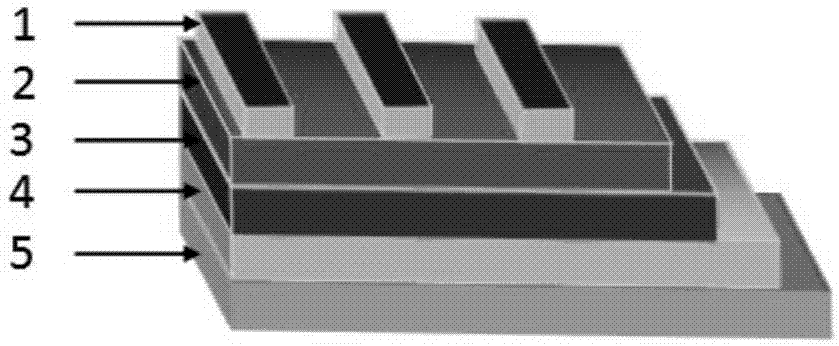

Plane structure hybrid solar cell based on antimony trisulfide compact film

An antimony trisulfide, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high requirements for thin film experimental equipment, reduced battery efficiency, long preparation time, etc., and achieves easy large-area production, high efficiency , the effect of good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] 1 Preparation of precursor solution

[0039] (1) Take 1.37g SbCl 3 , and then drop N-N dimethylamide;

[0040] (2) Stir the solution in step (1) at room temperature for 30 minutes;

[0041] (3) After stirring for 30 minutes, add 0.675g~1.125g of thiourea to the solution, and stir at room temperature for 30 minutes.

[0042] 2 Substrate processing

[0043]The substrate used in the test is conductive glass (ITO conductive glass or transparent flexible plastic, FTO conductive glass or transparent flexible plastic, AZO conductive glass or transparent flexible plastic, which are commercially available products or known technologies). slices for cleaning. Cut the conductive glass sheet into a suitable shape and size, clean it with a detergent, rinse it with tap water, rinse it with deionized water, and then put it in an ultrasonic cleaner to wash it with deionized water, ethanol once, acetone once, and acetone and ethanol for 15 minutes, and finally dried in an oven to o...

Embodiment 1

[0071] (1) Clean the FTO glass slides: first put the glass slides into a solution containing a detergent (such as Liby brand liquid detergent) and soak for 10 minutes, then repeatedly scrub and rinse with clean water; then polish with polishing powder ; Then put them into containers with deionized water, acetone and alcohol for 15 minutes respectively; finally put them in an oven and dry them at 100 degrees to eliminate stress;

[0072] (2) Preparation of electron transport layer: TiO 2 The precursor solution was swirled on the FTO glass substrate at a forward rotation speed of 750 rpm for 12 s, and a rear rotation speed of 4000 rpm for 30 s; the swirled TiO 2 The film was calcined at 550°C for 60min in a muffle furnace;

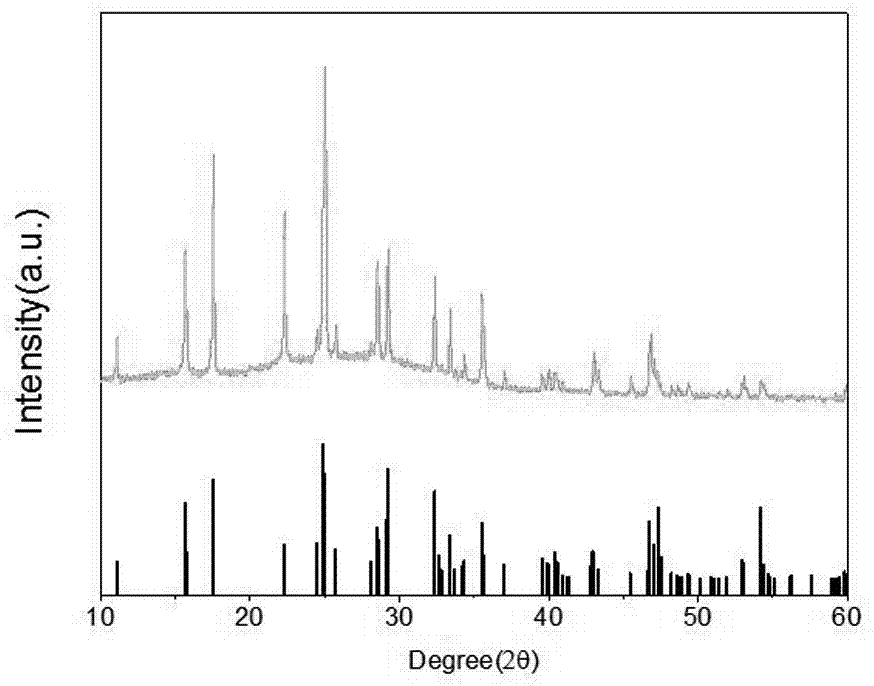

[0073] (3) Preparation of light absorbing layer: Take 1.37g SbCl 3 and 0.9g of thiourea (Sb:S 1:2) of Sb 2 S 3 The precursor solution is swirled on the conductive glass substrate, and the working conditions are: the forward rotation speed is 750 rpm, the...

Embodiment 2

[0078] (1) cleaning FTO glass sheet: same as embodiment 1;

[0079] (2) Preparation of electron transport layer: same as Example 1;

[0080] (3) Preparation of light absorbing layer: Take 1.37g SbCl 3 and 0.9g of thiourea (Sb:S 1:2) of Sb 2 S 3 The precursor solution is swirled on the conductive glass substrate, and the working conditions are: the forward rotation speed is 750 rpm, the time is 12s, the rear rotation speed is 3000 rpm, and the time is 60s; the swirled Sb 2 S 3 The film was heated on a hot stage at 140°C for 10 min; the spin coating and heating reaction steps were repeated, and the Sb 2 S 3 A layer of Sb was spin-coated on the film 2 S 3 thin film, and then annealed at 340°C for 15min under Ar atmosphere, Sb 2 S 3 The thickness is 580 nm;

[0081] (4) Preparation of hole transport layer: same as Example 1;

[0082] (5) Preparation of electrode: Same as Example 1.

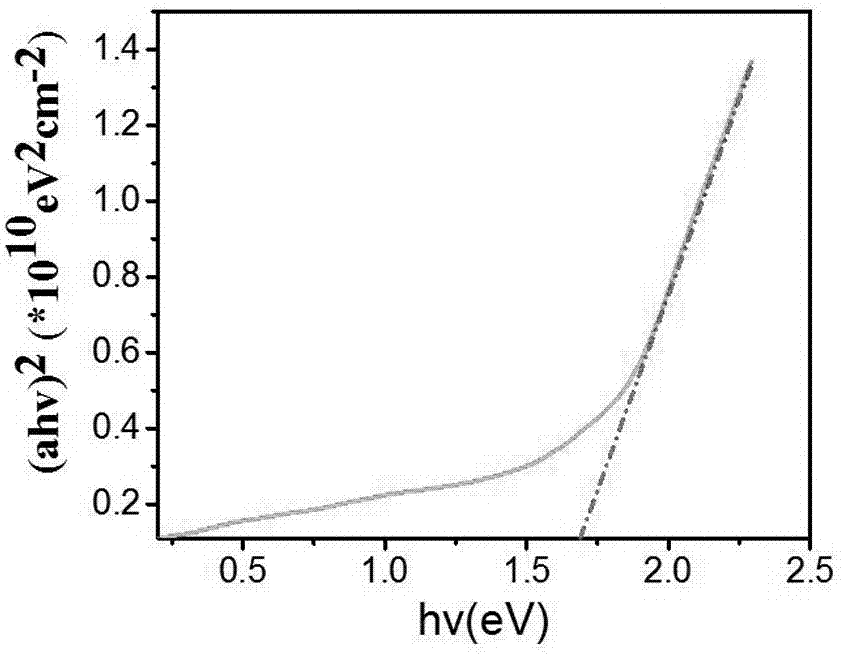

[0083] The performance of the battery is described as Figure 5 Shown: The open circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com