Coking coal stamping method and apparatus for top coal loading coke oven

A technology for tamping coke and coke oven, which is applied in the method, coking coal tamping device, and the field of tamping coke in top-loading coal coke ovens, and can solve problems such as the inability to smelt tamping coke in top-loading coal coke ovens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

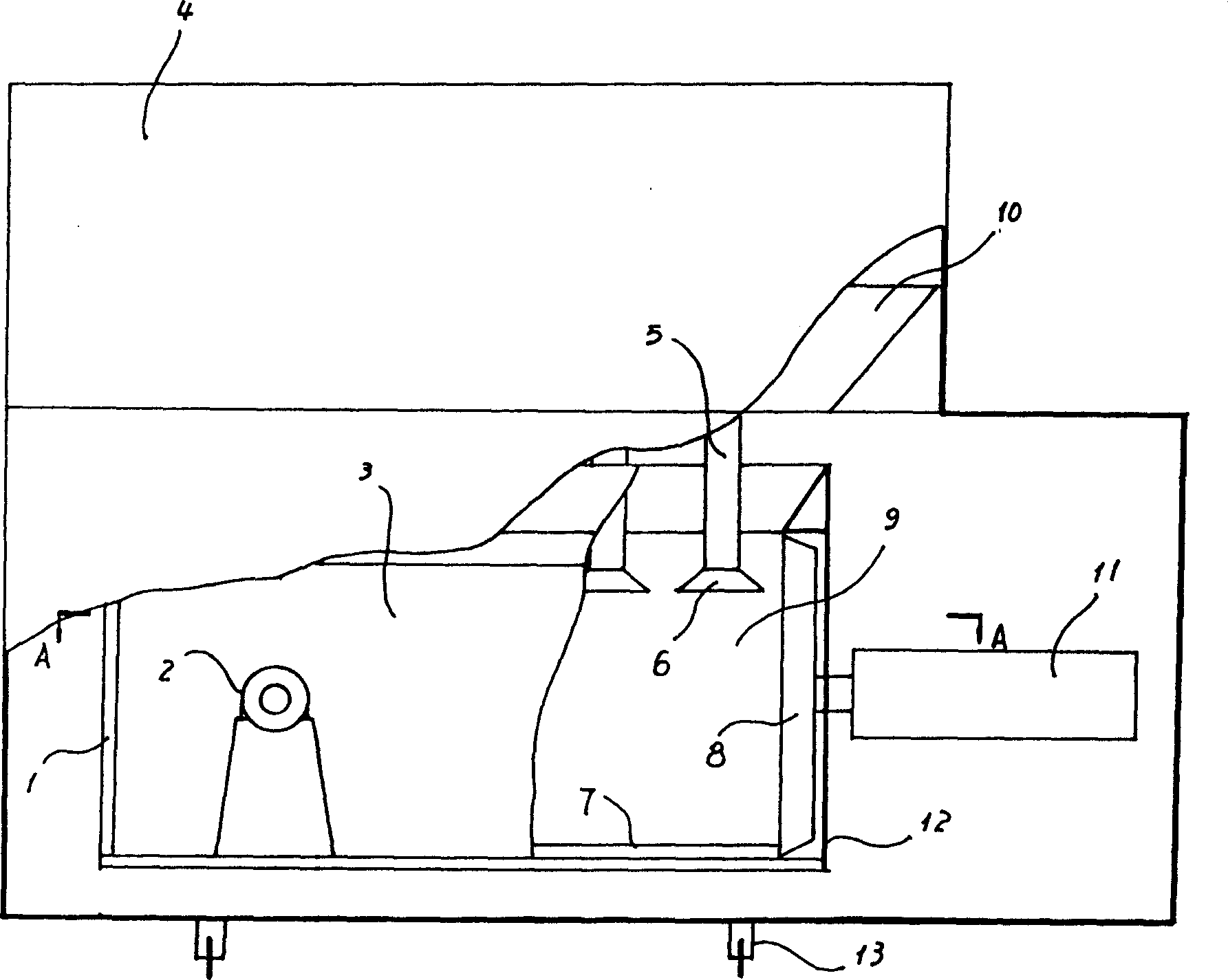

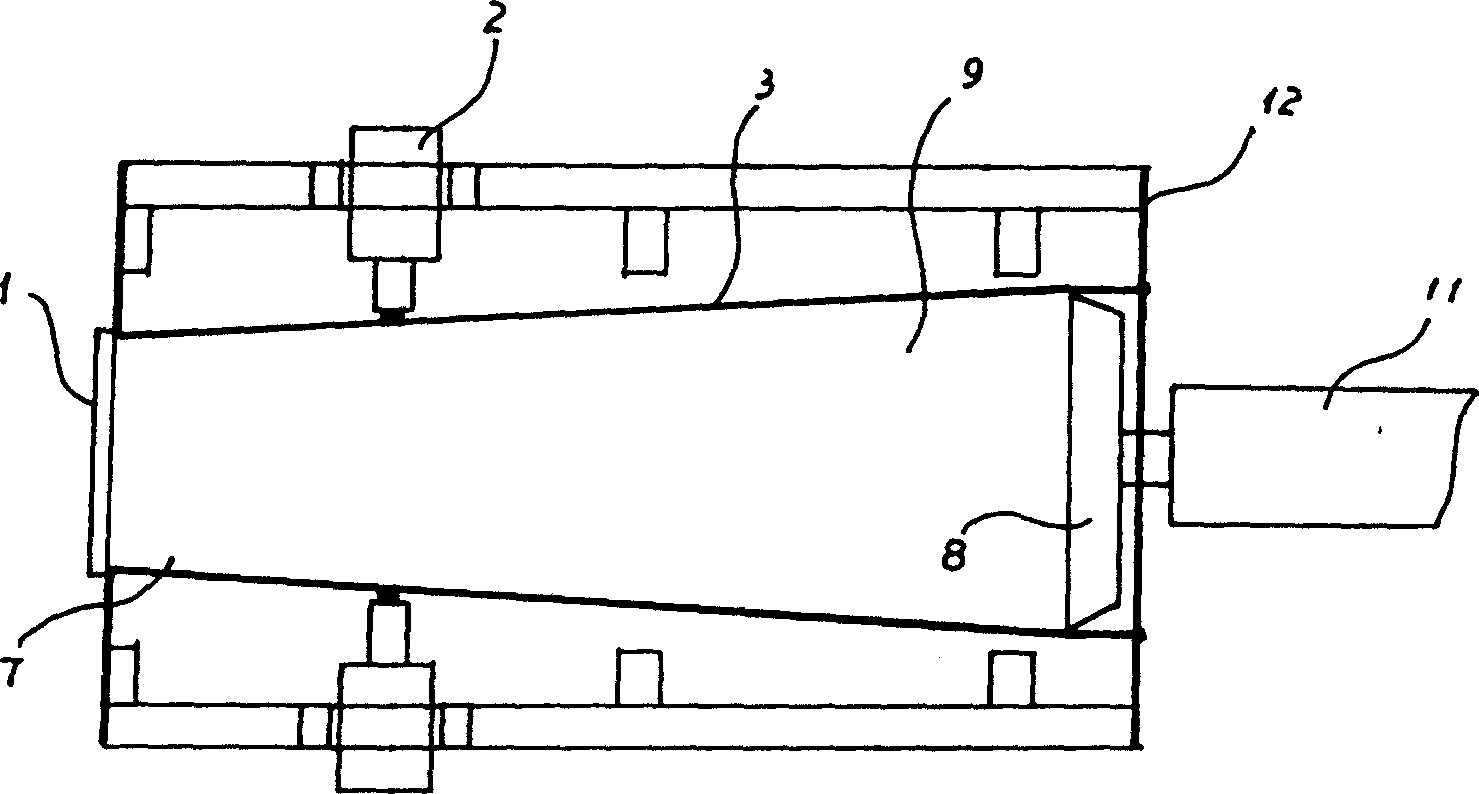

[0011] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation.

[0012] The method for smelting tamping coke in the top-loading coal coke oven in this plan is to set a coking coal tamping device at the coke outlet end of the existing top-loading coal coke oven. The horizontal cross-section of the top-charging coal coke oven carbonization chamber corresponds to a trapezoidal shape, and is sent into the top-charging coal coke oven carbonization chamber through the coke outlet door of the top-charging coal coke oven for normal coking. The coal loader on the original top-loaded coal coke oven is moved to the upper part of the coking coal tamping device. And the coal charging port on the top surface of the original top-charging coke oven is closed.

[0013] The coke tamping device used for the method of making tamping coke in a top-loaded coal coke oven can be seen from the accompanying drawings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com