'Whole clear' process of brewing aroma type white spirit

A kind of Luzhou-flavor liquor and process technology, applied in the field of fermentation cellar, can solve the problems of susceptibility to foreign smell, uncoordinated trace components, large loss of alcohol volatilization, etc., to avoid infection of foreign smell, easy to implement, and low input cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

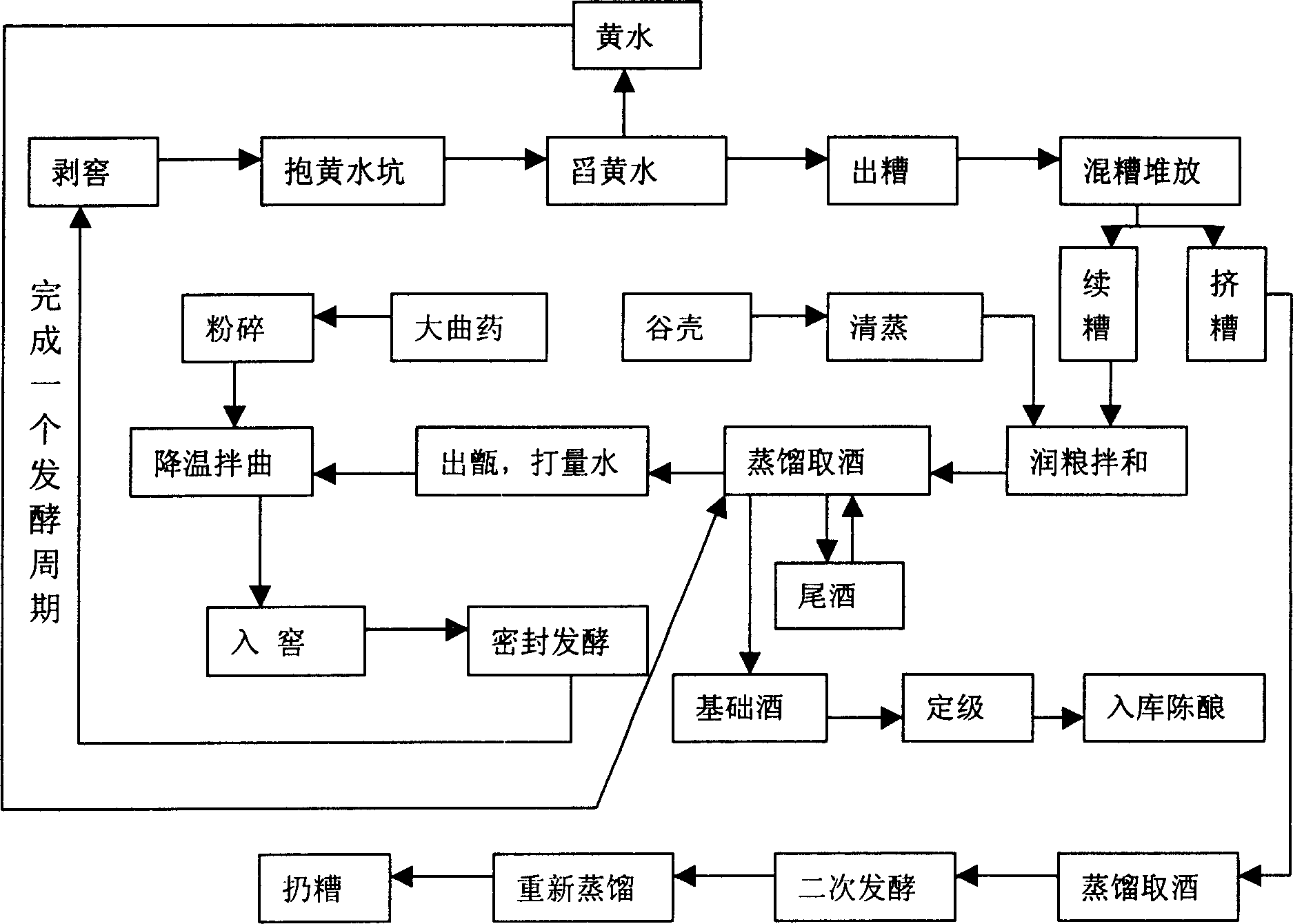

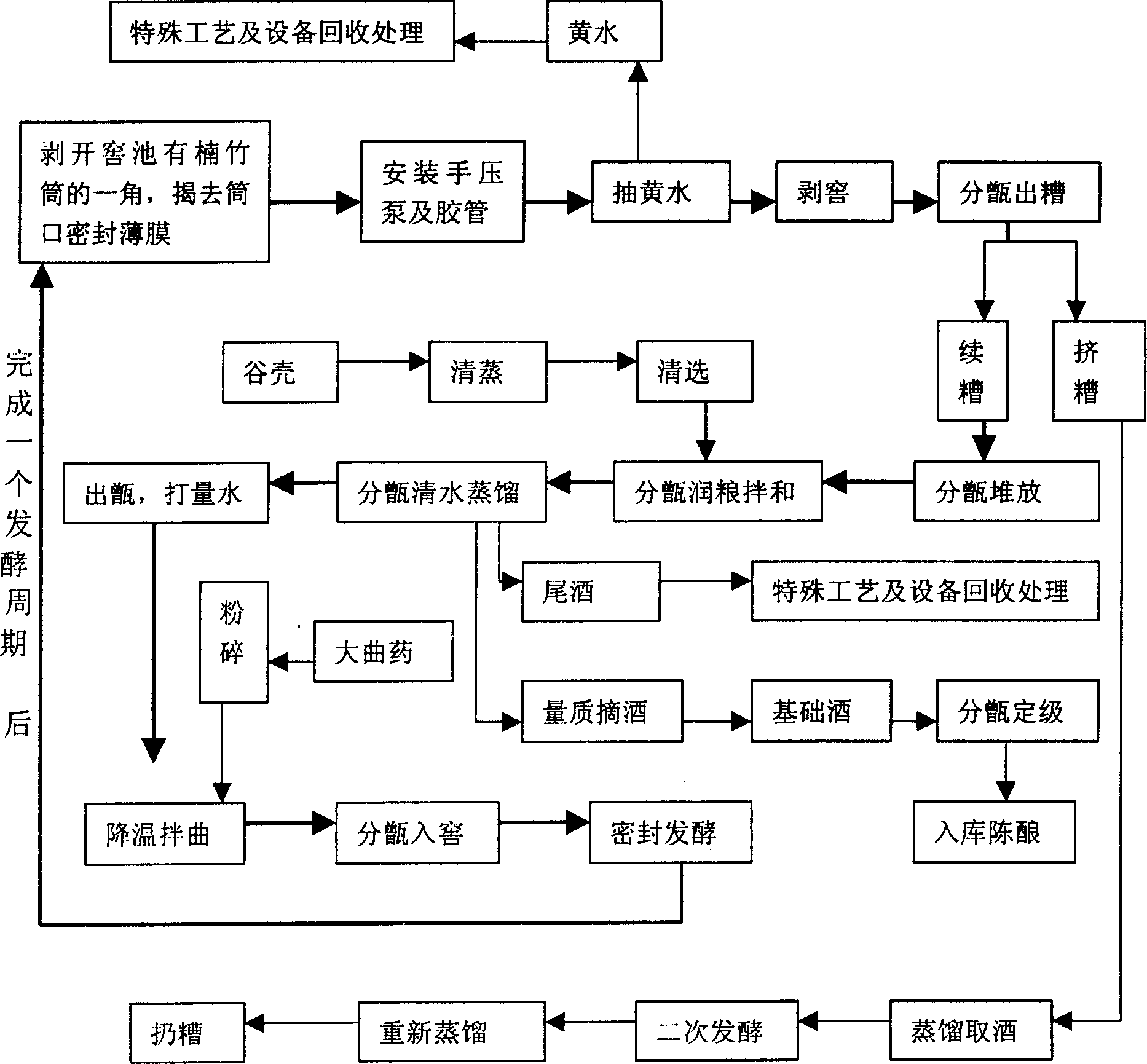

Method used

Image

Examples

Embodiment Construction

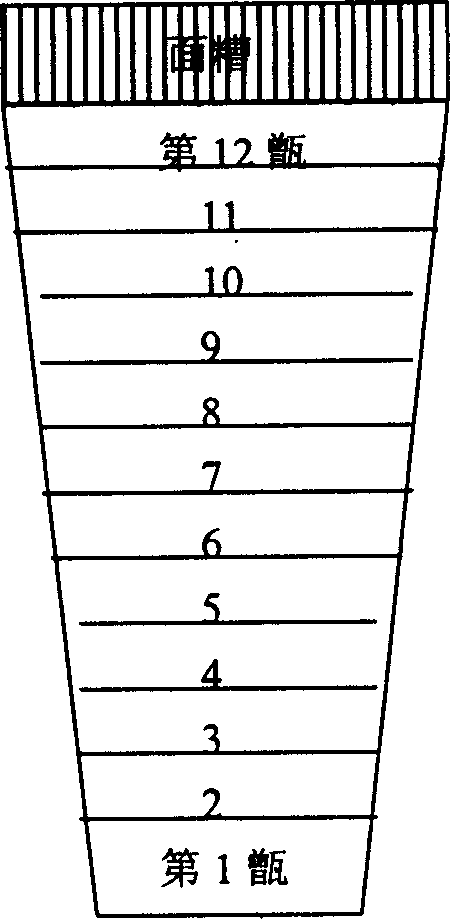

[0055] 1. Make and install the yellow water extraction device (see accompanying drawings 8, 9, 10):

[0056] Dig an isosceles triangle pit with a length of 45-55cm on both sides and a depth of 30cm at a corner of the wall at the bottom of the fermentation cellar. The inner wall is inlaid with refractory bricks to prevent the pit mud from falling off. Place an equilateral triangular grate with a small gap and a side waist of 60 cm above the pit. The grate should completely cover the pit mouth, and then open a round hole with a diameter of 10 cm in the middle. Insert a bamboo tube about 3 meters long into the round hole of the grate. Its length should be equal to the depth of the cellar. The diameter of the lower end of the bamboo tube is 8-9 cm. The slope of the ground is ≥60° to ensure that the yellow water can enter the tube smoothly; the diameter of the upper end is 6-7cm, leaning against the corner of the cellar wall above the pit, and the inside of the bamboo tube is hollo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com