Coal-based activated coke for desulfuration and preparation method thereof

An activated coke, coal-based technology, applied in the field of coal chemical industry, can solve problems such as endangering human health, destroying the ecological environment, affecting human genes, etc., and achieves the effect of large heap ratio, high activation yield and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

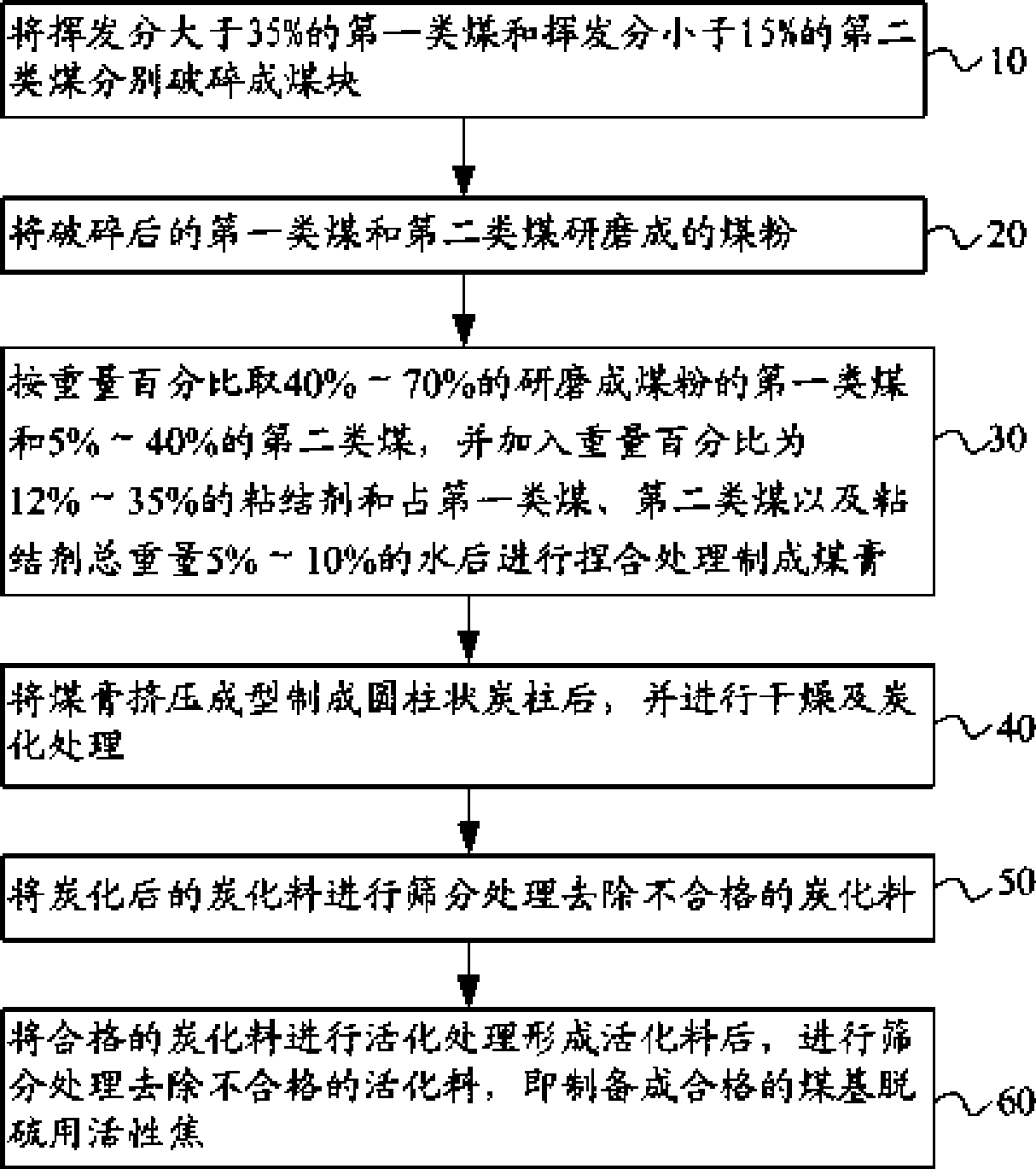

[0028] figure 1 It is a schematic flow chart of the method for preparing activated coke for coal-based desulfurization of the present invention. Such as figure 1 Shown, this preparation method comprises the following steps:

[0029] Step 10, breaking the first type of coal with a volatile content greater than 35% and the second type of coal with a volatile content less than 15% into coal blocks respectively.

[0030] Volatile matter is an important basis index for coal classification, that is, the content of coal after the moisture is subtracted from the escaped substance (gas or liquid) when the coal is heated in isolation from the air at a certain temperature. The first type of coal and the second type of coal are respectively broken into coal pieces smaller than 3 cm. The first type of coal is lignite, and the second type of coal is bituminous coal or anthracite.

[0031] Step 20, pulverized coal obtained by grinding the crushed first type coal and second type coal.

...

Embodiment 1

[0049] Firstly, the lignite and bituminous coal are respectively crushed into coal pieces smaller than 3 cm; then, the crushed lignite and bituminous coal are ground into 190-mesh coal powder; secondly, 50% lignite and 30% bituminous coal are taken by weight percentage, and added The coal tar of 20% by weight and the water accounting for 5% of the total weight of lignite, bituminous coal and coal tar are kneaded at 50°C to make coal paste; again, the coal paste is extruded under a pressure of 15 MPa After making a cylindrical carbon column with a diameter of 5 mm, it is naturally dried and carbonized at 600 ° C for 40 minutes; then, the carbonized carbonized material is screened to remove unqualified carbonized material; finally, the qualified After the activated carbonized material is activated at 800°C for 60 minutes to form the activated material, it is screened to remove the unqualified activated material, and then the qualified activated coke for coal-based desulfurization...

Embodiment 2

[0051] Firstly, the lignite and bituminous coal are respectively broken into coal pieces smaller than 3 cm; then, the crushed lignite and bituminous coal are ground into 160-mesh coal powder; secondly, 45% lignite and 32% bituminous coal are taken by weight percentage, and Add 23% by weight of pitch and 10% of the total weight of lignite, bituminous coal and pitch, and knead at 90°C to make coal paste; again, the coal paste is extruded under a pressure of 18 MPa. After forming a cylindrical carbon column with a diameter of 9 mm, dry it at 40°C and carbonize it at 625°C for 60 minutes; then, sieve the carbonized carbonized material to remove unqualified carbonized material; finally, put Qualified carbonized materials are activated at 825°C for 40 minutes to form activated materials, and then sieved to remove unqualified activated materials to prepare qualified activated coke for coal-based desulfurization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com