A plc-controlled automatic nano-calcium carbonate digestion production line

A nano-calcium carbonate, fully automatic technology, applied in the direction of calcium carbonate/strontium/barium, program control, nanotechnology, etc., can solve the problem of affecting the consistency of nano-calcium carbonate particles, the inability to coordinate and unify the front and back control, and the unreasonable preparation of production equipment, etc. problem, to achieve the effect of no dust flying, stable temperature, easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

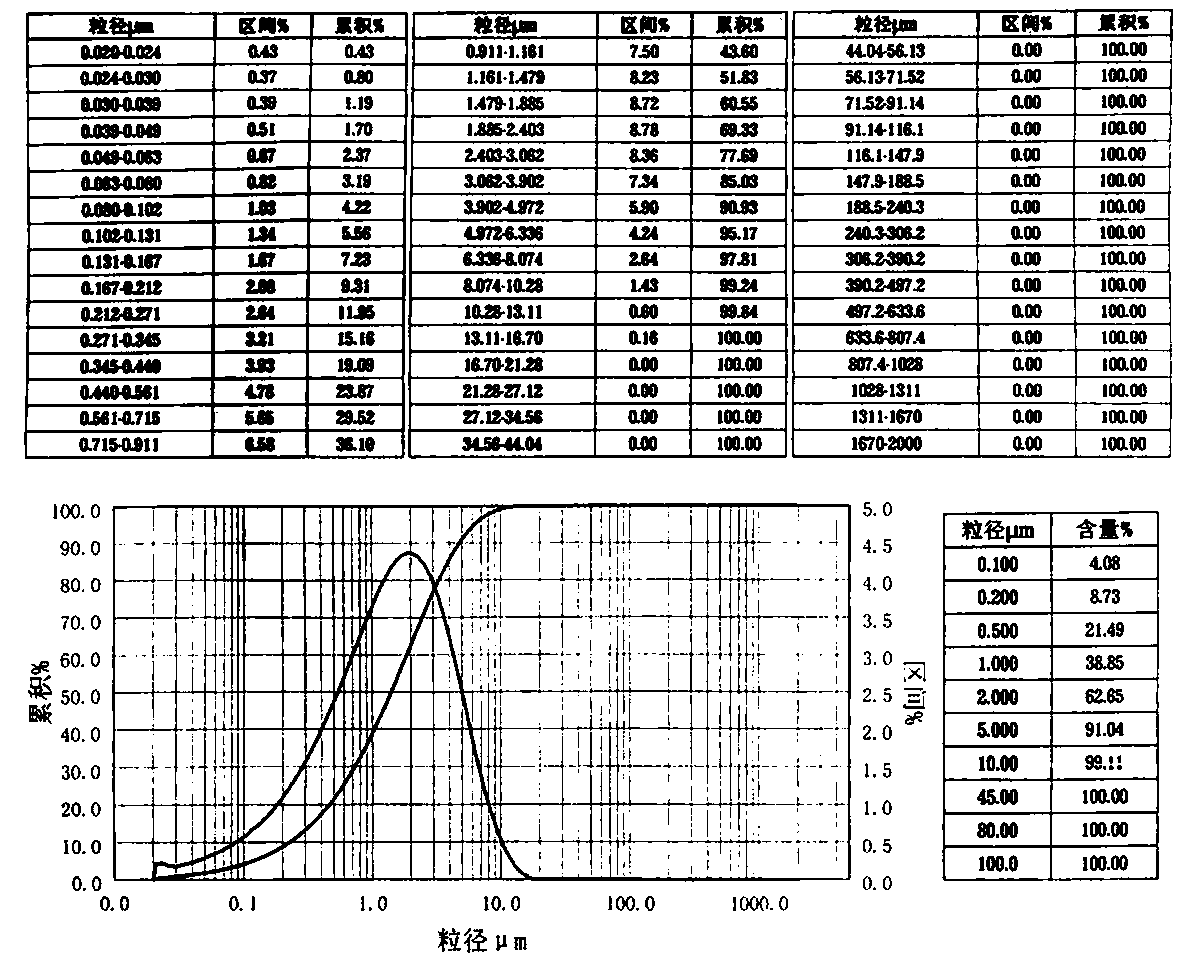

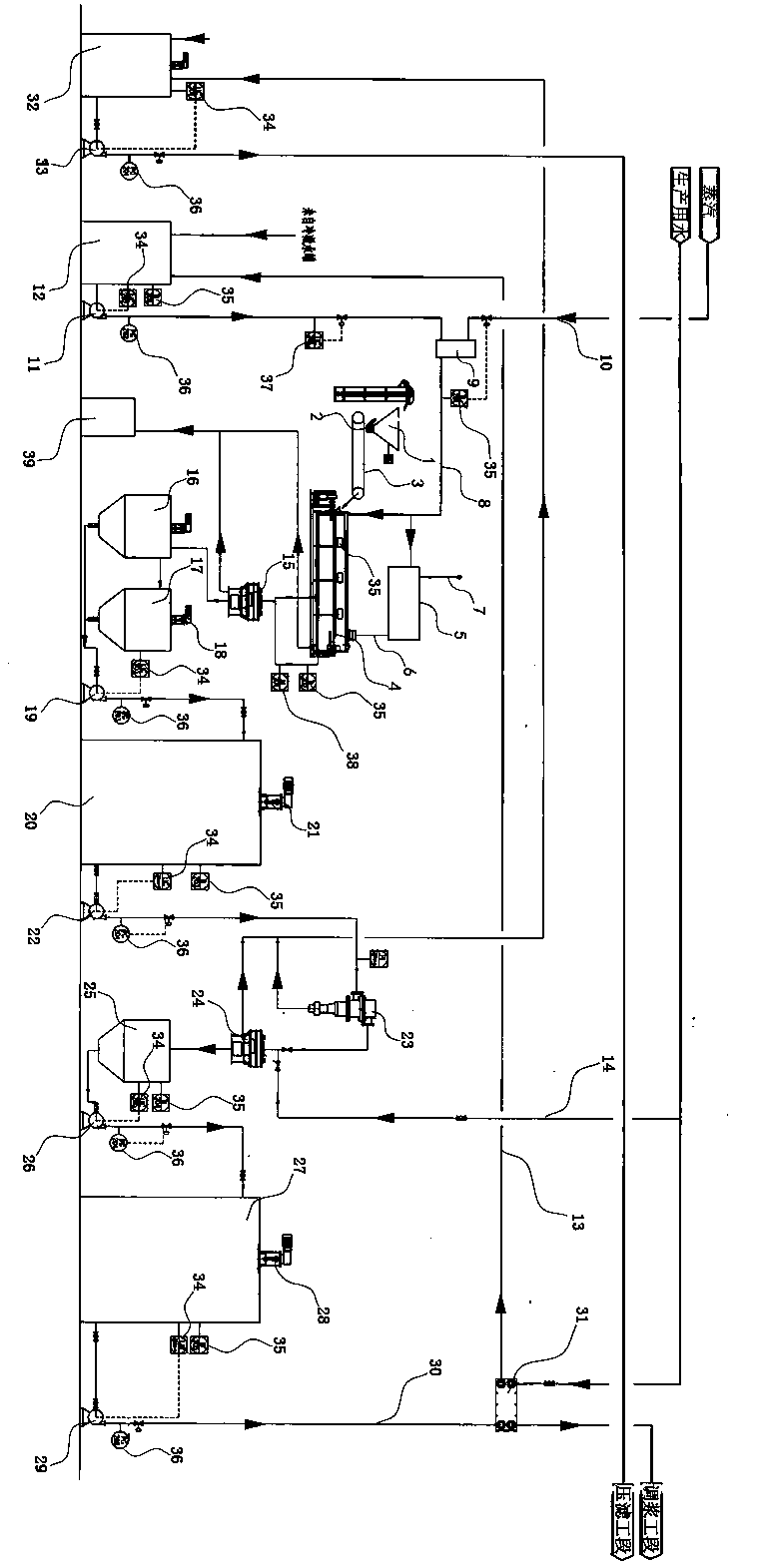

[0034] The nano-calcium carbonate production line of the present invention comprises a full-automatic PLC control system and on-site production equipment.

[0035] The structure of the on-site production equipment is as follows figure 1 As shown, it mainly includes trough digester 4, quicklime feeding device, digested water tank 12, first heat exchanger 9, first circular vibrating screen 15, coarse slurry tank, waste water tank 39, secondary coarse slurry tank 20, rotary Liquid separator 23, second circular vibrating screen 24, recovery water tank 32, fine slurry tank 25, fine slurry tank 27 and second heat exchanger 31.

[0036]The trough digester 4 of the present invention is a three-slot digester, the feed end of the first tank of the three-slot digester is respectively connected to the quicklime feeding device and the digestion water pipe, and the discharge end of the third tank is connected to the first circular vibrating screen 15, The waste water discharge end of the t...

Embodiment 2

[0051] Utilize the process that the production line described in embodiment 1 produces nano-calcium carbonate is:

[0052] (1) The screened quicklime is sent to the silo 1, and the quicklime in the silo passes through the electromagnetic vibrating feeder 2, falls on the weighing belt conveyor 3, and is transported to the trough digester 4; the production water flows along the water supply pipe The second branch 13 of the road enters the digested water tank 12 after the second heat exchanger 31 initially heats up. The digested water in the digested water tank 12 is pumped by the digested water pump 11 into the digested water pipeline 8, the digested water in the digested water pipeline 8 exchanges heat with the steam in the steam pipeline 10 in the first heat exchanger 9, and enters the In the trough digester 4, quicklime in the trough digester 4 reacts with digested water to obtain a coarse slurry of calcium hydroxide.

[0053] (2) The coarse slurry enters the coarse slurry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com