Patents

Literature

220results about How to "Improve hygiene quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

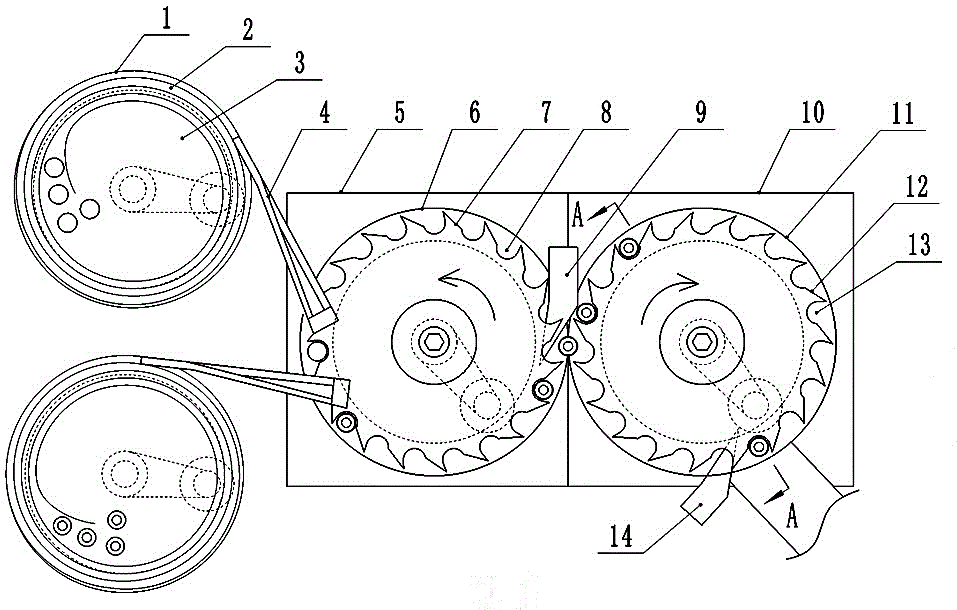

Technology for mechanical and clean processing of black tea in different shapes

InactiveCN1792200ARich shapeIncrease color varietiesPre-extraction tea treatmentBlack teaEngineering

A technology for mechanically preparing to black tea with different shapes including needle shape, spiral shape, flat shape and particles is disclosed.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

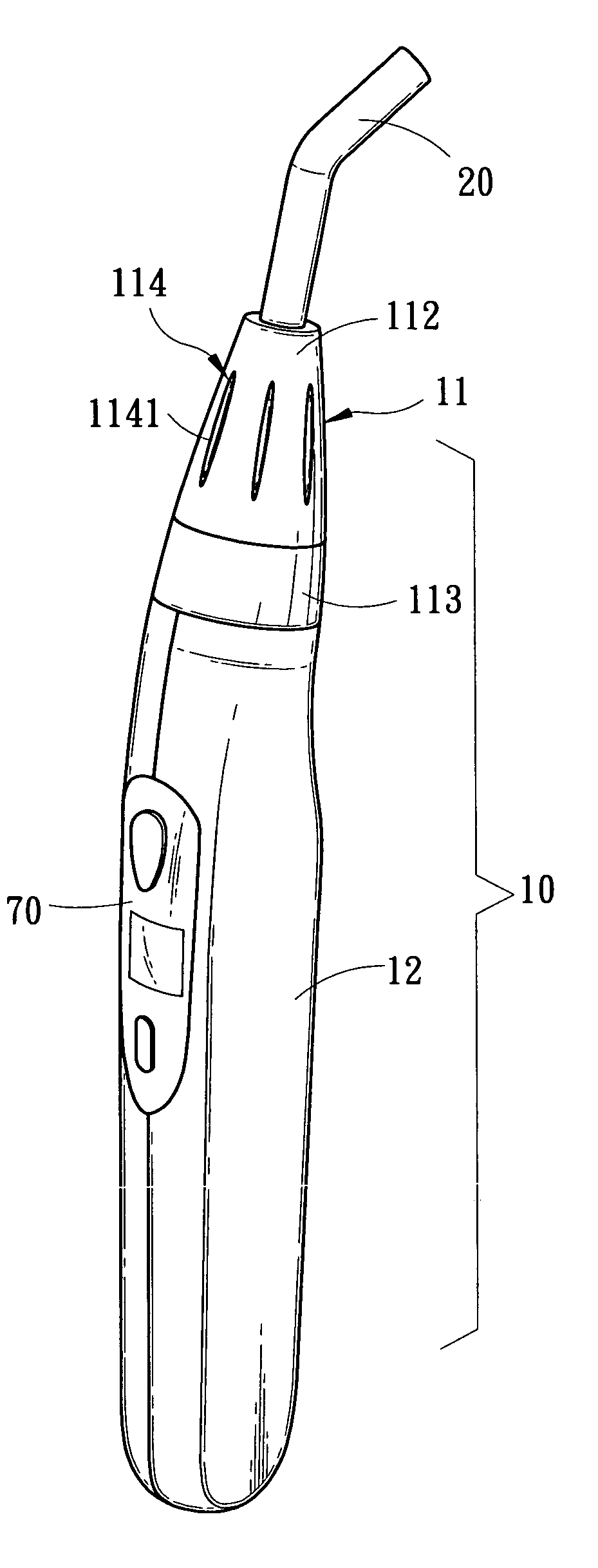

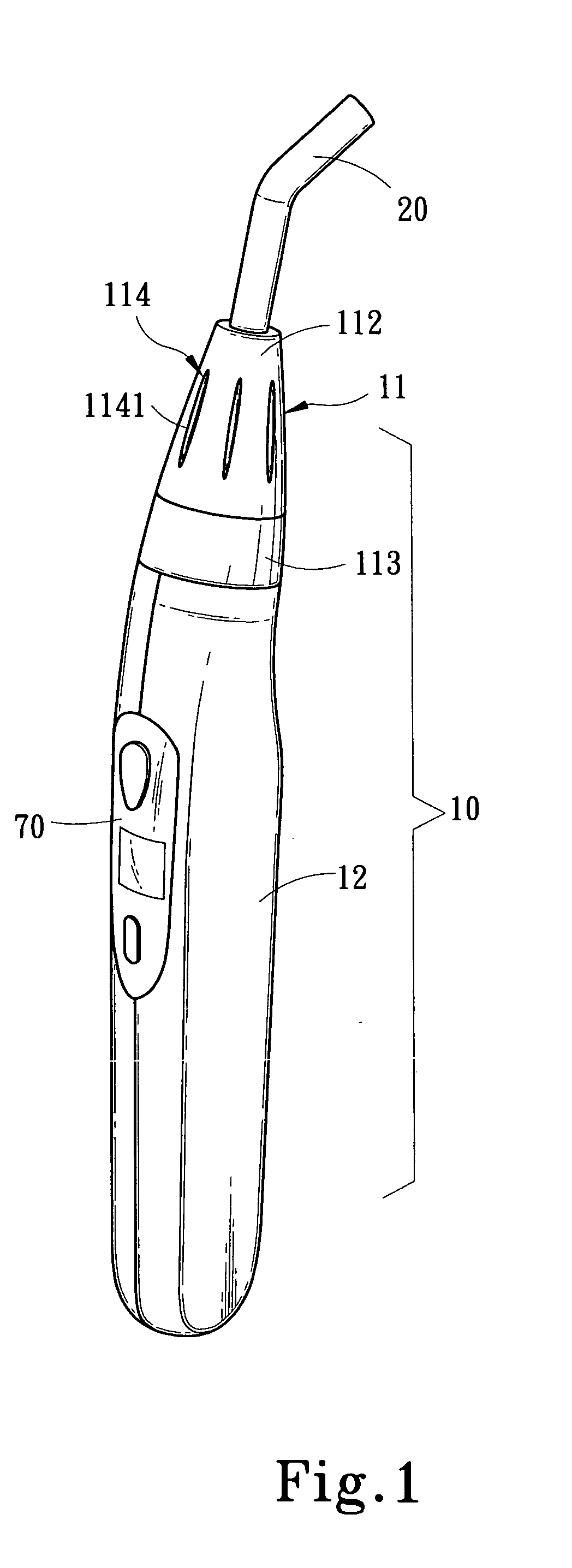

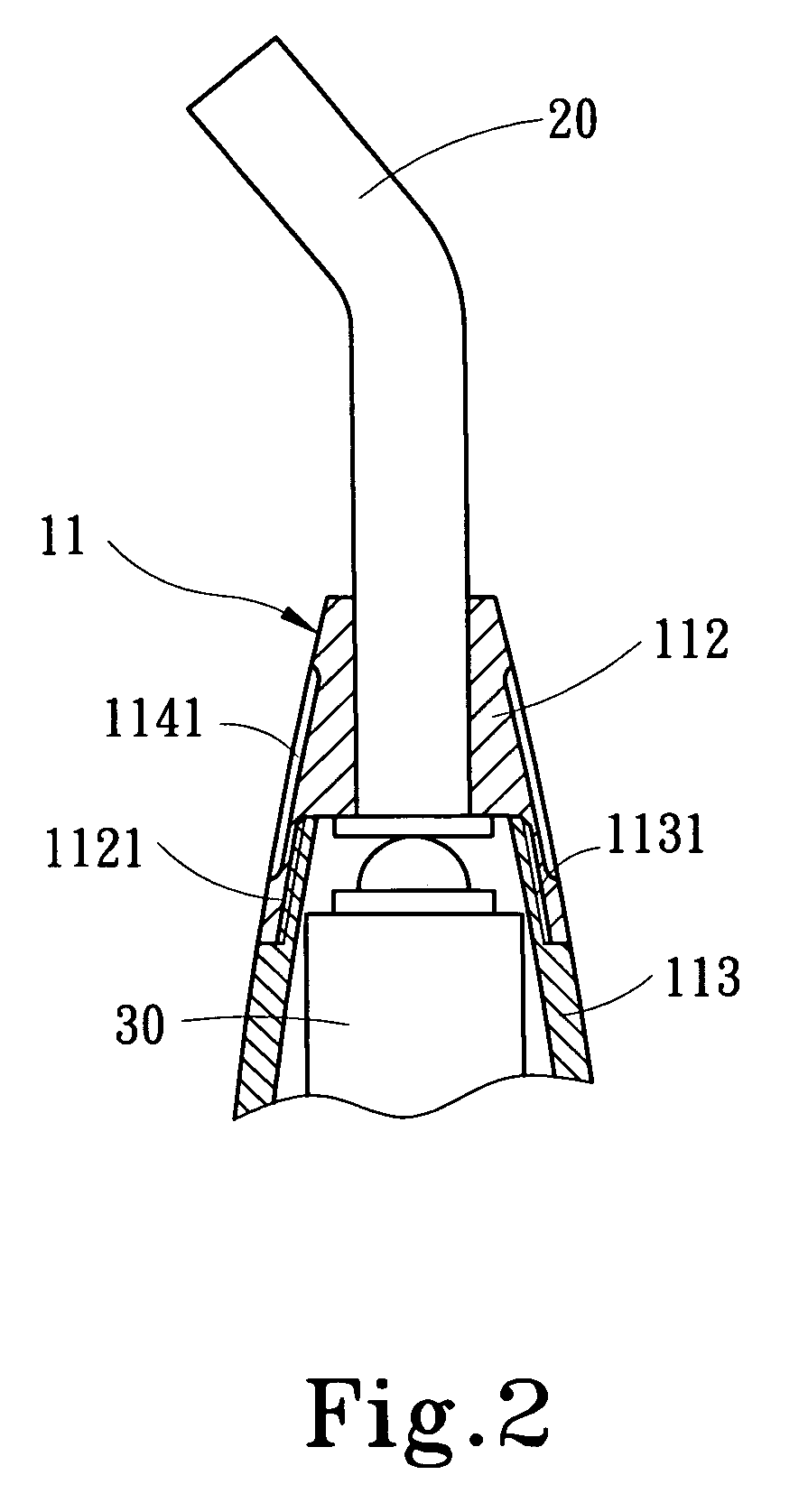

Optical curing apparatus

An optical curing apparatus includes a front shell body which consists of a first shell and a second shell that are coupled in a detachable and turnable manner. A light channeling member is fastened to the first shell and may be adjusted angularly to suit user's requirements. The light channeling member and the first shell are detachable. They are adaptable to the light channeling member of various diameters, and may be removed for sterilizing, or become a disposable and replaceable item. A radiation member and an electric power supply unit are provided and detachably coupled through a connector. The radiation member is reusable even if the case is damage or other elements are breakdown.

Owner:WANG SHU LUNG

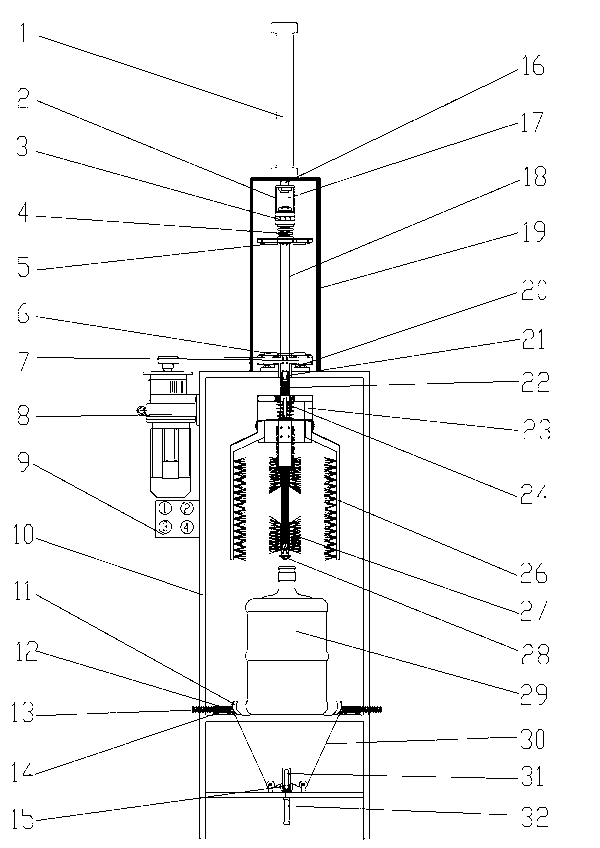

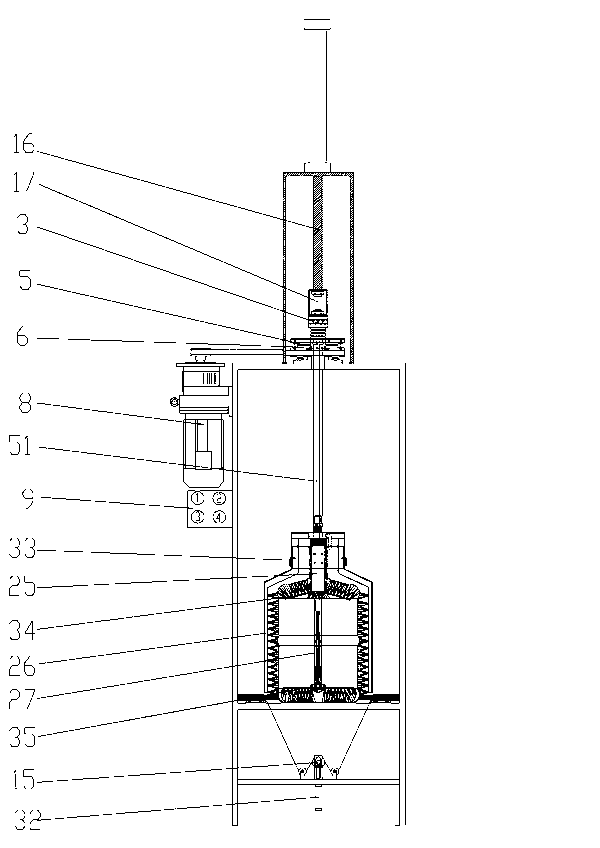

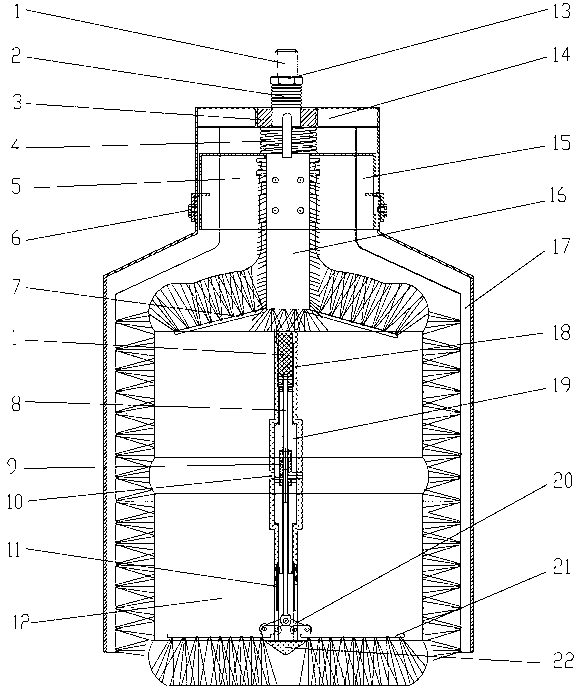

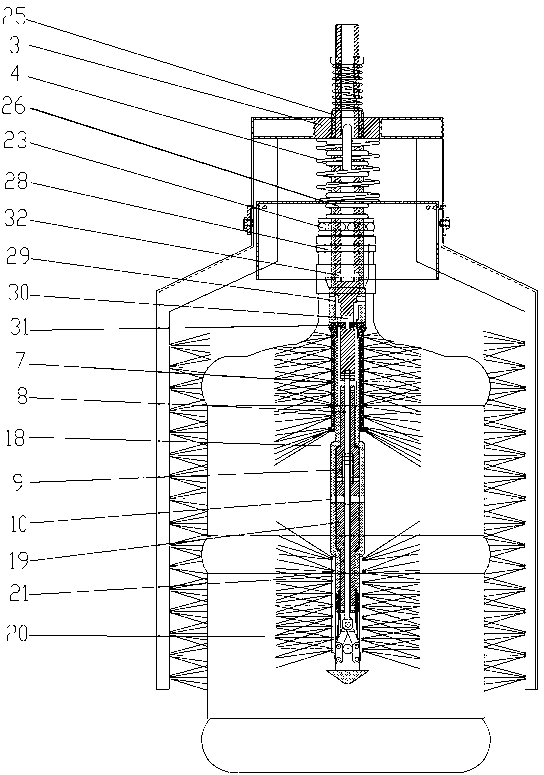

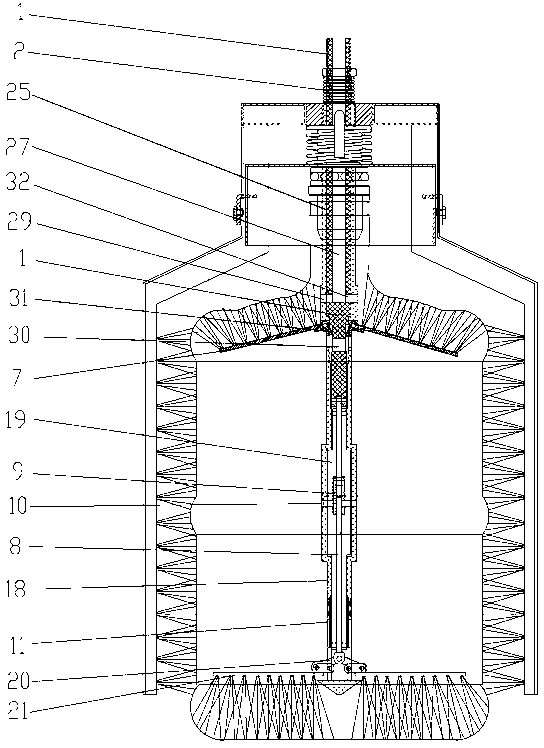

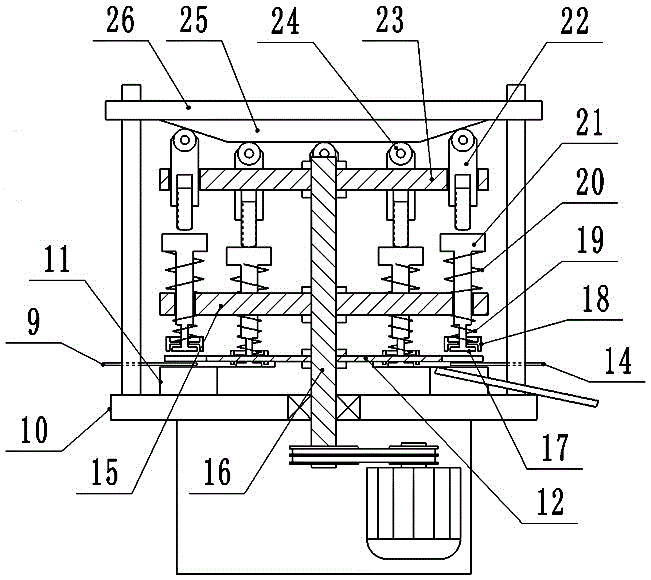

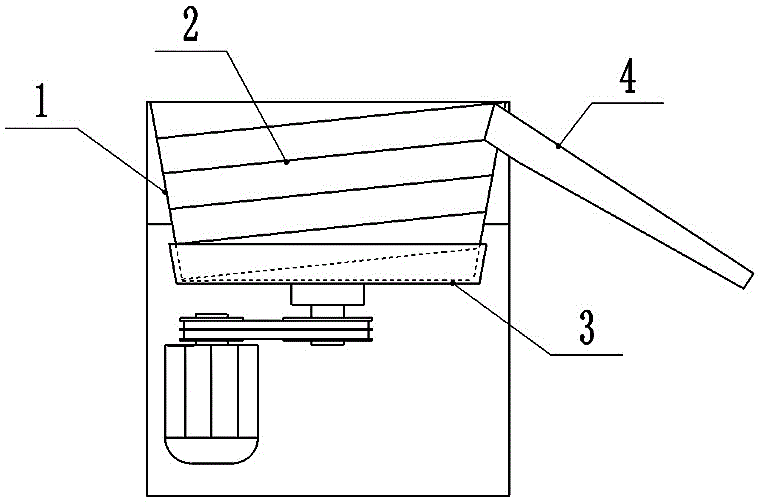

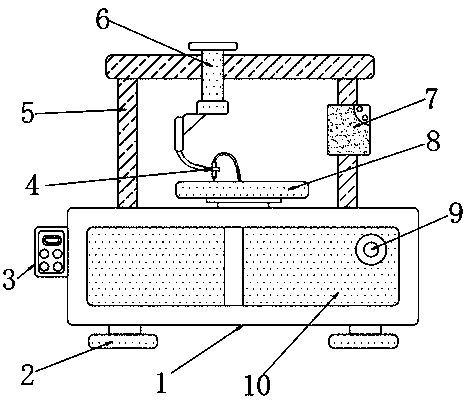

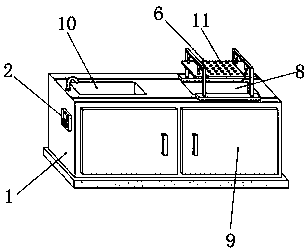

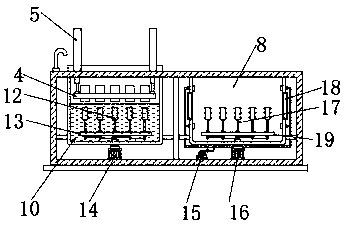

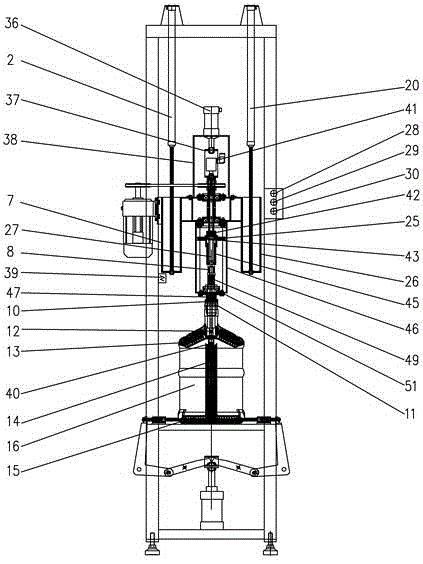

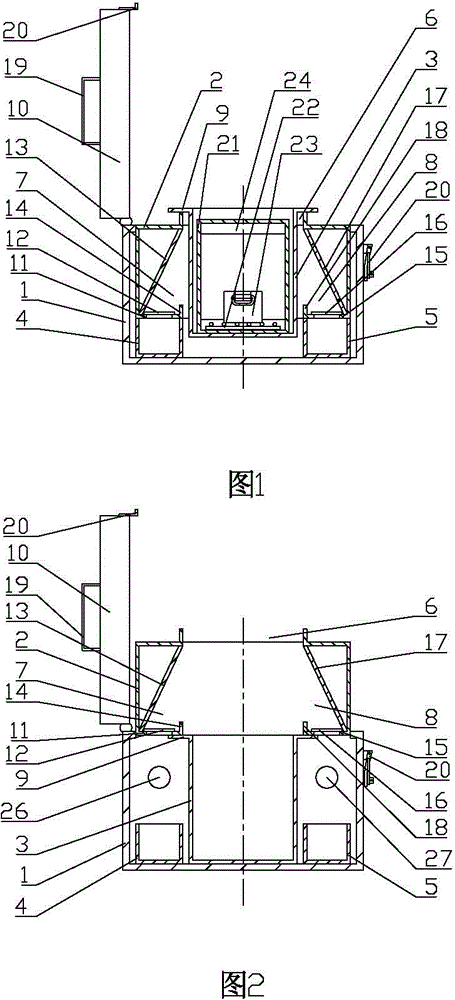

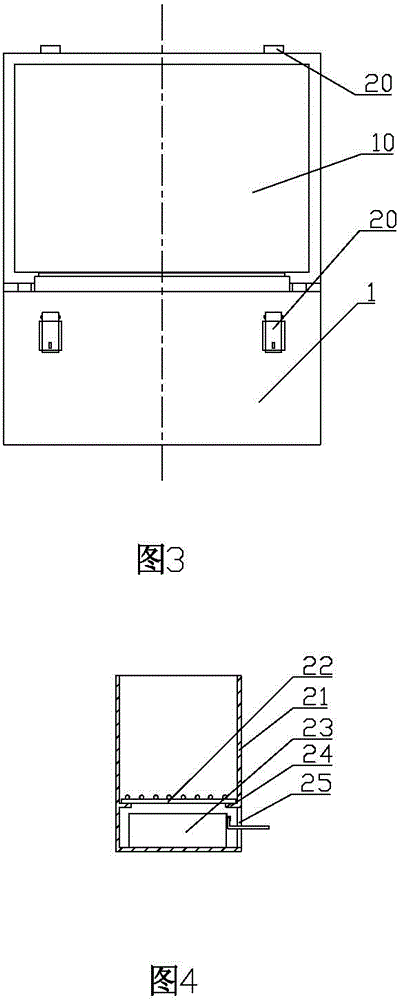

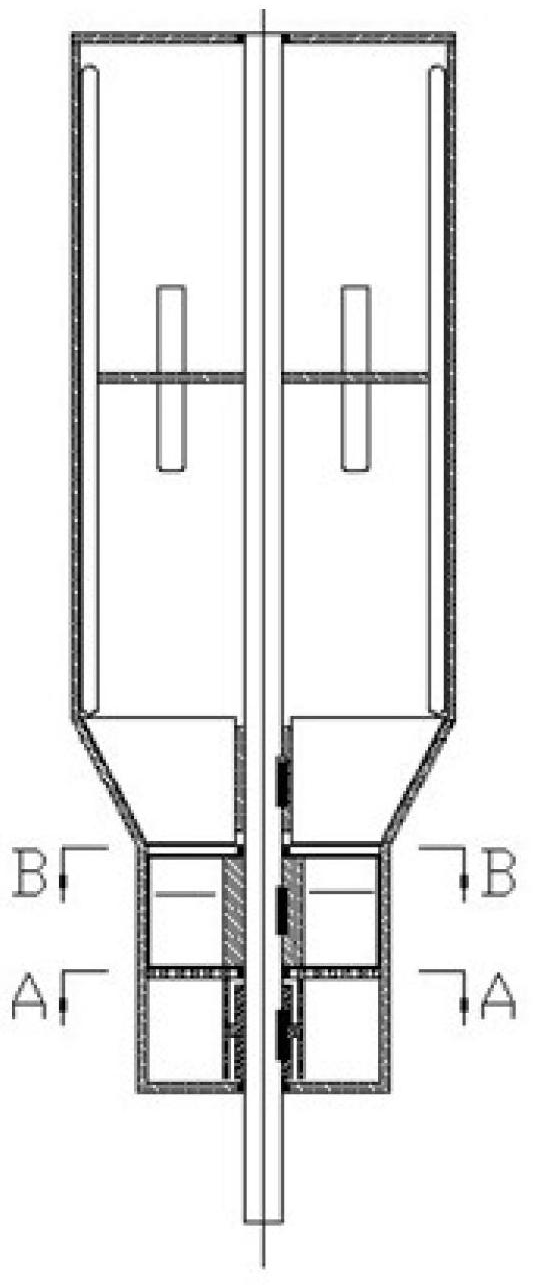

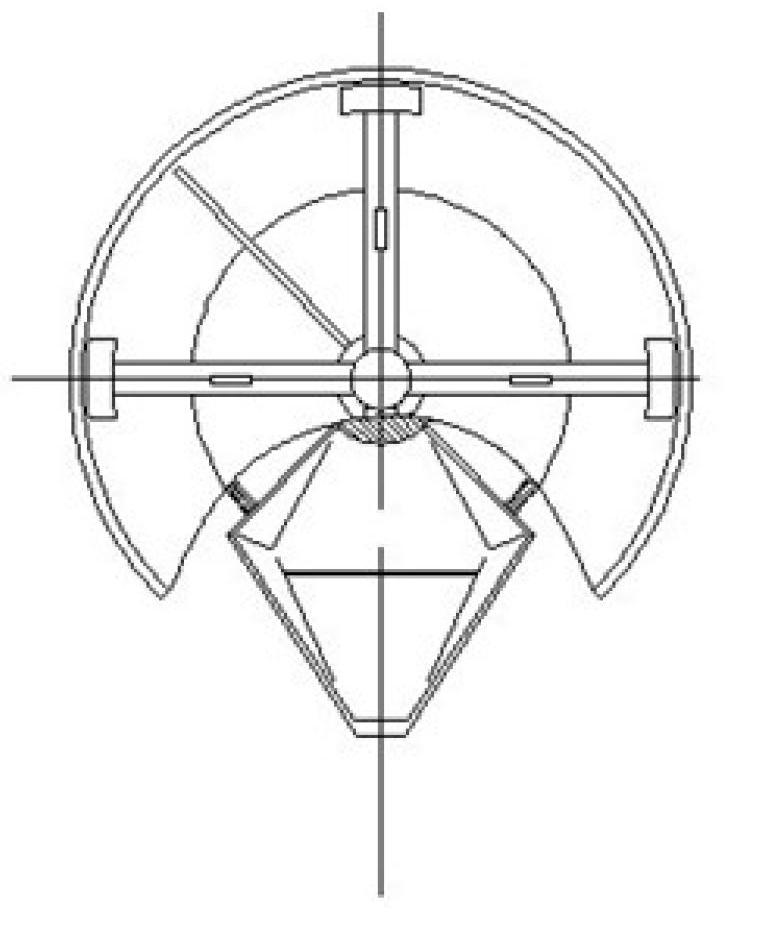

Vertical bucket internal and external washing machine

InactiveCN102989730AImprove hygiene qualityChange the working environmentHollow article cleaningHealth qualityPurified water

The invention provides a vertical bucket internal and external washing machine. The invention relates to purified water bucket washing equipment and particularly relates to a half-automatic purified water bucket internal and external washing machine, which can automatically expand, rotate and contract inside a bucket and can wash the bucket internally and externally. The problem existing in a background technology that the de-dusting effect cannot be reached because the buckets of large-scale and small-scale purified water plants in China are washed by an original washing method, namely smashed cloth bounded by one end of an iron rod or a wooden rod is placed in the buckets, and dust inside the buckets is entirely removed, can be solved. The vertical bucket internal and external washing machine provided by the invention adopts the technical scheme for solving the technical problem: the vertical bucket internal and external washing machine mainly consists of an air cylinder, a rack, a motor, brushes inside and outside the bucket, a bucket clamping device and the like, wherein the brushes can be automatically expanded and rotated within the bucket, so that the speed is high, no dead angle exists in a washing process, the health quality of drinking water is greatly improved, and the working condition of the water plants can be changed to a certain extent.

Owner:宋树建

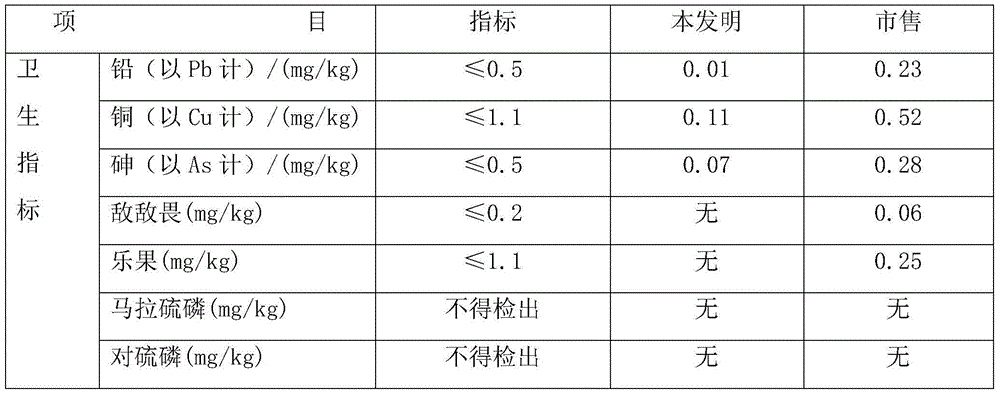

Nutrient regulation and control agent for reducing lead and cadmium content of leaf vegetables and using method thereof

ActiveCN101921144ARaise the pHIncrease productionFertilising methodsFertilizer mixturesCadmium CationBiology

The invention discloses a nutrient regulation and control agent for reducing the lead and cadmium content of leaf vegetables, which comprises the following substances in percentage by weight: 18%-24% of sodium silicate, 16%-20% of calcium carbonate, 9%-12% of magnesium sulfate, 22%-30% of urea, 9%-11% of diammonium phosphate and 16%-21% of potassium sulfate. The using method of the nutrient regulation and control agent comprises the following steps: before planting the vegetable, uniformly mixing the sodium silicate, calcium carbonate, magnesium sulfate, urea, diammonium phosphate and potassium sulfate to obtain a mixture; base-applying all of the mixture, 20-60 kg per mu; turning over and harrowing uniformly so that the regulation and control agent and the polluted soil are uniformly mixed and seeding or transplanting can be performed; or base-applying half of the mixture, and uniformly dispersing the other half of the mixture into the soil after final singling of seedlings; and loosening the soil and sprinkling water. The regulation and control agent of the embodiment of the invention reduces the bioactivity of heavy metals in the soil, reduces absorption of the heavy metals of the leaf vegetable and improves the soil fertility.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

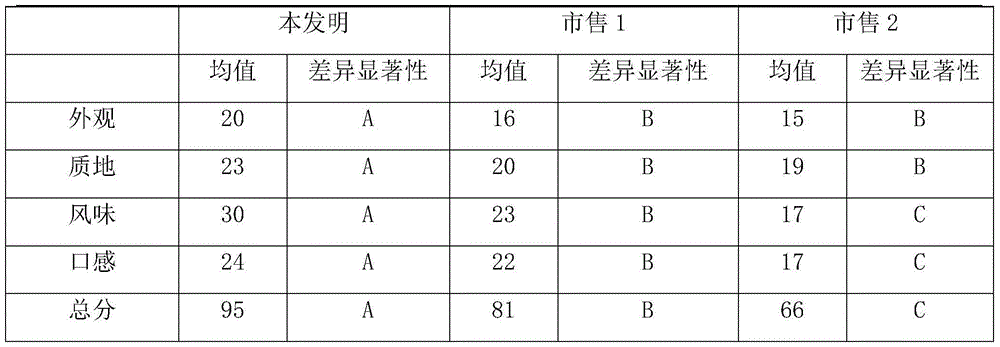

Germinated whole grain and preparation method thereof

InactiveCN104855837AMaintain the content of heat-sensitive substancesAvoid pollutionFood processingFood ingredient functionsFiberOrganoleptic

The invention discloses a germinated whole grain and a preparation method thereof, and belongs to the technical field of deep processing of grains. The whole grain is subjected to ultrasonic washing, high-voltage pulsed electric field treatment, biological enzymolysis or combined high-voltage pulsed electric field and biological enzymolysis treatment in a soaking process, and a segmented soaking and germination manner for germination is adopted, so that the sensory quality, germination yield and quality of a germinated whole grain product are improved, and germination loss is reduced. The preparation method is simple, low in soaking and germination temperature, short in cycle, energy-saving and environment-friendly. The content of functional, nutritional and bioactive substances in the germinated whole grain product is remarkably increased, and food safety is remarkably improved. For example, for brown rice, germinated brown rice prepared by the preparation method has gamma-aminobutyric acid content of 303.8 to 312.6 mg / 100 g, glutathione content of 16.8 to 18.3 mg / 100 g, IP6 content of 460.8 to 484.4 mg / 100 g and dietary fiber content of 3.5 to 3.6 mg / 100 g.

Owner:宁夏家道回乡农业开发有限公司

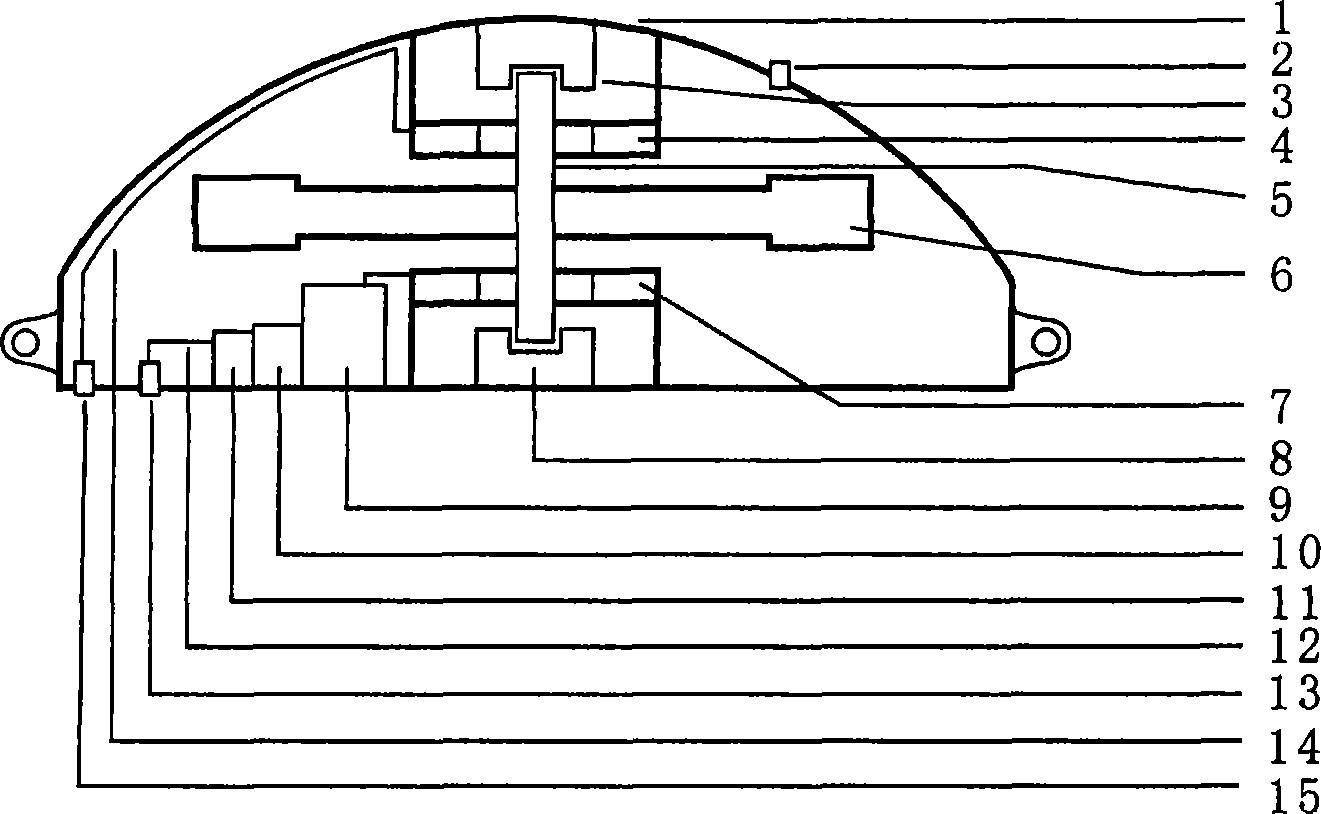

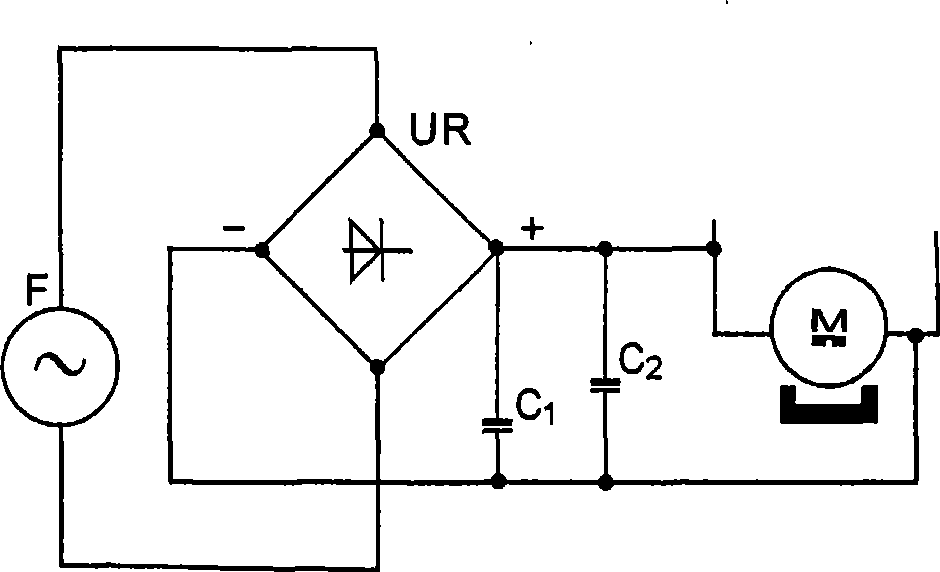

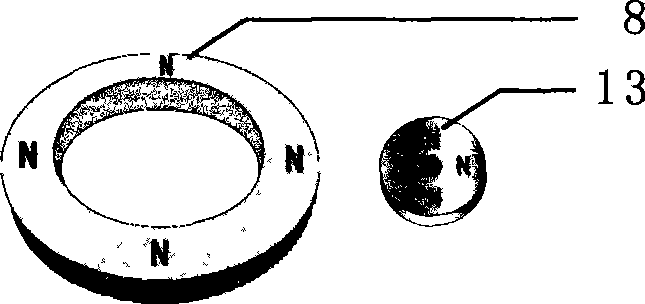

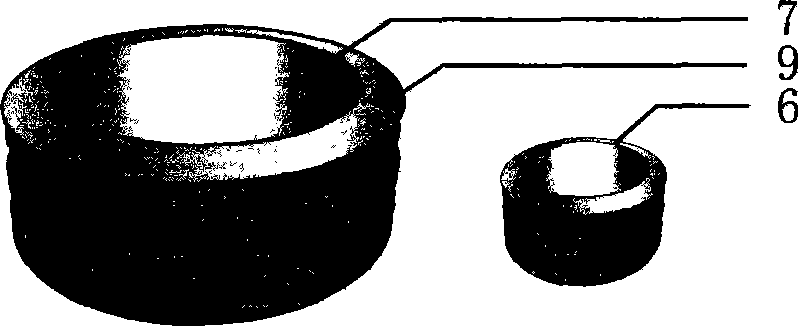

Permanent magnetic body self-induction magnetic suspending power generation device

InactiveCN101242128AEmission reductionImprove cleanlinessMachines/enginesMechanical energy handlingFull bridgeSelf induction

The invention provides a magnet power generation self-induced magnetic levitation device, which makes full use of human extrusion force and counterforce of the ground in the production and living areas and the existing wind power, running water power and the wave power in nature., and converts them into electrical energy. The invention can be widely used in water, land and air. The device makes use of the work force which can be very weak or powerful and is composed of a permanent magnetism suspension bearing, an axis, a motor, a flywheel, a generator, a Full-bridge rectifier reactor, a filter capacitor, a large value capacitor, conducting wires, a plug socket, a conductive coil and the skeleton pine thereof, a permanent magnetism piece, a soft magnetic materials hoop, an elastic device and cables, a pulley, a heavy bob and a heavy anchor, which are sealed in an evacuated chamber and a corrosion-resistant bellows-like flexible plastic enclosure. The device is a generating set with a mechanical drive system without a gear, a connecting bar, etc., and has the advantages of no noise, needing no lubrication, and being waterproof and gaseous-corrosion-proof.

Owner:石才俊

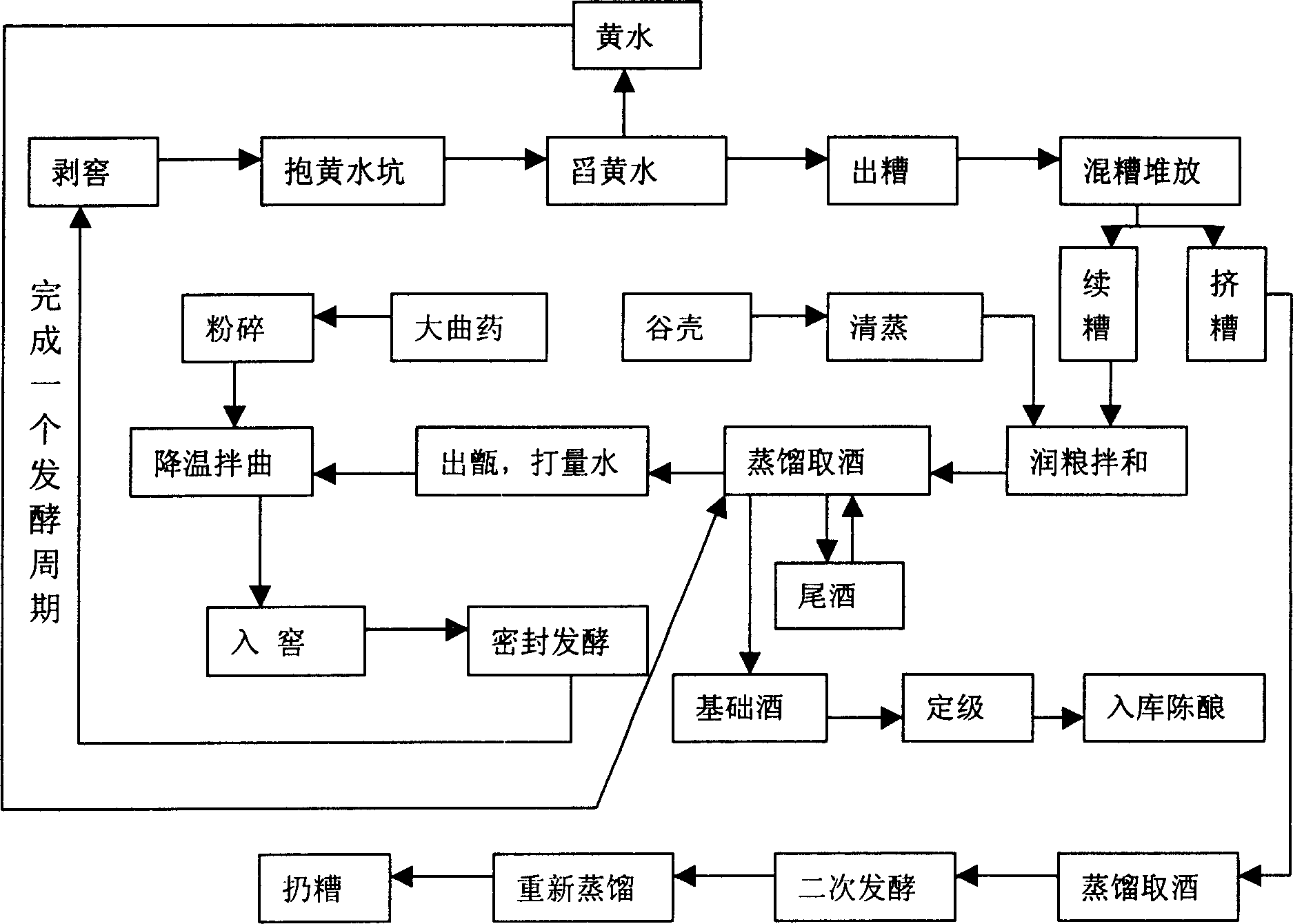

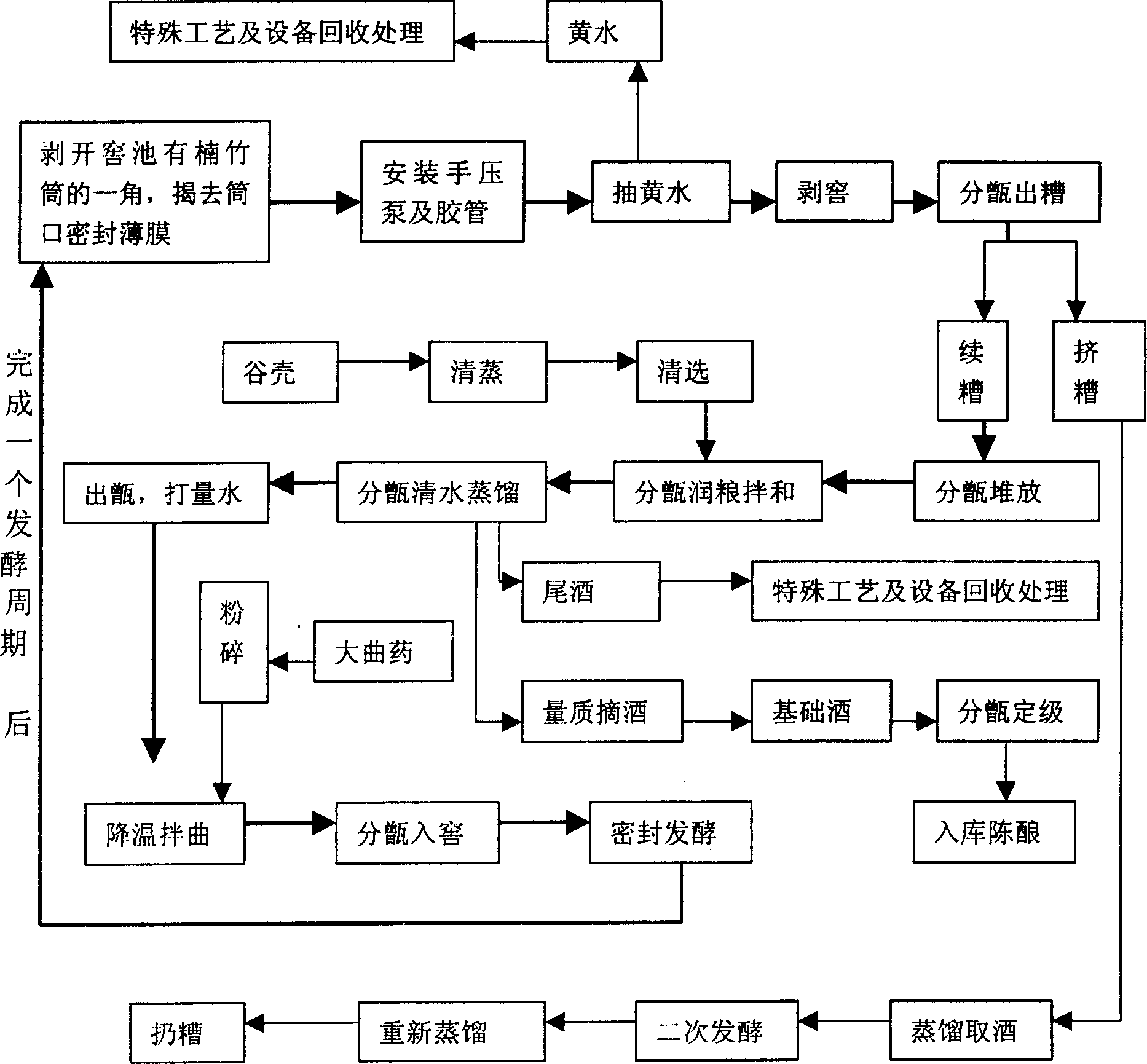

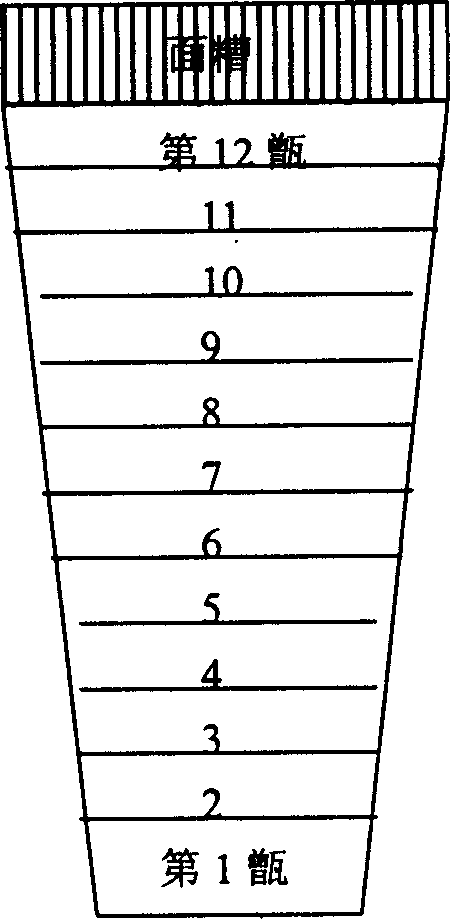

'Whole clear' process of brewing aroma type white spirit

ActiveCN1733888AReduce dosageReduce furfural contentAlcoholic beverage preparationTissue/virus culture apparatusEngineeringDrinking straw

The invention discloses a technique to brew aromatic wine, based on traditional technique, which relates to reform and innovate to draw water, steam supplementary material, distill to obtain wine, and put dreg into cellar clear layered. Wherein, the said four steps are technical core; the cellar is constructed on bottom of pond near wall with inner wall fixed and cover on its head with center hole inserted hollow pipe; after putting dreg into cellar, sealing the pipe and cellar for fermentation; before putting out, stripping off the yellow mud to show pipe mouth, and taking out seal; inserting sucker to draw the yellow water in cellar by connected pump as possible as far; mixing, obtaining wine, storing in cellar; all processes with Zeng(traditional measuring tool) as unit. The method can decrease labor strength, save material, and increases wine quality.

Owner:SICHUAN TUOPAI SHEDE WINE

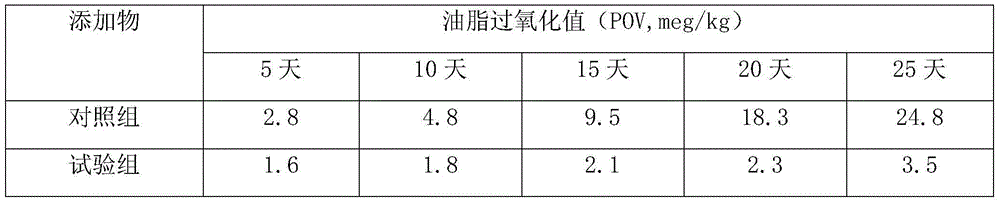

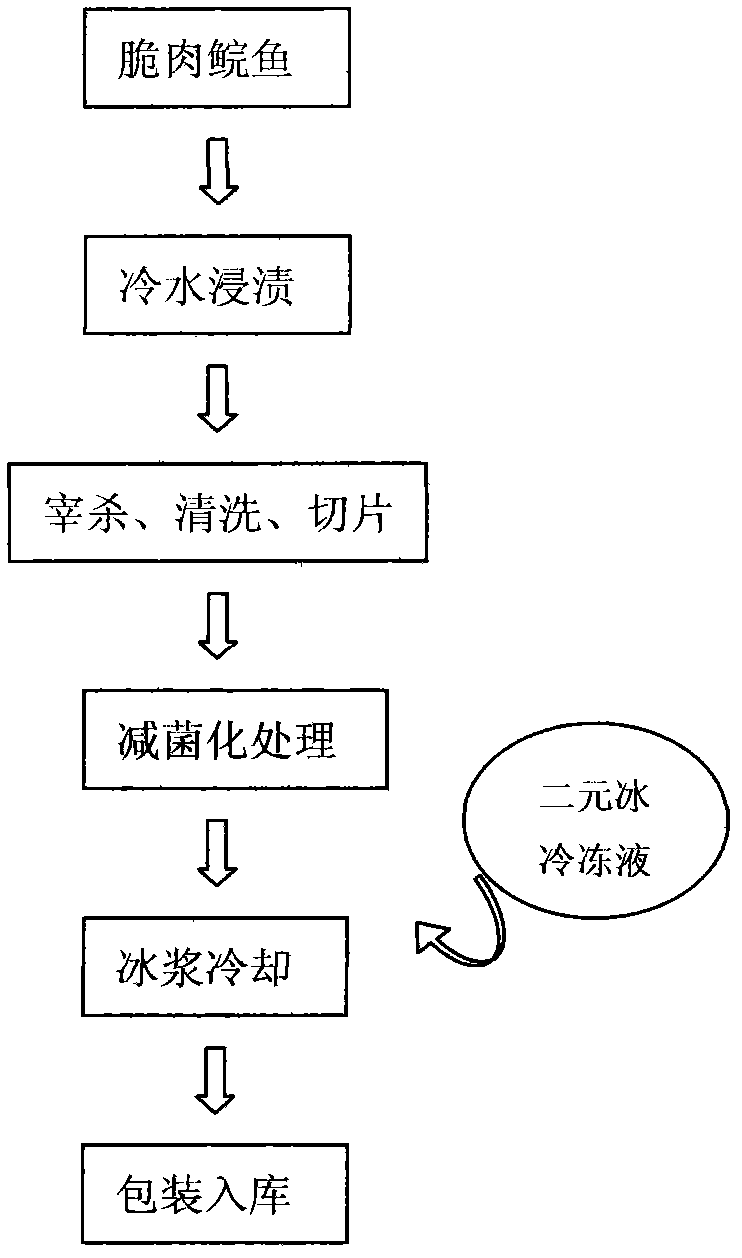

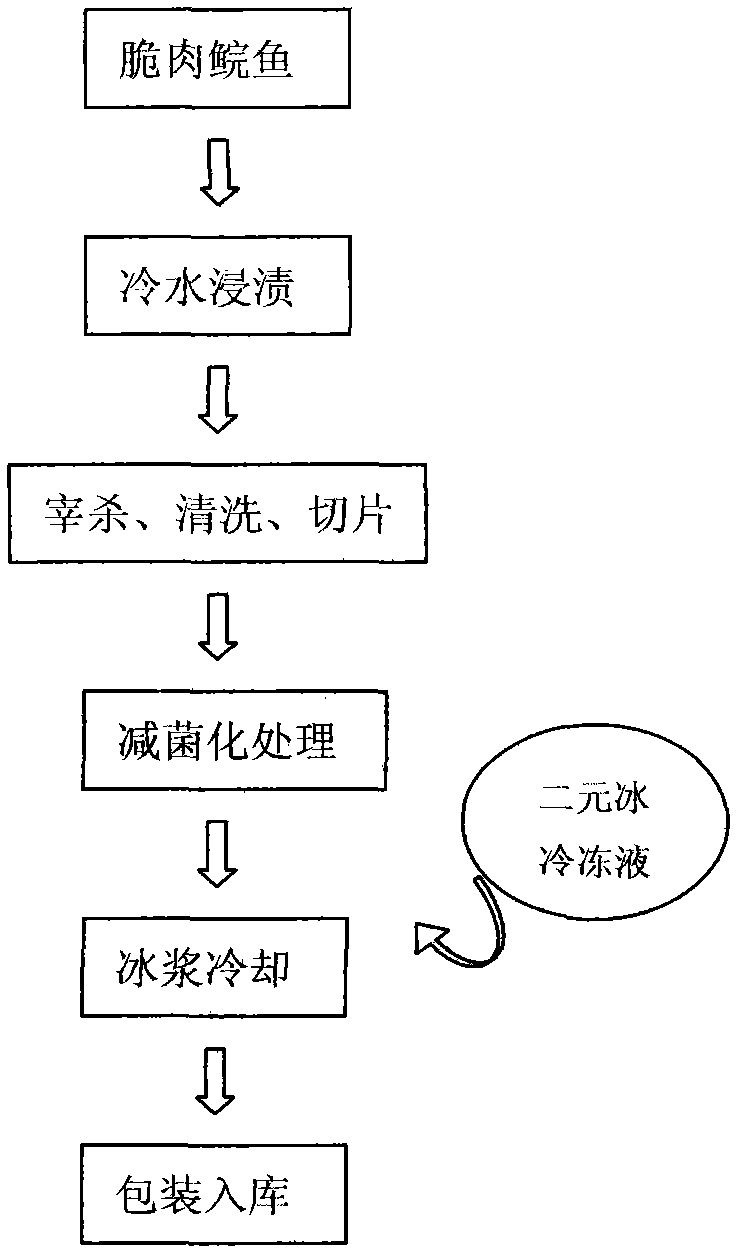

Binary ice refrigerating fluid and method for refrigerating crisp grass carp fillets by using same

InactiveCN101965859AImprove hygiene qualityCrisp tasteMeat/fish preservation by freezing/coolingAlcoholSimple component

The invention discloses a binary ice refrigerating fluid and a method for refrigerating crisp grass carp fillets by using the same. The binary ice refrigerating fluid is characterized by comprising the following components with contents by weight: 7.89 g / 100mL-23.67 g / 100mL of edible alcohol, 4 g / 100mL-6 g / 100mL of cane sugar, 0.5 g / 100mL-2 g / 100mL of salt and the balance of distilled water. The method comprises the following steps of: A, soaking a fresh crisp grass carp into cold water, and then killing, cleaning, slicing and sterilizing; B, placing the processed crisp grass carp the binary ice refrigerating fluid cooled to -26 DEG C, and fast refrigerating to the central temperature of -5 DEG C; and C, packaging, and then placing into a refrigeratory at -18 DEG C for storage. The invention aims to provide the binary ice refrigerating fluid which has simple component and good refrigerating effect to overcome the defects of the prior art. The invention additionally aims to provide themethod for refrigerating the crisp grass carp fillets by using the binary ice refrigerating fluid.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

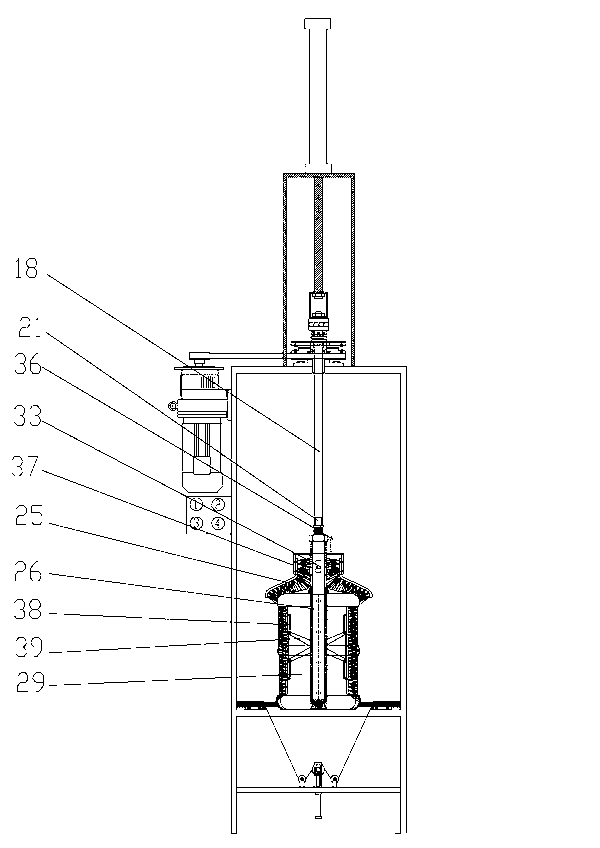

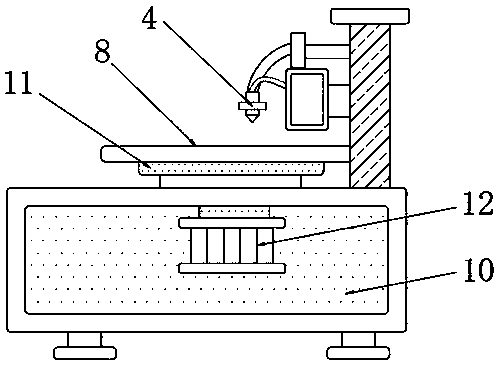

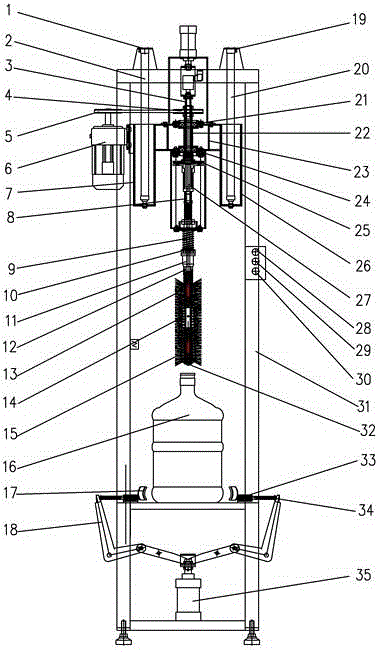

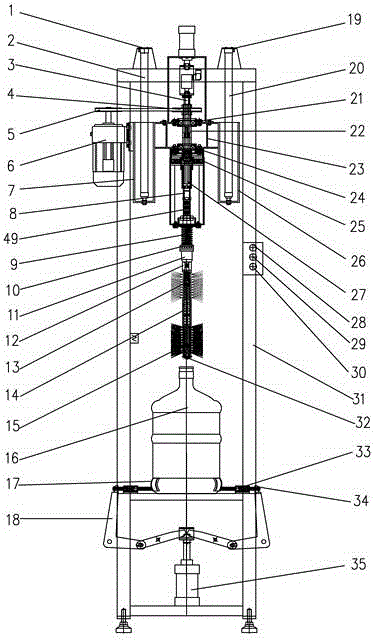

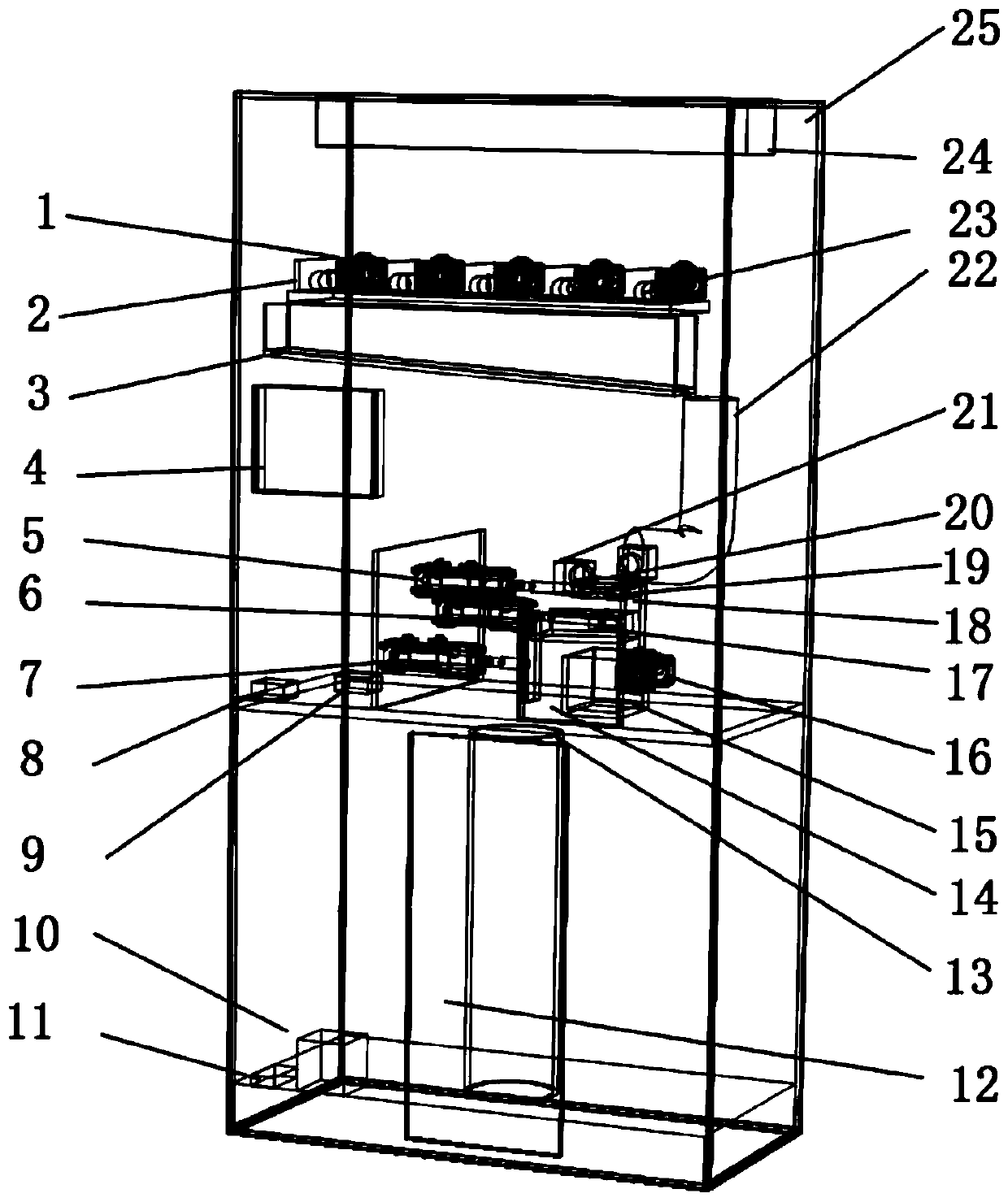

Novel internal-external bucket cleaning brush

InactiveCN102989731AHigh speedImprove hygiene qualityHollow article cleaningHygienic qualityPush pull

The invention discloses a novel internal-external bucket cleaning brush, relates to a pure water bucket cleaning tool, and in particular relates to a novel internal-external bucket cleaning brush which can be used for cleaning internal and external buckets while expanding, spraying water, rotating and shrinking in the buckets under the condition with pressure and power. The invention aims at solving the problems that the conventional cleaning method is still adopted in the bucket cleaning of big or small pure water works in China, wherein dirt in the bucket is manually removed little by little by attaching cloth waste to an iron stick or a wood stick and then putting the iron stick or the wood stick to the bucket, and the dirt cannot be radically removed. The technical scheme for solving the technical problems is as follows: the novel internal-external bucket cleaning brush mainly comprises an inner brush shaft, an inner brush shaft slide sleeve, a centre pushing-pulling sheet, a supporting rod pushing-pulling sheet, a bucket-bottom fur bush, wherein the fur brush can expand and rotate in the bucket for quickly and completely cleaning without dead corners. Moreover, the internal-external bucket cleaning brush can be arranged on various power devices in a mated manner for use, so that the hygienic quality of the drinking water is improved.

Owner:宋树建

Industrialized jasmine tea processing method

ActiveCN104872344AQuality improvementIncrease productionTea substituesActivated carbonCamellia oleifera

The invention discloses an industrialized jasmine tea processing method. The industrialized jasmine tea processing method adopting a sectional industrialized technical process includes: jasmine fragrance release with temperature, humidity and air controlled, fragrance gathering by means of negative-pressure air suction and activated carbon adsorption, and subcritical extraction of initial essential oil and flower residue essential oil (in a first blossom stage); tea leaf fragrance adsorption with essential oil temperature controlled, constant-temperature hermetic fragrance curing and low-temperature drying (in a second non-blossom stage). The industrialized jasmine tea processing method has the advantages that automatic and precise control of a jasmine fragrance release environment is realized, and fragrance release time is prolonged; effectiveness in collection of fragrant substances is realized by means of fragrance adsorptive gathering techniques, and owing to subcritical extraction, essential oil quality is improved, and industrial production is facilitated; by means of 'jasmine essential oil-tea' scenting, a traditional scenting mode of mixture of jasmine flowers and tea leaves is broken, possibility of production of scented tea in non-blossom seasons is realized, and automation and industrialization in production of scented tea are realized.

Owner:闽榕茶业有限公司

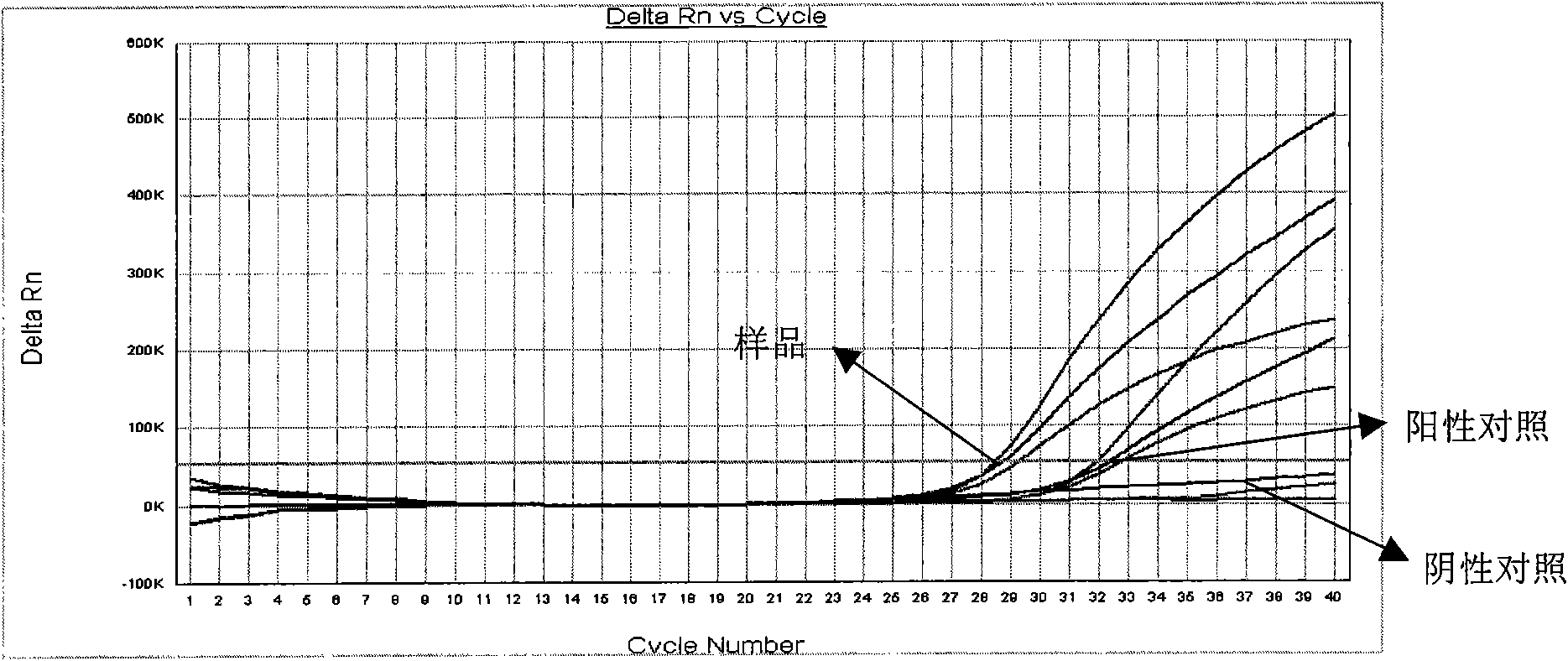

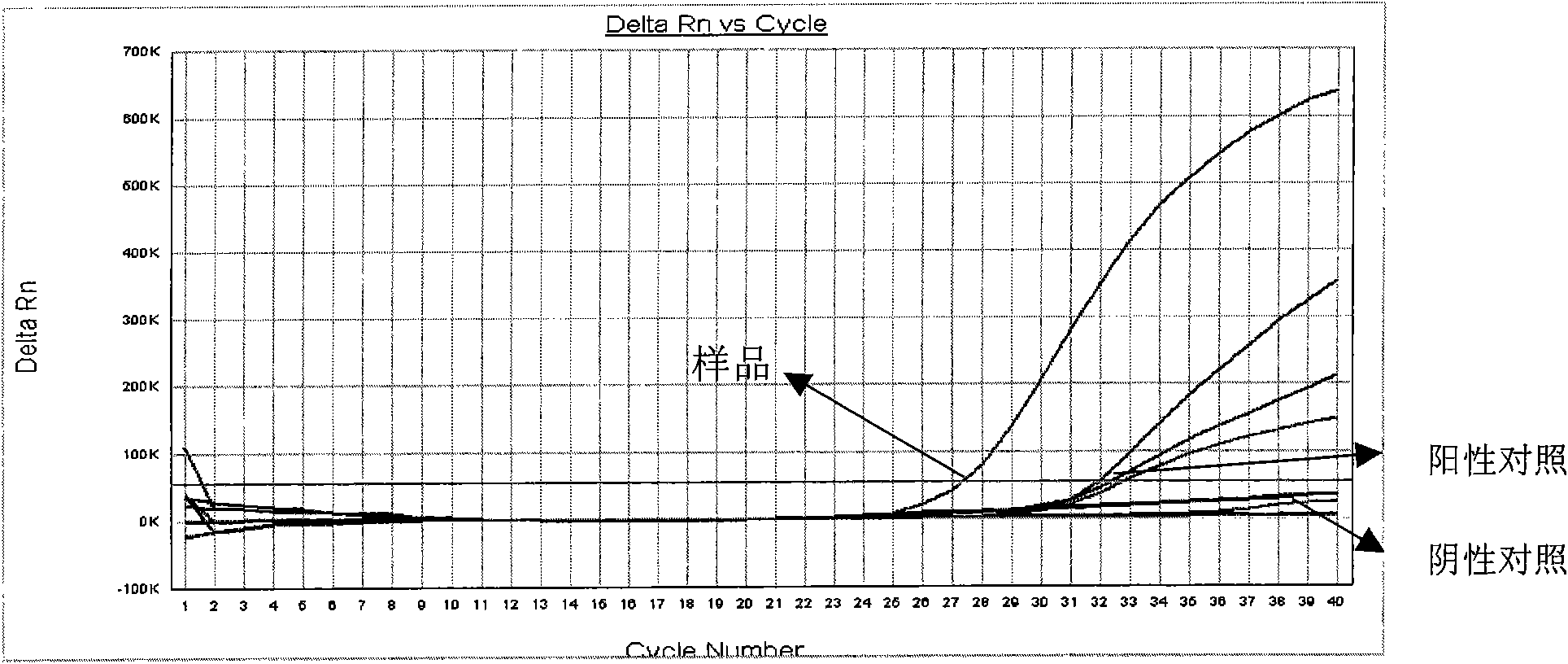

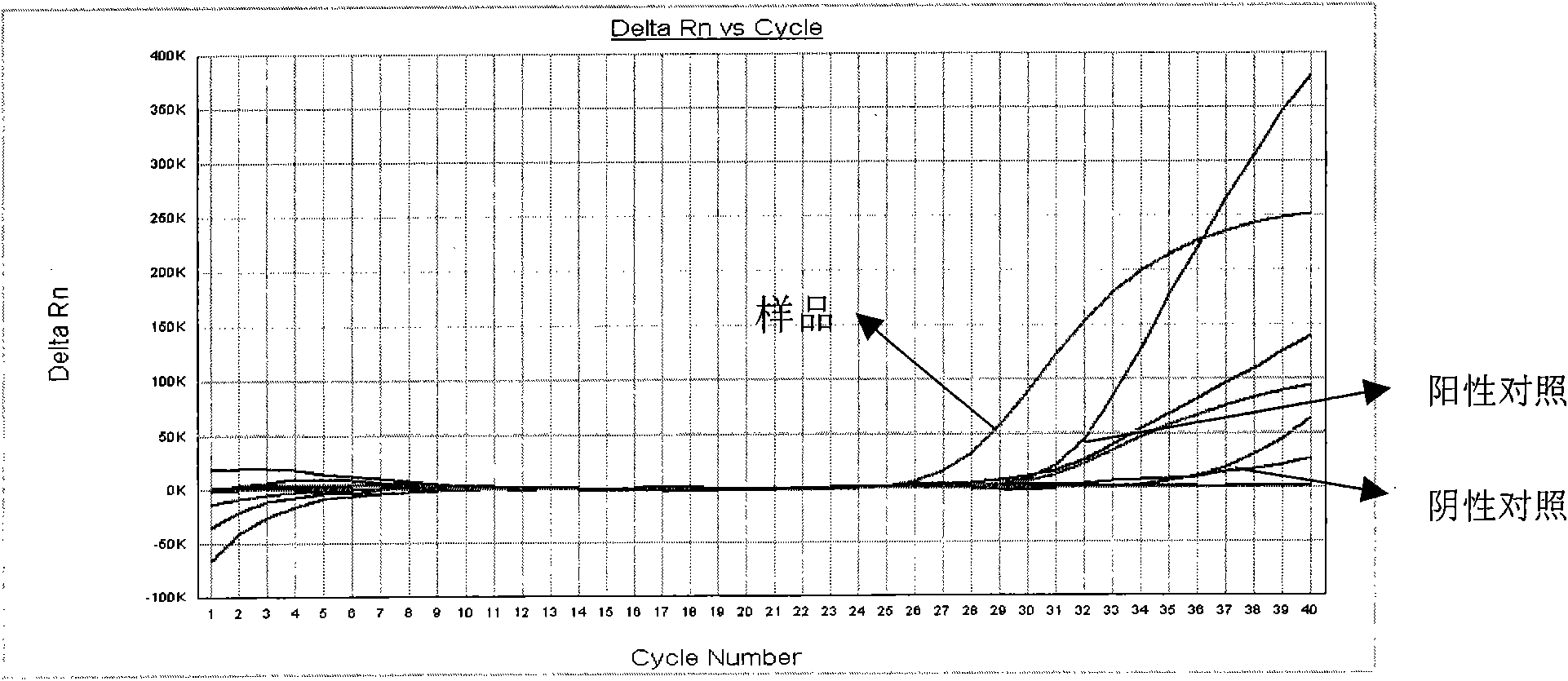

Multiplex fluorescent quantitative PCR detection method for main pathogenic bacteria in aquatic product

ActiveCN102121051ARapid specific detectionSensitive and specific detectionMicrobiological testing/measurementMicroorganism based processesSpecific detectionVibrio parahemolyticus

The invention discloses a multiplex fluorescent quantitative polymerase chain reaction (PCR) detection method for main pathogenic bacteria in an aquatic product. The method is characterized by comprising the following steps of: (1) performing enrichment culture on a sample to be detected in enrichment solution for 4 to 8 hours; (2) extracting genome DNA from the cultured sample by adopting a boiling method; (3) performing multiplex fluorescent quantitative PCR detection by using specific primers and TaqMan probes; and (4) performing result judgment according to the detected specific S amplification curve and threshold value (Ct value). Compared with the prior art, the method has the advantages that: one-tube multi-detection actual requirement can be met, and a solid technical guarantee can be provided for quick, sensitive and specific detection of vibrio parahaemolyticus, vibrio cholerae and listeria monocytogenes.

Owner:中华人民共和国舟山出入境检验检疫局

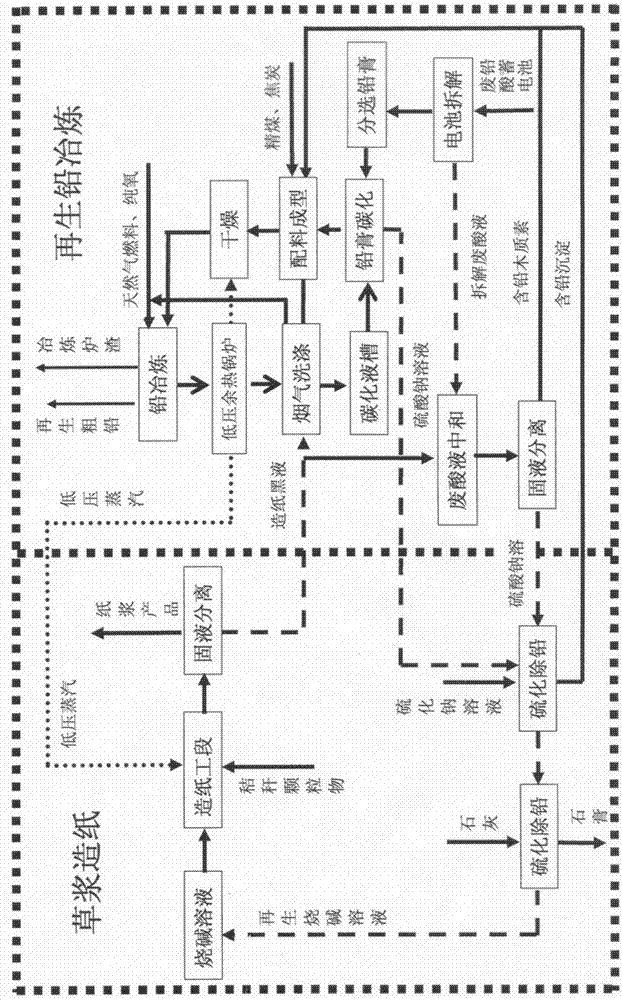

Energy-conserving and environment-protecting regenerated lead smelting and paper pulp cogeneration technology

ActiveCN104498716AEliminate smoke pollutionImprove gypsum qualityPulp liquor regenerationUsing liquid separation agentCogenerationLead smelting

The invention discloses an energy-conserving and environment-protecting regenerated lead smelting and paper pulp cogeneration technology. The energy-conserving and environment-protecting regenerated lead smelting and paper pulp cogeneration technology is characterized by comprising the following steps: recovering flue gas waste heat of a crude lead smelting furnace as a heat source for producing paper pulp; washing a lead smelting flue gas with a strong alkaline paper-making black liquor, and absorbing CO2 and a trace of SO2 in the flue gas, thus obtaining a sodium carbonate solution, carbonizing a lead plaster; neutralizing and disassembling a waste acid generated by a waste battery by using the paper-making black liquor; washing the flue gas with the black liquor, neutralizing the waste sulfur acid, and then merging the obtained sodium sulphate solution; and causticizing with lime, returning the obtained NaOH solution to a paper-making section. According to the technology disclosed by the invention, lead smelting and closed cycle of pulp production wastewater and the flue gas are achieved; the flue gas waste heat of the regenerated lead smelting furnace is utilized; the alkalinity of paper-making pulping and an acid waste liquid of the regenerated lead are mutually neutralized; and the technical problem of waste liquid treatment of the regenerated lead smelting industry and the paper-making production industry is solved by using waste to treat waste.

Owner:HEFEI UNIV OF TECH

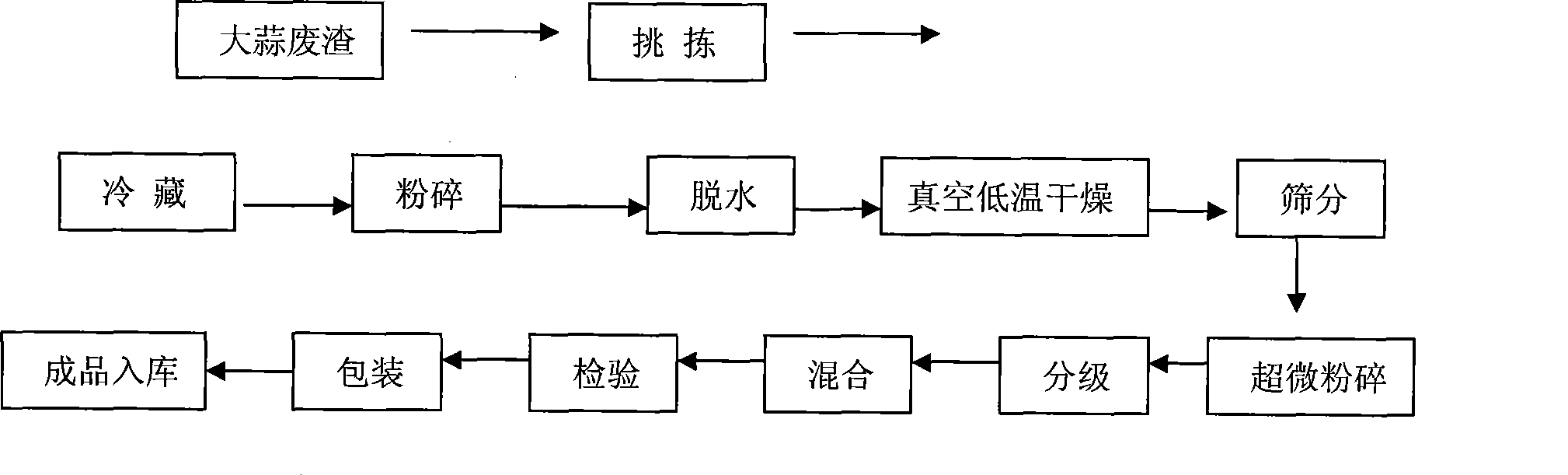

Garlic residues ultramicro powder and preparation method thereof

InactiveCN101361522APromote dissolutionImprove efficacyAnimal feeding stuffWorking-up animal fodderFowlAdditive ingredient

The invention relates to abandoned garlic residues which are chosen, refrigerated, stored, grinded, pulverized, vacuum cold dried and micronized, the effective ingredients are not be destroyed and lost definitely, the obtained submicron powder improves bioavailability, effects and range of application of the product for large superficial area and high tensiometric property, can be widely used in compound feed, feed additive and additive premix of marine products such as fowl and livestock.

Owner:张奎昌

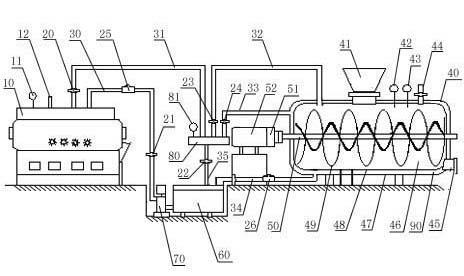

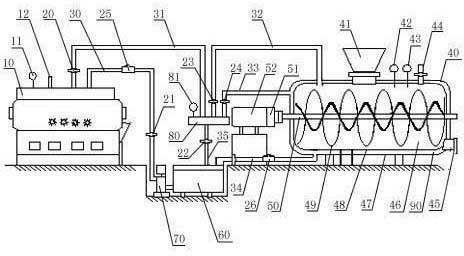

Feed maturation method and high-temperature maturation device

The invention discloses a feed maturation method and a high-temperature maturation device. The feed maturation method includes the following steps that: steam generated by a boiler is delivered to a maturation pot filled with materials; the materials are constantly stirred so that the materials can be fully matured; the matured materials are taken out and dried; and finally, fragmentation is carried out on the resulting materials to obtain a finished product. A novel feed processing technology and a device are provided in the present invention, being characterized in that the raw materials of feed after maturation, can make starch more easily digestible, protein content higher and protein more easily absorbed; and being advantaged in simple operation, energy conservation, low carbon, environmental protection and greatly reduced cost of feed processing.

Owner:明雷

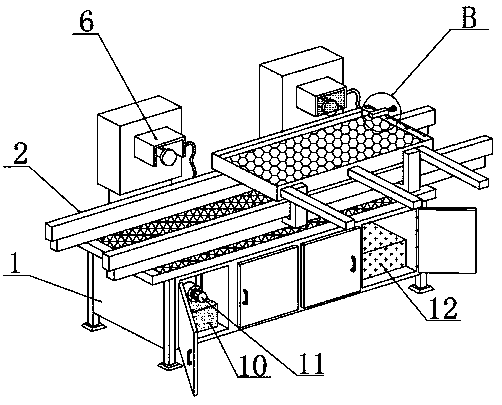

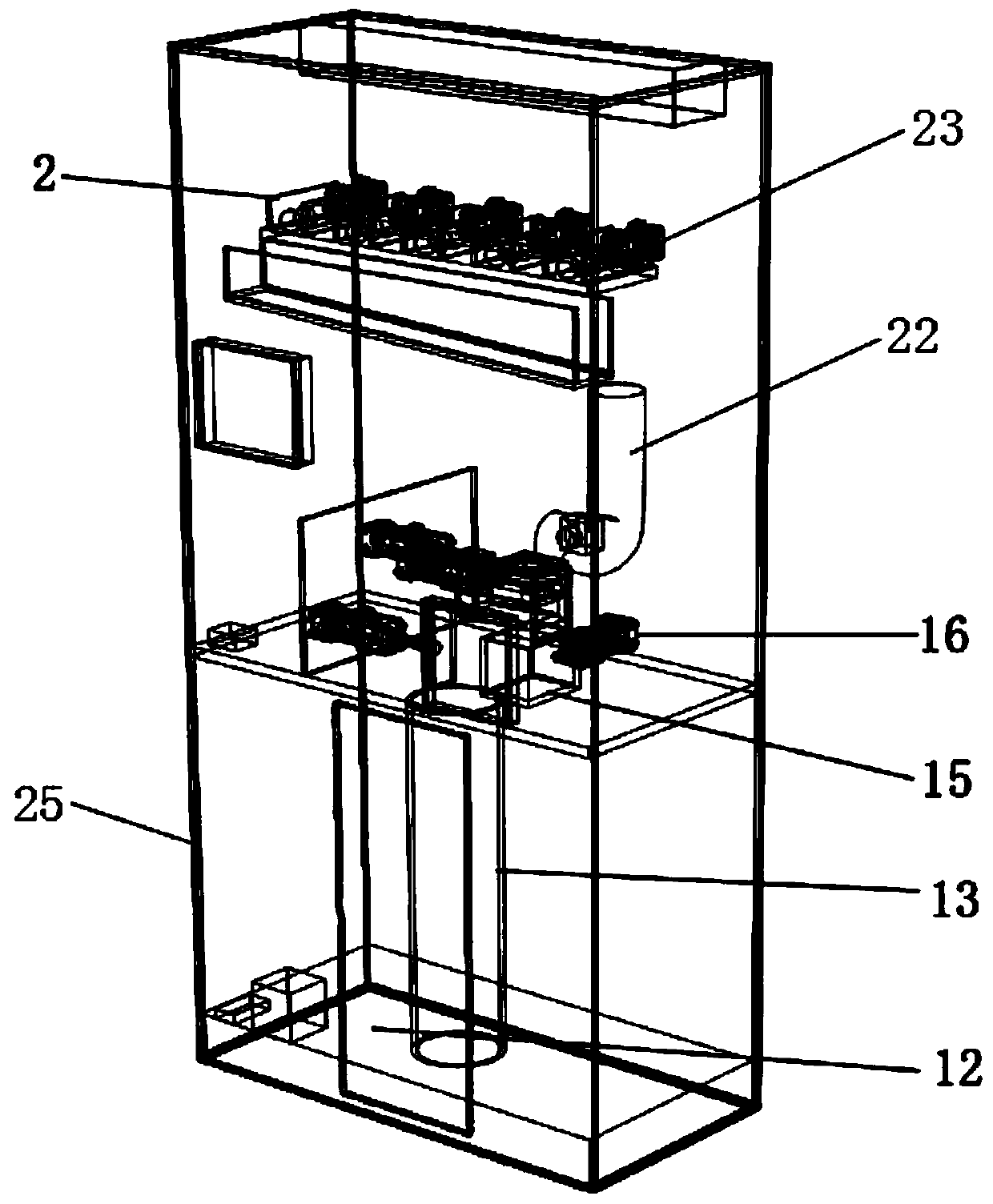

Aluminum plastic bottle cap laminating machine

InactiveCN106395315ARealize fully automatic mechanized productionIncrease productivityMetal working apparatusConveyor partsEngineeringBottle cap

The invention discloses an aluminum plastic bottle cap laminating machine. The aluminum plastic bottle cap laminating machine consists of a plastic pad supplying device, an aluminum cap supplying device, an aligning and conveying device and an aluminum plastic cap laminating device, wherein the plastic pad supplying device and the aluminum cap supplying device are the same in structure and each consists of a rotary chassis, a helical feeding cylinder and a discharging guide rail; the aligning and conveying device consists of an aligning cushion board, an aligning gasket and an aligning and conveying rotary disc; the aluminum plastic cap laminating device consists of a laminating cushion board, a laminating gasket, a laminating rotary disc and a laminating machine; the jacking head of the laminating machine is mounted in a fixing hole of an upper positioning disc; a pressing shaft of the laminating machine is mounted in the fixing hole of a middle positioning disc; a fixing disc is mounted at the upper part of a frame of the aluminum plastic cap laminating device; a circular arc-shaped lower pressing ring is mounted below the fixing disc; the inlet end and the outlet end of the lower pressing ring are each designed with a pressure changing bevel; a pulley on the jacking head of the laminating machine is used for supporting the lower pressing ring. By adopting the aluminum plastic bottle cap laminating machine disclosed by the invention, full-automatic mechanical production of an aluminum plastic composite cap applied to a medicine bottle can be realized, the production efficiency of the aluminum plastic composite cap is greatly improved, product rejection rate is reduced, and the sanitation quality is improved.

Owner:通海恒鑫包装材料有限公司

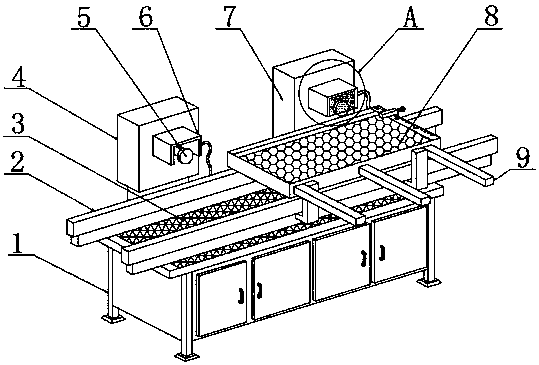

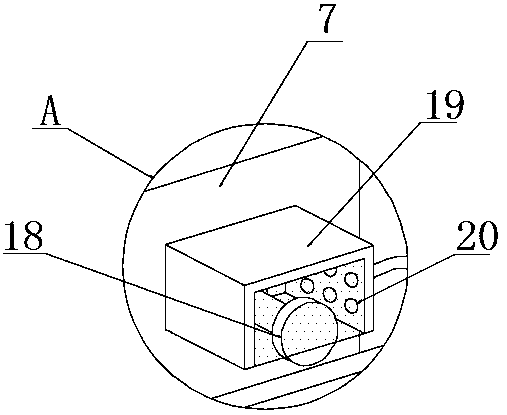

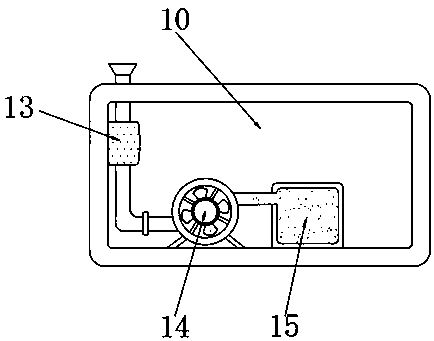

Accurate cutting device for processing wear-resistant building materials

ActiveCN109176919AFixed and accurateShorten the timeEdge grinding machinesWorking accessoriesGratingWear resistant

The invention discloses an accurate cutting device for processing wear-resistant building materials. The accurate cutting device comprises a device body, two sliding rails are horizontally and correspondingly arranged on the two sides of the upper end of the device body, and a grating is embedded in the upper surface of the device body. According to the accurate cutting device, ceramic tile cutting and grinding integration can be achieved, time and labor is saved for manual cutting and grinding in construction engineering, the processing speed is increased, a clamping ruler is additionally arranged on a placing plate, so that the to-be-cut position of the ceramic tile to be cut can be accurately fixed, the cutting accuracy is improved; a spraying cover is additionally arranged on the outerside of the cutting wheel, spraying water is sprayed to the cutting position of the cutting wheel by the aid of the spraying holes when the cutting wheel is cut, the problem that the service life ofthe cutting wheel is affected due to the fact that the cutting wheel is damaged due to excessively high temperature during cutting is avoided; a dust suction cover is additionally arranged on the outer side of the polishing wheel, dust impurities generated during grinding of the cutting part of the ceramic tile are sucked through the suction holes, so that dust can be prevented from flying aroundso as to influence the working environment.

Owner:广东铭扬建设集团有限公司

Full-automatic welding equipment

PendingCN107755932AEasy to filter and purifyAffect healthWelding/cutting auxillary devicesDirt cleaningAir purifiersElectric machinery

The invention discloses full-automatic welding equipment. The full-automatic welding equipment comprises a welding machine body, a dust suction tank is arranged at the position, close to the upper ends of supporting legs, of the lower end of the welding machine body, an air purifier is arranged at the position, on the other side of a workbench, of the upper end of the welding machine body, a rotary plate is arranged at the lower end of the workbench, and a motor is arranged at the upper end of the interior of the dust suction tank. Dust generated by the welding machine body can be convenientlyfiltered and purified by the air purifier and prevented from affecting air in the working environment and the physical health of workers; the welding machine body can be swept through the dust suction tank, so that the sanitary quality of the welding machine body is improved conveniently, and the working quality of the welding machine body is also improved; and the workbench can be rotated through the rotary plate and the motor so that a welding head can conduct all-around welding on objects needing to be welded on the workbench conveniently, and the welding quality is improved.

Owner:JINLING INST OF TECH

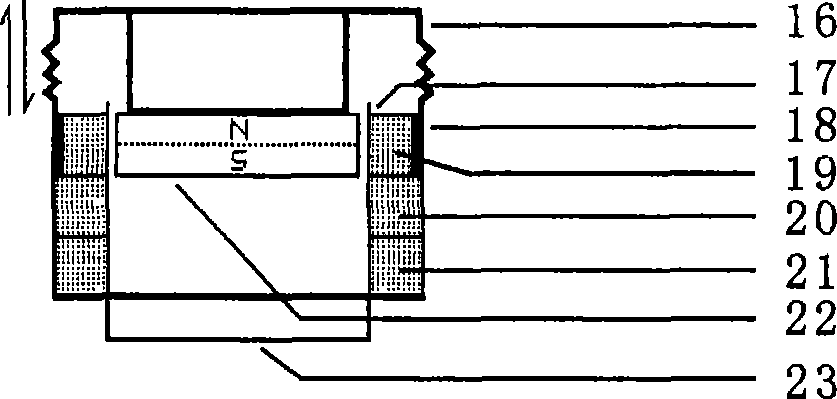

Permanent magnet auto-conduction magnetic levitation magnetic force pressure generator

InactiveCN101436813AEmission reductionImprove cleanlinessDynamo-electric machinesMagnetic tension forceEngineering

The invention provides a permanent-magnet self-inductance magnetic-suspension magnetic-mortar type pressure generator, which can be widely used in water, on land and in the air, fully utilizes and converts extruding force and reacting force to the ground in the production and living field of human beings, as well as wind power, flowing water power and wave force existing in the nature into electric energy, is superior to a single permanent-magnet reciprocating-motion pressure generator, and generates electricity with electricity magnetic energy. The generator can at least utilize one permanent magnetic ring, bears the action of external force to do reciprocating motion and cut a conductive coil through a magnetic force line so as to generate electric energy, and simultaneously shoots magnetic shots by using a magnetic cannon so as to mortar another permanent magnet to do reciprocating motion rapidly, thereby increasing the magnetic flux of a conductive coil winding in unit time and greatly improving power and stabilizing current and voltage. The force which is utilized to do work by the generator can be weak or quite strong. The generator consists of a pressure conducting piece sealed in an anticorrosion elastic corrugated seal cover, a buffer anti-noise pad, a positioning cover plate, the conductive coil winding and a framework thereof, the permanent magnetic ring, the permanent magnet with a central hole, a soft magnetic material hoop, a soft magnetic material, a reset elastic device, an upper buffer anti-noise elastic device, a lower buffer anti-noise elastic device, a guide rail and a final assembly bottom board. The generator is a generating device which has no gear, connecting rod or other mechanical transmission system, produces no noise, needs no lubrication, and can prevent water as well as gas corrosion.

Owner:石才俊

Method for removing environment hormone dimethyl phthalate in water body

InactiveCN101700923AReduce contentImprove safety and qualityWater contaminantsWater/sewage treatment by flocculation/precipitationWater sourceTherapeutic effect

The invention provides a method for removing environment hormone dimethyl phthalate in water body; the treated water is mainly used for water supplying in towns and cities and being stored in water plants; the method comprises the following steps: (1) flocculating agent-poly-dimethyl diallyl ammonium chloride is added in a reactor with source water, and the source water and the flocculating agent are completely stirred uniformly. (2) The source water treated in the step (1) is placed still for a while, and then the source water is discharged for subsequent treatment after carrying out flocculating settling. In the invention, the poly-dimethyl diallyl ammonium chloride is used as the flocculating agent to adsorb dimethyl phthalate in source water, and then the content of the dimethyl phthalate is effectively reduced through flocculating settling, so as to greatly improve the municipal engineering water supplying safety and hygienic quality. The method has the characteristics of convenient operation, low treating cost, easily-controlled conditions and stable treatment effect and can remove more than 60 percent of dimethyl phthalate organic matters in source water.

Owner:CHONGQING TAIKE ENVIRONMENTAL PROTECTION TECH CO LTD

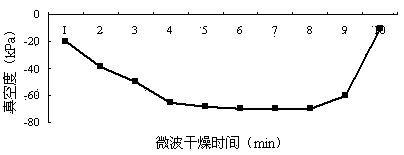

Preparation method of pucker-free non-cleaning dried jujubes

ActiveCN103843875AImprove qualitySolve the darkening of jujube skinFruits/vegetable preservation by dehydrationCold airPhysical chemistry

The invention discloses a preparation method of pucker-free non-cleaning dried jujubes, belongs to the technical field of food drying processing, and relates to a method of carrying out microwave vacuum puffing drying on red dates, aiming at solving the technical problems that jujube skin pucker, surface color darkening, nutritional ingredient loss, and the like appearing in a drying process of the red dates. According to the adopted technical scheme, the preparation method of the pucker-free non-cleaning dried jujubes comprises the following steps: pickling jujubes, grading the jujubes, rejecting defective fruits and impurities in materials; cleaning jujubes; drying water on the surfaces of the red dates by an air knife after cleaning the red dates; pre-drying for 3 hours-6 hours by cold air, regulating moisture of the red dates, and keeping the moisture of the red dates uniform, so that moisture content of the red dates reaches 35%-38%; carrying out microwave vacuum puffing drying on the red dates; spreading materials which are pre-dried by the cold air in a tray of a microwave vacuum unit, exhausting and then reducing pressure, wherein the conditions for carrying out the microwave vacuum puffing drying are as follows: vacuum degree is 65kPa-75kPa, microwave power is 6W / g-10W / g, drying time is 5 minutes-10 minutes, and final moisture content is controlled at 20%-25%.

Owner:交城天娇红农业科技有限公司

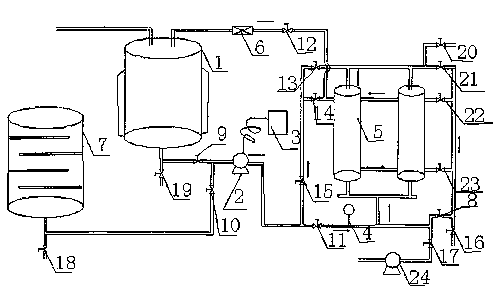

Biological enzyme purification separating device

InactiveCN103131630AStay activeKeep activeApparatus sterilizationMicroorganism fixing/supporting apparatusHollow fibreTraffic volume

The invention provides a biological enzyme purification separating device. The biological enzyme purification separating device comprises a raw material storage tank, a Graef pump, a micro-filter tube, a rejection liquid collection pump, a wash tank, a flow adjusting device, a valve, a pressure gage, a flow gauge, and a material tube. The biological enzyme purification separating device can achieve continuous filtering and separating of high turbidity liquid under the fully sealed condition and maintaining of high activity of zymin. Due to the fact that the micro-filter tube, with the pore diameter of 0.1-0.2 microns and high-strength, acid-base resistance and corrosion resistance, of a hollow fiber organic membrane or ceramic or acstainless steel component is adopted, the biological enzyme purification separating device can efficiently conduct edulcoration and degerming and achieve separation and purification effect, at the same time, cannot damage an original ingredient, an original structure, an original special flavor, and original energy activity, improves sanitary quality of products. The biological enzyme purification separating device is widely applied for filtering and separation of variousbiological enzymes with strict demands for microorganismsanitation and enzyme activity and at the same time is further suitable for filtering and separation of certain simple liquid state drinks and condiments.

Owner:XIAN REJE BIOLOGICAL TECH

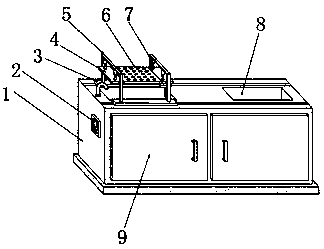

Cleaning device for chemical experiment teaching aid

InactiveCN108580485AEasy to removeEliminates the hassle of manual cleaningHollow article cleaningDrying gas arrangementsEngineeringControl switch

The invention discloses a cleaning device for a chemical experiment teaching aid. The cleaning device comprises a box. The side face of the box is fixedly provided with a control switch. A first sliding base is fixedly arranged at the upper end of the box, and the position, located on the inner side of the first sliding base, of the upper surface of the box is provided with a disinfection tank. Through a test tube plate and a cleaning tank, the trouble of manual test tube cleaning is saved, operation is convenient, cleaning is more thorough, and the cleaning time is saved for experimenters; the disinfection tank is utilized for conducting air drying and disinfection on cleaned test tubes, test tube cleaning, air drying and disinfection integration is achieved, the sanitation quality of thetest tubes is improved, and reusing is convenient; and through bolts and a second sliding base, the test tube plate can be conveniently detached after the test tubes are cleaned and disinfected, theexperimenters conveniently store the test tube plate and the test tubes, and the test tubes can be protected and prevented from being damaged. According to the design, the structure is simple, the function is practical, and cleaning is more rapid and thorough.

Owner:胡耀丹

Novel bucket washing brush

InactiveCN105834182AAvoid harmImprove hygiene qualityHollow article cleaningHygienic qualityEngineering

The present invention relates to a new type of bucket washing brush. To solve the problem in the background technology: it is more difficult to clean the moss and dirt in the bucket. Put sand, cleaning agent, and water into the bucket, and the workers hold the bucket and shake it with their hands. The speed is slow, wastes manpower and material resources, and the ideal cleaning effect cannot be achieved. The technical solution to solve this technical problem is: a bucket clamping device, Composed of a lifting device, a frame, a bucket brush and a rotating device, the invention has the advantages of fast brushing speed, cleanness and thoroughness, no damage to the bucket, high degree of automation, labor-saving, and labor-saving, and improves the hygienic quality of bottled water.

Owner:宋树建

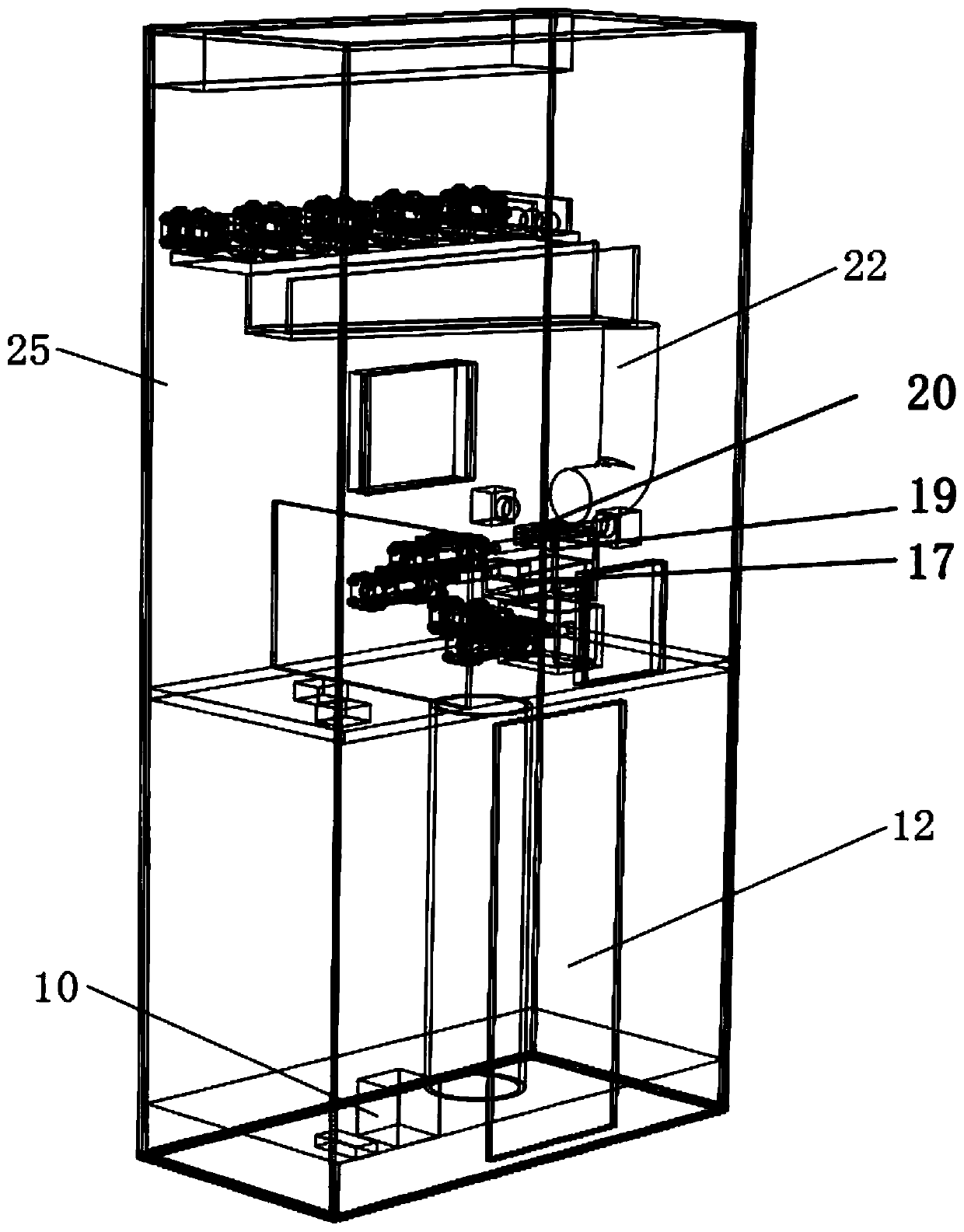

Unmanned fruit and vegetable selling container based on image recognition and implementation method thereof

PendingCN110164037AImprove preservation qualityImprove hygiene qualityCoin-freed apparatus detailsCharacter and pattern recognitionQuality controlPush pull

The invention discloses an unmanned fruit and vegetable selling container based on image recognition and an implementation method thereof, and relates to the technical field of unmanned fruit and vegetable selling; the unmanned fruit and vegetable selling container comprises a box body and an environment adjusting device used for controlling the internal environment of the box body and arranged atthe top end of the interior of the box body, wherein a storage partition plate is correspondingly arranged under the environment adjusting device; cargoes are placed on the upper surface of the storage partition plate; and a cargo discharging push-pull rod used for pushing the cargoes is arranged at the position, corresponding to the cargos, of the rear side face of the storage partition plate. According to the designed unmanned fruit and vegetable selling container, a quality detection scheme and the environment adjusting device based on image recognition are designed for the fruit and vegetable products, and a product quality detection device is additionally arranged at the goods outlet, so that the quality control in the fruit and vegetable selling process is guaranteed, the freshness,the internal environment and the sanitary quality of the fruit and vegetable products are further improved, and meanwhile, the automatic purchasing of consumers is facilitated.

Owner:SOUTH CHINA AGRI UNIV

Smokeless environment-friendly portable oven and using method thereof

The invention relates to the technical field of portable ovens, in particular to a smokeless environment-friendly portable oven and a using method thereof. The oven comprises a barbecue component, an oven body and a cover. The barbecue component comprises an oven head, a collecting tank, a left ash tank and a right ash tank; the detachable left ash tank and right ash tank are arranged in the left and right sides of the oven body; at least one ventilation ports are distributed in the front and rear sides of the oven body corresponding to the positions above the left ash tank and the right ash tank. The using method includes 1, operating a fastener component, opening the cover, and fetching an igniter, barbecue needles, a fuel clamp, a barbecue screen, a fire leading component, the collecting tank and the oven head sequentially. The oven is reasonable and compact in structure; the assembled barbecue components are placed into the oven body, so that the oven is convenient to carry; the combustion chambers with inward openings are formed in left and right sides of the oven head, so that the heat can be accumulated in a heat channel, flying ash can be reduced, fume can be prevented effectively, and air pollution is reduced.

Owner:颜兴明

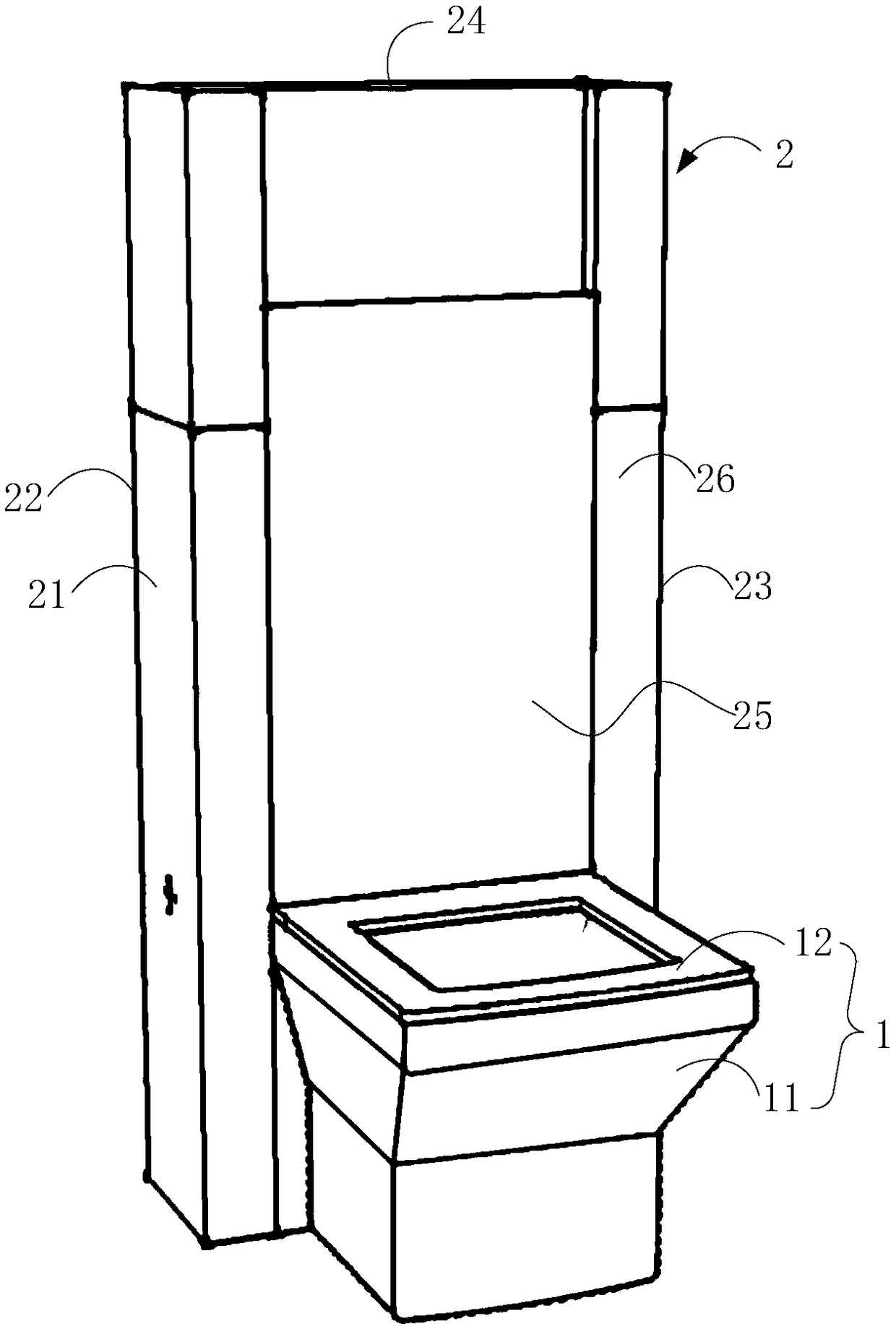

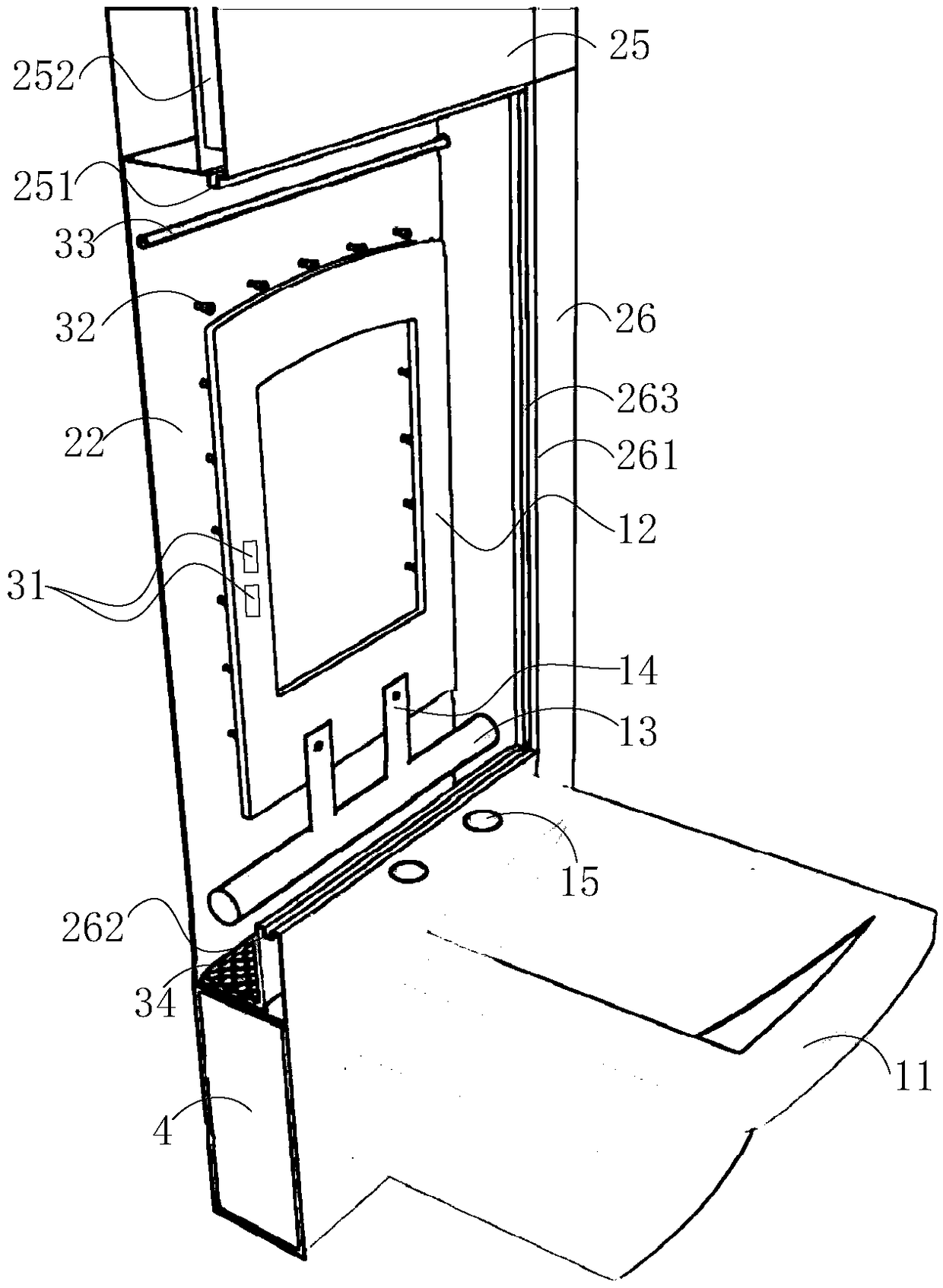

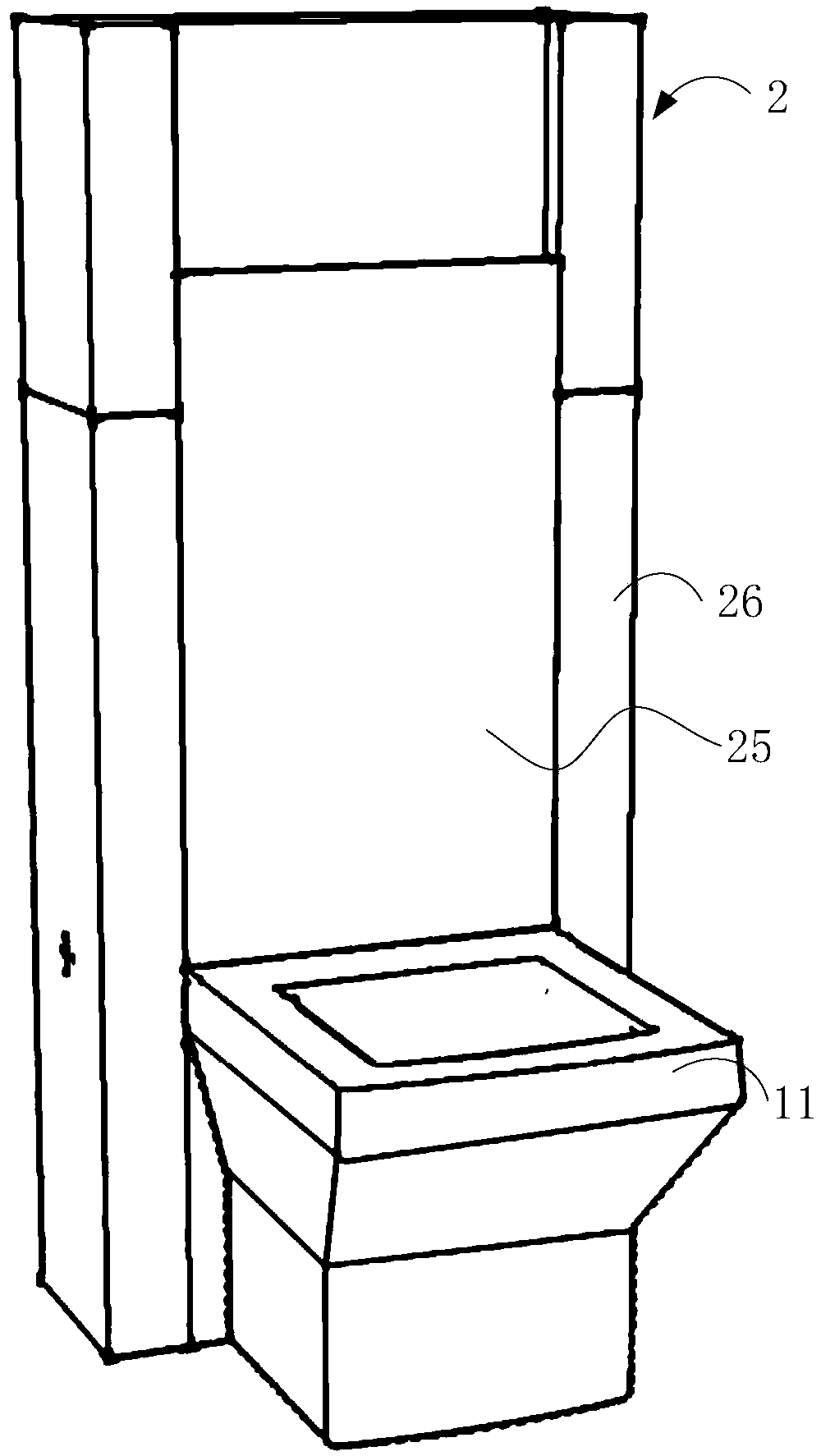

Toilet seat self-cleaning system and self-cleaning method thereof

The invention relates to the technical field of sanitary ware, in particular to a toilet seat self-cleaning system and a self-cleaning method thereof. The toilet seat self-cleaning system comprises atoilet seat including a toilet seat body and a toilet seat ring rotatably connected with the toilet seat body; A wall body arranged behind the toilet bowl, wherein a receiving cavity is arranged in the wall body, and the receiving cavity is used for receiving the toilet bowl seat; a Self-cleaning assembly, including a sensing component, a control component and a shower component, wherein the sensing component is provided on the toilet seat ring and is electrically connected with the control component, the sensing component is used for sending detection information to the control component whendetecting that that toilet bowl is unused; the control components is used for controlling the automatic turning of the toilet seat into the accommodation chamber when the detection information is received and is also connected to a shower component; and the control component is further configured to control the shower component to wash the toilet seat in the accommodation chamber after the toilet seat is automatically turned into the accommodation chamber. The toilet seat self-cleaning system can realize automatic cleaning, and has the functions of washing, draining, drying and the like.

Owner:SHENZHEN MICRO SPACE CONSTR TECH CO LTD

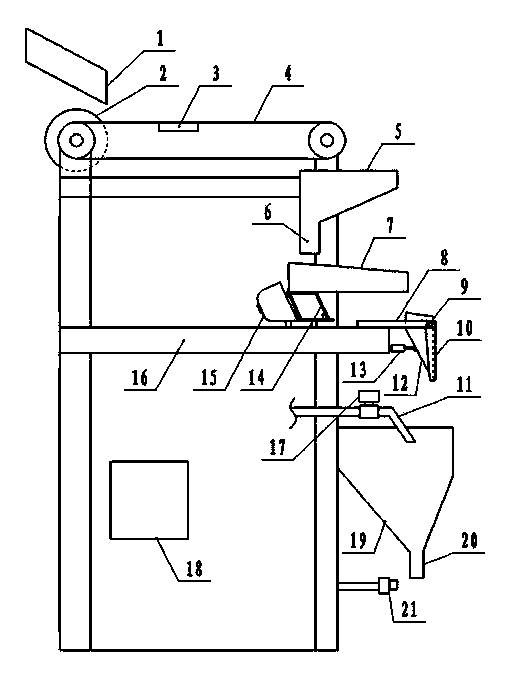

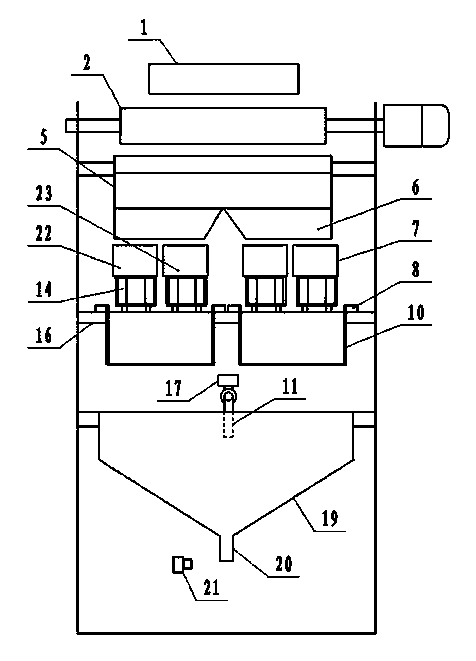

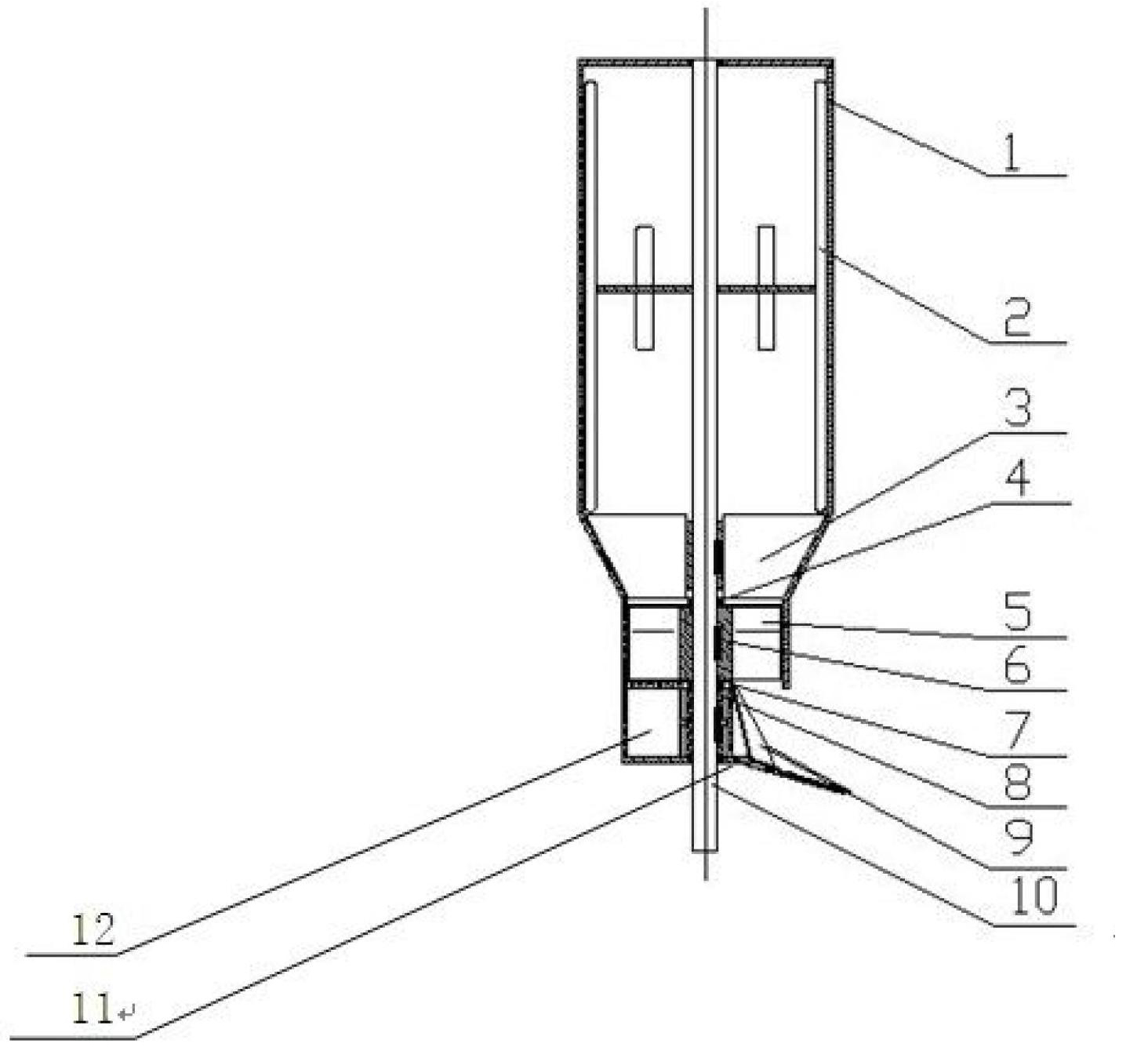

Capsicum frutescens pickled pepper quantitative bagging machine

InactiveCN103723291AIncrease productivityImprove hygiene qualitySolid materialLiquid materialAgricultural engineeringElectric control

Disclosed is a capsicum frutescens pickled pepper quantitative bagging machine. A speed-adjusting conveying belt is mounted below a raw material input port, a material distributing bin is mounted below the front end of the speed-adjusting conveying belt, two discharging ports are arranged at the lower end of the material distributing bin, two vibration conveying plates are mounted below the discharging ports respectively and includes a main material conveying plate and a fine-adjustment material conveying plate, a weighing bucket is mounted below the main material conveying plate and the fine-adjustment material conveying plate and composed of a fixed plate and a movable plate, the fixed plate is fixedly mounted on a weight sensing arm, the rear side of the movable plate is connected with an electromagnetic switch rod, a canning bucket is mounted below the weighing bucket, a soup input pipe is mounted in the canning bucket, a soup flow electromagnetic control valve is mounted on the soup input pipe, a bagging pipe is mounted at the lower end of the canning bucket, and a bagging sensing head is mounted on one side of the bagging pipe. When the machine is in use, a worker only needs to sleeve a packaging bag on the bagging pipe, then the sensing head can inform an electric control system to automatically complete automatic metering and bag canning.

Owner:YUNNAN SUNSHINE FOOD

Corn germ pretreatment processing technology to eliminate mycotoxin in corn oil

ActiveCN106010771AReduce or even eliminate mycotoxinsImprove hygiene qualityFatty-oils/fats refiningFatty-oils/fats productionOzone SterilizationFungal Toxins

A corn germ pretreatment processing technology to eliminate mycotoxin in corn oil includes ozone fumigation of the corn germ, cleaning, impurity removal, modulation and softening, rolling, and alkali puffing. The ozone fumigation treatment is carried out in a closed chamber at a temperature of 5 DEG to 50 DEG C; ozone is introduced when the moisture content of corn germ is 7%-25% for ozone sterilization and mycotoxin pre-degradation for 0.5-48 h, wherein the ozone concentration is 5-50ppm. The alkali puffing is as below: adding alkali lye or steam with concentration of 5%-30% into the corn germ before corn puffing treatment or in the puffing process, wherein the addition amount is calculated by the content of mycotoxin in corn germ and the acid value of corn oil. The corn oil prepared from corn germ contains mycotoxins, such as aflatoxin B1 (AFB1) and zearalenone (ZEN), less than the national limit standard. The final product has the characteristics of low mycotoxin content, small acid value, light color, and little loss in refining.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Automatic food selling machine

InactiveCN102693583AReduce laborImprove hygiene qualityCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringFood storage

An automatic food selling machine includes a food storage bucket and a food distributing bucket that are arranged on a center shaft, wherein the food distributing bucket is connected below the food storage bucket and isolated from the food storage bucket through a gapped solid plate; a food stirring spoon and a food pushing plate are arranged on the center shaft in the food storage bucket; a food distributing plate connected with a weight sensor is arranged on the center shaft in the food distributing bucket; a food outlet is arranged on the food distributing bucket; and the center shaft is connected with a numerical control system. The center shaft can drive the food stirring spoon, the food pushing plate, the food distributing plate and an oil control plate to rotate to enable the food to be portioned and discharged through the food outlet to lunch boxes as driven by the numerical control system, thereby realizing the automatic operation of food selling, not only reducing the labor amount of the workers, but also improving the sanitary quality of food, improving the food selling speed and ensuring the freshness of food. The automatic food selling machine has a simple structure, and is convenient to operate and safe to use.

Owner:XIAN UNIV OF TECH

Meal replacement powder for invigorating spleen, nourishing stomach and controlling energy and preparation method of meal replacement powder

PendingCN108391817AControl energy intake wellIncrease satietyFood ingredient as colourFood preservationBearded toothSpleen

The invention relates to the field of food processing, in particular to meal replacement powder for invigorating the spleen, nourishing the stomach and controlling energy and a preparation method of the meal replacement powder. The meal replacement powder comprises the following components in parts by weight of 55-70 parts of rice, 10-20 parts of black rice, 5-10 parts of black beans, 1-2 parts ofblack sesame seeds, 1-2 parts of Chinese wolfberry fruits, 1-2 parts of hericium erinaceus, 1-2.5 parts of coix seeds, 1-2.5 parts of poria cocos, 0.5-1 part of lotus seeds, 1-2 parts of Chinese yams, 0.5-1 part of (artificially planted) ginseng, 5-10 parts of konjaku flour, 2.5-5.0 parts of xylooligosaccharide and 0.25-0.5 part of fish collagen peptide. The meal replacement powder has the advantages of being good in reconstituability, easy to digest and absorb, capable of invigorating the spleen, nourishing the stomach, controlling energy and the like.

Owner:江西德煦实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com