Anaerobic ammoxidation sludge embedding immobilization method

A technology of anaerobic ammonium oxidation and immobilized pellets, applied in anaerobic digestion treatment, chemical instruments and methods, sludge treatment, etc., can solve the problem of low anammox microbial biomass Difficulty, time-consuming start-up of the ammoxidation reactor, etc., to achieve the effect of simple production process, good economic and environmental benefits, and increased weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Using immobilized anammox pellets to treat nitrogen-containing wastewater under batch culture conditions, the specific process is as follows:

[0030] Weigh polyvinyl alcohol, sodium alginate, powdered activated carbon and magnetic powder to make a solution. In terms of mass percentage, the concentration of polyvinyl alcohol is 10wt%, the concentration of sodium alginate is 2wt%, the concentration of powdered activated carbon is 2wt%, and the concentration of magnetic powder is 2wt%, stirred evenly to make a mixed embedding agent, and then mixed with the anammox sludge at a volume ratio of 1:1 (after the anammox sludge was washed with a potassium bicarbonate buffer solution with a pH of 6.0 4000r / min centrifugation, 15min each time), the above mixed solution was added dropwise to 4wt%CaCl via a peristaltic pump 2 solution (CaCl 2 The volume of the solution is 4 times the volume of the mixed embedding agent and sludge), sealed and shading, and put it in a refrigerator a...

Embodiment 2

[0033] Using immobilized anammox pellets to treat nitrogen-containing wastewater under continuous culture conditions, the specific process is as follows:

[0034] Weigh polyvinyl alcohol, sodium alginate, powdered activated carbon and magnetic powder to make a solution. In terms of mass percentage, the concentration of polyvinyl alcohol is 6wt%, the concentration of sodium alginate is 3wt%, the concentration of powdered activated carbon is 1wt%, and the concentration of magnetic powder is 4wt%, stirred evenly to make a mixed embedding agent, and then mixed with the anammox sludge at a volume ratio of 1:1 (after the anammox sludge was washed with a potassium bicarbonate buffer solution with a pH of 7.0 centrifugation), the above mixture was added dropwise to 5wt% CaCl via a peristaltic pump 2 solution (CaCl 2 The volume of the solution is 4 times the volume of the mixed embedding agent and sludge), sealed and shading, put it in a refrigerator at 4°C for 8 hours to cross-link t...

Embodiment 3

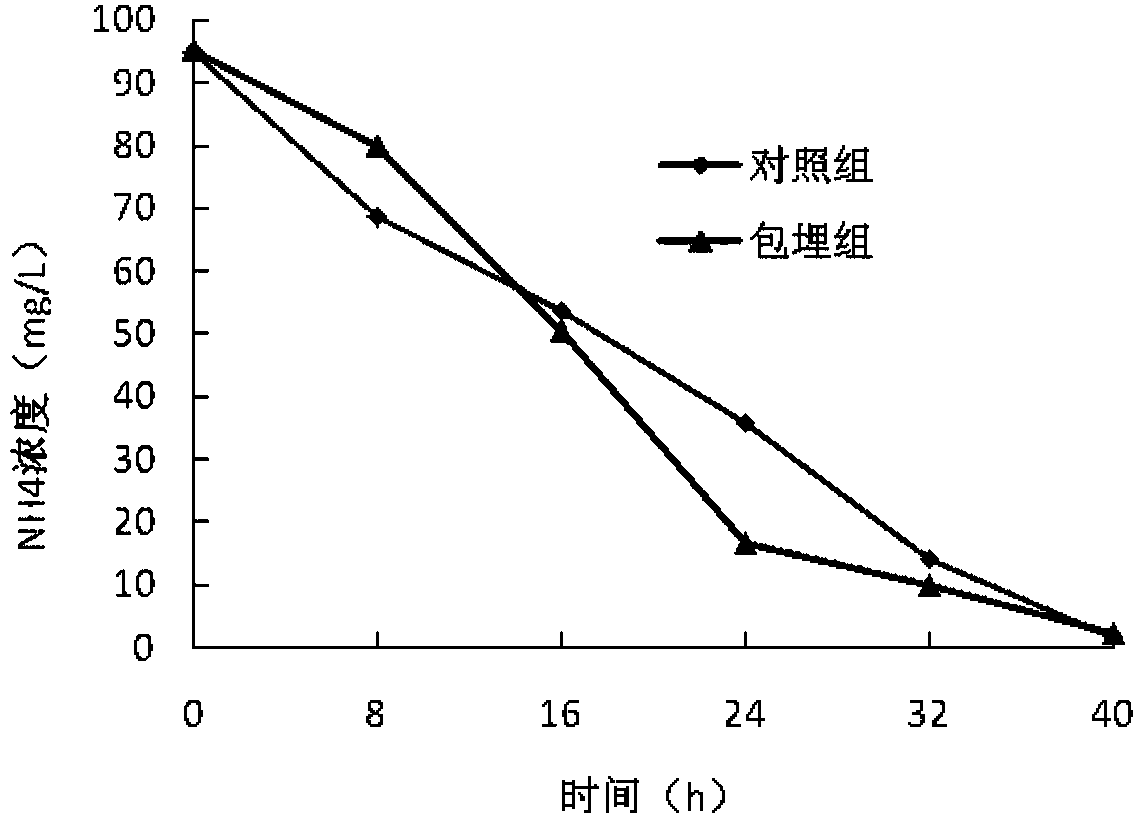

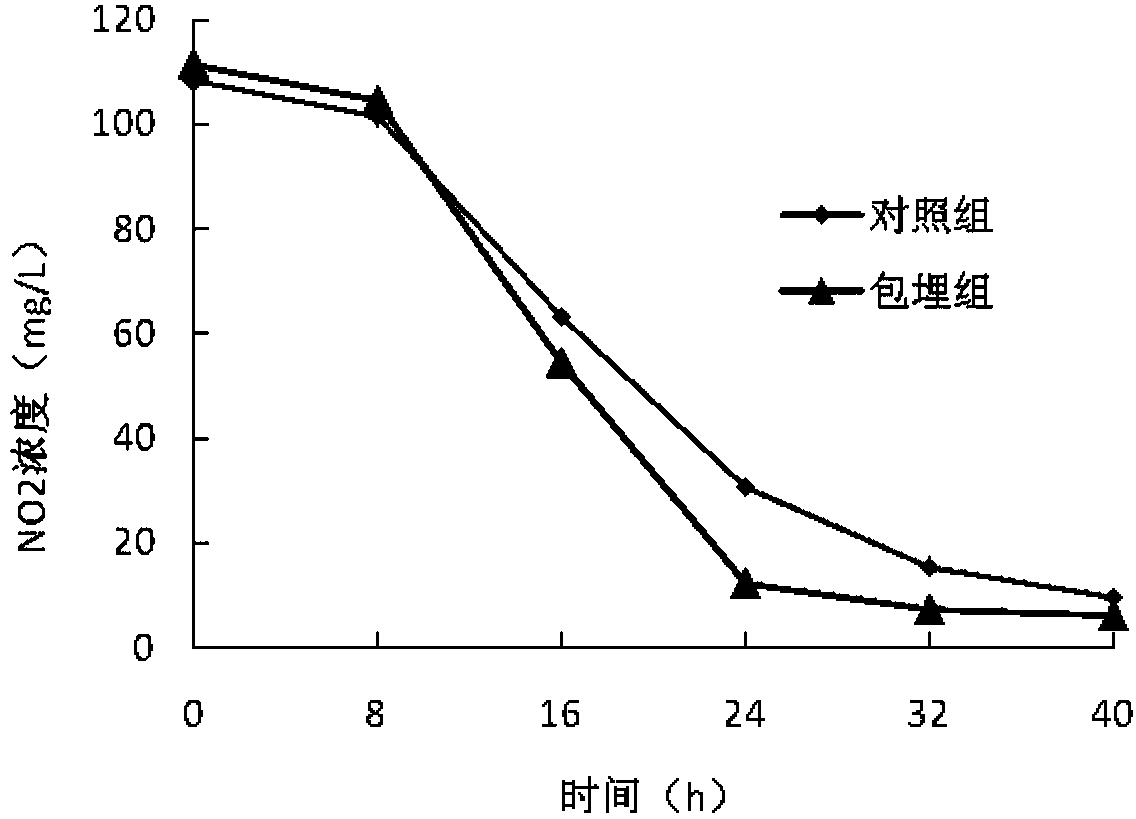

[0037] The comparison test of using immobilized anammox pellets to treat nitrogen-containing wastewater and non-embedded anammox sludge to treat nitrogen-containing wastewater, the specific process is as follows:

[0038] Weigh polyvinyl alcohol, sodium alginate, powdered activated carbon and magnetic powder to make a solution, in terms of mass percentage, the concentration of polyvinyl alcohol is 6wt%, the concentration of sodium alginate is 2wt%, the concentration of powdered activated carbon is 1wt%, and the concentration of magnetic powder is 2wt%, stirred evenly to make a mixed embedding agent, and then mixed with the anammox sludge at a volume ratio of 1:1 (after the anammox sludge was washed with a potassium bicarbonate buffer solution with a pH of 8.0 centrifugation), the above mixture was added dropwise to 6wt%CaCl via a peristaltic pump 2 solution (CaCl 2 The volume of the solution is 5 times the volume of the mixed embedding agent and sludge), sealed and shaded, pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com