Aluminum plastic bottle cap laminating machine

A technology of pressing machines and aluminum-plastic covers, which is applied to conveyors, conveyor objects, rotary conveyors, etc., can solve the problems of low production efficiency, poor hygiene quality, and high product scrap rate, so as to reduce the scrap rate and improve production efficiency. The effect of improving efficiency and improving hygiene quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

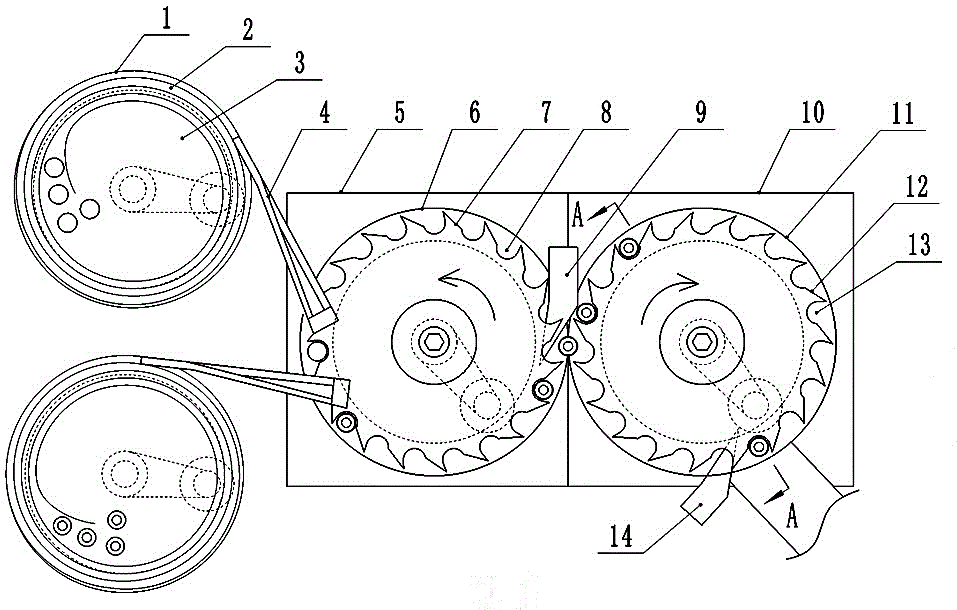

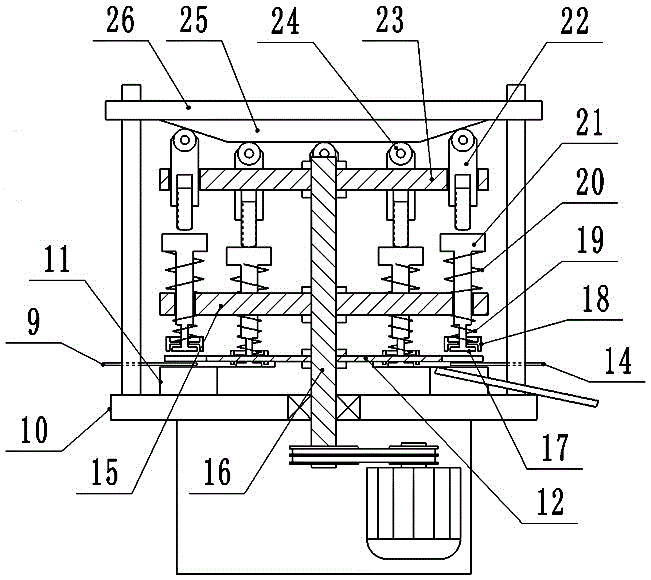

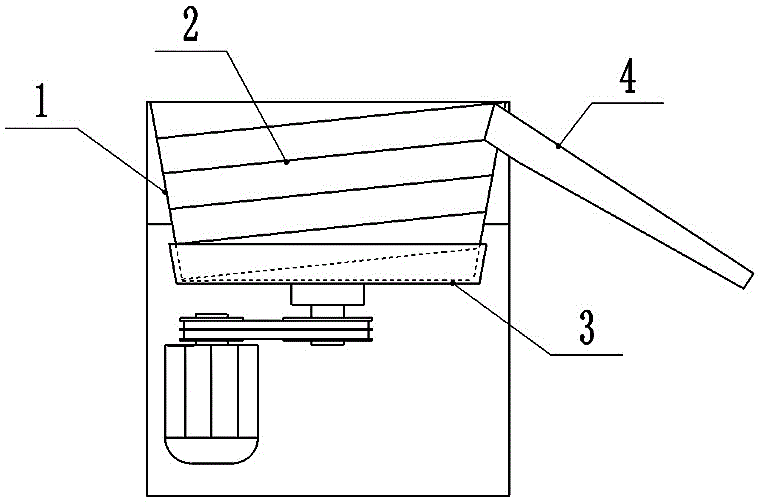

[0012] Examples such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Shown: An aluminum-plastic bottle cap pressing machine, the machine is composed of a plastic pad supply device, an aluminum cap supply device, an alignment conveying device, and an aluminum-plastic cap pressing device. The plastic pad supply device has the same structure as the aluminum cap supply device , consisting of a rotating chassis 3, a screw feeding barrel 1 and a discharge guide rail 4, the screw feeding barrel 1 is fixed on the frame, the rotating chassis 3 is set on the open lower opening of the screw feeding barrel 1, and the side of the screw feeding barrel 1 A spiral feeding trough 2 is processed on the wall, and a discharge guide rail 4 is installed on the upper end of the spiral feeding trough 2, and the fixed rotating shaft below the rotating chassis 3 is connected with the rotating shaft belt of the motor; The alignment backing plate 5 is equipped with an alignment washer 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com