Patents

Literature

248results about How to "Improve wine quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of making liquor by virtue of solid fermentation with bamboos as fluff

ActiveCN104651199APromote fermentationEasy to distillAlcoholic beverage preparationDistillationFood flavor

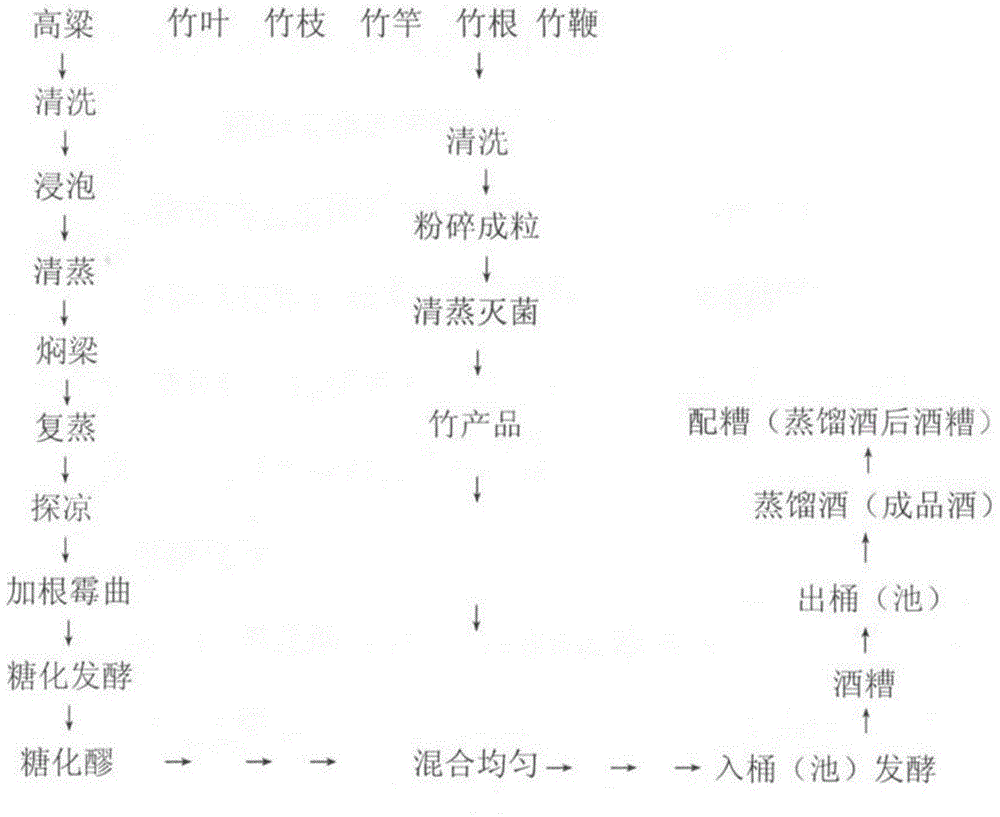

The invention discloses a method of making liquor by virtue of solid fermentation with bamboos as fluff. The method comprises the following steps: crushing clean bamboo products into particles with the particle size of 3-10mm, then steaming the particles of the bamboo products for 10-30 minutes, cooling, mixing the particles serving as the fluff, grains and vinasse, and carrying out solid fermentation to brew Fen-flavor bamboo wines, strong-flavor bamboo wines or soy sauce flavor bamboo wines, wherein the bamboo products are one or more of bamboo stems, bamboo leaves, bamboo branches and bamboo rhizome; and after crushing, the particle sizes of the bamboo rhizome and the bamboo stem are 8-10mm, the particle size of the bamboo branch is 5-8mm, and the particle size of the bamboo leaf is 3-5mm. According to the method disclosed by the invention, the bamboo products and the grains are used for brewing according to a certain ratio, so that the grains can be saved by 10-15 percent under the condition of the same yield of liquor; as different parts of the bamboos in different particle sizes are mixed as the fluff for brewing, the traditional hulls can be completely replaced; meanwhile, as the bamboos and the grains form a particle size gradient, fermentation and distillation of the grains are facilitated.

Owner:四川活之酿酿酒公社有限公司

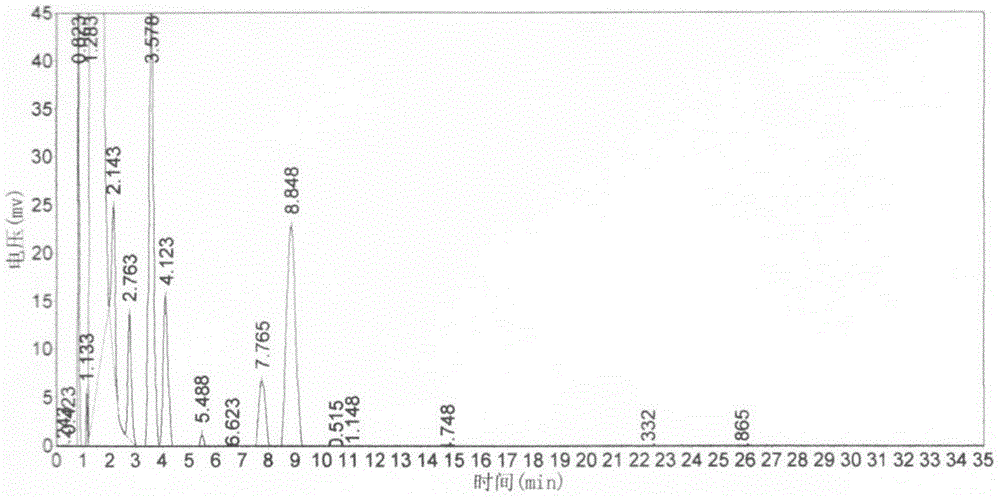

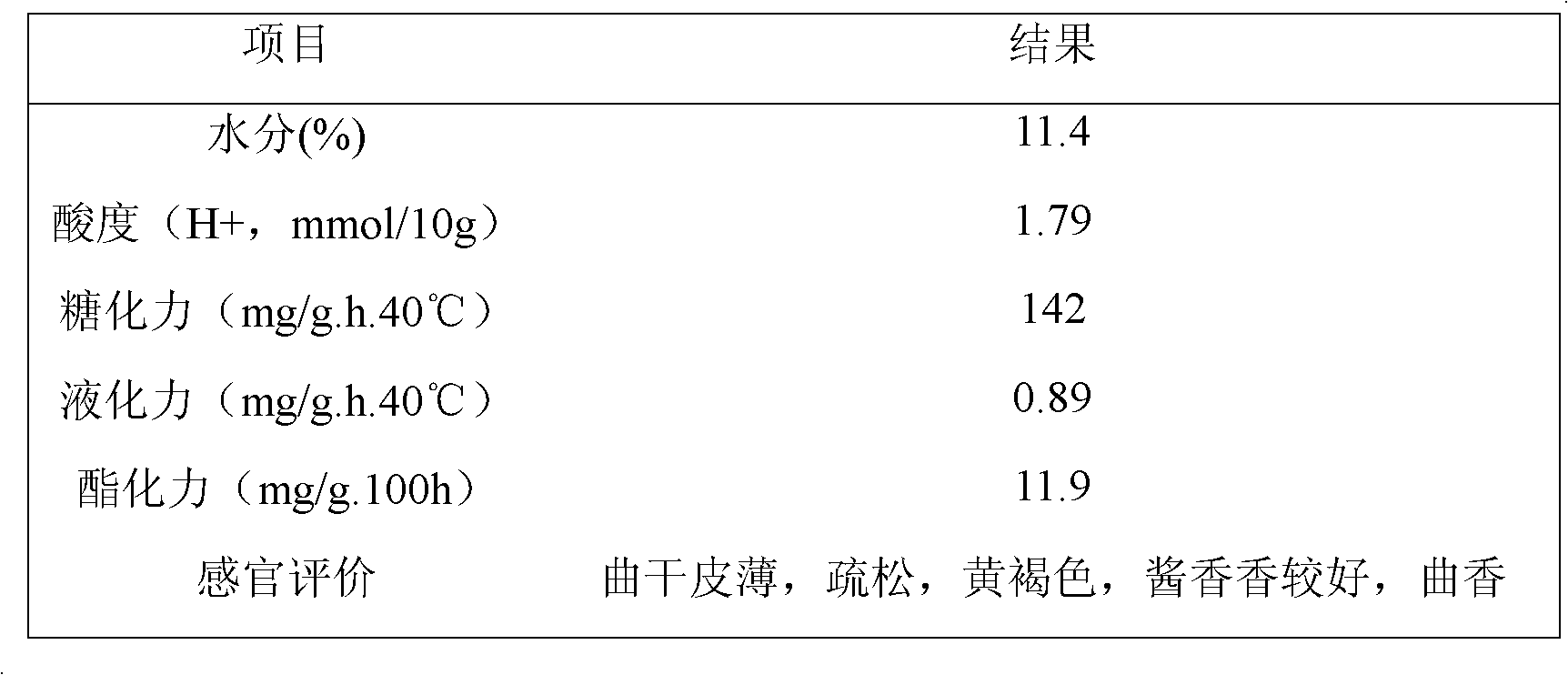

Esterifying enzyme compound bacteria liquid preparation method

ActiveCN102839077AImprove esterification powerHigher premium wine ratesAlcoholic beverage preparationEnzymeCulture mediums

The invention provides an esterifying enzyme compound bacteria liquid preparation method, and relates to the technical field of white spirit. The method comprises the following steps: sieving 20g of high-quality pit mud from old pit mud; thermally processing for 10 minutes at about 80 DEG C to obtain the esterifying enzyme compound strain purifying liquid; inoculating the purified liquid to the prepared and sterilized culture medium based on inoculating volume of 30%; culturing in a constant temperature culturing box for 7 to 8 days at about 36 DEG C so as to obtain a first-grade seed liquor; inoculating the first-grade seed liquor into the prepared and sterilized culture medium based on 22.5% of inoculating volume, and culturing for 7 to 8 days at 36 DEG C in the constant temperature culturing box to obtain the second-grade seed liquor; inoculating the second-grade seed liquor into the prepared and sterilized culture medium based on inoculating volume of 16%, and culturing for 7 to 8 days at about 36 DEG C in the constant temperature culturing box, so as to obtain the third-grade seed liquor; and expanding to culture the sieved and exuberant three-grade seed liquor in a common way to obtain the esterifying enzyme compound bacteria liquid for production. According to the method, the esterifying enzyme compound bacteria liquid is separated, purified and optimally selected from the high-quality pit mud, and the esterifying enzyme compound bacteria liquid has obvious effect during being applied in the production.

Owner:安徽省金裕皖酒业有限公司

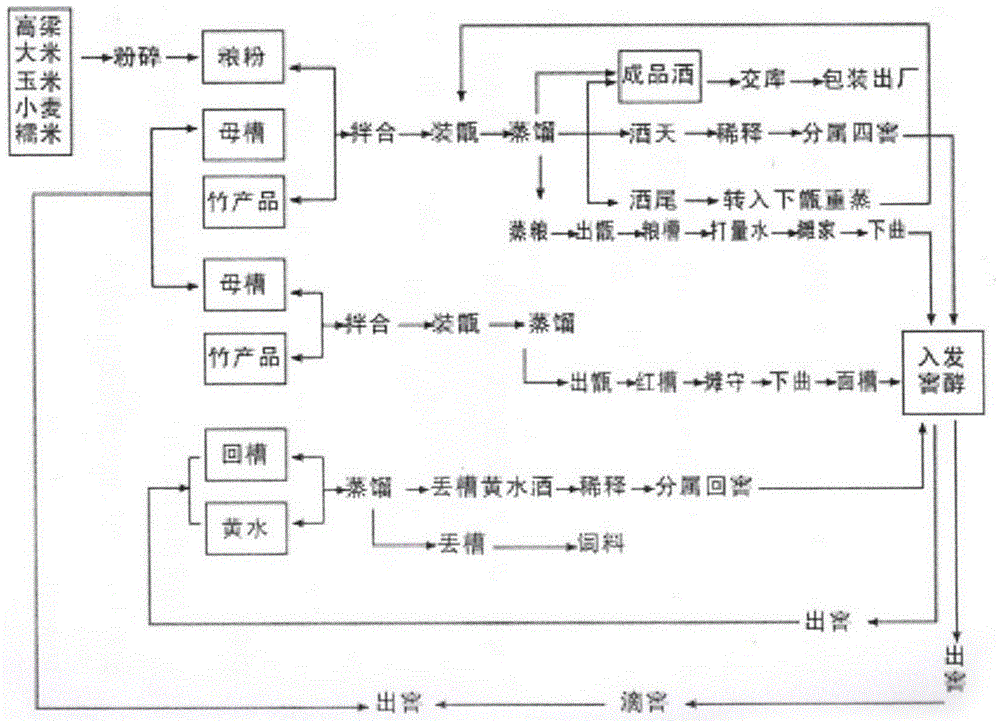

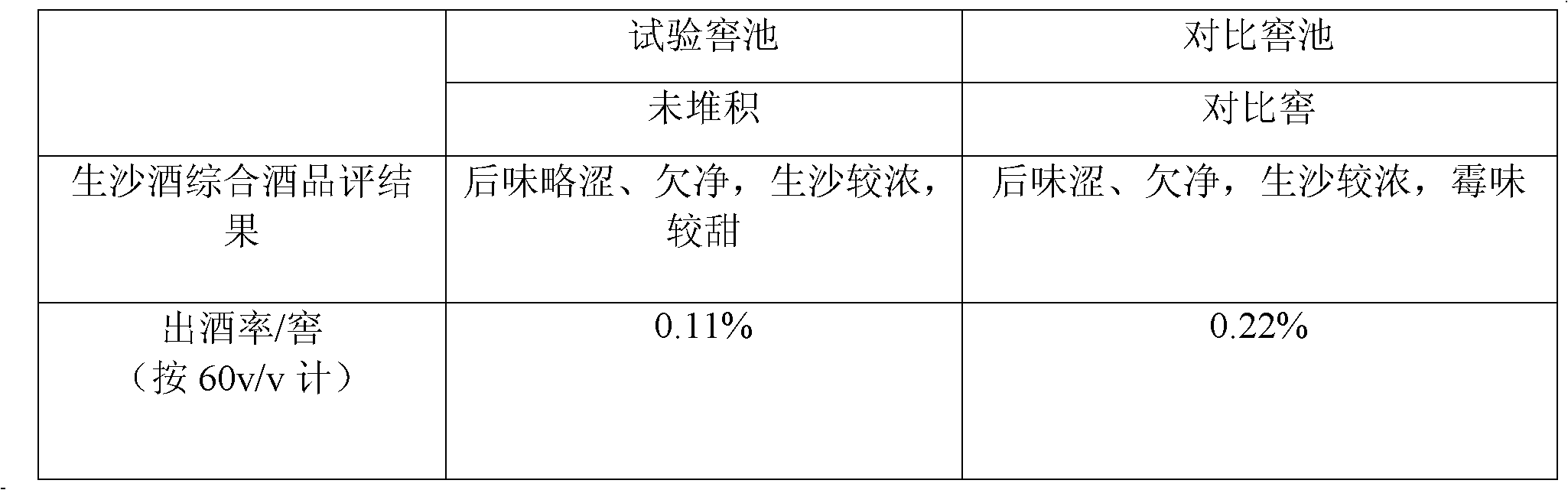

Production technique of Maotai-flavor liquor

The invention discloses a production technique of Maotai-flavor liquor, belonging to the field of production of Maotai-flavor liquor. Compared with the prior art, the method disclosed by the invention has the advantage that the first feed residues are not piled up, but directly put into a pit. According to the method disclosed by the invention, the first material is not piled up in the Maotai-flavor liquor production, so that the raw liquor produced in the traditional first material technique does not have heavy astringency and musty odor, but is thick and sweet, and can become high-quality liquor without fermentation in the pit again. The invention breaks the routine of 8-times fermentation and 7-times liquor taking in the traditional Maotai-flavor liquor production, and adopts the technique of 8-times fermentation and 8-times liquor taking. Meanwhile, the invention can reduce the quantity of liquor produced in the first time and second time of the Maotai-flavor liquor production process, obviously increase the quantity of higher-quality liquor in the third time, fourth time, fifth time and sixth time, and enhance the utilization ratio of the raw material. The Maotai flavor of the product is superior to that of the Maotai-flavor liquor prepared by the existing method, and thus, the Maotai-flavor liquor prepared by the method disclosed by the invention has wide application prospects.

Owner:LUZHOU PINCHUANG TECH CO LTD

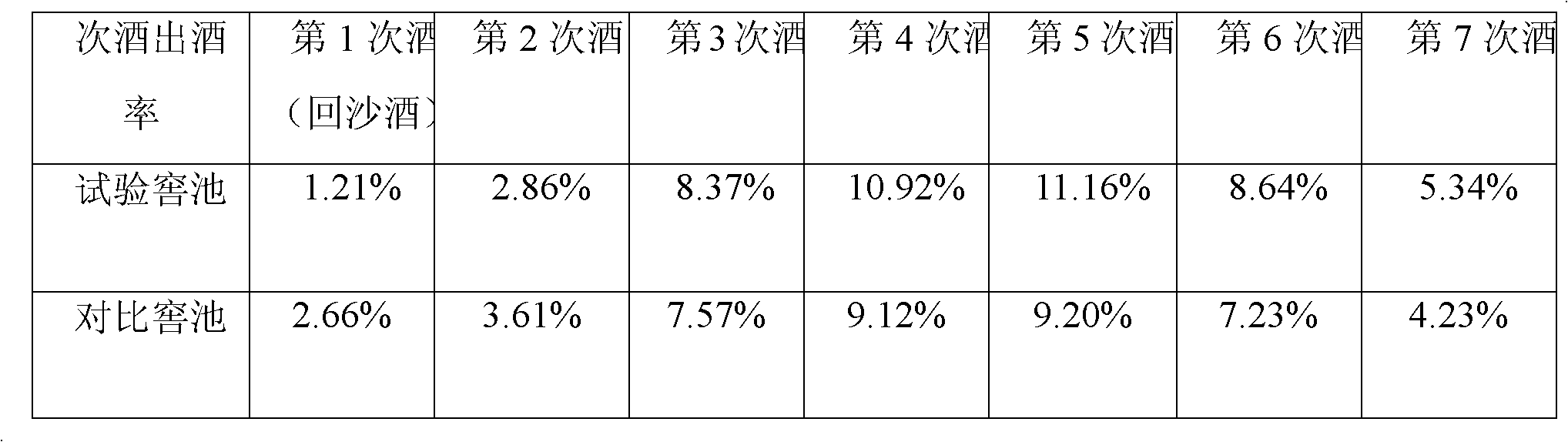

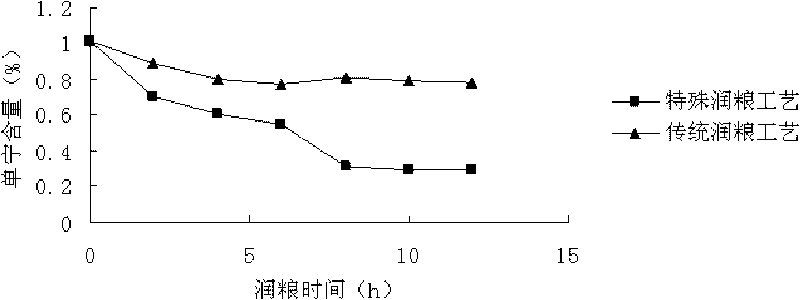

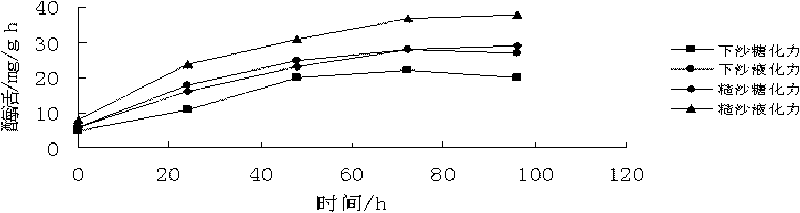

Method for preparing Maotai-flavor liquor

ActiveCN101705171AReduce contact areaImprove wine qualityAlcoholic beverage preparationYeastContinuous use

The invention relates to a method for preparing Maotai-flavor liquor and belongs to the technical field of wine brewing. The method for preparing the Maotai-flavor liquor comprises the process steps of first sorghum feeding, second sorghum feeding, cyclic sorghum fermentation, third to eighth cyclic liquor making and the like. The method is characterized in that: the liquor yield in the first three cycles is improved and the liquor quality is improved due to whole sorghum grain feeding for fermentation, special grain moisturizing, constant use of coarse high-temperature yeasts for making hard liquor in the first three cycles and the control of the stacking time of sorghum fed at the first time and the sorghum fed at the second time; 'eight times of liquor making and eight times of fermentation' instead of 'seven times of liquor making and eight times of fermentation' are performed; the liquor yield of liquor from the whole cyclic fermentation is improved by 2 to 3 percent; and the liquor yield in the first three cycles is reduced to 9 to 11 percent from the 13 to 15 percent in the traditional method, so the liquor yield of high-quality liquor in the late several cycles is improved by 5 to 6 percent.

Owner:LUZHOU PINCHUANG TECH CO LTD

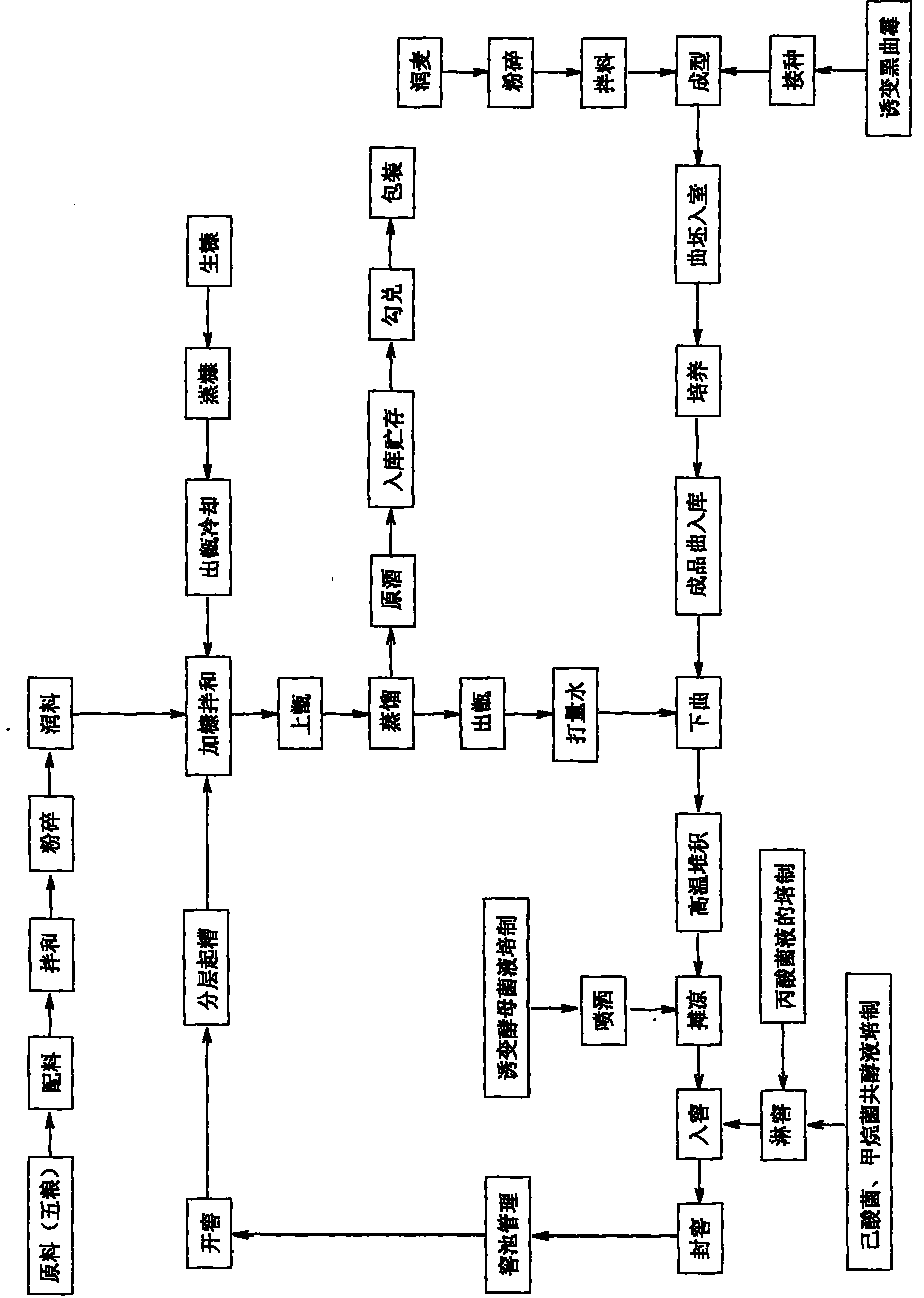

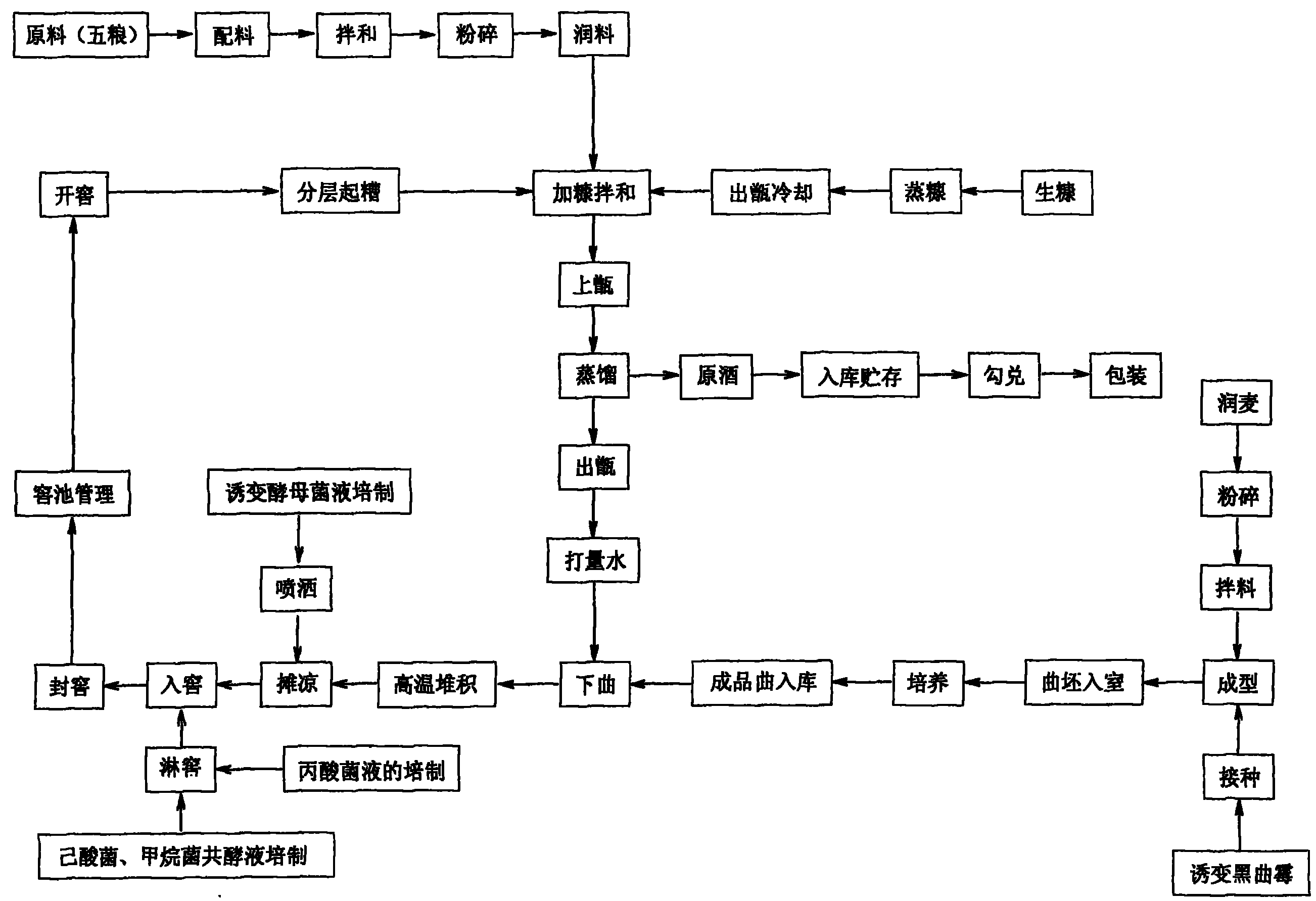

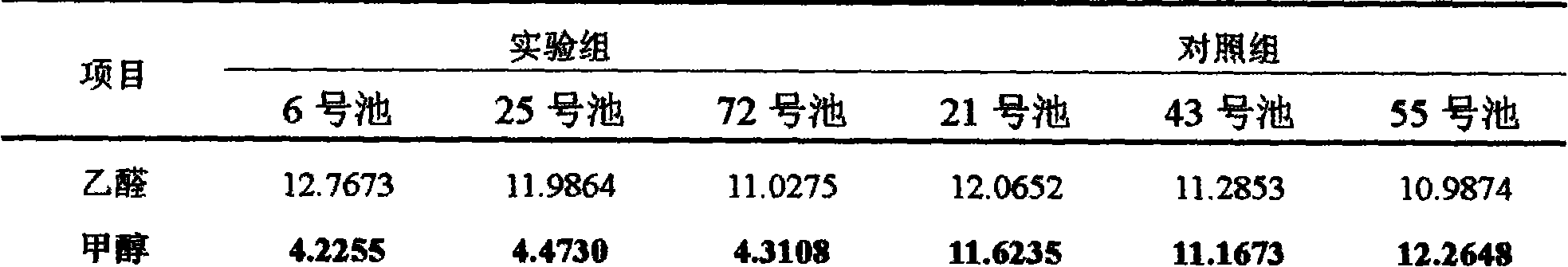

Production process of highly-fragrant health care wine

InactiveCN101921685AMellow tasteDelayed spawn rateAlcoholic beverage preparationMicroorganism based processesPropanoic acidHazardous substance

The invention relates to a production process of a highly-fragrant health care wine, which comprises the steps of manufacturing, fermentation and distillation of yeasts, storage and blending of raw wine and packaging of finished wine, wherein Aspergillus niger is added and manufactured into mouldy brans in the manufacturing process of yeasts, the mouldy brans are added to a yeast culture medium according to a ratio of 3% and manufactured into mould starters, and the mould starters are manufactured into the yeasts according to an input ratio of 10%; in the fermentation and distillation processes, a yeast culture liquid is spread over fermented grains before cellar entry, and a caproic acid bacterium, methane bacterium co-fermented liquid and a propanoic acid bacterium liquid are spread in the cellar; and other steps are the same with those in the conventional wine brewing process. By adding the propanoic acid bacterium liquid, the caproic acid bacterium and methane bacterium co-fermented liquid which can activate cellar environment and maintain fragrance in the cellar fermentation process, adding the Aspergillus niger in the yeast manufacturing process and combining other improvement measures in the traditional wine brewing production, the invention reduces the generation speed of harmful substances in the cellar, and simultaneously produces multiple active ingredients beneficial to human health, thereby maintaining the fragrance of the traditional wine and greatly reducing the generation of methanol and fusel oil.

Owner:湛江市新鸿业贸易有限公司

Black tea manufacture

InactiveUS6348224B1Improve wine qualityQuality improvementPre-extraction tea treatmentAnimal feeding stuffBlack teaFermentation

A method for manufacturing black leaf tea. The method involves macerating freshly plucked tea leaves, treating the leaves with ammonium bicarbonate, fermenting the treated leaves, firing the leaves to arrest fermentation and then drying them to yield black leaf tea.

Owner:THOMAS J LIPTON DIV OF CONOPCO

Preparation method of blueberry wine

InactiveCN104232426AStable chemical propertiesShorten the brewing cycleAlcoholic beverage preparationMicroorganism based processesPectinaseFruit juice

The invention relates to a preparation method of a blueberry wine. The preparation method comprises the following steps of cleaning blueberry fruits, and then, smashing the blueberry fruits to form blueberry slurry; adding pectinase into the blueberry slurry to carry out enzymolysis, carrying out enzyme deactivation, cooling to the room temperature to obtain cooled blueberry slurry, adding alcohol and an active dry yeast for a wine to ferment, and when the sugar content is measured to be up to 1 BoX, ending the fermentation to obtain a raw blueberry wine; and adding an antacid into the raw blueberry wine, filtering, blending the raw wine by using the alcohol to ensure that the alcohol strength is up to 9-12 degrees, and then, filtering to obtain the blueberry wine. According to the method disclosed by the invention, insoluble substances such as pectin substances, cellulosics and polysaccharides in the raw wine are effectively dissolved by using a pectinase enzymolysis agent, so that fruit juice is clarified within short time; and the blueberry wine with stable chemical property is brewed by using processes such as fermenting by using an active dry yeast for a wine, ageing and filtering, and the brewing period is shortened from more than three years consumed by using the traditional method to three to five months, so that the working period is shortened, the utilization ratio of equipment is increased, and the labor cost is reduced.

Owner:天津绿丛洲农业发展有限公司

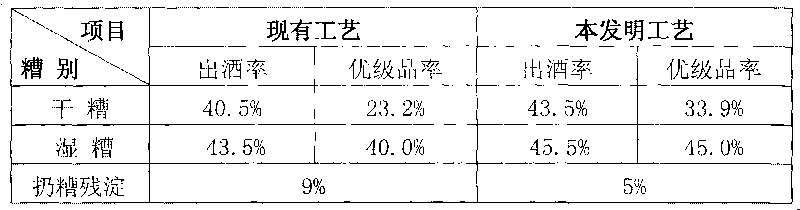

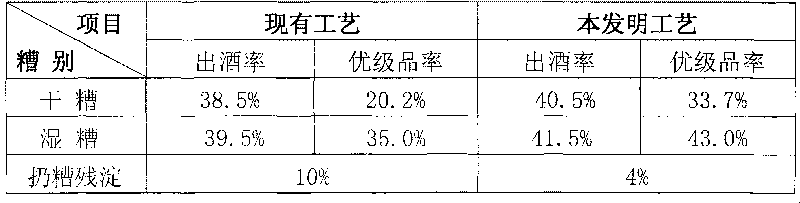

Method for improving quality of strong aromatic dry distilled grain

ActiveCN101705167AIncrease the acidity in the cellarQuality improvementAlcoholic beverage preparationChemistryPre treatment

The invention discloses a method for improving quality of strong aromatic dry distilled grain, comprising the steps of pretreating the materials, piling and fermenting, taking out of a pit, stirring the mixed grains, getting wine and steaming grains, getting out of a steamer and proportioning water, reducing temperature and mixing the rice flour, entering the pit and sealing the pit. The method is characterized in that new measures about a pit mud maintenance in contact with the dry grains and about a prevention of mixed bacteria infection are carried out by not crushing part of the materials for wine making, increasing the mixed grain amount and reducing the use quantity of bran shells, thereby improving acidity of fermented grain for pit entry and water retention property of the fermented grain, and greatly improving the quality of the dry distilled grain. The method improves the quality of dry grains, improves the high-quality yield of the dry distilled grain by about 35%, improves the high-quality yield of the wet grain by above 10% and improves wine yield by above 3% so that the whole pit can brew high-quality wine. The invention has simple technology, easy operation, low production cost, good wine quality and easy implementation, thereby providing reliable guarantee for large-area application of technical reform in strong aromatic wine production enterprise.

Owner:SICHUAN TUOPAI SHEDE WINE

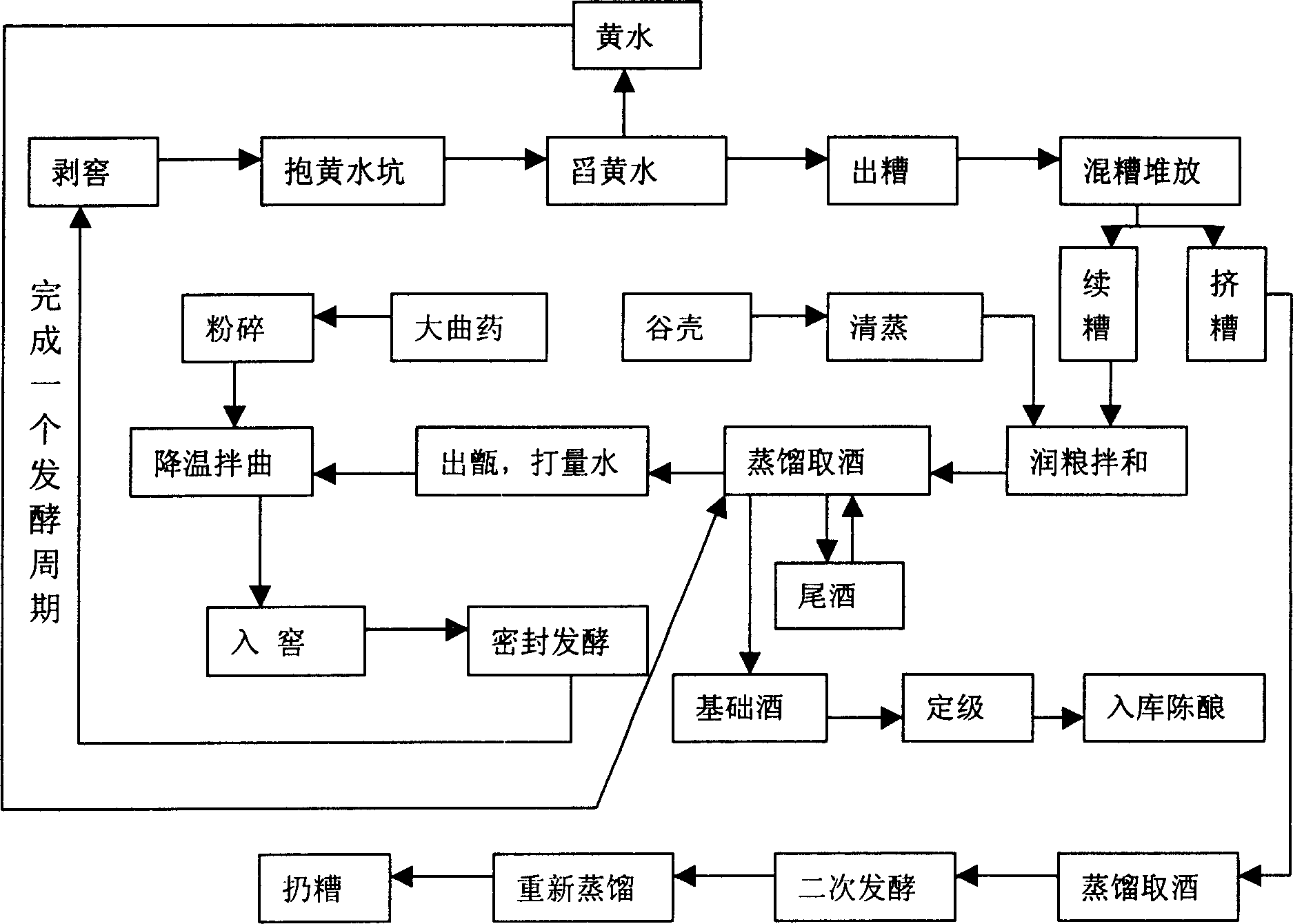

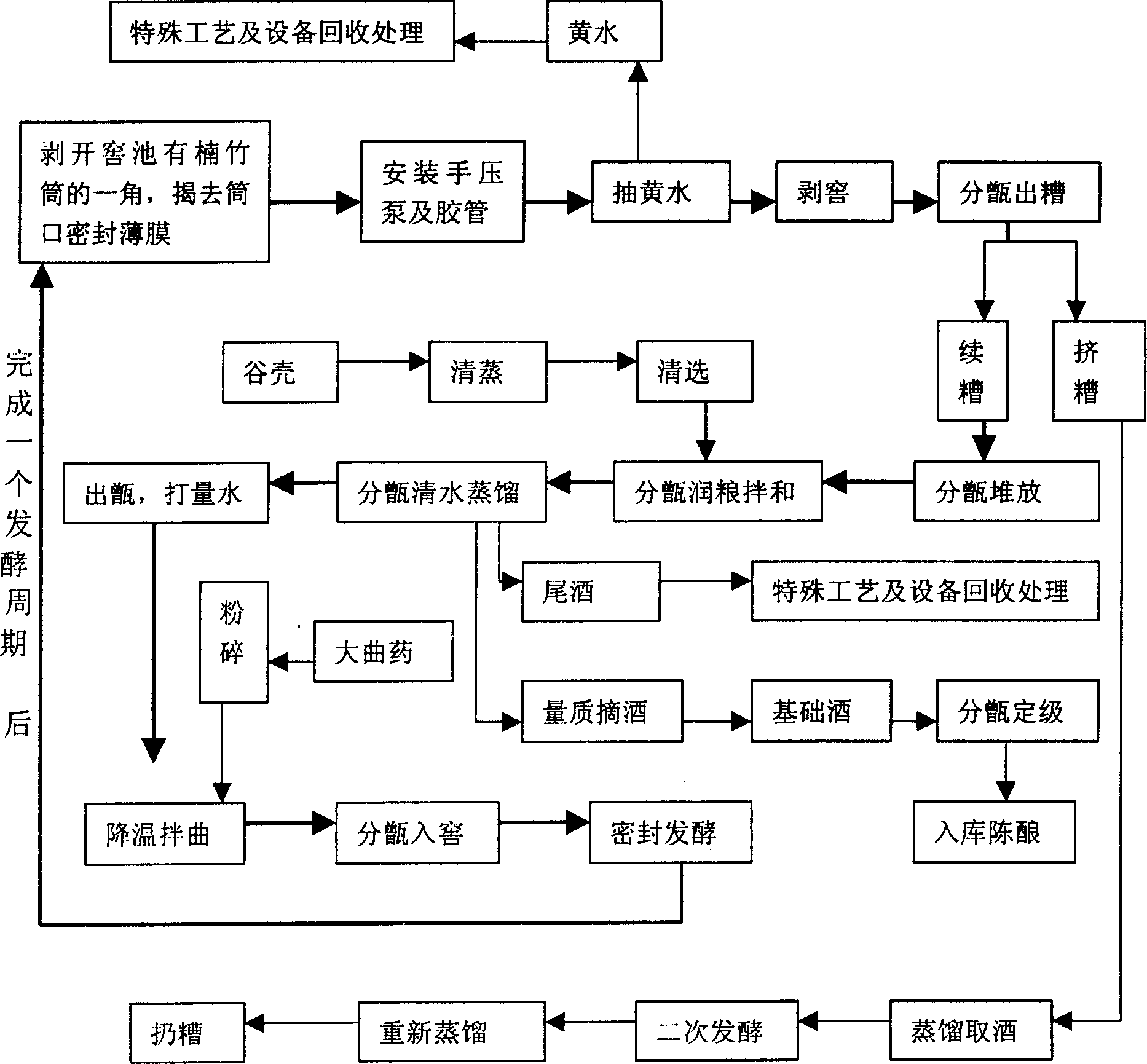

'Whole clear' process of brewing aroma type white spirit

ActiveCN1733888AReduce dosageReduce furfural contentAlcoholic beverage preparationTissue/virus culture apparatusEngineeringDrinking straw

The invention discloses a technique to brew aromatic wine, based on traditional technique, which relates to reform and innovate to draw water, steam supplementary material, distill to obtain wine, and put dreg into cellar clear layered. Wherein, the said four steps are technical core; the cellar is constructed on bottom of pond near wall with inner wall fixed and cover on its head with center hole inserted hollow pipe; after putting dreg into cellar, sealing the pipe and cellar for fermentation; before putting out, stripping off the yellow mud to show pipe mouth, and taking out seal; inserting sucker to draw the yellow water in cellar by connected pump as possible as far; mixing, obtaining wine, storing in cellar; all processes with Zeng(traditional measuring tool) as unit. The method can decrease labor strength, save material, and increases wine quality.

Owner:SICHUAN TUOPAI SHEDE WINE

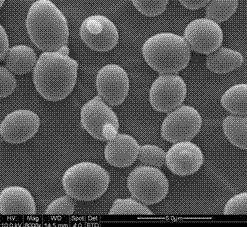

High-tolerance ester-producing yeast strain and application thereof

InactiveCN103232946AIncrease productionIncreased total ester contentFungiAlcoholic beverage preparationBiotechnologyAcetic acid

The invention discloses a high-tolerance ester-producing yeast strain and application thereof, and belongs to the field of biochemical engineering. The strain is preserved at the China Center for Type Culture Collection, and named as ester-producing yeast BTL-Y01 Hansenula anomala BTL-Y01; the preservation number is CCTCC NO:M2013115; the highest tolerable temperature of BTL-Y01 is 38 DEG C; the proper growth temperature is 32 DEG C; the high-tolerance ester-producing yeast strain is good in acid resistance, and good in growth in the environment of which pH is 1; the proper growth pH is 4; the highest tolerable alcohol strength is 12%; the yield of ethyl acetate, which is stewed, cultured and fermented, is higher than that cultured by a table in an oscillating manner; the wheat saccharified liquid is taken as ester culture medium; and the yield of the ethyl acetate can be up to 3.903g / L. The strain is suitable for making wine; content of ethyl acetate and total ester in white spirit can be improved; the clinical flavor of the aromatic white spirit is improved; the vinosity can be improved; and the economic benefit is also improved.

Owner:HUBEI UNIV OF TECH

Production method of rice wine

InactiveCN101993802ASimple production processSimple processAlcoholic beverage preparationHorticultureSour taste

The invention relates to a production method of wine, in particular to a production method of rice wine. The production method of the rice wine comprises the following steps of: 1, steaming sticky rice to be cooked and become sticky rice; 2, cooling the sticky rice to 24-36 DEG C; 3, uniformly mixing wine koji with the sticky rice, and preserving at 20-30 DEG C for 30-48 hours to form rice wine mesostroma; 4, adding grain spirit to the rice wine mesostroma, and hermetically placing for more than one month, wherein the sticky rice and sweet Chinese yeasts are blended according to the mass ratio of 100:0.6-2, and the sticky rice and the grain spirit are blended according to the mass ratio of 100:70-120. The invention has the advantages of simple process and good vinosity, and the like, does not have sour taste or go to heads.

Owner:黄志林

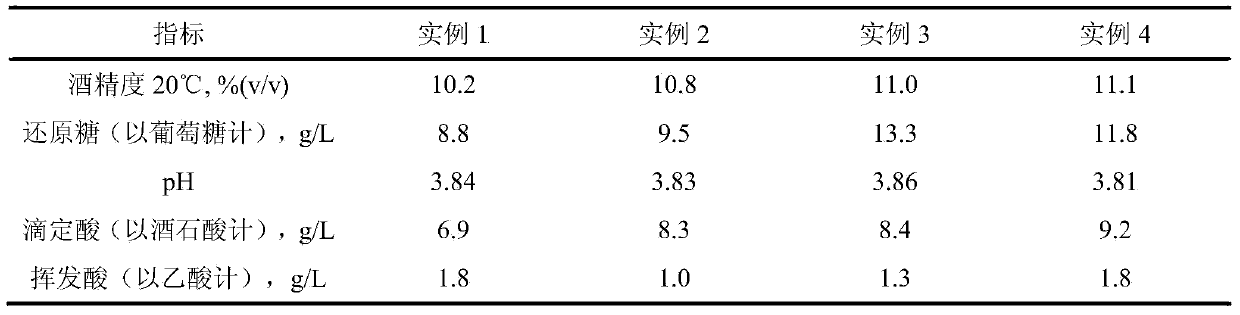

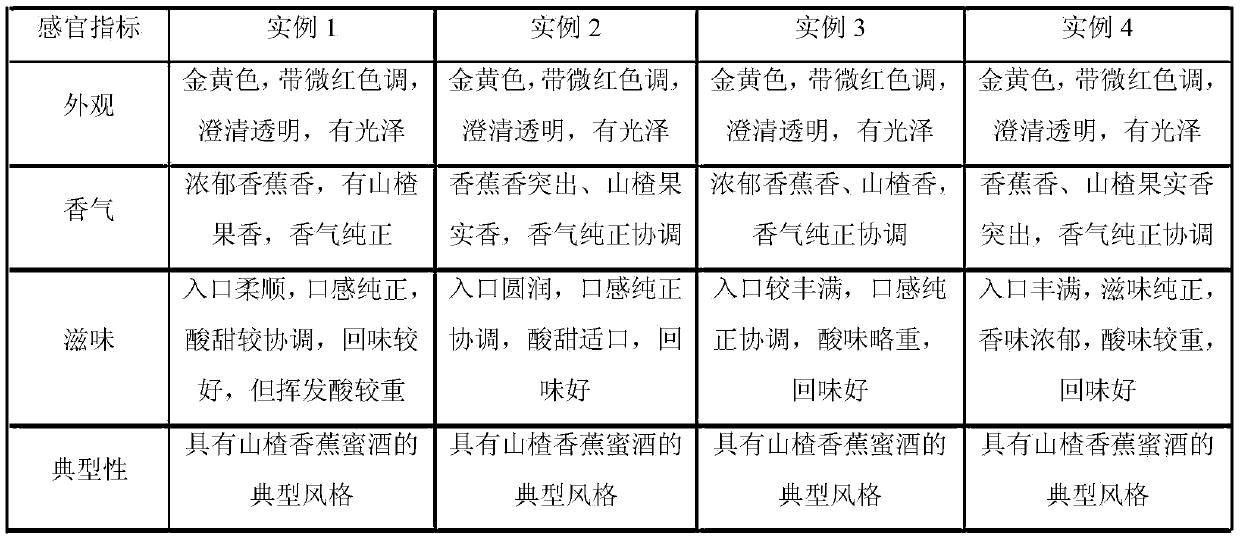

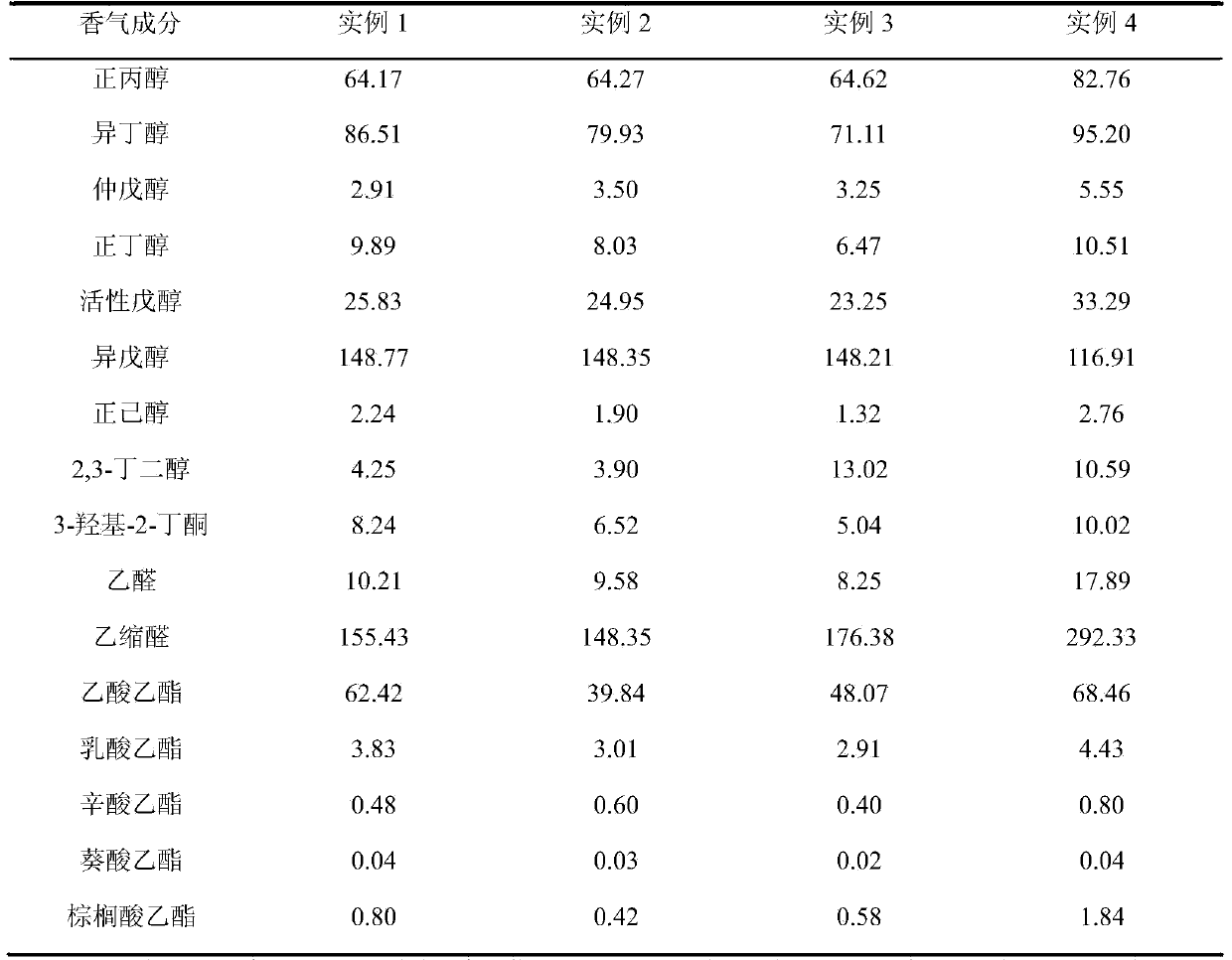

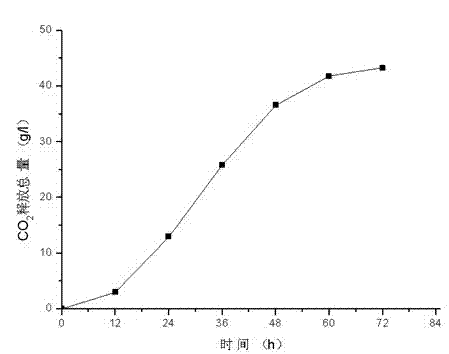

Method for brewing hawthorn-banana-honey wine

ActiveCN103773653AIncrease vitalityShort fermentation cycleAlcoholic beverage preparationMicroorganism based processesOrganic acidFruit wine

The invention relates to a method for brewing hawthorn-banana-honey wine. According to the method for brewing the hawthorn-banana-honey wine, the hawthorn and the banana serve as raw materials; honey and sterile water are added to prepare a solution with hawthorn, banana and honey; then a fruit wine yeast culture solution is inoculated to prepare and obtain the hawthorn-banana-honey wine. According to the method, a high-quality apple juice is used for preparing a yeast culture solution of the hawthorn-banana-honey wine; the yeast is high in activity and short in fermentation period; howthorn pectin, which is dissolved out, is reduced; browning of the banana pulp is avoided; meanwhile, the honey is used in the raw material firstly for replacing white granulated sugar in mixed fermentation with the banana and the hawthorn, so that pantothenic acid and VB 1 (vitamin B1) in the honey can be used for culturing the yeast, thus the fermentation performance of the yeast is improved, the fermentation speed of ethyl alcohol is improved and the fermentation time is shortened. According to the method for brewing the hawthorn-banana-honey wine, a mixed fermentation ratio of hawthorn, banana, honey and water is firstly defined as (1-2.5):10:6:10 (m / m), so that the characteristics of hawthorn wind of high content of organic acid and strong acid taste are complementary with the disadvantages of banana wine of low content of organic acid and high content of volatile acid.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for preparing Rui chang yam white wine

InactiveCN102816670AImprove wine qualityHigh yieldAlcoholic beverage preparationMicroorganism based processesFlavorDistillation

The invention discloses a method for preparing Rui chang yam white wine. The method includes taking dried Rui chang yam as a main wine stock, not adding or adding rice according to a ratio, crushing and refining the mixture, performing high temperature cooking, adding compound bran koji, using compound yeast wine, mixing the mixture according to a ratio of 2:1:2, using a multi-strain and multi-enzyme solid state saccharifying fermentation technology, performing solid state fermentation and solid state distillation to obtain the Rui chang yam white wine which is 30 V% to 60 V% fragrant and mellow and good in quality. The mouth mellow taste of white wine is improved, and defects that the good and the bad are intermingled in flora of traditional wine yeast, the wine yield is low and the wineforeign flavor is heavy are overcome. According to the Rui chang yam white wine prepared by the method, the taste of special mouth sticking and lingering and unique fragrance and special flavors of the Rui chang yam white wine are added on the basis that special flavors of traditional white wine are guaranteed, unique effects of invigorating spleen and supplementing qi and benefiting kidney and solidifying vitality are provided if the Rui chang yam white wine is taken frequently, and a good way is provided for the current Rui chang yam industry.

Owner:付桂明 +4

Method for brewing wine by using wormwood

ActiveCN101619281AImprove wine qualityRich and mellow tasteAlcoholic beverage preparationAnti virusAnti coagulation

The invention relates to a method for brewing wine by using wormwood, which comprises the following steps: (1) taking 100 parts of glutinous rice by mass, placing in water for soaking for 4-8 hours, scooping up the glutinous rice, cooking, spreading for cooling till 20-28 DEG C, adding 0.5-0.6 part of syeast by mass, evenly stirring and placing into a container; (2) adding 5-10 parts of pure rice wine of 50 degrees by mass after carrying out fermentation of the cooked glutinous rice for 12-20 hours, evenly stirring, squeezing after 100-200 days of sealed fermentation and obtaining juice; (3) taking 0.5-2.5 parts of dry wormwood by mass, adding into 5-10 parts of pure rice wine of 35 degrees by mass for leaching for 3-5 hours and obtaining leaching solution; and (4) mixing the juice with the leaching solution, then heating to 80-90 DEG C, keeping the temperature to 6-8 hours, cooking, removing the wormwood, filtering and obtaining the wine. The wine prepared by the invention has stable wine quality, mellow taste, fragrance and rich nutrition and is rich in amino acids, vitamins and the like, and the wine brewed by the wormwood has the effects of dredging meridians, promoting blood circulation, stopping bleeding, anti-coagulation, anti-bacteria, anti-virus and enhancing immunity.

Owner:邓金城 +1

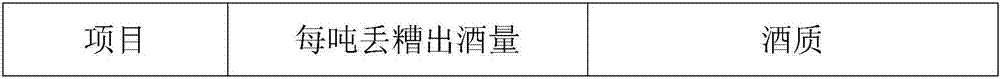

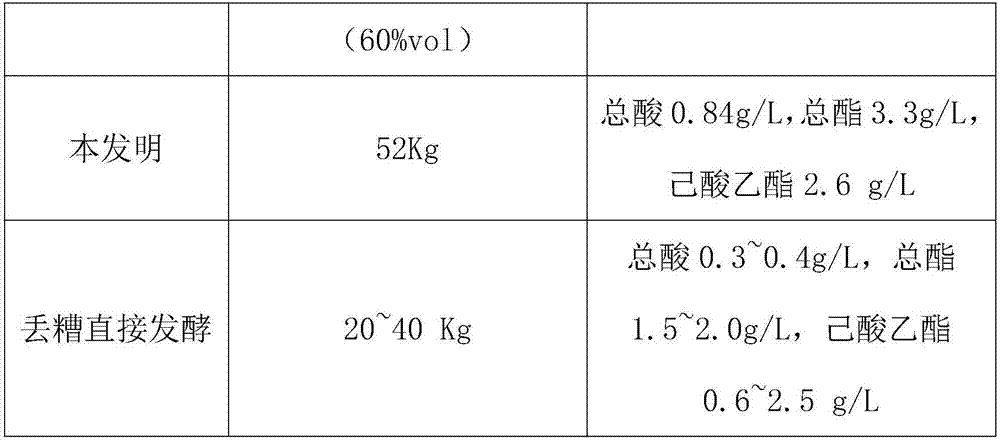

Low starch waste distiller's grain brewed Chinese liquor and brewing method thereof

ActiveCN106987500AImprove overall utilizationReduce pollutionAlcoholic beverage preparationChemistryRetort

The invention discloses a low starch waste distiller's grain brewed Chinese liquor and a brewing method thereof. The method includes the steps of: (1) crushing sorghum, conducting moistening with water, and then steaming the sorghum thoroughly; (2) mixing yellow water, end liquor, pot-bottom water, composite caproic acid bacteria liquid, esterified red yeast rice, medium-high temperature Daqu, and pit mud evenly, and conducting fermentation to prepare esterified liquid; (3) spreading sorghum for cooling, mixing the sorghum with medium-high temperature Daqu evenly, spraying a small amount of esterified liquid before adding the mixture into a fermentation pool, and starting fermentation; (4) taking the yellow water out from the fermentation pool, and pouring it all into the bottom of a retort, putting fermented grains to the retort for distillation, and taking the end liquor for standby use; (5) taking the distiller's grains after distillation, and performing spreading for cooling, adding medium-high temperature Daqu and distiller's yeast, mixing the substances evenly, performing piling, spraying a small amount of esterified liquid before adding the mixture into the fermentation pool, and starting fermentation; and (6) pouring the rest esterified liquid and the end liquor of step (4) into pot bottom, and putting the fermented grains into the retort for steaming. The method provided by the invention utilizes fermentation garbage waste distiller's grain with very low starch content to brew Chinese liquor, has high resource utilization rate and saves grains, and the liquor has excellent quality.

Owner:HUBEI UNIV OF TECH

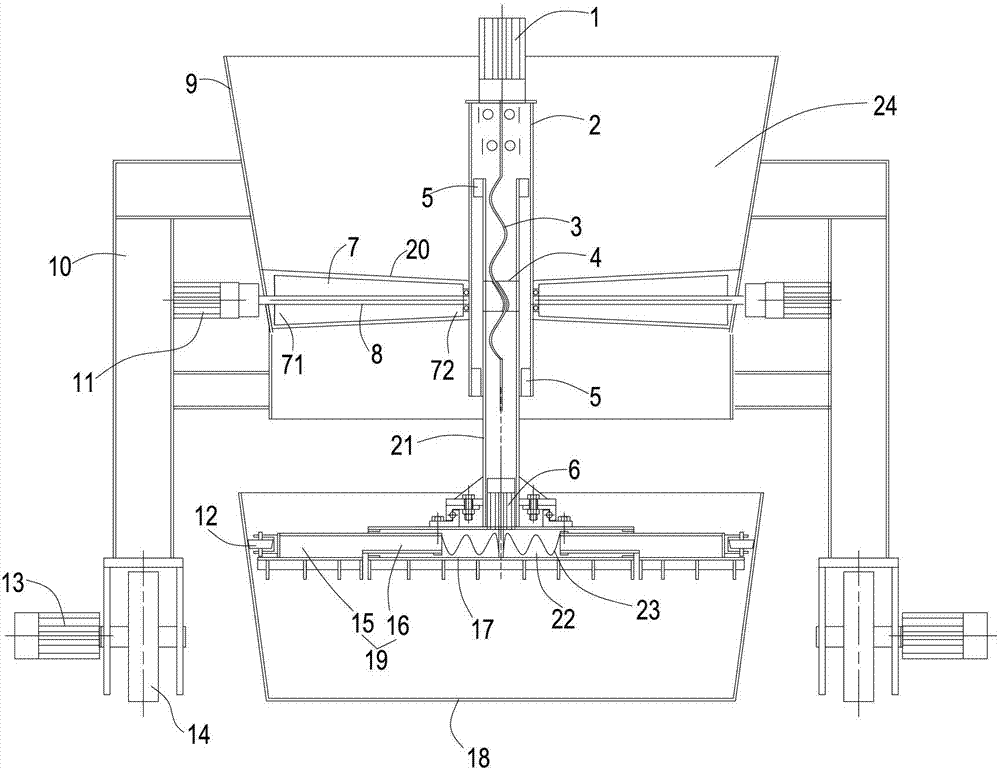

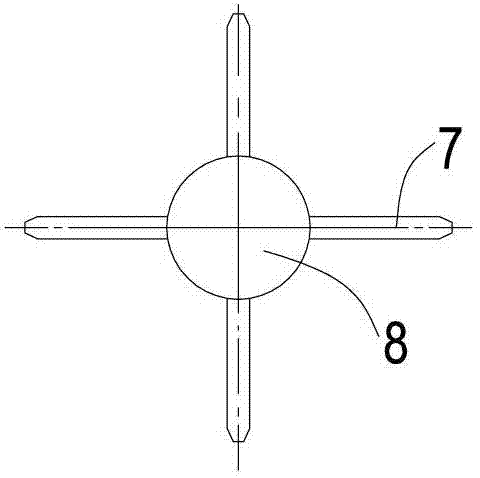

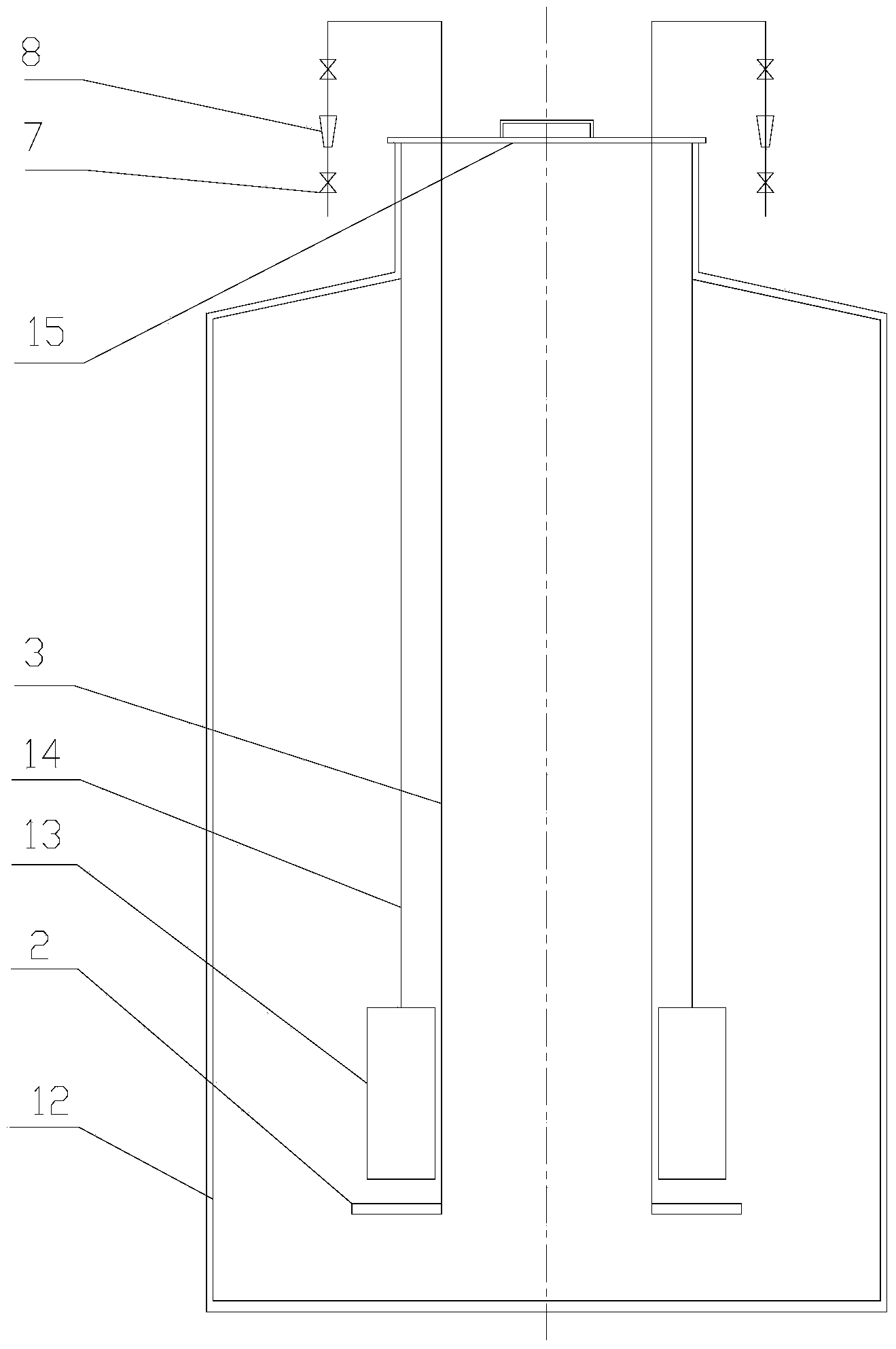

Automatic distillation device

ActiveCN103045422AImprove labor intensityImprove process consistency and specificationAlcoholic beverage preparationEngineeringDistillation

The invention discloses an automatic distillation device, which is favorable to the guarantee of the uniformity for spreading vinasse and has high distillation efficiency. The automatic distillation device comprises a hopper, wherein a material loading cavity is formed inside the hopper, a material conveying port is formed at the bottom of the material loading cavity, a material conveying mechanism which is connected with the hopper is arranged inside the hopper below the material conveying port, a lifting mechanism which is connected with the hopper is also arranged inside the hopper, and a feeding mechanism which is connected with the bottom of the lifting mechanism is arranged below the hopper. The automatic distillation device further comprises a hopper driving device which drives the hopper to move in a horizontal direction. The device can guarantee the uniformity for spreading vinasse, has high distillation efficiency, achieves mechanical distillation operation, improves the labor intensity of workers, the consistency and the standardization of the process, and is favorable to the stability of the liquor quality and the increase of the liquor yield.

Owner:WULIANGYE

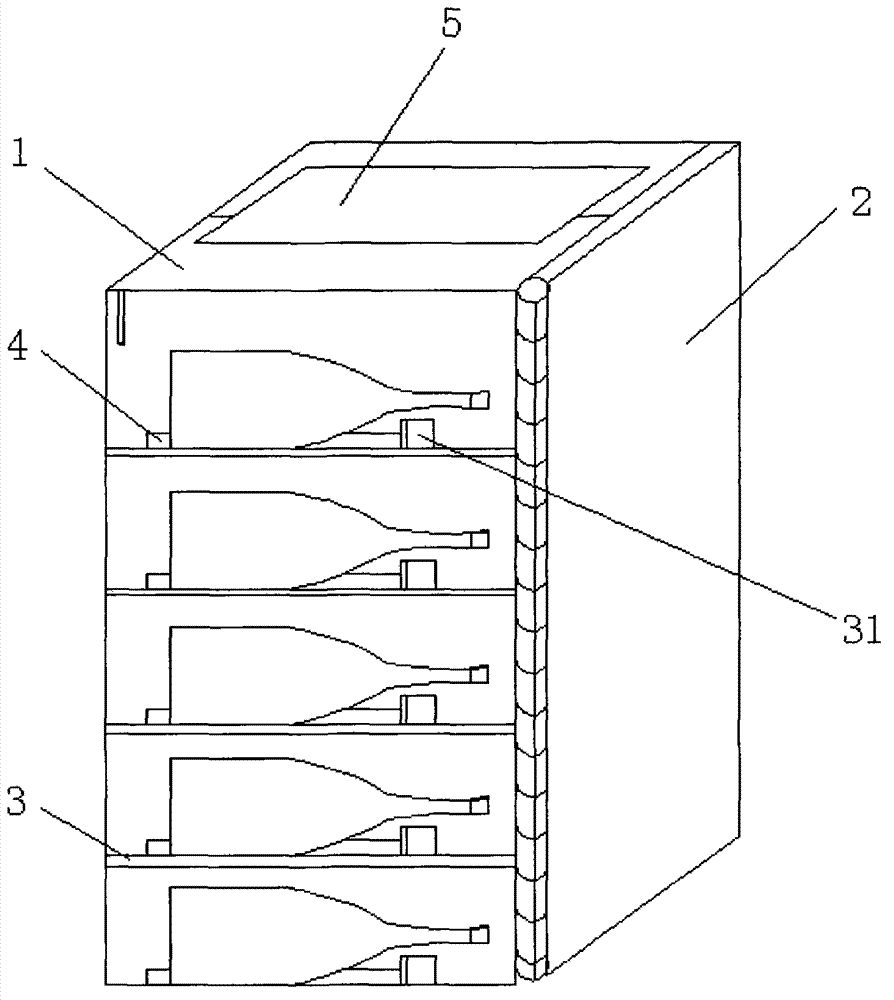

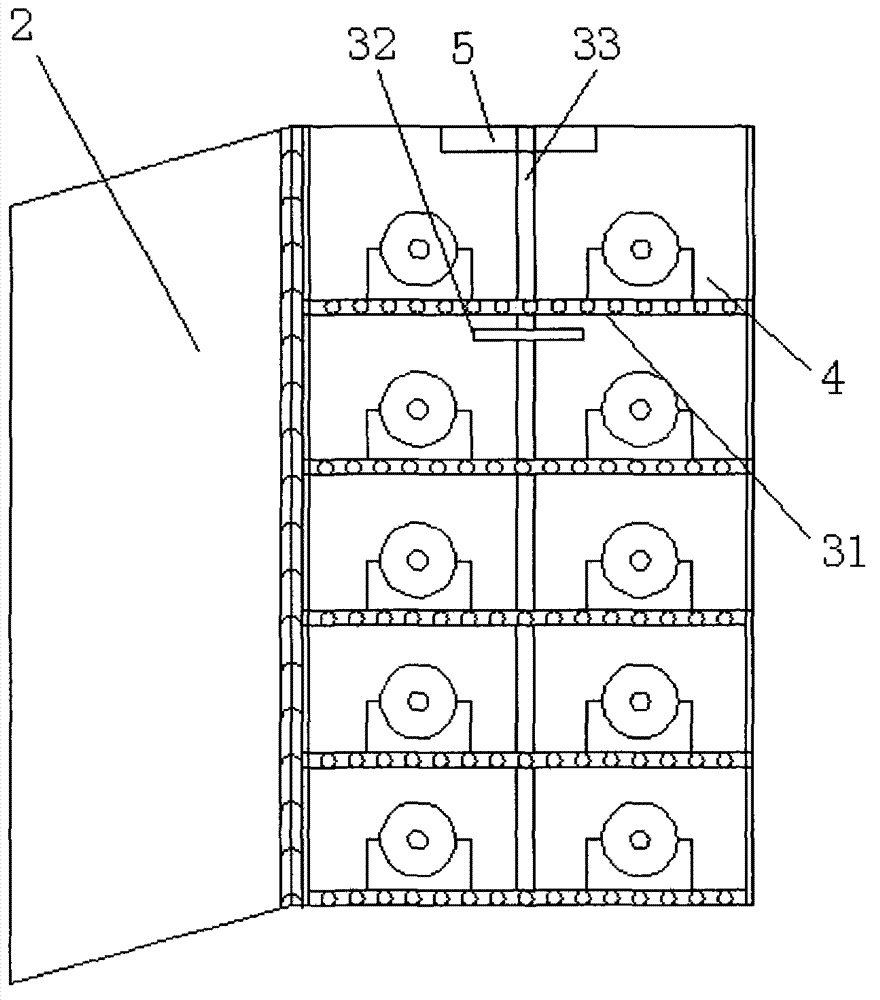

Wine cabinet allowing taking wine without opening door

InactiveCN102853629AWill not destroy the constant temperature environmentSmall open areaDomestic cooling apparatusLighting and heating apparatusEngineeringMechanical engineering

The invention relates to field of household appliances, in particular to a wine cabinet. A wine cabinet allowing taking wine without opening a door comprises a cabinet body and a cabinet door, wherein the cabinet door is hinged on the cabinet body; a plurality of rows of support frames are arranged in the cabinet body; wine racks are arranged on the support frames; a skylight is arranged on the top of the cabinet body; a vertical guide rail is arranged at a position on the inner wall of the cabinet body which corresponds to the skylight; elevating support plates are arranged on the guide rail; conveying belts are arranged on the support frames; through holes are formed in positions on the support frames which correspond to the skylight; and the conveying belts are used for driving the wine racks. According to the wine cabinet allowing taking wine without opening the door, wine is taken through the elevating support plates and the skylight, and the opening area is small every time, so that the constant-temperature environment in the wine cabinet is not damaged, and the wine quality is improved.

Owner:中山市优盛电器有限公司

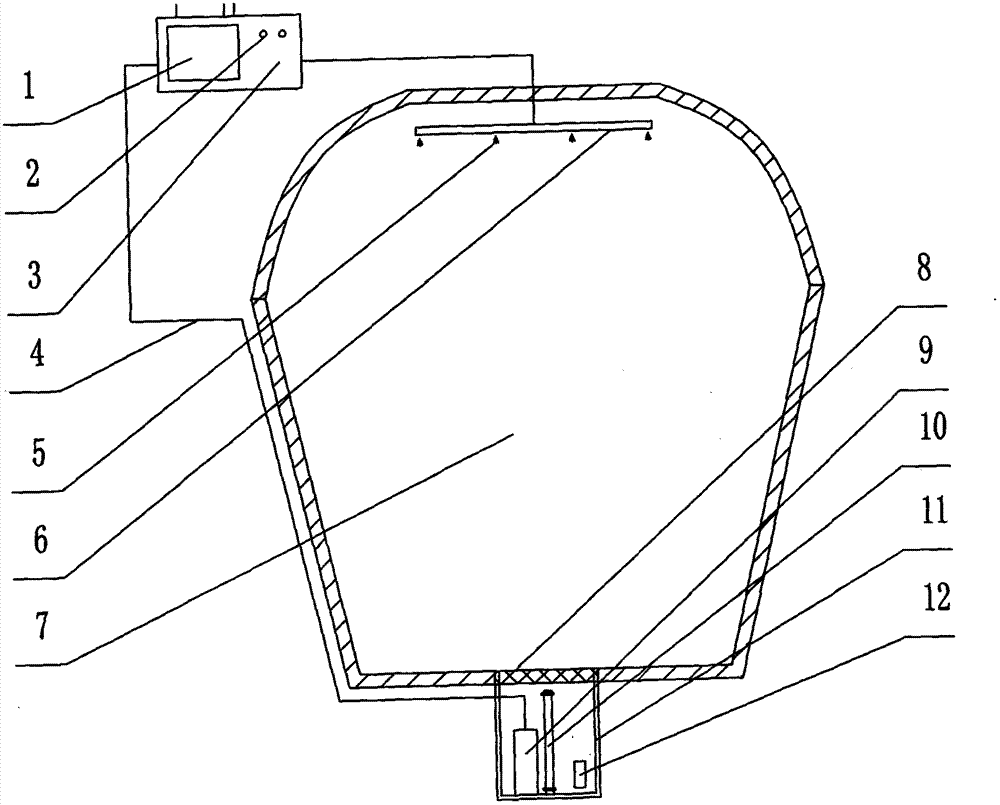

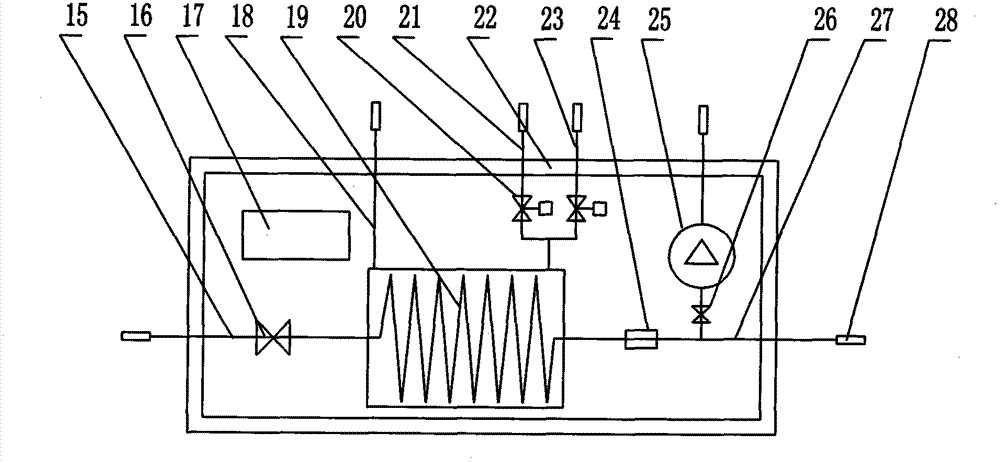

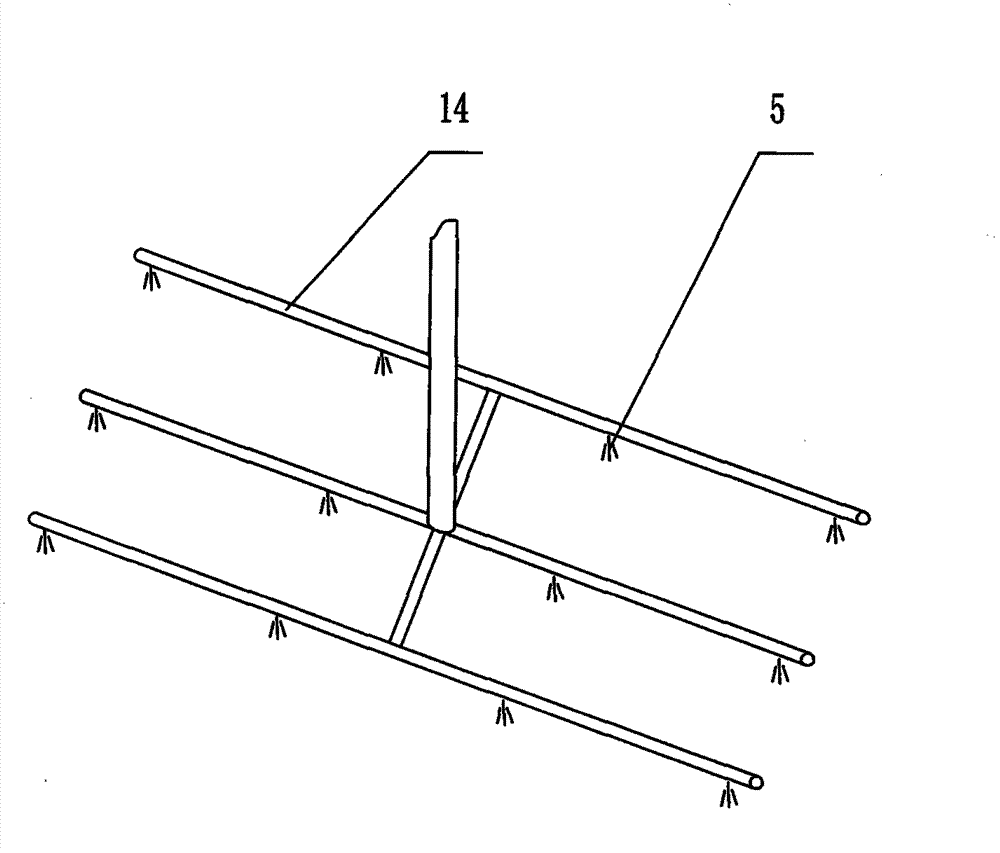

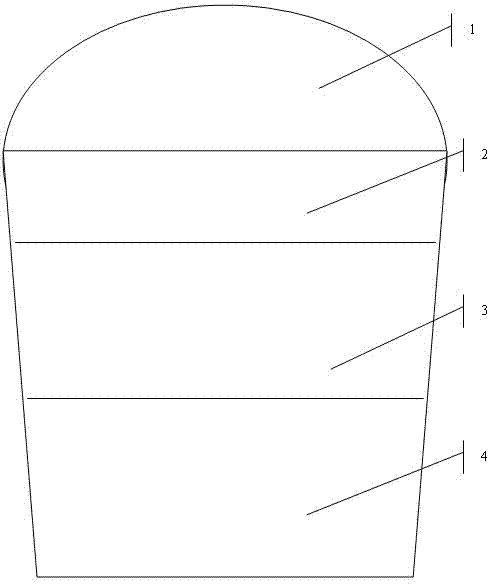

Yellow water circulation and fermentation method and yellow water circulation device

InactiveCN102827725AConsistent qualityImprove qualityAlcoholic beverage preparationTemperature curveWater circulation

The invention relates to a yellow water circulation and fermentation method and a yellow water circulation device. The yellow water circulation and fermentation method is characterized in that repeated use of the yellow water in a cellar is realized through artificial intervention of yellow water in the cellar, fermented grains in the cellar can form a solid / liquid uniform fermentation state, thereby the fermentation quality of the Luzhou-flavor liquor can be increased. The yellow water circulation and fermentation method comprises the following steps: yellow water in the cellar enters into a yellow water gathering tank; the yellow water enters into a portable control case through a pipe pump by a yellow water pump, the portable control case can automatically regulate the temperature according to preset fermentation temperature curve of the fermented grains, the yellow water after temperature regulation is subjected to return-sprinkling in the cellar, the yellow water is continuously and repeatedly performed the circulation, and the fermented grains is fermented under the corresponding temperature of the fermented grains fermentation temperature curve. The yellow water circulation device is an apparatus for realizing the yellow water circulation and fermentation method, which comprises the elements of a nozzle in the cellar, the yellow water gathering tank under the cellar, the portable control case and the pipeline connected the above elements.

Owner:泸州科源生物科技有限公司 +1

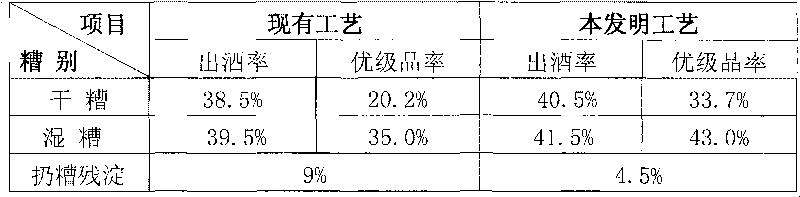

Highly-flavored liquor production method capable of reducing extruded waste vinasse residual starch

ActiveCN102787040AReduce residue contentRich cellar aromaAlcoholic beverage preparationLeesYield (wine)

The present invention discloses a highly-flavored liquor production method capable of reducing extruded waste vinasse residual starch. The method comprises processes of: stripping a pit to take vinasse out of the pit; preparing vinasse and mixing; carrying out wine obtaining grain steaming; preparing nutrition vinasse; inoculating vinasse and culturing; preparing surface vinasse; splashing water and adding distiller's yeast powder; transferring to the pit; and carrying out pit sealing fermentation. With the method of the present invention, the extruded waste vinasse residual starch content issignificantly reduced to 2-5%, and waste lees can be prepared without secondary fermentation so as to significantly reduce production cost; the upper layer vinasse with poor quality can be changed into the surface vinasse, then changed into the extruded waste vinasse, and finally changed into the waste lees in each turn of the method, and the lower layer vinasse can be continuously adopted as thegrain vinasse to enter the pit so as to improve vinasse quality and wine quality; use amount of bran hulls, water and other ingredients between retorts are regular; acidity of the vinasse entering the pit, starch content, and water content of the vinasse are easily grasped; quality product rate and wine yield of the whole pit output are respectively increased by 0.5-1%; and the method has characteristics of simple process, easy operation, no addition of production equipment, and good quality of produced wine, and provides a reliable guarantee for promotion and application of highly-flavored liquor production enterprises.

Owner:SICHUAN TUOPAI SHEDE WINE

Complex enzyme and use thereof

InactiveCN101381665AFully hydrolyzedPromote hydrolysisAlcoholic beverage preparationCellulosePhytase

The invention relates to complex enzyme and application thereof, which belongs to the technical field of the brewing of distillate spirits. The complex enzyme comprises the following enzyme preparations and yeasts: 200 to 225 U / g of saccharifying enzyme (wheat), 80 to 100 IU / g of pullulanase (wheat), 10 to 15 IU / g of acid protease (wheat), 15 to 20 IU / g of cellulose (wheat), 15 to 20 IU / g of beta-dextranase (wheat), 5 to 10 IU / g of beta-mannase (wheat), 10 to 15 IU / g of xylanase (wheat), 5 to 10 IU / g of phytase (wheat), 5 to 10 IU / g of pectase (wheat), 1.5 to 2 percent of high temperature resistant saccharomyces cerevisiae (W / W), and 1 to 1.5 percent of aroma-producing yeast (W / W). The complex enzyme is applied as an additive to the production of wheat type distillate spirits. The complex enzyme can increase fermentable sugar, improve the utilization rate of raw materials, and improve the distillation yield; at the same time, the complex enzyme releases and synthesizes more flavor substances, and has the advantages of improving the quality of the distilled spirits and increasing the high-quality product rate of xiaoqu distillate spirits and so on; and the complex enzyme can be widely applied to the production of wheat type distillate spirits.

Owner:YUNNAN NORMAL UNIV

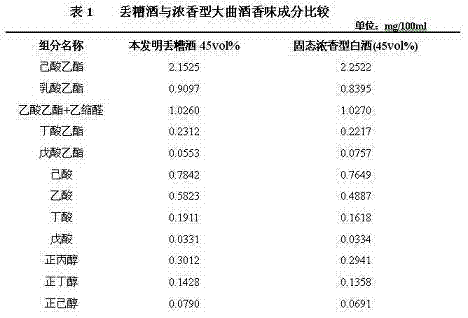

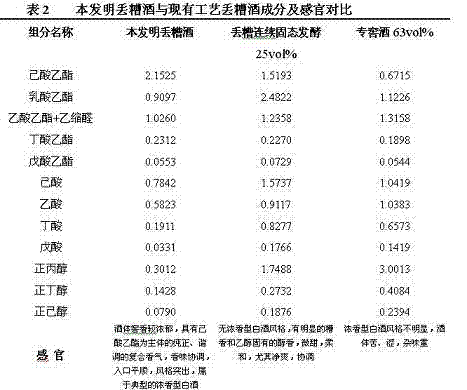

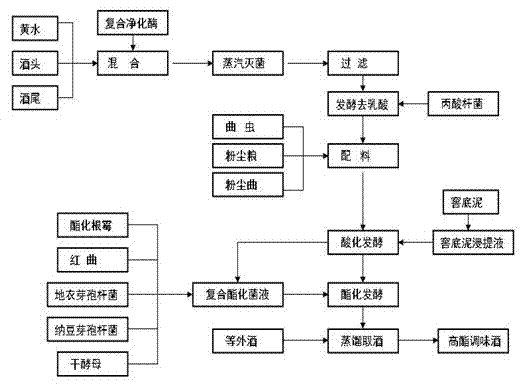

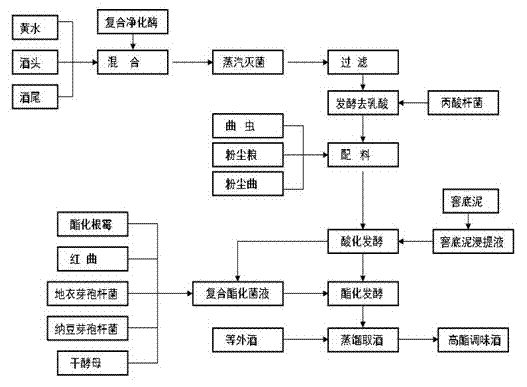

High-fat flavoring wine containing healthy flavor components and preparation method thereof

ActiveCN102408967ARemarkable fragrance functionTypical wine styleAlcoholic beverage preparationMicroorganism based processesBiotechnologyFuran

The invention discloses a high-fat flavoring wine containing healthy flavor components. The high-fat flavoring wine is prepared by a method comprising the following processes: pretreating raw materials; fermenting and removing lactic acid; burdening; acidifying and fermenting; and distilling and taking out wine. The preparation method comprises the following steps: mixing yellow water and foreshot with feint and then adding composite purification enzyme for sterilization and filtration to obtain a mixed liquor; inoculating propionibacterium in the mixed liquor for fermentation to remove lactic acid; adding powder starter, powder grain and starter pest powder; adding kiln bottom mud leach liquor for seal fermentation; preparing a composite esterified bacterium liquid with a fermented material; adding the composite esterified bacterium liquid in the remained fermented material for fermentation to obtain an esterified liquor; and preparing the high-fat seasoning wine by using overgauge wine and the esterified liquid, discarding stillage and distilling and taking out wine. Ethyl caproate, ethyl lactate, ethyl acetate, ethyl butyrate, Monacolin-K, tetramethylpyrazine, soy ketone, benzofuran, 5-hydroxymethyl-2-furfural and chitin are contained in distilled spirit with the alcohol strength of 50-68V / V%. After the flavoring wine is blended with the distilled spirit, the healthy flavorcomponents are duplicated. The high-fat flavoring wine in the invention can be used as a health distilled spirit.

Owner:SICHUAN TUOPAI SHEDE WINE

White spirit distiller grain yeast and white spirit brewing method

InactiveCN105255644AEffective degradation and utilizationImprove the quality of the wineAlcoholic beverage preparationRhizopusAlpha-amylase

The invention discloses white spirit distiller grain yeast. The white spirit distiller grain yeast is prepared from, by weight, 30-50 parts of glucose amylase special for high-activity wine brewing, 30-45 parts of rhizopus bran, 5-15 parts of yeast starter, 1-10 parts of white spirit yeast, 1-6 parts of high-temperature-resistant and high-activity saccharomyces cerevisiae, 1-6 parts of high-activity aroma-producing yeast, 1-5 parts of whole-cell esterification yeast enzyme, 1-5 parts of acid protease, 1-5 parts of cellulase and 1-3 parts of medium-temperature alpha-amylase. The technology for adopting the distiller grain yeast for brewing comprises the steps of distiller grain cooling, distiller grain yeast mixing and smashing, distiller grain yeast activating, yeast discharging, fermenting in a tank and liquor steaming, substances such as starch, organic acid and alcohol remaining in white spirit distiller grain can be fully utilized for fermenting, the conversion rate is high, the wine quality is good, operation is easy, and the problems that the existing distiller grain white spirit brewing technology is low in conversion rate, few aromatic substances are generated, the wine quality is poor and the technology is complex are solved.

Owner:WUHAN SUNHY BIOLOGICAL

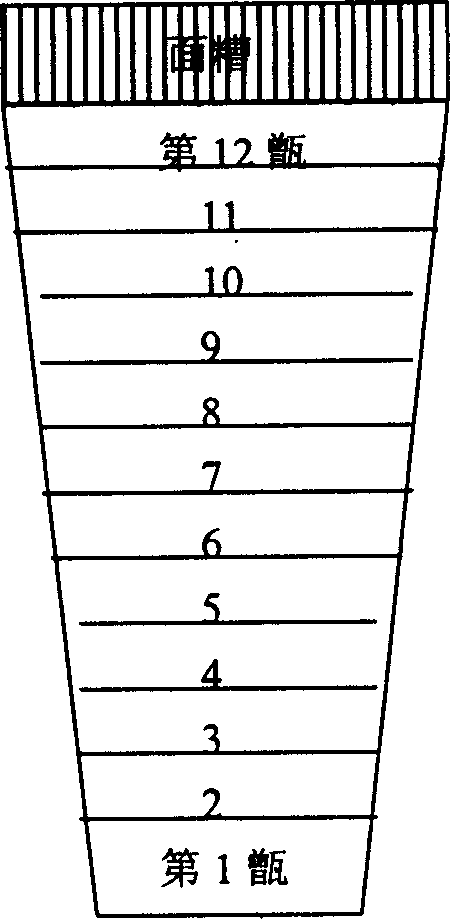

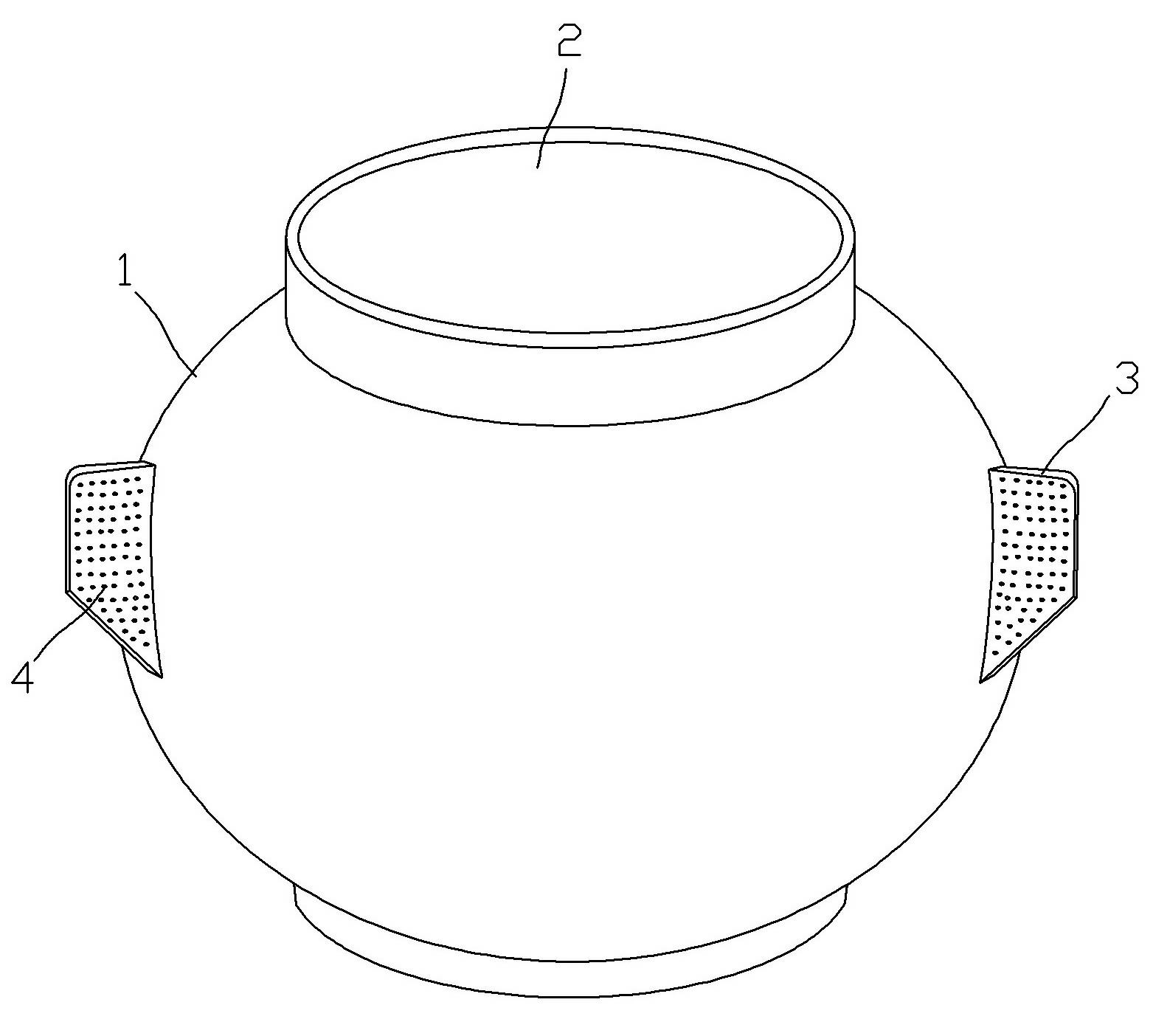

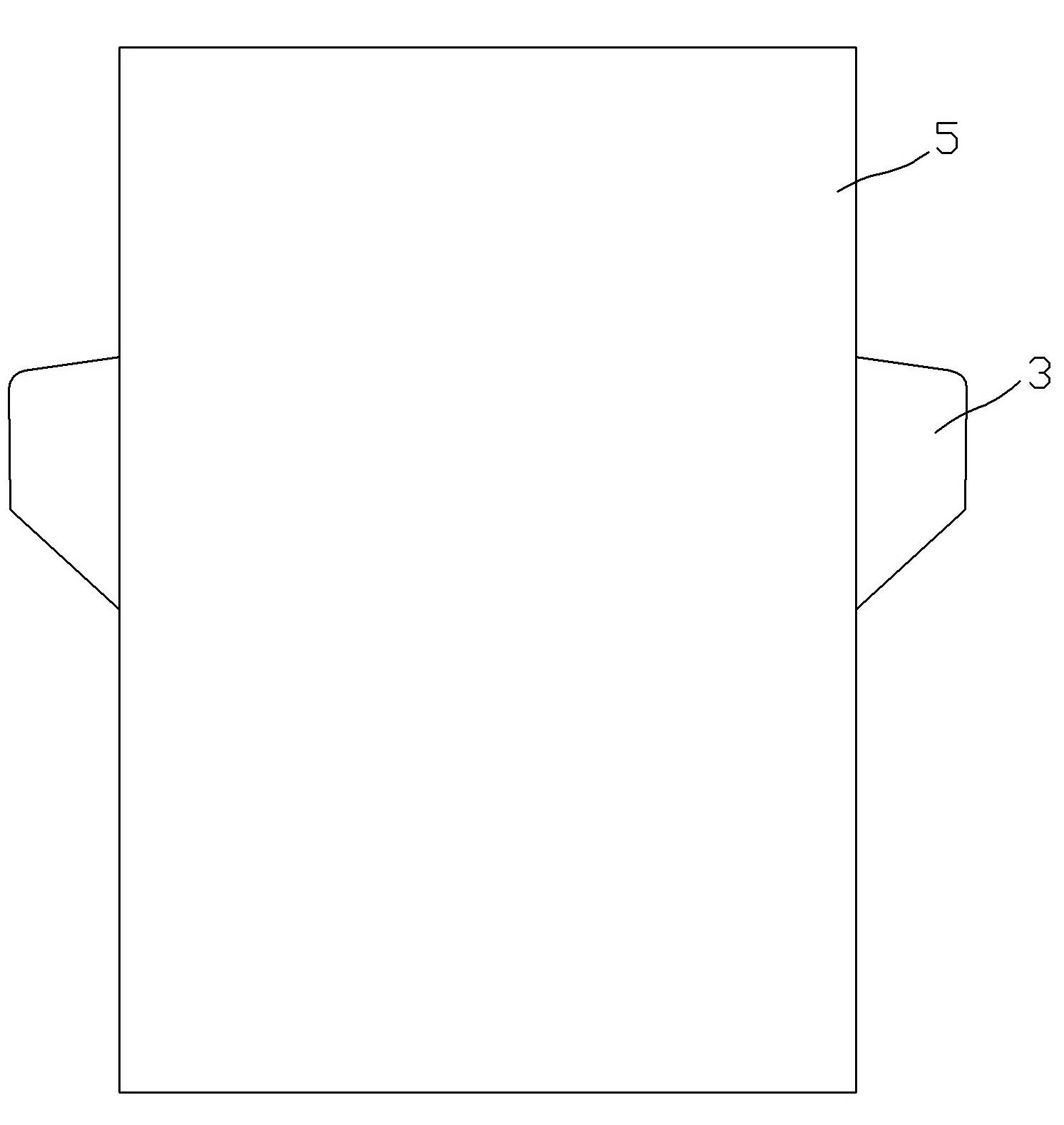

Fermentation and Brewing Technology of Xiaoqu Fen-flavor Liquor in Small Dressing Ceramic Jar and Small Dressing Ceramic Jar

InactiveCN102286335AReduce dosageReduce or avoid infectionAlcoholic beverage preparationFlavorMetallurgy

The invention relates to a brewing process of xiaoqu elegant white wine by using small-capacity ceramic jar fermentation. The brewing process comprises selecting grains, washing the grains, soaking, cooking, spreading and airing, mixing with yeast, saccharifying, fermenting and distilling steps; and the brewing process is characterized by adding yeast-mixed and saccharified fermented grains to a ceramic jar, pottery jar or porcelain jar, uniformly compacting, adding water the amount of which is 90-120% the weight of the fermented grains, sealing and fermenting, adjusting the ambient temperature to guarantee that the internal temperature of the fermentation jar reaches 38-40 DEG C in winter and spring and 33-36 DEG C in summer and autumn within 72 hours, maintaining the ambient temperatureat 24-26 DEG C after the fermented grains is added to the jar for 90-120 hours, and after the fermentation is carried out for 6-8 days or the residual sugar in the fermented grains is approximate to zero, pouring the fermented grains into a retort pot for distilling. In the brewing process provided by the invention, a small-capacity ceramic jar is used as a fermentation container, thereby facilitating cleaning and disinfection, improving wine quality and taste and improving wine yield; and the white wine brewed by the brewing process provided by the invention has elegant and pure flavor as well as mellow, sweet and refreshing taste, and is gentle, natural, harmonious and joyful.

Owner:河南东坡酒业集团有限公司

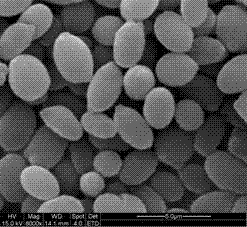

Technology for preparing rice aroma type distiller's yeast

InactiveCN105969582ASimplify the production processReduce manufacturing costMicroorganism based processesAlcoholic beverage preparationHorticultureSaccharomyces cerevisiae

The invention provides a preparation process of rice-flavored koji. The preparation process includes the following steps: 1) Cultivation of seed koji: 1.1) Cultivation of strains in inclined test tubes, 1.2) Cultivation of Rhizopus seed koji, 1.3) Cultivation of yeast seed koji Cultivation; 2) Treatment of koji materials; 3) Cultivation of distiller's yeast. The preparation process of the rice-flavored distiller's yeast of the present invention simplifies the production process, has low production cost, and is applicable to wine enterprises of different scales. This process screens out excellent Rhizopus and Saccharomyces cerevisiae, and innovates the production process. The rice-flavored distiller's yeast prepared has stable quality, high saccharification power and fermentation power, and the yield and quality of wine are significantly improved. The improvement of distiller's yeast also upgrades and simplifies the production process of distiller's yeast.

Owner:GUANGXI TIANLONGQUAN WINE CO LTD

Esterification accelerant and method for preparing esterifying liquid by using same

InactiveCN101962607ASignificantly progressiveSolve the problem of hexanoylation inhibitionAlcoholic beverage preparationOrganic acidIsobutyl alcohol

The invention relates to an esterification accelerant consisting of alcohol substances and a method for preparing high-titer esterifying liquid by using the same. The esterification accelerant is one or more selected from n-propanol, isobutyl alcohol, butanol, hexanol and beta phenethanol. After the esterification accelerant of the invention is added during the preparation of the biological esterifying liquid, high-efficiency biological esterification synthesis can be performed on organic acids, such as caproic acid and the like, and simple raw materials, such as foreshot, feint and the like, so as to obtain flavor components, such as ethyl caproate and the like; and the accelerant and the method also have an obvious effect on the synthesis efficiency of esters in a kiln.

Owner:HUBEI UNIV OF TECH

Technique for processing Qiyexian apple dry white wine and products thereof

InactiveCN101260350AYellowish colorGood appearanceAlcoholic beverage preparationFood flavorFermentation

The invention discloses a fermentation type fruit wine beverage and particularly relates to a Qiyuexian apple dry white wine processing technology and a product thereof, wherein, the Qiyuexian apple dry white wine processing technology takes advantage of new breed apples 'Qiyuexian' to brew through enzyme engineering, high negative potential flavor enhancement and quality maturing, chitosan clarification and membrane separation process. The product is prepared by Qiyuexian apples, pectase, H2SO3, white granulated sugar, CaCO3, yeast and chitosan. The Qiyuexian apple dry white wine has the characteristics of light yellow luster, limpidness, rich nutrition, peculiar flavor, good appearance and internal quality, steady wine quality, and no precipitation after the wine is bottled and so on.

Owner:辽宁省果树科学研究所

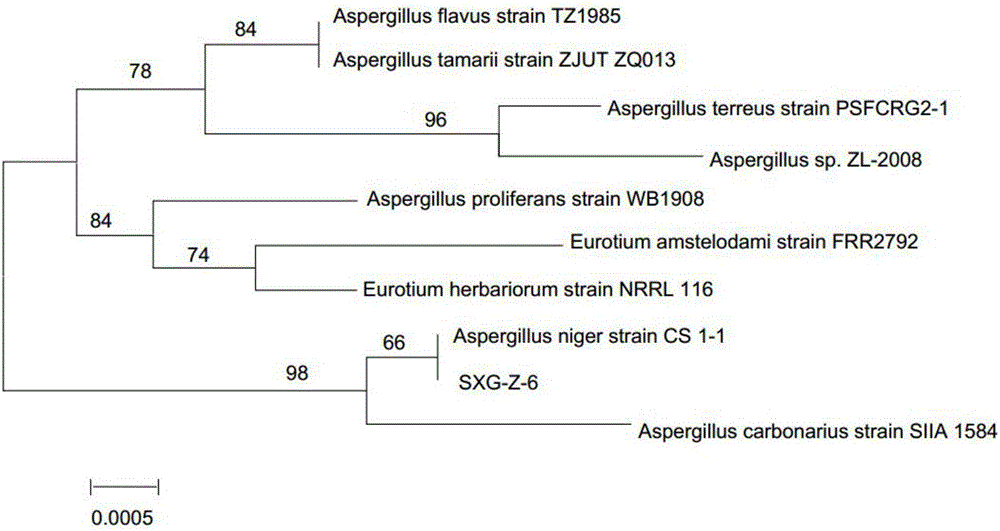

Aspergillus niger strain of complex enzyme for liquor making

ActiveCN105112303AIncrease profitIncreased total ester contentFungiMicroorganism based processesEnzymatic synthesisAspergillus niger

The invention discloses an aspergillus niger strain of a complex enzyme for liquor making, and belongs to the technical field of fermentation. The aspergillus niger strain is collected in China general microbiological culture collection center in July 9, 2015, and the collection number is CGMCC No.11064. Through culture medium optimization, a crude enzyme fluid obtained after 48 hours of solid fermentation contains various enzymes, wherein esterifying enzyme activity is 615.8mg.100mL<-1>, saccharifying enzyme activity is 7828.9U.g<-1>, and cellulase activity is 106.68U.g<-1>. Distilled liquid of esterified liquid obtained through enzymatic synthesis of esterifying enzymes generated from the strain has a typically rich and pure aroma of Luzhou-flavor liquor, and the content of ethyl hexanoate reaches 82.04% of the total flavor component. By the enzymes of the complex enzyme, utilization rate of starch-type substances in liquor-making raw materials, liquor yield and the content of esters in liquor bodies can be increased, liquor body flavors can be improved, high-quality liquor rate can be increased, and development of the liquor making industry can be promoted.

Owner:JIANGNAN UNIV

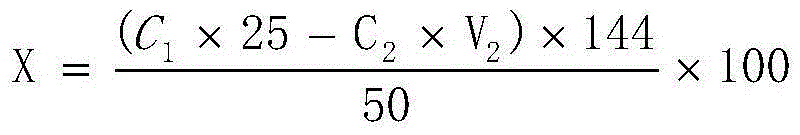

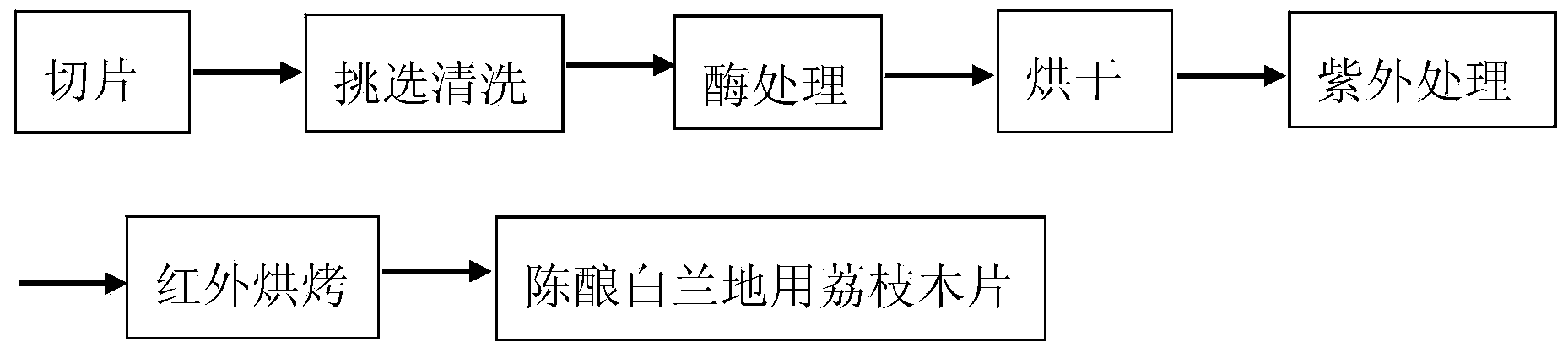

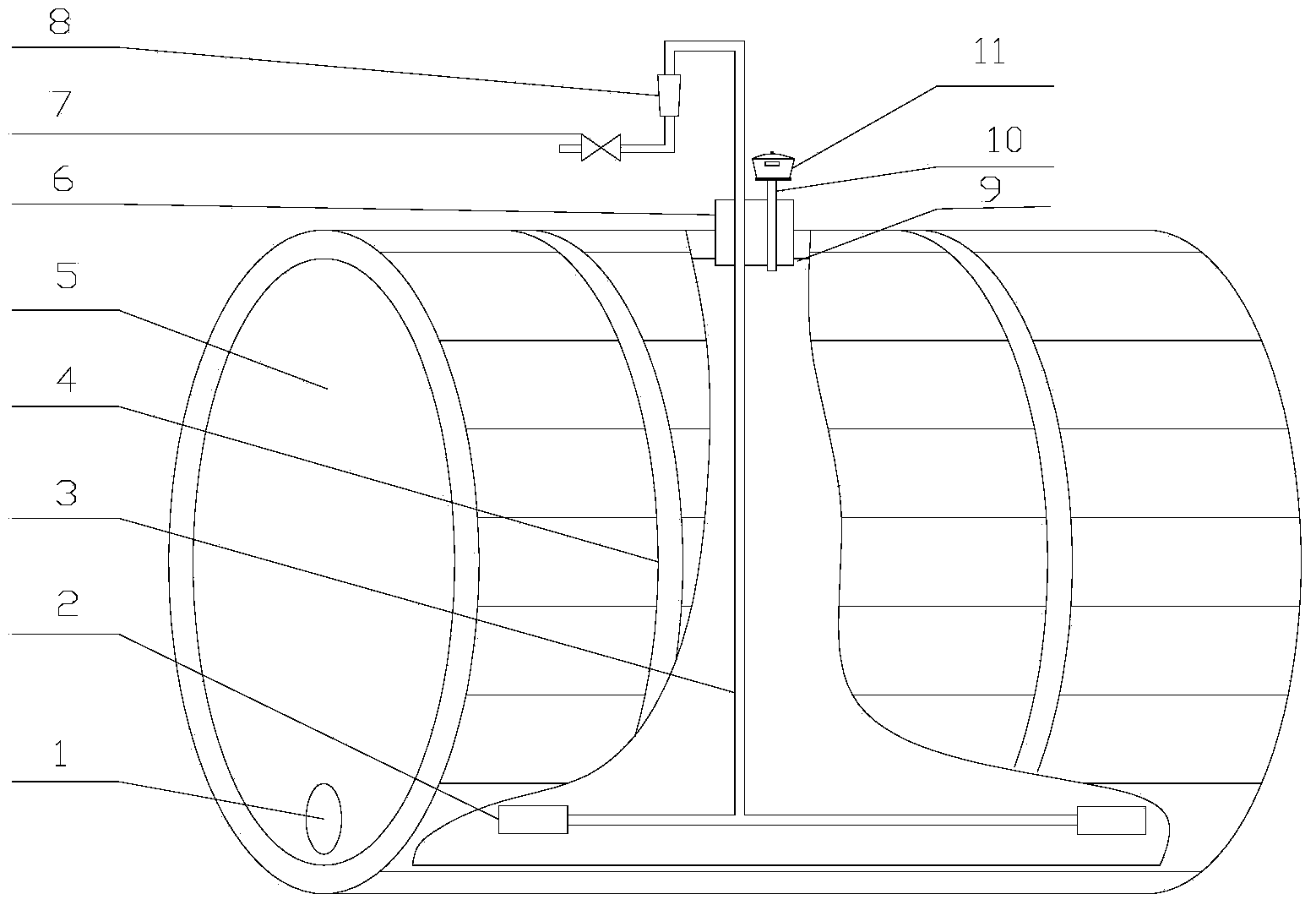

Litchi wood chip for ageing brandy, preparation and application process of litchi wood chip

ActiveCN103659974AQuality improvementReduce lossWood treatment detailsAlcoholic beverage preparationFruit wineAge method

The invention discloses a litchi wood chip for ageing brandy, preparation and application process of the litchi wood chip, and belongs to the field of fruit brandy ageing technology. The invention further discloses a preparation method of the litchi wood chip for ageing brandy, and provides the application process of the litchi wood chip for ageing brandy after the litchi wood chip for ageing brandy is obtained. According to the invention, the novel litchi wood chip for ageing fruit brandy is adopted, the micro-oxygenation technology is utilized, and the litchi wood chip and litchi wood products are combined to enable fruit brandy to mature within relatively short period, and endow the fruit brandy with elegant and comfortable fragrance and soft and rich taste, and the litchi wood chip can be used for ageing various fruit brandy. With adoption of the application process of the litchi wood in ageing brandy, the problems that the existing fruit brandy ageing method consumes longer time, uses a large amount of containers, and is large in labor intensity and great in fruit wine loss, are solved.

Owner:广东省九江酒厂有限公司

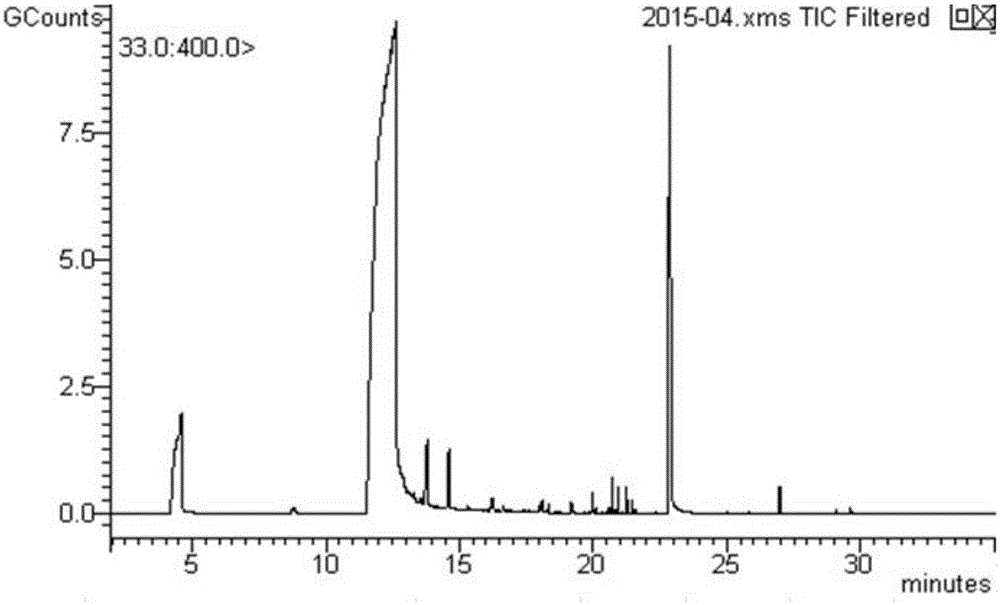

Screening and application of yeast CGMCC 4747 for high production of ethanol and low production of fusel oil in production of Chinese Maotai-flavor liquor

InactiveCN102766586AReduce manufacturing costSimple production processFungiMicroorganism based processesBiotechnologyHigh concentration

The invention relates to screening and application of yeast CGMCC 4747 for high production of ethanol and low production of fusel oil in production of Chinese Maotai-flavor liquor, belonging to the technical field of biological engineering. A strain is of saccharomyces cerevisiae CGMCC 4747. The strain is obtained by separation from various Daqu, fermented grains, brewing raw materials and brewing environments of multiple famous liquor factories in China; and the screening method comprises the following steps of: taking substances of Daqu samples, fermented grains, brewing raw materials or brewing environments, diluting, coating a TTC (triphenyltetrazolium chloride) prescreening flat plate, selecting colonies with significant red color, further transferring into shaking flask culture for rescreening, determining the content of each of the ethanol and the fusel oil in a fermentation solution by adopting a distillation specific gravity method and HS-SPME-GC-MS respectively, and screening to obtain the strain with high concentration of the ethanol and low concentration of the fusel oil. The strain can be applied to food industry and brewed liquor industry.

Owner:JIANGNAN UNIV

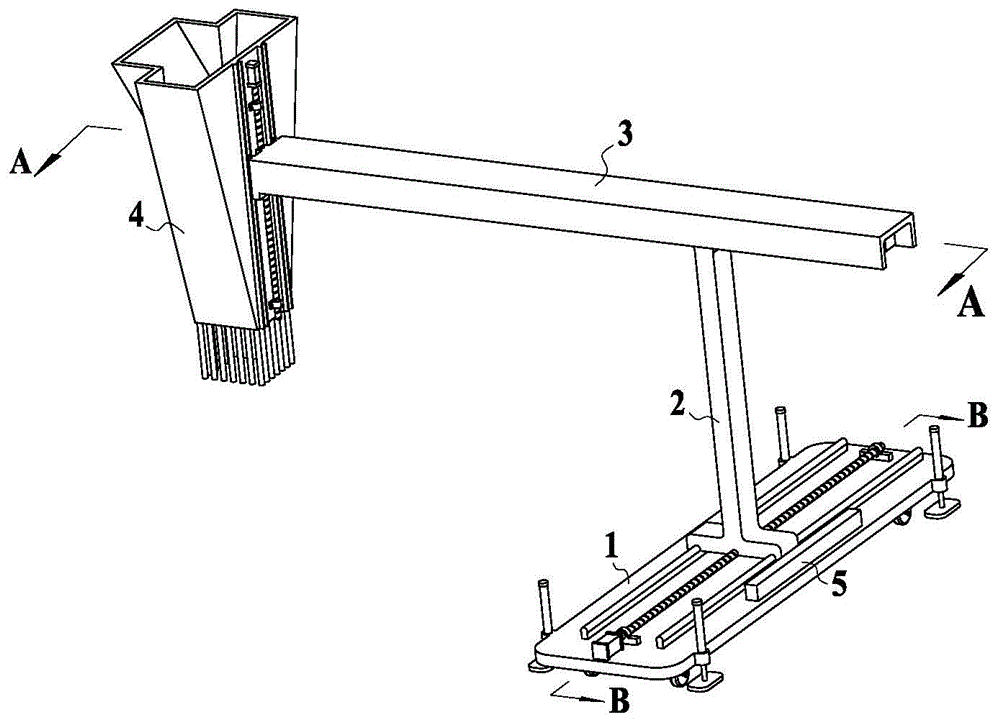

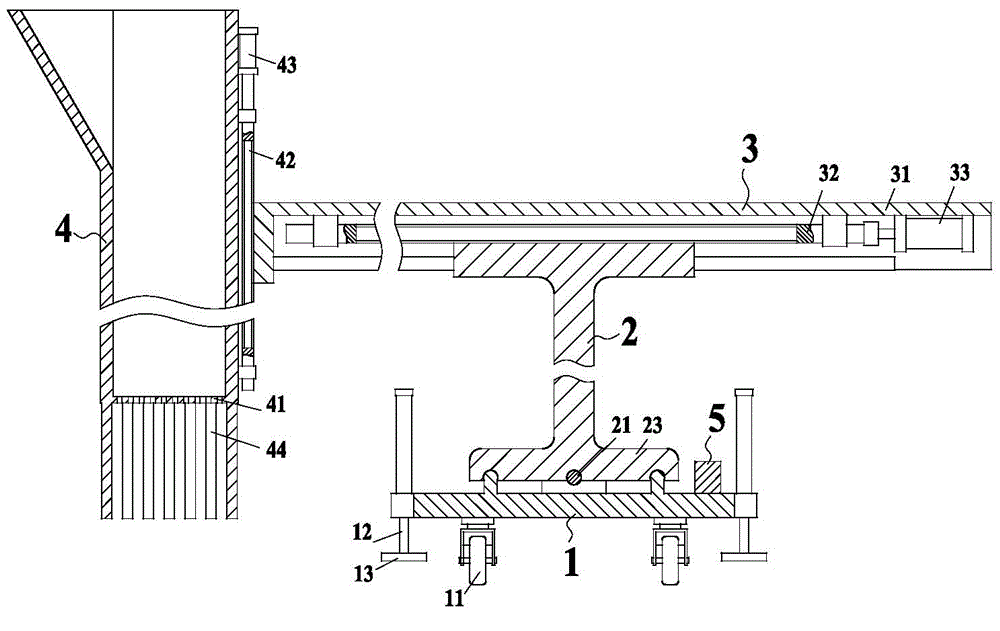

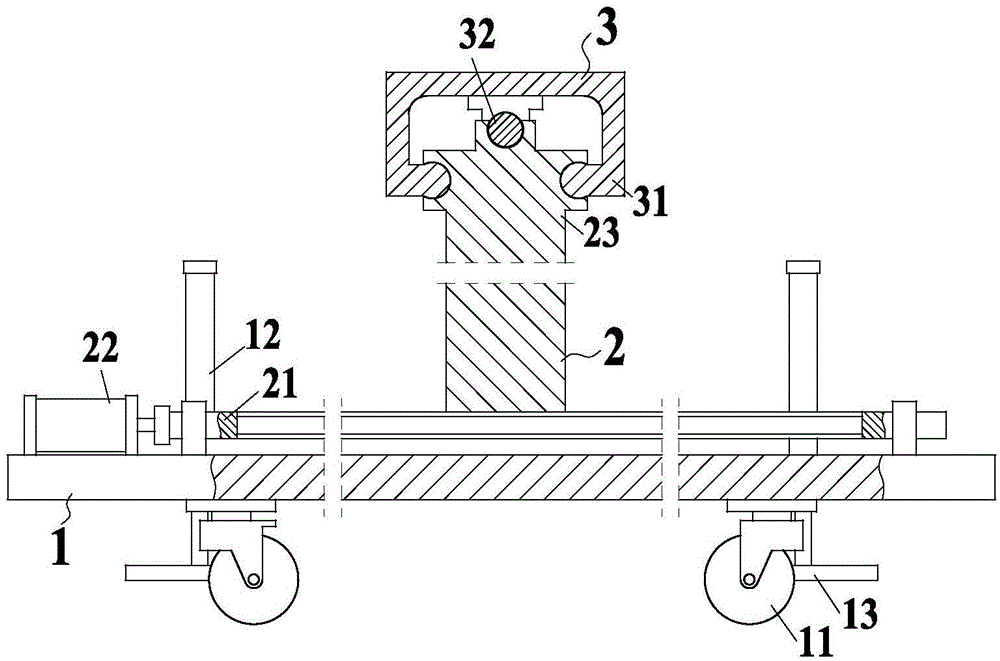

White spirit brewing retort loading dispersing machine suitable for multiple types of liquor retorts

ActiveCN104911053AAchieve flatnessImprove wine qualityAlcoholic beverage preparationLarge containersMechanical engineeringBrewing

The invention relates to the field of white spirit brewing equipment and specifically relates to a white spirit brewing retort loading dispersing machine suitable for multiple types of liquor retorts. The white spirit brewing retort loading dispersing machine comprises a base, a left-right moving device, a front-back moving device, a dispersing hopper and a counterweight iron block; the base is entirely of a flat cuboid structure; the left-right moving device is located above the base; the left-right moving device is used for pushing the dispersing hopper to move left and right; the front-back moving device is located above the left-right moving device and used for pushing the dispersing hopper to move forwards and backwards; the dispersing hopper is located in front of the front-back moving device; the polishing hopper is capable of moving up and down. The white spirit brewing retort loading dispersing machine is used for overcoming the defects of the existing retort loader that the materials below are compacted in the gradual stacking process of the materials to affect liquor quality and the existing retort loader fails to be adapted to the retorts different in volume.

Owner:罗定市丰智酒业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com