Litchi wood chip for ageing brandy, preparation and application process of litchi wood chip

A technology of lychee wood chips and brandy, which is applied in the direction of manufacturing tools, wood processing utensils, preparation of alcoholic beverages, etc., can solve the problems of high labor intensity, large loss of wine liquid, occupation of large containers, etc., so as to reduce the land area and labor costs. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

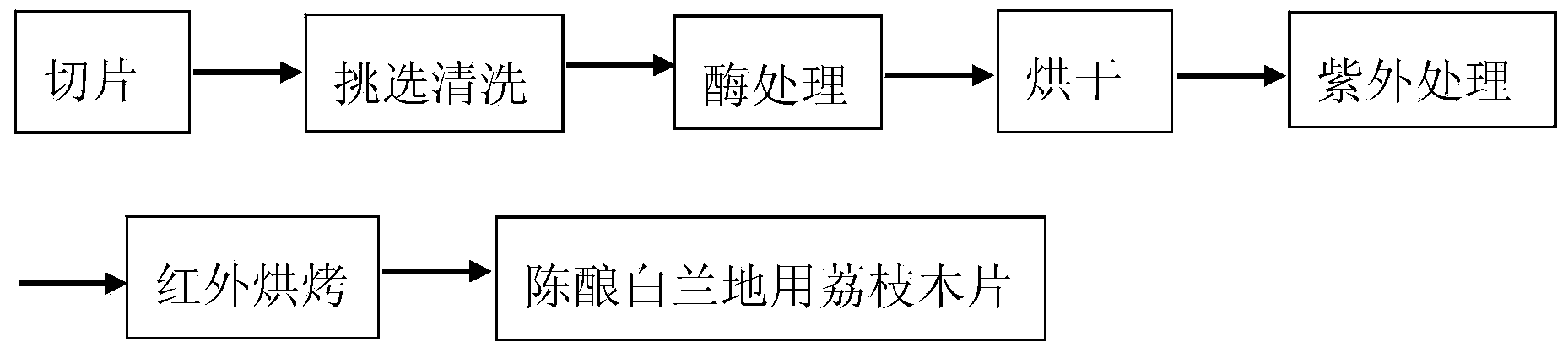

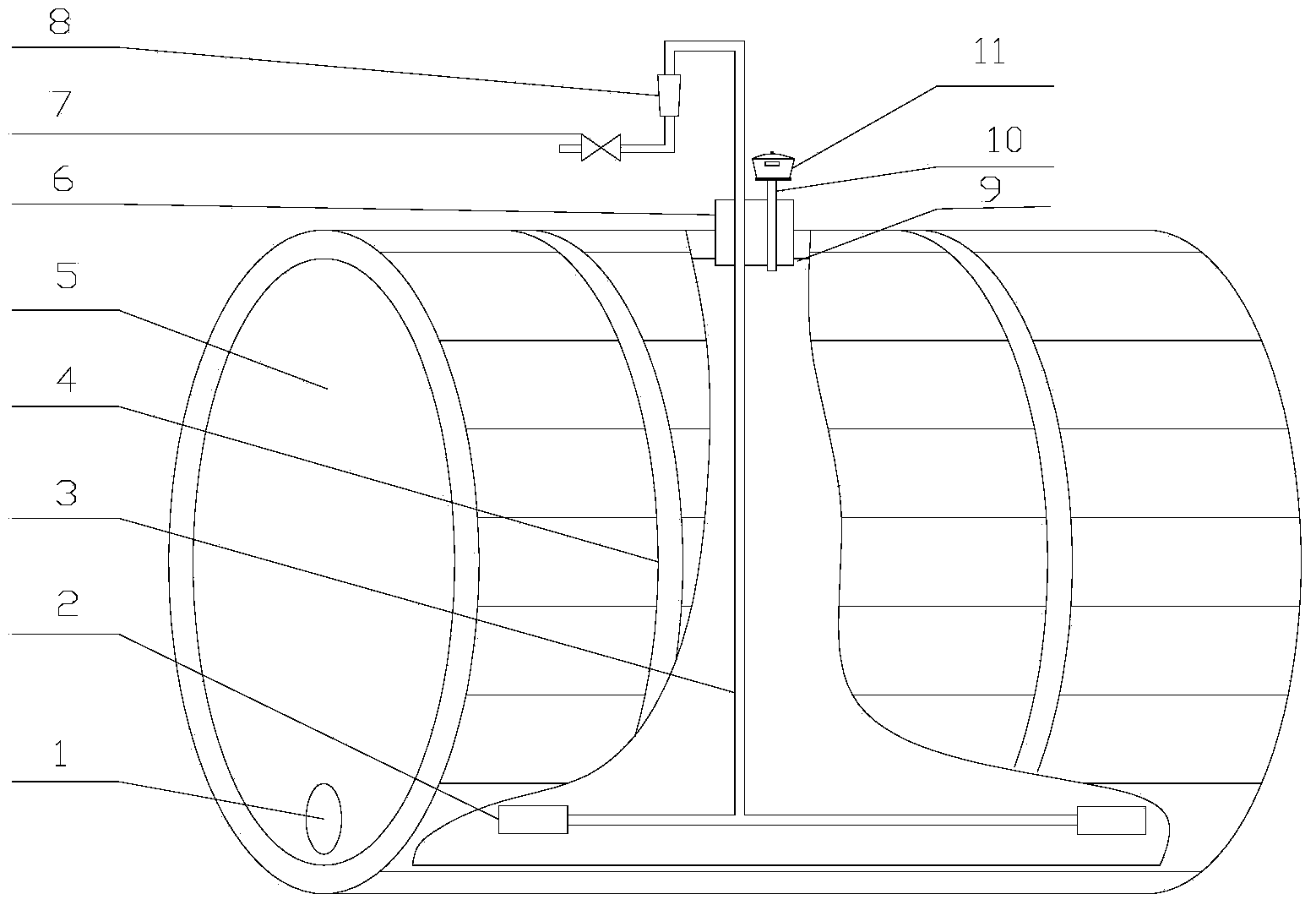

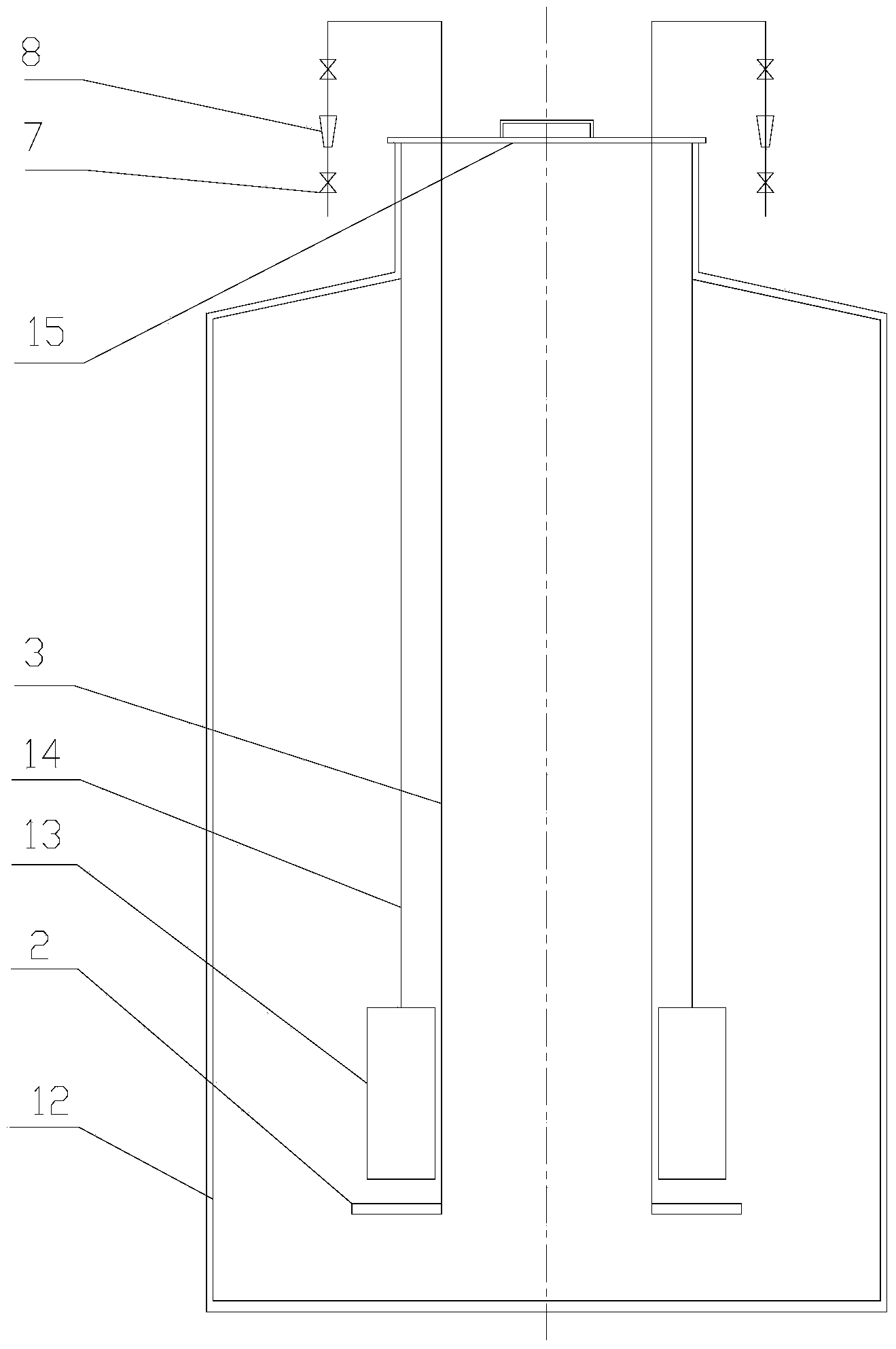

[0057] Aging of lychee brandy: 20-50 years old lychee wood removes the bark and slices. The size of the slices is 70-90mm long, 20-30mm wide, and 2-5mm thick. Select the darker wood chips and wash them with water and volume fraction Wash away impurities with 50% ethanol, remove and dry, bake in an oven at 100°C for 48 hours, and then irradiate with ultraviolet light with a wavelength of 250nm for 48 hours to degrade part of the lignin of lychee wood, and then lychee wood chips enter the infrared In the baking process, it is treated in an infrared oven at 180°C for 25 minutes to destroy the functional groups of lignin, further degrade part of lignin, and produce a special roasted aroma. After the treated lychee wood chips are cooled, they are sealed and stored for later use. The fermented lychee brandy is stored in 250L lychee wood aging barrels, aging ceramic vats, and large stainless steel aging tanks. Add 1 to 5‰ of lychee wood chips into the wine. Pass clean air into the wi...

Embodiment 2

[0059] Aging of dragon fruit brandy: 20 to 50 years old lychee wood, remove the bark slices, the size of the slices is 70 to 90mm long, 20 to 30mm wide, and 2 to 5mm thick. Wash away impurities with 50% ethanol, remove and dry, bake in an oven at 100°C for 48 hours, and then irradiate with ultraviolet light with a wavelength of 250nm for 48 hours to degrade part of the lignin of lychee wood, and then lychee wood chips enter In the infrared baking process, treat in an infrared oven at 180°C for 25 minutes to destroy the functional groups of lignin, further degrade part of lignin, and produce a special roasted aroma. After the treated lychee wood chips are cooled, they are sealed and stored for later use. The fermented dragon fruit brandy is stored in 250L lychee wood aging barrels, aging ceramic vats, and large stainless steel aging tanks. Add 1 to 5‰ litchi wood chips into the liquor. Clean air is introduced into the liquor to control the oxygen content in the liquor to 5-15mg...

Embodiment 3

[0061] Aging of green plum brandy: Remove bark slices from lychee wood over 50 years old. The size of the slices is 70-90mm long, 20-30mm wide, and 2-5mm thick. % ethanol to wash away impurities, remove and dry, bake in an oven at 100°C for 48 hours, and then irradiate with an ultraviolet lamp with a wavelength of 250nm for 48 hours to degrade part of the lignin of the litchi wood, and then the litchi wood chips enter the infrared oven. In the roasting process, treat in an infrared oven at 180°C for 25 minutes to destroy the functional groups of lignin, further degrade part of lignin, and produce a special roasted aroma. After cooling, the treated lychee wood chips are sealed and stored for later use. The fermented green plum brandy is stored in 250L lychee wood aging barrels, aging ceramic vats, and large stainless steel aging tanks. Add 1 to 5‰ of lychee wood chips into the wine. Pass clean air into the wine to control the oxygen content in the wine to 5-15mg / L. Circulate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com