Thermoplastic elastomer foamed door seal strip and preparation method thereof

A technology of thermoplastic elastomer and foam door, which is applied in the field of preparation of thermoplastic elastomer foam door seals, which can solve the problems of high transportation conditions, slow recovery of surface deformation, and large specific gravity, and achieve a wide range of hardness and compression recovery. Good, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

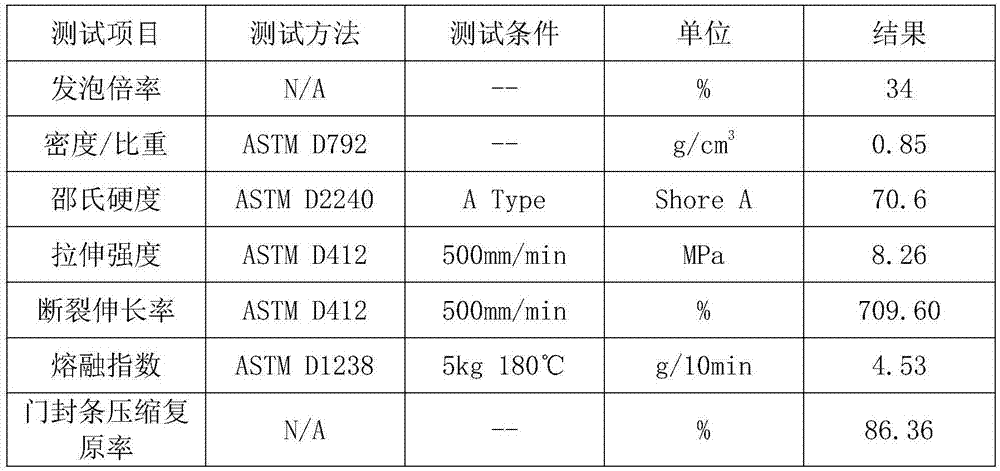

[0020] Embodiment one, with reference to figure 1 The door seal material is weighed according to the following material parts: 110 parts of styrene elastomer, 30 parts of high-density polyethylene, 40 parts of polypropylene, 90 parts of filler oil (choose naphthenic oil), 80 parts of mineral filler (choose calcium carbonate) 50 parts of lubricant, 3 parts of coupling agent, 0.4 part of antioxidant, 0.8 part of crosslinking agent, 2.5 parts of foaming agent (microsphere foaming agent in physical foaming agent).

[0021] Mix styrene-based elastomer and naphthenic oil in a high-speed mixer for oil extension, then add the remaining materials step by step according to the components, and mix well to obtain powder. The above-mentioned mixed powder is extruded and granulated by a twin-screw extruder. When the twin-screw extruder is extruded and granulated, the vacuum port and the vent hole must be closed, and the melt pump should be turned off to minimize the material in the screw. ...

Embodiment 2

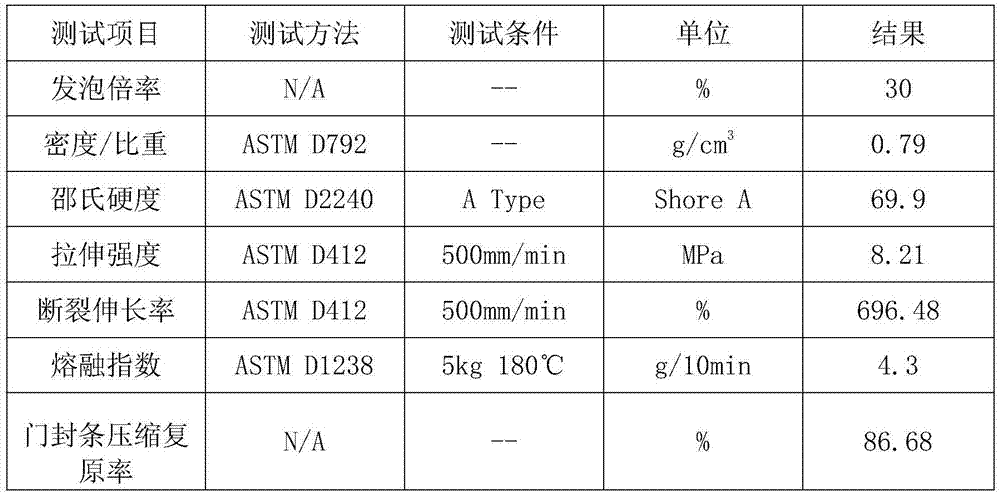

[0023] Embodiment two, refer to figure 2 The door seal material is weighed according to the following material parts: 110 parts of styrene elastomer, 30 parts of high-density polyethylene, 40 parts of polypropylene, 90 parts of filler oil (choose naphthenic oil), 80 parts of mineral filler (choose calcium carbonate) 5 parts, lubricant 5 parts, coupling agent 3 parts, antioxidant 0.3 parts, crosslinking agent 0.5 parts, foaming agent (select chemical foaming agent) 1.2 parts.

[0024] Mix styrene-based elastomer and naphthenic oil in a high-speed mixer for oil extension, then add the remaining materials step by step according to the components, and mix well to obtain powder. The above-mentioned mixed powder is extruded and granulated by a twin-screw extruder. When the twin-screw extruder is extruded and granulated, the vacuum port and the vent hole must be closed, and the melt pump should be turned off to minimize the material in the screw. The residence time, the speed of th...

Embodiment 3

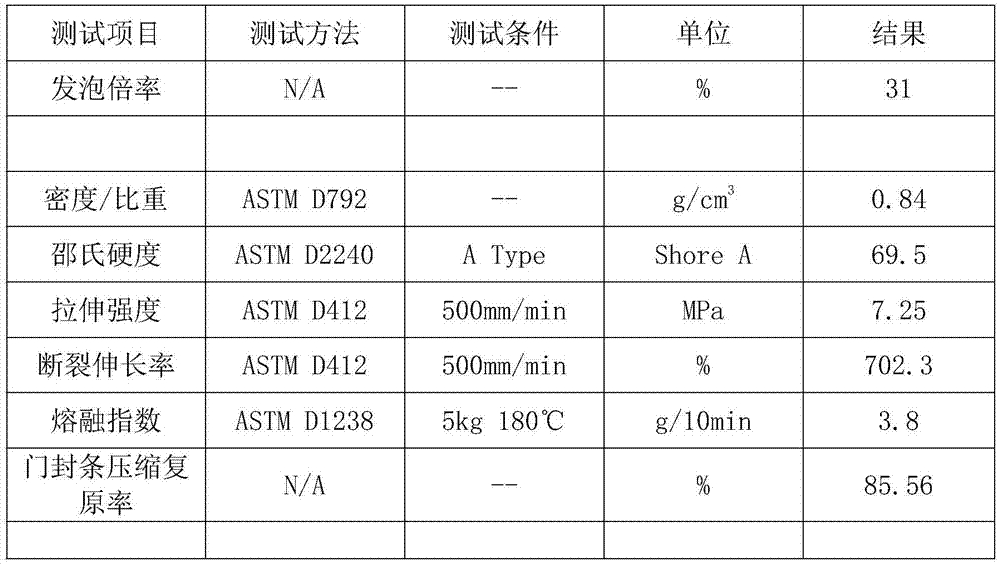

[0026] Embodiment three, refer to image 3 The door seal material is weighed according to the following material parts: 110 parts of styrene elastomer, 30 parts of high-density polyethylene, 40 parts of polypropylene, 90 parts of filler oil (choose naphthenic oil), 80 parts of mineral filler (choose calcium carbonate) part, 5 parts of lubricant, 3 parts of coupling agent, 0.6 part of antioxidant, 0.5 part of crosslinking agent, foaming agent (select 0.6 part of microsphere foaming agent in physical foaming agent, select 0.4 part of chemical foaming agent ) 1 serving.

[0027] Mix styrene-based elastomer and naphthenic oil in a high-speed mixer for oil extension, then add the remaining materials step by step according to the components, and mix well to obtain powder. The above-mentioned mixed powder is extruded and granulated by a twin-screw extruder. When the twin-screw extruder is extruded and granulated, the vacuum port and the vent hole must be closed, and the melt pump sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com