Active carbon for deeply purifying drinking water and preparation method thereof

A technology of activated carbon and carbonization, applied in inorganic chemistry, silicon compounds, adsorbed water/sewage treatment, etc., can solve the problems of ineffective utilization of coal tar resources, high production cost, complicated production process, etc., and achieve the function of deep purification of drinking water. , low cost and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

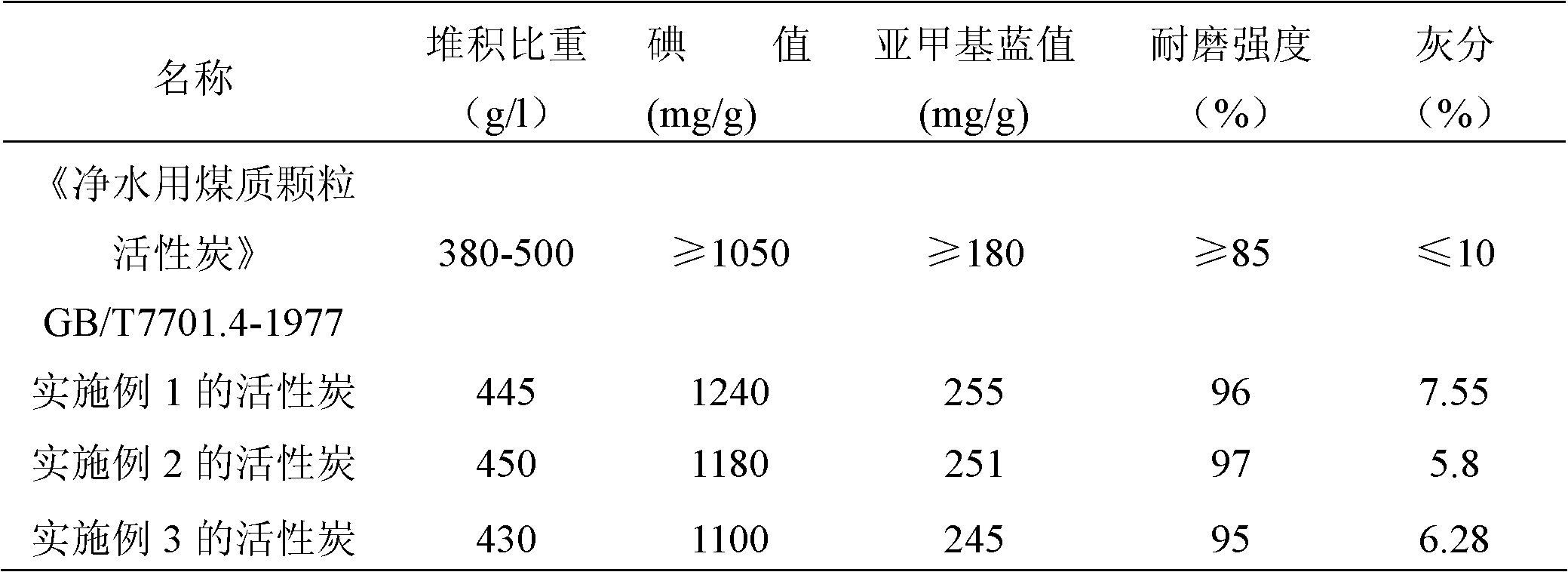

Examples

Embodiment 1

[0031] Embodiment 1, the preparation of activated carbon for water purification

[0032] (1) Crushing: crush anthracite and coking coal into particles with a particle size of 5mm, then mix the anthracite and coking coal in a ratio of 7:2.5 by mass to obtain a mixture; put the above mixture through a ball milling mechanism powder to obtain mixed powder, wherein more than 99% of the mixed powder can pass through a 200-mesh sieve;

[0033] (2) Briquetting molding: mix asphalt with the above-mentioned mixed powder, wherein the mass and fraction ratio of the amount of asphalt added to the anthracite is 0.7:7, and then use the double-roller high-pressure molding equipment to mix the obtained powder The material is subjected to dry briquetting under a pressure of 20MPa to obtain a briquette;

[0034] (3) Carbonization: Carbonize the briquette material obtained above in an externally heated rotary furnace to obtain an activated material. The final temperature of carbonization is 580°...

Embodiment 2

[0037] Embodiment 2, the preparation of gac for water purification

[0038] (1) Crushing: crush anthracite and coking coal into particles with a particle size of 3mm, then mix the anthracite and coking coal in a ratio of 7:1 to obtain a mixture; put the above mixture through a ball milling mechanism powder to obtain mixed powder, wherein more than 99% of the mixed powder can pass through a 200-mesh sieve;

[0039] (2) Briquetting molding: mix asphalt with the above-mentioned mixed powder, wherein the mass and number ratio of the amount of asphalt added to anthracite is 0.3:7, and then use the roller high-pressure molding equipment to mix the obtained powder The material is subjected to dry briquetting under a pressure of 30MPa to obtain a briquette;

[0040] (3) Carbonization: Carbonize the briquette material obtained above in an externally heated rotary furnace to obtain an activated material, the final temperature of carbonization is 500°C, the controlled heating rate is 6°...

Embodiment 3

[0043] Embodiment 3, the preparation of gac for water purification

[0044] (1) Crushing: crush anthracite and coking coal into particles with a particle size of 5mm, then mix the anthracite and coking coal in a ratio of 8:2 to obtain a mixture; put the above mixture through a ball milling mechanism powder to obtain mixed powder, wherein more than 99% of the mixed powder can pass through a 200-mesh sieve;

[0045] (2) Briquetting molding: mix asphalt with the above-mentioned mixed powder, wherein the mass and number ratio of the amount of asphalt added to anthracite is 0.5:8, and then use the roller high-pressure molding equipment to mix the powder The material is subjected to dry briquetting under a pressure of 25MPa to obtain a briquette;

[0046] (3) Carbonization: Carbonize the briquette material obtained above in an externally heated rotary furnace to obtain an activated material, the final temperature of carbonization is 650°C, the controlled heating rate is 8°C / min, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com