Automatic spring tube end surface processing device

A technology of end face processing and spring tube, which is applied in the field of mechanical parts processing, can solve the problems of low production efficiency and heavy labor of workers, achieve product quality assurance, ensure continuous production efficiency and quality, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following specific embodiments are described below in conjunction with the drawings, but the present invention is not limited to the following embodiments.

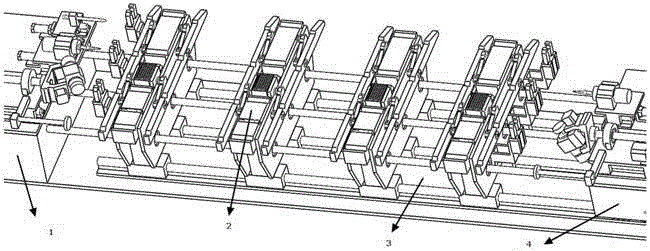

[0036] The whole set of devices such as figure 1 , Including distance adjustable worktable 3, length adjustable feeding device 2, grinding and deburring device, reaming device, blowing through hole device. The length-adjustable feeding device is composed of four identical units and is connected to the base through a supporting rail.

[0037] The distance adjustable workbench 3 can be divided into a fixed workbench 1 and a movable workbench 4. A grinding and deburring device 56, a reaming device 55, and a blow through hole device 54 are installed side by side on the fixed workbench; a grinding and deburring device 56 and a reaming device 55 are installed side by side on the movable workbench.

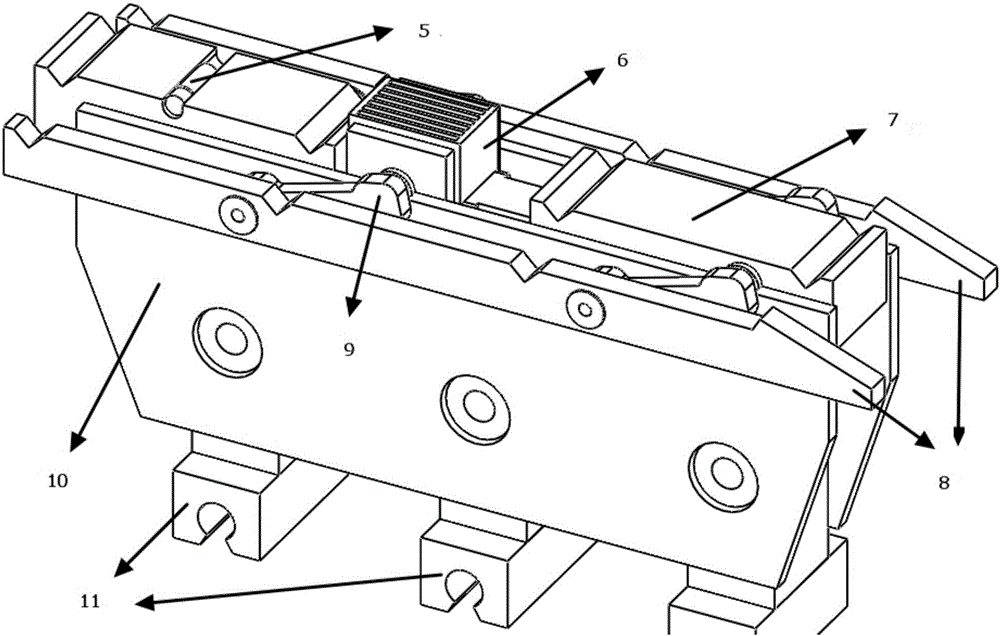

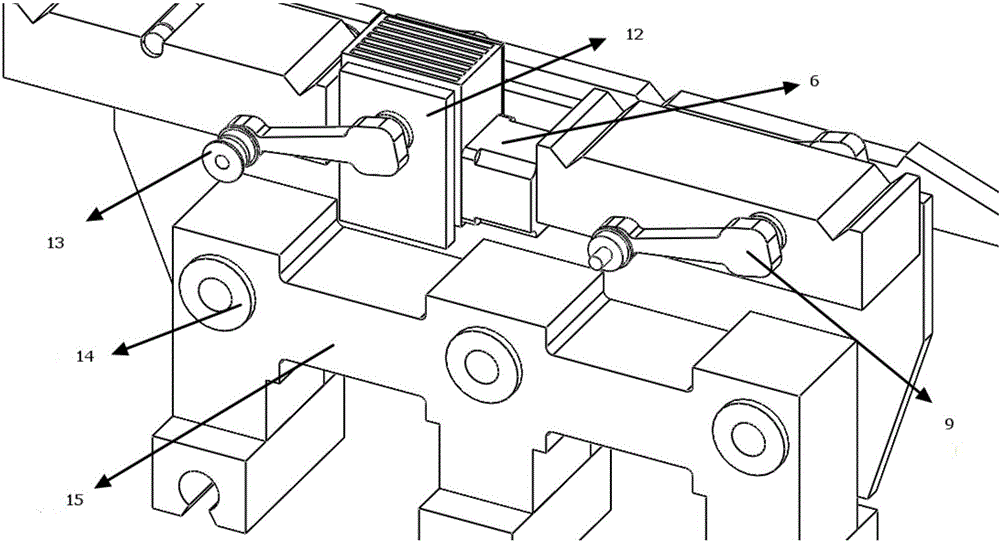

[0038] The main internal structure of the movable workbench box is as Picture 9 , Picture 10 . The box body is surrounded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com