Patents

Literature

143results about How to "High specific gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexagonal ferrite magnetic powder, method for producing the same and magnetic recording medium

ActiveUS20070020489A1High strengthHigh specific gravityMaterial nanotechnologySynthetic resin layered productsMagnetic powderThermal treatment

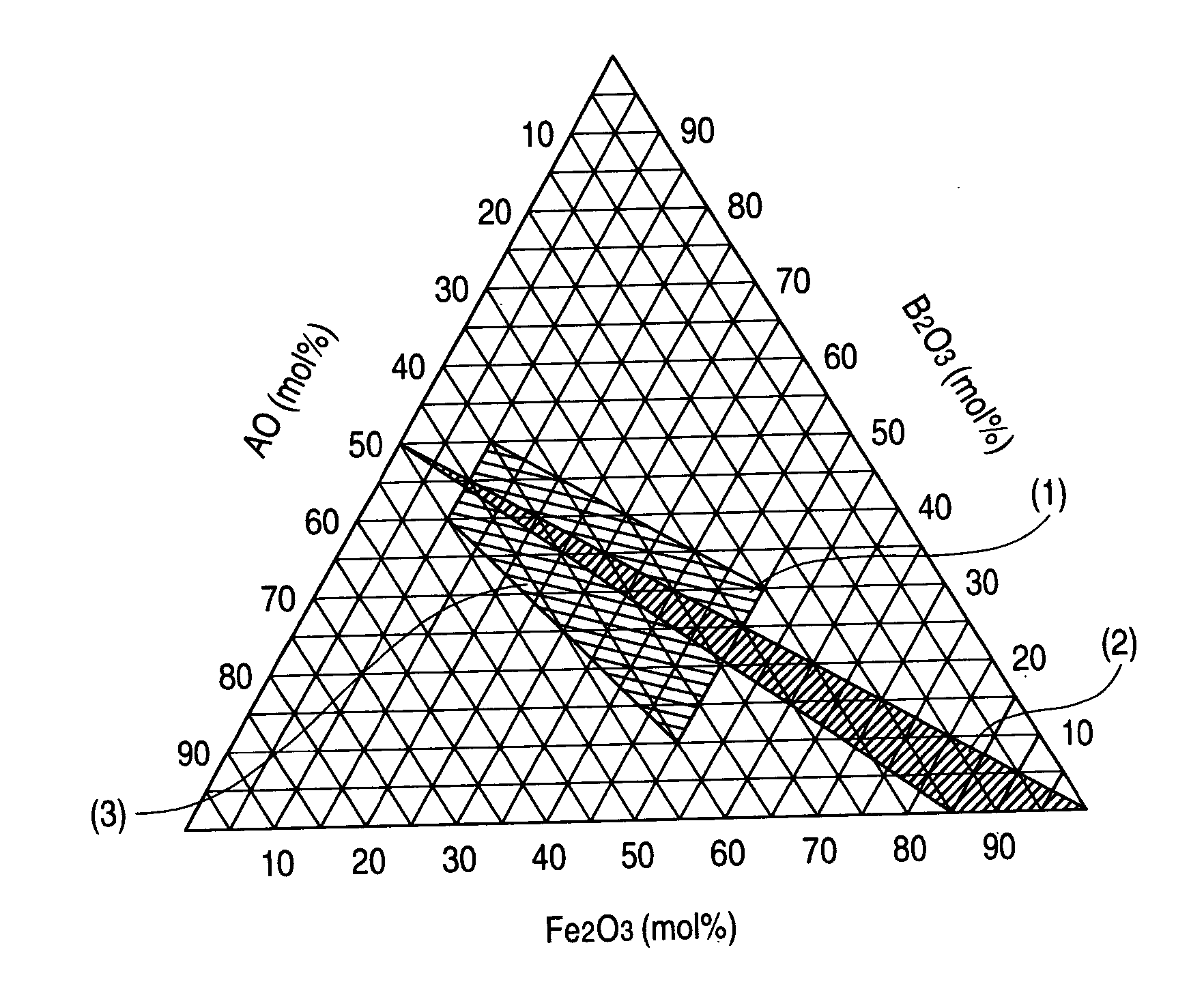

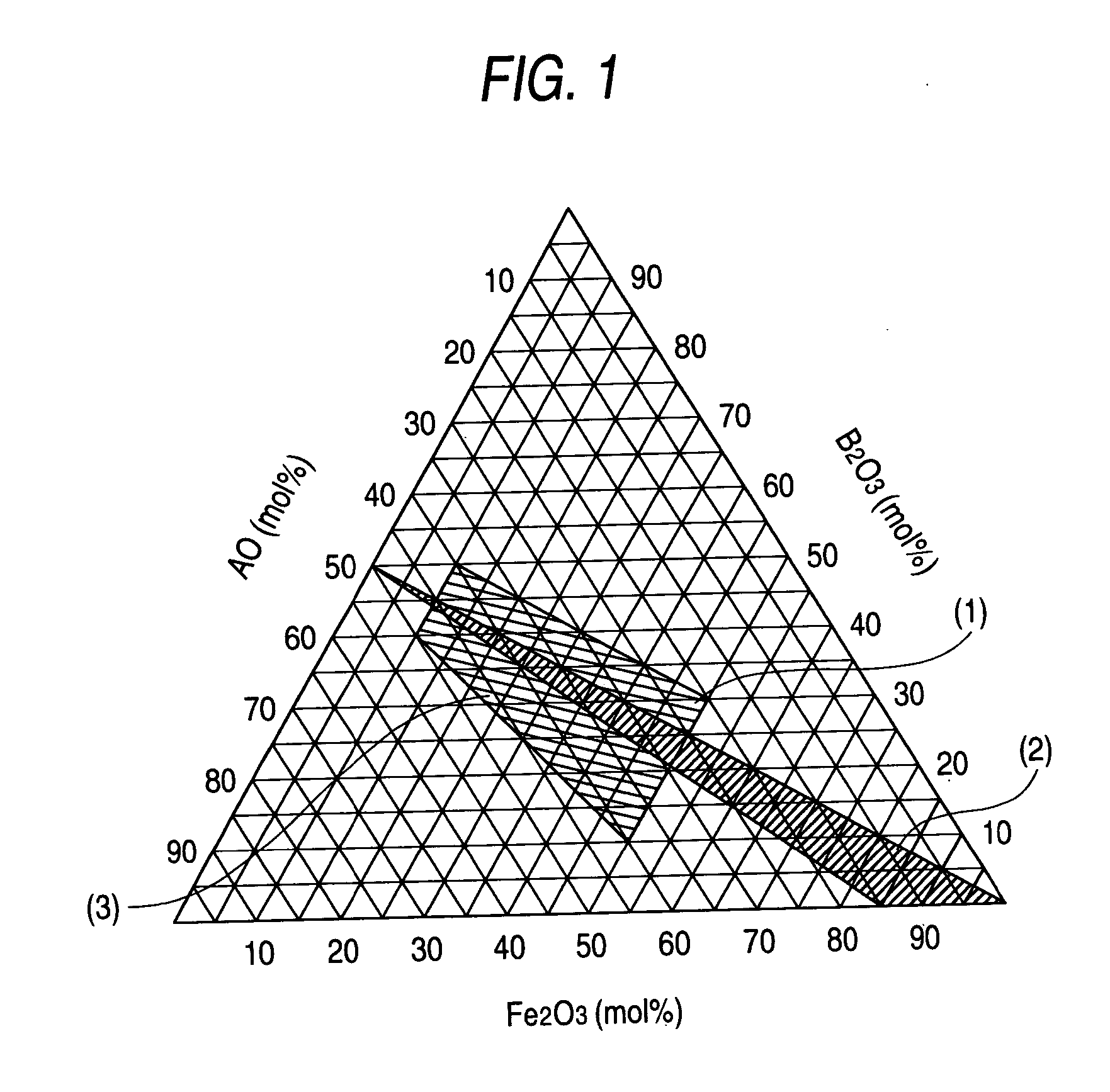

A hexagonal ferrite magnetic powder having an average tabular diameter of from 15 to 28 nm, a coercive force (Hc) of from 2,000 to 5,000 Oe (from 160 to 400 kA / m), a switching field distribution (SFD) of from 0.3 to 0.7 and a D70 / D50 of from 1.05 to 1.25. This magnetic powder can be obtained by melting and quenching starting materials to obtain an amorphous product, and thermally treating the product, which comprises increasing a temperature at a rate of 300 to 500° C. / hr in a temperature range of 550 to 600° C. in the thermal treatment before the temperature reaches the thermally treating temperature.

Owner:FUJIFILM CORP +1

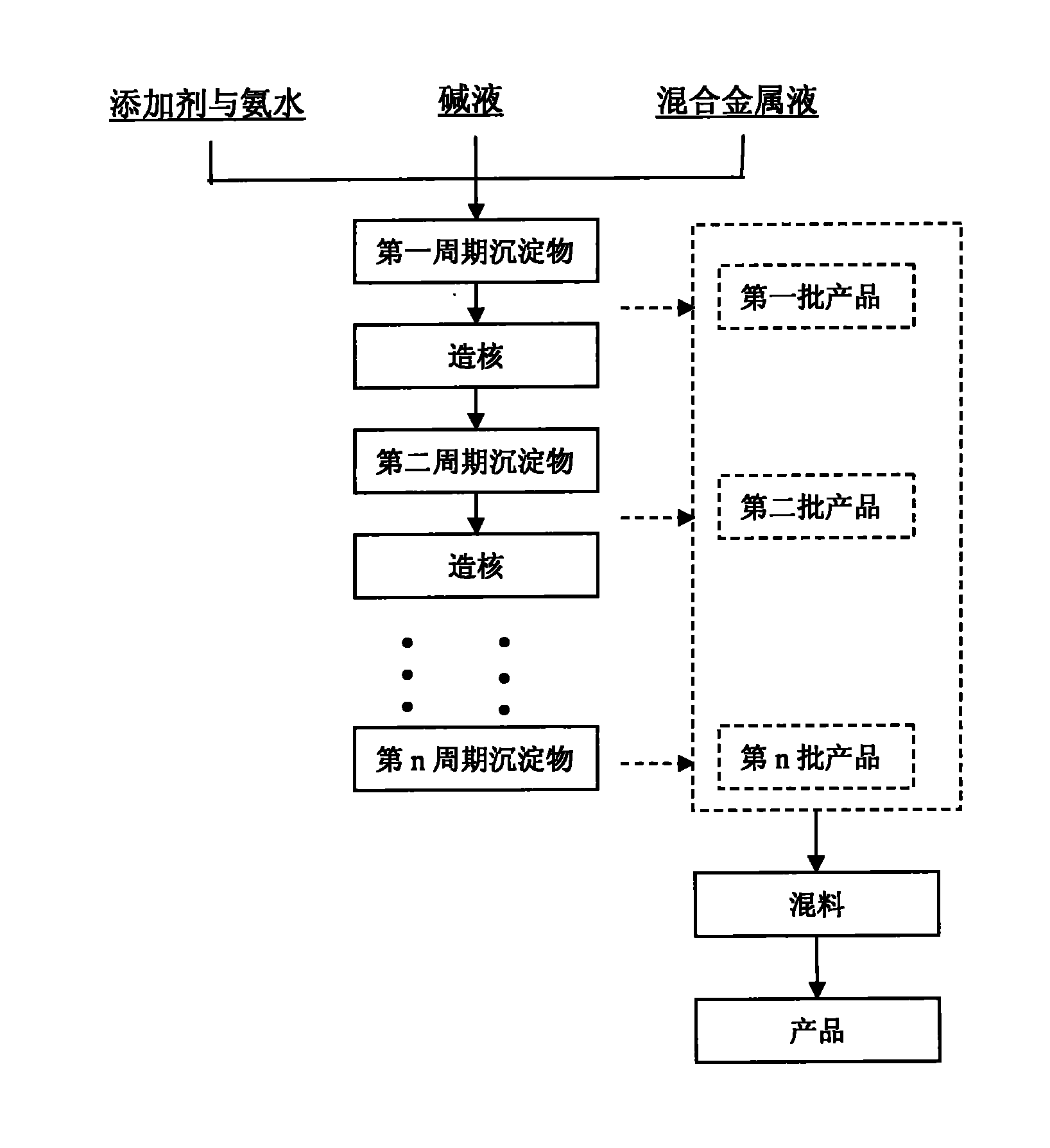

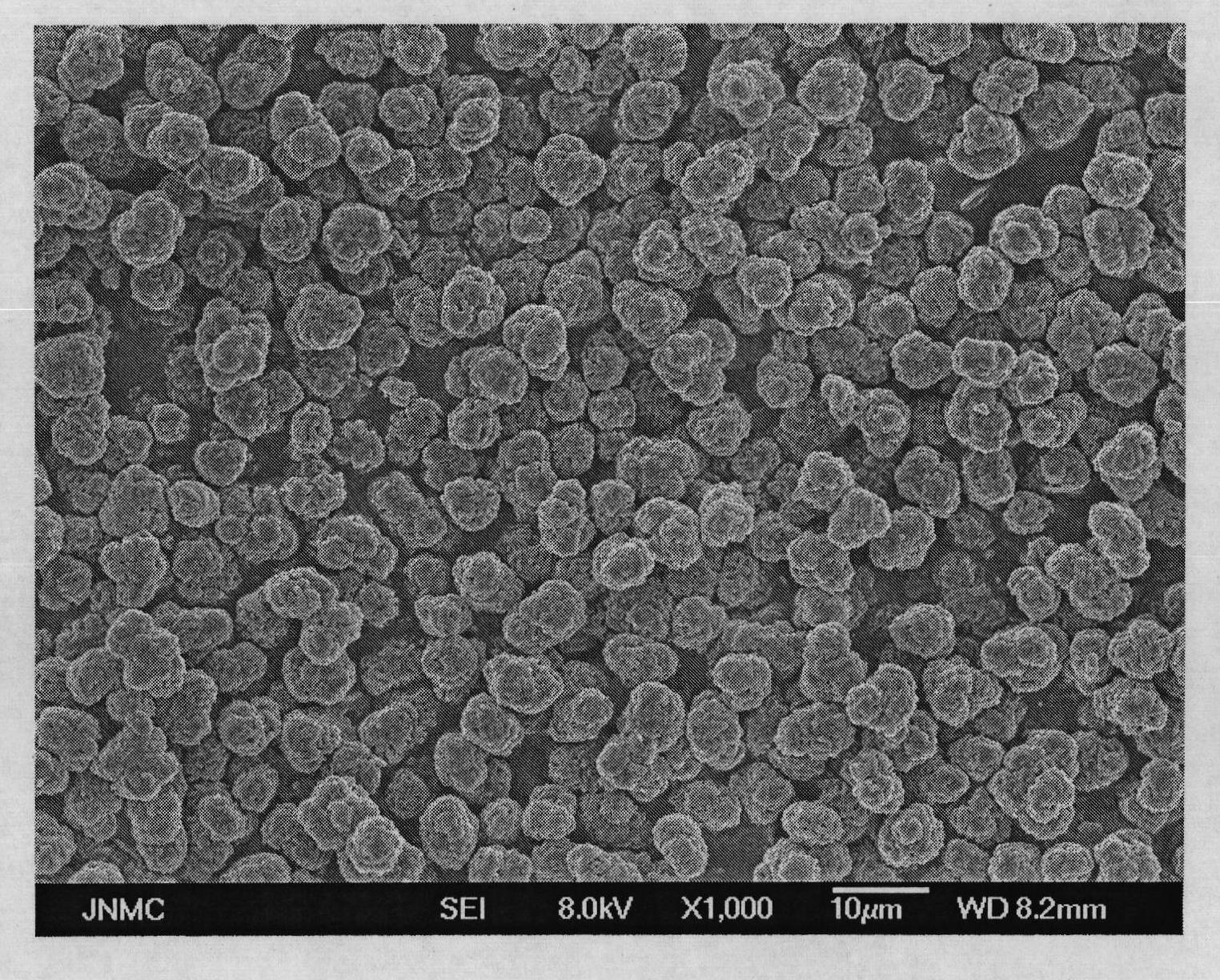

Method for continuously synthesizing precursor of lithium ion battery positive material

InactiveCN102092798AInhibition formationSolve the problem of easy oxidationCell electrodesManganese oxides/hydroxidesSynthesis methodsManganese

The invention provides a method for continuously synthesizing a precursor of a lithium ion battery positive material, relating to an improvement of a synthesis method of a nickle cobalt manganese termary positive material nickle cobalt lithium manganate of the lithium ion battery positive material. The method is characterized in that the synthesis process is as follows: merging a complexing agent ammonia, an aqueous solution of metal nickle cobalt manganese ions and a precipitator sodium hydroxide solution and then continuously adding the substances into a reaction kettle for a synthesis reaction under the strong stirring condition in the presence of protective gas; and aging, filtering and washing the effluent from the reaction kettle, and then drying to obtain the lithium ion battery positive material precursor spherical nickle cobalt manganese termary hydroxide. The method has the advantages that the preparation process is continuous, the particle size of the prepared nickle cobalt manganese compound hydroxide powder is controlled in a range of 5-20 microns, and the prepared nickle cobalt manganese compound hydroxide powder is even in distribution and excellent in electrochemistry property. The method has the advantages of high production efficiency, low production cost and significant economic and social benefits, and the energy is saved.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH +1

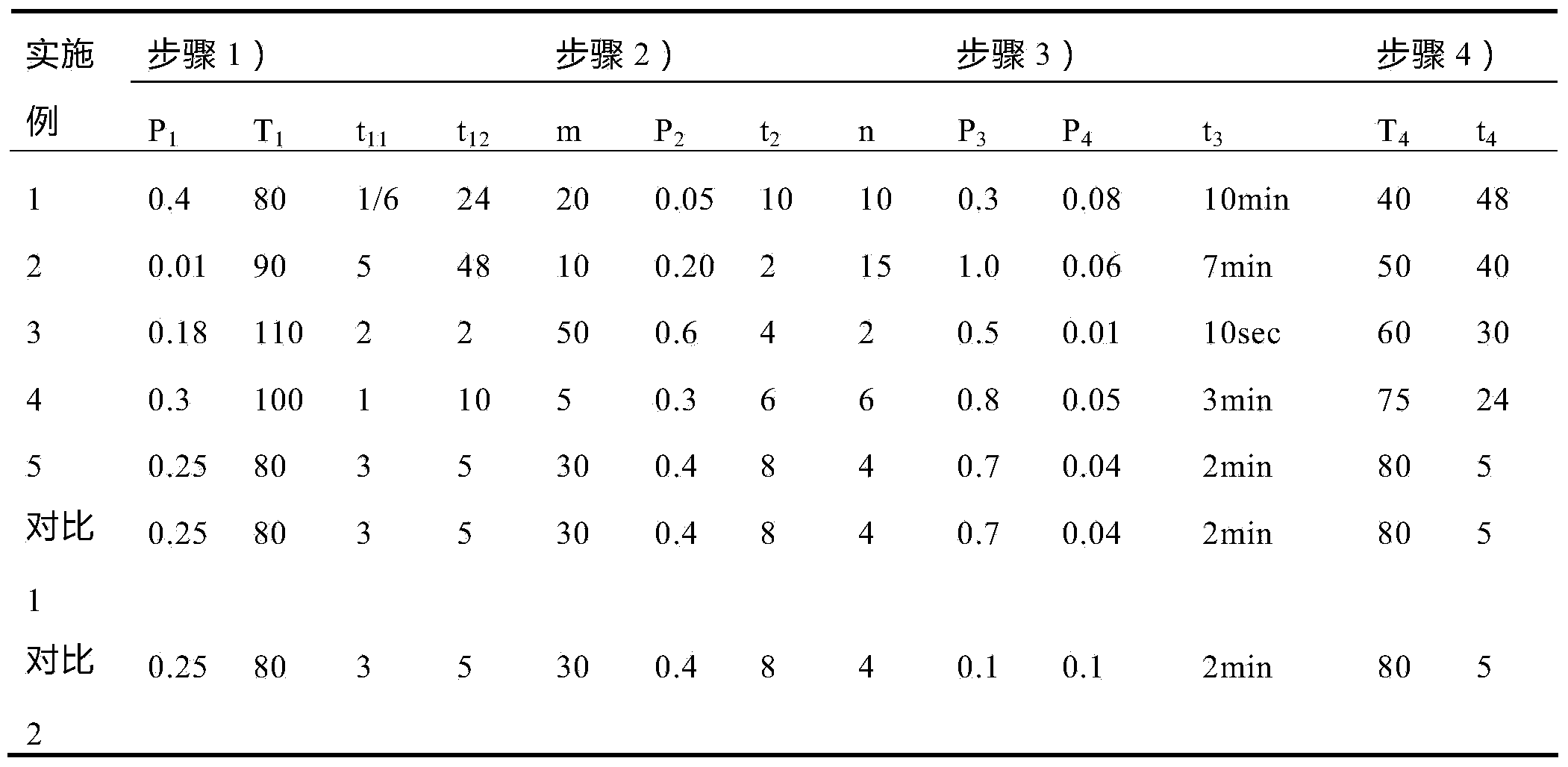

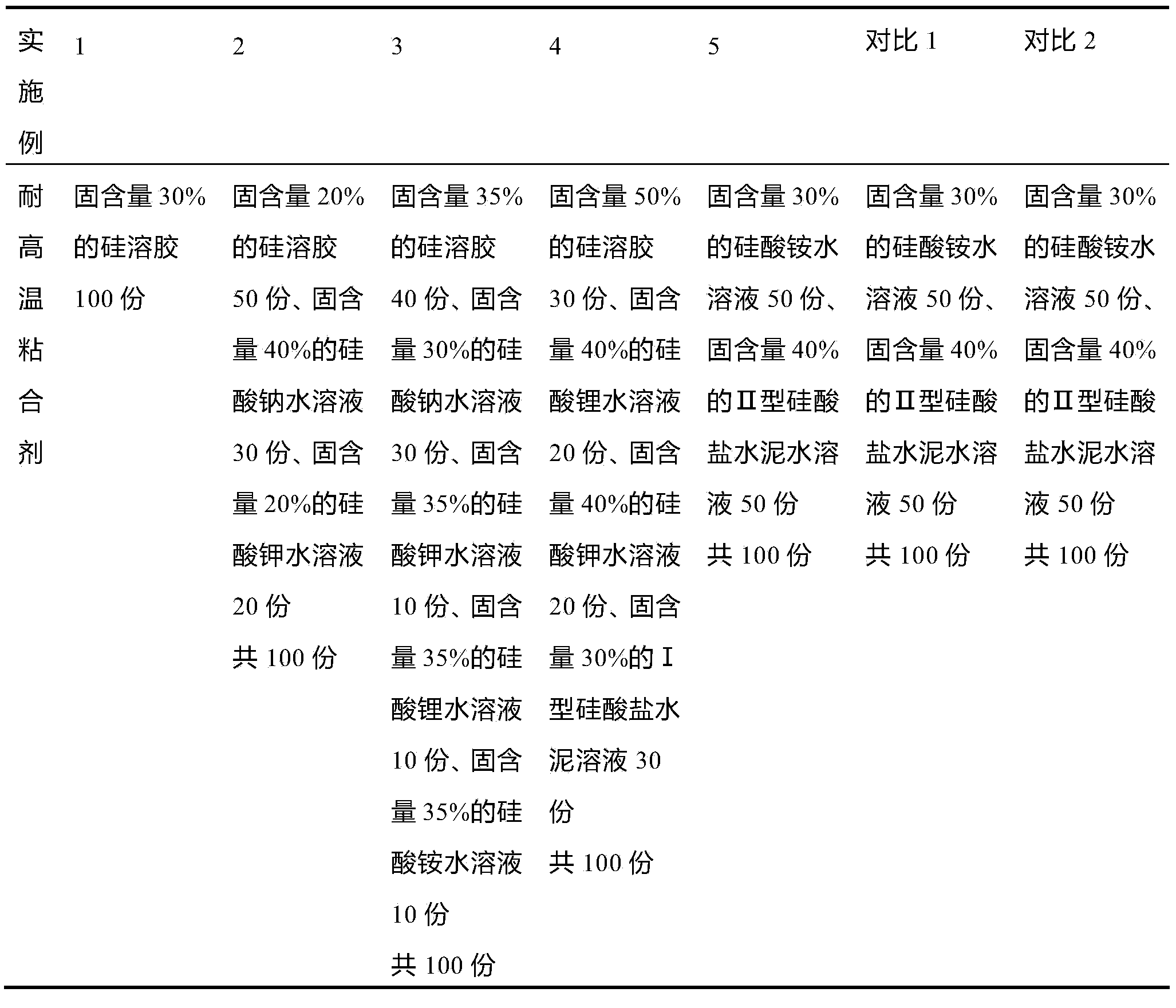

Fire-proof adhesive and application thereof

ActiveCN104099028AReduce total calorific valueImprove thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionAdhesive

The invention discloses a fire-proof adhesive and application thereof. The fire-proof adhesive comprises the following components by parts: 100 parts of high-temperature bonding agent, 10-70 parts of fire retardant, 0.5-50 parts of flame retardant synergist, 5-50 parts of strength enhancer, 0.05-20.0 parts of water-proof modifying agent and 0.01-2.0 parts of curing modifying agent. By adopting the fire-proof adhesive and a preparation method of a fire-retardant EPS (Expandable Polystyrene) foam heat-insulating plate, the combustion performance and physicochemical performance of the fire-retardant EPS foam heat-insulating plate can be improved remarkably. For example, the heat-conducting coefficient can be lowered below 0.055w / m.k, the specific gravity can be lower than 150Kg / M<3>, the compressive strength is higher than 150KPa, and the heat value is less than 3MJ / kg.

Owner:应急管理部四川消防研究所

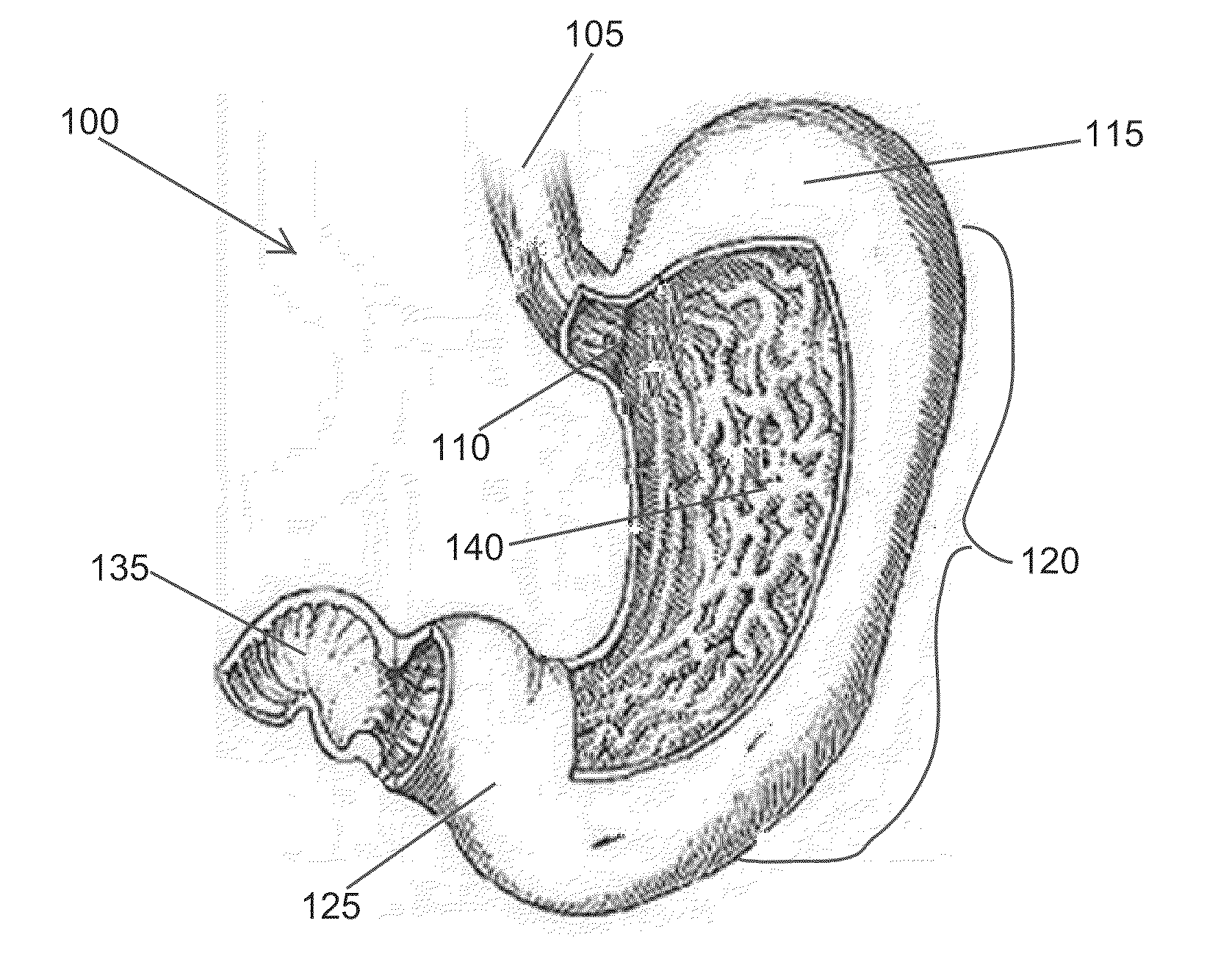

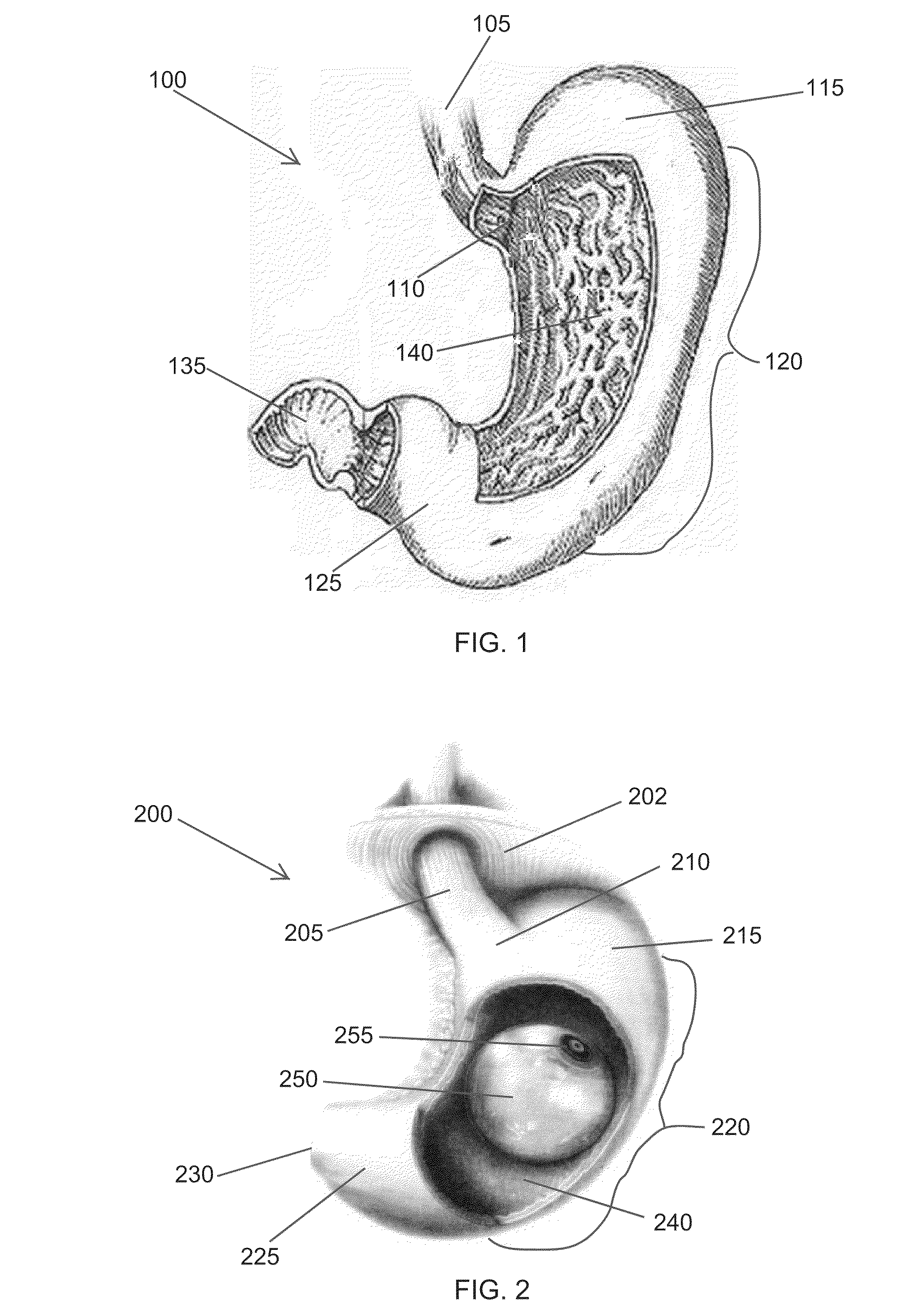

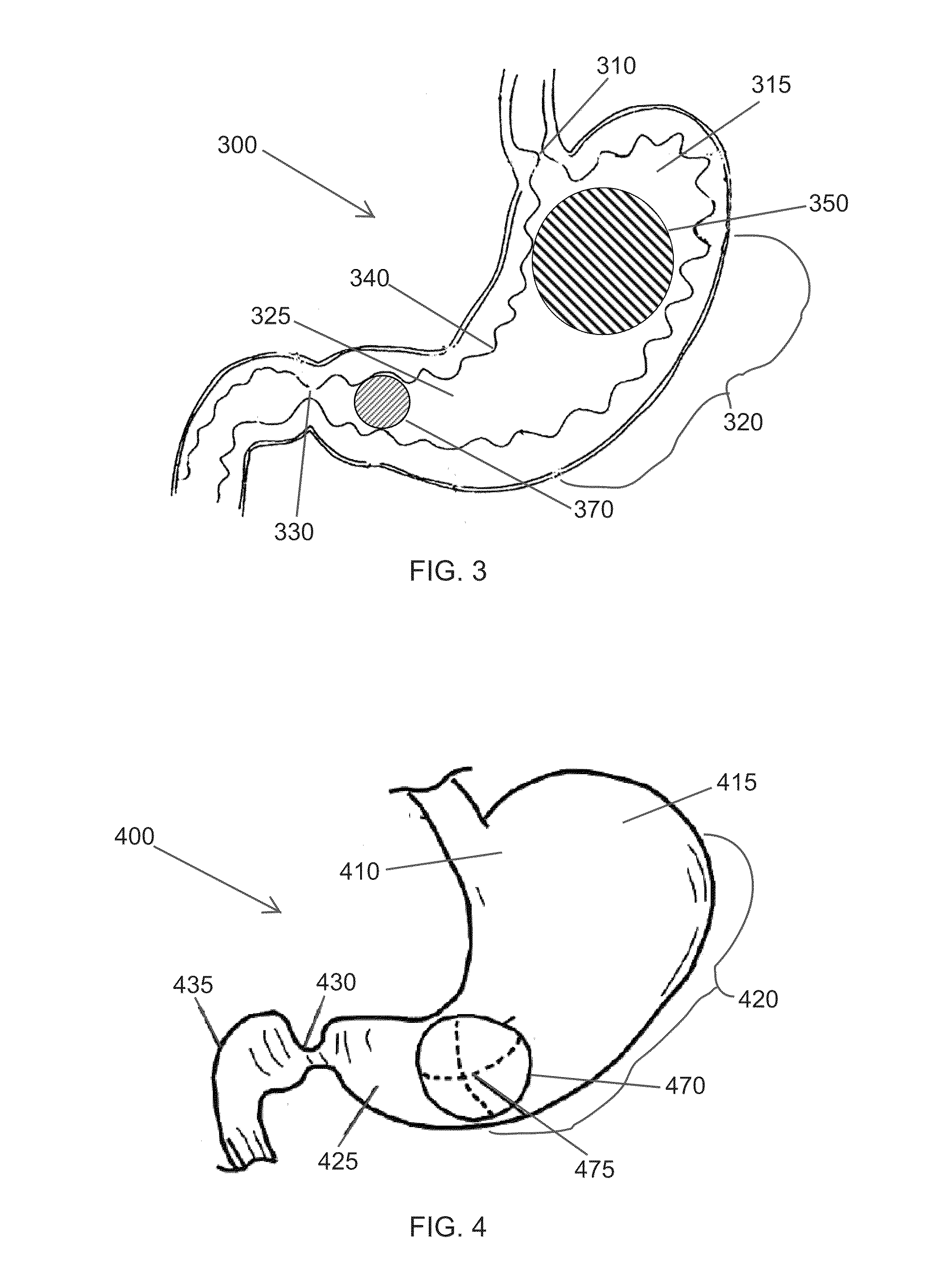

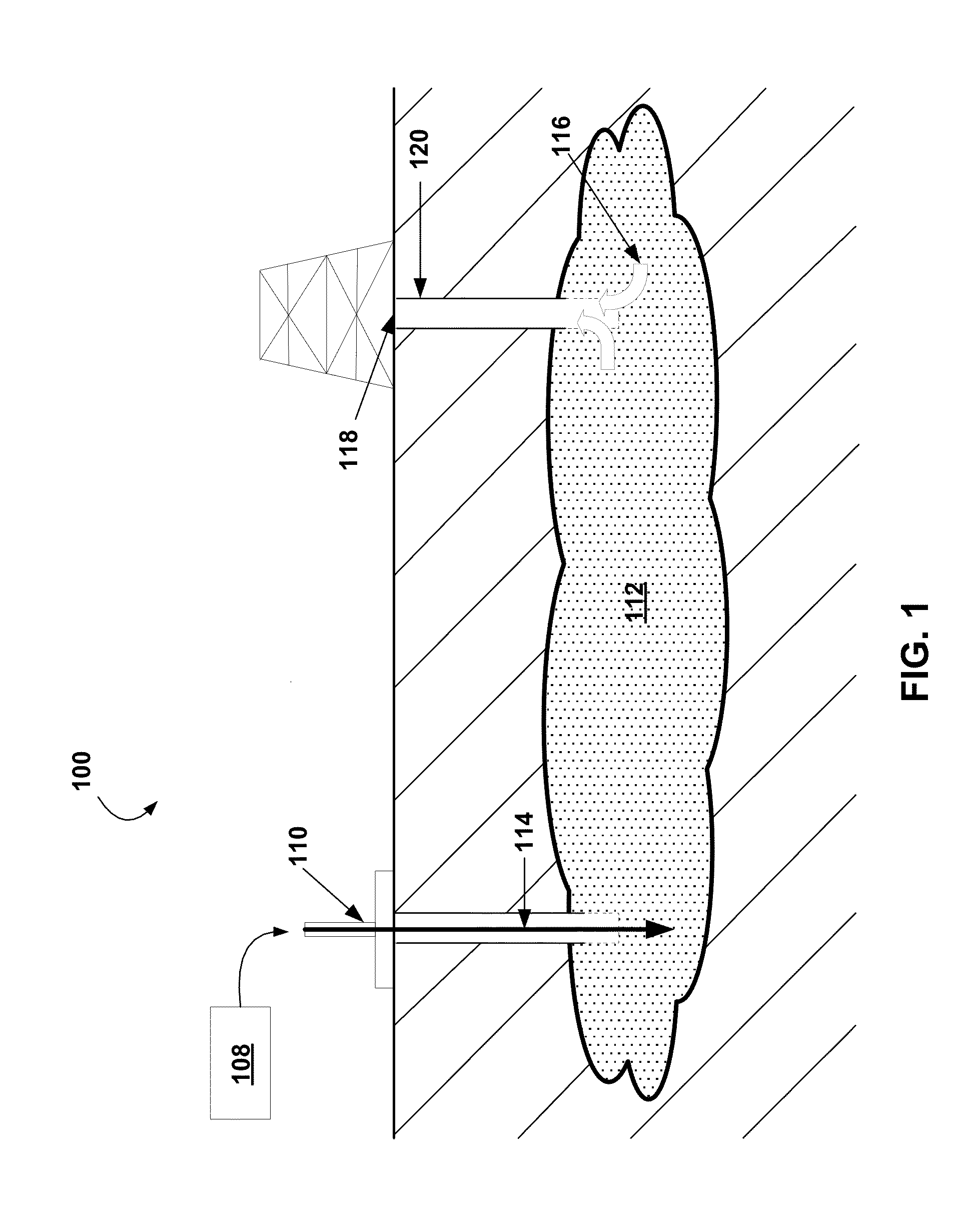

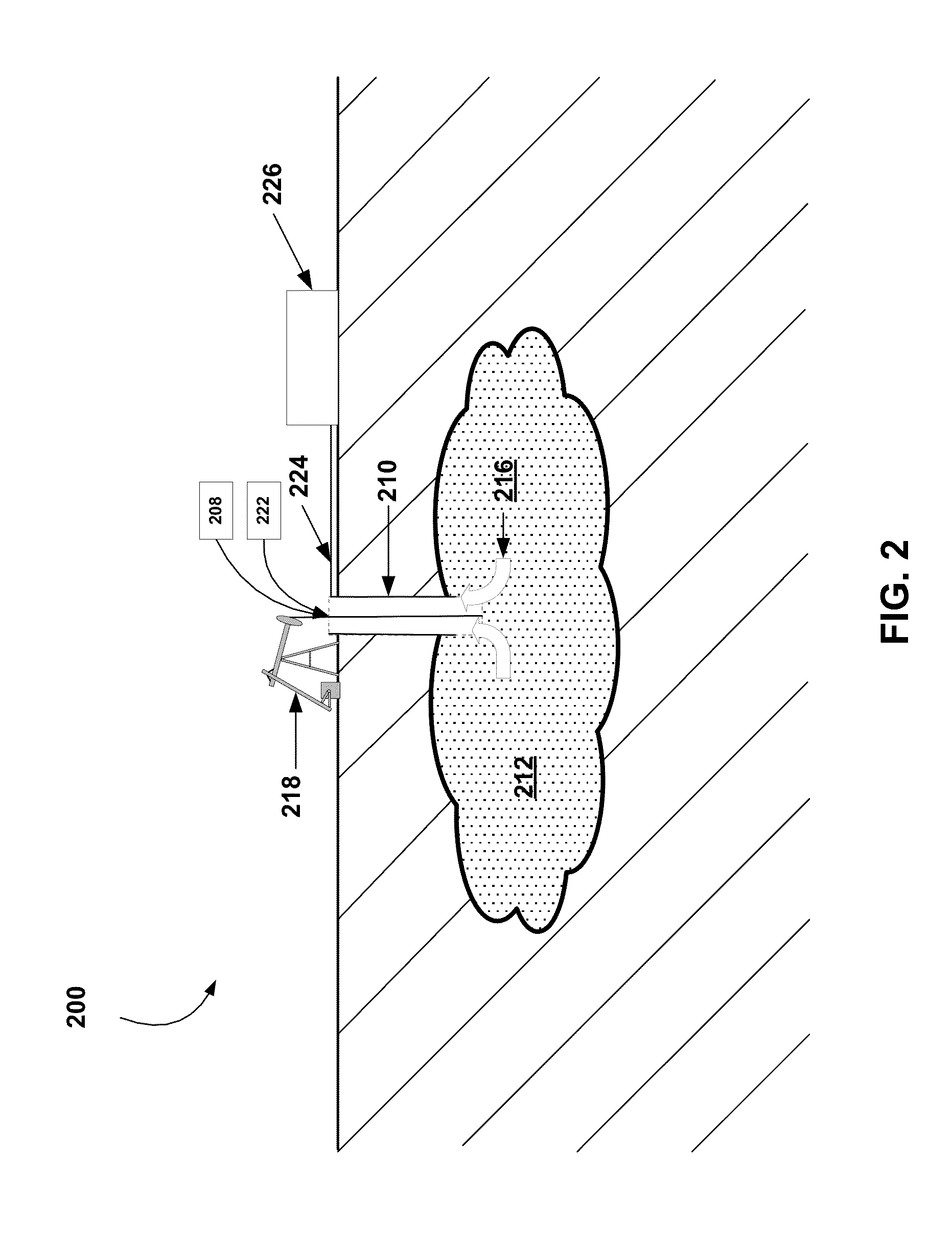

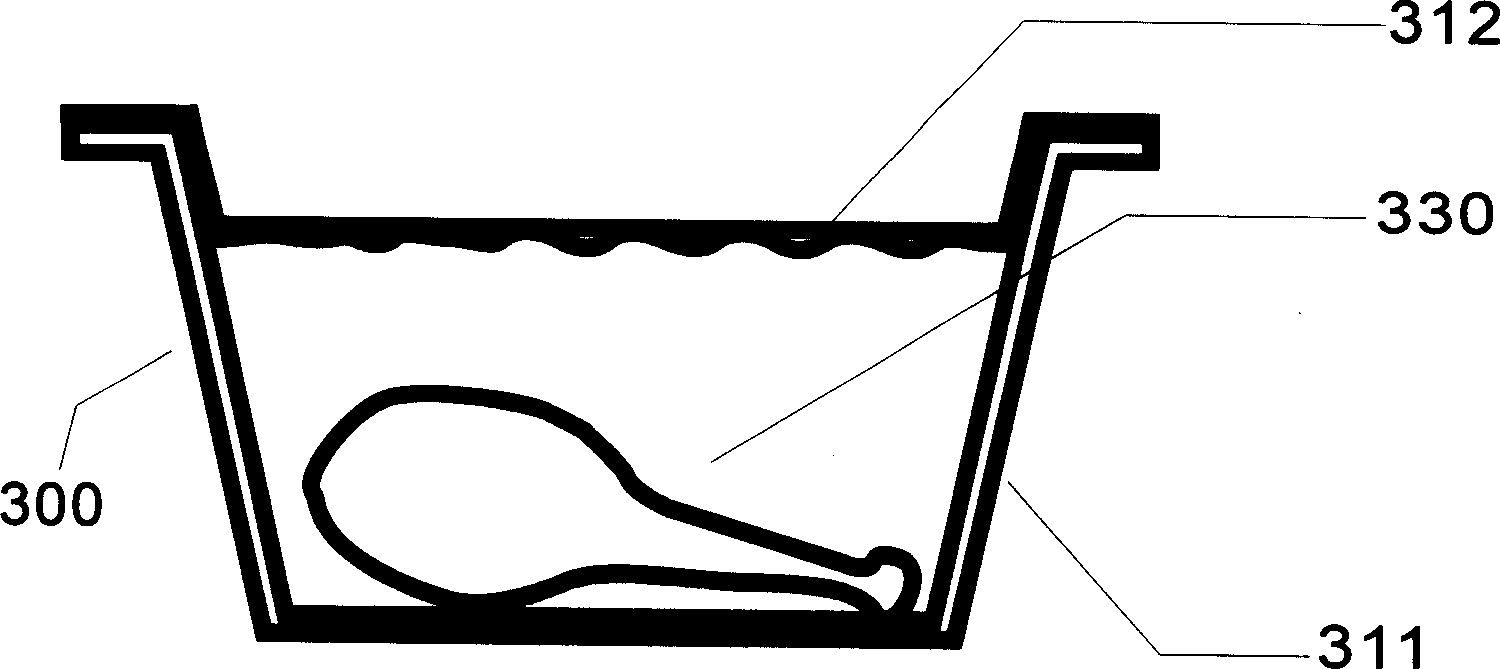

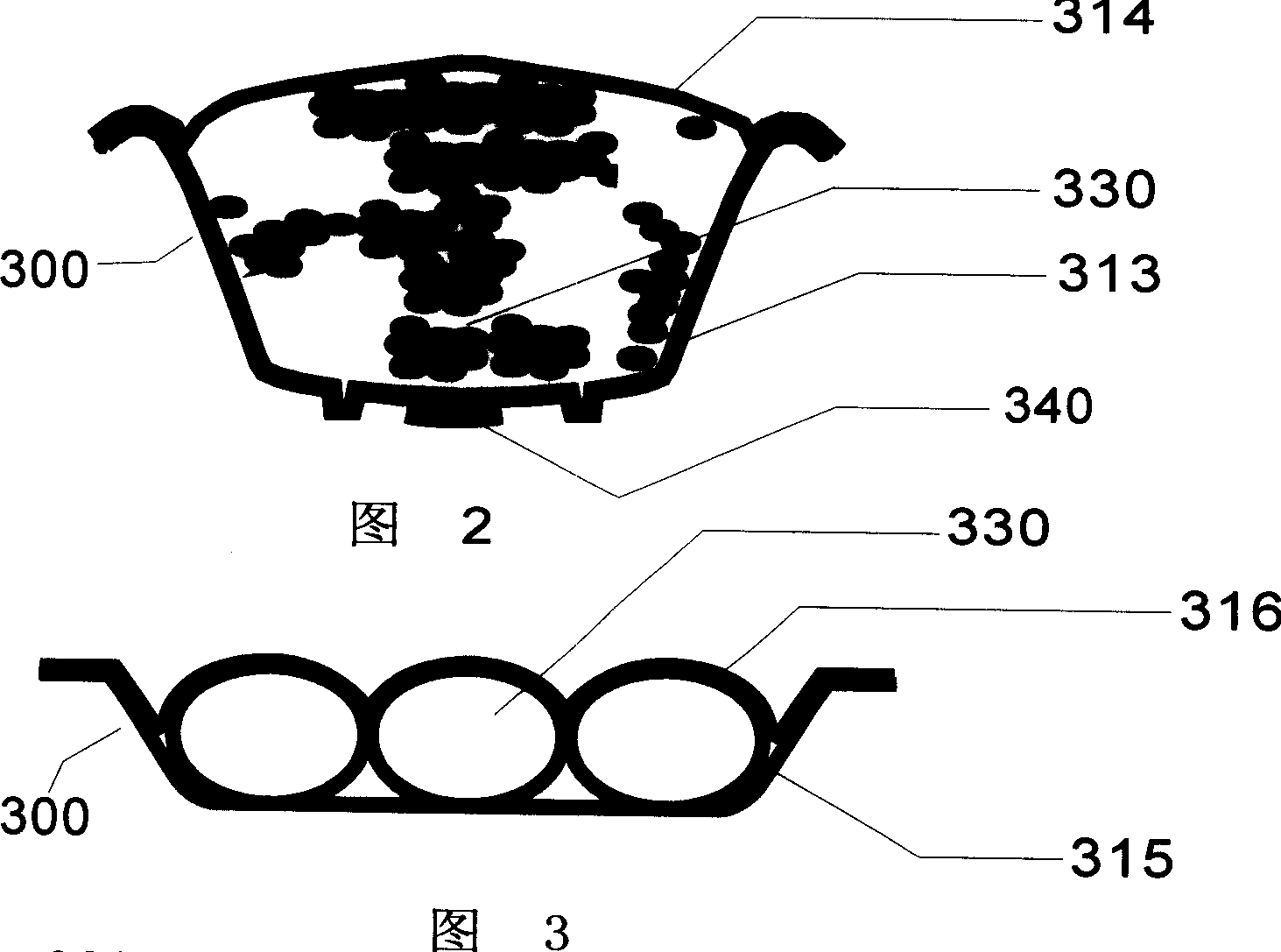

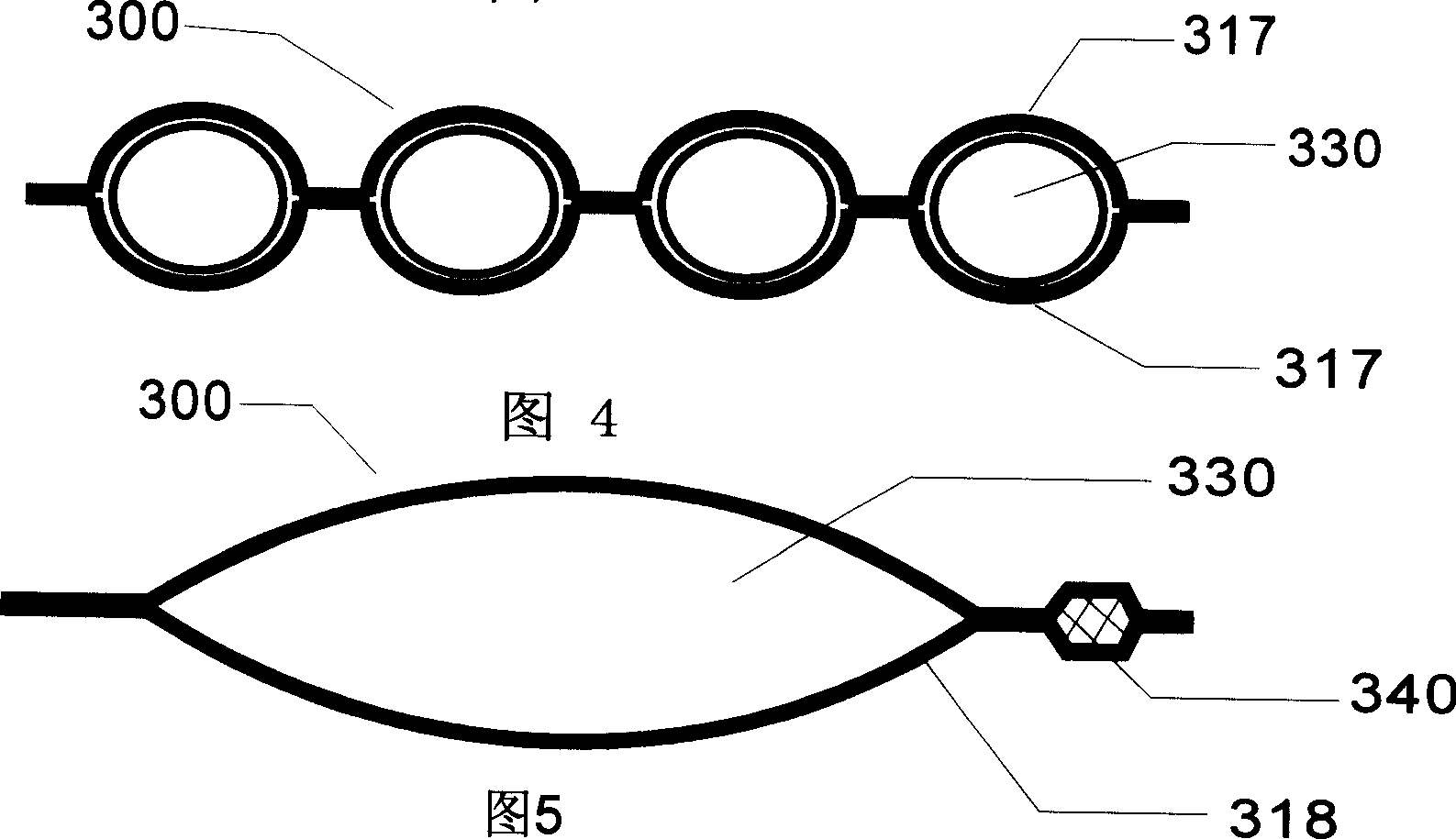

High specific gravity intragastric device

The teachings are directed to an intragastric device comprising a flexible and expandable bladder having a predetermined shape upon expansion for contacting the antrum of the stomach of a subject. The device is designed to avoid passage of any part of the device beyond the pylorus and lower esophageal sphincter while the bladder is expanded during use. In these embodiments, the bladder can contain a high specific gravity material when expanded; wherein, the high specific gravity material contributes to an in vivo specific gravity of the device that ranges from about 1.2 g / ml to about 2.1 g / ml and functions to direct the device to the pyloric antrum of the subject during use of the device. Moreover, these embodiments can include a filling material comprising a biocompatible fluid component and a hydrogel component to make the device substantially leakproof and contribute to the in vivo specific gravity of the device.

Owner:HANCOCK JOHN

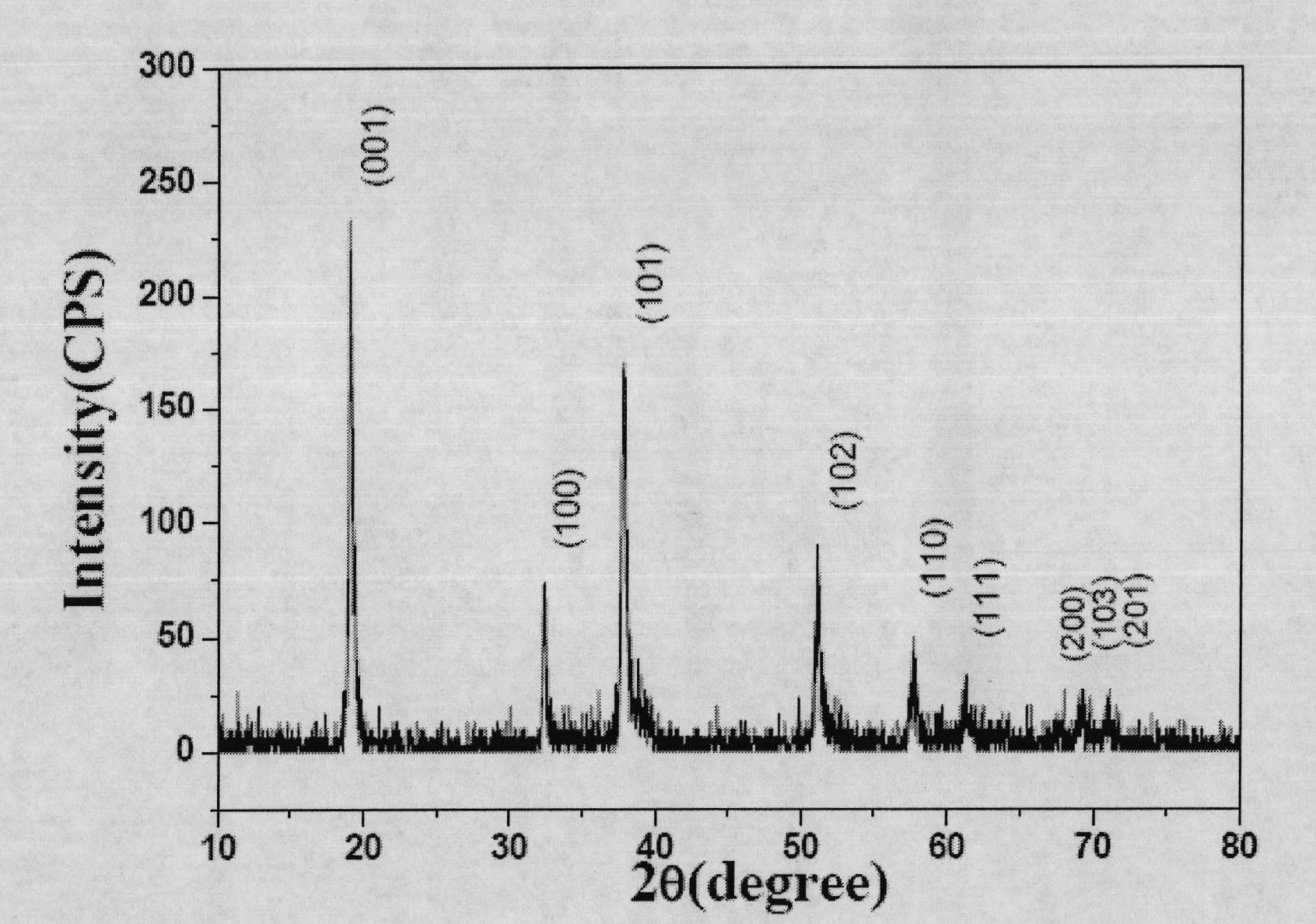

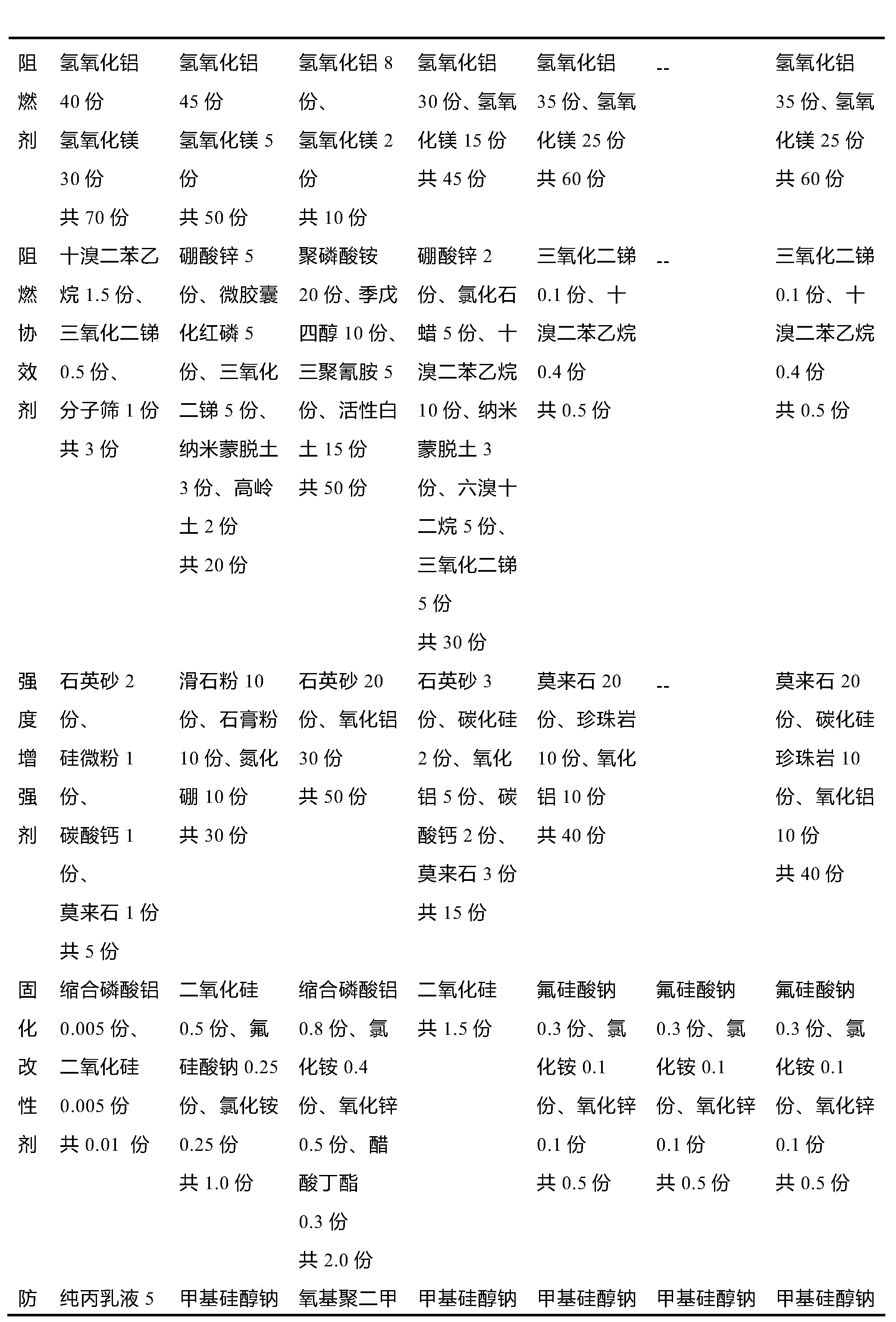

Multicomponent doping spherical lithium iron phosphate anode material and method of manufacturing the same

ActiveCN101369657AImprove conductivityImprove processing behaviorCell electrodesChemical/physical/physico-chemical processesPhosphateMaterials science

The invention provides a multi-doping spherical ferric phosphate lithium anode material and manufacture method thereof, the chemical formula of the anode material is Li1.03-xMgx / 2Fe1-yTiy / 2PO4-z / 2Fz / C, wherein 0<x<=0.1; 0<y<=0.1; 0 <z<=0.1. The anode material according to the invention comprises high unit capacity (>160mAh / g) and compaction proportion (1.45 to 1.75g / cm3), which efficiently enhance conduction ability thereof with excellent unit capacity. The raw material of the anode material according to the invention uses villaumite to reduce reaction activation energy, increase liquidoid during reaction process in order to control product particle feature to obtain spherical particle and enhance compaction proportion, being beneficial to improve manufacture process of electrode paste, simplify preparation and coating of battery paste and process the plate electrode; by being doped with magnesium, titanium and fluorine in the material structure to form semiconductors, the conduction ability of the material can be improved. The invention has simply process, low costs, being convenient to realize industrial manufacture.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Antioxidant, anti-wear and antirust lubricating oil for automobile gear and preparation method thereof

The invention discloses antioxidant, anti-wear and antirust lubricating oil for an automobile gear. The lubricating oil is characterized by being prepared from the following raw materials: base oil, a clearing agent, a dispersing agent, a preservative, an extreme-pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an antirust agent, a pour point depressant and an antifoaming agent, wherein in the base oil of the lubricating oil, the kinematic viscosity below 100 DEG C is 1.5-40mm<2> / s, the viscosity index is over 100, the pour point is below -25 DEG C, and the sulfur content is below 0.01% by mass. The lubricating oil for an automobile gear, disclosed by the invention, has the advantages of simple composition, low cost, relatively good viscosity index, high anti-wear property and long service life; the compatibility between the lubricating oil additive and the base oil is relatively good, and the lubricating oil is of relatively high stability; and compared with existing automobile lubricating oil, the automobile lubricating oil disclosed by the invention has high corrosion resistance, the preparation technology of the lubricating oil is simple, and the steps are simple and environment-friendly and easy to implement.

Owner:高安市超鹰科技有限公司

Hydrophilic carrier for microbial biofilm formation

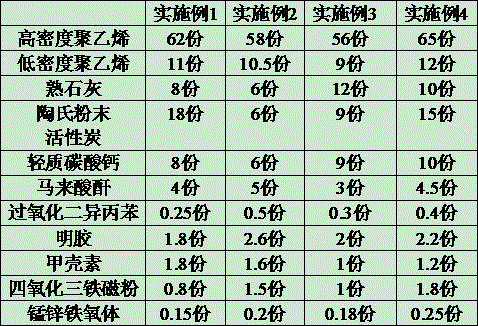

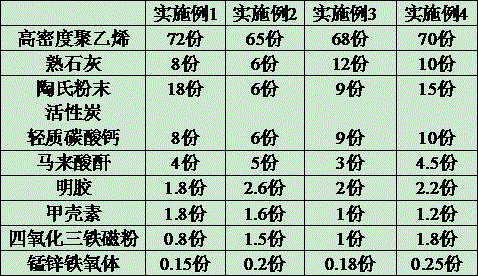

InactiveCN105621595ANot easy to fall offPromote sheddingTreatment with microorganism supports/carriersLow-density polyethyleneMicrobial Biofilms

The invention discloses a hydrophilic carrier for microbial biofilm formation. The hydrophilic carrier comprises a hollow short tube, and a first concentric ring and a second concentric ring which are sequentially concentrically arranged outside the hollow short tube, wherein the surface of the outermost second concentric ring is toothed; and the microbial filler is composed of the following components in parts by weight: high-density polyethylene, low-density polyethylene, white lime, Dow powder activated carbon, light calcium carbonate, maleic anhydride, dicumyl peroxide, gelatin, chitin, ferroferric oxide magnetic powder and manganese-zinc ferrite. The density of the microbial filler is 0.96-0.98 g / cm<3>. The hydrophilic carrier for microbial biofilm formation prolongs the contact time between microbes and organic matters, so that the organic matters are degraded quickly and thoroughly; and the biological oxidation can restore the surface adsorption capacity of the activated carbon.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

Container culture medium prepared from edible fungi residue and production method thereof

InactiveCN102210256ALarge particlesPromote growthCultivating equipmentsSoilless cultivationBiotechnologyPlant roots

The invention relates to a container culture medium prepared from edible fungi residue and a production method thereof, and the container culture medium comprises the edible fungi residue. The container culture medium comprises the following raw materials and auxiliary raw materials in naturally stacked parts by volume: 50-60 parts of the edible fungi residue, 30-70 parts of grass carbon, 0.8-1.2 parts of vermiculite, 0.3-0.7 part of pearlite, 5-20 parts of cake fertilizer, and 2-4 parts of mineral fertilizer. Wood chips, wheat bran, residual mycelia and other larger particles are contained in the edible fungi residue, thereby having higher air porosity and good water retention property and permeability, being more conductive to growth of a plant root system, creating a good rooting zone environment for growth of crops and providing a large number of nutrients for the crops; and the supply of the edible fungi residue is sufficient, and the material can be got from local resources, thereby reducing the production cost of the container culture medium to the maximal extent.

Owner:TIANJIN HONGFENGLIN MIAOMU CULTIVATION PROFESSIONAL COOP

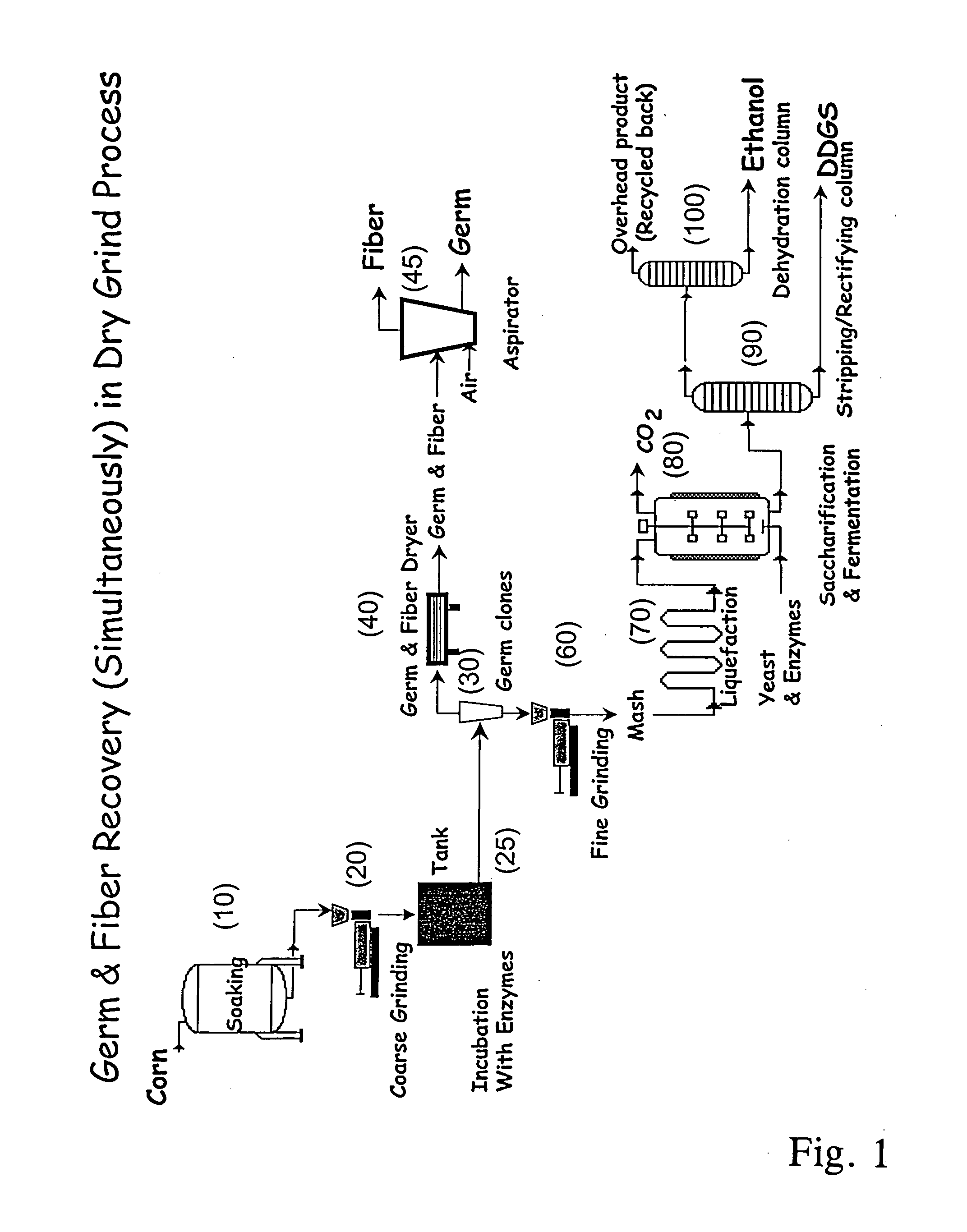

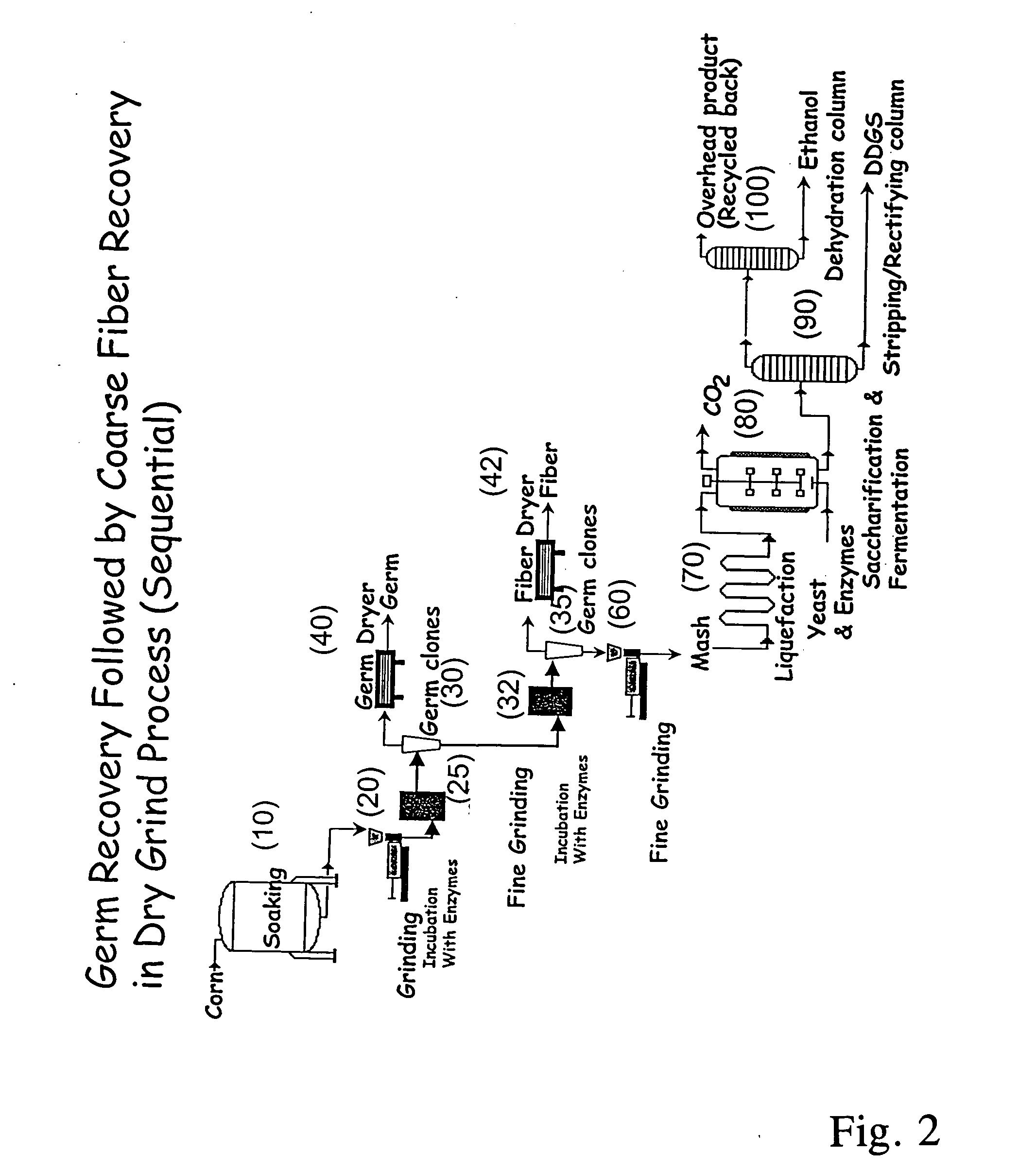

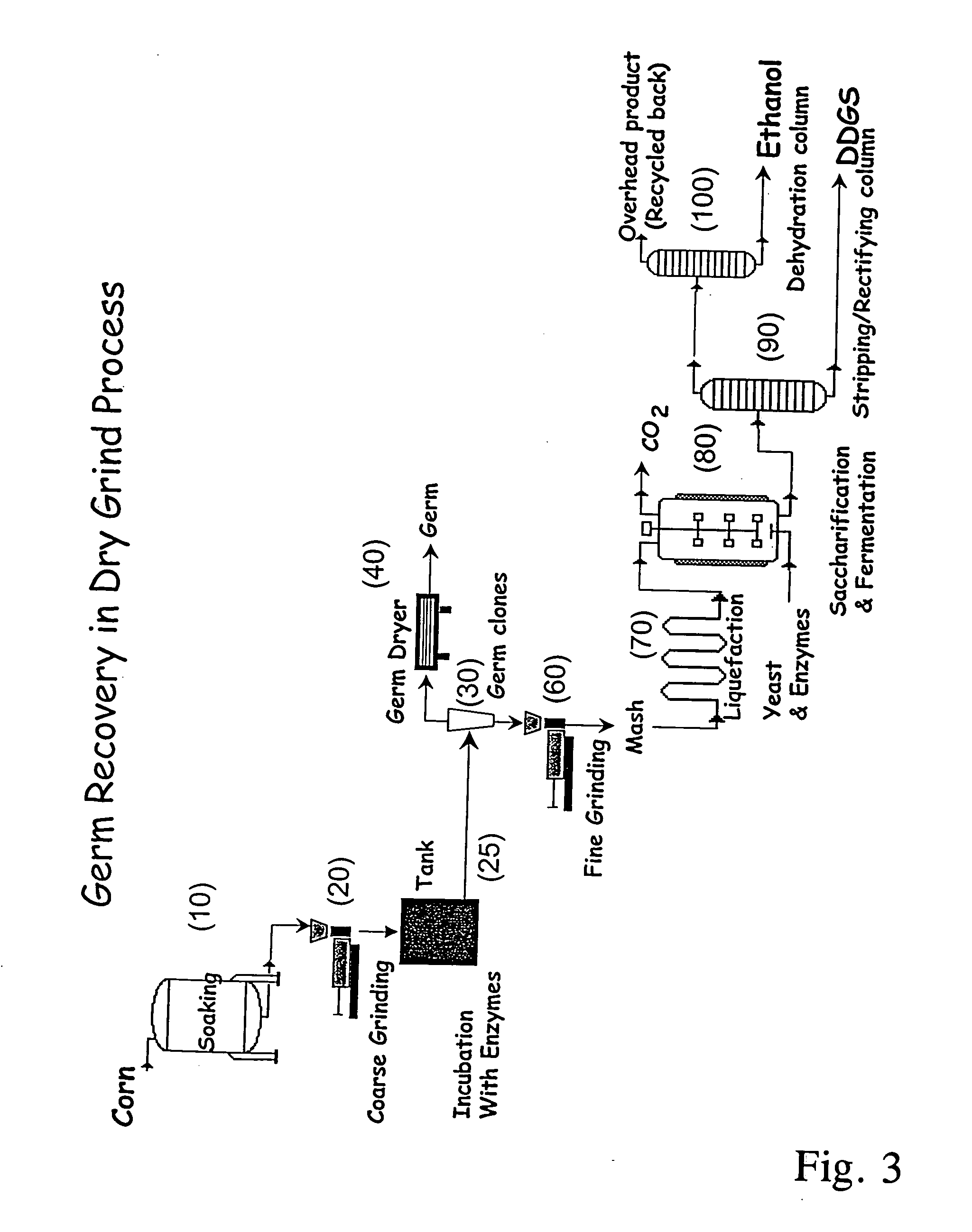

Processes for recovery of corn germ and optionally corn coarse fiber (pericarp)

InactiveUS20050009133A1High specific gravityIncrease gravityGrain huskingGrain polishingAmylaseFiber

A process for recovering corn germ and corn coarse fiber from corn in a dry grind process, involving soaking corn kernels in water to produce soaked corn kernels, grinding the soaked corn kernels to produce a ground corn slurry, and incubating the ground corn slurry with at least one enzyme(amylase(s), protease(s), cell wall degrading enzyme(s), or mixtures thereof, and optionally other enzyme(s)) to increase the specific gravity of the slurry to about 10-about 16 Baume so that the corn germ and corn coarse fiber floats to the top of the slurry, recovering the corn germ and the corn coarse fiber, and optionally producing ethanol from the slurry no longer containing the corn germ and corn coarse fiber. The process does not involve the addition of starch, a salt, a sugar syrup, or mixtures thereof to the slurry.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

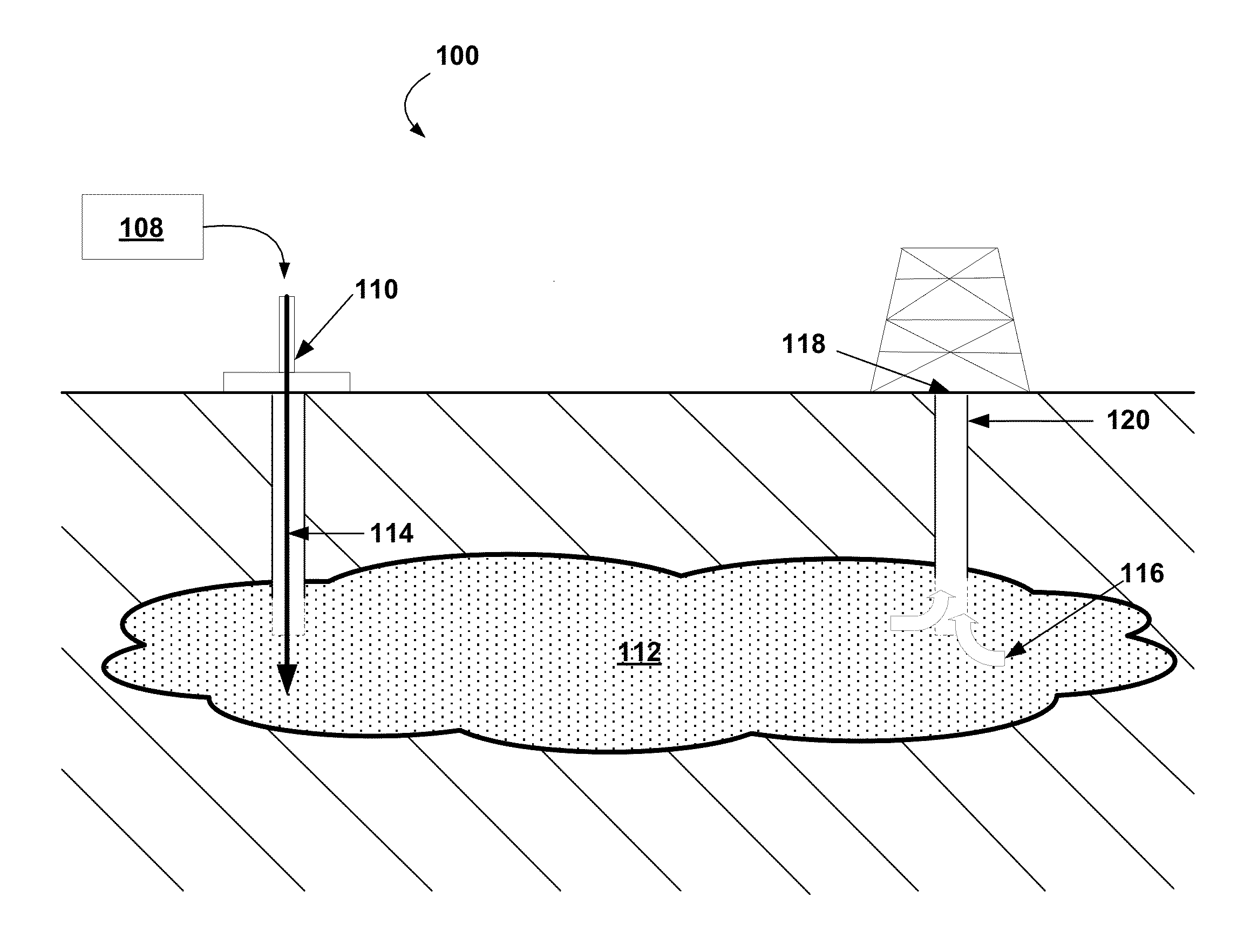

Composition and method for recovering heavy oil

InactiveUS20130045902A1Low viscosityHigh specific gravityFluid removalLiquid hydrocarbon mixture productionSpecific gravityContaminated soils

A chemical composition and methods for use in the recovery of viscous oil and other desired hydrocarbons from subterranean reservoirs and from excavated material comprising oil sands or oil shale, and to remediate contaminated soil and subterranean reservoirs. Adding the composition to viscous oil renders it pipelineable by significantly reducing its viscosity. The chemical composition comprises an alkane, an ether, and an aromatic hydrocarbon. The composition is an organic solvent mixture that interacts highly favorably with non-polar hydrocarbons but is mostly immiscible with water and acts as a diluent, lowering the viscosity and raising the specific gravity of viscous oil. Additional water and heat are not required. Methods of using the composition in subterranean reservoirs and with excavated material including oil sands or oil shale and contaminated soil and subterranean reservoirs needing remediation, are highly efficient, economical, and reduce or eliminate adverse environmental consequences.

Owner:THOMPSON TODD MATTHEW +1

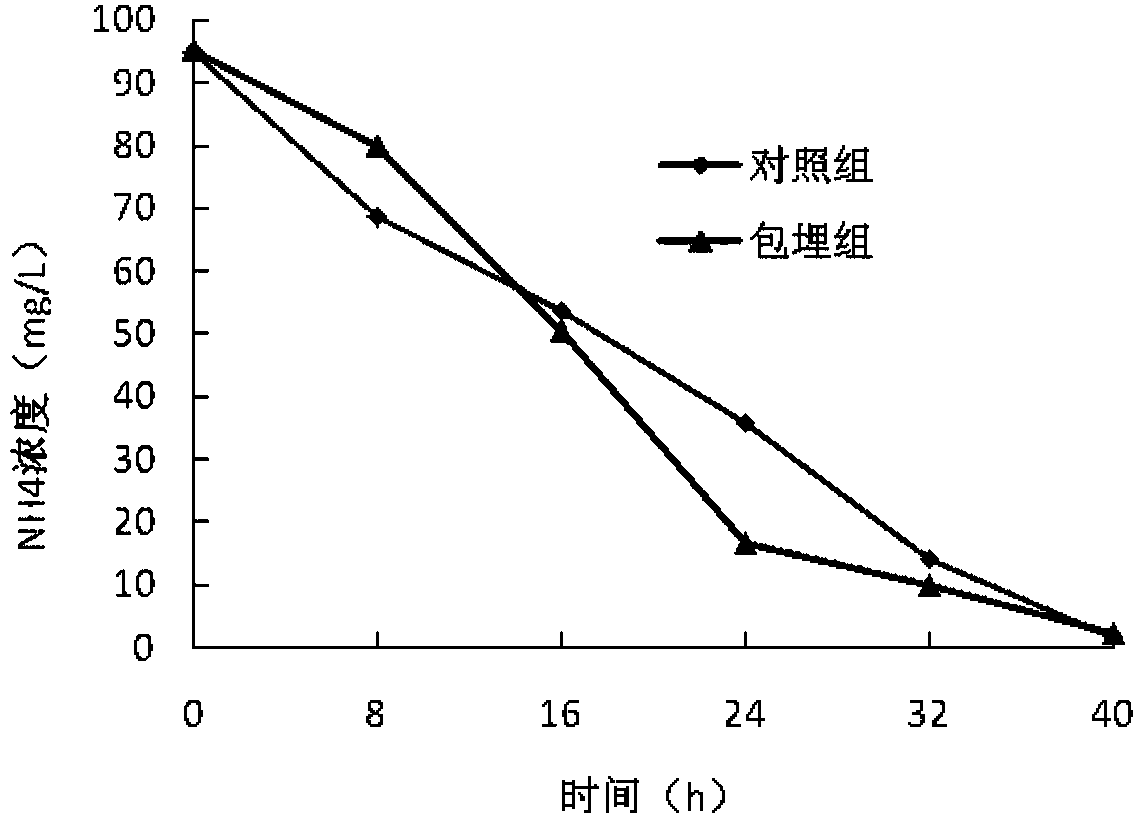

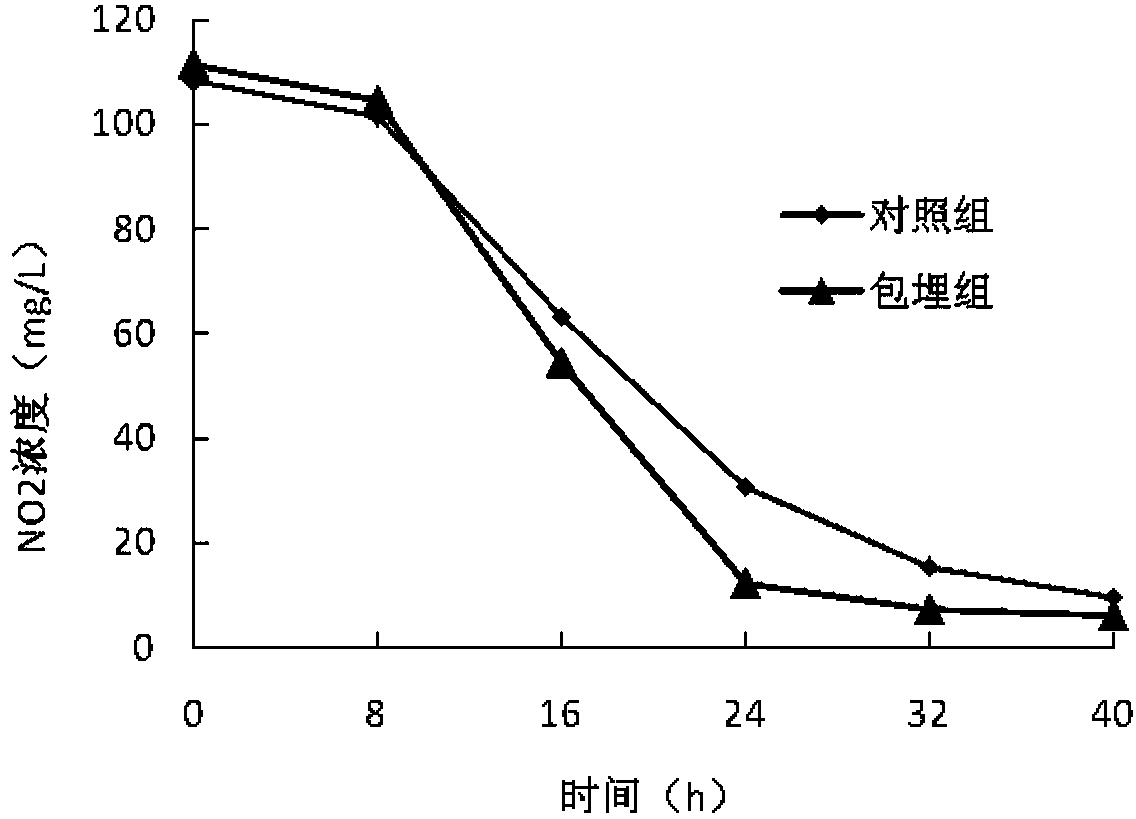

Anaerobic ammoxidation sludge embedding immobilization method

ActiveCN103408133AHigh mechanical strengthPromote swellingSludge treatmentTreatment with anaerobic digestion processesActivated carbonSludge

The invention relates to an anaerobic ammoxidation sludge embedding immobilization method belonging to the field of sewage treatment, and particularly provides a method for performing embedding immobilization on anaerobic ammoxidation sludge by adding magnetic powder and powdered activated carbon. The method comprises the following steps: preparing an embedding agent, mixing anaerobic ammoxidation sludge with the embedding agent, preparing immobilized anaerobic ammoxidation balls, activating the immobilized anaerobic ammoxidation balls and the like. The preparation of the embedding agent comprises the following steps: weighing polyvinyl alcohol (PVA), sodium alginate (SA), powdered activated carbon and magnetic powder, and preparing into a solution, wherein on the basis of percentage in mass, the concentration of the PVA is 6-10wt%, the concentration of the SA is 2-3wt%, the concentration of the powdered activated carbon is 1-2wt%, and the concentration of the magnetic powder is 2-4wt%; and uniformly stirring, thus preparing the mixed embedding agent. The method is simple in preparation process, easy to operate and low in preparation cost; and the prepared embedding immobilization anaerobic ammoxidation balls are high in activity, favorable in stability and suitable for industrial production, and can achieve favorable economic and environmental benefits.

Owner:BEIJING UNIV OF TECH

Suspended filler for quick biofilm culturing of microorganisms

InactiveCN105461083AFast film formationImprove processing efficiencyWater contaminantsSustainable biological treatmentBiocompatibility TestingBiology

The invention discloses a suspended filler for quick biofilm culturing of microorganisms. The suspended filler is prepared from, by weight, 65-75 parts of high-density polyethylene, 5-15 parts of slaked lime, 5-20 parts of Dow powdered activated carbon, 6-10 parts of light calcium carbonate, 3-5 parts of maleic anhydride, 0.2-0.6 part of dicumyl peroxide, 1.5-3 parts of gelatin, 1-2 parts of chitin, 0.8-2 parts of ferroferric oxide magnetic powder and 0.1-0.3 part of manganese zinc ferrite. The density of the suspended filler for quick biofilm culturing of microorganisms is 0.96-0.98 g / cm3. The biofilm culturing speed is high, disengagement does not occur easily, treatment efficiency is high, and the suspended filler is suitable for treating low-concentration organic matter and ammonia nitrogen in sewage and low-concentration organic waste water. The suspended filler has extremely high hydrophilia and biocompatibility, the filler has high adsorption strength on biological films, biofilm culturing time is remarkably shortened, and the COD and ammonia nitrogen removal rate is increased remarkably.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

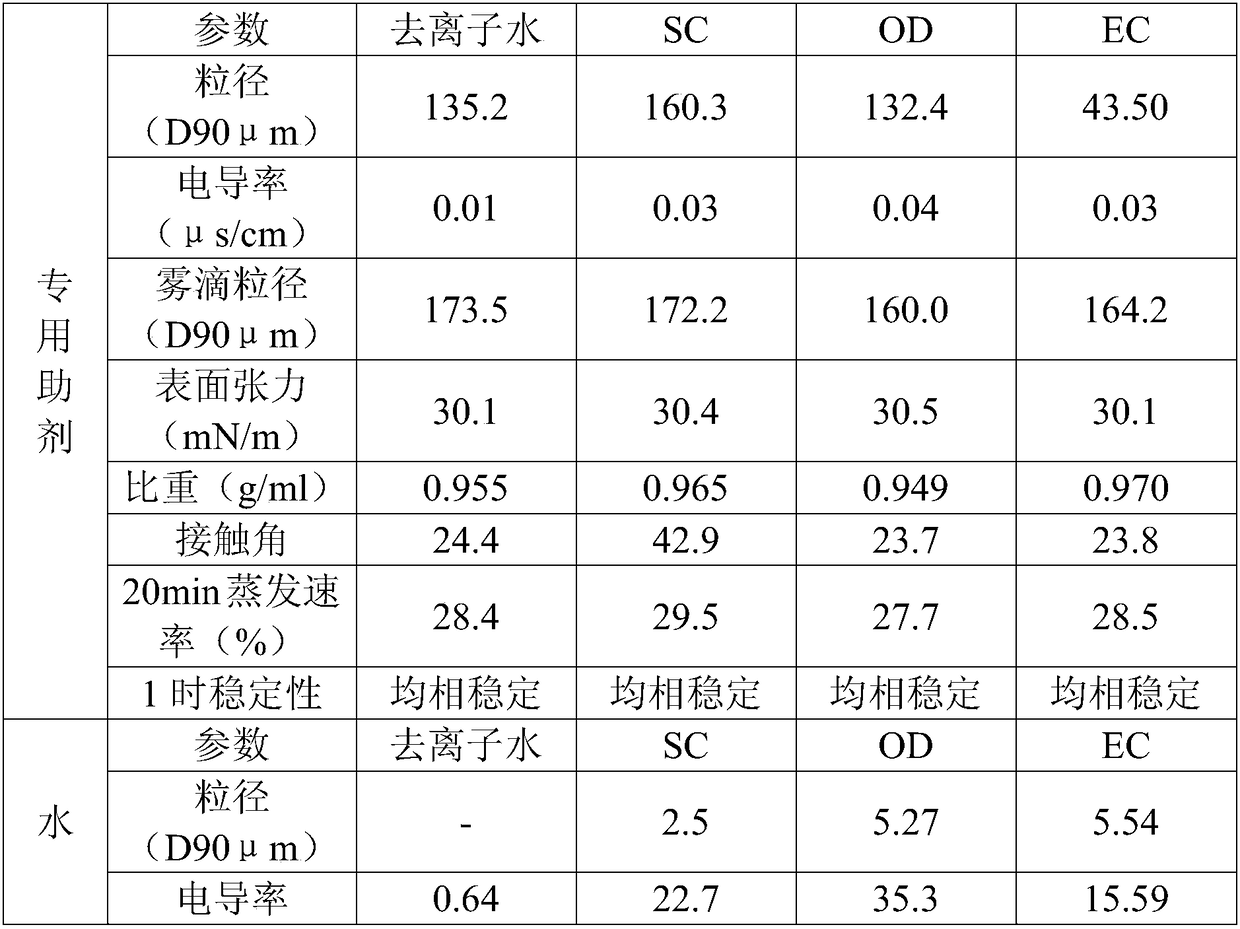

Air control spray additive as well as preparation method and application thereof

ActiveCN109430262AReduce bouncing effectHigh specific gravityBiocideAnimal repellantsOil phaseWater in oil emulsion

The invention discloses an air control spray additive as well as a preparation method and an application thereof and belongs to the technical field of pesticide preparations and pesticide application.The air control spray additive comprises 70-94% of plant oil, 5-20% of an emulsifier and 1-10% of a co-emulsifier in percentage by mass; during preparation of a spray liquid, the additive is mixed with a pesticide and water, wherein the oil and water form an emulsion (turbid) liquid in the water-in-oil form under an effect of the emulsifier and the co-emulsifier; active ingredients in the pesticide preparation are uniformly dispersed in oil phase or water phase of oil-based emulsion (turbid) liquid, and is sprayed by using a hydraulic or centrifugal nozzle to form water-in-oil fog drops withmedium particle sizes; therefore, the influence of excessive oil on leaf surfaces of crops is reduced; the fog drops rapidly spread during moving to the surfaces of plants so that the interference ofa wind field generated by rotors of an unmanned aerial vehicle to settlement and adhesion behaviors of the fog drops can be obviously reduced; after water is added, the water-in-oil emulsion liquid isformed to improve the specific weight of the additive, accelerate the settlement of the fog drops and reduce the drifting of the fog drops.

Owner:ZHEJIANG UNIV

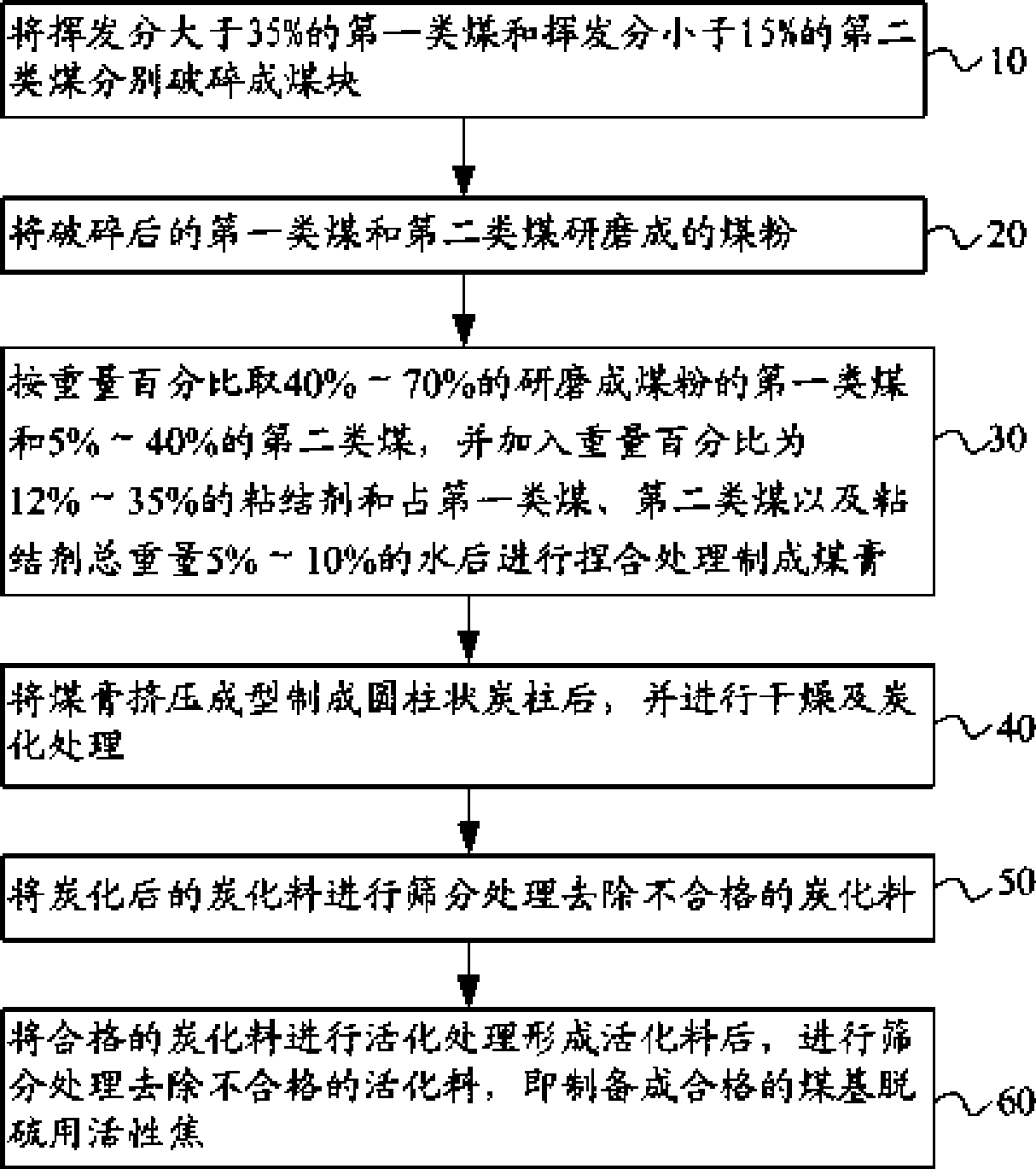

Coal-based activated coke for desulfuration and preparation method thereof

ActiveCN101485972AHigh activation yieldHigh specific gravityOther chemical processesCoal briquetteCoal

The invention relates to a method for preparing active coke for coal based desulfurization. The method comprises the following steps: crushing the first-class coal and the second-class coal into coal briquettes respectively; grinding the coal briquettes into pulverized coal; picking up the coal which is ground into the pulverized coal, adding a binder and water, and subjecting the mixture to kneading treatment to obtain coal paste; after forming the coal paste by extrusion to obtain a cylindrical charcoal column, drying and charring the charcoal column; screening the charring material which is charred to remove the unqualified charring material; and activating the qualified charring material to form an activated material, namely preparing the qualified active coke for coal based desulfurization. In the method, the first-class coal with low added-value and the second-class coal with high added-value are used to prepare macro-aggregate active coke products particularly for fume desulfurizatio with the advantages of low production cost, desirable quality, obvious desulfurizatio effect and strong market competitive power.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

Resin Composition for Manufacturing Marble Chips, Method for Manufacturing Marble Chips, and Artificial Marble Made From Marble Chips

InactiveUS20100311867A1Good chemical resistanceUniform chip distributionFilm/foil adhesivesMulticolor effect coatingsEpoxyHeat resistance

Provided are a resin composition for the manufacture of marble chips including a halogenated epoxy resin binder and showing high heat resistance, high chemical resistance, high impact resistance, high specific gravity and high transparency, a marble chip manufacturing method using the resin composition and an artificial marble made from marble chips.

Owner:KIM YOUNG MIN

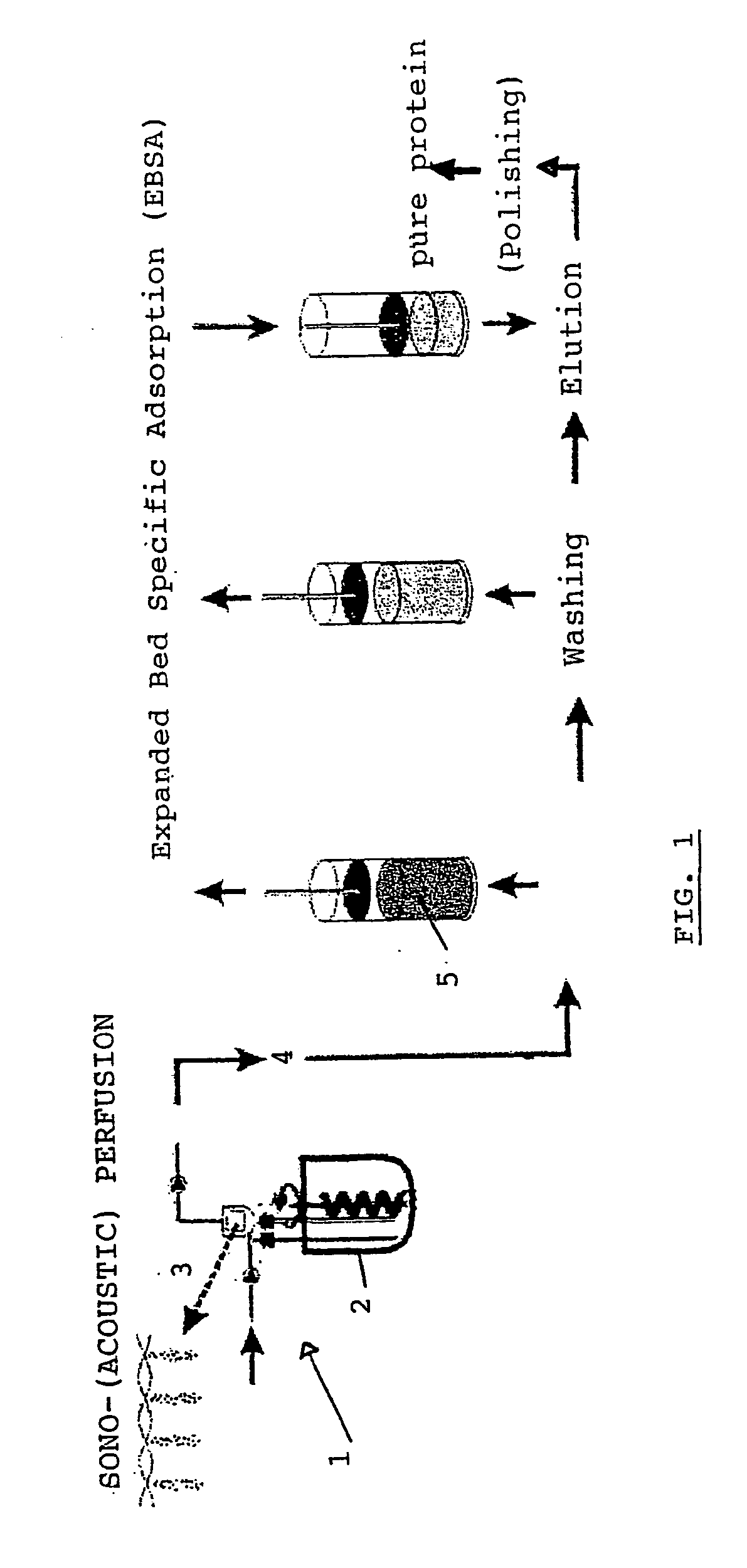

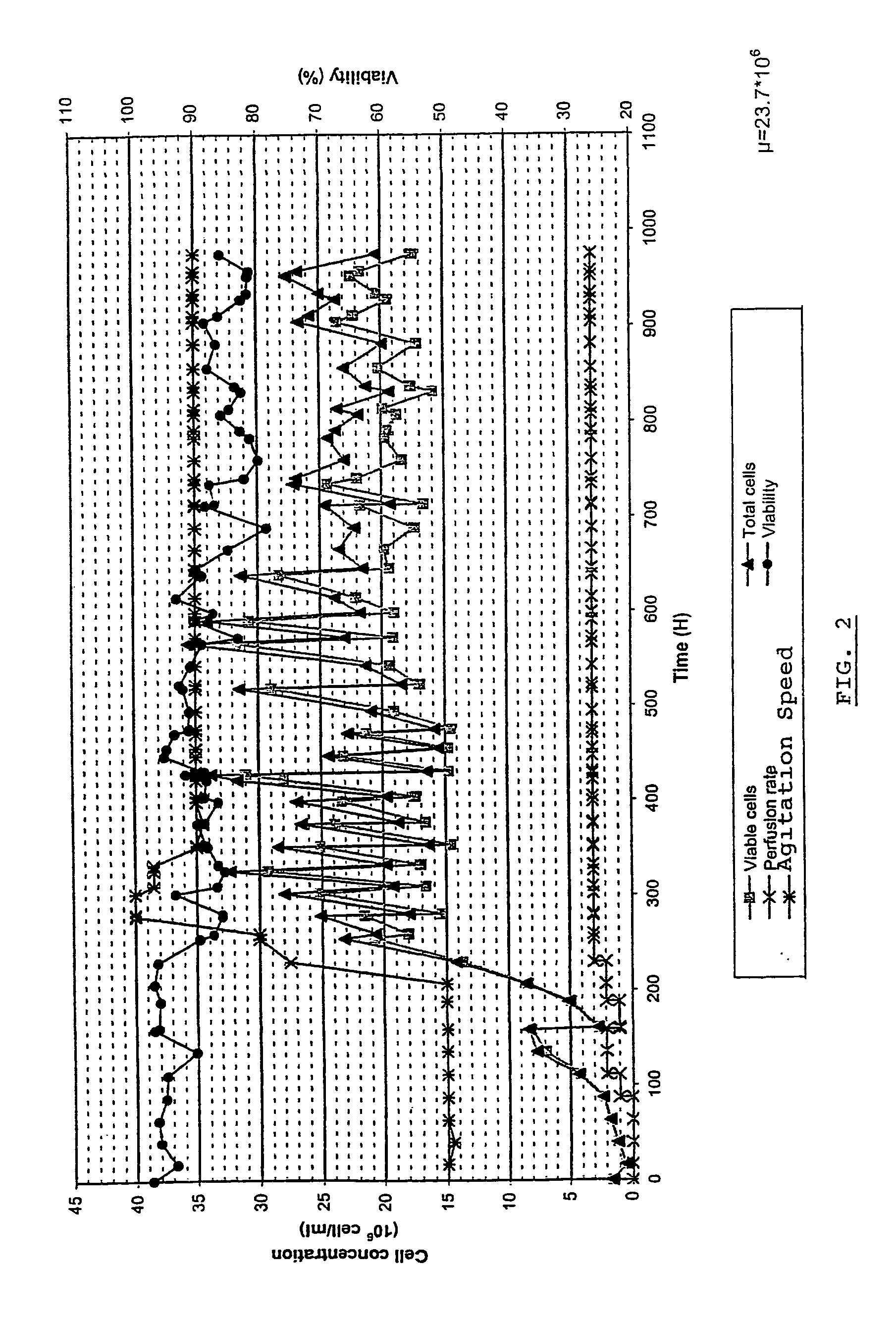

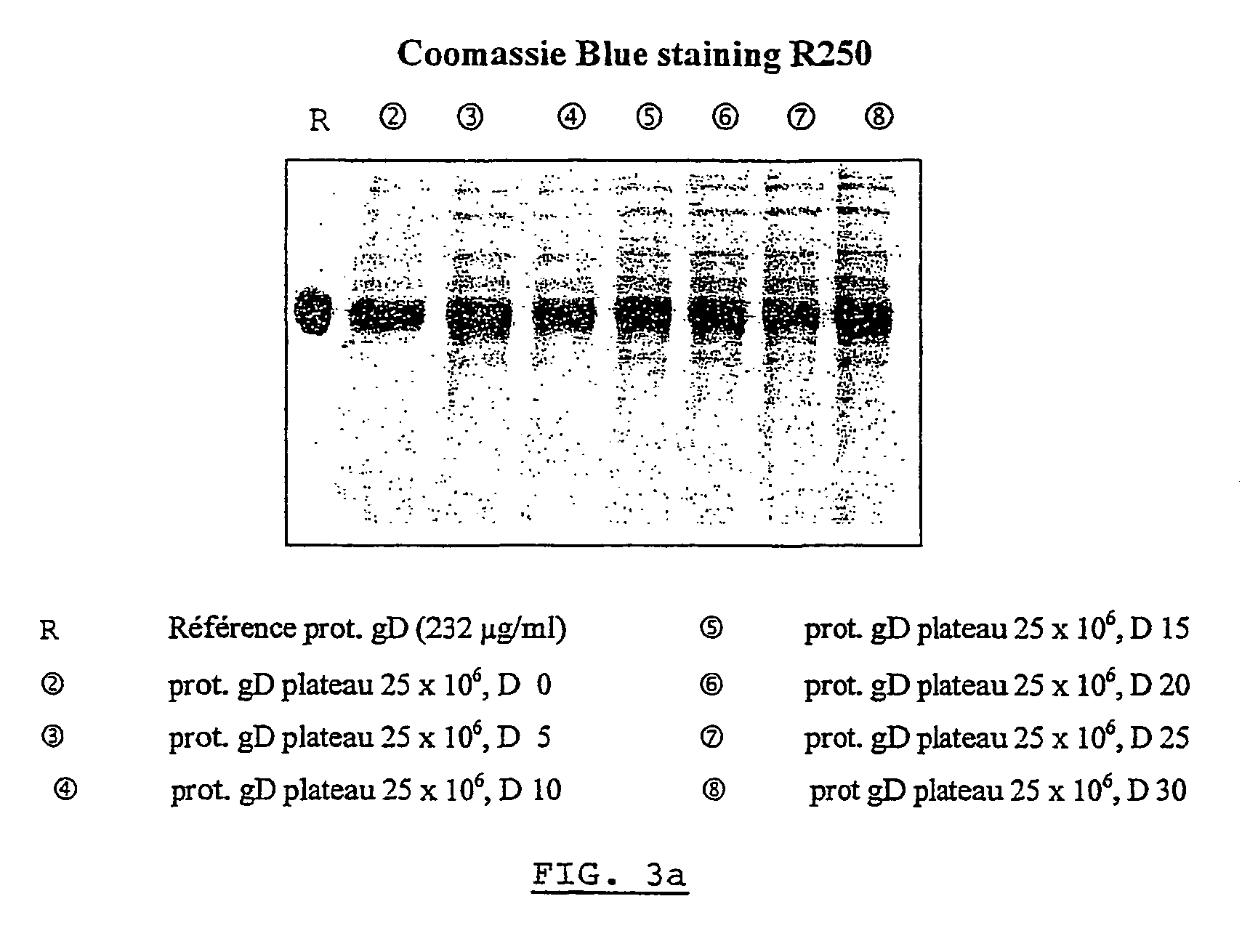

Integration of high cell density bioreactor operation with ultra fast on-line downstream processing

InactiveUS20040033562A1High yieldHigh purityBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion CultureHigh cell

The present invention is related to a recovery and purification method of (a) biological(s) of interest produced by cells retained in a bioreactor under appropriate conditions and by appropriate means for producing the biological(s) inside the bioreactor having a volume higher than 1,5 l culture, and cultivated at a high cell density, preferably at a cell density higher than 10x10<6 >cells / ml, said bioreactor being submitted to an acoustic sonoperfusion allowing the recovery of a sonoperfused medium from said bioreactor, characterised in that it is submitted thereafter directly to an Expanded Bed Specific Adsorption for the direct recovery and uninterrupted purification of said biological(s). The present invention is also related to a process unit for recovering and purifying said biological(s) of interest.

Owner:COMP CELL CULTURE CENT SA +1

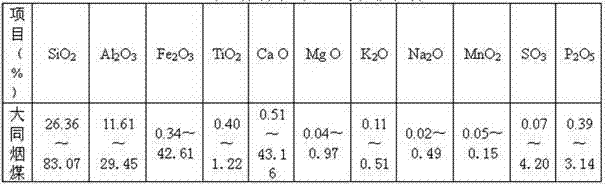

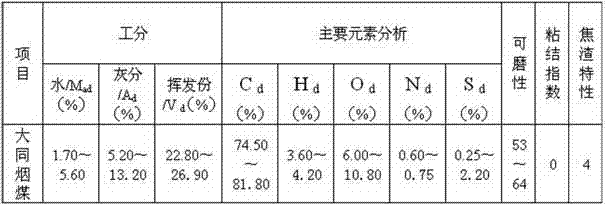

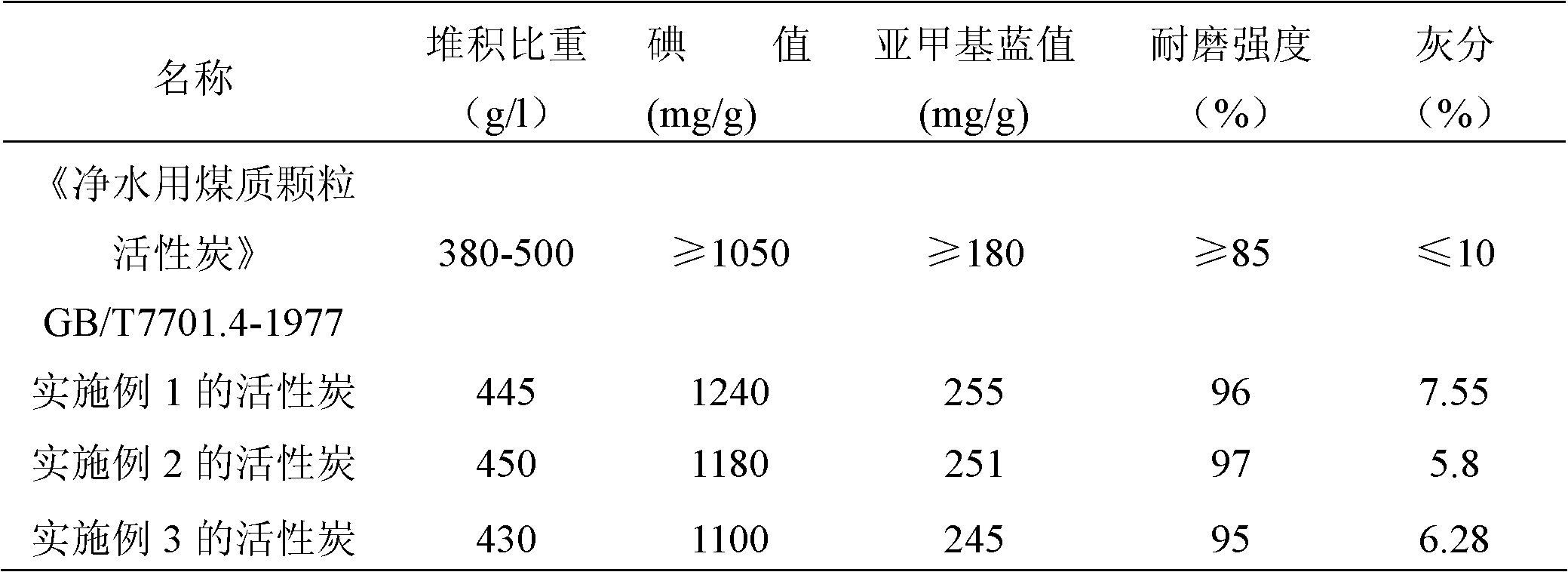

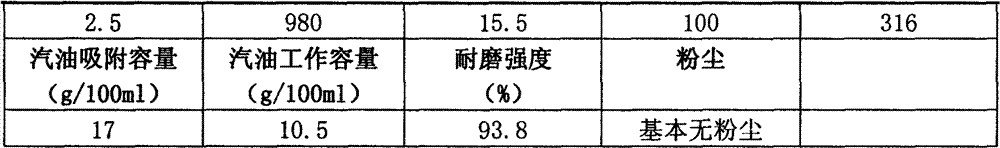

Method for producing drinking water deep purification activated carbon by utilizing Datong coal

InactiveCN102530938ASimple processReduce manufacturing costCarbon compoundsActivated carbonPotable water

The invention relates to a method for producing briquetting activated carbon, in particular to a method for producing drinking water deep purification activated carbon by utilizing Datong coal, which solves the problems of complex method, high product production cost and unstable performance of existing briquetting activated carbon production. The method utilizes the Datong bituminous coal as raw material coal and comprises the steps of crushing (achieving crushing of the Datong bituminous coal into granularity of 3-5mm), powder grinding (above 99% of powder particles needing to pass through a screen with 200 meshes), briquetting (achieving briquetting forming under the pressure of 20-30 MPa), carbonization (achieving the carbonization at the temperature of 500-700 DEG C for 30-90 minutes with temperature rising speed of 2-10 DEG C / min), activation (achieving the activation at the temperature of 700-950 DEG C for 180-270 minutes with water vapor as activator) and screening. The method breaks through the limitation that coal blending and addition of additive are carried out on raw materials of the briquetting activated carbon at home when the briquetting activated carbon is produced, has stable performance, and is suitable for deep purification of drinking water.

Owner:DATONG COAL MINE GRP

Instant meal producing, storing and transporting process and apparatus

InactiveCN1810583AEasy to put inHigh specific gravityFood preservationContainers preventing decaySalt waterProcess engineering

The instant meal producing, storing and transporting process includes the following steps: making and packing staple food, dishes, dish mate separately to form several sealed packages; providing container capable of holding high temperature water at 55-95 deg.c, container capable of holding low temperature water at 5-10 deg.c and container capable of holding low temperature salt water at -5 to +10 deg.c; setting the food in corresponding containers; sealing the containers to form the instant meal; storing or transporting. The instant meal producing, storing and transporting apparatus includes package for instant meal, container capable of holding high temperature water at 55-95 deg.c, container capable of holding low temperature water at 5-10 deg.c and container capable of holding low temperature salt water at -5 to +10 deg.c.

Owner:余姚市三宜食品机械工贸有限公司

Active carbon for deeply purifying drinking water and preparation method thereof

ActiveCN102432004AAbundant resourcesSimple processSilicon compoundsWater/sewage treatment by sorptionActivated carbonCarbonization

The invention discloses active carbon for deeply purifying drinking water and a preparation method thereof. The method comprises the following steps: (1) mixing anthracite and coking coal, and successively crushing and milling to obtain mixed powder; (2) briquetting the mixed powder to obtain a block material; and (3) carrying out carbonization and activation on the block material to obtain the active carbon. The active carbon for deeply purifying drinking water and the preparation method using anthracite as a main raw material aim at the disadvantages of products and production methods in the prior art and combine the domestic current situation of raw material coal resources. The prepared active carbon has the advantages of good performance, low cost, and good effect of deeply purifying the drinking water, and is top grade active carbon for deeply purifying drinking water.

Owner:CCTEG CHINA COAL RES INST

Suspended microbial packing for wastewater treatment and preparation method thereof

InactiveCN105481083AFast film formationNot easy to fall offWater treatment compoundsTreatment with microorganism supports/carriersMaleic anhydrideBiomass

The invention discloses suspended microbial packing for wastewater treatment and a preparation method thereof. The suspended microbial packing is prepared from, by weight, 65-75 parts of high density polyethylene, 5-15 parts of slaked lime, 5-20 parts of Dow powdered activated carbon, 6-10 parts of light calcium carbonate, 3-5 parts of maleic anhydride, 1.5-3 parts of gelatin, 1-2 parts of chitin, 0.8-2 parts of ferromagnetic oxide powder and 0.1-0.3 part of manganese zinc ferrite. The suspended microbial packing is high in film formation speed, not prone to fall off, high in treatment efficiency and suitable for treatment of low-concentration organic matter and ammonia nitrogen in sewage and low-concentration organic wastewater. The biological packing has the extremely high hydrophilicity and biocompatibility, has the very high adsorption strength to a biological film and is beneficial for interception and accumulation of biomass on a packing carrier, and therefore the packing can better adapt to wastewater treatment under the low concentration condition.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

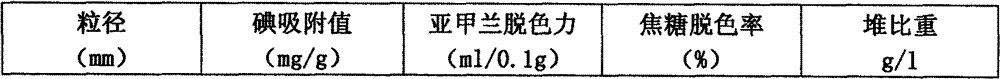

Method for producing active carbon for gasoline vapor adsorption

InactiveCN102698724AIncrease weight absorption capacityReduce working volumeOther chemical processesCarbon compoundsPhosphoric acidMechanical wear

The invention discloses a method for producing active carbon for gasoline vapor adsorption. The method comprises the steps of: taking other wood material containing carbon as raw materials, and taking zinc chloride, phosphoric acid and the like as activating agents, and mixing, kneading, extruding, drying, activating, soaking and conducting other steps to prepare a finished product. According to the method disclosed by the invention, bulk specific weight can be improved effectively, namely the weight adsorption amount of the carbon is improved, so that the gasoline adsorption amount of the active carbon for gasoline vapor adsorption can be improved to be 16g / 100ml; the displacement volume is improved to be 9g / 100ml; the working volume of an adsorption plant is reduced; the application range is expanded; the abrasive resistance of the active carbon for gasoline vapor adsorption is improved to be over 93%; mechanical wear of the active carbon in the using process is reduced; the operating life is prolonged; the floating dust on the surface of the active carbon is basically removed; airflow resistance is reduced, and the method is not only used for gasoline vapor adsorption, but also suitable for recovery of benzene and high-boiling point solvents.

Owner:淮北市大华环保科技有限公司

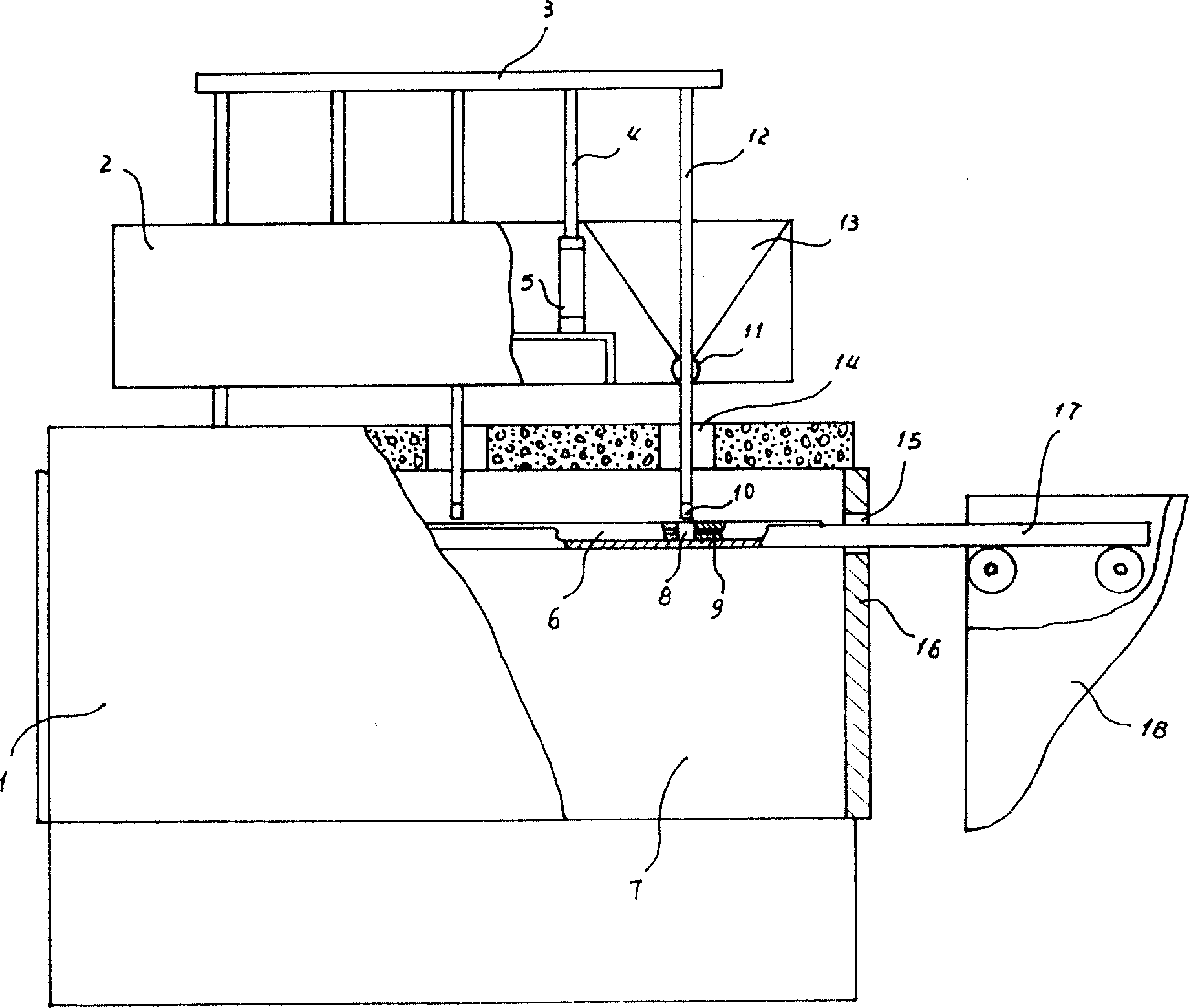

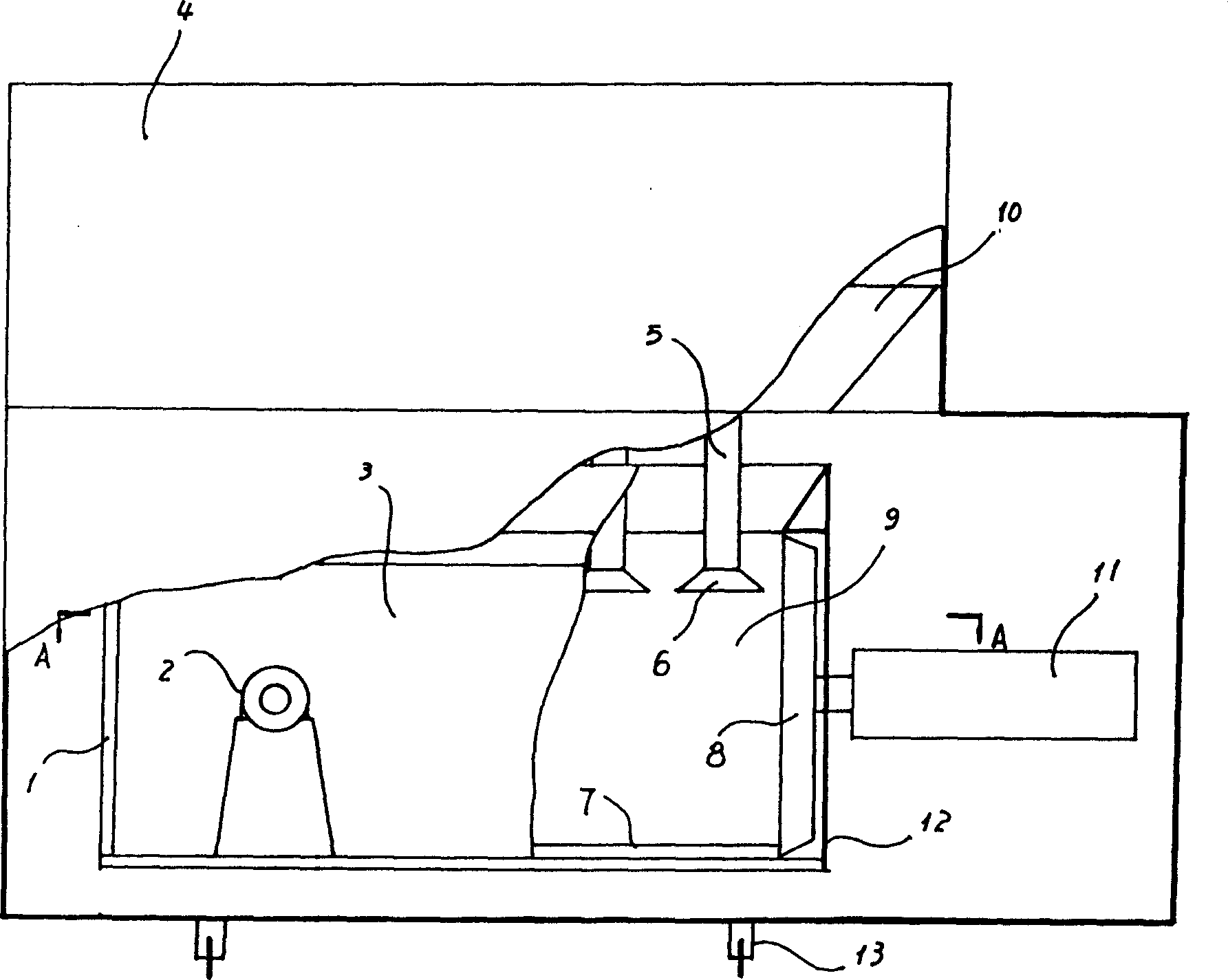

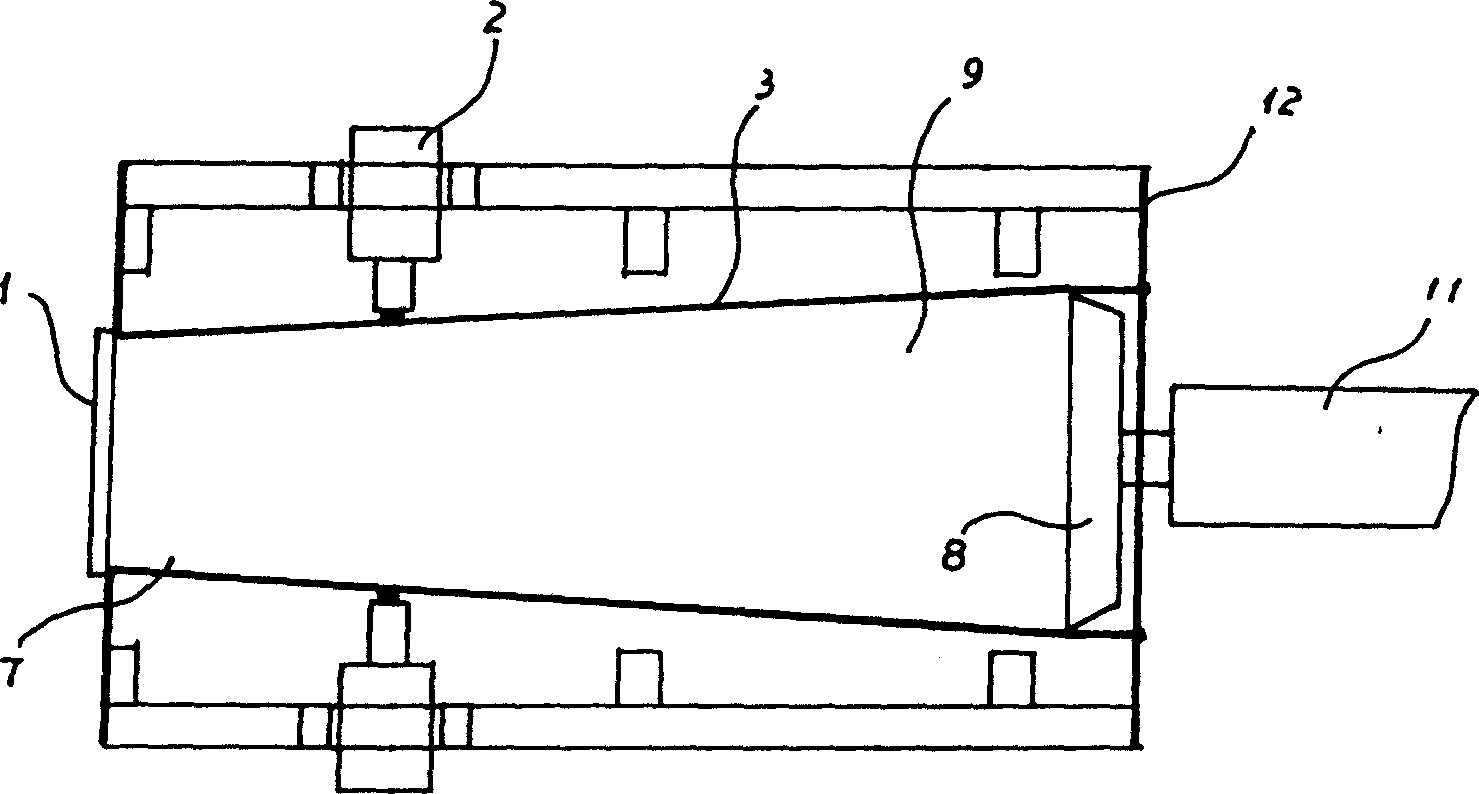

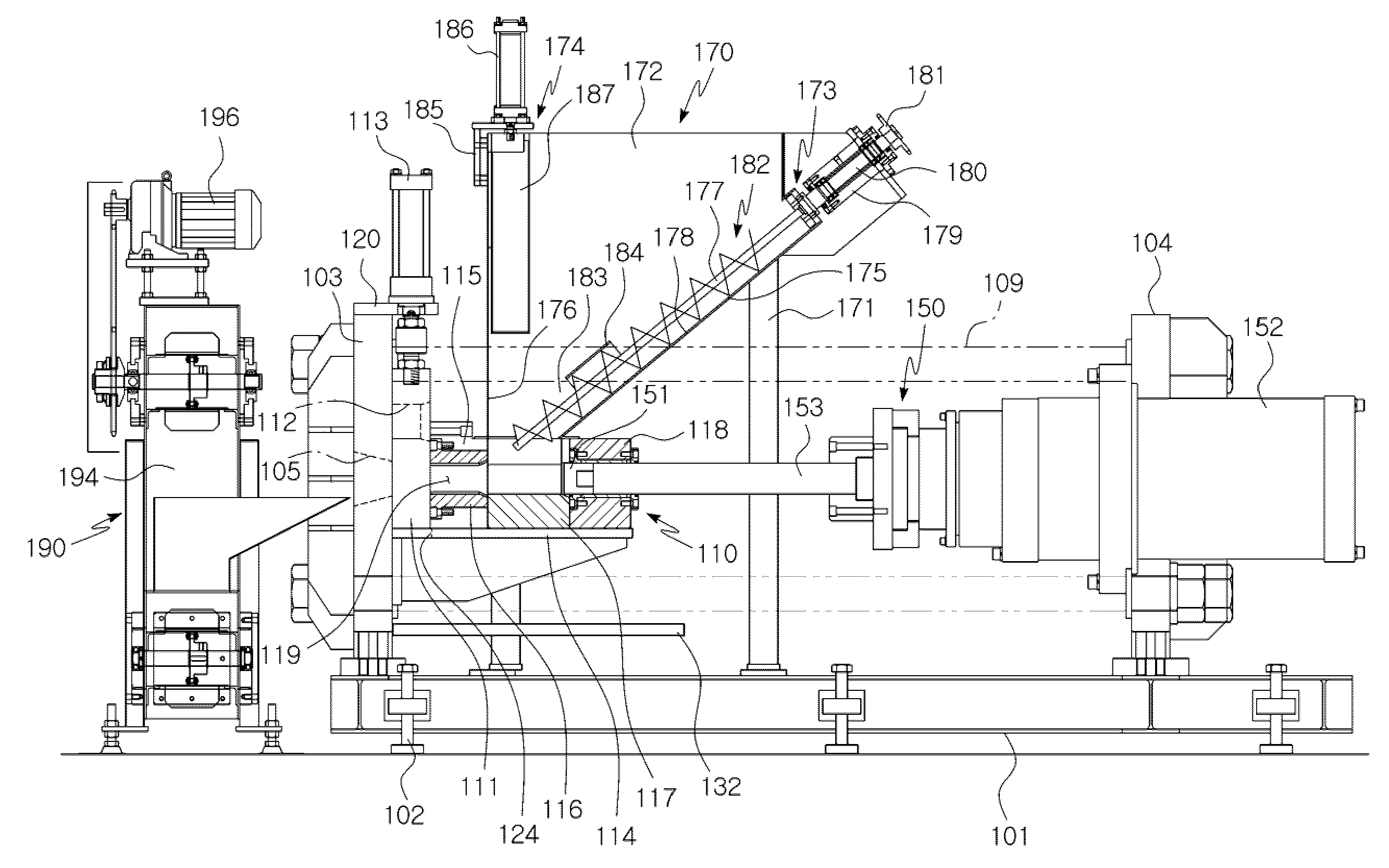

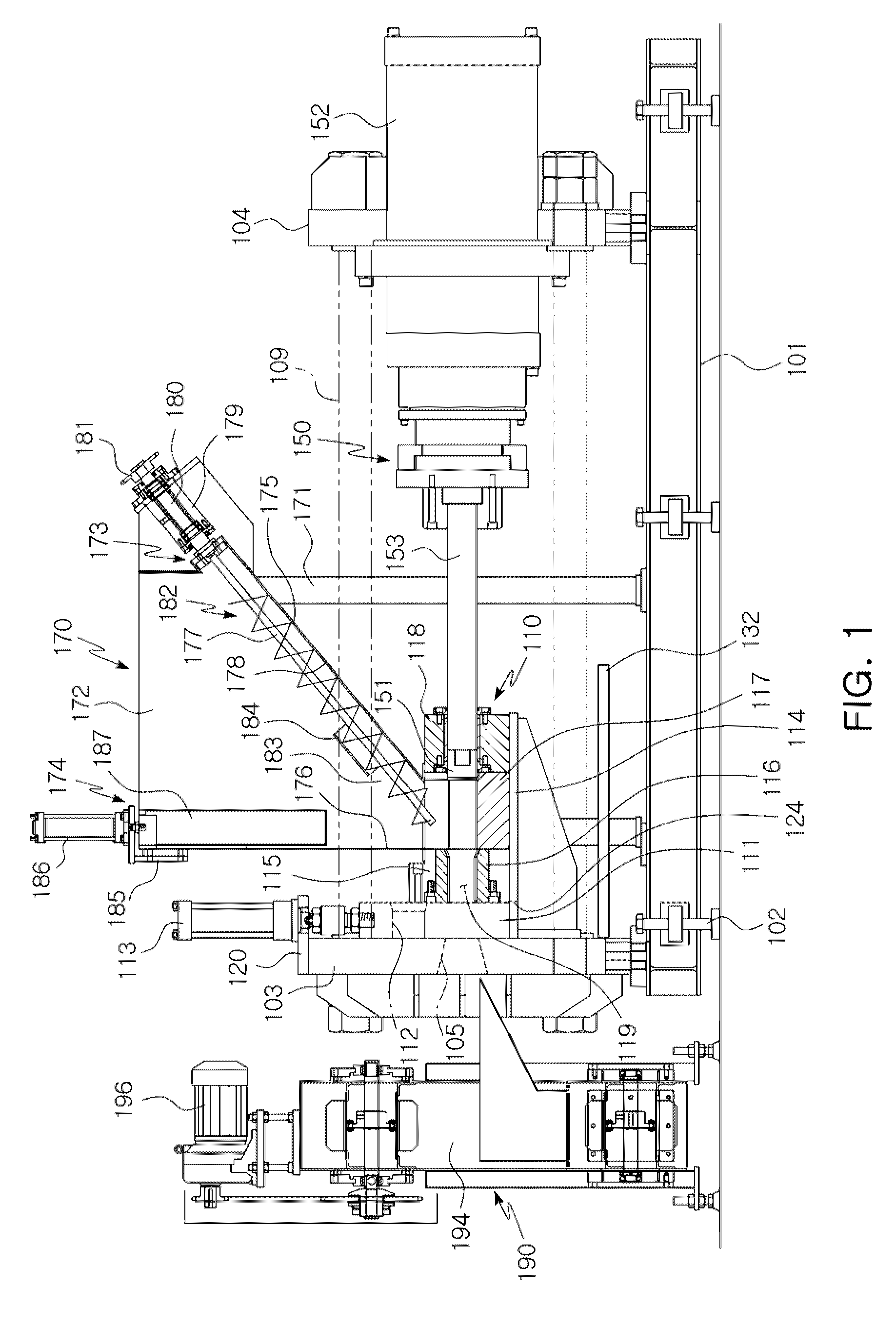

Coke stamping method and apparatus for top coal loading coke oven

InactiveCN1706913AHigh specific gravityIncrease productionCoal charges mechanical treatmentCoke ovenEngineering

The present invention is one kind of technological scheme of stamping method and apparatus in top coal loading coke oven, and the technological scheme has coal stamping inside the carbonizing chamber. By means of the coal leveling rods capable of being stretched into the carbonizing chamber, bar pressure heads may set on the coal leveling rods and loaded into the carbonizing chamber, and pressure rods connected to the bar pressure head are stretched into the carbonizing chamber through the coal loading ports. The coal leveling rods are first unloaded from the carbonizing chamber, and while loading coal, the bar pressure heads driven by the pressure rods and the lifting mechanism stamp the coking coal. The coal leveling rods are then stretched into the carbonizing chamber to support the bar pressure heads for separating with pressure rods and withdrawing from the carbonizing chamber before entering the coking step.

Owner:SHANDONG IRON & STEEL CO LTD

Coking coal stamping method and apparatus for top coal loading coke oven

InactiveCN1706914AHigh specific gravityImprove production efficiencyCoal charges mechanical treatmentCoal briquetteCoke oven

The present invention is one kind of technological scheme of coking coal stamping method and apparatus in top coal loading coke oven, and the technological scheme features coking coal stamping apparatus in the coke discharging end of the top coal loading coke oven. The coking coal stamping apparatus forms stamped coal cake in the shape corresponding to the carbonizing chamber and the coal cake is fed into the carbonizing chamber via the coke discharging door before coking. The coking coal stamping apparatus is one stamping machine, which has stamping bin in the shape corresponding to that of carbonizing chamber and with side walls capable of being opened by means of the bin wall moving mechanism.

Owner:SHANDONG IRON & STEEL CO LTD

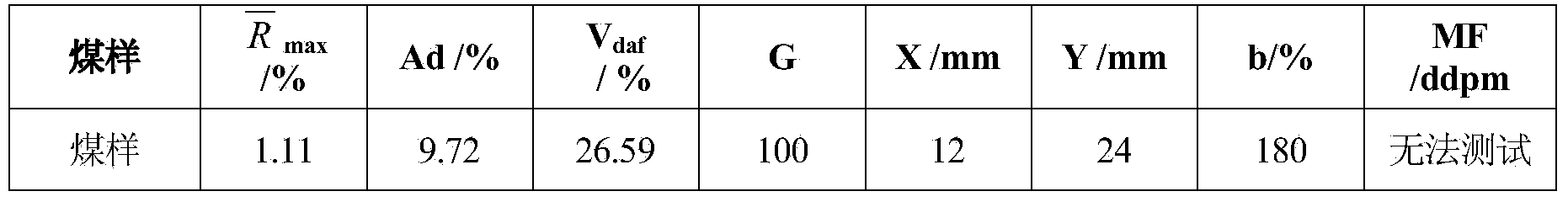

Coal blending and coking method with low-flow high-expansion low-shrinkage-degree coking coal involved

ActiveCN104140836AHigh bonding strengthHigh-quality matching effectCoke ovensPoor mobilityProcess engineering

The invention discloses a coal blending and coking method with low-flow, high-expansion and low-shrinkage-degree coking coal involved. The method comprises the following steps that 1), the coal blending structure and the proportion are determined; 2), various types of single coking coal are dried, water in all types of the single coking coal is controlled to be 2.0-5.0%, and the bulk specific weight of the blended coal is 800 kg / m<3>-950 kg / m<3>; 3), the coking coal enters a coke oven, and coal blending and coking are carried out. According to the method, the low-flow, high-expansion and low-shrinkage-degree coking coal is used as fat coal, after the coal types and the proportion of other types of the single coking coal are selected and determined, the bulk specific weight of the blended coal is increased by reducing the amount of the water in all the single coking coal, and the defect that due to poor mobility, the low-flow, high-expansion and low-shrinkage-degree coking coal can not be combined with other coal easily and fully in the expanding process of the plastic mass can be overcome; the strength of the combination with other coking coal is improved remarkably, the thermal performance of coke is obviously improved, and the blending effect of the high-quality fat coal can be achieved.

Owner:武汉钢铁有限公司

Preparation method for domestic carbon cloth pre-impregnated adhesive tape

The invention discloses a preparation method for a domestic carbon cloth pre-impregnated adhesive tape. The method comprises the following steps of: 1, weaving domestic T3100 level 1K carbon fibers into 1K plane weave carbon cloth by using the conventional weaving method; 2, placing the carbon cloth on a cloth placing rack of an impregnator and feeding into a thermal treatment furnace to perform thermal treatment; 3, feeding the carbon cloth which is subjected to the thermal treatment into an adhesive tank of the impregnator, and pre-impregnating with phenolic resin adhesive solution under a constant temperature condition to obtain adhesive fabric; and 4, feeding the adhesive fabric into a drying furnace to dry, and then coiling and packaging the dried adhesive fabric to obtain the domestic carbon cloth pre-impregnated adhesive tape. The domestic carbon cloth pre-impregnated adhesive tape prepared by using the method provided by the invention has unified quality; each item of performance reaches the technical requirements of the pre-impregnated adhesive tape in GJB3402-98 carbon cloth / phenolic aldehyde-high silica cloth / phenolic aldehyde composite winding product specification, and the production demand and the quality stability requirements of a heat insulating layer of a spray pipe expansion section of a solid rocket engine are met.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

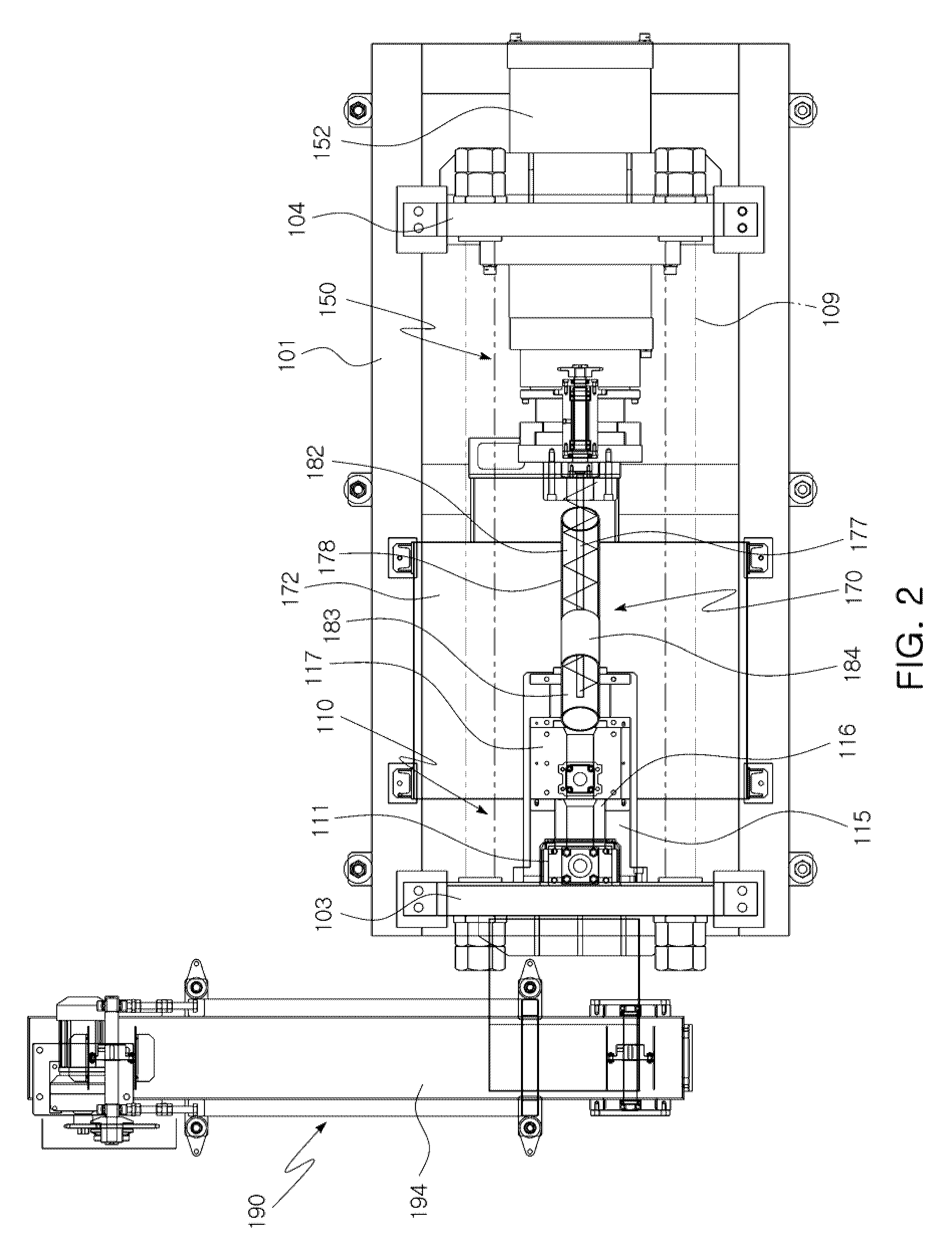

Apparatus for recycling metal scraps

ActiveUS20100330217A1Increase rate of recoveryHigh specific gravityTailstocks/centresConfectioneryScrapEngineering

An apparatus for recycling metal scraps includes a mold having an inner conversion cavity for converting the metal scraps, an inlet disposed in one longitudinal end thereof, and an outlet disposed in the other longitudinal ends thereof, the inlet and the outlet communicating with the cavity; a gate movably mounted near the outlet of the mold so as to open and close the outlet of the mold as the gate moves; a gate actuator moving the gate to an opening or closing position; a scrap feeder supplying the metal scraps into the cavity of the mold, a conversion plunger intruded into the cavity via the inlet of the mold and compacting the metal scraps to form a solid compact having a shape corresponding to the cavity; and a press actuator reciprocating the conversion plunger between inside and outside of the mold so as to provide a conversion pressure.

Owner:KOREA INST OF IND TECH

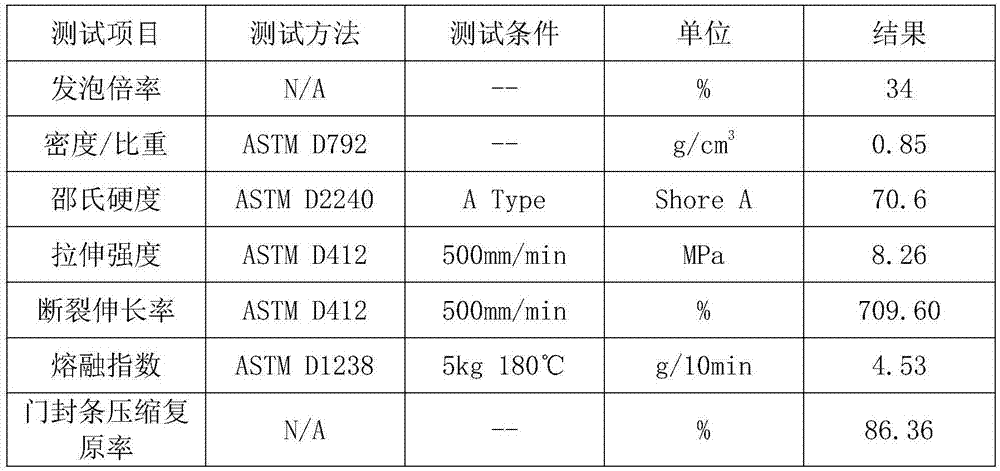

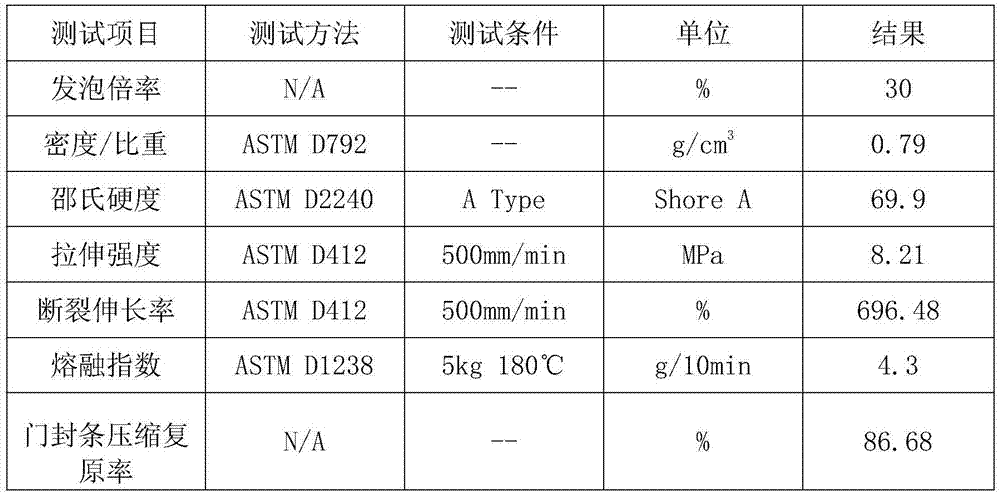

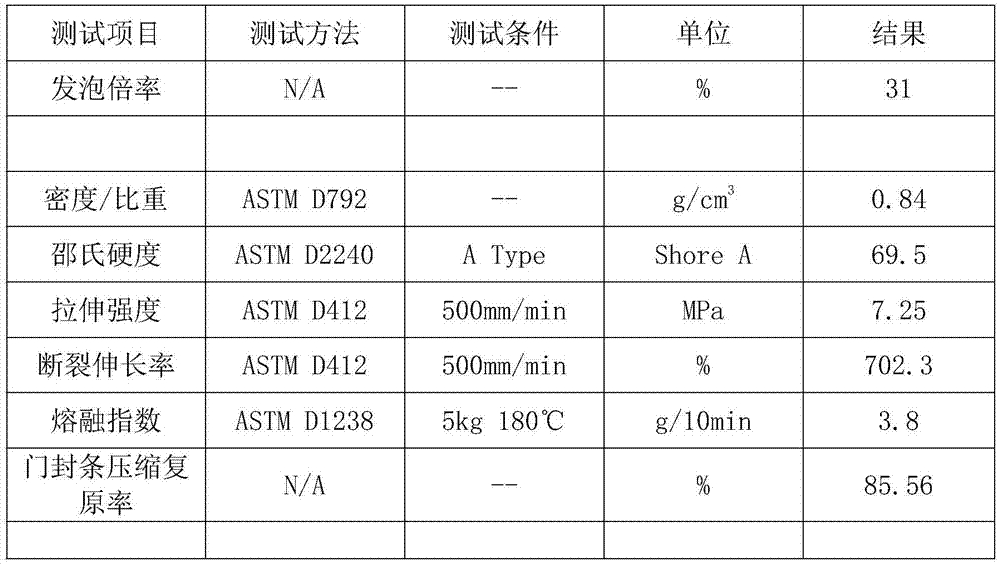

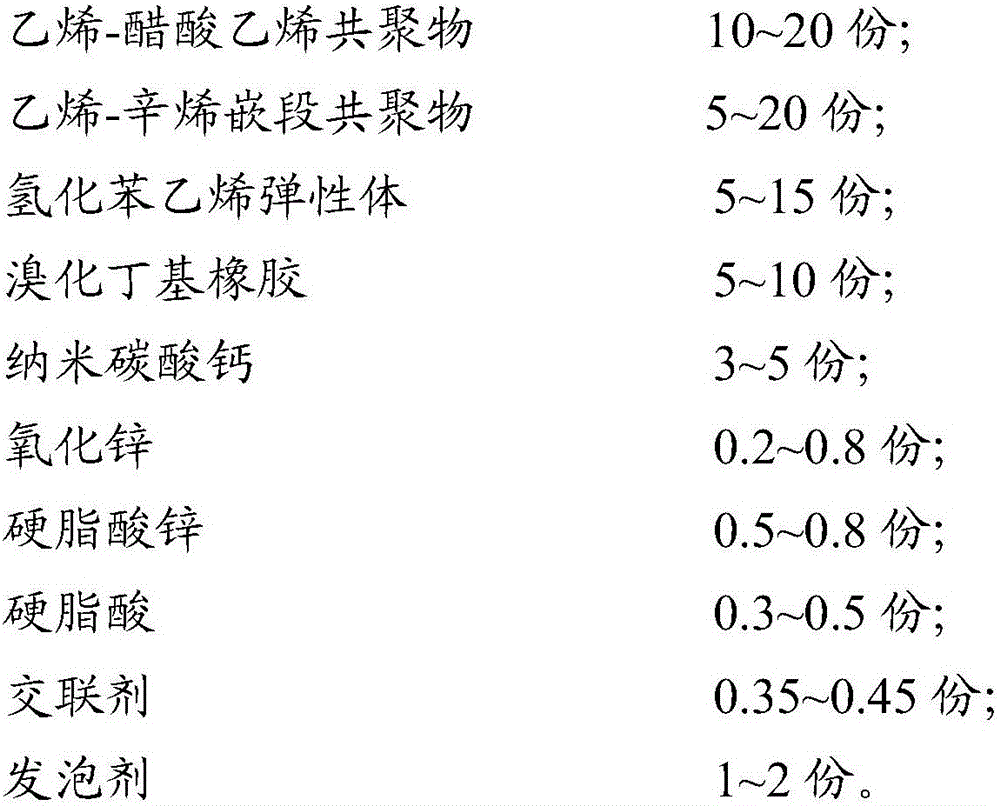

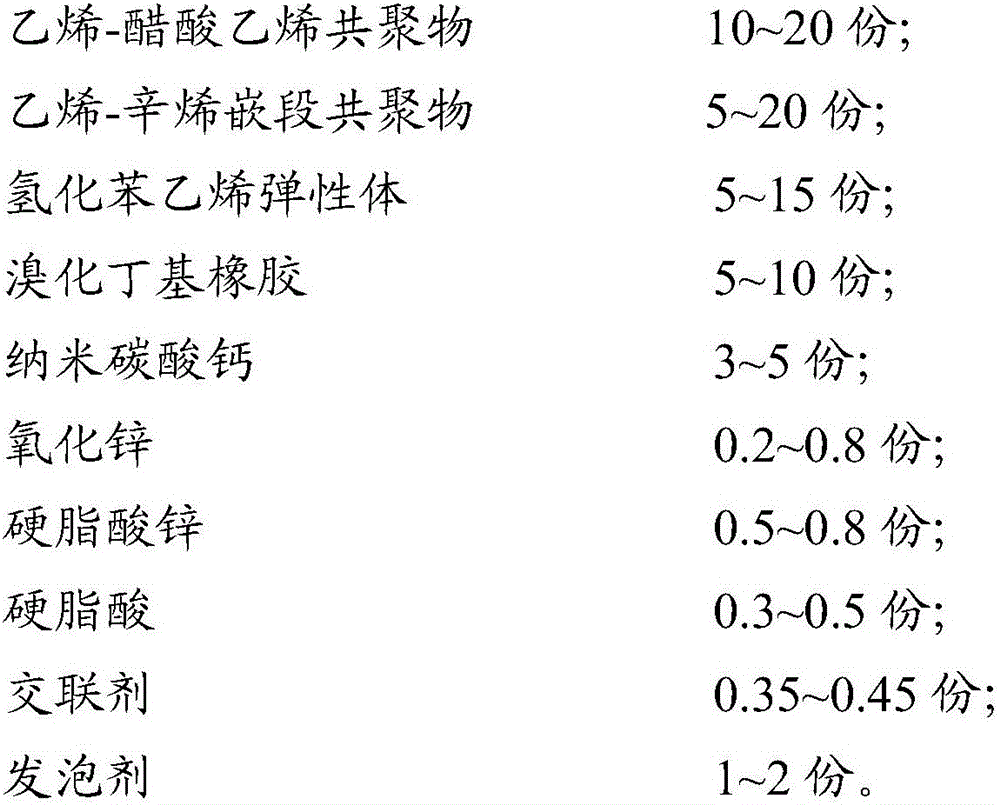

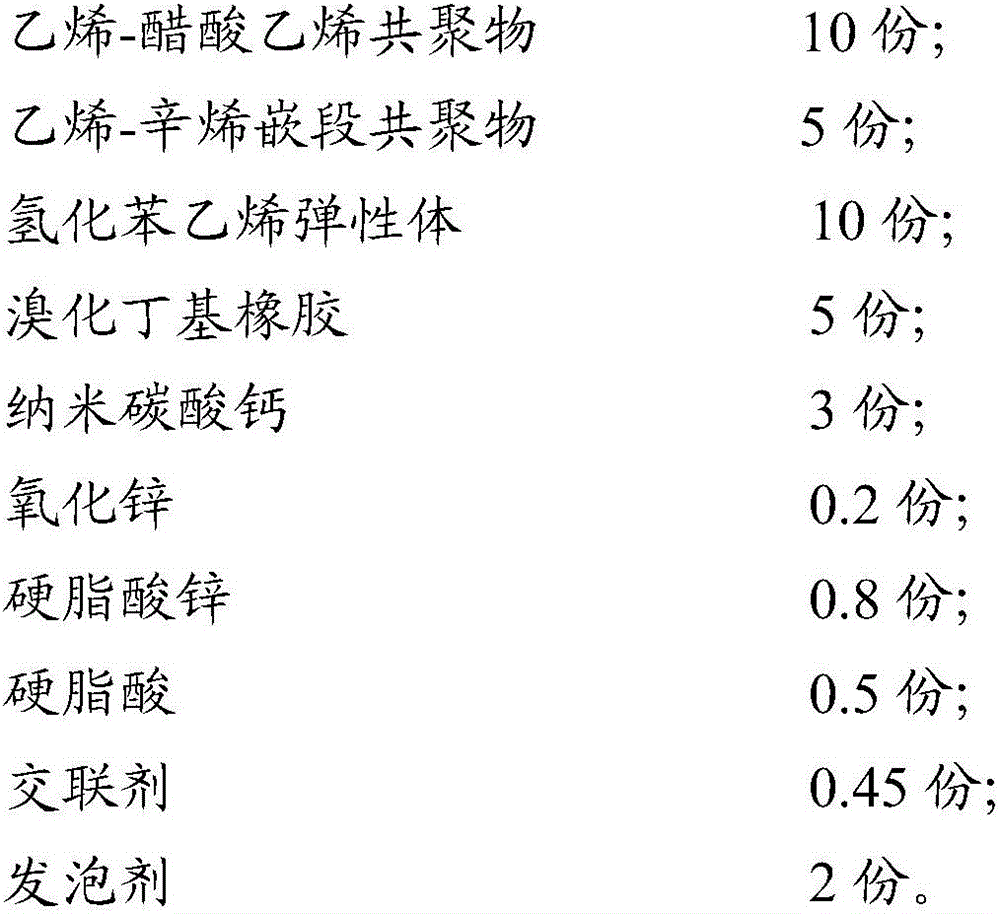

Thermoplastic elastomer foamed door seal strip and preparation method thereof

The invention discloses a thermoplastic elastomer foamed door seal strip and a preparation method thereof. The thermoplastic elastomer foamed door seal strip is characterized by being prepared from the following materials for preparation in parts by weight: 60 to 110 parts of styrene elastomer, 10 to 30 parts of high-density polyethylene, 10 to 40 parts of polypropylene, 60 to 110 parts of filling oil, 30 to 80 parts of mineral filler, 1 to 5 parts of lubricant, 1 to 5 parts of coupling agent, 0.1 to 2 parts of antioxidant, 0 to 5 parts of crosslinking agent and 1 to 8 parts of foaming agent. The preparation method is as follows: the styrene elastomer and the filling oil among the materials according to parts by weight are first sufficiently mixed for absorption, the other components are then added and uniformly mixed, the uniformly mixed materials are extruded by a double-screw extruder for pelletization, and the pelletized material is sent into a single-screw extruder and extruded out to be shaped. According to the preparation method, in the process of production, no wastewater and waste gas are produced, no solvents are discharged, halogen is not contained, scraps can be recycled, and a product has the advantages of good elasticity, high strength, good compressive resilience, low specific gravity, adjustable density, smooth surface and good welding effect.

Owner:ANHUI HIGASKET PLASTICS CO LTD

High-heat-resistance and low-expansion-coefficient carbon fiber vinyl ester composite material and preparation method thereof

The invention discloses a high-heat-resistance and low-expansion-coefficient carbon fiber vinyl ester composite material and a preparation method thereof. The composite material is prepared by carrying out a series of procedures, including stirring, spreading and molding on the following components in parts by weight: 40-50 parts of vinyl resin, 20-30 parts of glass fiber, 40-70 parts of carbon fiber powder, 70-90 parts of inorganic mineral filler, 2-5 parts of magnesium oxide, 2-6 parts of a mold release agent and 1-3 parts of a curing agent. The high-heat-resistance and low-expansion-coefficient carbon fiber vinyl ester composite material has the advantages of simple composition, convenience in preparation, properties of a metal substrate and a nonmetallic substrate, wider application range, simple and convenient steps, simple equipment, convenience in implementation and popularization, low production cost and very high economic benefit. The properties of high temperature resistance, noninflammability, corrosion resistance, heat resistance, high sound insulating property, high tensile strength and high electrical insulating property of glass fiber are fully used and the properties of low dead weight and high strength of carbon fiber are fully utilized, and high heat resistance, small expansion coefficient and low contraction rate are realized on the premise of ensuring low specific weight.

Owner:YUZHOU YUANDA PLASTIC ELECTRICAL APPLIANCE

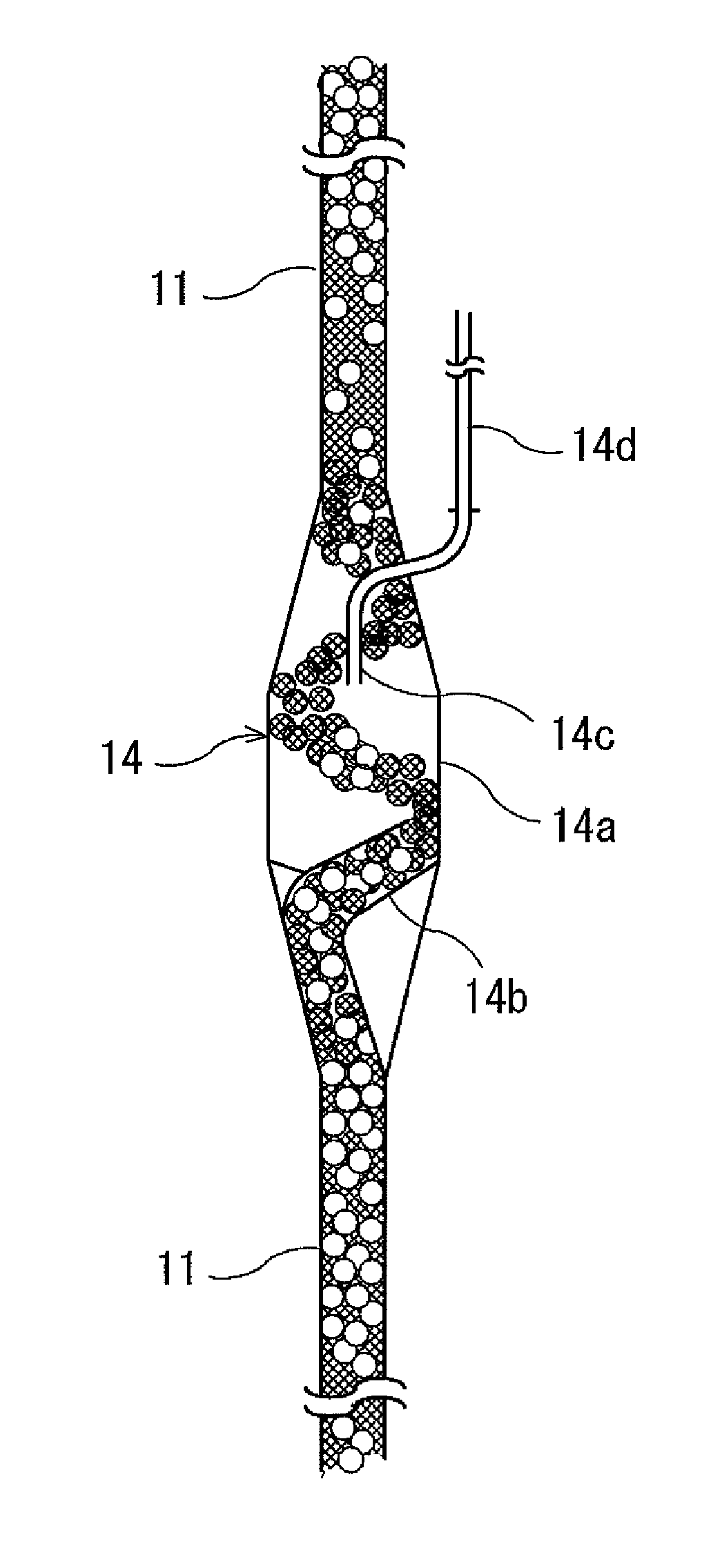

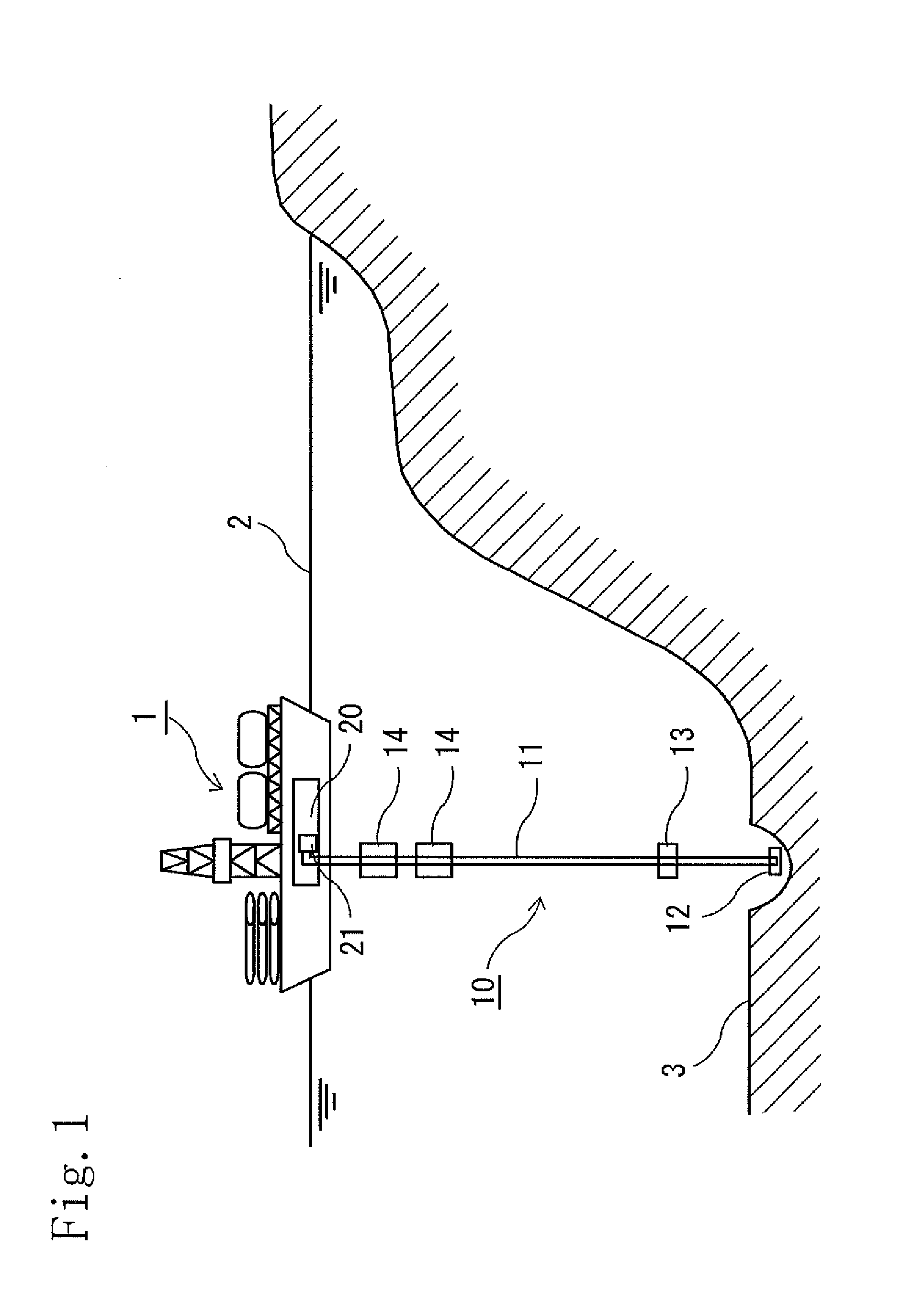

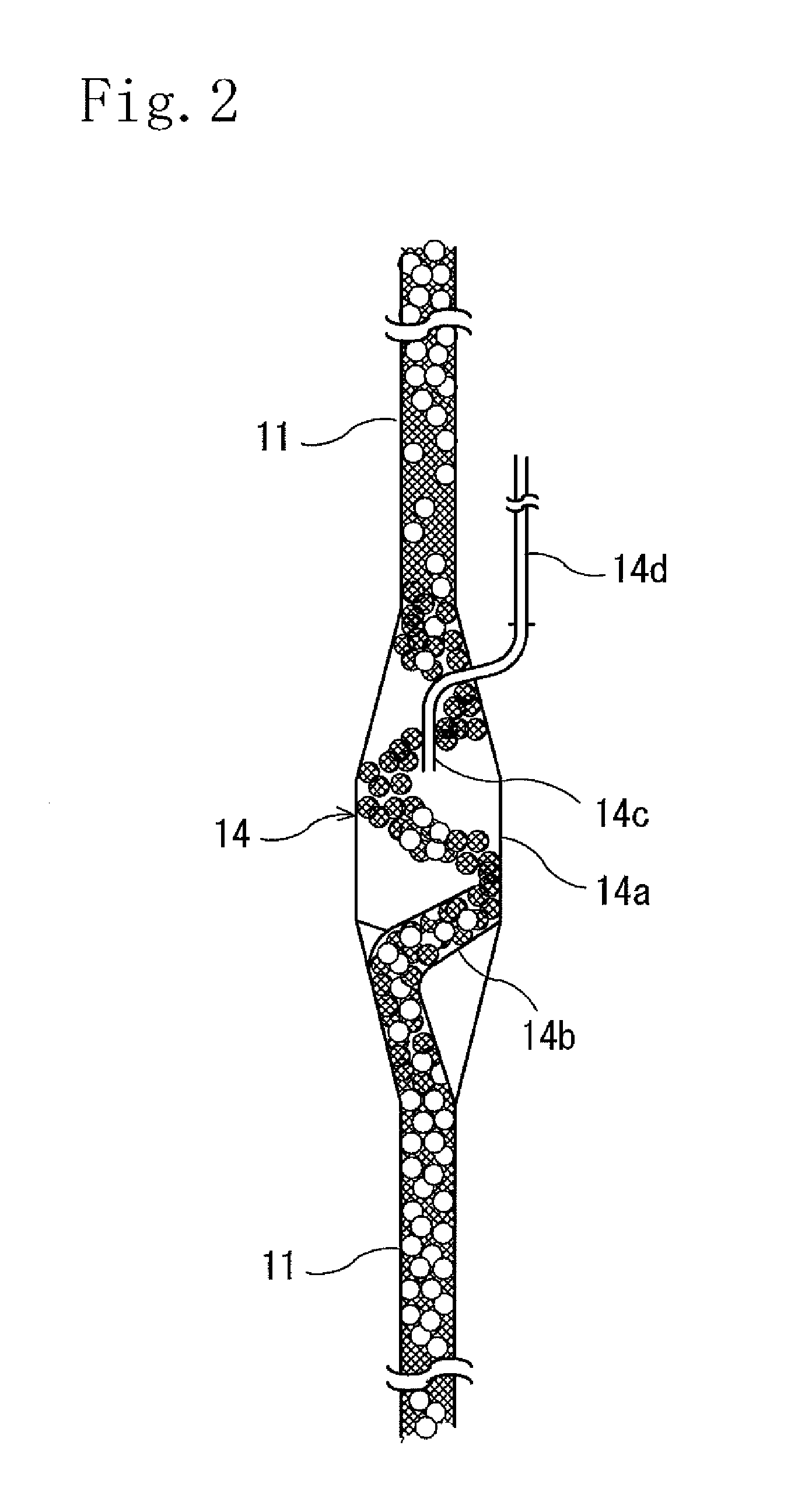

Bubble lift system and bubble lift method

ActiveUS20140169989A1High specific gravityReduce pressure lossLiquid degasificationPressure pumpsLift systemEngineering

In a bubble lift system 10, a pressurized chamber 21 is provided at an upper end portion of a riser pipe 11, and applies a pressure to an upper portion inside the riser pipe 11 to suppress an increase in the volume ratio of bubbles to a fluid mixture rising inside the riser pipe 11 in a shallow water region. In this configuration, the upper end of the riser pipe 11 is not opened to the atmosphere but is inserted into the pressurized chamber 21 under a high pressure to thereby prevent expansion of the bubbles and gas. In addition, a deaerator 14 for discharging bubbles separated by a centrifugal force is also provided in a middle portion of the riser pipe 11 in a shallow water region to thereby make the bubbles distributed more evenly inside the whole riser pipe 11. Thus, provided are the bubble lift system 10 and a bubble lift method that are efficient and employable even in a deep water region.

Owner:MODEC

Vibration-absorption material, preparation method of vibration-absorption material, and shoe sole made of vibration-absorption material

InactiveCN106750847AGood shock absorption performanceGood shock absorptionSolesSpecific gravityHardness

The invention provides a vibration-absorption material, which has excellent vibration-absorption performance without needing to set any vibration-absorption structure. An experiment result of the embodiment shows that a shoe sole obtained through the vibration-absorption material provided by the invention has excellent hardness, tension strength, elongation, right-angled tearing strength, specific gravity, wear-resisting property and vibration-absorption performance, and a vibration-absorption performance G value is less than or equal to 35, which is far better than the vibration-absorption performance (45 or higher) of a common shoe sole.

Owner:福建省龙麒新材料发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com