Method for increasing quality of strong aromatic white spirit covered arak

A technology of Luzhou-flavor liquor and distiller's grains, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of obvious miscellaneous flavors, poor quality of covered lees, and weak taste of wine, so as to increase the content of aroma substances, good economic benefits, increase Effect of aroma substance concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Spread the distiller's grains obtained after distilling the wine by conventional methods to a temperature of 26°C, add koji and mix evenly to cover the distiller's grains; put the conventional distiller's grains into the cellar and cover the surface with a layer of distiller's grains for sealed fermentation; the fermentation is over Finally, the covered distiller's grains are separated, and the covered distiller's grains are obtained after distillation.

[0015] The amount of koji added is 21% of the mass of distiller's grains, and the mass ratio of high-temperature Daqu to medium-temperature Daqu is 1:1. When the fermented grains enter the cellar, the acidity is 1.6 and the moisture is 59%.

Embodiment 2

[0017] Spread the distiller's grains obtained after distilling and extracting the wine by conventional methods to a temperature of 27°C, add koji and mix evenly to cover the distiller's grains; put the conventional distiller's grains into the cellar and cover the surface with a layer of distiller's grains for sealed fermentation; the fermentation is over Finally, the covered distiller's grains are separated, and the covered distiller's grains are obtained after distillation.

[0018] The amount of koji added is 22% of the mass of distiller's grains, and the mass ratio of high-temperature Daqu to medium-temperature Daqu is 1.5:1. The acidity of the fermented grains in the cellar is 1.8, and the moisture is 60%.

Embodiment 3

[0020] Spread the distiller's grains obtained after distilling and extracting the wine by conventional methods to a temperature of 27°C, add koji and mix evenly to cover the distiller's grains; put the conventional distiller's grains into the cellar and cover the surface with a layer of distiller's grains for sealed fermentation; the fermentation is over Finally, the covered distiller's grains are separated, and the covered distiller's grains are obtained after distillation.

[0021] The amount of koji added is 22% of the mass of distiller's grains, and the mass ratio of high-temperature Daqu to medium-temperature Daqu is 2:1. wine grains into the cellar

[0022] The acidity is 1.9 and the moisture is 61%.

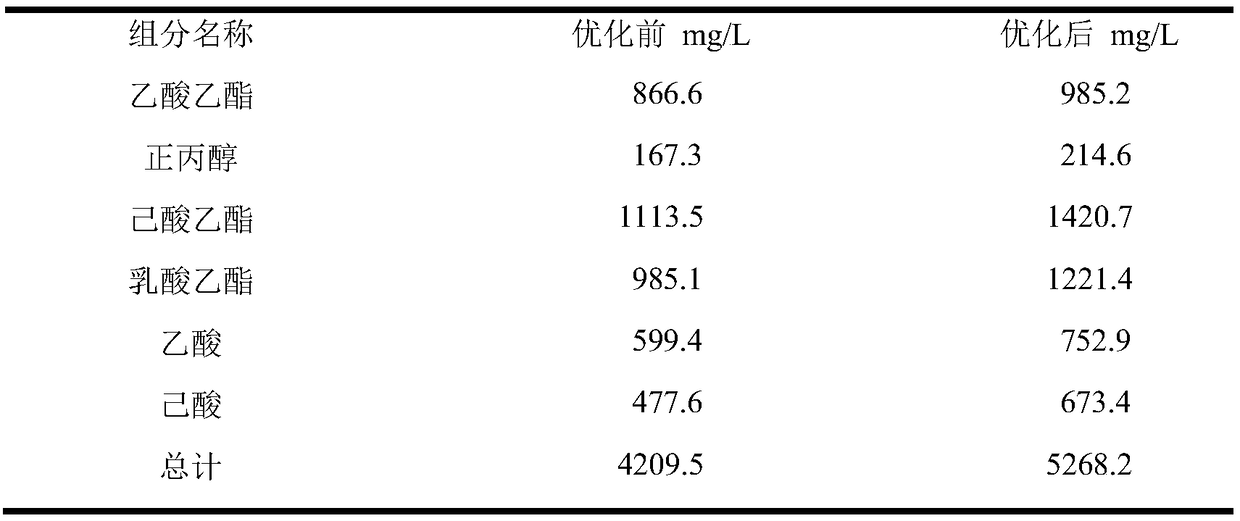

[0023] Through comparative experiments, professional sommeliers' evaluation and chromatographic analysis showed that the quality of the produced wine was significantly improved compared with that before optimization.

[0024] 1. Chromatographic analysis and comparison of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com