Low-temperature microwave expansion process of cut tobacco

A technology of microwave expansion and shredded tobacco, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of poor quality and achieve the effects of reducing miscellaneous flavor, good processing resistance, and low crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]Honghe C3F sliced tobacco, re-moisture to 15% water content and cut into shreds, and then carry out 5 times of grading and re-wet expansion, the first time make the water content of cut tobacco reach 25%, and store for 30 minutes; Store at 35% water content for 30 minutes; rake for the third time to re-moisture to 45% water content, store for 30 minutes; rake for the fourth time to re-moisture to 55% water content and store for 30 minutes; fifth time to rake and re-moisture to 60 % water content. After the moisture expansion is completed, put it into a 400×400×40mm mold and freeze it to -45°C, and quickly send the frozen shredded tobacco into the "microwave continuous freeze-drying system" for sublimation drying. It takes about 25 minutes to transport the tobacco to the outlet, and then the shredded tobacco that has been expanded and shaped by microwave at low temperature can be obtained. However, the moisture content of the shredded tobacco at the outlet is about 5% a...

Embodiment 2

[0048] Yuxi C3F sheet tobacco, re-moisture to 18% water content and cut into shreds, then carry out 4 times of grading and re-moisture expansion, the first time make the water content of cut tobacco reach 25%, and store for 30 minutes; Re-moisture to 35% water content, and store for 30 minutes; rake for the third time and re-moisture to 45% water content, and store for 30 minutes; re-moisture to 52% water content after the fourth rake. Put it into a rectangular mold of 400×400×40mm after re-wetting and swelling, and after freezing to -45°C, quickly send the frozen shredded tobacco into the "microwave continuous freeze-drying system" for sublimation drying. It takes about 23 minutes for the system to be transported to the outlet, and the shredded tobacco that has been expanded and shaped by microwave at low temperature can be obtained. But at this time, the moisture content of the shredded tobacco at the outlet is about 5%, and then it can be used in subsequent processes after i...

Embodiment 3

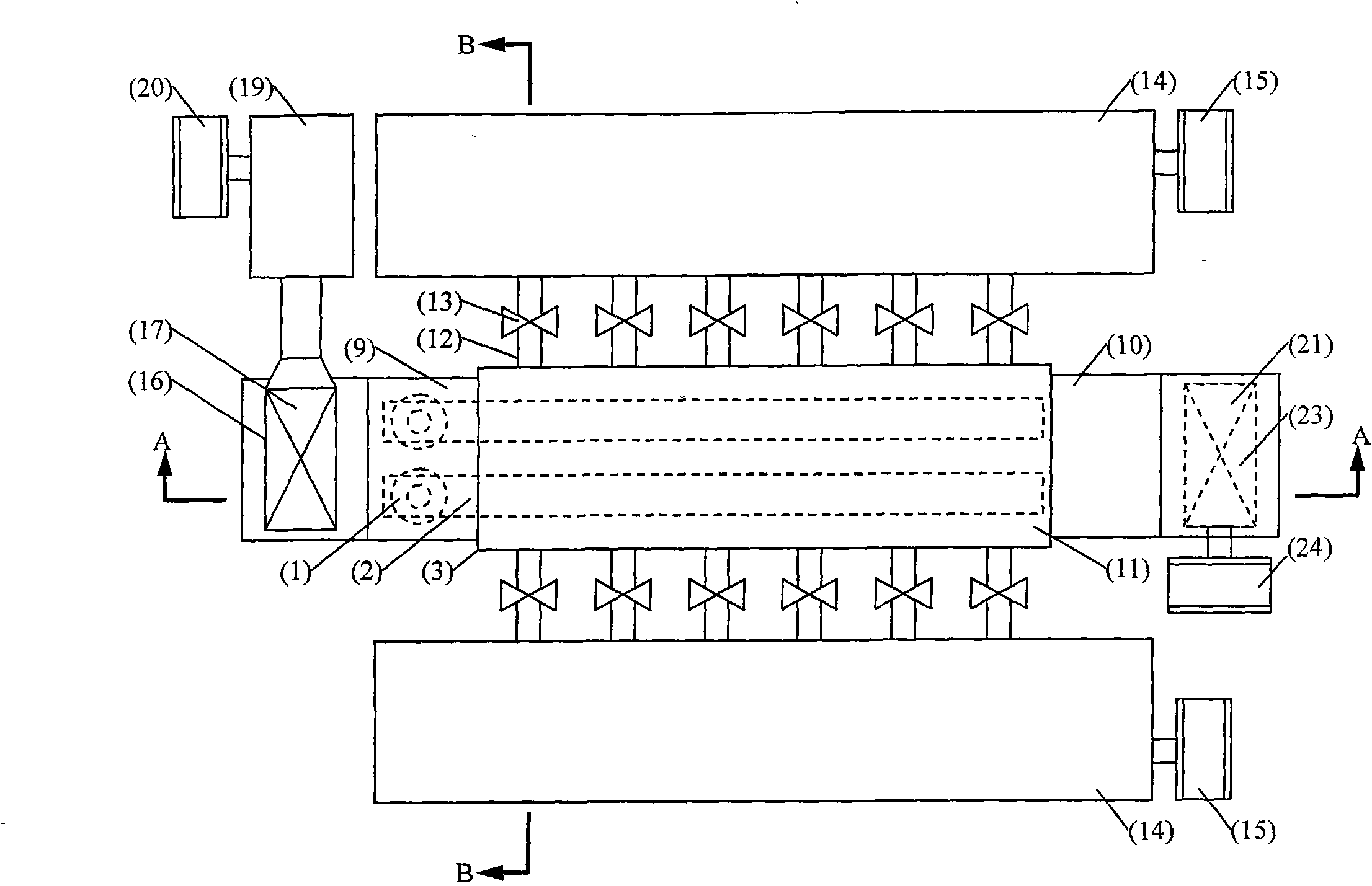

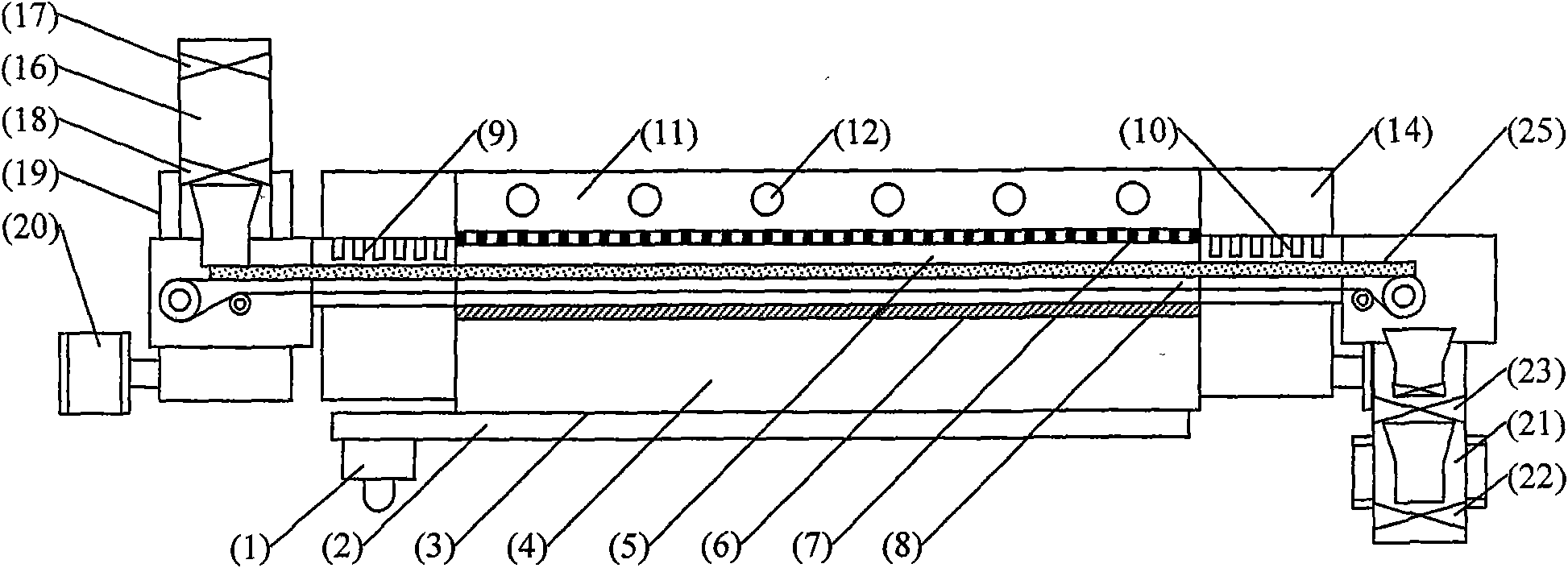

[0050] As the accompanying drawings of the present invention. The present invention can be implemented using a microwave continuous freeze-drying system. The microwave continuous freeze-drying system includes a microwave vacuum freeze-drying device, a vacuum water catcher, a vacuum feeding device, and a vacuum discharging device, wherein the microwave vacuum freeze-drying device includes a microwave generator 1, a microwave antenna 2, and an atmospheric pressure microwave cavity 4 , vacuum microwave cavity 5, vacuum partition 6, porous and breathable microwave shielding plate 7, low-loss conveyor belt 8, front-end vacuum microwave suppressor 9, rear-end vacuum microwave suppressor 10, characterized in that: in the microwave vacuum freeze-drying device A composite freeze-drying chamber 3 composed of an atmospheric pressure microwave chamber 4 and a vacuum microwave chamber 5 is provided, between the atmospheric pressure microwave chamber 4 and the vacuum microwave chamber 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com