Column shape active carbon cutting shaper

A molding device and activated carbon technology, applied in the field of columnar activated carbon cutting and molding devices, can solve the problems affecting the quality and yield of finished products, uneven length of finished products, uneven sections, etc., and achieve ideal cutting effect, simple structure, and neat section. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

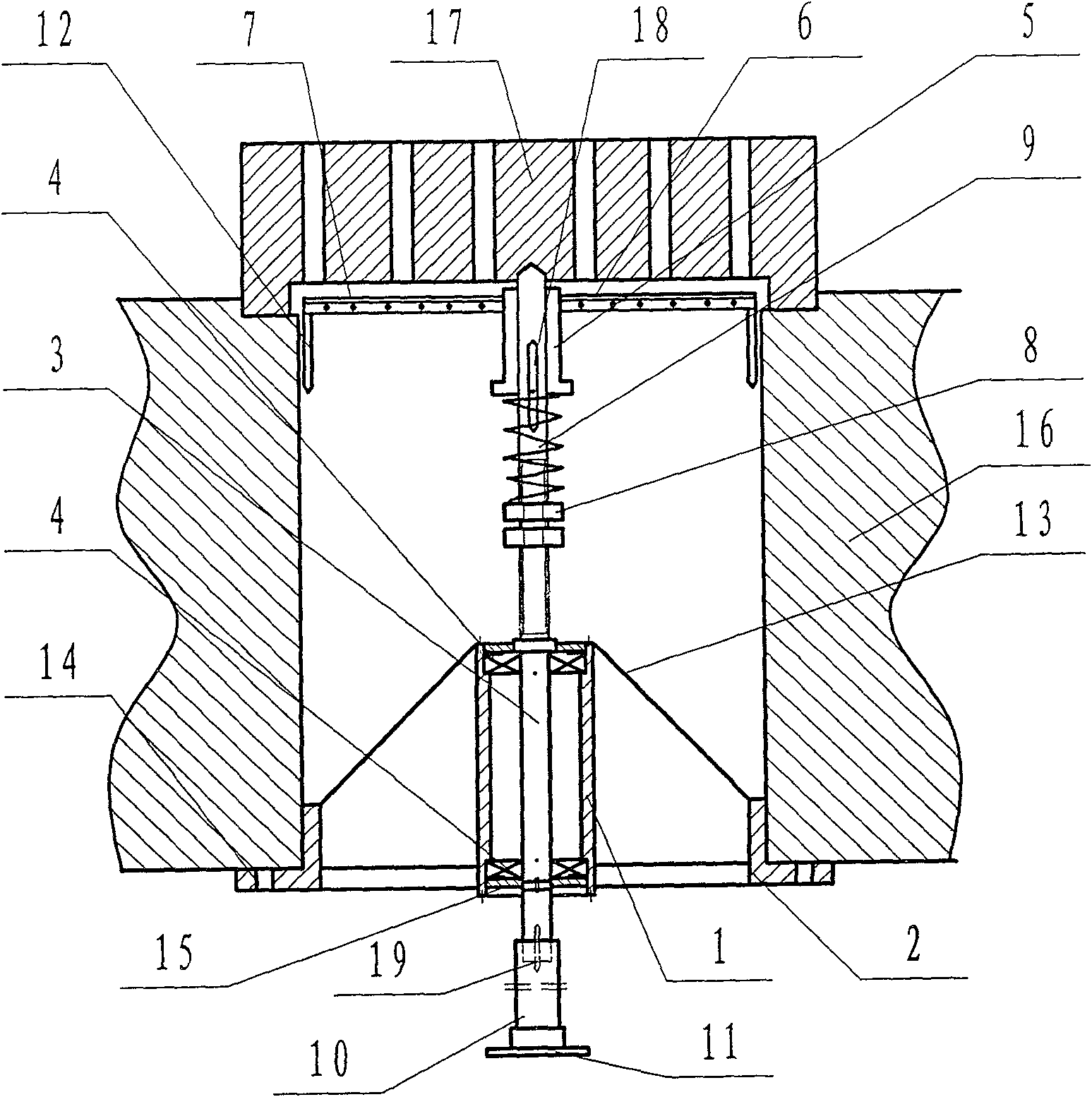

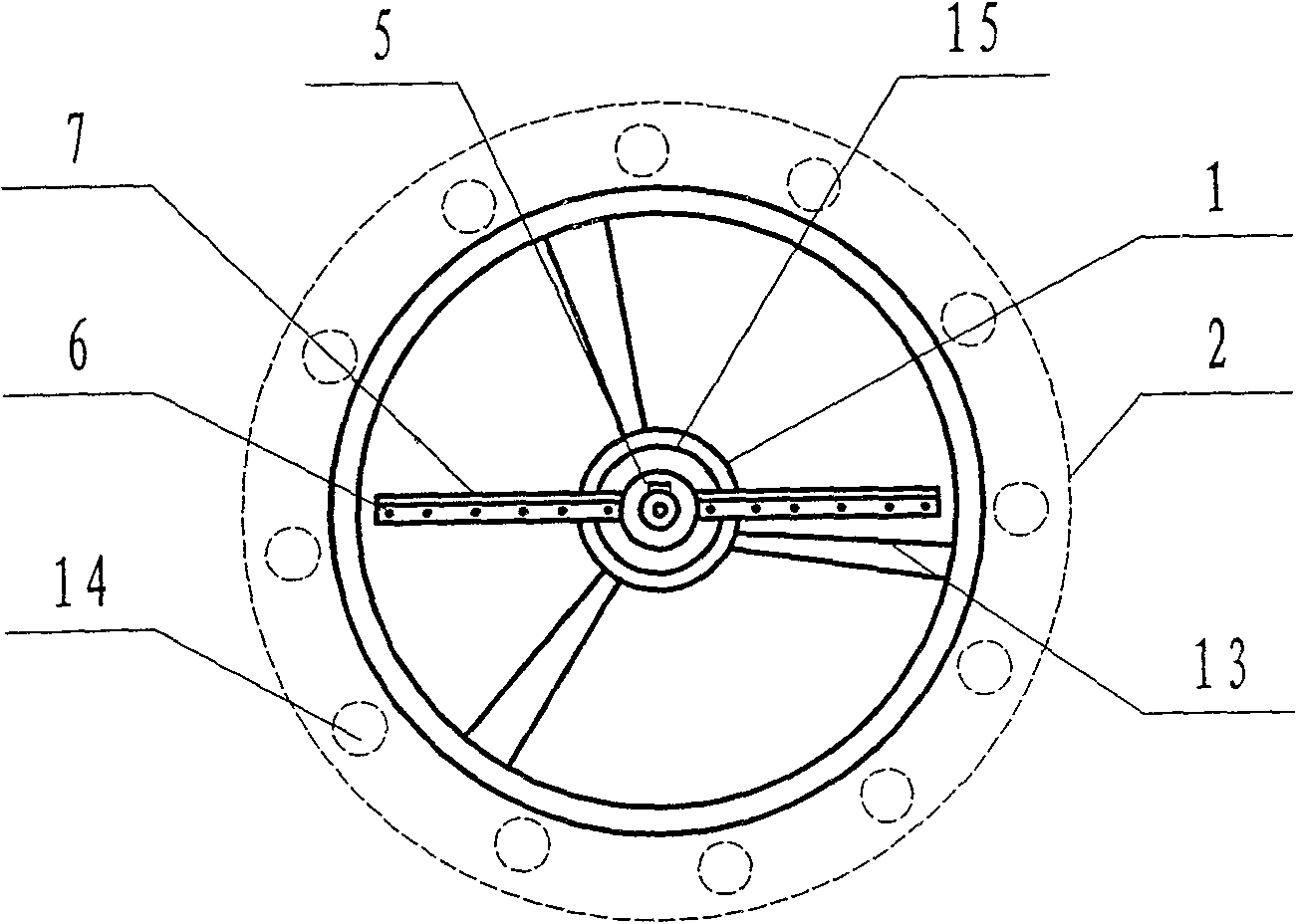

[0016] The cylindrical activated carbon cutting and forming device includes a shaft sleeve 1, a disc 2 connected with the shaft sleeve 1, and a rotating shaft 3 passing through the shaft sleeve 1. A reinforcing rib 13 is provided between the disc 2 and the shaft sleeve 1, and the disc 2 Positioning holes 14 are provided on the circumference, and the rotating shaft 3 is installed in the shaft sleeve 1 through the rolling bearings 4 located at both ends of the shaft sleeve 1. The upper and lower ends of the shaft sleeve 1 are respectively provided with bearing caps 15, and the upper end of the rotating shaft 3 is sleeved with a knife. Frame cover 5, knife rest cover 5 both sides are respectively fixed with knife rest 6, and blade 7 is fixed horizontally on the knife rest 6, and knife rest cover 5 is connected with rotating shaft 3 by key 18; 3, the rotating shaft 3 between the knife rest cover 5 and the axle sleeve 1 is provided with threads, the threaded section is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com