Vibration-absorption material, preparation method of vibration-absorption material, and shoe sole made of vibration-absorption material

A technology of shock-absorbing materials and raw materials, which is applied in the field of composite materials for shoes, can solve the problems of increasing the design cost and production cost of soles, and achieve the best shock-absorbing effect, strong wear resistance, and excellent hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

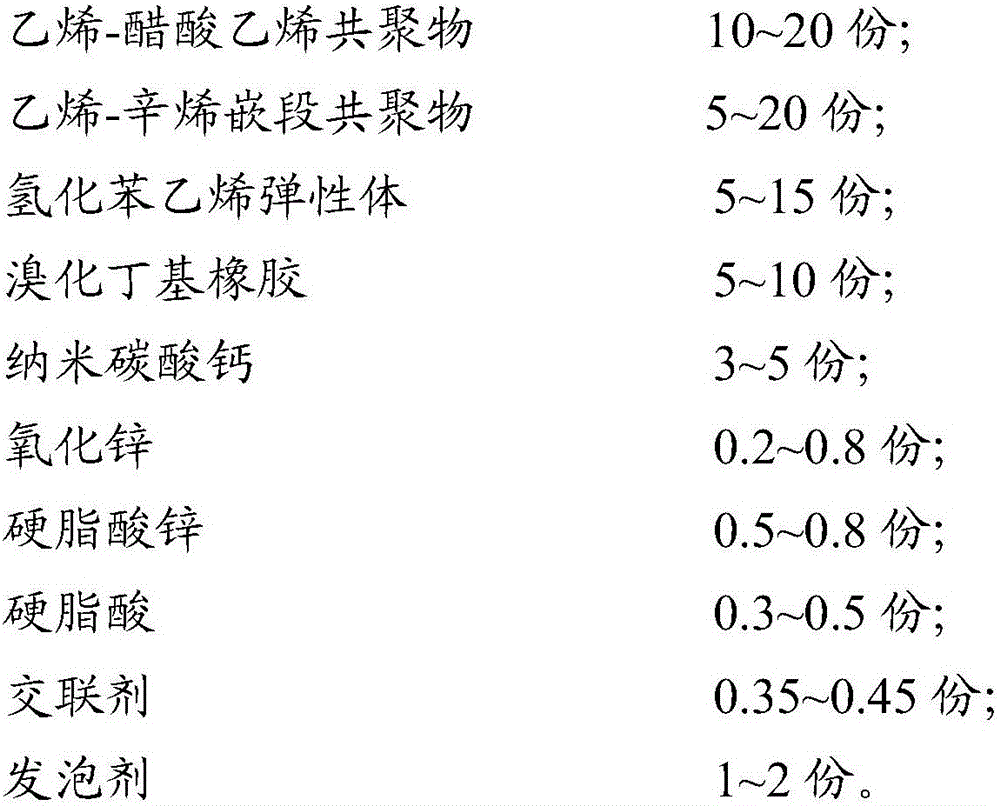

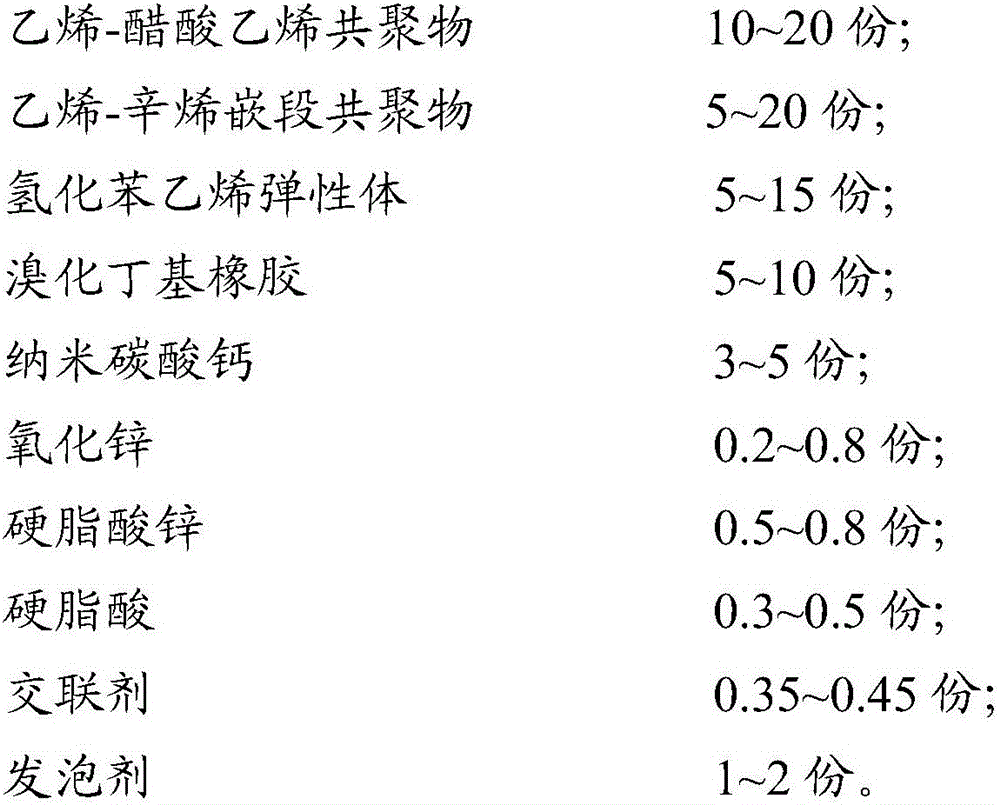

[0039] When the shock-absorbing material does not contain wear-resistant agent and colorant components, the present invention provides a method for preparing the above-mentioned shock-absorbing material, comprising the following steps:

[0040] The first blending of a mixture containing ethylene-vinyl acetate copolymer, ethylene-octene block copolymer, hydrogenated styrene, bromobutyl rubber, nano calcium carbonate, zinc oxide, zinc stearate and stearic acid Refining to obtain the first-grade mixed material;

[0041] Mixing the primary mixing material with a crosslinking agent and a foaming agent for second mixing to obtain a secondary mixing material;

[0042] Carry out kneading on the secondary mixing material to obtain a shock-absorbing material.

[0043]The invention mixes ethylene-vinyl acetate copolymer, ethylene-octene block copolymer, hydrogenated styrene, brominated butyl rubber, nano calcium carbonate, zinc oxide, zinc stearate and stearic acid to obtain a mixture. ...

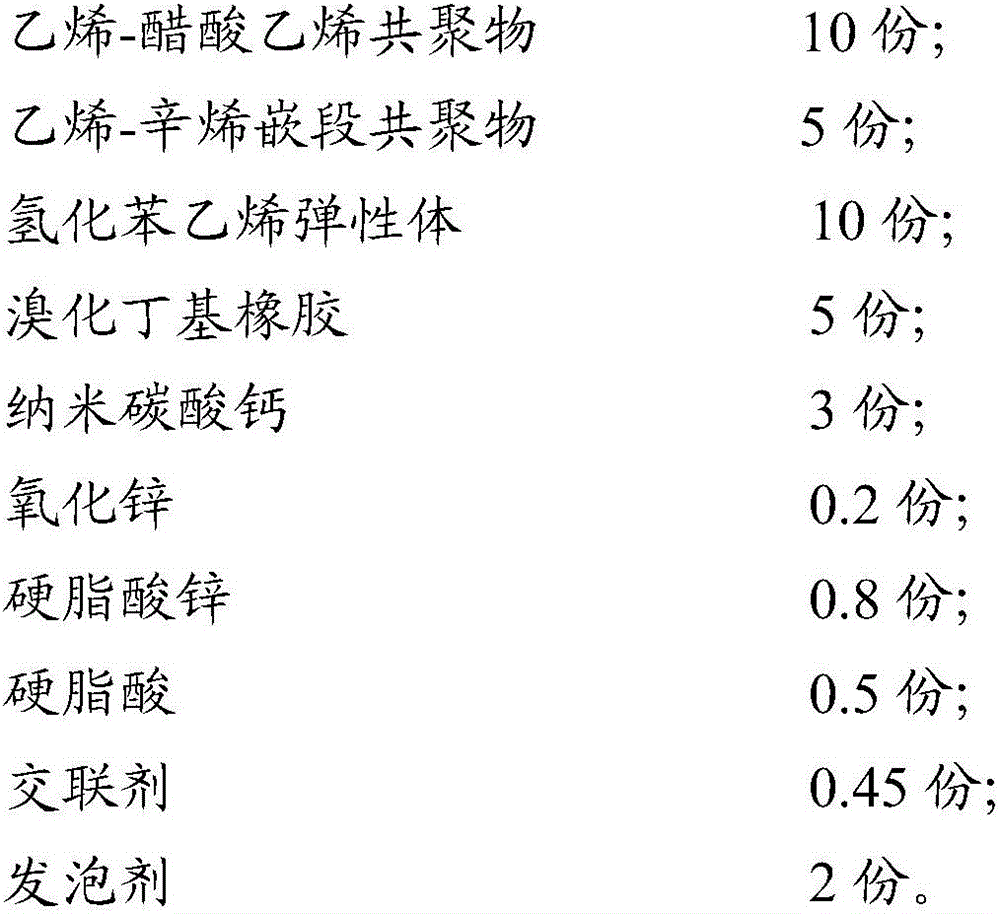

Embodiment 1

[0068]

[0069] For mixtures containing ethylene-vinyl acetate copolymer, ethylene-octene block copolymer, hydrogenated styrene, brominated butyl rubber, nano calcium carbonate, zinc oxide, zinc stearate and stearic acid in an internal mixer The first mixing was carried out to obtain the primary mixed material; the temperature of the first mixing was raised from room temperature to 95° C. for 8 minutes.

[0070] The primary mixing material was mixed with the crosslinking agent and foaming agent for the second mixing to obtain the second mixing material; the temperature of the second mixing continued to rise to 105° C. for 2 minutes.

[0071] The secondary mixed material is practiced in a practice machine to obtain a shock-absorbing material. The training process is as follows: first thickening once, thickness 3mm, then thinning twice, each time thickness 1mm, thickening once again, thickness 3mm, to obtain shock-absorbing material.

Embodiment 2

[0073] Put the damping material obtained in Example 1 into a single-screw extrusion granulator. The temperature of the die head of the granulator is 75°C, the temperature of the barrel is 70°C, and the particle size is 3mm. The prepared pellets are left at room temperature for more than 2 hours. Put the static granules into a drying barrel to dry for 1 hour at a drying temperature of 45°C.

[0074] Inject the dry shock-absorbing particles into shoe soles in the injection machine: the injection gun of the injection machine is preferably divided into 4 sections, and the temperatures of the four sections are: 80°C, 82°C, 84°C, and 88°C; The piston is divided into 5 steps of continuous and uninterrupted advancement, the injection rate is 15g / s, and the injection pressure from the first to the fourth section is 80bar, 75bar, 70bar, 65bar; the mold temperature of the injection machine: 175°C, vulcanization The time is 450 seconds; the 5 ovens of the injection machine are connected a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com