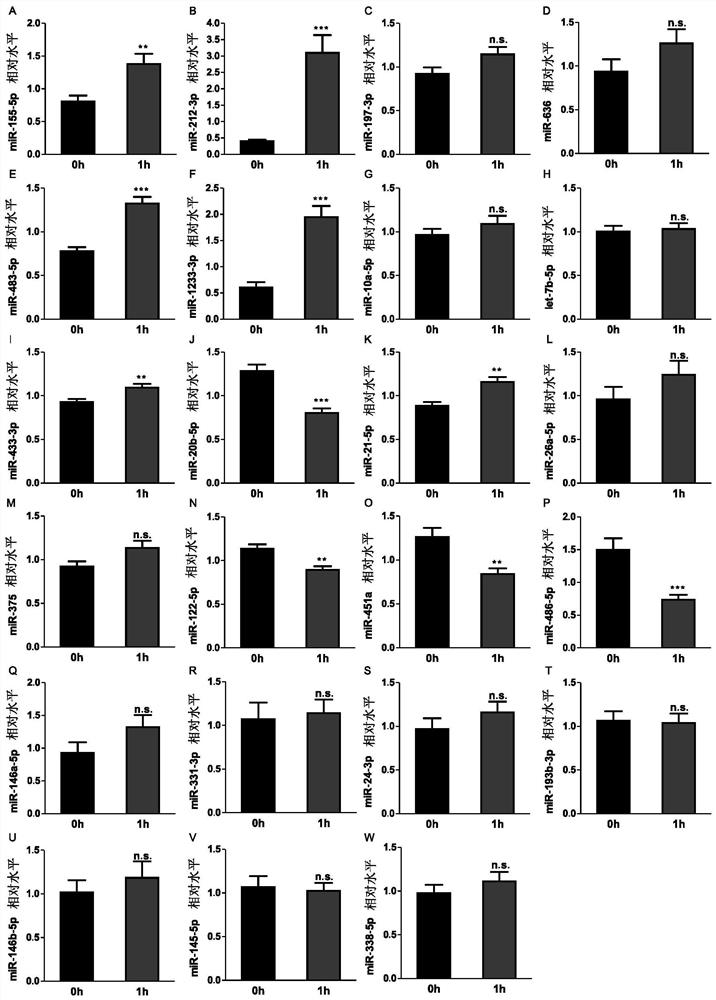

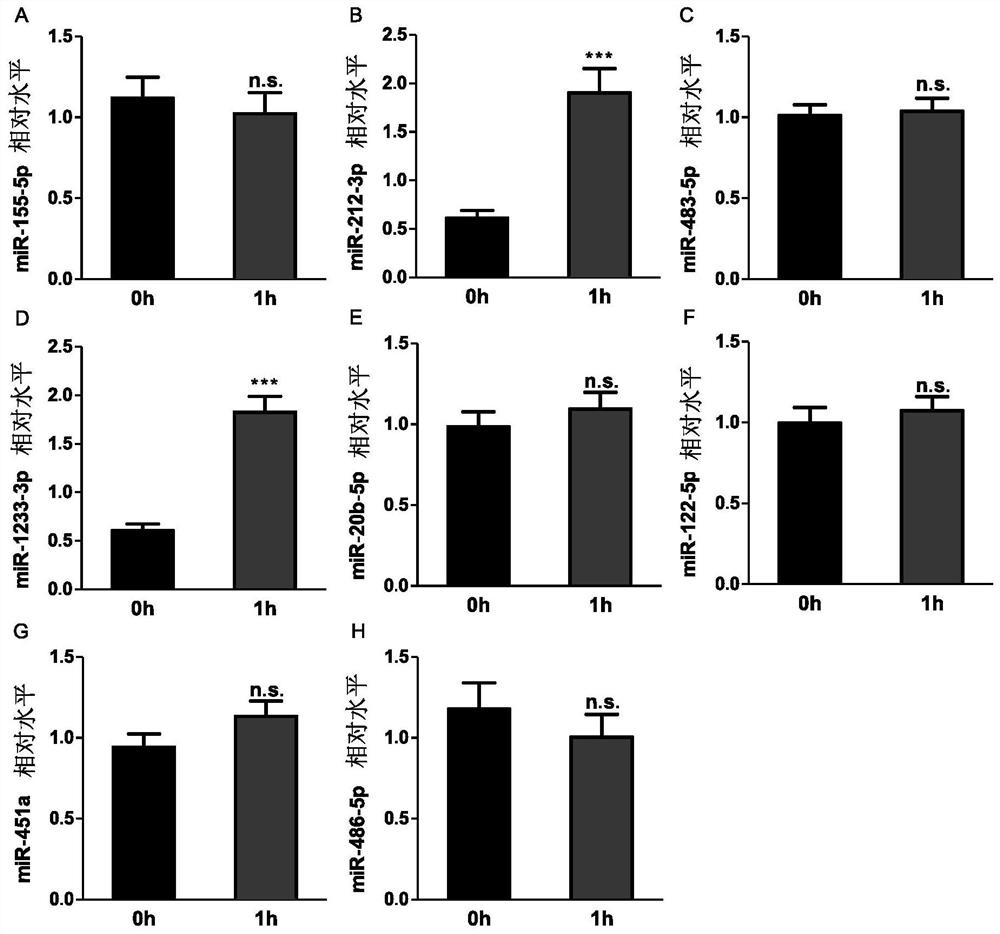

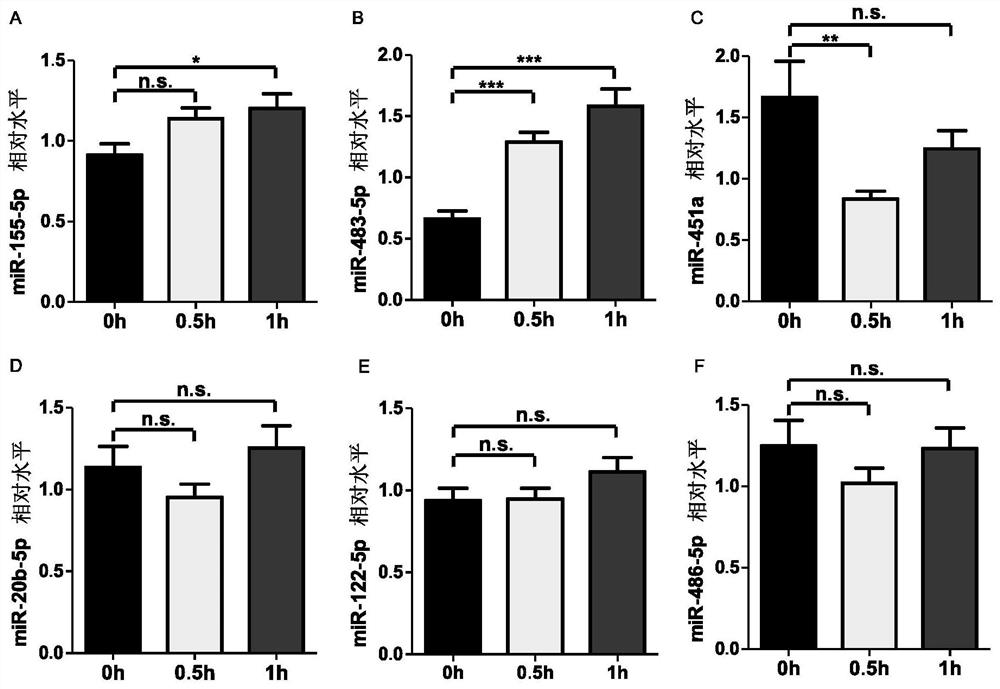

Kit and application of reagent in preparation of kit

ActiveCN107130017ALess miscellaneousMicrobiological testing/measurementCoronary plaqueACS - Acute coronary syndrome

The invention provides application of a reagent in the preparation of a kit; the kit is used for diagnosing acute coronary syndrome; the reagent is used for detecting at least one of miR-155-5p, miR-483-5p, and miR-451a. The inventor discovers through experiments that miR-155-5p, miR-483-5p or miR-451a has significant expression differences before and after plaque rapture, and has good diagnostic value in the early diagnosis for the rapture of coronary plaque; the kit prepared with the reagent for detecting at least one of miR-155-5p, miR-483-5p, and miR-451a is effectively applicable to the early diagnosis of the rupture of coronary plaque, and has the advantages of high sensitivity and high specificity.

Owner:PEOPLES HOSPITAL PEKING UNIV

Method of using microchannel reactor to prepare coffee essence

InactiveCN107125404AShort reaction timeImprove catalytic reaction efficiencyCoffee flavouringReaction systemEnzyme

The present invention relates to a method of using a microchannel reactor to prepare coffee essence. The method comprises the following steps: step 1, a coffee bean enzymolysis reaction solution and an enzyme solution are pumped into the microchannel reactor, the materials are mixed in a first mixing module, and the mixture enters into a reaction module to be subjected to an enzymolysis reaction; step 2, an activity of enzymes is inactivated using a high temperature and the enzymolysis reaction is terminated; step 3, a reaction system is fully mixed with reducing sugar and refined oil to obtain a mixed reaction system; step 4, the mixed reaction system enters a second high temperature module, a temperature is rapidly increased to the temperature required by a technology, and a Maillard thermal reaction is conducted; and step 5, the reaction system flows through a low temperature module and flows out the microchannel reactor to obtain the coffee essence crude products. The method can accurately control the enzymolysis processes and can conduct the rapid and accurate control of the temperature of the thermal reaction and the temperature of a post-treatment. The microchannel reactor is free of amplification effects and easy to upgrade and amplify, and can realize the seamless amplification from research and development to production.

Owner:ENZYMECODE BIOTECHNOLOGY CO LTD

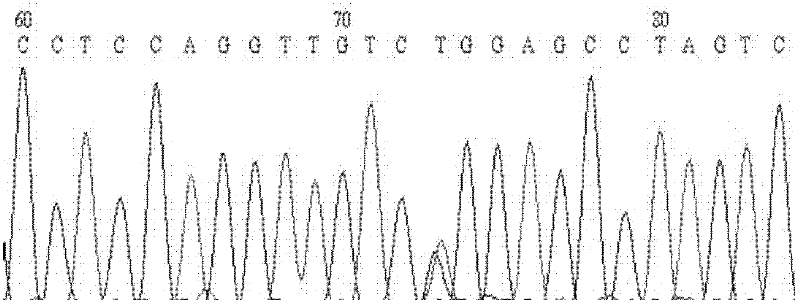

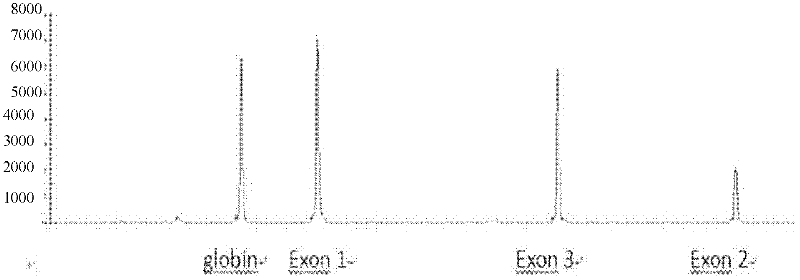

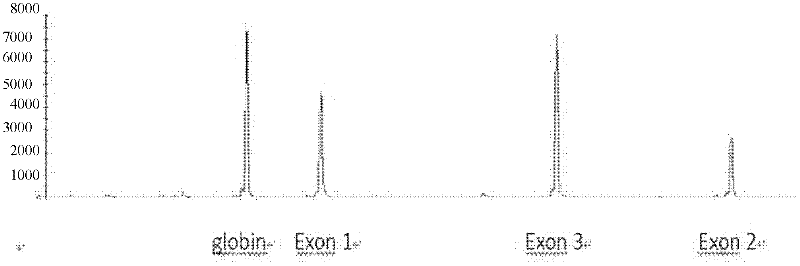

Kit for diagnosing Von Hippel-Lindau (VHL) disease

ActiveCN102242200ALess miscellaneousGood primer specificityMicrobiological testing/measurementDNADisease cause

The invention discloses a kit for diagnosing Von Hippel-Lindau (VHL) disease. The kit for diagnosing the VHL disease comprises a primer pair 1 consisting of deoxyribonucleic acid (DNA) molecules shown as SEQ ID No.1 and DNA molecules shown as SEQ ID No.2, a primer pair 2 consisting of DNA molecules shown as SEQ ID No.3 and DNA molecules shown as SEQ ID No.4, and a primer pair 3 consisting of DNA molecules shown as SEQ ID No.5 and DNA molecules shown as SEQ ID No.6. Experiments prove that the kit ensures that a polymerase chain reaction (PCR) amplification product has a specific strip and hardly has a mixed strip, has a specific, clear and accurate sequencing result, and does not have any uncertain alkali group, namely the primers in the kit have high specificity, and a few mixed strips exist; and the kit provides convenience for screening family members with the VHL disease, and lays a foundation for fulfilling the aims of early discovery, early diagnosis and early treatment.

Owner:上海仁东医学检验所有限公司

Method for preparing chocolate essence by using micro-channel reactor

InactiveCN107149131AShort reaction timeImprove catalytic reaction efficiencyFood scienceReaction systemChemistry

The invention relates to a method for chocolate essence by using a micro-channel reactor. The method comprises the following steps: step one, pumping a cacao bean enzymatic hydrolysis solution and an enzyme solution into the micro-channel reactor, mixing the cacao bean enzymatic hydrolysis solution with the enzyme solution in a first mixing module, and then feeding the mixture into a reaction module for enzymatic hydrolysis; step two, passivating enzyme activity at high temperature to stop enzymatic hydrolysis; step three, fully mixing a reaction system with reducing sugar and refined oil to obtain a mixed reaction system; step four, enabling the mixed reaction system to enter a second high-temperature module, rapidly heating to the temperature which meets the process requirement, and carrying out Maillard thermal reaction; and step five, enabling the reaction system to flow through a low-temperature module and flow out of the micro-channel reactor to obtain a chocolate essence coarse product. The enzymolysis process can be controlled accurately, and thermal reaction temperature and aftertreatment temperature are rapidly and accurately controlled; and by the micro-channel reactor, the amplification effect does not exist, upgrading amplification is facilitated, and seamless amplification from research and development to production can be realized.

Owner:ENZYMECODE BIOTECHNOLOGY CO LTD

Method for preparing rich-fragrance sesame seed oil by adopting microchannel reactor

InactiveCN107418715AShort reaction timeImprove catalytic reaction efficiencyFatty-oils/fats refiningFatty-oils/fats productionReaction systemScale effects

The invention relates to a method for preparing rich-fragrance sesame seed oil by adopting a microchannel reactor. The method comprises the following steps: (1) pumping a sesame seed enzymolysis reaction solution and an enzyme solution into the microchannel reactor, carrying out mixing in a first mixing module, and then, subjecting the mixture to an enzymolysis reaction in a reaction module; (2) passivating enzyme activity by a high temperature to terminate the enzymolysis reaction; (3) thoroughly mixing the reaction system with reducing sugar and sesame seed oil, so as to obtain a mixed reaction system; (4) enabling the mixed reaction system to enter a second high-temperature module, rapidly heating the temperature of the mixed reaction system to a process required temperature, and carrying out a Maillard thermal reaction; and (5) enabling the reaction system to flow through a low-temperature module and flow out of the microchannel reactor, thereby obtaining a crude rich-fragrance sesame seed oil product. According to the method, an enzymolysis process can be accurately controlled, and a thermal reaction temperature and an aftertreatment temperature can be rapidly and accurately controlled; and by using the microchannel reactor, no scale effect is caused, upgrading scaling is facilitated, and seamless scaling from research and development to production can be achieved.

Owner:ENZYMECODE BIOTECHNOLOGY CO LTD

Lotus seed wine and brewing technology thereof

InactiveCN107384681AReduce wasteTake advantage ofAlcoholic beverage preparationResource savingHorticulture

The invention relates to lotus seed wine and a brewing technology thereof. The lotus seed wine is brewed by using primary lotus seed processing wastes, namely lotus seed shells, ground lotus powder and lotus seed core powder, as raw materials according to a solid state fermentation method. The wastes produced in the primary lotus seed processing process are used as the wine brewing raw materials, so that the brewing technology is not only a deep lotus seed processing technology, but also a method for improving the economic efficiency of the lotus seed industry, and furthermore meets a requirement of creating a resource-saving and environment-friendly society. By the brewing technology, the cost of the raw materials of the lotus seed wine can be reduced to 10%, but the wine yield rate and the wine quality are not affected, and more customers can drink the high-quality and cheap lotus seed wine. By the lotus seed wine brewing technology, all parts of the lotus seeds are used as the raw materials, and the brewed lotus seed wine is puree wine without any additive and has the characteristics of clearness, transparence, strong lotus seed fragrance and pure mouth feel.

Owner:湘潭县泽润生态农业发展有限公司

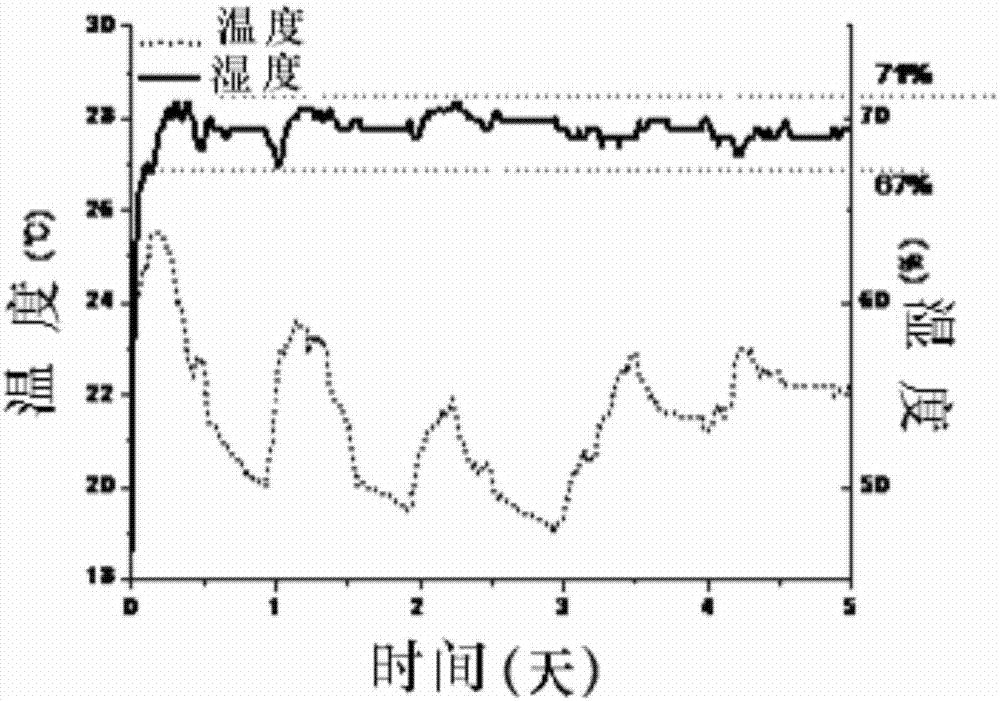

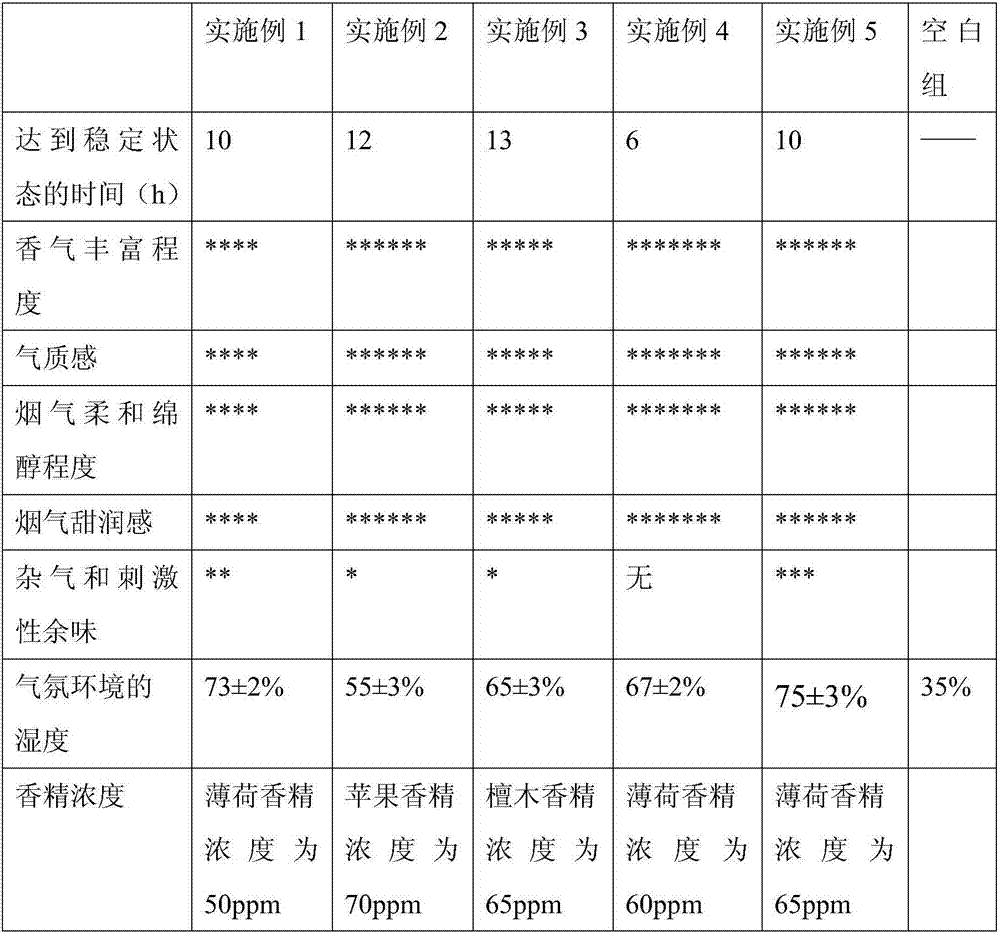

Intelligent tobacco atmosphere adjusting device and tobacco storing device with same

ActiveCN107082193AImprove retention qualityImprove stabilityPackaging under vacuum/special atmosphereStable stateGas passing

The invention discloses an intelligent tobacco atmosphere adjusting device and a tobacco storing device with the same. The adjusting device comprises an air-permeable liquid-impermeable film sleeve and a tobacco atmosphere adjusting solution filling the film sleeve. The film sleeve comprises at least one polymer film with intelligent gas micropore channels which can regulate and control the passing amount of gas obtained after volatilization of the tobacco atmosphere adjusting solution, so that when the set temperature and humidity of the environment are achieved, partial pressure of the gas controlled by the intelligent gas micropore channels is in a stable state. The adjusting device can adjust the atmosphere of the environment where tobaccos are located through volatilization of the internal adjusting solution, and when the specific temperature and humidity are achieved, the adjusting solution is released from the intelligent gas micropore channels at a certain speed, namely the gas passing amount is regulated and controlled to achieve the stable state. The intelligent tobacco atmosphere adjusting device does not make contact with the tobaccos directly, and the tobacco moisture retention quality and stability are improved. The smoking smell of the processed tobaccos is solidified and stabilized, the aroma rich feeling is increased, smoke is soft and mellow, and the sweet sense is increased.

Owner:UNIV OF SCI & TECH BEIJING

Sour flavoring wine produced by using smaller lumped koji solid white spirit waste lees

ActiveCN101805680BImprove qualityLess miscellaneousMicroorganism based processesAlcoholic beverage preparationWhite spiritChemistry

The invention relates to a sour flavoring wine produced by using smaller lumped koji solid white spirit waste lees, which is prepared by saccharifying, fermenting and distilling the smaller lumped koji solid white spirit waste lees. The sour flavoring wine produced by using the smaller lumped koji solid white spirit waste lees is used for adjusting the acidity in blending a smaller lumped koji white spirit, which not only saves grains and reduces the production cost of the smaller lumped koji white spirit, but also improves the quality of the white spirit.

Owner:CHONGQING JIANGJIN WINERY GROUP

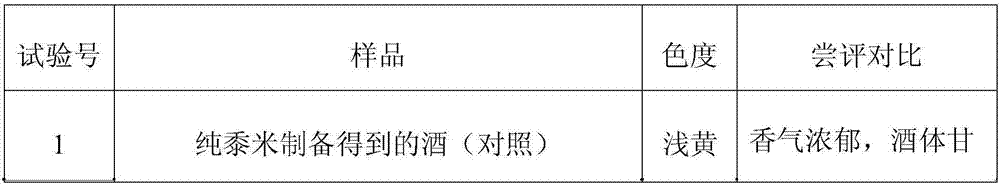

Pericarpium citri reticulatae health wine and preparing method thereof

InactiveCN107034070ALess miscellaneousFast water absorptionFood processingDigestive systemPericarpium citri reticulataeBrewing

The invention provides pericarpium citri reticulatae health wine and a preparing method thereof. The pericarpium citri reticulatae health wine is prepared from, by weight, 77-87 parts of milled glutinous broomcorn millet, 3-13 parts of pericarpium citri reticulatae, 9.9 parts of yeast for making hard liquor and 0.1 part of yeast. The preparing method comprises the steps of adding pericarpium citri reticulatae accounting for 20-50% of the total weight of pericarpium citri reticulatae to baijiu for soaking; soaking milled glutinous broomcorn millet in hot water and then conducting boiling; cooling boiled milled glutinous broomcorn millet to 24-26 DEG C, adding water, yeast for making hard liquor, yeast and the rest of pericarpium citri reticulatae, conducting fermentation for 3-5 days, adding baijiu, adding soaked medicinal wine and medicinal residues, and continuing fermentation to obtain mash; and preparing the pericarpium citri reticulatae health wine by means of the mash. The traditional yellow wine brewing technology and wine soaking technology are innovatively and organically combined, effective constituents of the traditional Chinese medicine pericarpium citri reticulatae can be effectively blended into the wine liquid after long-time soaking and fermentation, on one hand, the pharmacodynamic effect of the medicinal wine is fully realized, on the other hand, the wine tastes harmonious and mild, and traditional drinking habits of people can be better met.

Owner:周然

Low-temperature microwave expansion process of cut tobacco

InactiveCN101919582BGuaranteed qualityOutstanding aromaTobacco preparationProcess engineeringAroma aroma

The invention relates to a low-temperature microwave expansion process of cut tobacco. The process comprises the following steps of: putting expanded cut tobacco with the water content of 40-70 percent by rating resurgence in a die; then, freezing into blocks at a temperature of 55 DEG C below zero to 35 DEG C below zero; conveying the cut tobacco blocks into a microwave continuous freeze-dried system to sublimate and dry until the water content is 3-8 percent; and finally resurging to the water content of 12-13 percent to obtain a finished product of expanded cut tobacco. The cut tobacco is expanded by the process of the invention has the advantages of remarkable aroma and fragrance, lower breakage rate, remarkably lessened odor and controllable expansion degree.

Owner:周川

Method for preparing strong-flavor corn oil by virtue of micro-channel reactor

InactiveCN107142147AShort reaction timeImprove catalytic reaction efficiencyFatty-oils/fats productionEnzymatic hydrolysisFood flavor

The invention relates to a method for preparing strong-flavor corn oil by virtue of a micro-channel reactor. The method comprises the following steps: (1) pumping corn enzymatic hydrolysis reaction liquid and an enzyme solution into the micro-channel reactor, mixing in a first mixing module so as to obtain a mixed solution, and introducing the mixed solution into a reaction module, so as to generate enzymatic hydrolysis reaction; (2) inactivating enzyme activity at a high temperature, and terminating the enzymatic hydrolysis reaction; (3) adequately mixing a reaction system with revertose and corn oil, so as to obtain a mixed reaction system; (4) introducing the mixed reaction system into a second high-temperature module, rapidly heating to a temperature required by a process, and carrying out Maillard thermal reaction; and (5) introducing the reaction system to flow through a low-temperature module and flow out of the micro-channel reactor, so as to obtain a strong-flavor corn oil crude product. By virtue of the method, the enzymatic hydrolysis process can be precisely controlled, and the thermal reaction temperature and the post-treatment temperature can be rapidly and accurately controlled; and by utilizing the micro-channel reactor, an amplification effect is avoided, the upgrade amplification is easily realized, and the seamless amplification from the research and the development to the production can be realized.

Owner:ENZYMECODE BIOTECHNOLOGY CO LTD

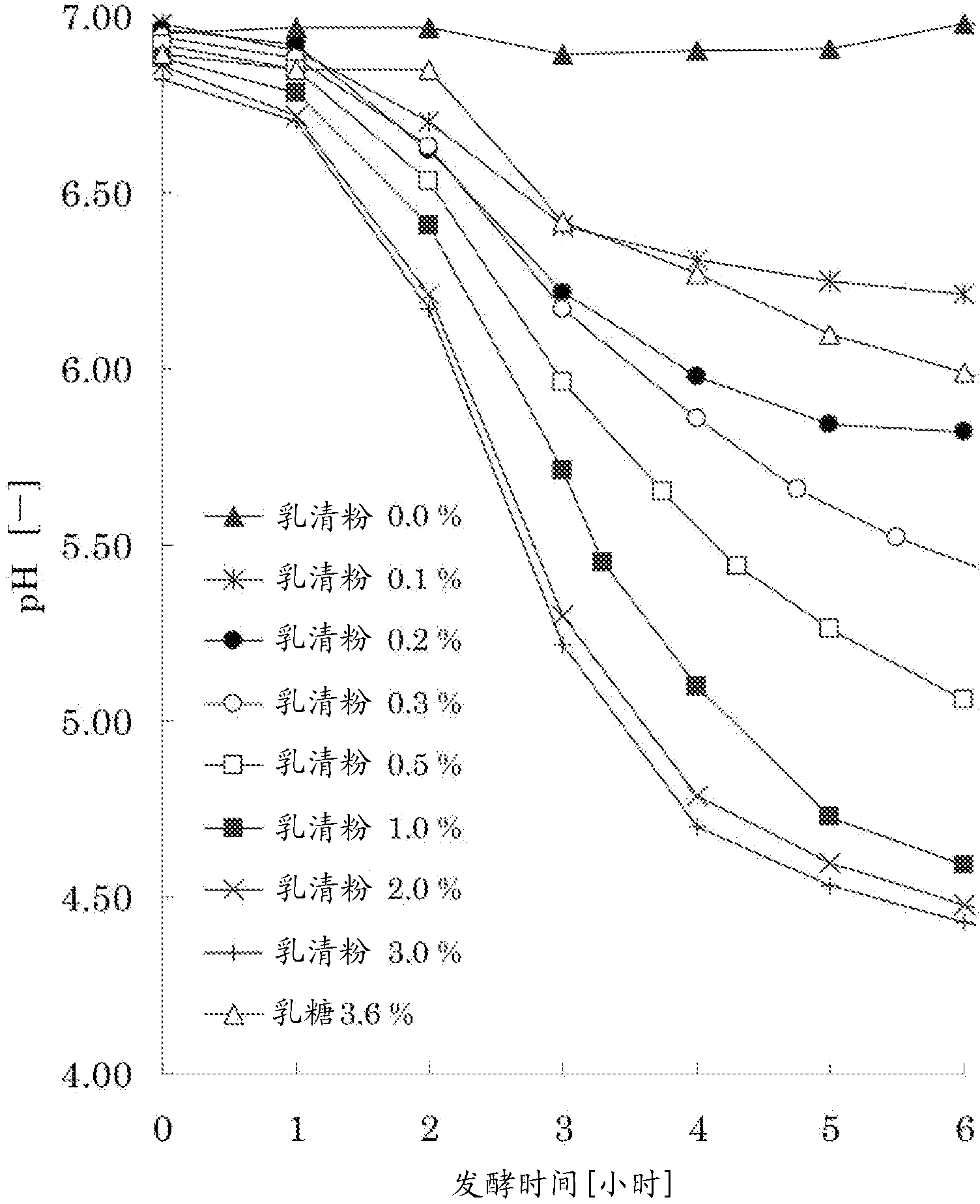

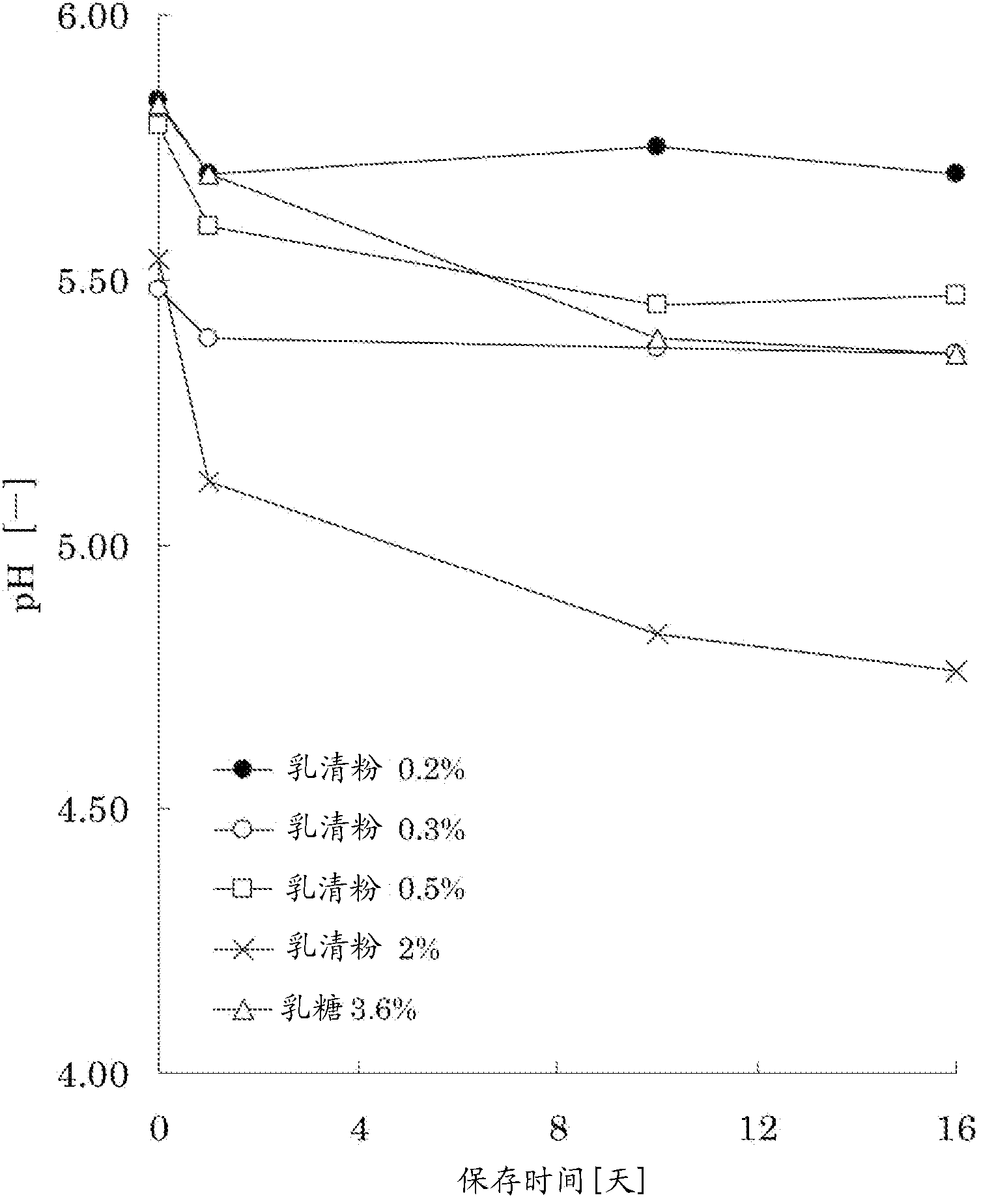

Dairy product in which whey is used, and method for manufacturing same

ActiveCN103491791ALess sourLess miscellaneousMilk preparationWhey manufactureMicroorganismTotal protein

The present invention addresses the problem of providing a dairy product with reduced milk odor specific to products in which fermented milk and whey protein are used. A method for manufacturing an edible gel, comprising: a starting material blending step for blending ß-lactoglobulin in a ratio of 70-100 wt% in the total protein of the starting material; a heating step performed after the starting material blending step; and a fermentation step by microorganisms after the heating step. The problem of the present invention is achieved by this method.

Owner:MEIJI CO LTD

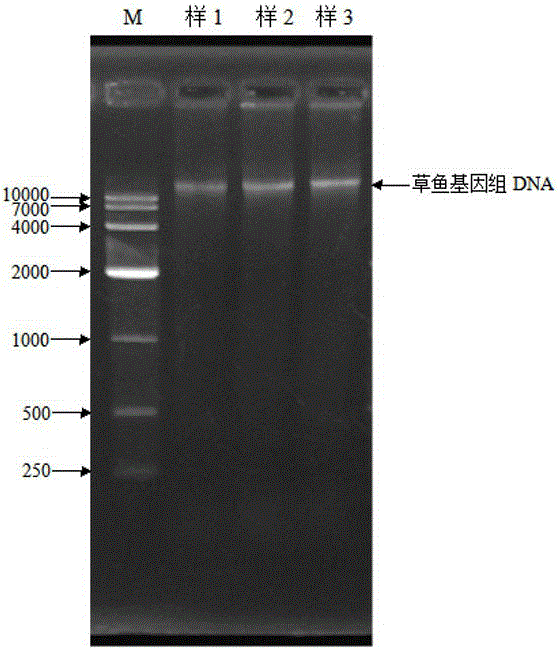

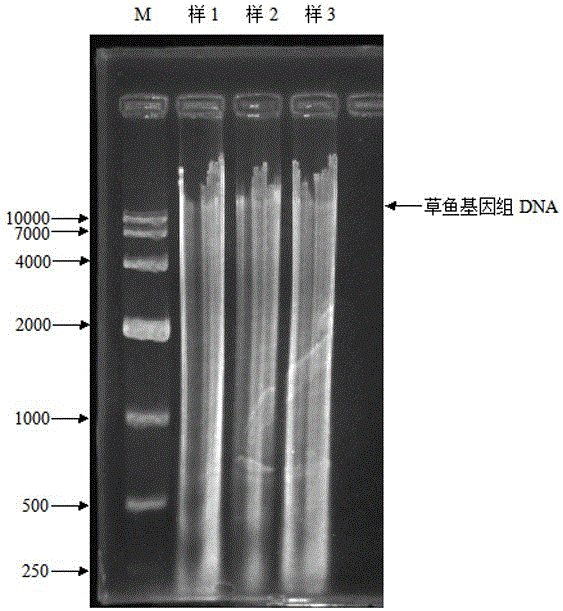

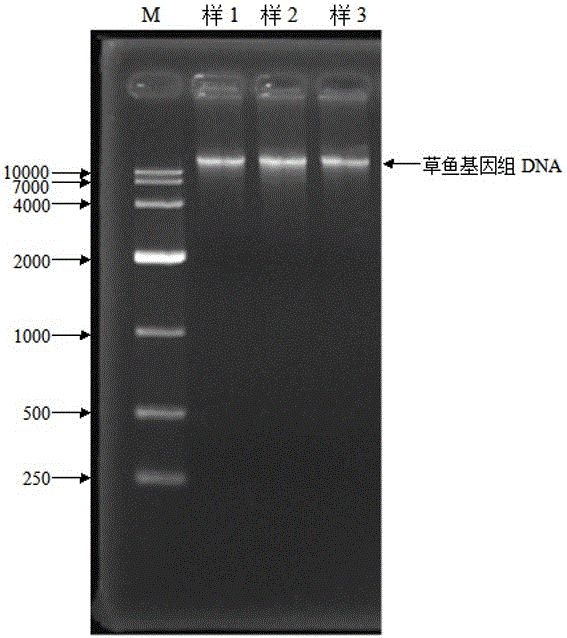

Extraction method of total genomic DNA of fish

The invention relates to an extraction method of total genomic DNA of fish. The extraction method comprises the following specific steps: A, taking the fish tissue containing DNA, washing, grinding, and placing into a centrifuging tube; B, adding with Chelex-100 solution, carrying out boiling water bath for 15-20 min, adding with proteinase K solution, and carrying out water bath at 50-60 DEG C for more then 3h; C, sucking liquid in the centrifuging tube, placing the liquid into another centrifuging tube, and carrying out centrifugal separation; D, taking the supernate, adding with RNase solution, carrying out water bath at 37 DEG C for more than 45 min; E, adding with Tris saturated phenol solution, uniformly mixing, carrying out centrifugal separation, and taking the supernate; F, adding with a suitable amount of chloroform and isoamylol mixed solution, uniformly mixing, carrying out centrifugal separation, and taking the upper solution; G, adding with alcohol, and placing for 1h or a longer time; H, carrying out centrifugal separation, and discharging the supernate; I, adding with alcohol, carrying out centrifugal separation, and discharging the supernate; J, removing the alcohol, adding with sterile water, and storing for later use. According to the extraction method, a reagent is convenient to fetch, the DNA extraction effect is good, the integrity of DNA is high, especially the extraction can be carried out by taking scale as the raw material, and limitation from the quantity of a sample is avoided.

Owner:NANCHANG UNIV

Baijiu brewing method for accelerating ripening and preventing retrogradation

InactiveCN110129170APromote oxidationPromote coordinationAlcoholic beverage preparationSelf-diffusionMouthfeel

The invention relates to a Baijiu brewing process, and in particular, relates to a Baijiu brewing method for accelerating ripening and preventing retrogradation. A method adopting Ru porcelain and / orRu porcelain glaze powder mixed in pit mud and / or distiller's grains in fermentation is adopted for Baijiu brewing. The method has the advantages that with the characteristics of piezoelectric effectproduced by the Ru porcelain or Ru porcelain glaze powder in the fermentation environment of Baijiu, an electromagnetic field which can promote reduction of the self-diffusion coefficient of ethanol molecular clusters can be produced, so the enhancement of the self-diffusion coefficient of ethanol at high temperature is restrained, the mouthfeel of Baijiu is improved and a ripening accelerating effect is played. On the other hand, the formation of compounds in Baijiu is basically completed in the process of fermentation, so when the fermentation of Baijiu is completed, the compounds in Baijiuform a relatively stable structure. Therefore, compared with a method of accelerating the ripening of Baijiu after completion of the fermentation, the method can effectively prevent retrogradation ofBaijiu.

Owner:泸州市凤凰老窖曲酒厂

Strawberry fishbone collagen sucking milk and making method thereof

InactiveCN104872725AEasy to cleanSimple and fast operationFood ingredient functionsFood preparationBiotechnologyBioactive peptide

The invention relates to strawberry fishbone collagen sucking milk and a making method thereof. The strawberry fishbone collagen sucking milk is characterized by comprising, by weight, 150-160 parts of silver carp bone, 150-160 parts of fresh grass carp bone, 100-110 parts of shark bone, 5-7 parts of ginger, 7-9 parts of perilla frutescens, 50-60 parts of strawberry, 25-30 parts of skim milk powder, 10-15 parts of coconut pulp and appropriate amount of water. The strawberry fishbone collagen sucking milk contains rich collagen, bioactive peptide, amino acid and various other nutritious elements.

Owner:刘卫春

Beauty nourishing and qi invigorating fishbone collagen steamed cake and preparation method thereof

InactiveCN104938922ASoft bouncyBright colorYeast food ingredientsFood ingredient functionsBiotechnologyNutrition

The invention relates to a beauty nourishing and qi invigorating fishbone collagen steamed cake and a preparation method thereof. The steamed cake is characterized by being prepared from the following raw materials by weight part: 150-160 of fresh silver carp fishbone, 150-160 of fresh grass carp fishbone, 100-110 of fresh shark fishbone, 3-5 of ginger, 5-7 of licorice, 30-35 of purple sweet potato, 25-30 of glutinous rice flour, 50-55 of wheat flour, 2-3 of yeast, 15-20 of candied date, and a proper amount of water. The beauty nourishing and qi invigorating fishbone collagen steamed cake provided by the invention has the characteristics of soft and elastic taste, crystal clear color, rich nutrition, and fragrant and sweet taste.

Owner:刘卫春

Method for preparing aroma rapeseed oil by adopting micro-channel reactor

InactiveCN106967492AShort reaction timeImprove catalytic reaction efficiencyFatty-oils/fats productionEnzymatic hydrolysisReaction temperature

The invention relates to a method for preparing aroma rapeseed oil by adopting a micro-channel reactor. The method comprises the following steps: step one, pumping a rapeseed enzymatic hydrolysis solution and an enzyme solution into the micro-channel reactor, mixing in a first mixing module and then entering into a reaction module to carry out enzymatic hydrolysis; step two, carrying out high-temperature enzymatic activity passivation, and ending the enzymatic hydrolysis; step three, sufficiently mixing a reaction system with reducing sugar and rapeseed oil so as to obtain a mixed reaction system; step four, the mixed reaction system entering into a second high temperature module, quickly raising the temperature to a technological requirement temperature, and carrying out a Maillard heat reaction; and step five, the reaction system flowing to a low temperature module, and flowing out of the micro-channel reactor to obtain a rapeseed oil crude product. According to the method, the enzymatic hydrolysis process can be accurately controlled, the heat reaction temperature and aftertreatment temperature can be quickly and accurately controlled; and by using an unamplifying effect of the micro-channel reactor, the method is easy for upgrading amplification, and can realize seamless amplification from research and development to production.

Owner:ENZYMECODE BIOTECHNOLOGY CO LTD

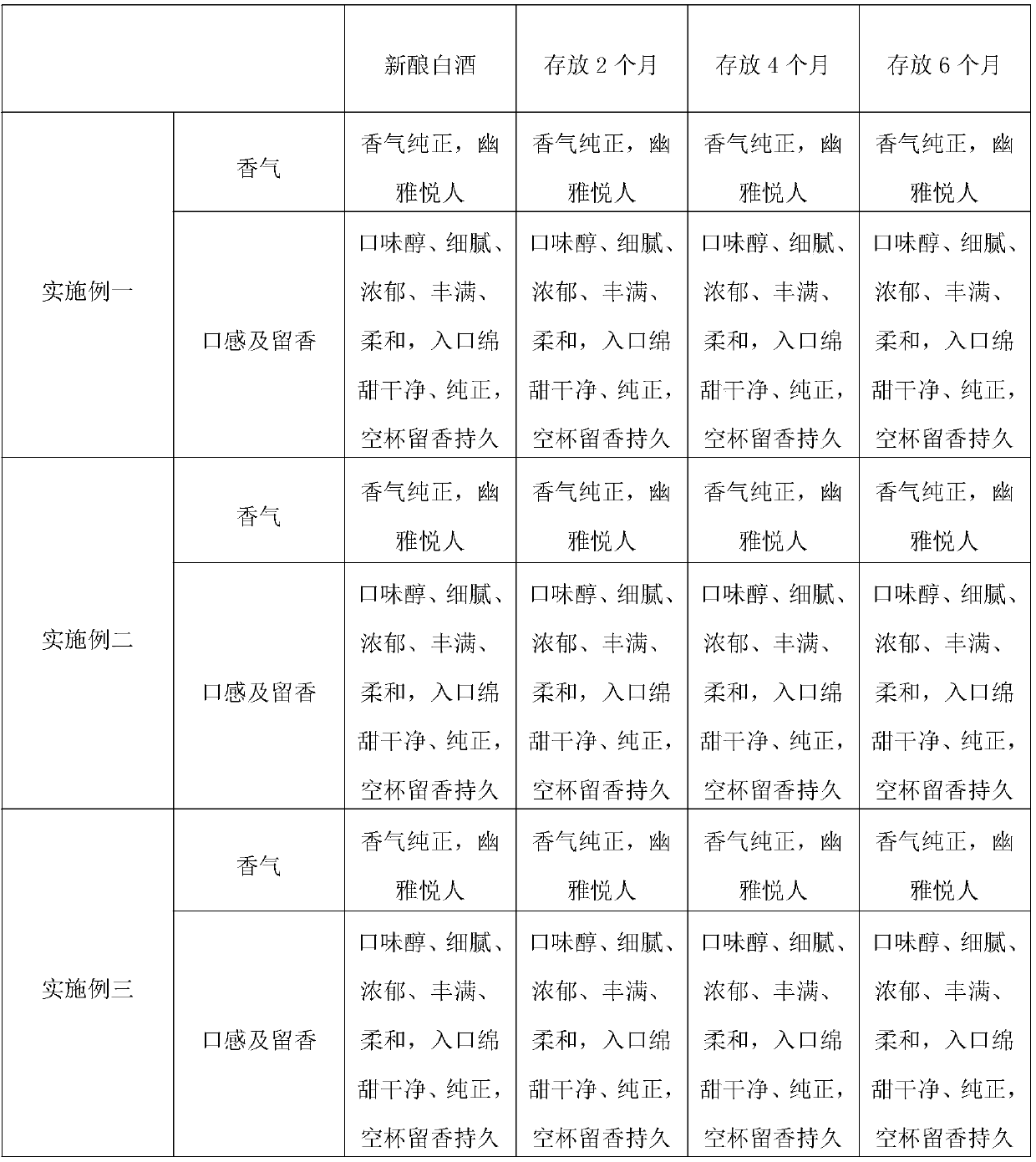

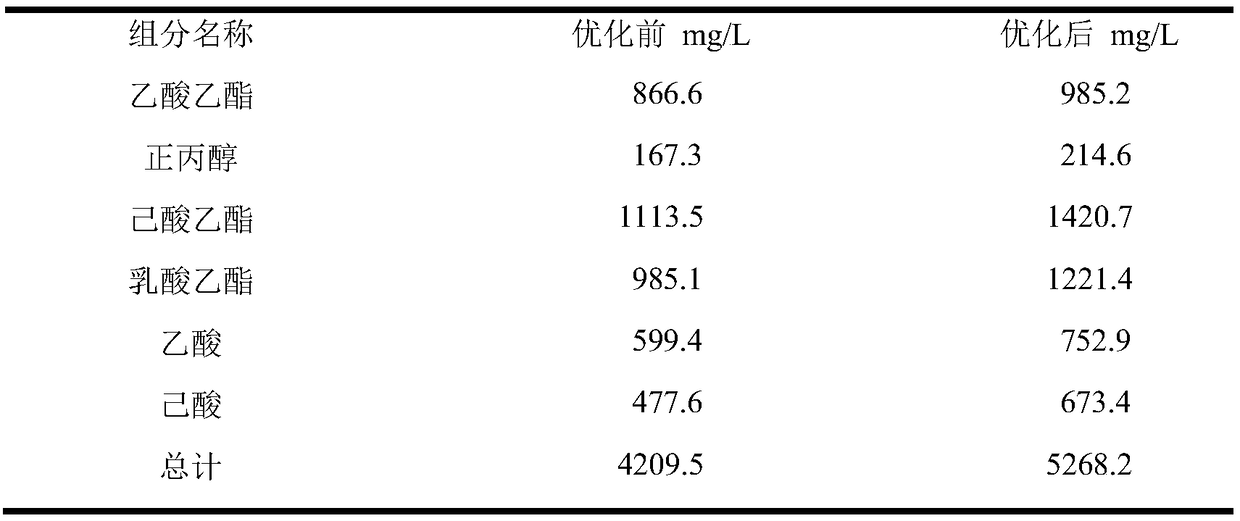

Method for increasing quality of strong aromatic white spirit covered arak

InactiveCN108949460AQuality improvementIncrease the concentration of aroma substancesAlcoholic beverage preparationWater contentFlavor

The invention discloses a method for increasing quality of strong aromatic white spirit covered arak. The method comprises the following steps: airing a vinasse acquired after distilling and taking white spirit according to a conventional method till water content is 58-63%, adding distiller yeast and uniformly stirring, thereby acquiring a covering vinasse; putting conventional fermented grains into a cellar and then covering a layer of covering vinasse on the surface, and performing sealing fermentation; separating and distilling the covering vinasse after the ending of fermentation, therebyacquiring the covered arak. According to the method disclosed by the invention, the quality of the covered arak is greatly increased, the concentration of flavor components in the wine is increased and the foreign flavors in the wine are reduced under the condition that the normal wine yield is guaranteed.

Owner:ANHUI GUJING DISTILLERY +1

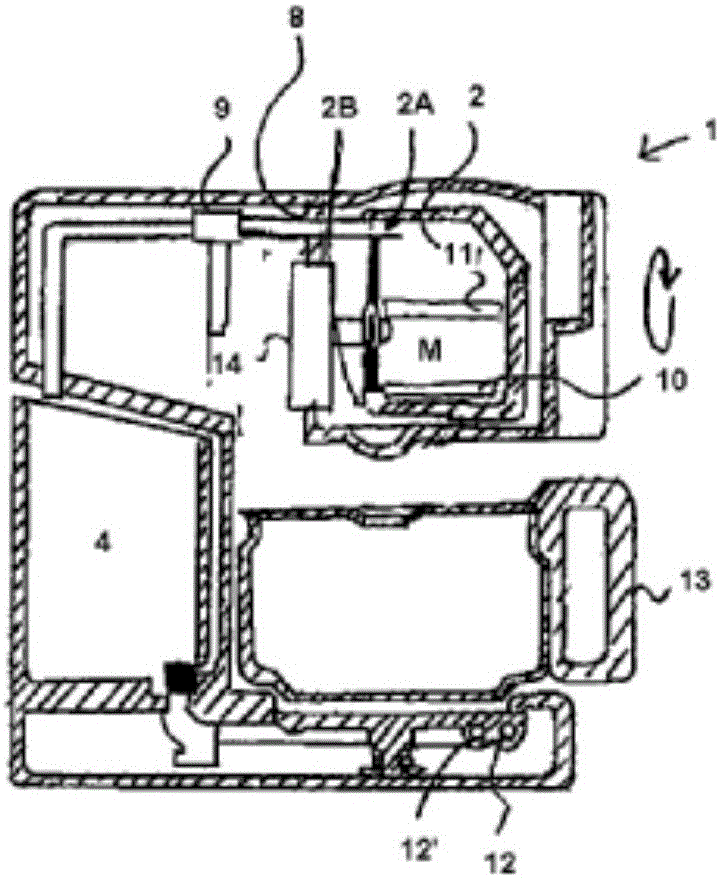

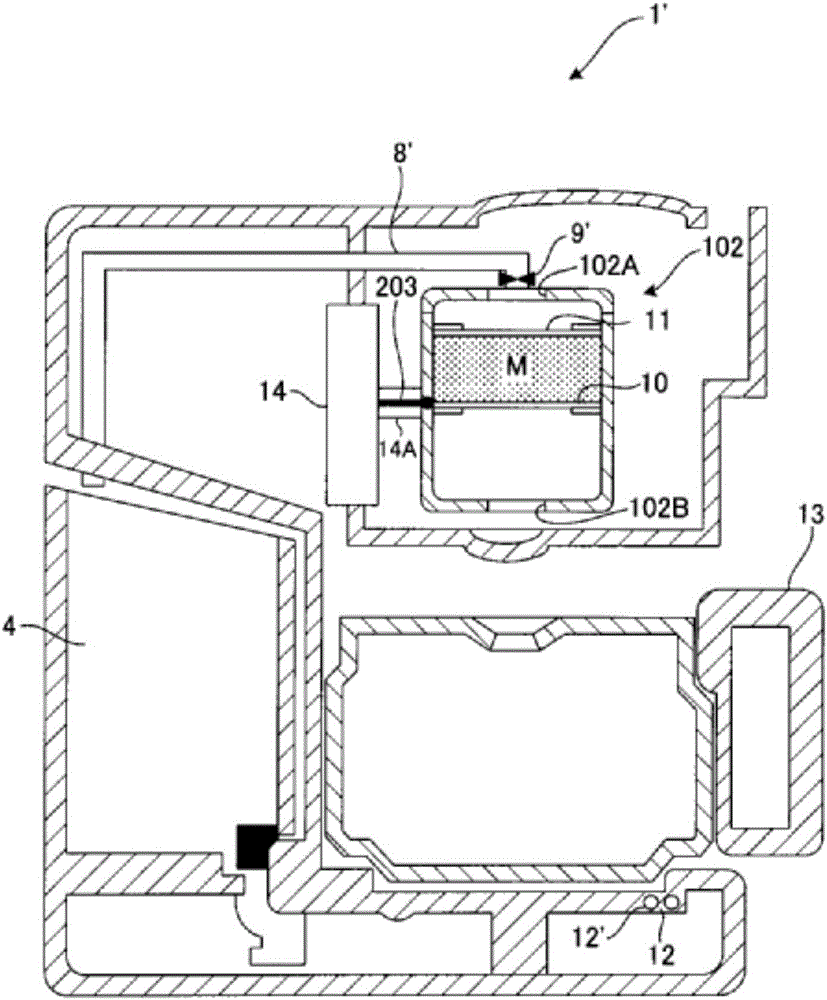

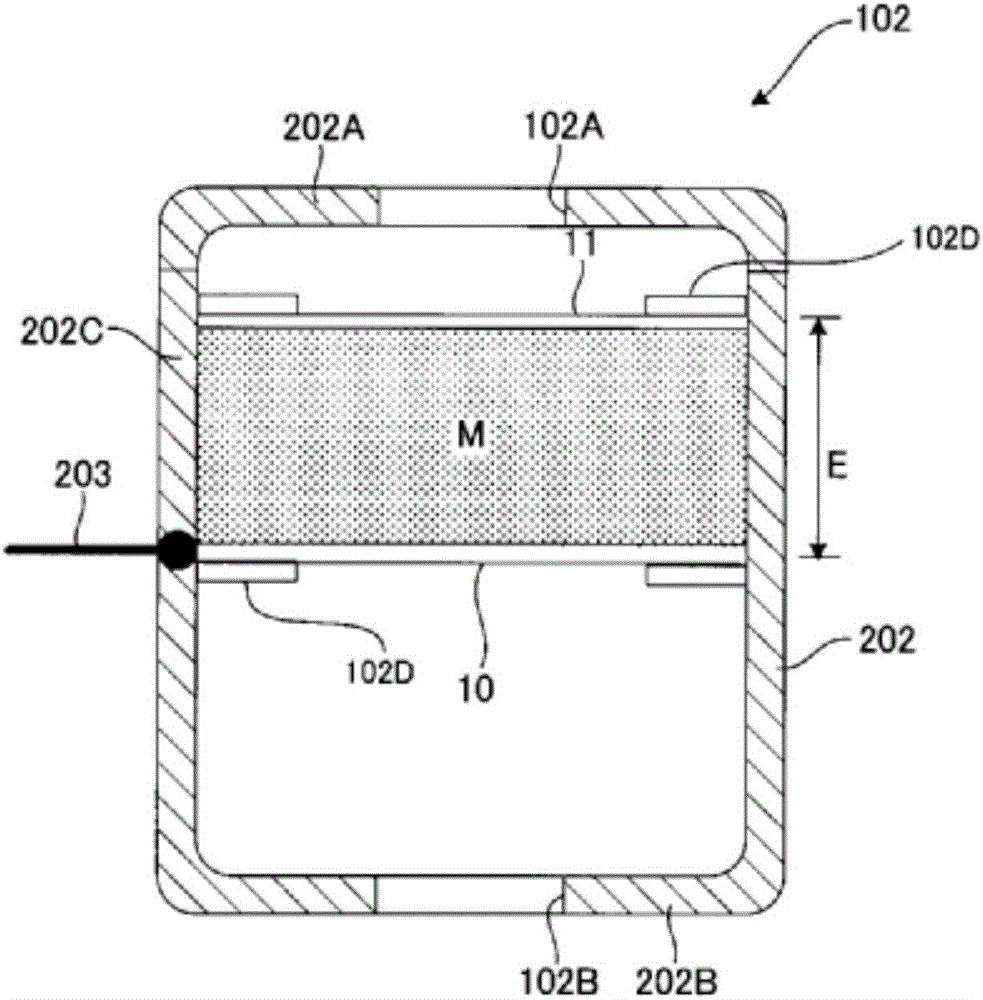

Beverage extraction device

Owner:SUNTORY HLDG LTD

Method for preparing strong-flavor soybean oil by virtue of micro-channel reactor

InactiveCN107142148AImprove efficiencyShorten the reaction time of enzymatic hydrolysisFatty-oils/fats productionChemistryEnzymatic hydrolysis

The invention relates to a method for preparing strong-flavor soybean oil by virtue of a micro-channel reactor. The method comprises the following steps: (1) pumping soybean enzymatic hydrolysis reaction liquid and an enzyme solution into the micro-channel reactor, mixing in a first mixing module so as to obtain a mixed solution, and introducing the mixed solution into a reaction module, so as to generate enzymatic hydrolysis reaction; (2) inactivating enzyme activity at a high temperature, and terminating the enzymatic hydrolysis reaction; (3) adequately mixing a reaction system with revertose and soybean oil, so as to obtain a mixed reaction system; (4) introducing the mixed reaction system into a second high-temperature module, rapidly heating to a temperature required by a process, and carrying out Maillard thermal reaction; and (5) introducing the reaction system to flow through a low-temperature module and flow out of the micro-channel reactor, so as to obtain a strong-flavor soybean oil crude product. By virtue of the method, the enzymatic hydrolysis process can be precisely controlled, and the thermal reaction temperature and the post-treatment temperature can be rapidly and accurately controlled; and by utilizing the micro-channel reactor, an amplification effect is avoided, the upgrade amplification is easily realized, and the seamless amplification from the research and the development to the production can be realized.

Owner:ENZYMECODE BIOTECHNOLOGY CO LTD

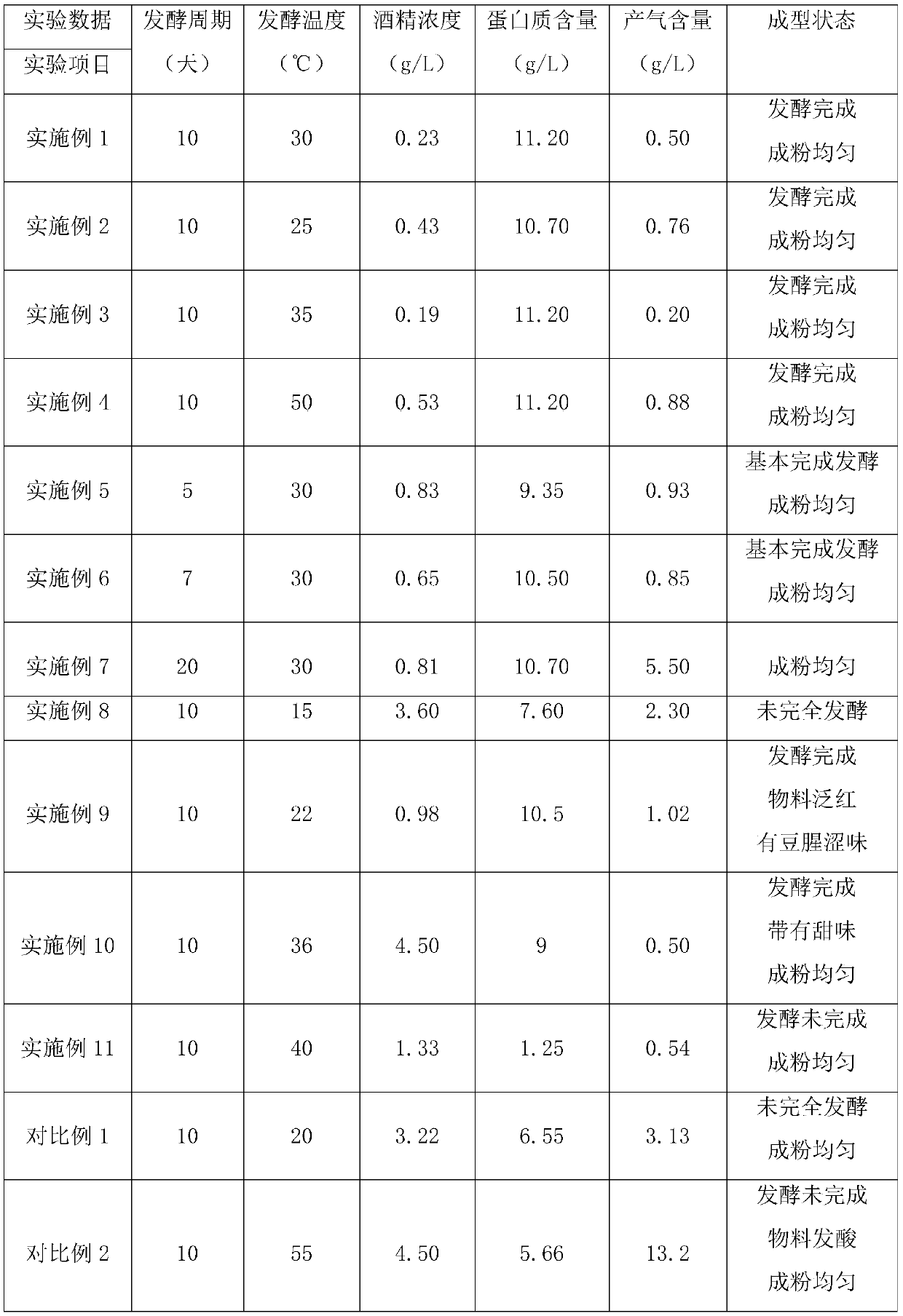

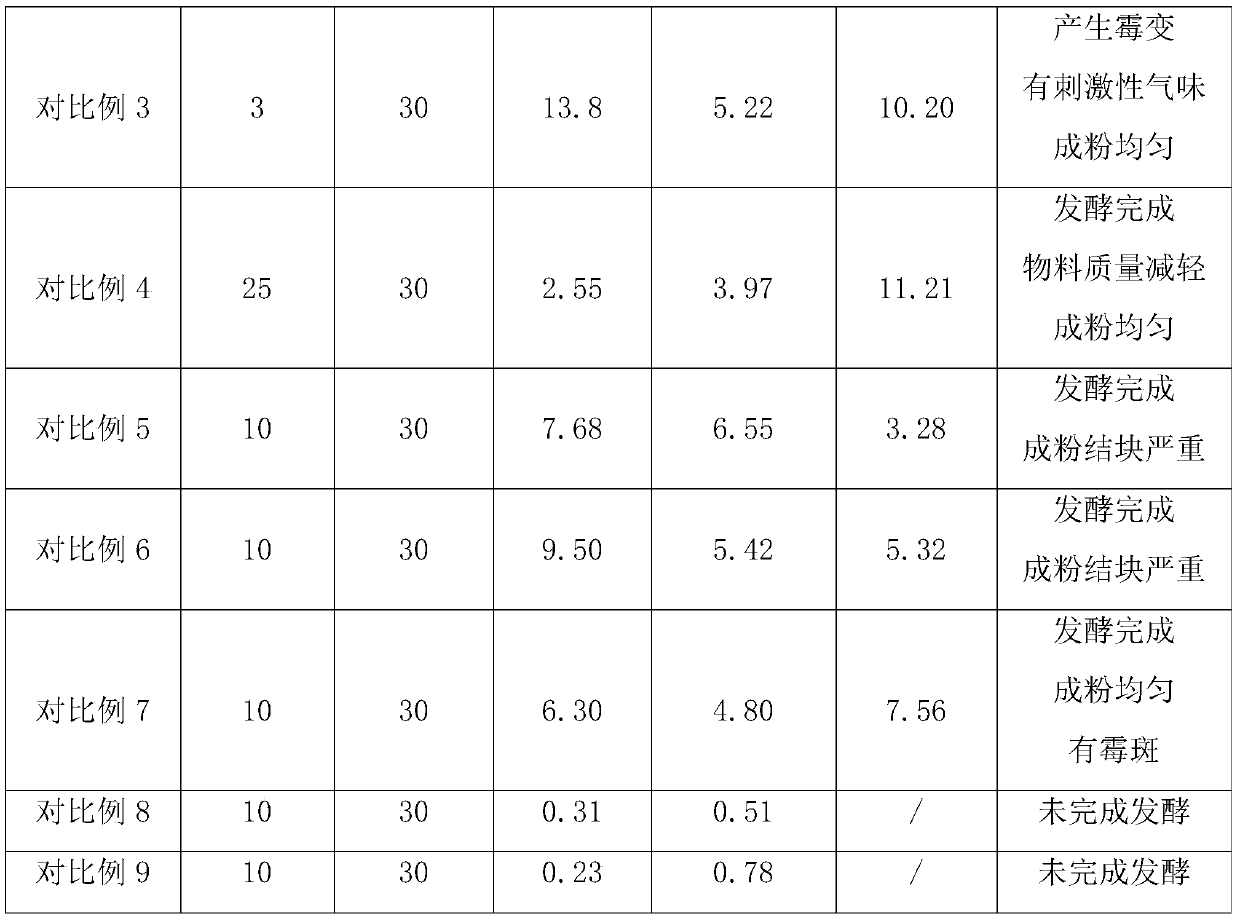

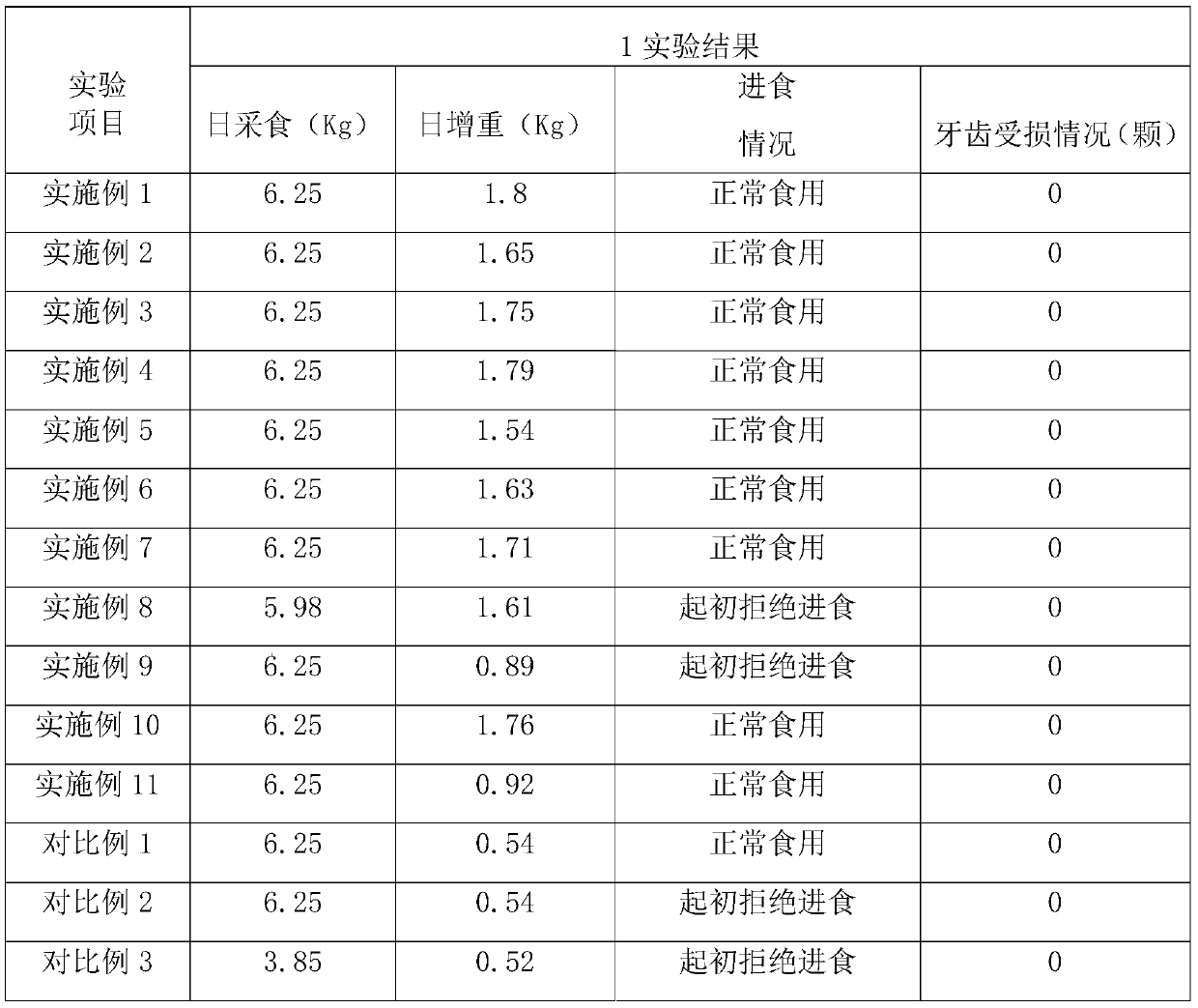

Preparation method of bamboo powder feed based on microbial fermentation

PendingCN111436528AImprove carrying capacityModerate pHAnimal feeding stuffAccessory food factorsBiotechnologyNutrition

In order to achieve the purposes, the invention provides a preparation method of a bamboo powder feed based on microbial fermentation. The preparation method comprises the following steps of carryingout selecting and trimming; cleaning and soaking; drying; crushing, sieving and weighing for later use; mixing and compounding microorganisms to obtain fermented materials; bagging; shading fermentation; inspecting; labeling; warehousing, that is, performing vacuum packaging in different bags, taking moso bamboo rods and bamboo leaves as raw materials and crushing into 40 to 100 meshes of bamboo powder, wherein under the condition that the bamboo hole complete state is maintained in a non-wall-breaking preservation mode, fermentation of composite microorganisms is carried out to accelerate growth of probiotic flora, while fermentation is carried out by vacuum anaerobic fermentation in an assisting mode, and stable fermentation is avoided while a situation of fungus pollution is avoided; and by means of the beneficial bacteria with activity, the feed is still kept in a uniform and loose state after being formed, the feed is used for feeding, the intestinal health is promoted, the disease-prevention and harm immunity is improved, the livestock is promoted to effectively absorb feed nutrition, and the purpose of producing high-quality moso bamboo fermented feed is achieved.

Owner:周玮生 +1

The use of kits and reagents in the preparation of kits

ActiveCN107130017BLess miscellaneousMicrobiological testing/measurementDNA/RNA fragmentationCoronary arteriesBiochemistry

The invention provides application of a reagent in the preparation of a kit; the kit is used for diagnosing acute coronary syndrome; the reagent is used for detecting at least one of miR-155-5p, miR-483-5p, and miR-451a. The inventor discovers through experiments that miR-155-5p, miR-483-5p or miR-451a has significant expression differences before and after plaque rapture, and has good diagnostic value in the early diagnosis for the rapture of coronary plaque; the kit prepared with the reagent for detecting at least one of miR-155-5p, miR-483-5p, and miR-451a is effectively applicable to the early diagnosis of the rupture of coronary plaque, and has the advantages of high sensitivity and high specificity.

Owner:PEOPLES HOSPITAL PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com