Preparation method of bamboo powder feed based on microbial fermentation

A technology of microbial fermentation and fermented materials, which is applied in the field of bamboo powder feed, can solve the problems of unstable fermentation and easy caking of bamboo powder feed, and achieve the effects of strong load capacity, appropriate pH and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

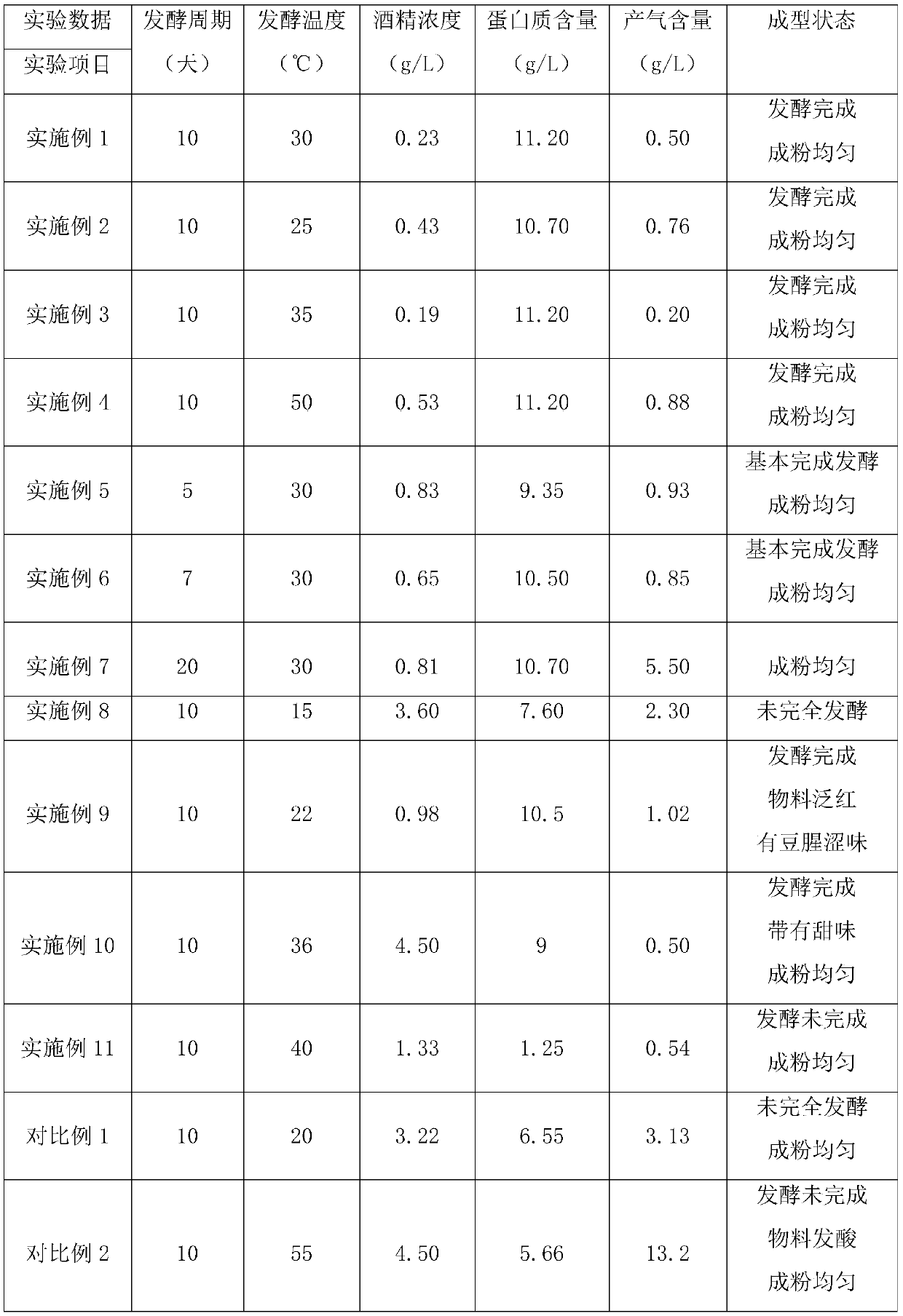

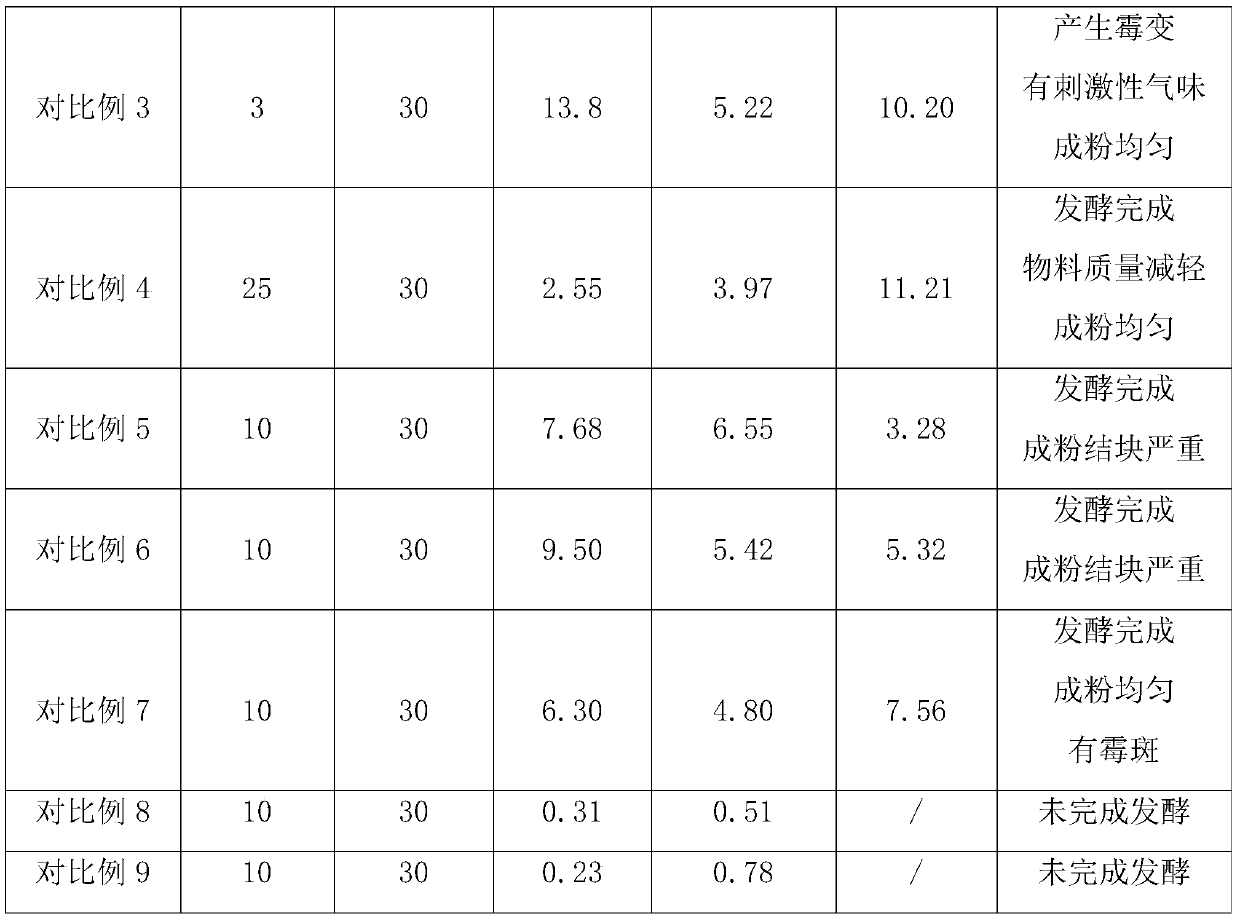

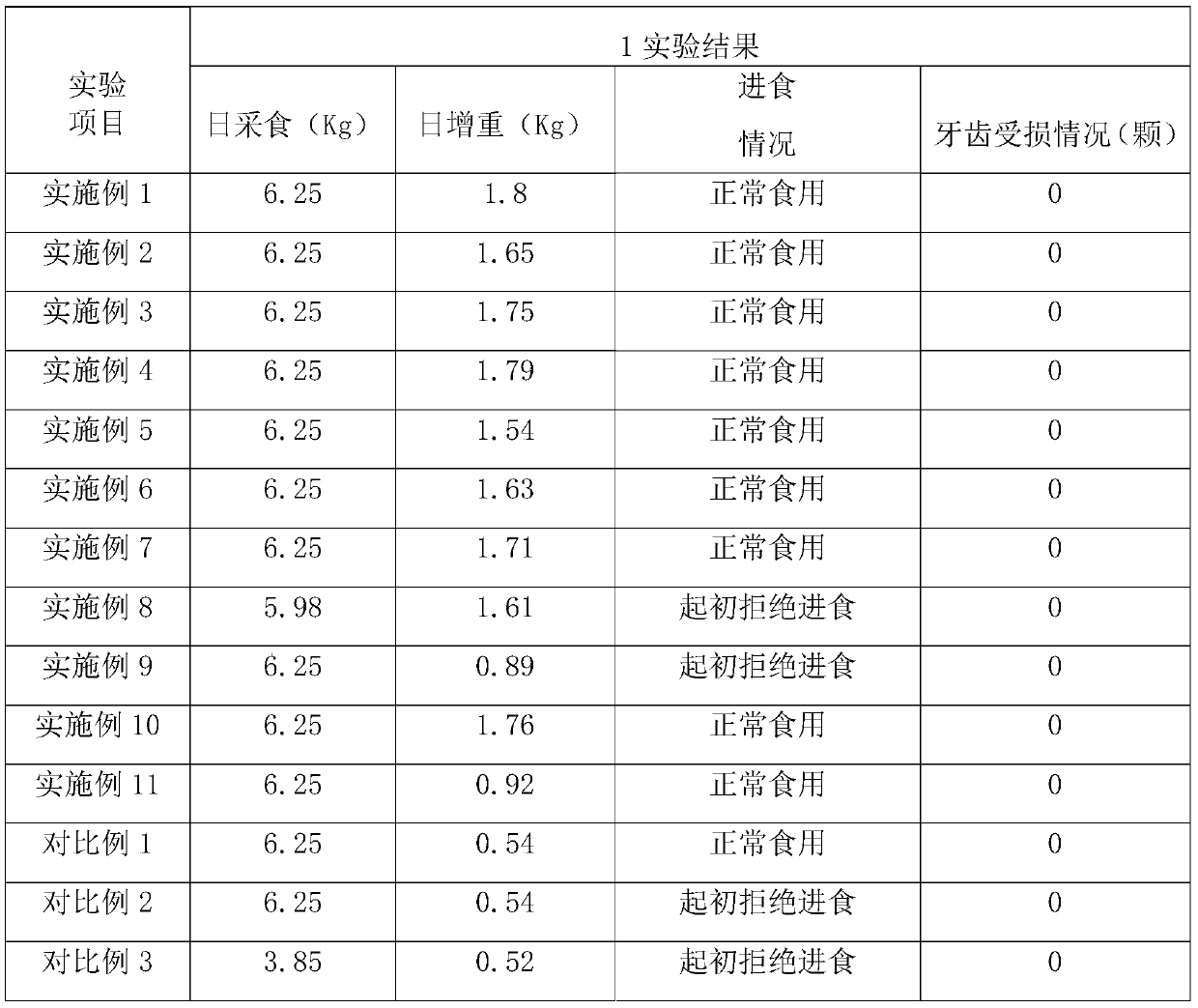

Examples

Embodiment 1

[0038] A method for preparing bamboo powder feed based on microbial fermentation includes the following steps:

[0039] S1: Select moso bamboo, select moso bamboo with a moisture content of 40%, remove the roots, and obtain rootless moso bamboo;

[0040] S2: Washing and soaking, after washing the rooted bamboos, put them in clean water and soak them for 2 hours to obtain infiltrated bamboos;

[0041] S3: Dry, stack the infiltrated bamboos in a dark place, and air dry until the moisture content of the bamboos is 10%-35% to obtain pretreated bamboos;

[0042] S4: The pretreated moso bamboo is pulverized by a bamboo wood grinder to obtain moso bamboo fine powder, and the prepared moso bamboo fine powder is passed through a 40 mesh and 100 mesh screen successively, and it is retained to pass through a 40 mesh screen without passing through 100 mesh. The bamboo fine powder of the sieve is reserved; among them, the bamboo wood crusher uses the spiral crushing process to grind the bamboo int...

Embodiment 2

[0050] A method for preparing bamboo powder feed based on microbial fermentation. The difference from Example 1 is that: in step 1, moso bamboo with a water content of 20% is selected, and in step 7, the fermentation temperature in the dark is 25°C.

Embodiment 3

[0052] A method for preparing bamboo powder feed based on microbial fermentation. The difference from Example 1 is that: in step 1, moso bamboo with a water content of 30% is selected, and in step 7, the fermentation temperature in the dark is 35°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com