Patents

Literature

89results about How to "Neat section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Distiller yeast, preparation process of distiller yeast and process for preparing health care liquor by utilizing distiller yeast

ActiveCN103421646AHarmonizeQuality improvementAlcoholic beverage preparationHordeum vulgareChinese liquor

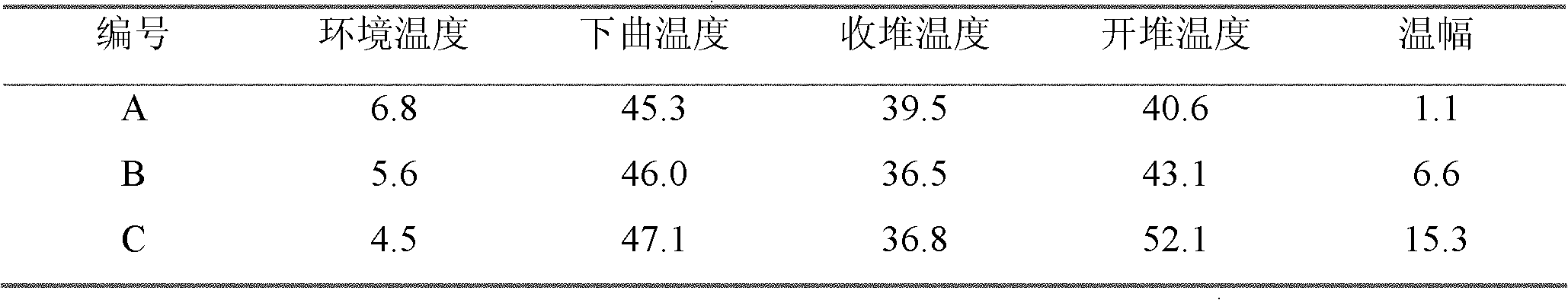

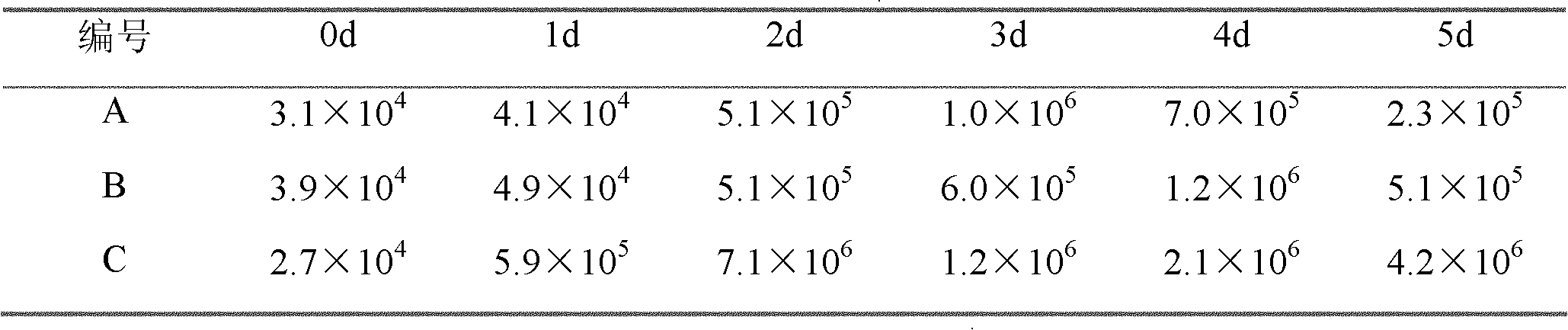

The invention relates to alcohol products, in particular to distiller yeast for manufacturing liquor and a process for preparing the distiller yeast, and further relates to a process for preparing health care liquor by utilizing the distiller yeast. A mixture of wheat, barley and peas is used as a raw materials formula, and the wheat, the barley and the peas are mixed, wherein the weight ratio of the wheat to the barley to the peas is 4:5:1. The raw material formula further comprises bighead atractylodes rhizome which, by weight, accounts for 0.5% of the mixture of the wheat, the barley and the peas, pericarpium citri reticulatae which, by weight, accounts for 0.3% of the mixture of the wheat, the barley and the peas, red jujube which, by weight, accounts for 0.2% of the mixture of the wheat, the barley and the peas, liquorice which, by weight, accounts for 0.3% of the mixture of the wheat, the barley and the peas and folium mori which, by weight, accounts for 0.3% of the mixture of the wheat, the barley and the peas. According to the distiller yeast and the process for preparing the distiller yeast, beneficial microorganisms in the yeast for making hard liquor are fully bred, the quality of the distiller yeast is improved, and a role in restraining infectious microbes is played by adding Chinese herbal medicine. The invention further provides the process for preparing the health care liquor, according to the process, the style characteristics of traditional Chinese liquor are kept, and the health care liquor has the effects of body building, fitness and disease treatment.

Owner:河南尧香酒业有限公司

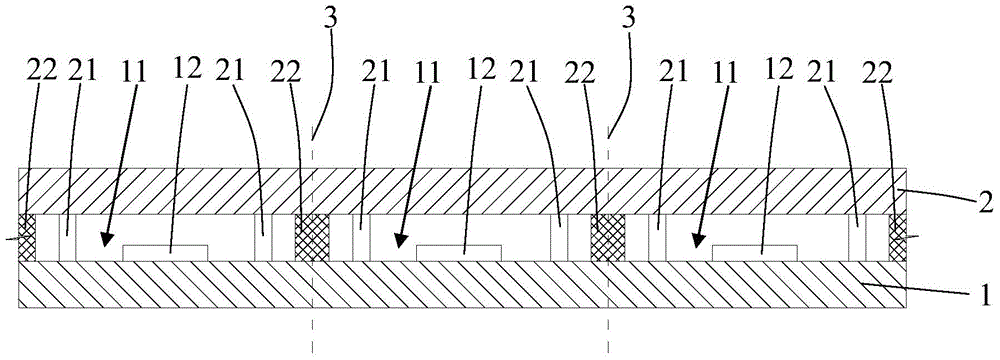

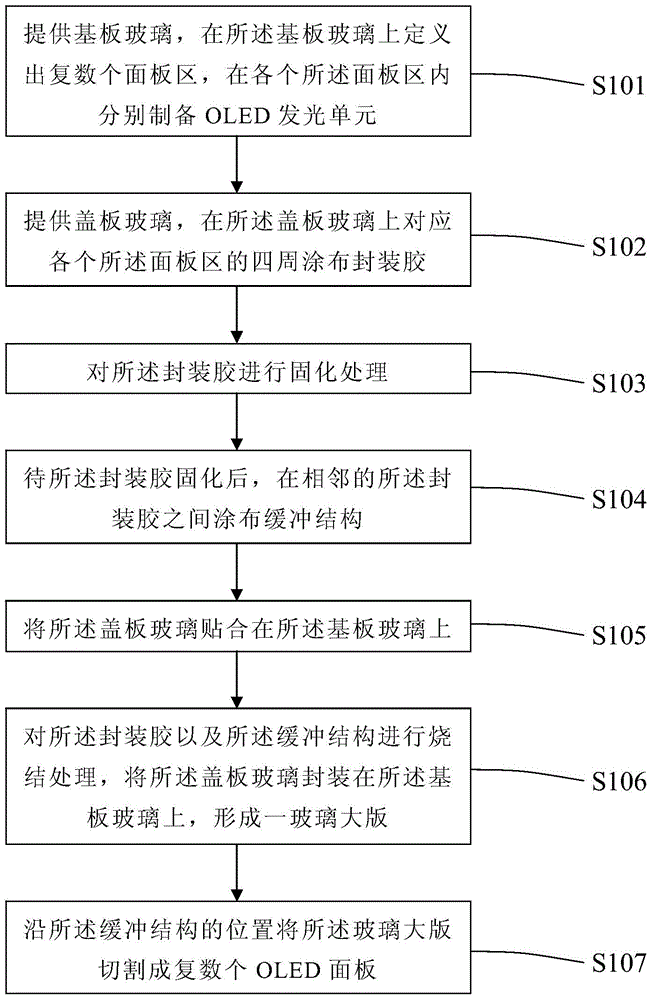

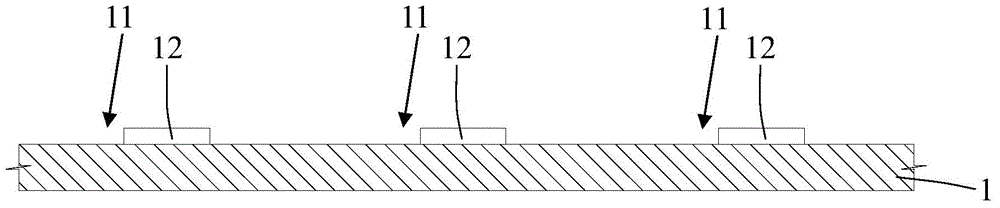

Packaging structure and preparation method of OLED (organic light emitting diode) panel

InactiveCN104485311AReduce shockImprove buffering effectSolid-state devicesSemiconductor/solid-state device manufacturingCutting glassEngineering

The invention discloses a packaging structure and a preparation method of an OLED (organic light emitting diode) panel. The preparation method comprises the following steps of providing substrate glass, defining a plurality of panel areas on the substrate glass, and respectively preparing an OLED light emitting unit in each panel area; providing cover plate glass, and coating packaging glue around the parts, corresponding to each panel area, of the cover plate glass; curing the packaging glue; after the packaging glue is cured, coating a buffer structure between the adjacent packaging glue; attaching the cover plate glass on the substrate glass; sintering the packaging glue and the buffer structure, and packaging the cover plate glass on the substrate glass to form a glass large template; cutting the glass large template into a plurality of OLED panels along the corresponding buffer structure. The preparation method has the advantage that by coating the buffer structure on the cover plate glass, when the glass is cut by a knife wheel, the shock caused by the glass cracks can be reduced by the buffer structures, the penetrating stress of the knife wheel and the stress of the glass cracks are absorbed, and the influence on the packaging glue by the cutting stress is reduced.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

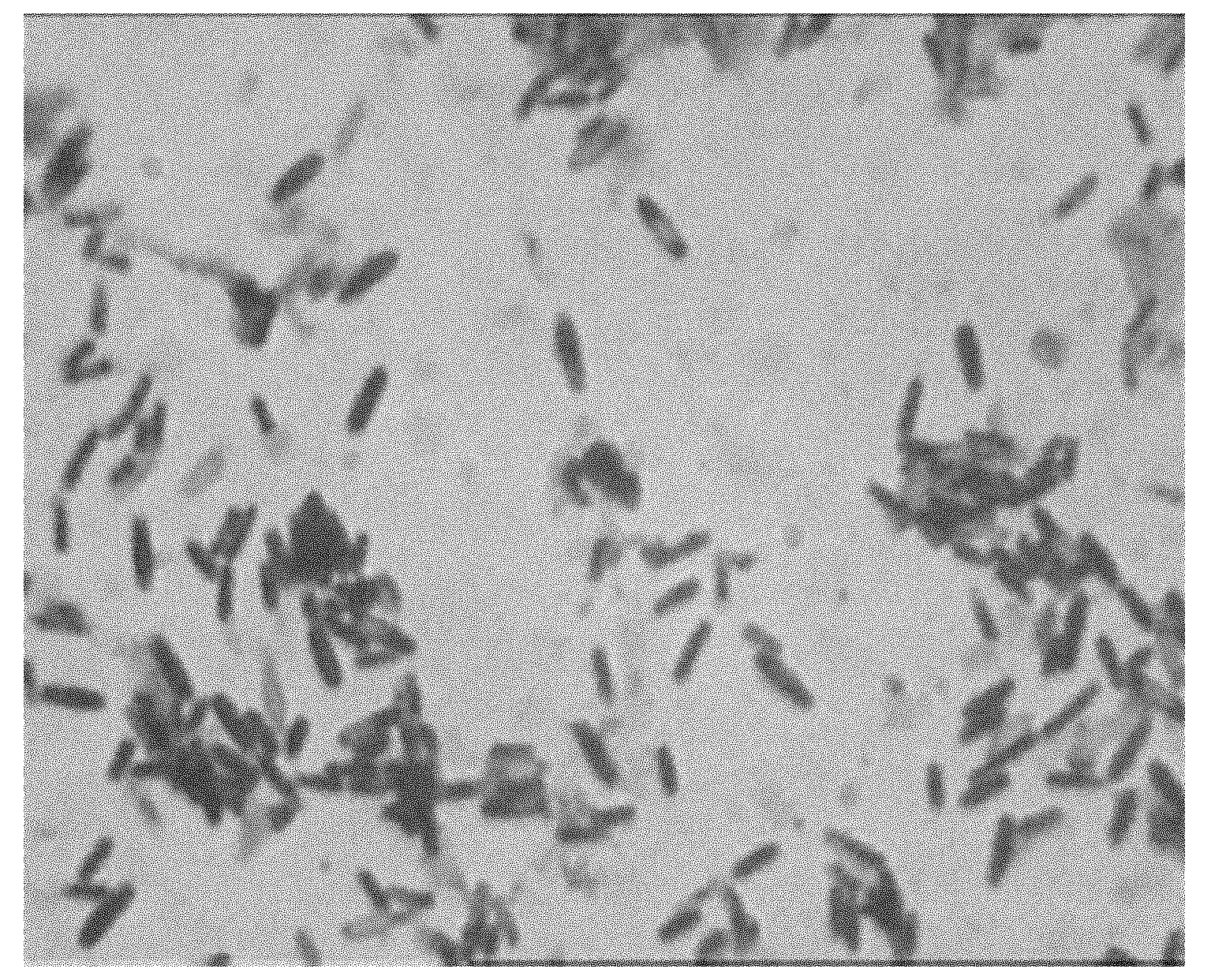

Method for preparing intensified daqu applied to nongjiang-flavor Chinese spirits

ActiveCN102140427AGood aroma productionQu Yi obviousBacteriaMicroorganism based processesFlavorChemistry

The invention relates to a method for preparing intensified daqu applied to nongjiang-flavor Chinese spirits from Bacillus thermophilus. The intensified daqu prepared by the method is high in fermentation speed, is added into a finished high-temperature starter for production, is used for brewing traditional Chinese spirits, can reduce the starter consumption in production, effectively solves the problem that fermented grains stacked in winter are difficult to heat, improves the spirit yield and premium quality good rate on the premise of keeping the flavor of the original spirits, can save massive brewing and fermentation equipment, manpower, field and energy, and has high use value.

Owner:湖北白云边酒业股份有限公司

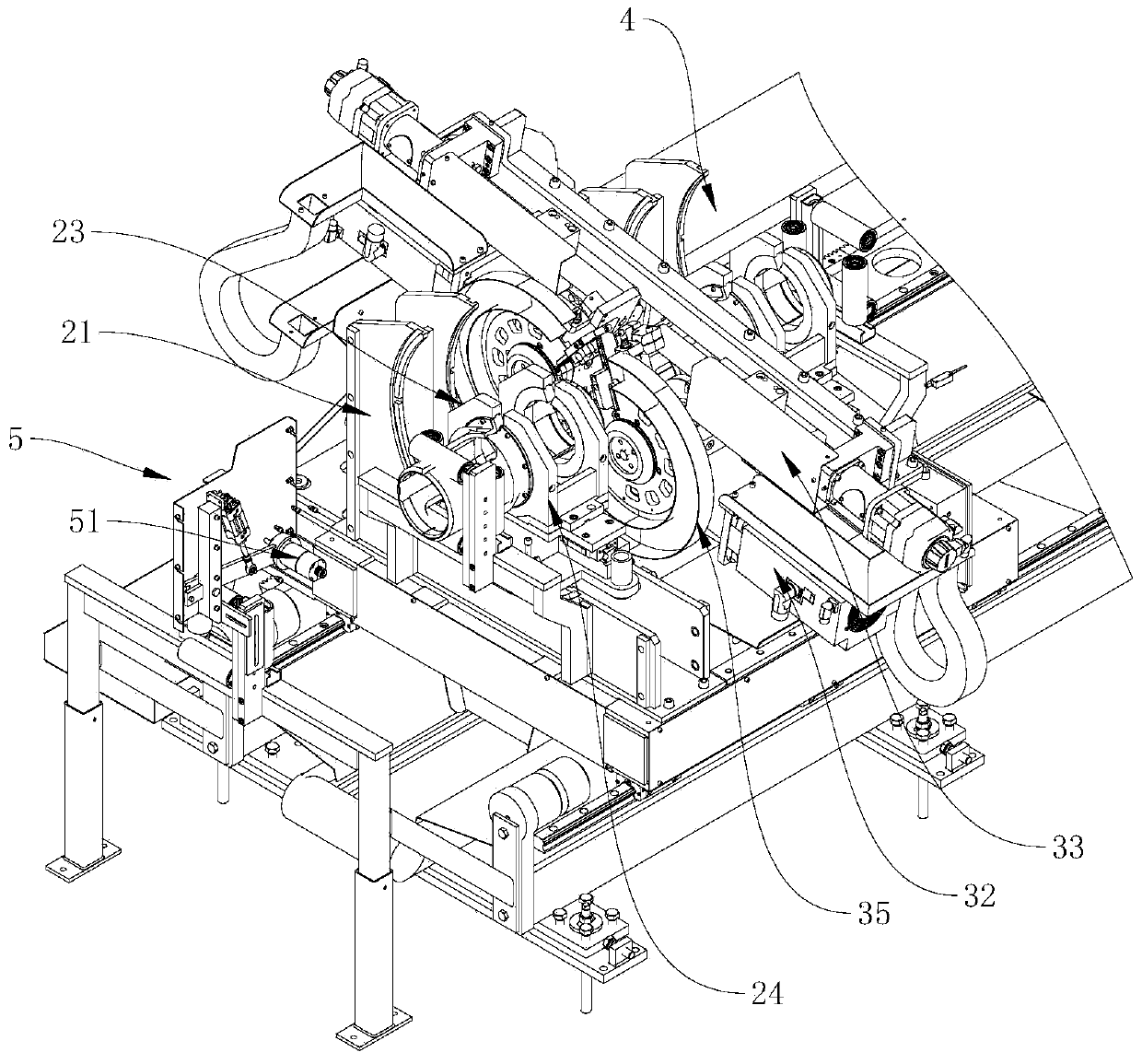

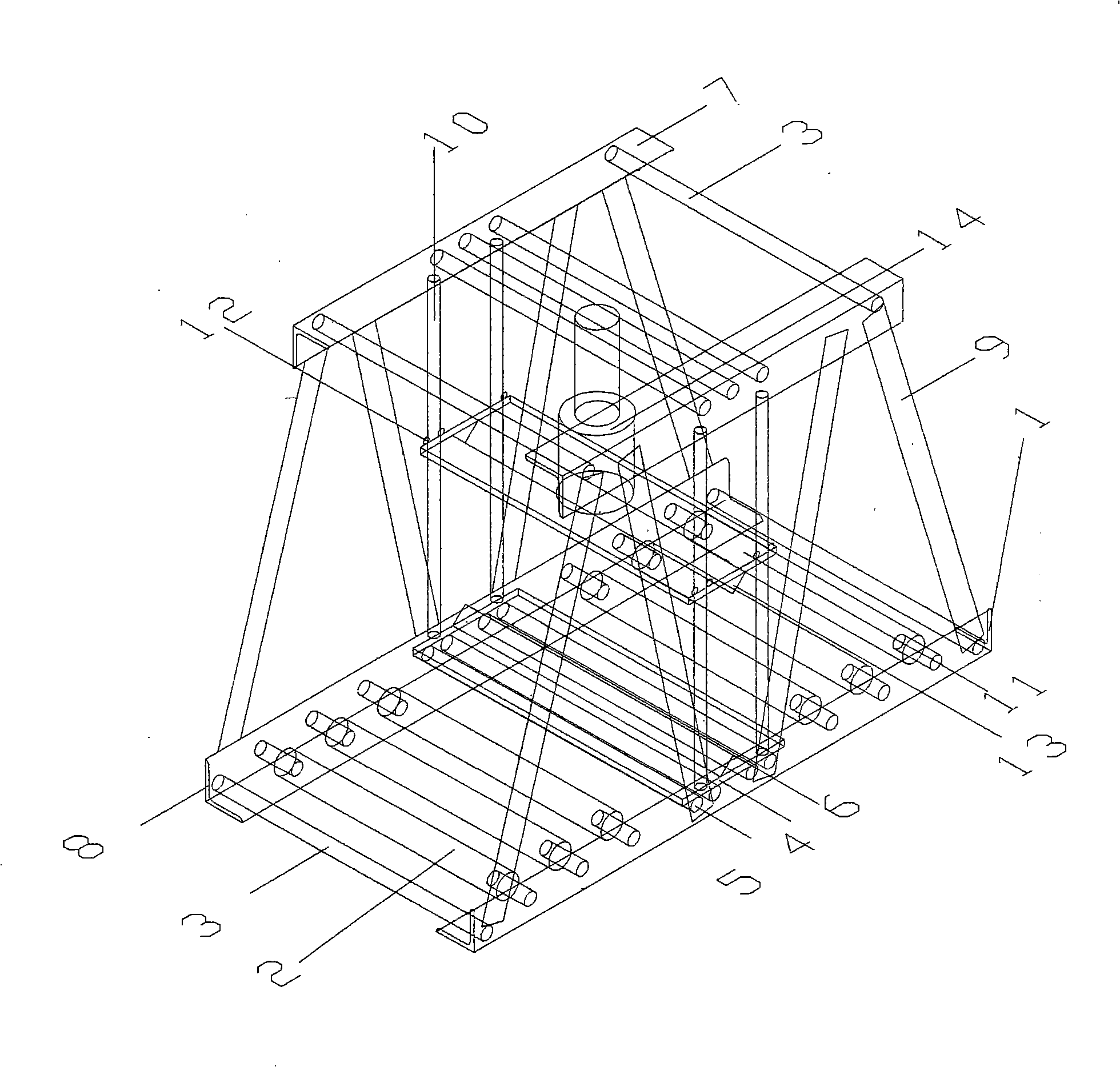

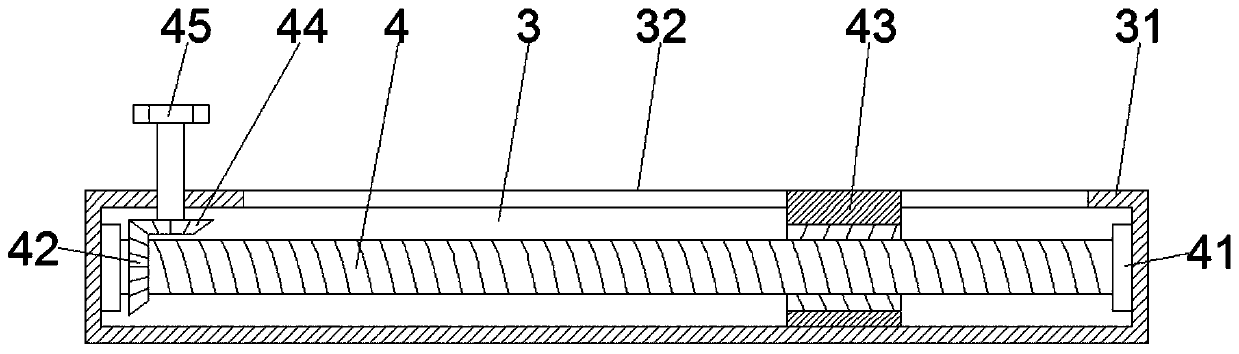

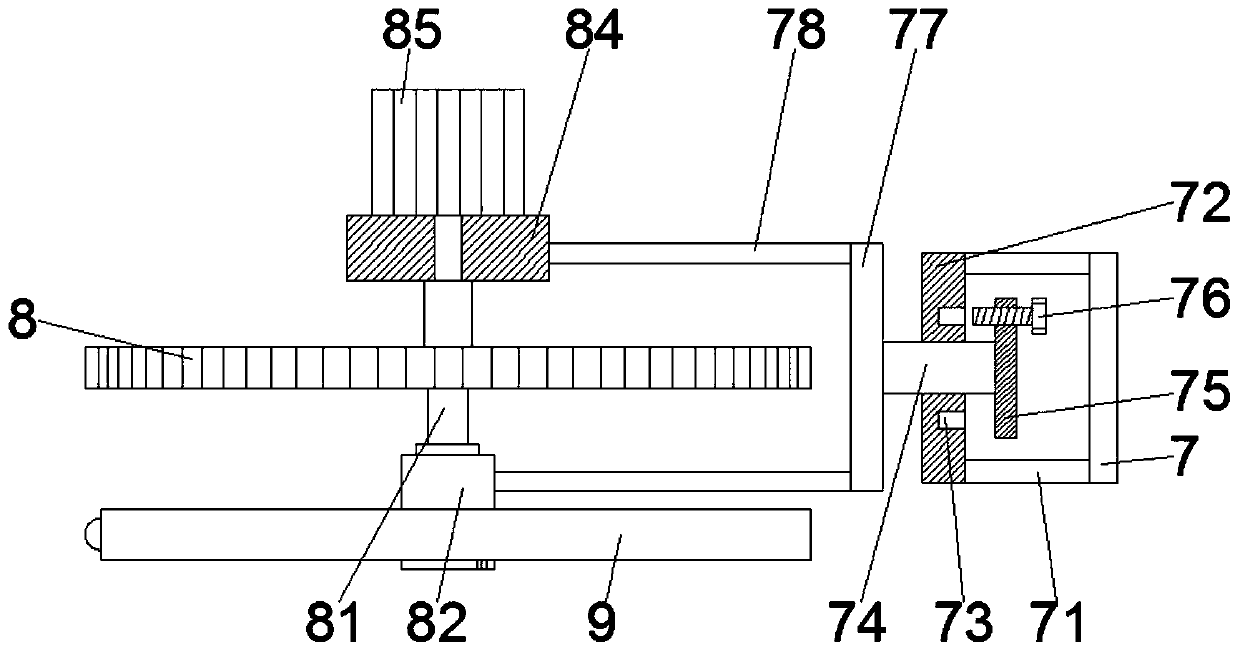

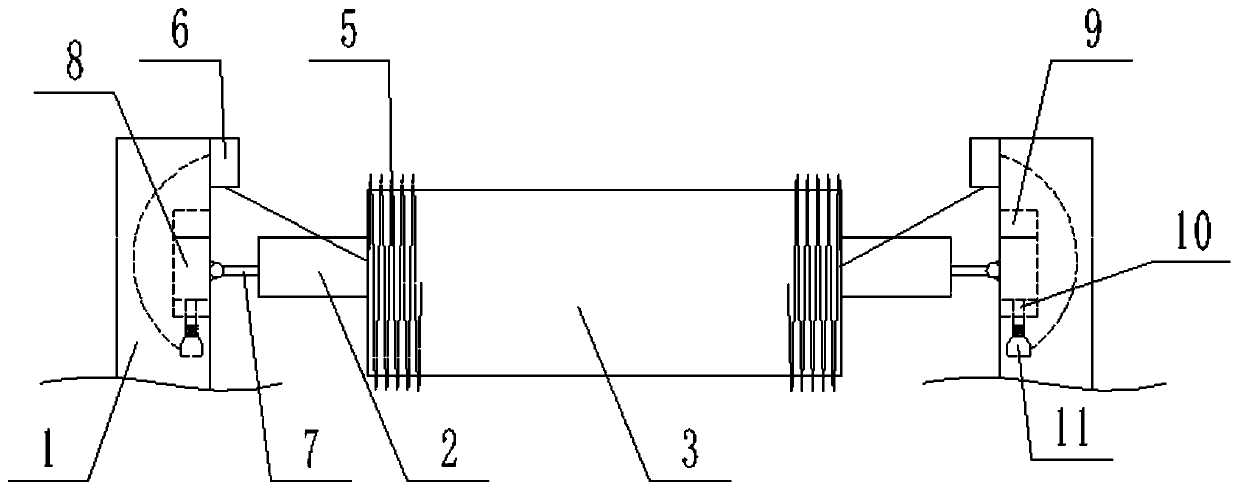

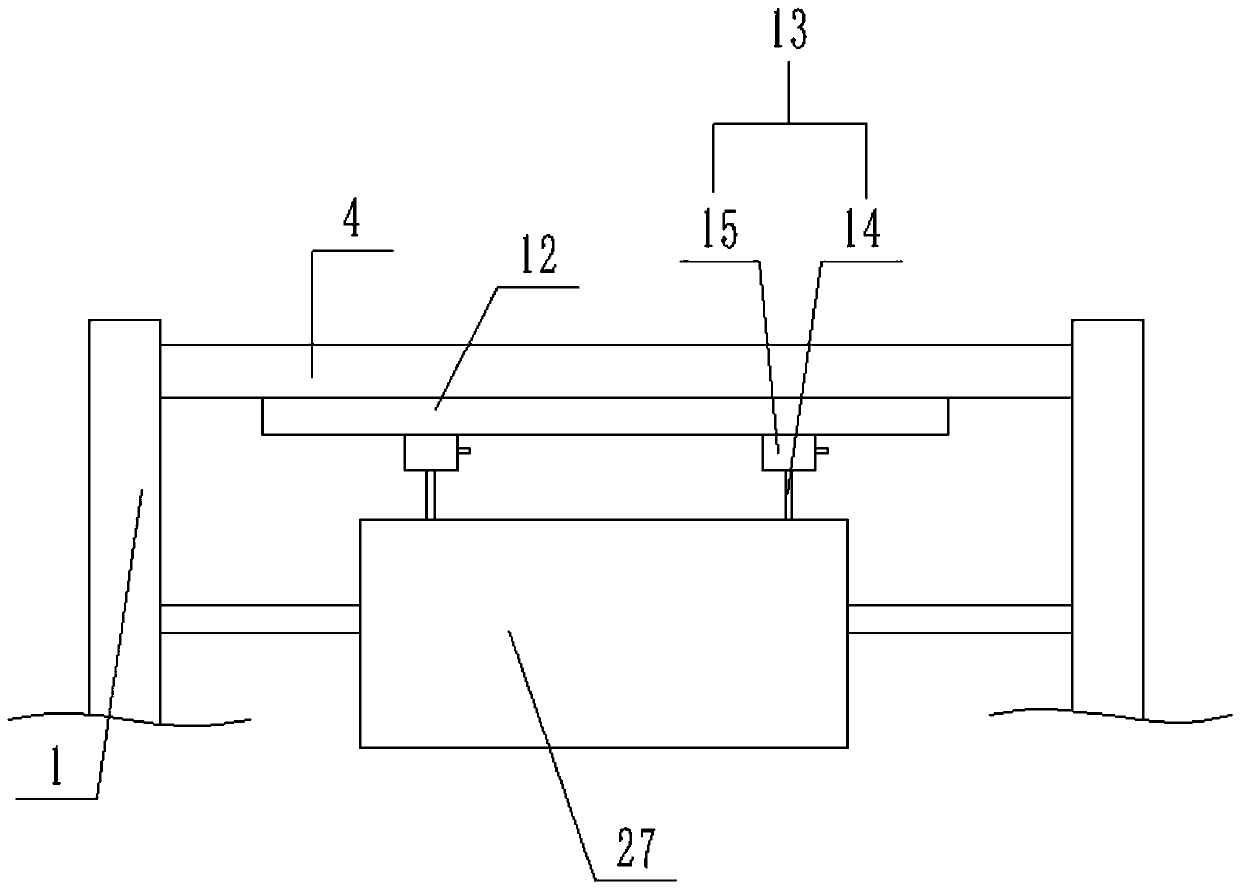

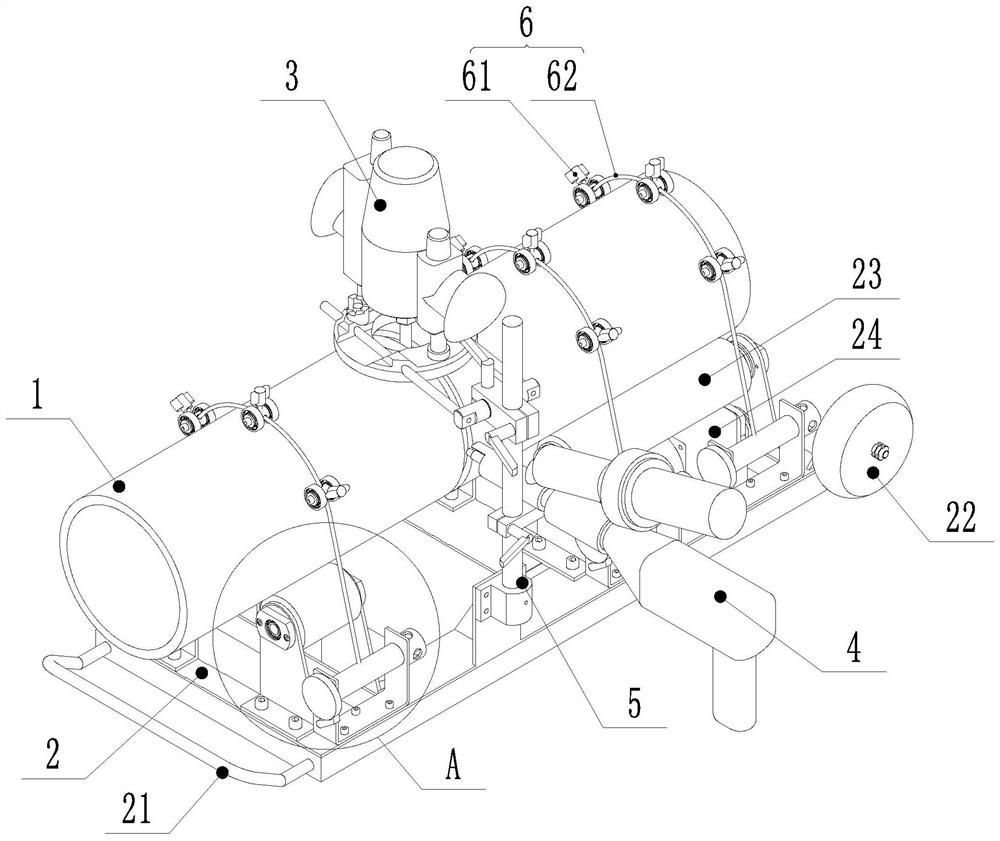

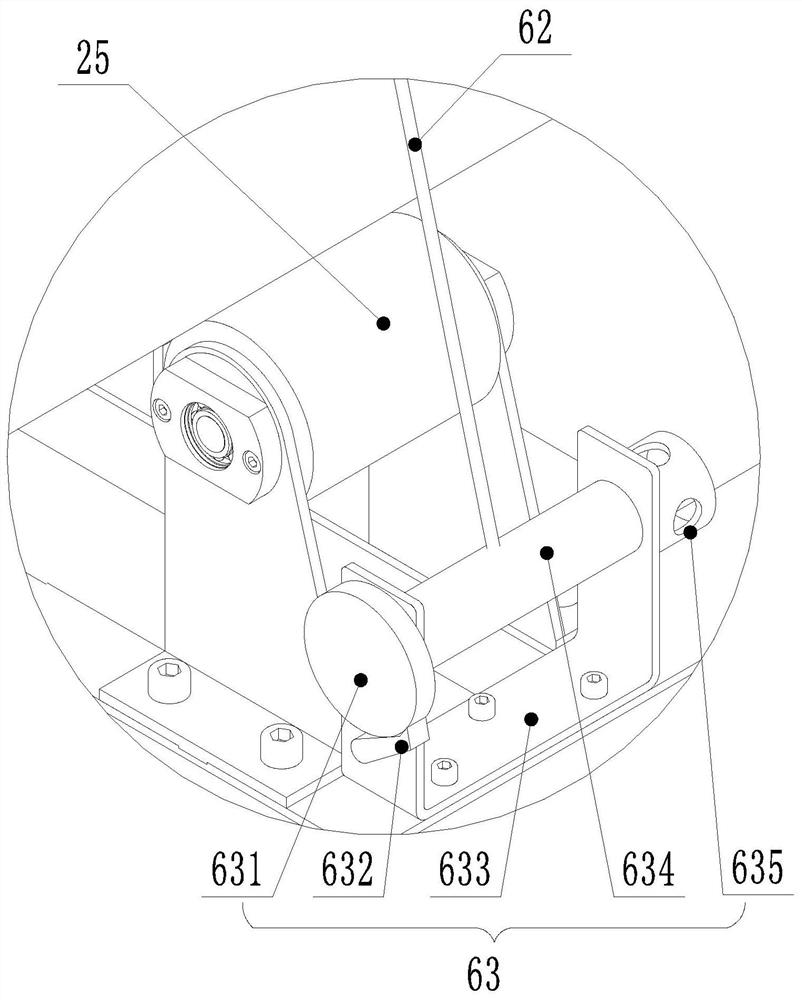

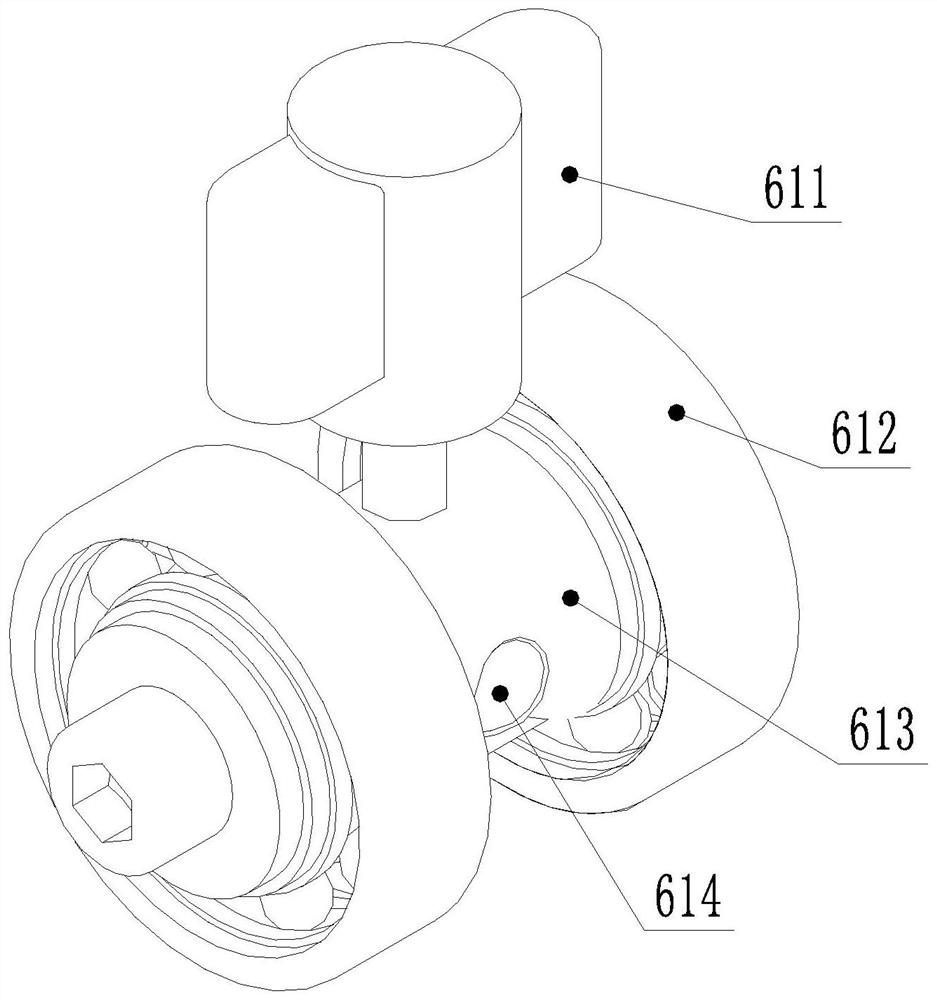

Saw cutting machine for special pipes

ActiveCN103801762ANot easy to shakeAvoid damageMetal sawing devicesEngineeringMechanical engineering

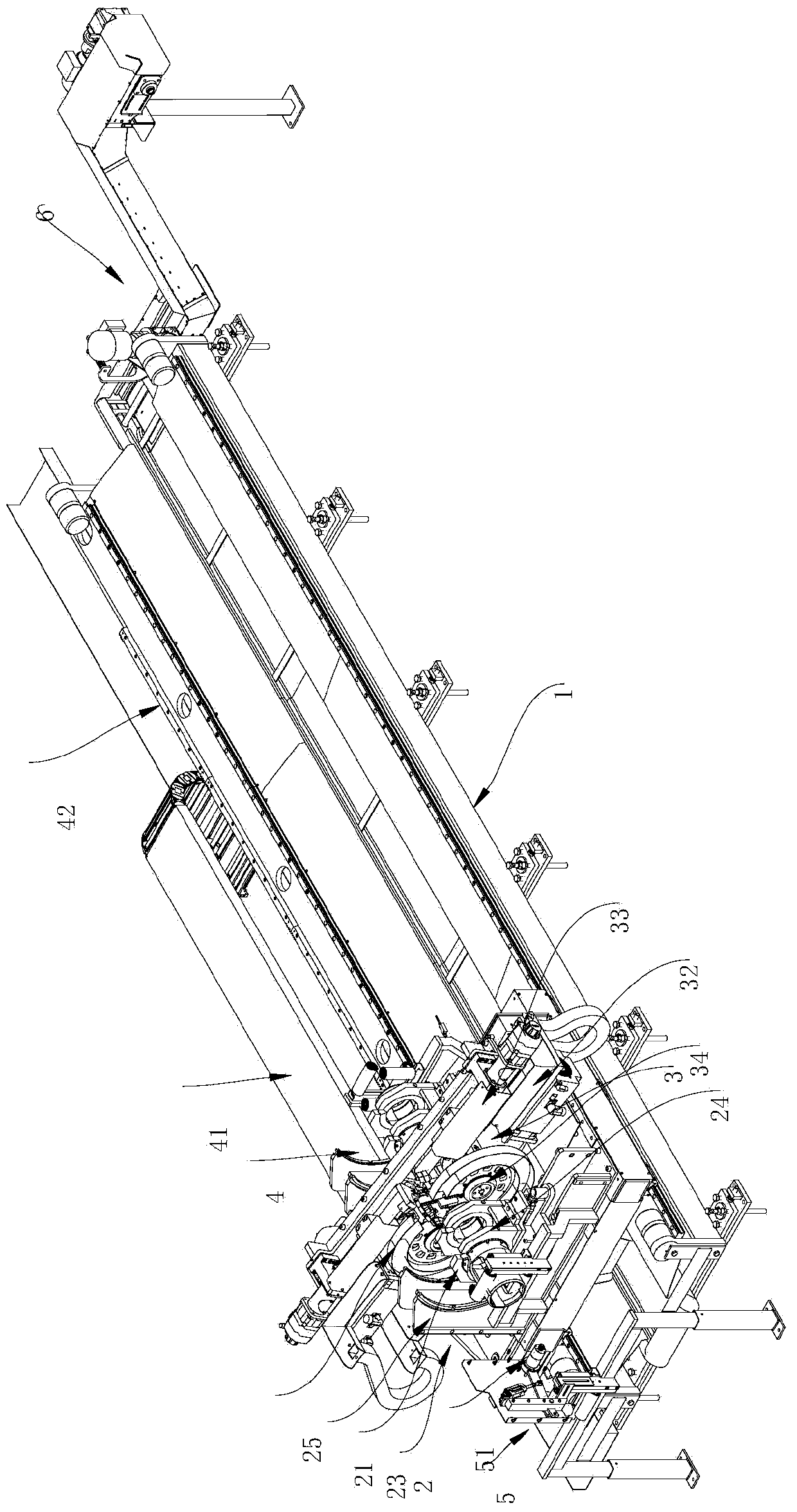

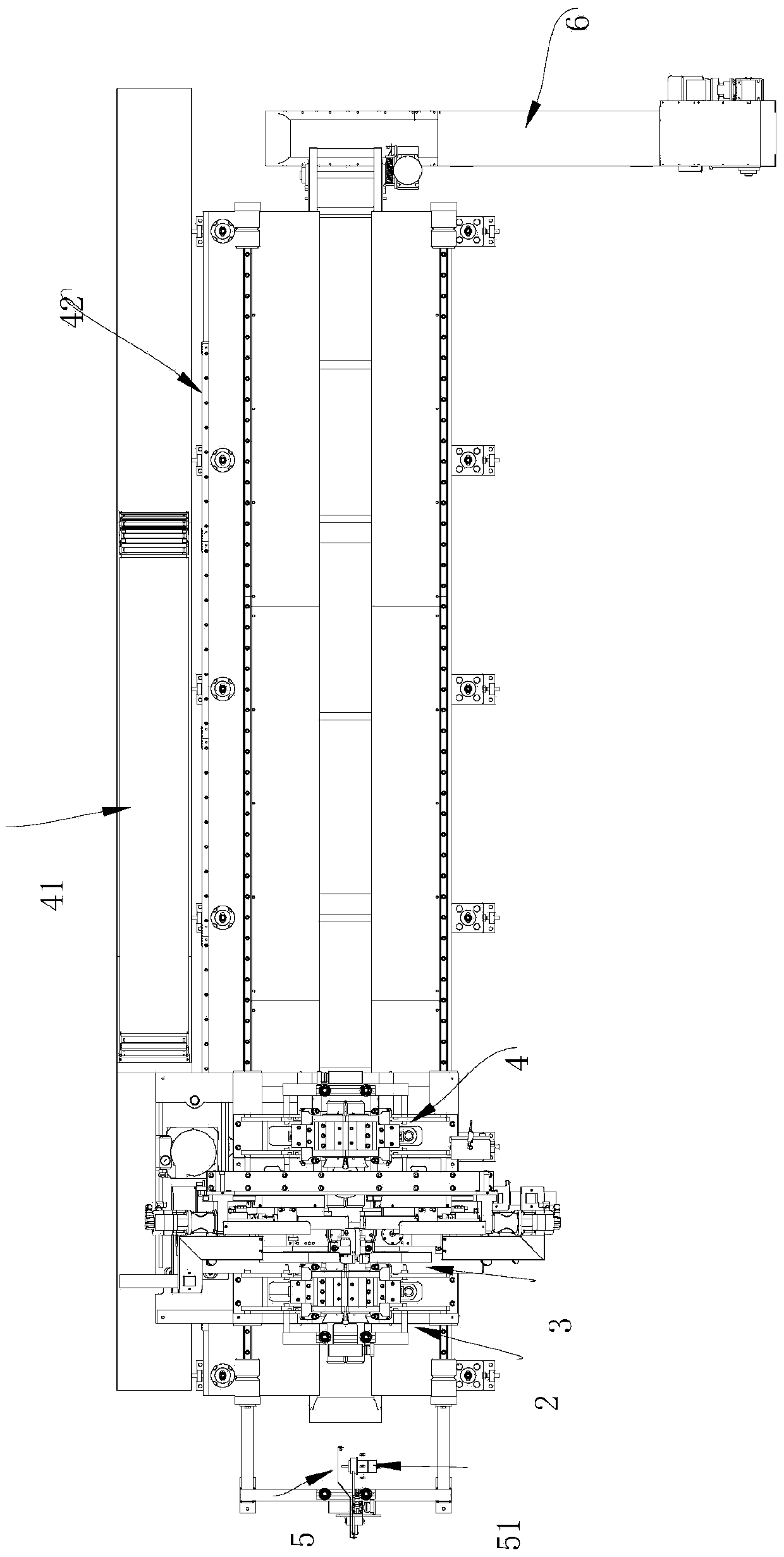

The invention discloses a saw cutting machine for special pipes. The saw cutting machine comprises a machine base, a feeding clamp assembly, a saw cutting device and a discharging clamp assembly. The saw cutting device is installed on the machine base. The feeding clamp assembly is fixed to the upstream side of the saw cutting device and comprises an arc-shaped chute base, a rotating base, a first clamp half body, a second clamp half body, a clamping power device and a locking device, wherein the arc-shaped chute base is fixed to the machine base, the rotating base is installed on the arc-shaped chute base and locked by the locking device, at least one of the first clamp half body and the second clamp half body is installed on the rotating base in a sliding mode, and the clamping power device is fixed to the rotating base to drive the first clamp half body or / and the second clamp half body to get close to each other or get away from each other in a sliding mode. The discharging clamp assembly is installed on the downstream side of the saw cutting device and driven by a discharging power device to slide. The saw cutting machine can clamp the pipes optionally in different directions, make cross sections of cut pipes neat, improve cutting quality and prevent damage to the surfaces of the pipes.

Owner:SUZHOU KINKALTECK MACHINERY TECH

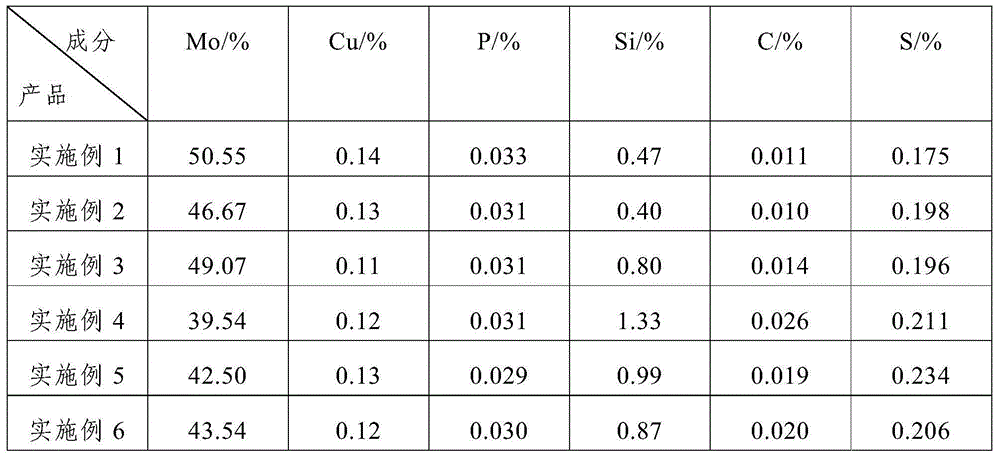

Method for smelting ferro-molybdenum from ammonia leaching residue to recover molybdenum

ActiveCN104152707AImprove resource utilizationReduce consumptionProcess efficiency improvementAluminiumResource utilization

The invention discloses a method for smelting ferro-molybdenum from ammonia leaching residue to recover molybdenum. The method comprises the following steps: 1, the ammonia leaching residue and an auxiliary material are added into a mixer to be mixed uniformly to obtain a mixture, wherein the auxiliary material comprises ferro-silicon, ferro-phosphorus, aluminum particles, sodium nitrate and a fluxing agent, and the fluxing agent adopts calcium oxide or fluorite; 2, the mixture is loaded in a smelting furnace, the surface of the mixture is covered with a layer of firelighter, and a reaction product is obtained after ignition for smelting; the reaction product stands still so that iron is precipitated to form smelting residue and a ferro-molybdenum ingot, the smelting residue is removed, the ferro-molybdenum ingot cools naturally to be solidified, and the purpose of smelting ferro-molybdenum from the ammonia leaching residue to recover molybdenum is achieved. According to the method provided by the invention, the ammonia leaching residue is mixed with the smelting auxiliary material on the basis of a silicon-aluminium thermal reduction method, and the smelting residue and the ferro-molybdenum ingot are produced by a ferro-alloy self-heating reaction technique, so that the effect of recycling molybdenum metal is achieved; when used for smelting ferro-molybdenum to recover molybdenum in ammonia leaching residue, the method has the advantages of high resource utilization rate, low smelting auxiliary material consumption, small environmental pollution and high metal recovery rate.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Technology for preparing micropore pipe through semi-molten continuous extrusion of high molecular powder

The invention relates to a technology for preparing a micropore pipe through semi-molten continuous extrusion of high molecular powder. The technology is characterized by comprising the following steps: (1) feeding solid powdered material in a screw extruding device through a hopper; (2) heating a barrel entering the screw extruding device, and performing initial compaction by a threaded rod at the same time so as to enable materials to be in a semi-molten state; (3) feeding the material in a handpiece for further compaction; (4) feeding the materials in a mould cavity of a neck mould of the screw extruding device to be tubular, determining inner and outer diameters under the effect of a vacuum cooling forming sleeve, and initially cooling; (5) cutting through a cutting device to obtain the micropore pipe. According to the technology, the high molecular powder is continuously extruded and formed when being in semi-molten state and the produced product does not need to be subjected to aftertreatment simultaneously when production of micropore pipes is realized, so that the production efficiency is greatly improved. According to the technology, a solvent is not used, and thus the micropore pipe is beneficial to environmental protection and health of operators.

Owner:SUZHOU KAHO POLYMER TECH CO LTD +1

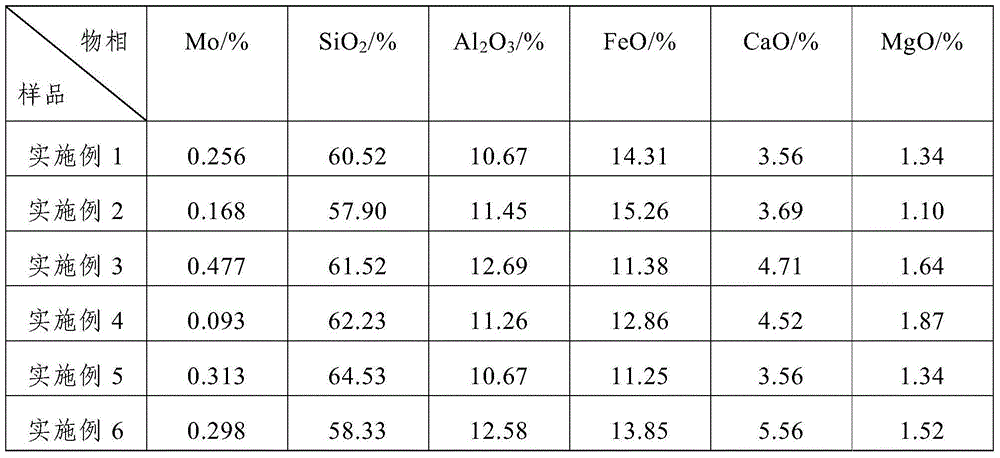

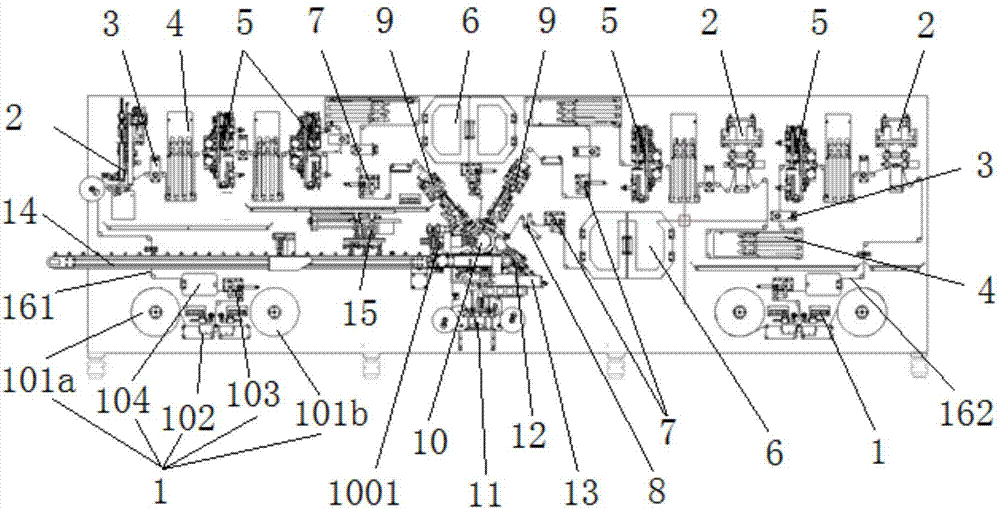

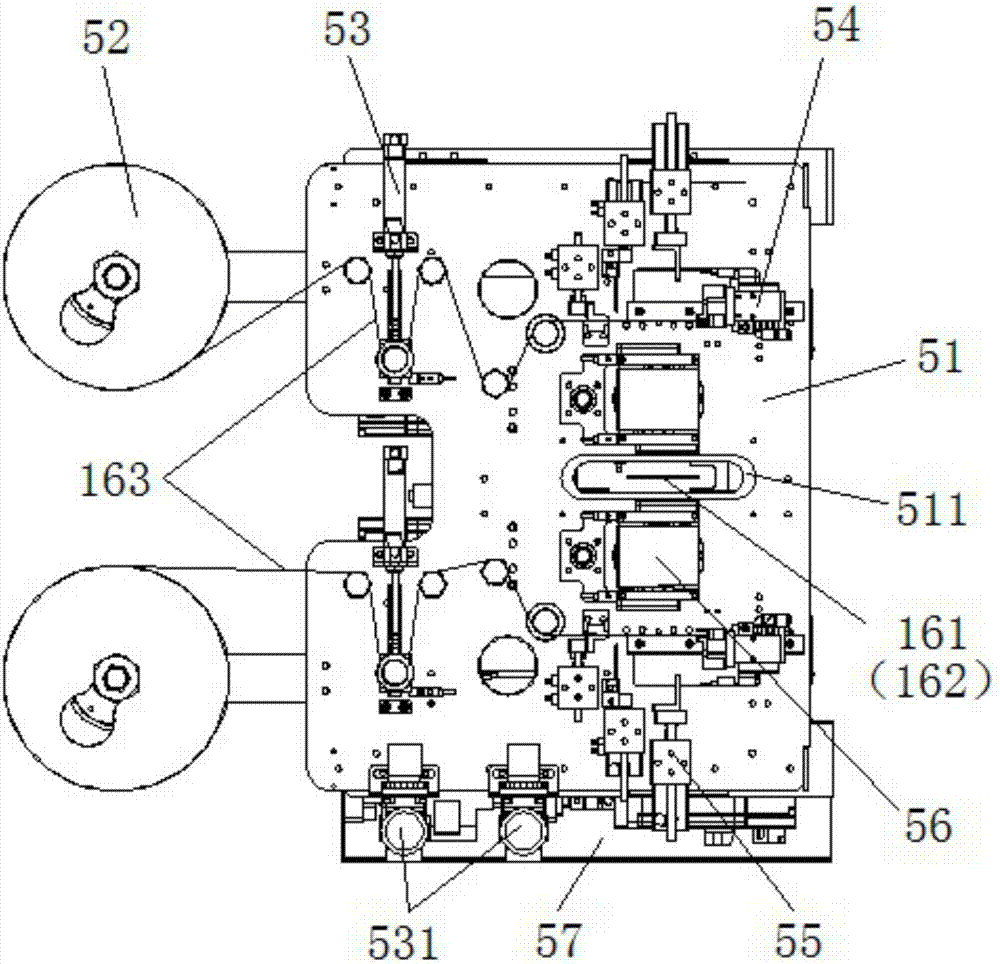

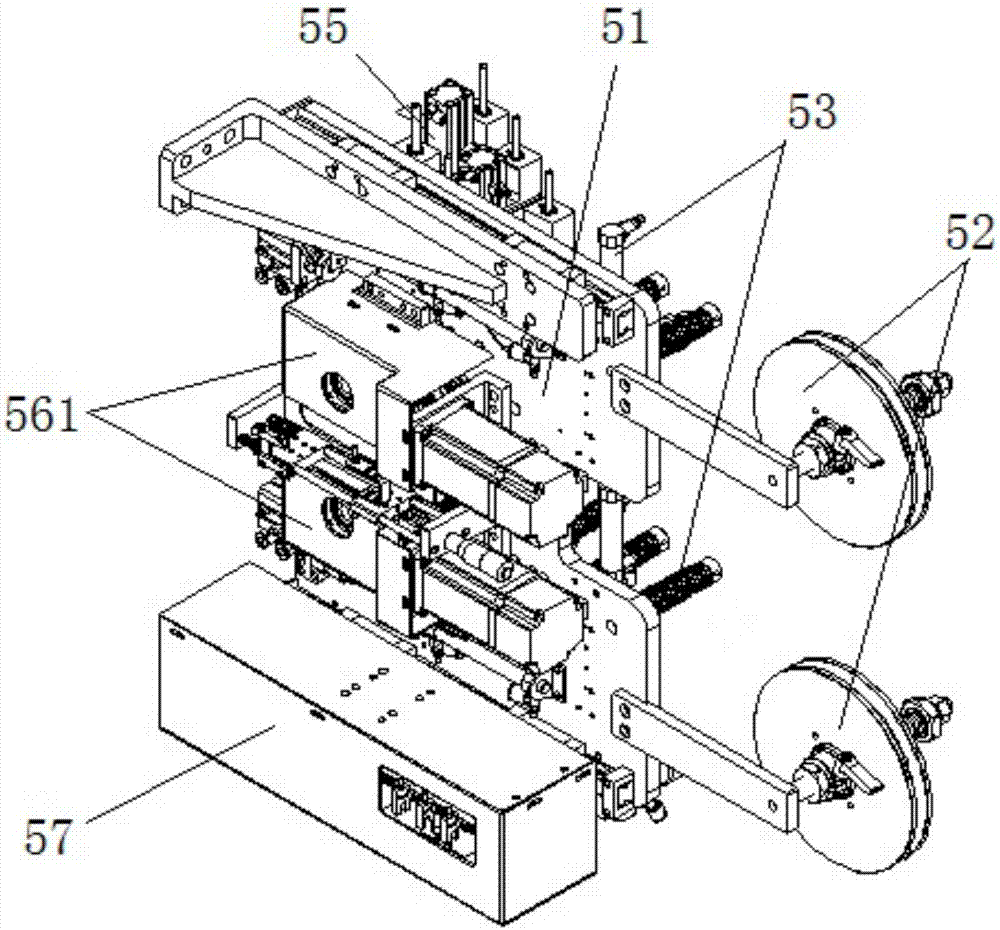

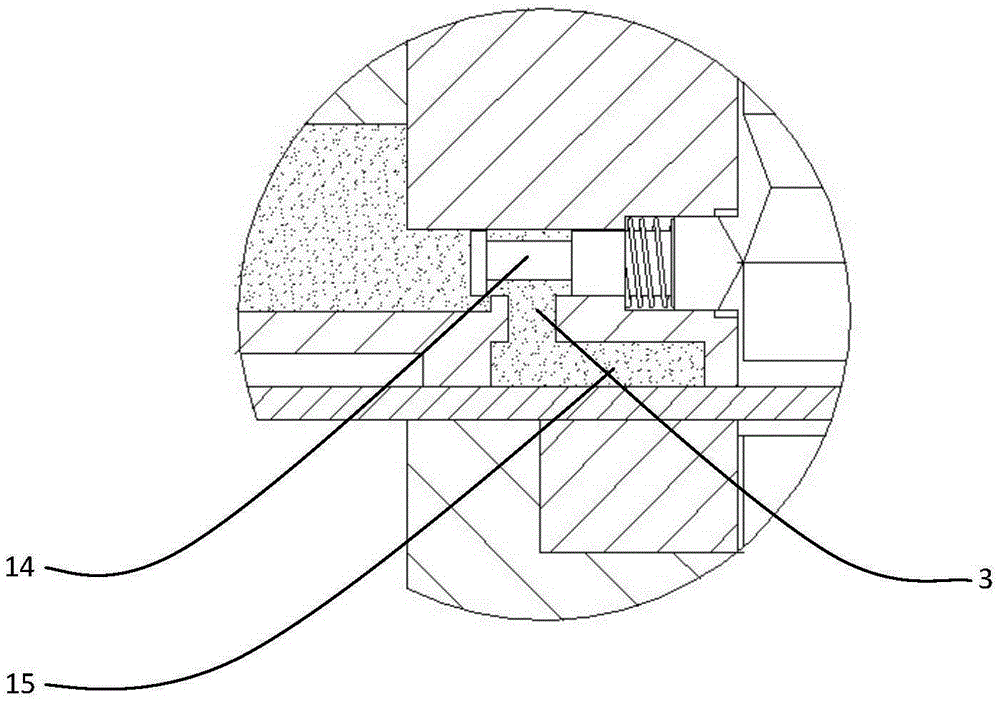

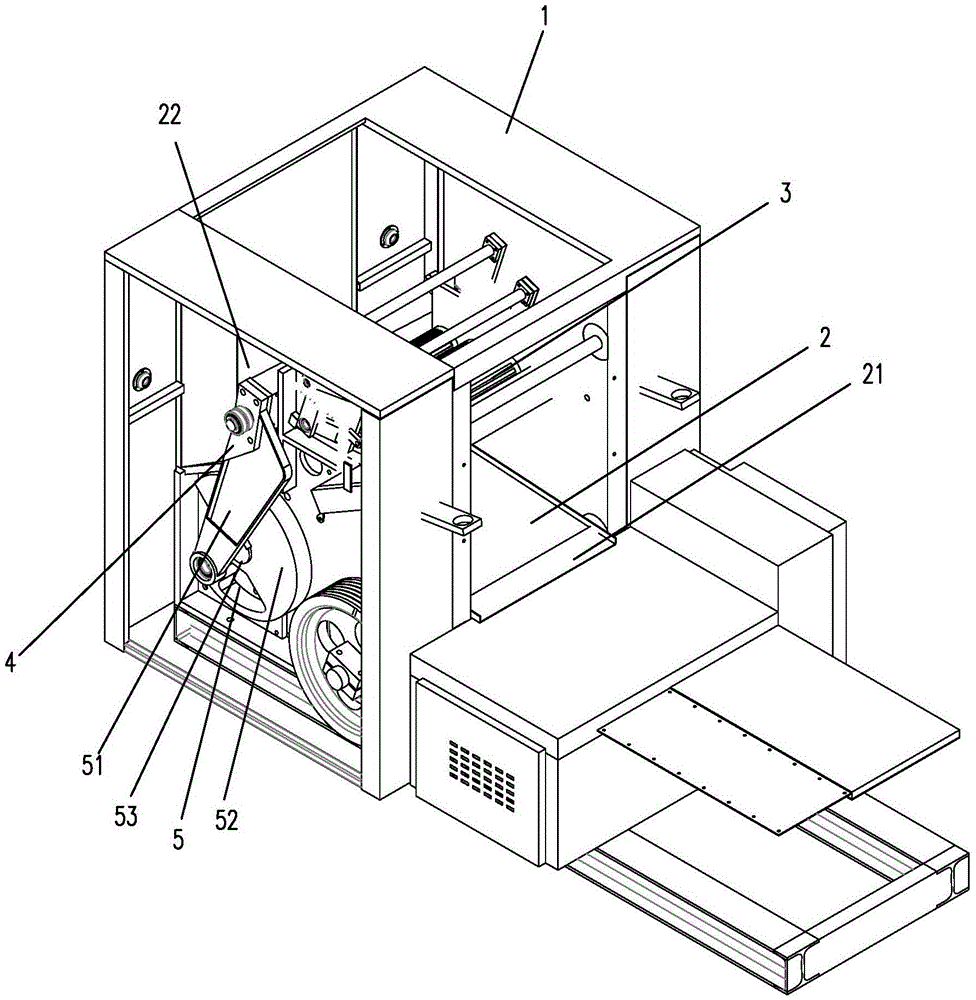

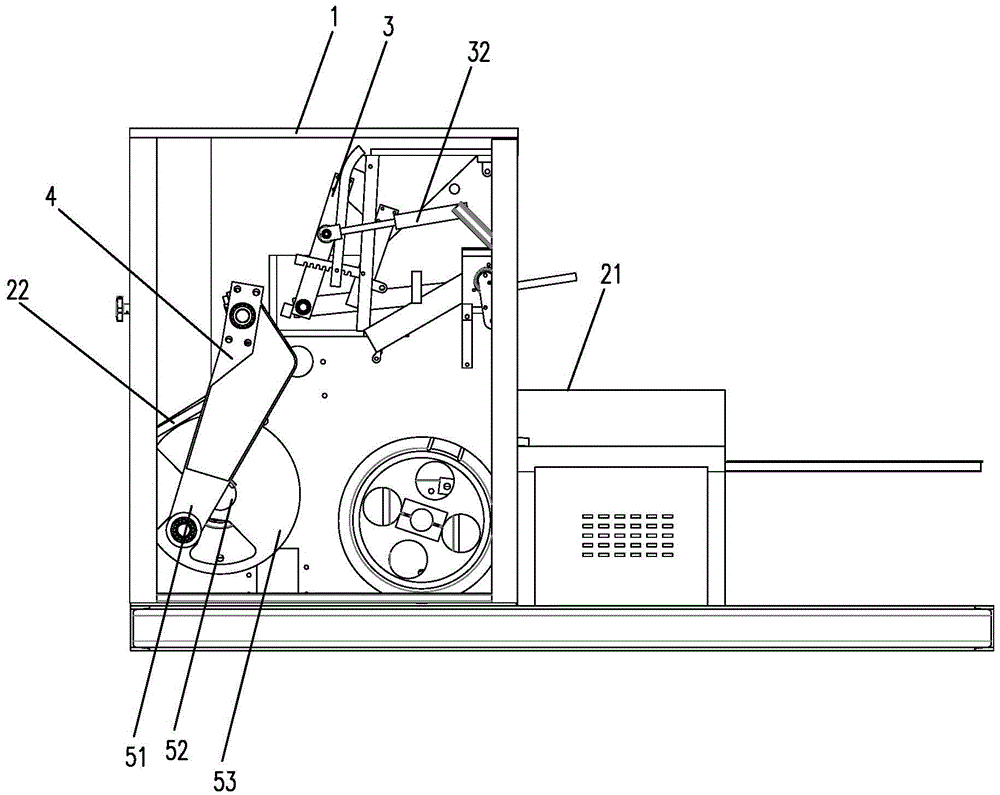

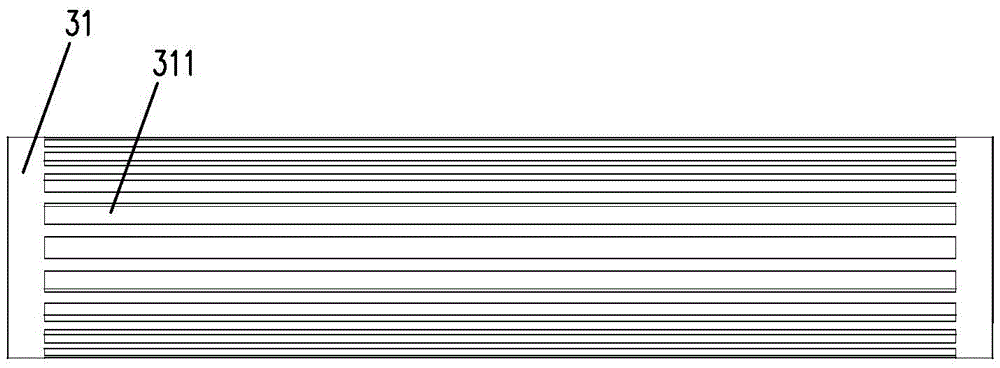

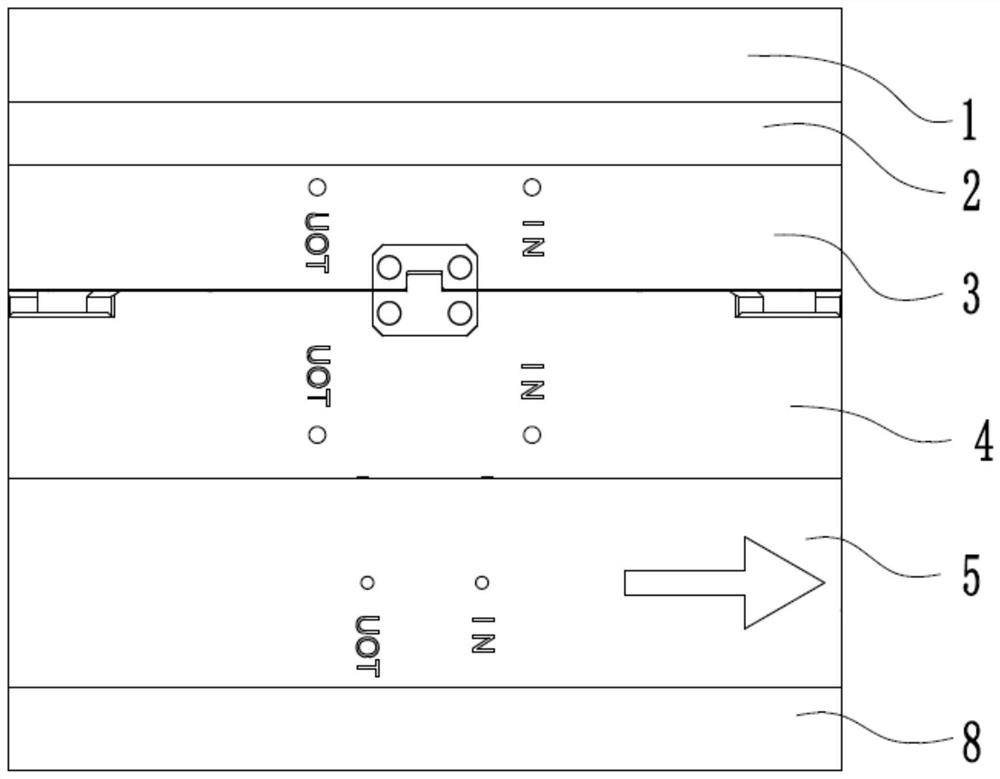

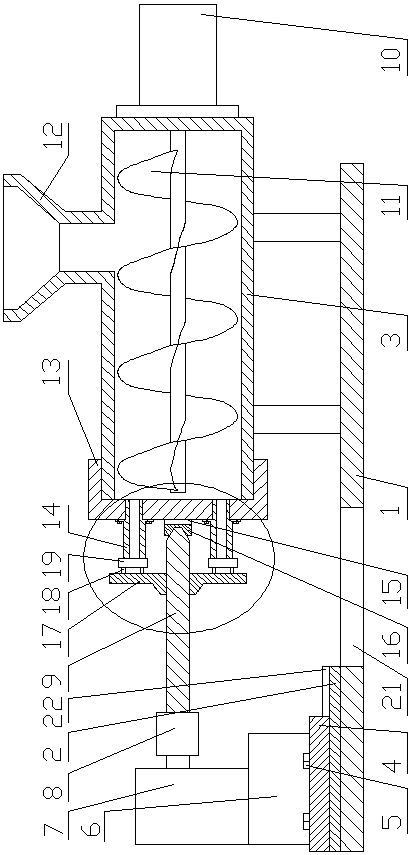

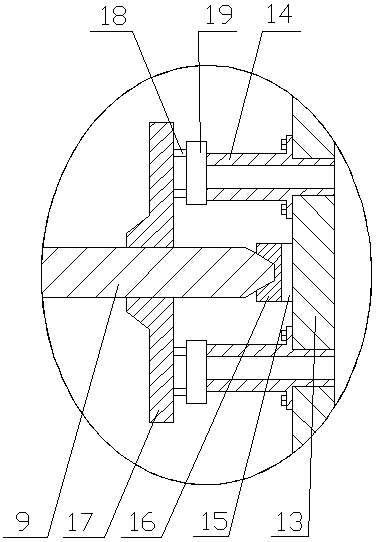

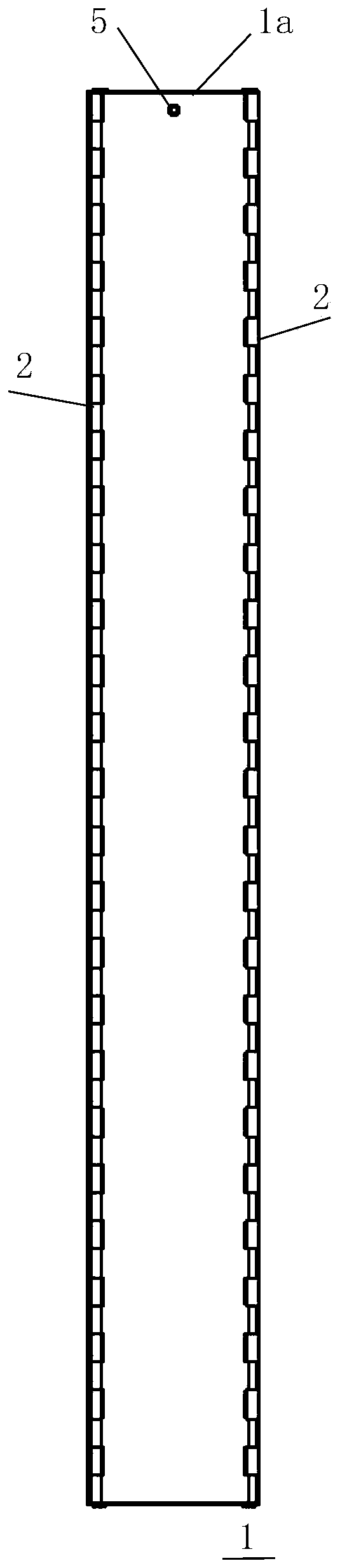

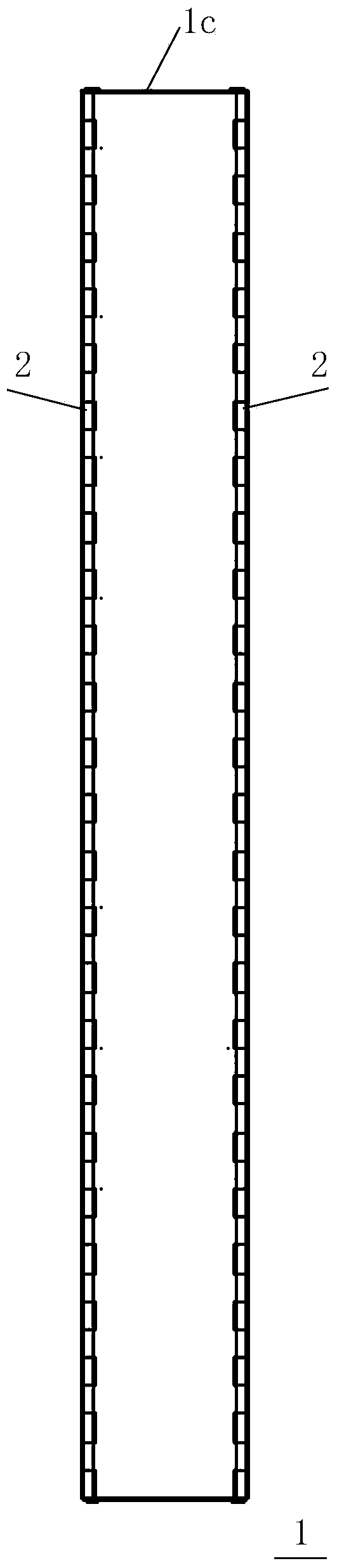

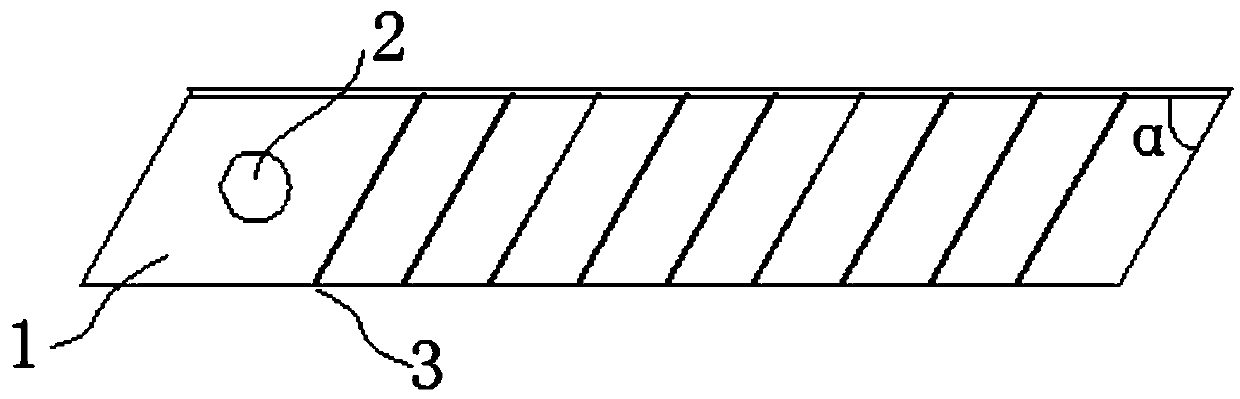

Battery cell polar piece making and winding all-in-one machine capable of cutting polar piece at high speed

ActiveCN107887653AQuick cutNeat sectionAssembling battery machinesFinal product manufactureEngineeringCam

The invention belongs to the technical field of battery manufacturing and relates to a battery cell polar piece making and winding all-in-one machine capable of cutting a polar piece at a high speed.The battery cell polar piece making and winding all-in-one machine comprises a polar piece conveying and cutting mechanism, wherein the polar piece conveying and cutting mechanism comprises a tractioncomponent and a cutting component arranged at the rear of the traction component. The polar piece conveying and cutting mechanism completes traction and cutting in a moving state respectively, and apolar piece cutter is utilized for driving a cam bit to drive a polar piece cutter follower, so as to realize rapid cutting of a polar piece cutter device, action is neatly, and section is tidy.

Owner:BOZHON PRECISION IND TECH CO LTD

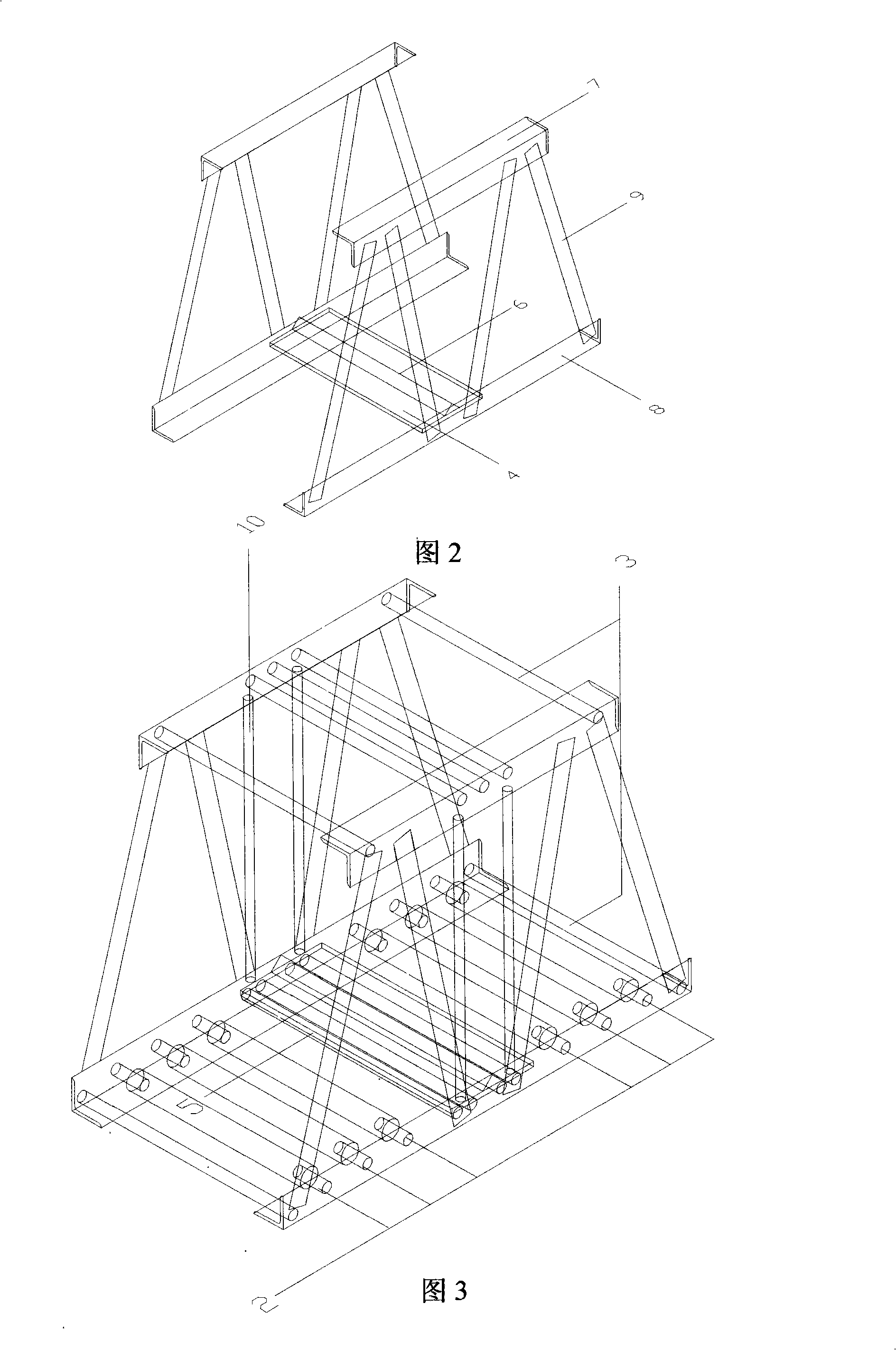

Method for cutting air-entrained concrete building blocks and cutter

InactiveCN101347965AReduce labor intensityIncrease productivityStone-like material working toolsIsosceles trapezoidArchitectural engineering

The invention discloses a method for cutting an aerated concrete building blocks and a dinking machine thereof. The invention comprises the steps that: A. a line is drawn on the aerated concrete building blocks; B. the marked aerated concrete building blocks are put into a reaction frame; C. an upper cutting point is put on the aerated concrete building blocks in the reaction frame; D. a jack is put on the cut; E. the jack is started to ensure that a piston for jack tightly goes against a reaction beam on the upper part of the reaction frame; F. the jack is started and the aerated concrete building blocks are sheared off; the reaction frame of the dinking machine is formed by welding two pieces of angle iron sheets with isosceles trapezoid by a connection reinforcing steel bar; the middle of the bottom of the reaction frame is welded with a lower cutting point armor plate stiffening rib welded with an lower cutting point armor plate; the steel insides of the upper base angle and the lower base angle of the angle iron sheets with the isosceles trapezoid of the reaction frame are respectively welded with two pairs of lead rails which slide on the upper cutting point; the armor plates of the upper cutting point are respectively sealed with an upper cutting point angle iron and two pairs of ear throughs which face the same direction. The method of the invention has the advantages of easy implementation, convenient usage, simple structure and light dead weight, and convenient move on site of the construction.

Owner:WUHAN CONSTR ENG

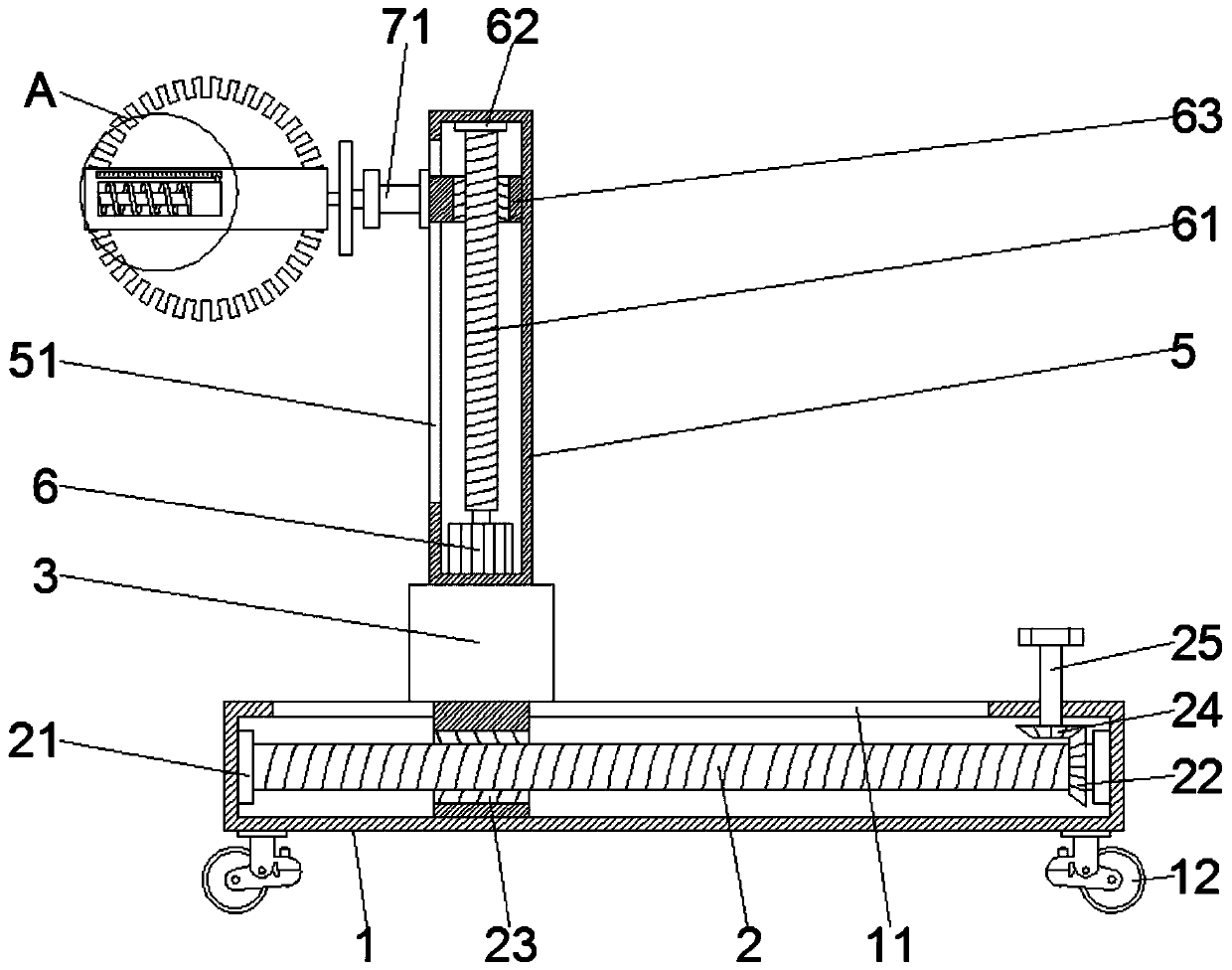

Novel wall cutting machine for home decoration

PendingCN111168866AAccurate locationNeat sectionWorking accessoriesStone-like material working toolsMachineHome improvement

The invention discloses a novel wall cutting machine for home decoration. The novel wall cutting machine comprises a bottom plate, wherein a sliding groove I is transversely formed in the upper end ofthe bottom plate, a threaded rod I is transversely arranged in the bottom plate, the left end and the right end of the threaded rod I are rotatably connected to the inner wall of the bottom plate, abevel gear I is arranged at the outer surface of the threaded rod I in a sleeving mode, and the bevel gear I is located on the right side of the sliding groove I; a bevel gear II is arranged in the bottom plate, the bevel gear II meshes with the bevel gear I, a threaded sleeve I is arranged on the outer surface of the threaded rod I in a sleeving mode, and the threaded sleeve I is located in the sliding groove I; and a movable device is longitudinally arranged at the upper end of the threaded sleeve I, and the movable device comprises a hollow plate and a threaded rod II, a sliding groove II is longitudinally formed at the upper end of the hollow plate, the threaded rod II is longitudinally arranged in the hollow plate, the front end and the rear end of the threaded rod II are rotationallyconnected to the inner wall of the hollow plate. According to the novel wall cutting machine for the home decoration, the position of a cutting opening is accurate, the cross section is neat, and theposition of a pointer on a dial gauge is observed, so that the depth of cutting the wall surface of a cutting wheel is quickly known, and meanwhile, the device further can cut the wall surface transversely and longitudinally.

Owner:SHANGHAI BETTER HOME DECORATION ENG CO LTD

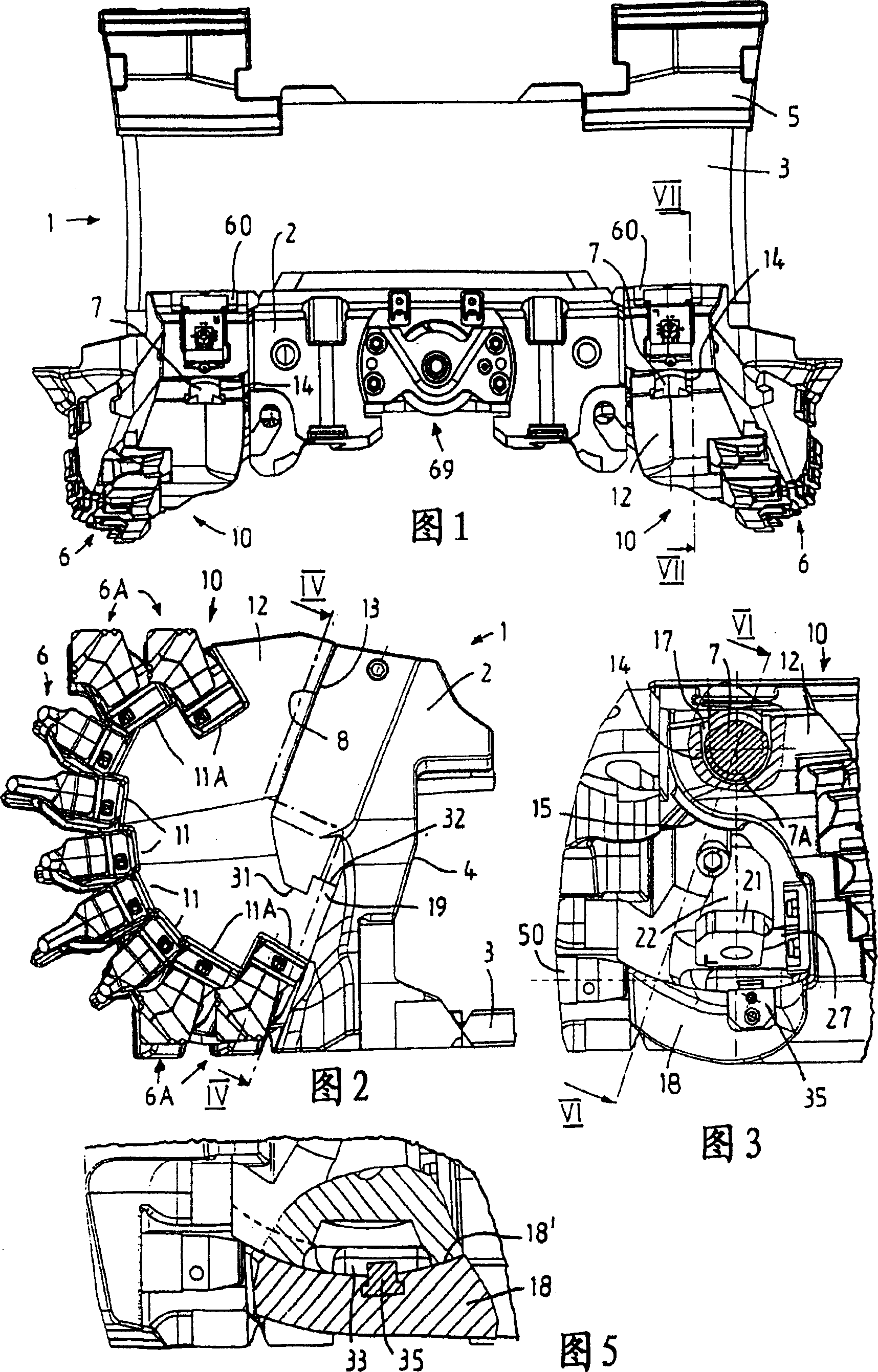

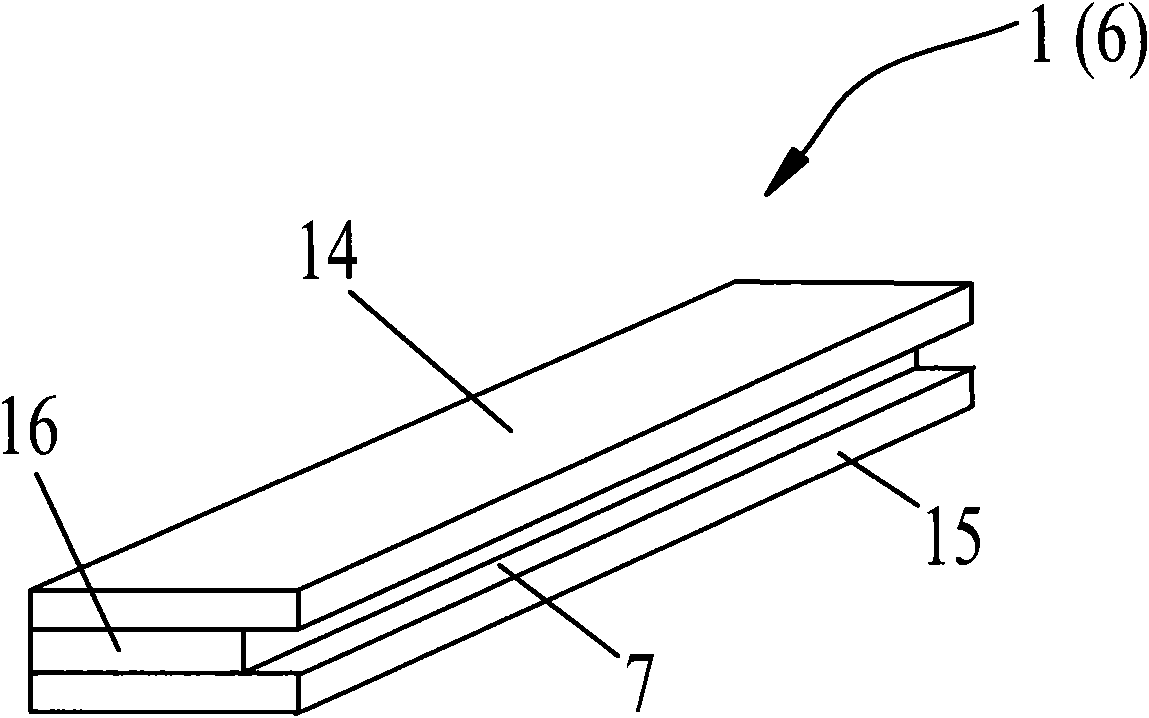

Mining plow

ActiveCN1952348ANo problem to install/removeEasy to installSlitting machinesEngineeringSupport surface

The invention relates to a recovery planer comprising a planer base (2) guided on a conveyor, which has a pivot pin on an inclined support surface (8) for any direction of movement of the planer (7) a swingable support for a knife rest (10), and includes two knife rests (10), each knife rest is supported swingably on the corresponding swing pin (7) by means of a swing support and has A base (18), by means of which the base tool holder (10) is guided on a pivoting surface (31) formed on the planer base below the bearing surface and oriented concentrically to the axis of rotation of the associated pivoting pin (7) . According to the invention, the swivel support of the tool holder (10) is formed as a groove (14) with open edges, by means of which the tool holder (10) can be pushed parallel to the support surface (8) onto the swivel pin (7) in a mounting swivel position. superior. Mounting of each tool holder can then be carried out relatively simply from below.

Owner:CATERPILLAR INC

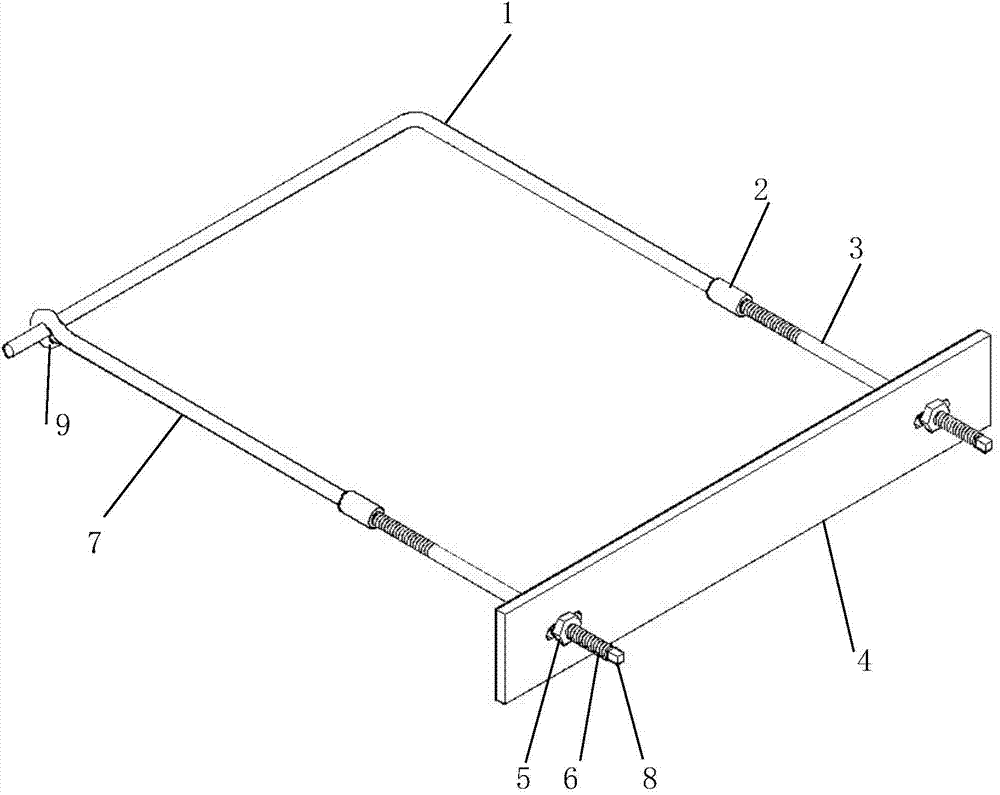

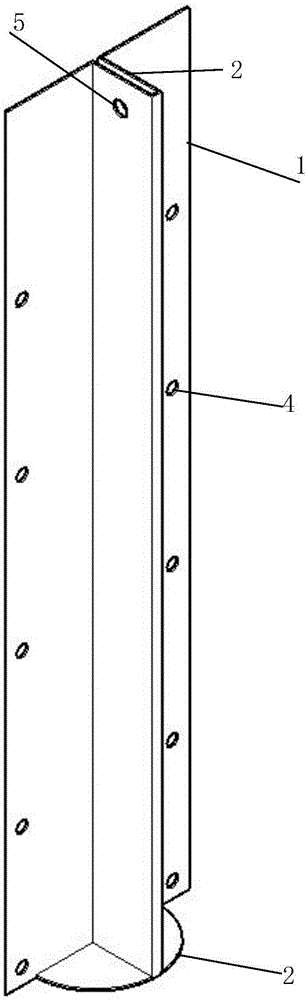

Method for application of concrete work expansion joint vertical water sealing structure fixing element

ActiveCN104727275AEasy to pourNeat sectionArtificial islandsUnderground chambersUnderwaterHydraulic engineering

The invention relates to an underground (underwater) building waterproof device, in particular to a method for application of a concrete work expansion joint vertical water sealing structure fixing element. The fixing element comprises a U-shaped embedded part formed by an embedded part body A and an embedded part body B, wherein the embedded part is provided with a connecting pipe, the connecting pipe is provided with internal threads so as to be in threaded connection with a connecting piece, flat iron is fixed to the connecting piece in an integrated mode with nuts to be used for fixing a vertical water sealing steel channel at the position of a concrete fracture surface, pitch is injected into the steel channel, and the connecting piece and the flat iron are disassembled after cooling and maintained, stored and reused. By the adoption of the method, the problem, appearing in a water conservancy project, of water seepage caused by differential settlement or diastrophism of a stratum can be solved, labor can be saved, construction time can be shortened, and resources can be saved.

Owner:云南建投第十一建设有限公司

Preparation method of ceramic electrician blade

ActiveCN106736892APromote whisker tougheningImprove toughnessCeramic shaping apparatusOther manufacturing equipments/toolsAdhesiveWhiskers

The invention discloses a preparation method of a ceramic electrician blade, belonging to the field of preparation method of special blades. The processing method comprises the following steps: (1) sintering of a ceramic blank; (2) sharpening both sides of the knife; (3) cutting a breaking groove; (4) processing a big knife edge; (5) processing a small knife edge; (6) accurate grinding of the small knife edge; (7) checking the knife blade; (8) packaging, etc. In the invention, a hot isostatic pressing method is adopted for sintering the raw material, the best sintering technology is selected according to the material composition, and some substances in an adhesive can be fully carbonized at 1,400 DEG C; and the carbonized components can promote the whisker toughening of aluminum oxide, and the toughness of the blank is enhanced. In the invention, during blade processing, the processing depth of the breaking groove is strictly controlled according to the length, width and thickness of the blade, and the defective percentage of the product is reduced.

Owner:安徽华天机械股份有限公司

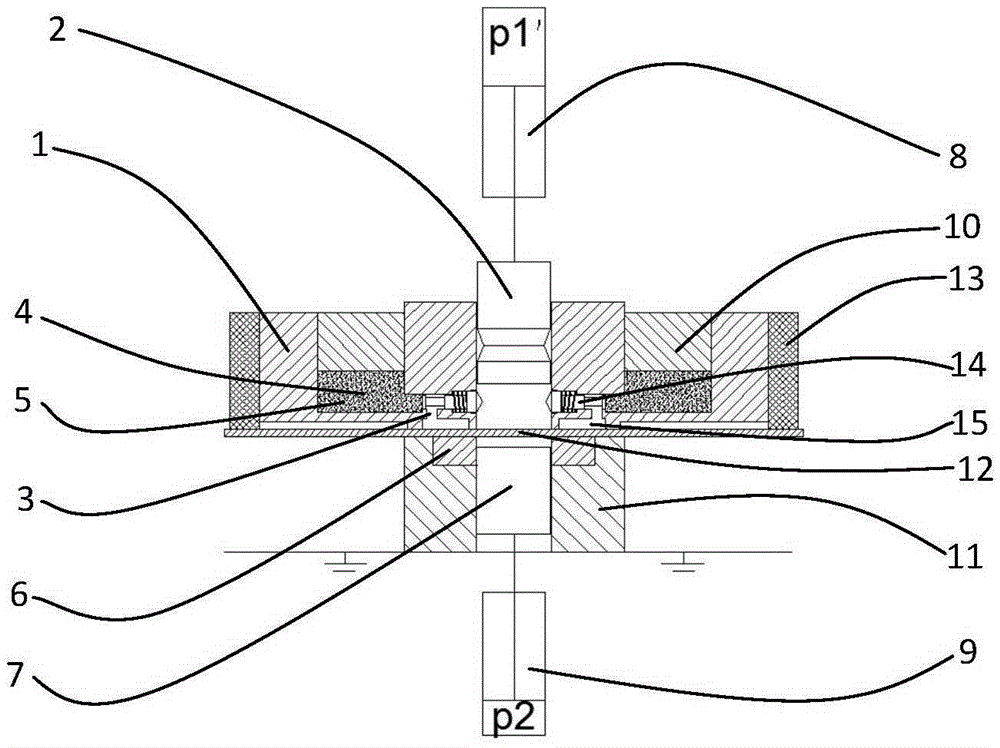

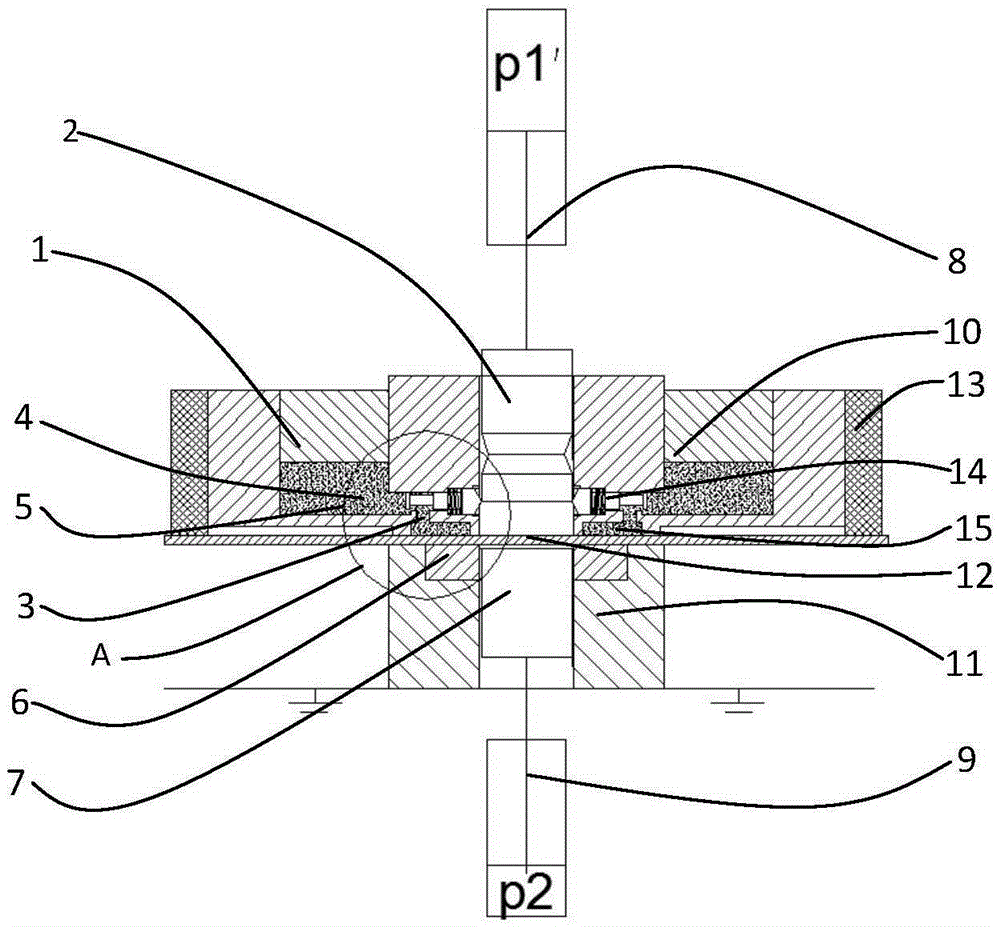

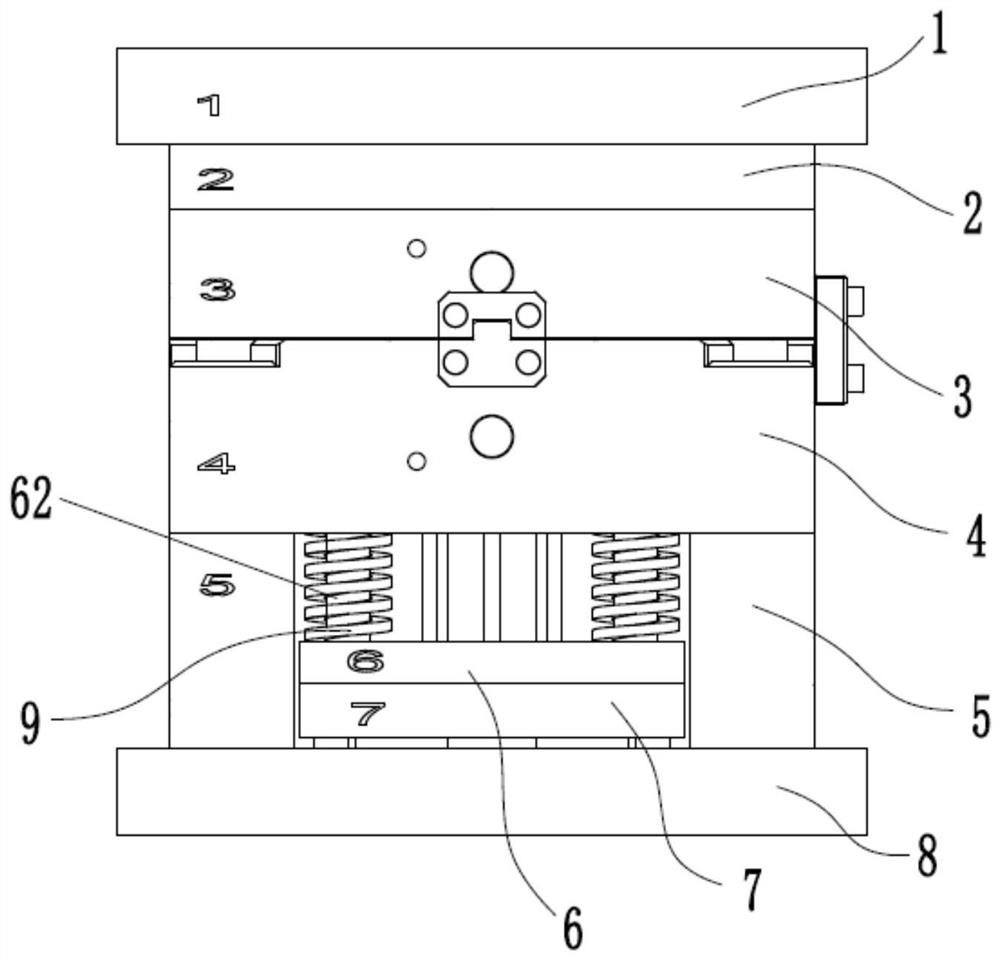

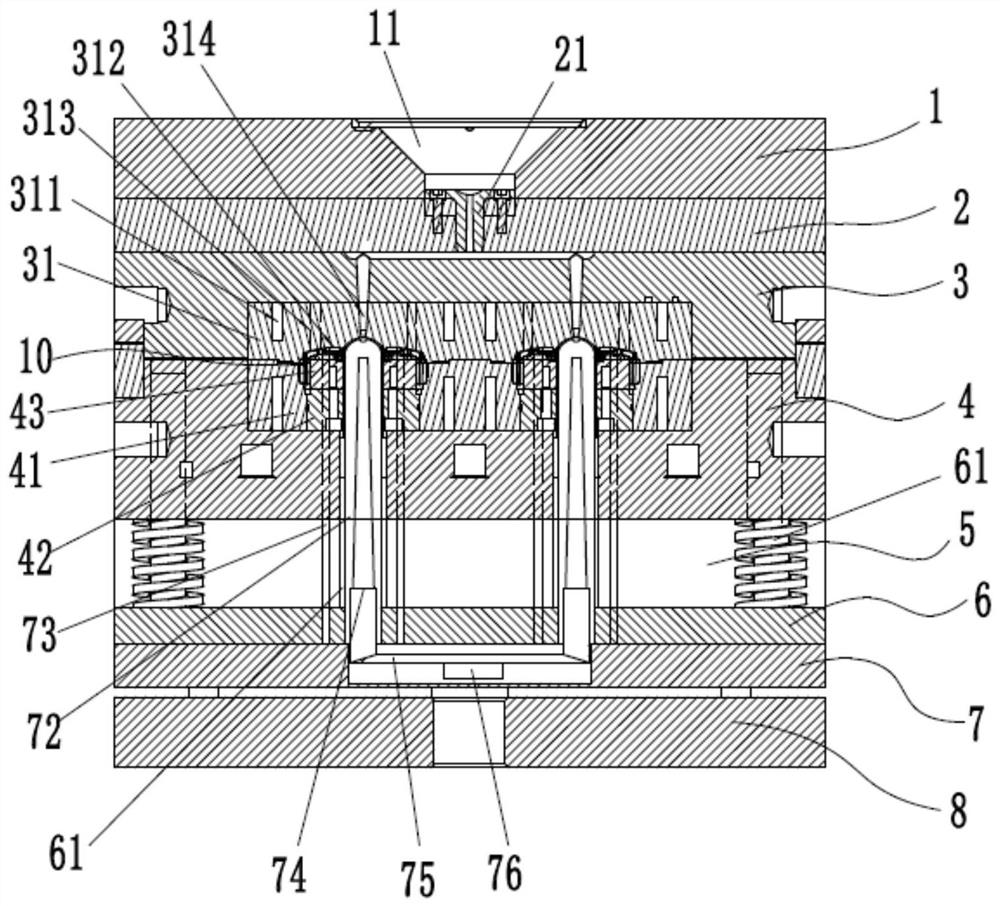

Deep-cooling punching-shearing forming device for blank holder of micro-miniature workpiece and forming method thereof

InactiveCN105382091AIncrease border brittlenessNeat sectionShaping toolsPerforating toolsPistonPunching shear

The invention relates to a deep-cooling punching-shearing forming device for a blank holder of a micro-miniature workpiece and a forming method thereof, and belongs to the field of mechanical engineering. The blank holder is provided with a storage groove for storing a low-temperature solution. A flow channel which leads to a plate and makes contact with the plate is formed in the bottom of the storage groove. A valve used for closing or opening is arranged in the flow channel. A male die driven by a hydraulic cylinder P1' moves in the blank holder to trigger the valve to be opened and closed. The storage groove is provided with a floating piston. The periphery of the blank holder is coated with a heat insulating material. A female die is arranged inside a female die support to be fixed. An ejection rod driven by a hydraulic cylinder P2 moves in the female die. The plate can be pressed on the edge of the female die by the blank holder under the action of force. The forming method based on the device comprises the five steps of plate clamping, cooling, punching and shearing, die releasing and shape detecting. The deep-cooling punching-shearing forming device for the blank holder of the micro-miniature workpiece and the forming method thereof have the advantages that the structure is novel, and when the micro-miniature workpiece is machined under the condition of deep cooling, it is beneficial to reducing rough edges and burrs, so that the machining precision of the workpiece is improved, and the mass production is achieved.

Owner:JILIN UNIV

Fine splitting machine for aluminum foil

The invention discloses a fine splitting machine for an aluminum foil. The machine comprises a rack, wherein a discharging mechanism, a traction mechanism and a winding machine hook are sequentially coupled to the rack in a shaft coupling mode; an automatic deviation rectifying device is arranged between the traction mechanism and the winding mechanism and comprises a deviation rectifying shaft; adeviation rectifying roller sleeves the deviation rectifying shaft; detection devices are arranged at two ends of the deviation rectifying roller; adjusting parts are arranged at two ends of the deviation rectifying shaft; the detection devices are used for transmitting signals to the adjusting parts; a cutting mechanism is arranged between the automatic deviation rectifying device and the winding mechanism; the cutting mechanism comprises a cutter frame; two ends of the cutter frame are fixedly connected to the rack; the cutter frame is connected with a cutter device in a sliding mode; a cutting roller is arranged at the lower part of the cutter frame; two ends of the cutting roller are coupled to the rack in a shaft coupling mode; the winding mechanism comprises a winding roller; a sliding differential shaft is inserted into the winding roller; and two ends of the sliding differential shaft are shafted to the rack. The machine is capable of automatically rectifying and regularly coiling off-tracking coiled materials.

Owner:ZHUOZHOU HAOYUAN FOIL IND +1

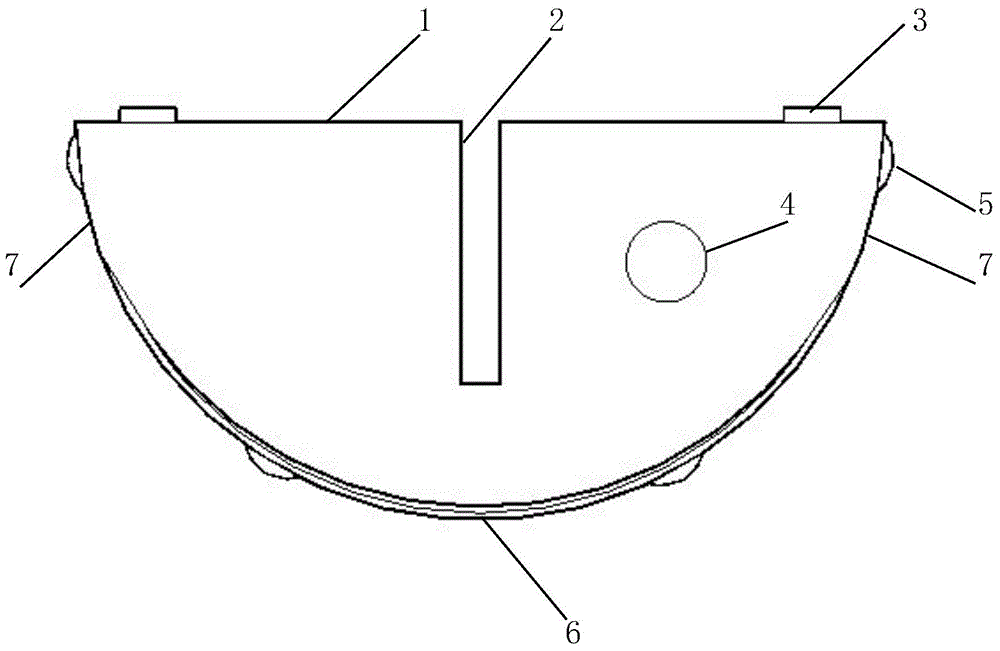

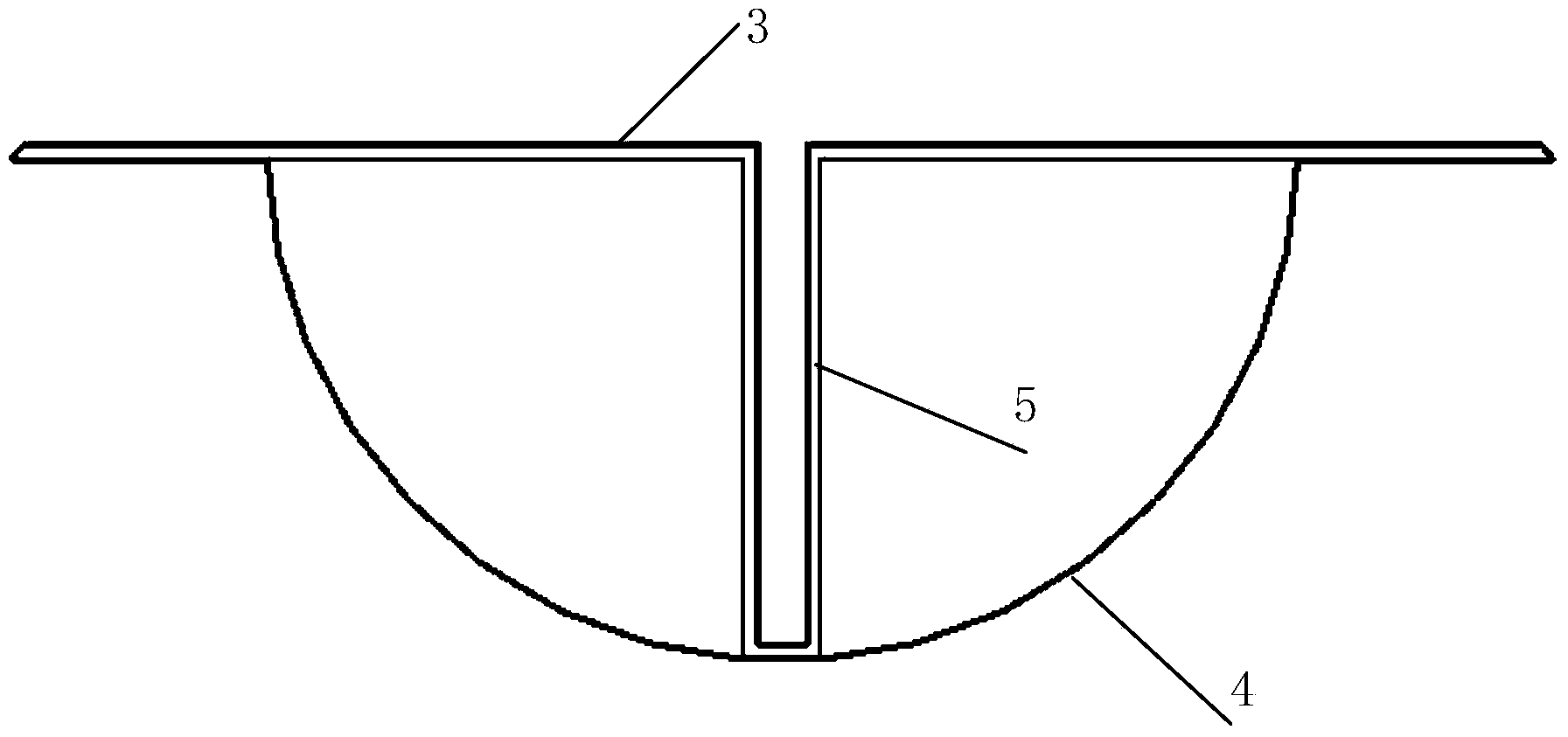

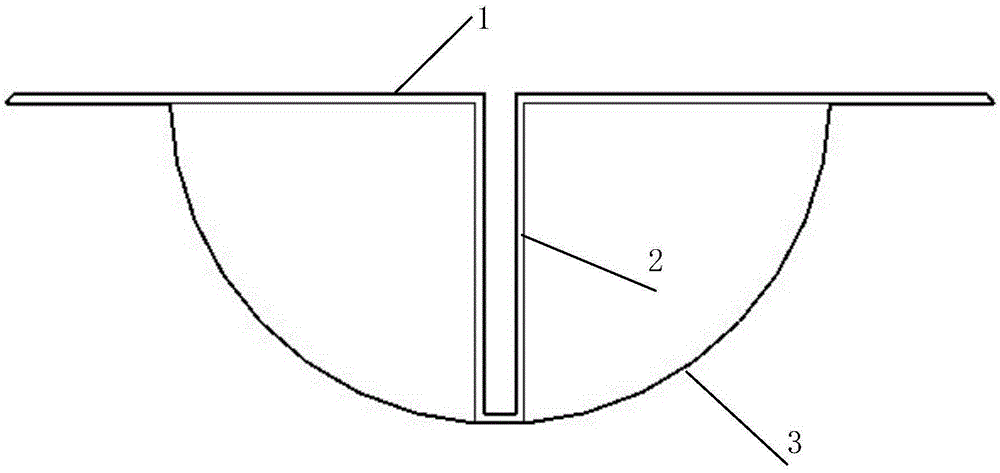

Concrete engineering cavity die gasbag and manufacturing method thereof

ActiveCN104452826AEasy to pourNeat sectionArtificial islandsProtective foundationFiberStructural engineering

The invention relates to a concrete engineering cavity die gasbag which comprises a hollow gasbag body. The gasbag is in a half-cylinder shape, a gasbag groove is formed in the middle of the gasbag, and fixing points are arranged on the two sides of the gasbag groove. An inflating valve is arranged at the upper end of the gasbag, and a sealing bottom is arranged at the bottom of the gasbag. Reinforced fiber filaments are mixed into the bag wall of the gasbag. Raised points or vertical and horizontal stripes are arranged on the circular-arc outer surface of the gasbag. The gasbag and a framework are matched to form a cavity die which is arranged on the fracture surface of first-stage concrete, air pressure is set in the gasbag, and second-stage concrete is poured in a layered mode; after the concrete is initially set, the air pressure in the gasbag is released, and the cavity die is hoisted out, so that a semicircular cavity is formed in the fracture surface of the second-stage concrete, and a water stopping effect is achieved when melting bitumen is injected into the cavity; and the cavity die can be repeatedly used.

Owner:湖南恒运建筑科技发展有限公司

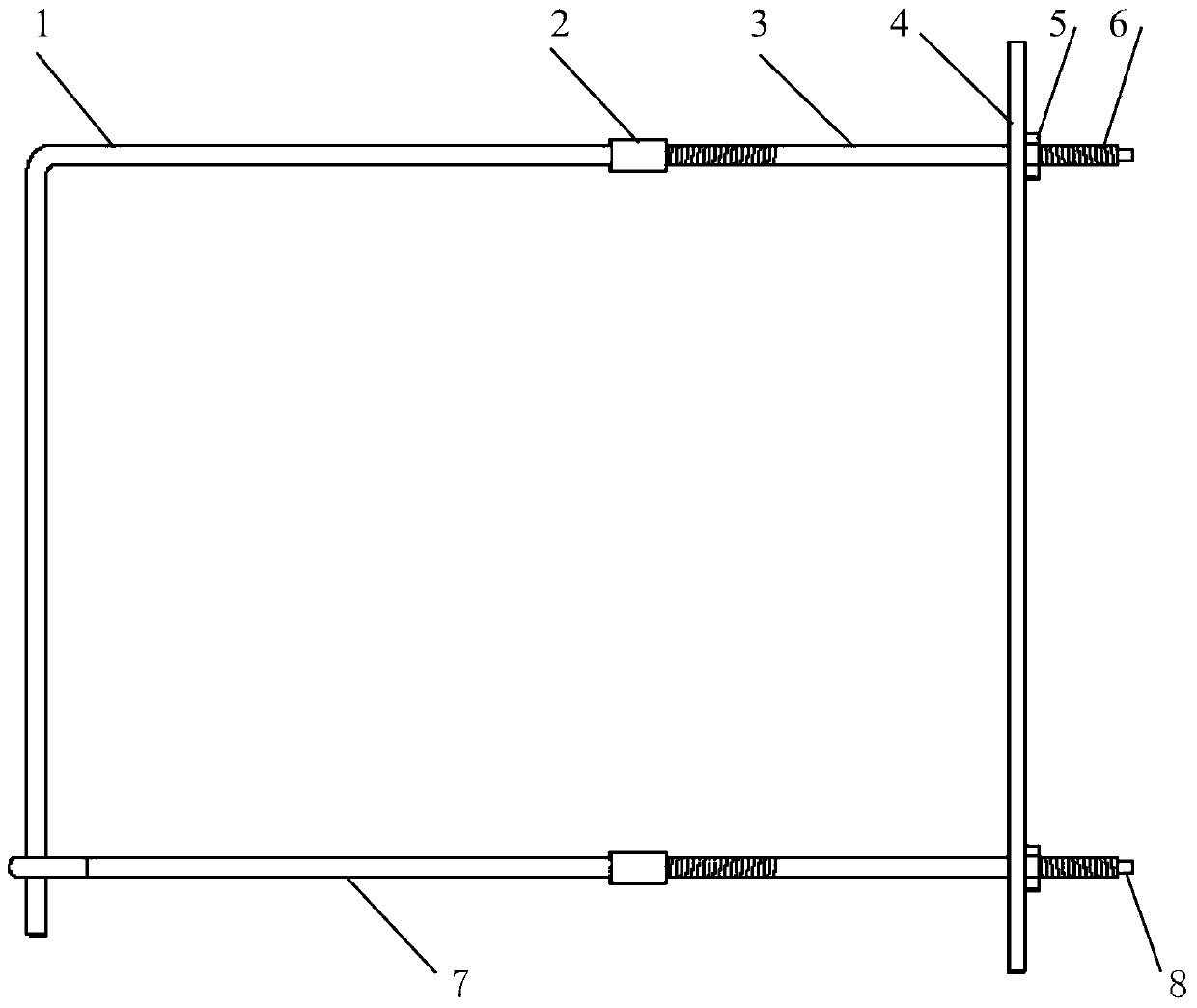

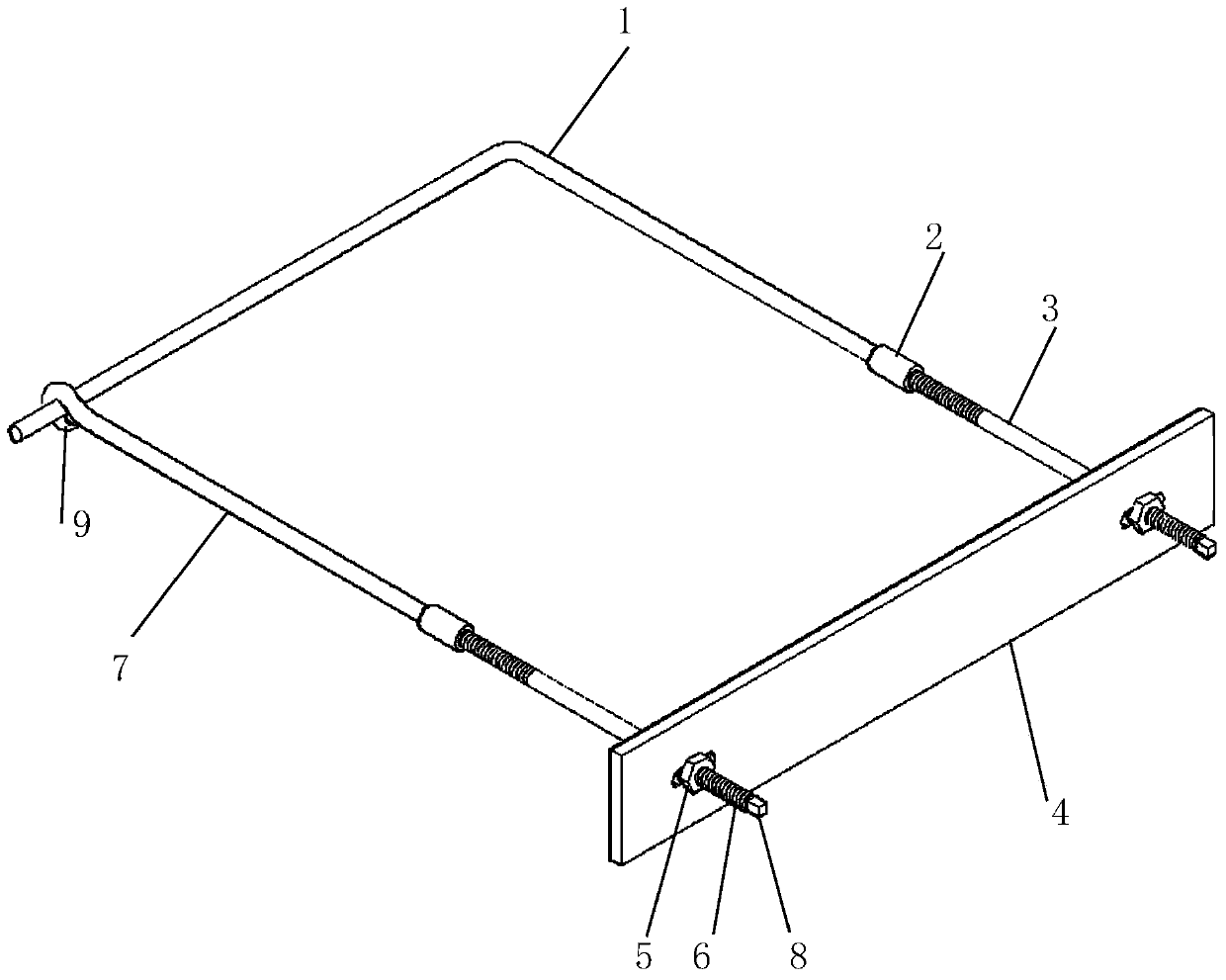

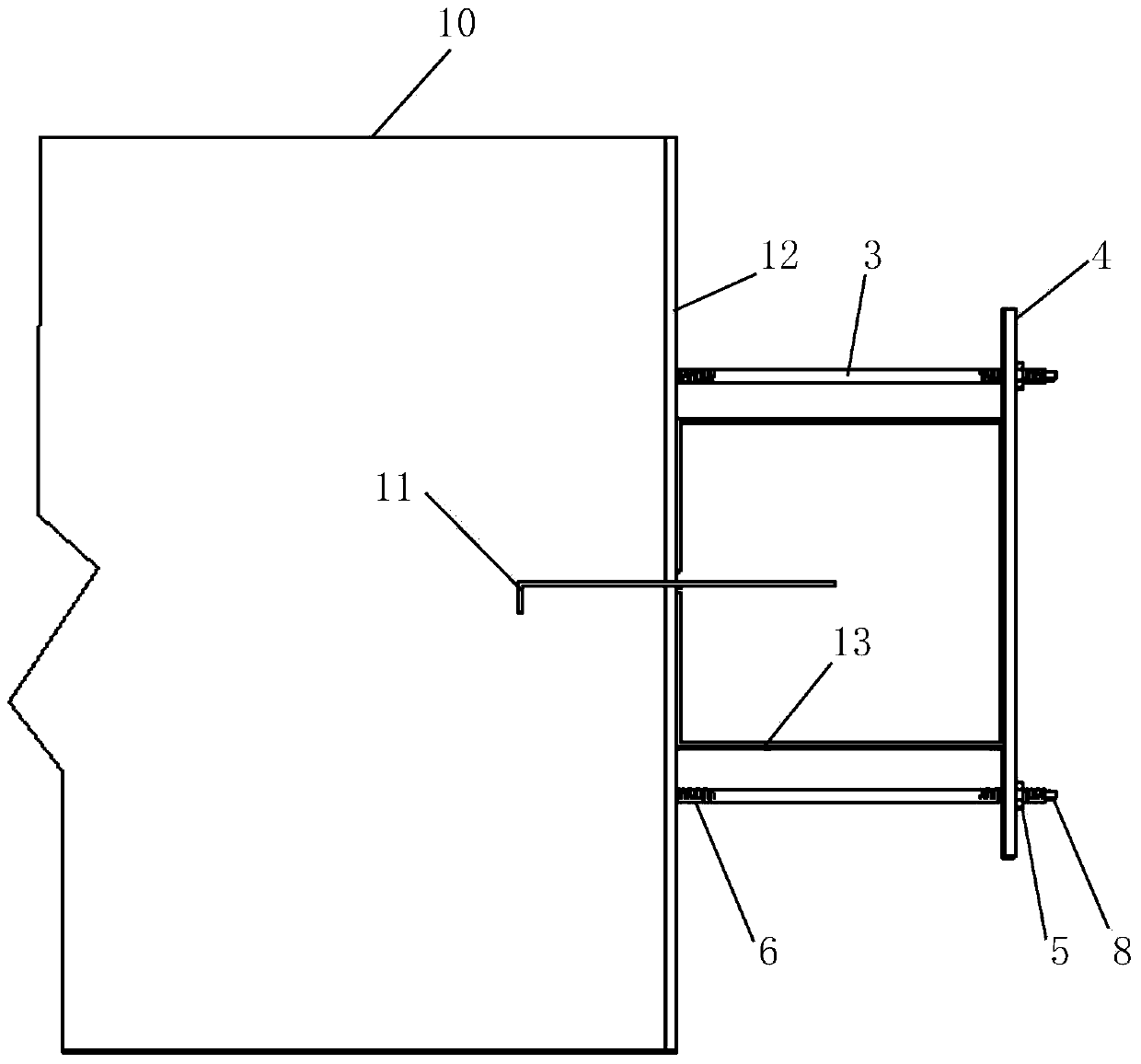

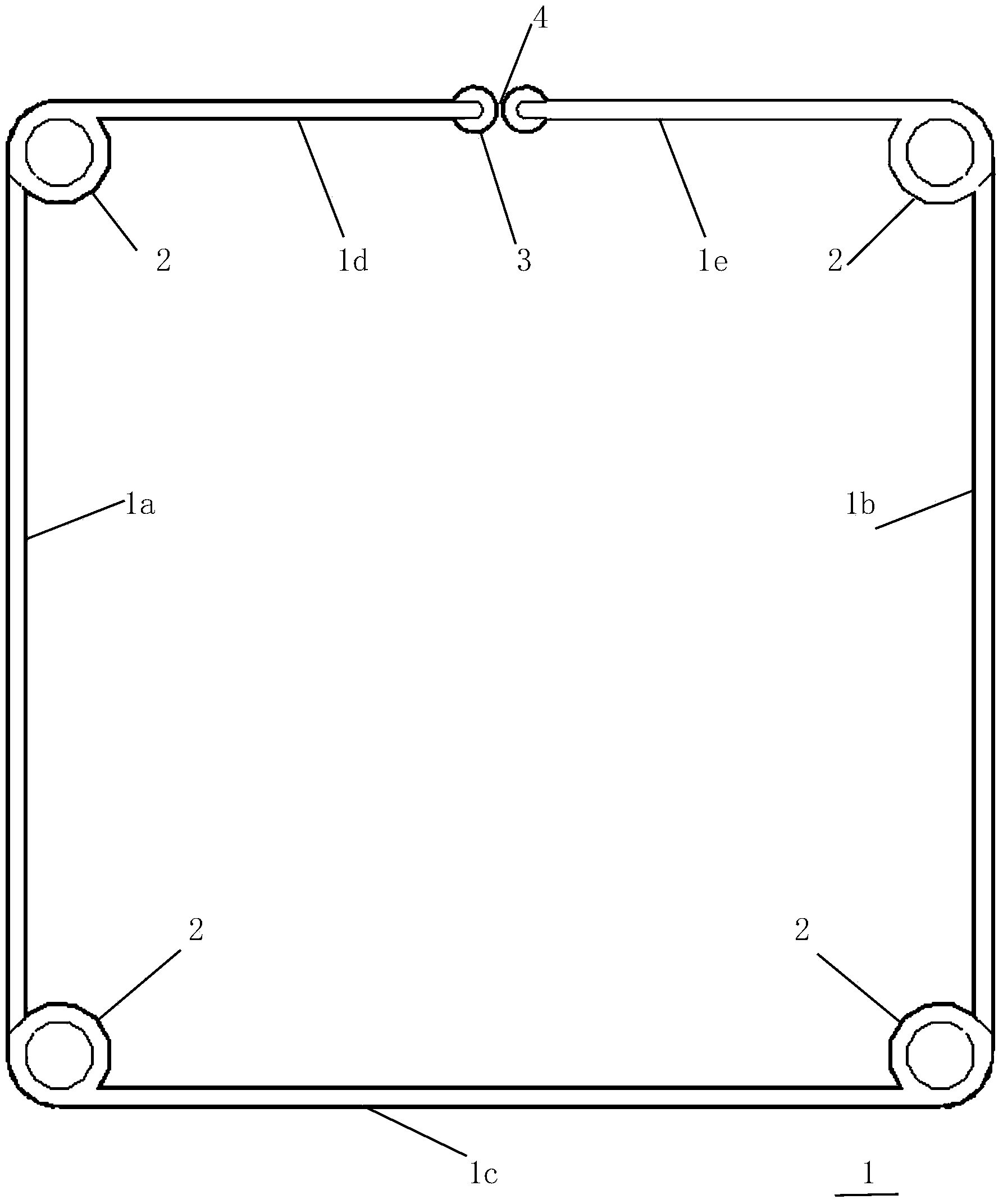

Eccentric shearing type low-impact expansion pipe double-groove plate separation device

ActiveCN112407341AHigh separation reliabilityReduce shockCosmonautic vehiclesCosmonautic component separationExplosive AgentsEngineering

The invention discloses an eccentric shearing type low-impact expansion pipe double-groove-plate separation device which comprises an explosive cable, filler, a flat pipe, an H-shaped separation plate, an upper end frame, a lower end frame, an upper fastening bolt and a lower fastening bolt. The H-shaped separation plate comprises an upper U-shaped groove, a lower U-shaped groove and a connectingarea; the upper U-shaped groove and the lower U-shaped groove are located in the upper side and the lower side of the connecting area respectively. The upper end frame and the upper U-shaped groove are installed in a butt joint mode and fastened through an upper fastening bolt. The lower end frame and the lower U-shaped groove are installed in a butt joint mode and fastened through a lower fastening bolt. The flat pipe is arranged between the lower end frame and the lower U-shaped groove; the flat pipe is hollow, and the explosive cable is arranged in a hollow cavity of the flat pipe; and thefiller is filled in a cavity between the flat tube and the explosive cable. Impact generated in the action process can be reduced while it is guaranteed that the structure has high separation reliability.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

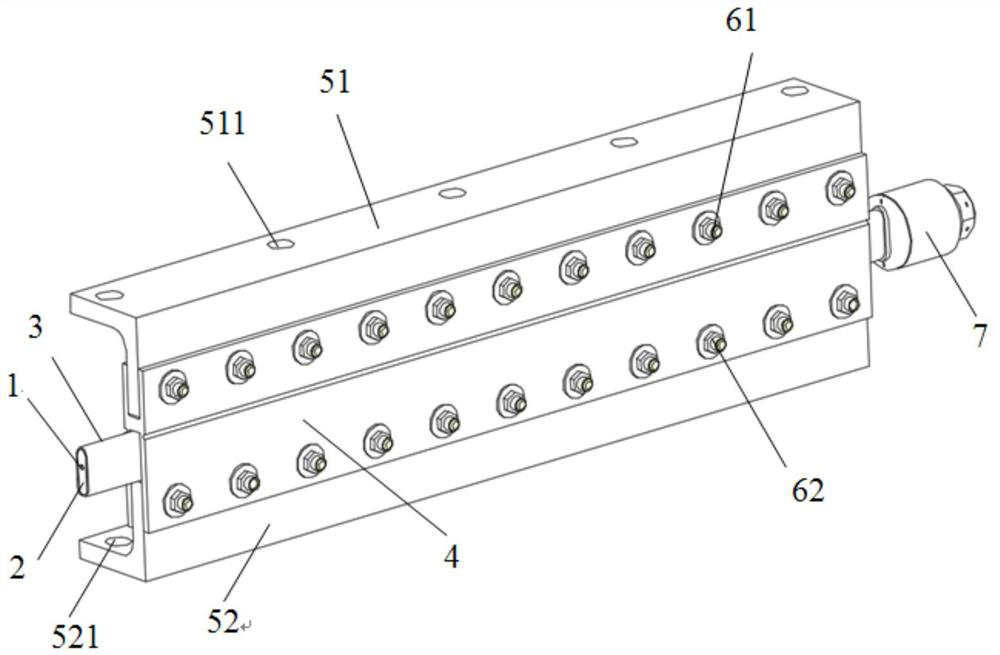

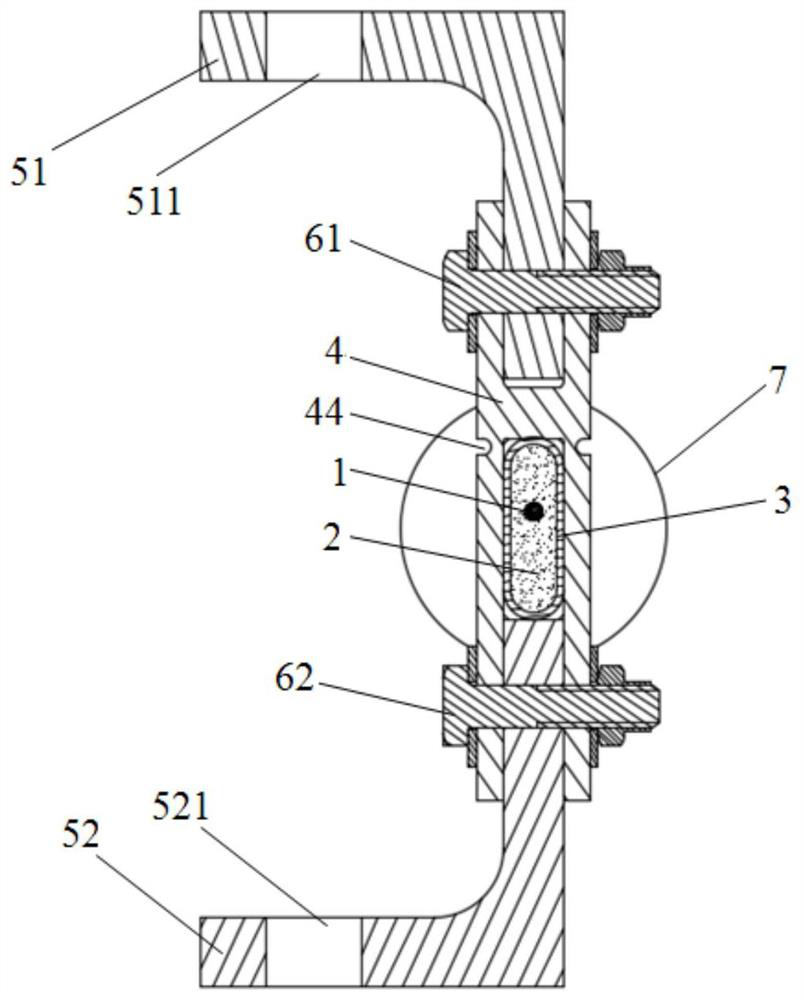

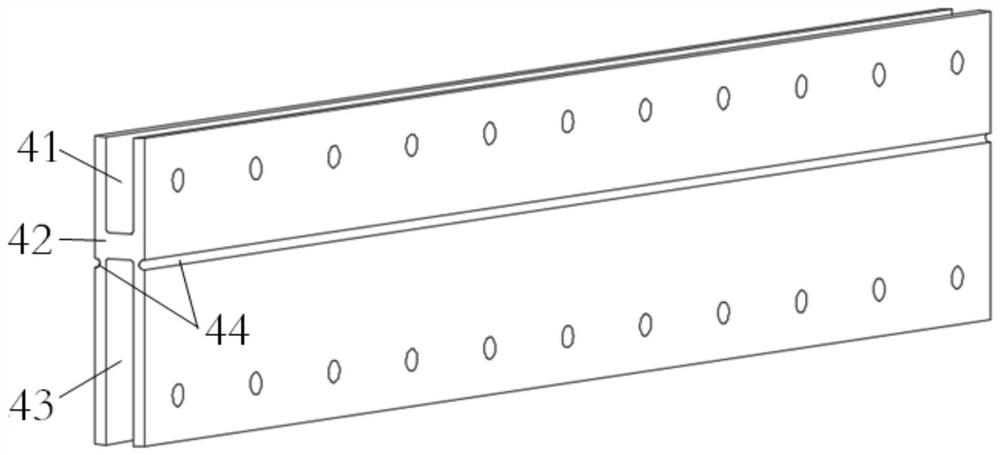

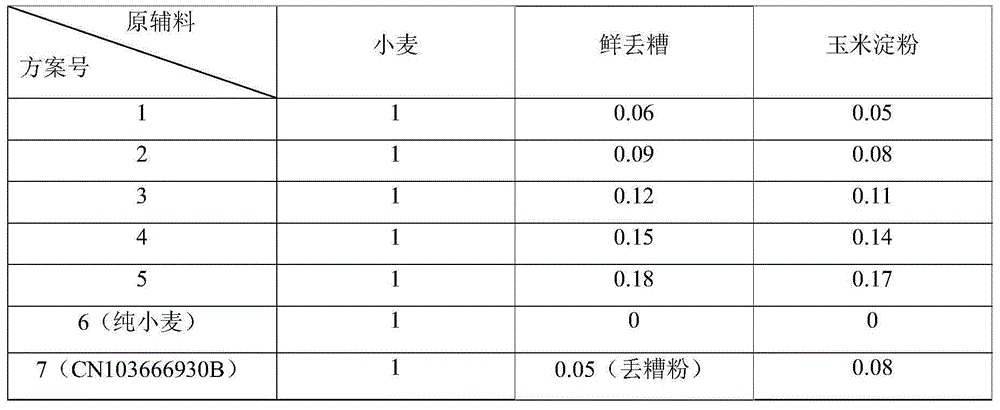

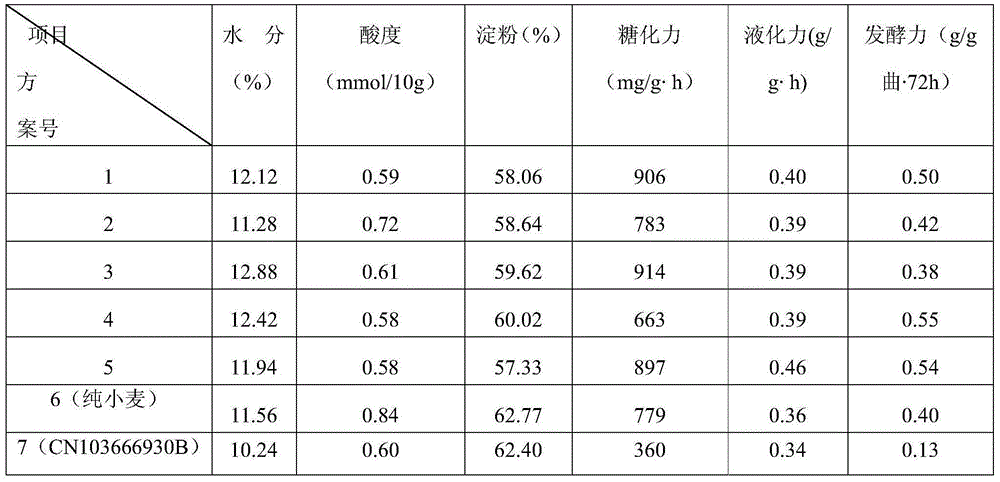

Luzhou-flavor yeast and manufacturing method thereof

The invention belongs to the technical field of wine making, and particularly relates to a production method of Luzhou-flavor yeast. The method mainly comprises the following steps: raw material impurity removal, wheat moistening, pulverization, mixing, yeast pressing, bacterium culture in chamber, yeast overturning, and warehousing for storage, thereby obtaining the finished product yeast. The method is characterized in that the raw and auxiliary materials for producing the Luzhou-flavor yeast comprise wheat, fresh waste lees and corn starch, wherein the fresh waste lees account for 6-28% of the wheat, and the corn starch accounts for 5-17% of the wheat. The method for producing the Luzhou-flavor yeast optimizes the physical and chemical indexes of the yeast, so that the yeast has the advantages of thinner sheet, regular cross section and plump and strong hypha. The porosity of the yeast billet is enhanced, and the growth of mold, leaven and other microbes is promoted, thereby enriching more beneficial microbes. The method obviously enhances the yeast quality, lowers the raw material cost by 2.5-15.5% and effectively reduces the environmental pollution caused by waste lees, thereby having wide application prospects.

Owner:LUZHOU PINCHUANG TECH CO LTD

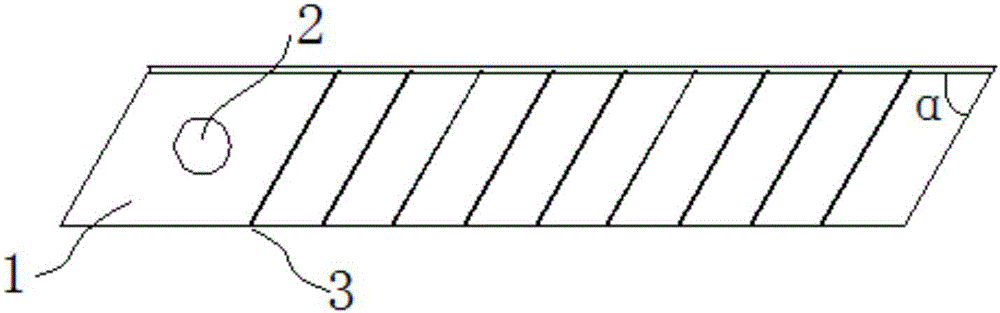

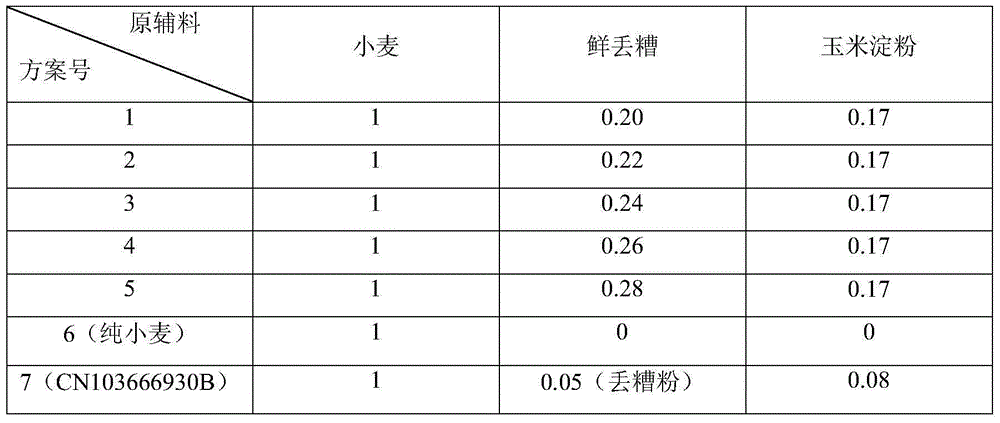

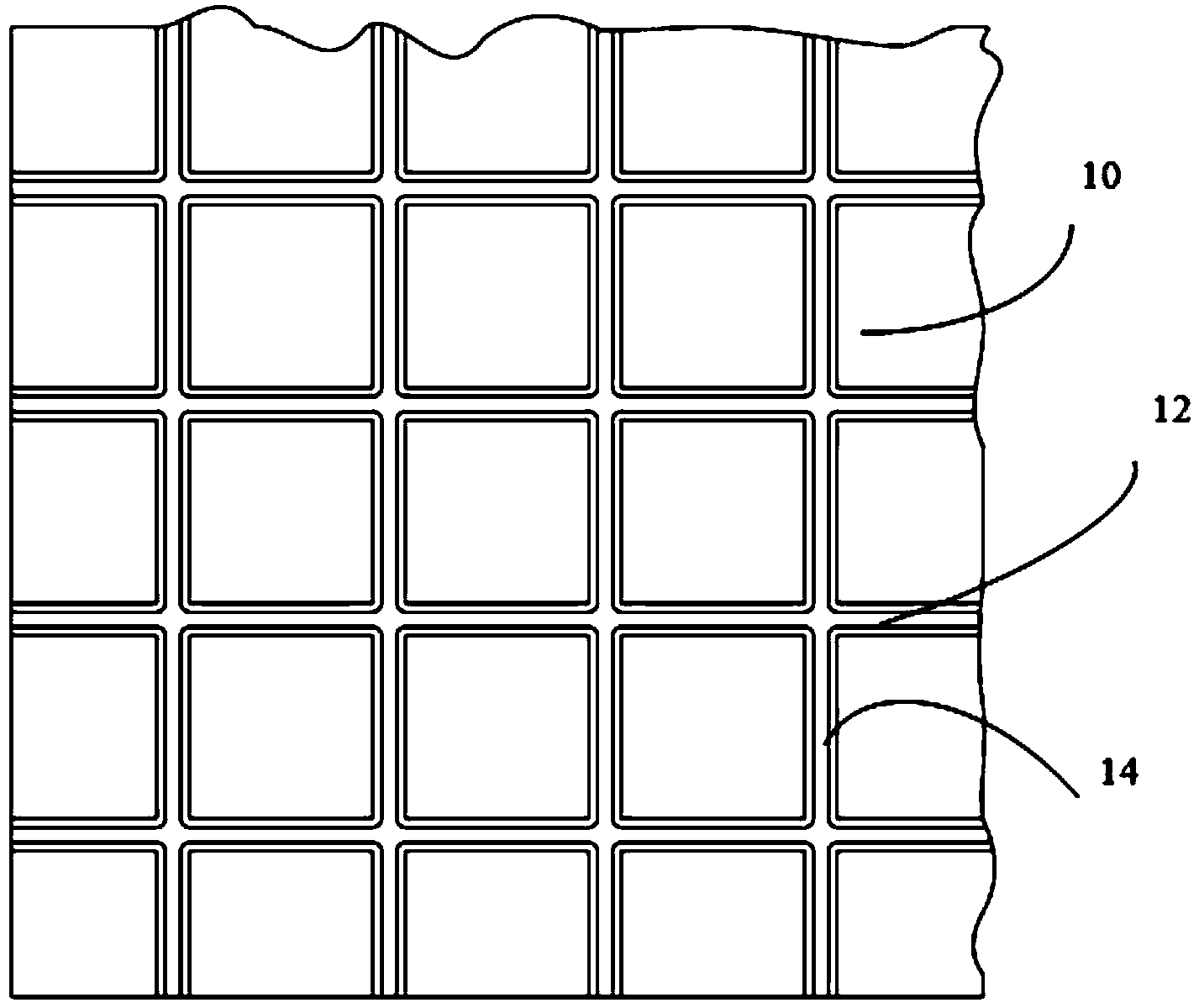

Flexible diaphragm type ceramic material and preparation method thereof

ActiveCN103963389AUniform sizeImprove physical performanceCeramic layered productsMetallurgyCeramic sintering

The invention discloses a flexible diaphragm type ceramic material and a preparation method thereof. The flexible diaphragm type ceramic material comprises a ceramic material layer and a flexible support diaphragm attached to at least one surface of the ceramic material layer, the ceramic material layer consists of ceramic fragments with uniform sizes and regular arrangement. The preparation method comprises the following steps: 1) a ceramic sintering piece printed with grid grooves is prepared; 2) at least one surface of the ceramic sintering piece is attached to the flexible support diaphragm with adhesion agents; 3) the ceramic sintering piece attached with the flexible support diaphragm is pressed or bent, so that the ceramic sintering piece is cracked along groove lines to form the ceramic fragments with uniform sizes and regular arrangement, and obtain the flexible diaphragm type ceramic material. Compared with the prior art, as the fragments of the ceramic material layer prepared by the flexible diaphragm type ceramic material have uniform sizes and neat fracture surfaces, favorable flexibility of the flexible diaphragm type ceramic material is ensured, the flexible diaphragm type ceramic material can be bent in arbitrary directions, and at the same time, the physical properties of products are effectively improved.

Owner:GUANGZHOU MAGNET ELECTRICITY

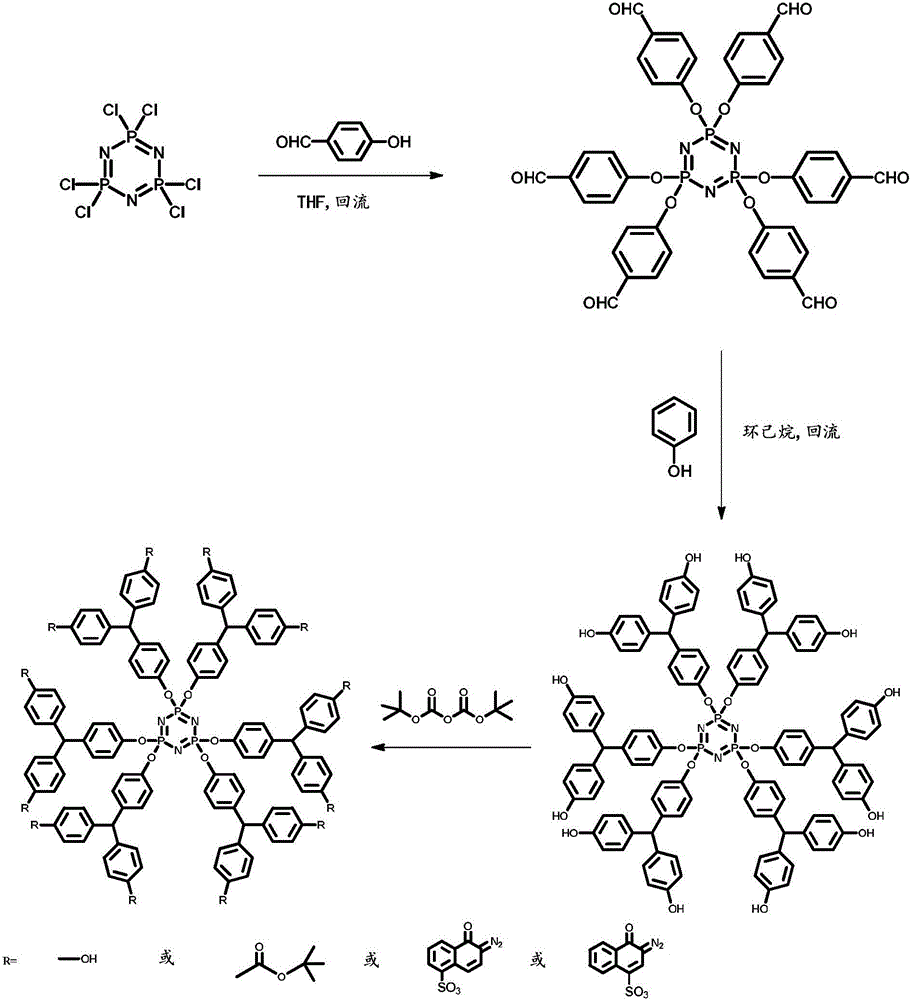

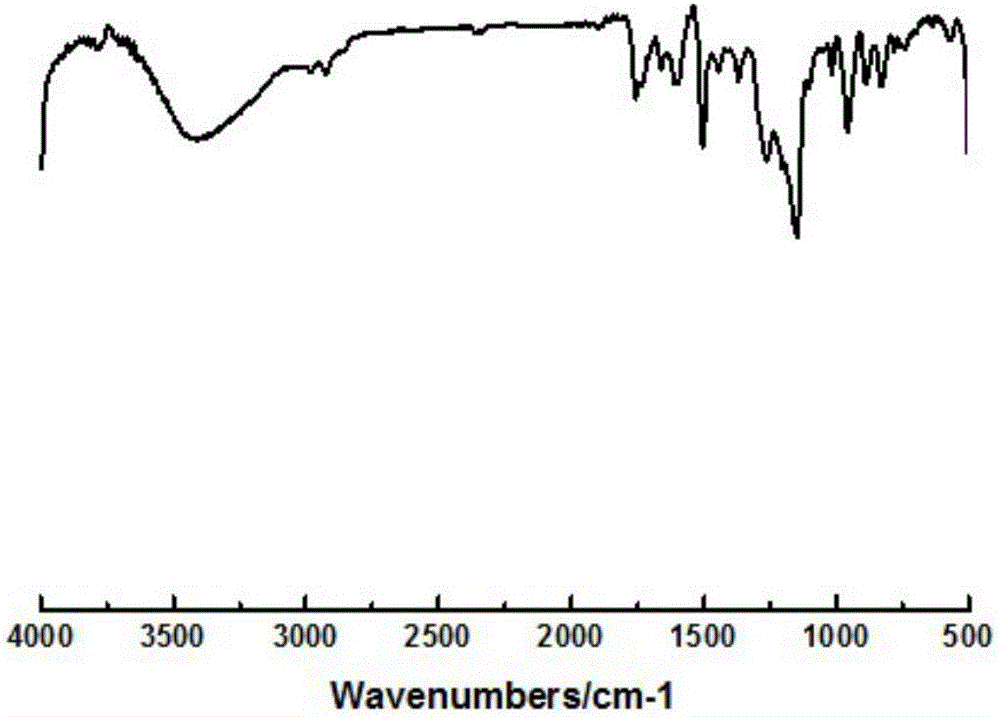

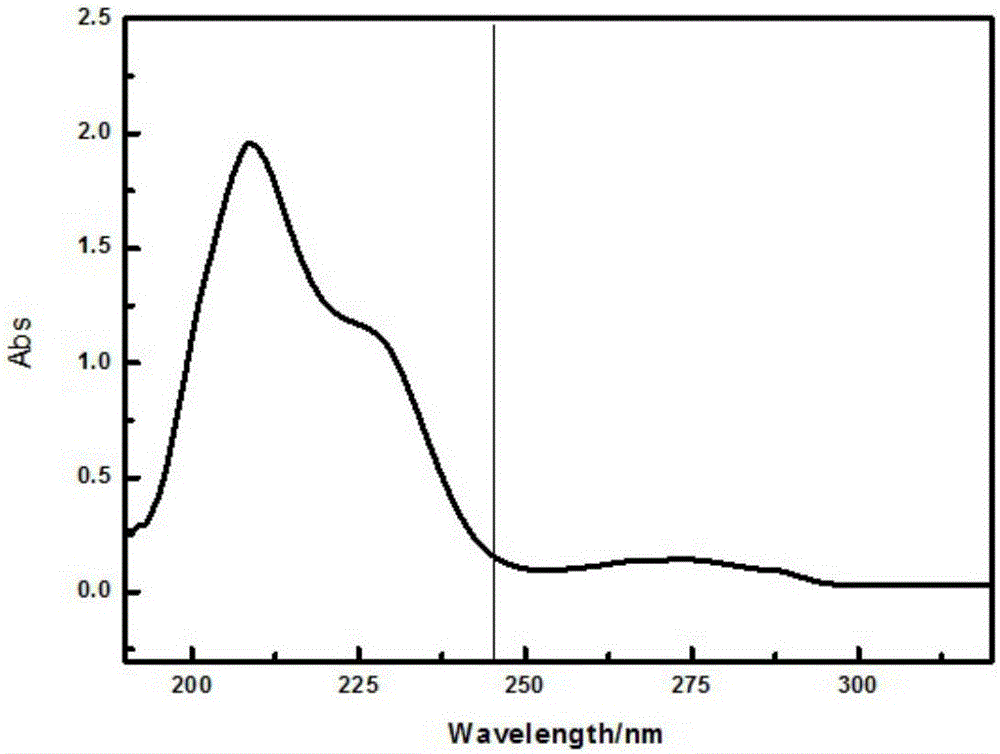

Branching macromolecule with cyclotriphosphazene as structural framework and photoresist composition prepared through branching macromolecule

InactiveCN106565787AImprove performanceMild reaction conditionsGroup 5/15 element organic compoundsPhotosensitive materials for photomechanical apparatusPhotoacid generatorSolvent

The invention discloses a branching macromolecule with cyclotriphosphazene as a structural framework and a photoresist composition prepared through the branching macromolecule. The composition includes, by weight, 8%-11% of the branching macromolecule, 79%-87% of solvents and a photoacid generator, wherein the photoacid generator accounts for 5%-10% of the weight of the branching macromolecule. Phosphonitrilic chloride trimer and 4-Formylbenzoic acid serve as reaction main monomers of the branching macromolecule, and the branching macromolecule is prepared through a series of formylation, hydroxylation and the photosensitive monomer reaction. A branching macromolecule synthesis method is simple, reaction conditions are moderate, and high heat resistance and good film forming performance are achieved. The prepared photoresist composition has good developing performance, low line edge roughness is achieved, and therefore the application field of cyclotriphosphazene derivative materials is also expanded.

Owner:JIANGNAN UNIV

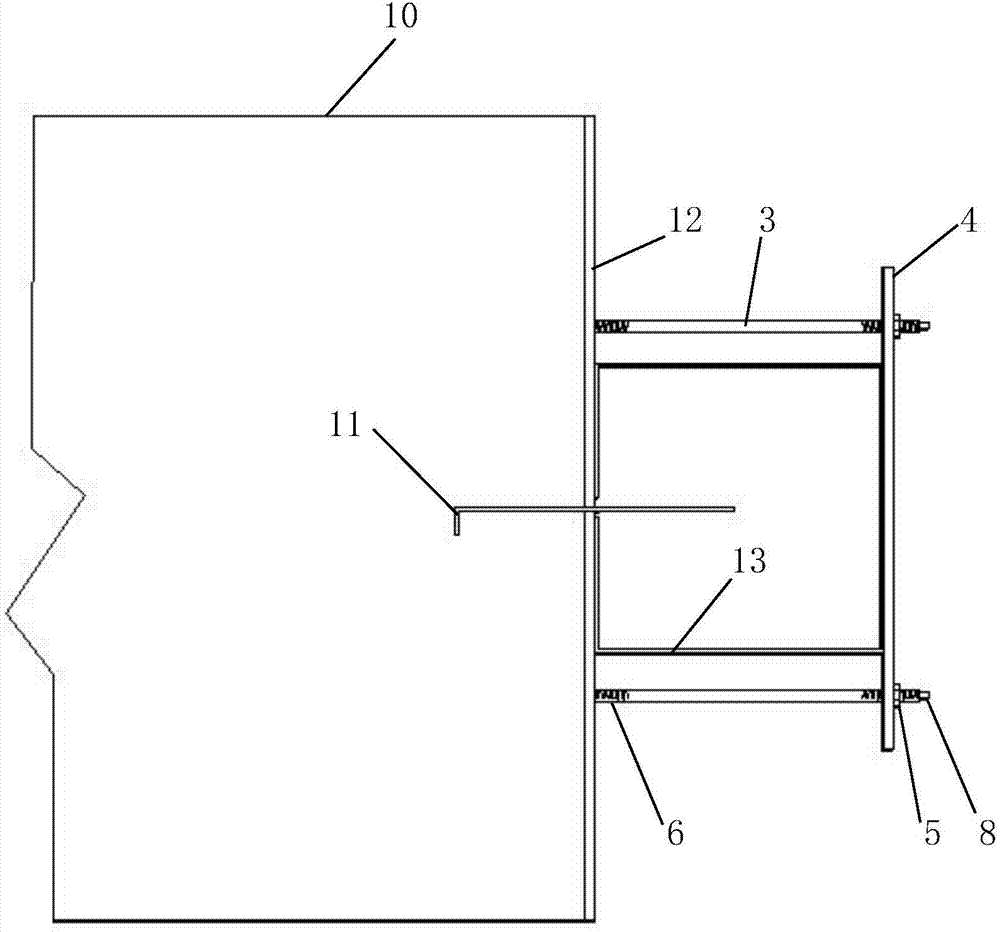

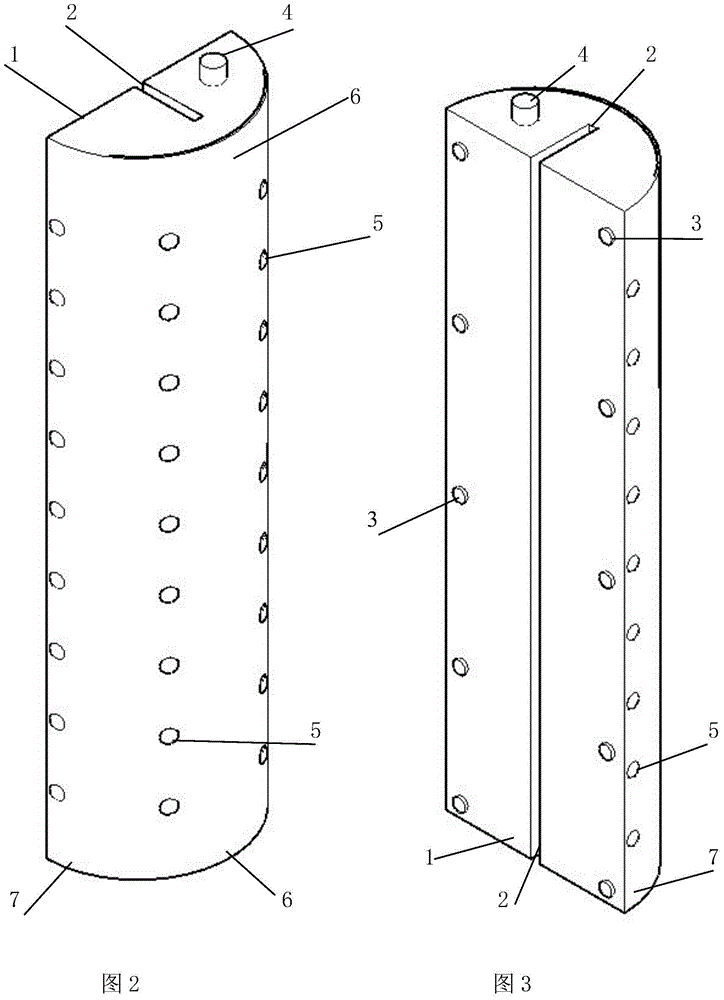

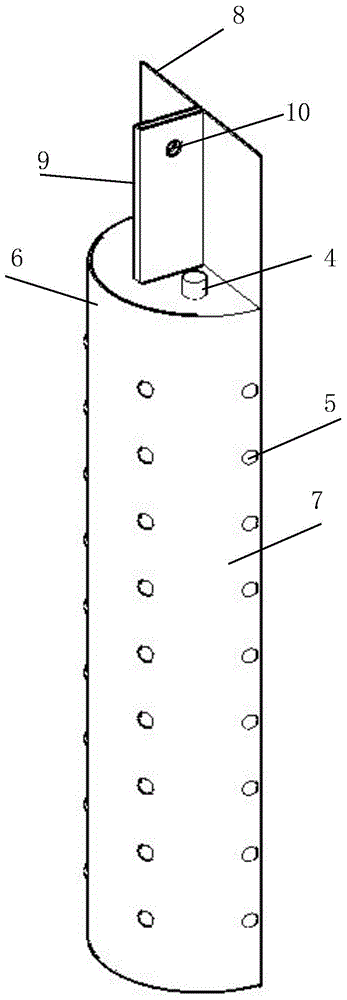

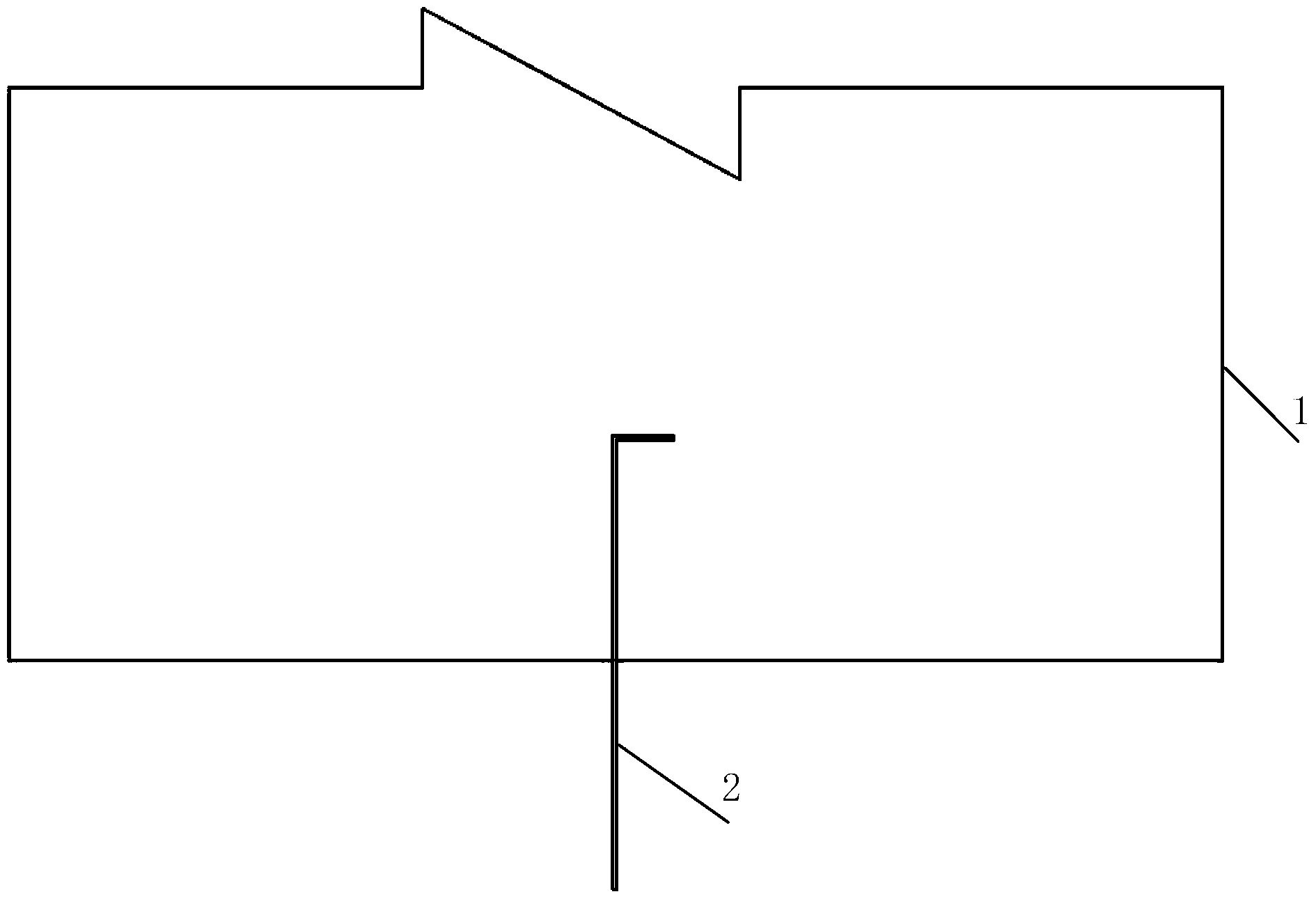

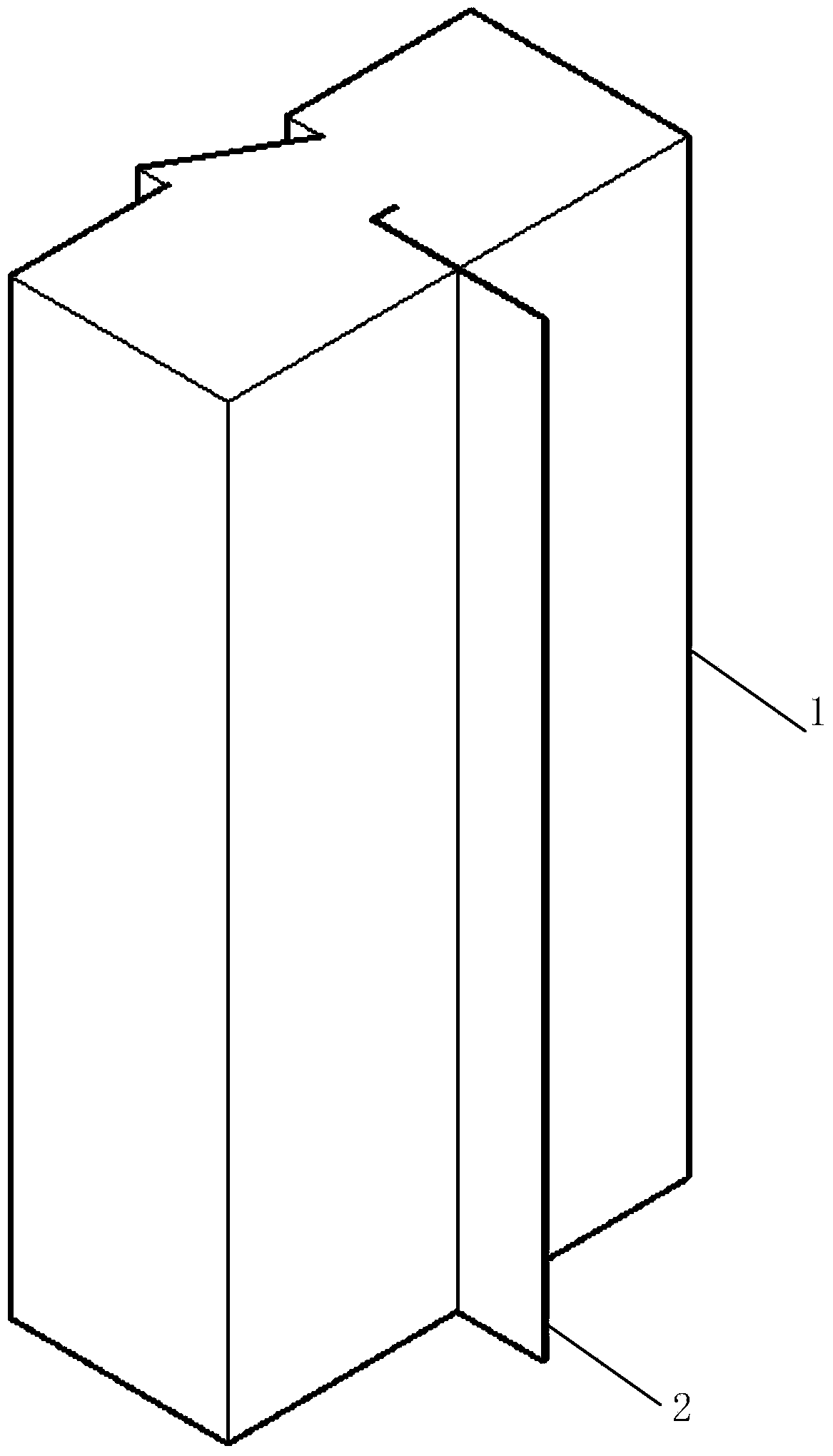

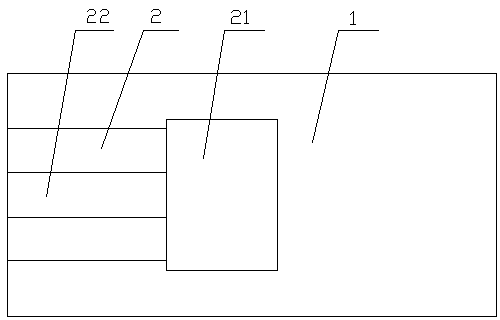

Concrete engineering deformation joint vertical water stop cavity die and construction method thereof

ActiveCN104314050AEasy to pourNeat sectionArtificial islandsProtective foundationEngineeringHydraulic engineering

The invention discloses a concrete engineering deformation joint vertical water stop cavity die. The cavity die comprises a water stop sheet, a framework and an air bag, wherein the air bag is connected with the framework and is arranged on the outer side of the framework; when the cavity die is applied, a part of the water stop sheet is pre-embedded in a first-stage concrete section; the framework is connected with the water stop sheet; the air bag is filled with gas with predetermined gas pressure; after initial setting of second-stage concrete, a semicircular cavity capable of injecting molten asphalt is formed in the second-stage concrete after the gas pressure in the air bag is released and the framework and the air bag are removed. The cavity die has a simple structure and is easy to assemble and use, the problem of seepage of an expansion and contraction joint caused by non-uniform settlement or distortion of a stratum in a water conservancy project can be effectively solved, and the cavity die can be recycled and is low in cost.

Owner:NANJING WATER PLANNING & DESIGNING INST

Rapid cutter for fireproof insulation boards

The invention discloses a rapid cutter for fireproof insulation boards, belongs to the technical field of board processing equipment, and overcomes the defects that products cut by existing insulation board cutters in the prior art are damaged seriously, the qualification rate is low, the demand for the solidification degree of a cement foaming blank is high, and accordingly the product cost is increased. The rapid cutter mainly comprises a frame, wherein an electric motor and a driving shaft are arranged on the frame; the electric motor is connected with the driving shaft through a belt pulley; one or more than one groups of cutting devices are arranged on the frame; each cutting device comprises a power wheel, a driven wheel one, a driven wheel two, a driven wheel three and a flexible cutter; the driven wheel one, the driven wheel two and the driven wheel three are surrounded by the flexible cutter; the driving shaft is connected with power wheels of the cutting devices through the belt pulley; cleaning brushes are arranged above the flexible cutters; and the flexible cutters adopt band saws. The rapid cutter for fireproof insulation boards is mainly used for processing boards.

Owner:贾付章

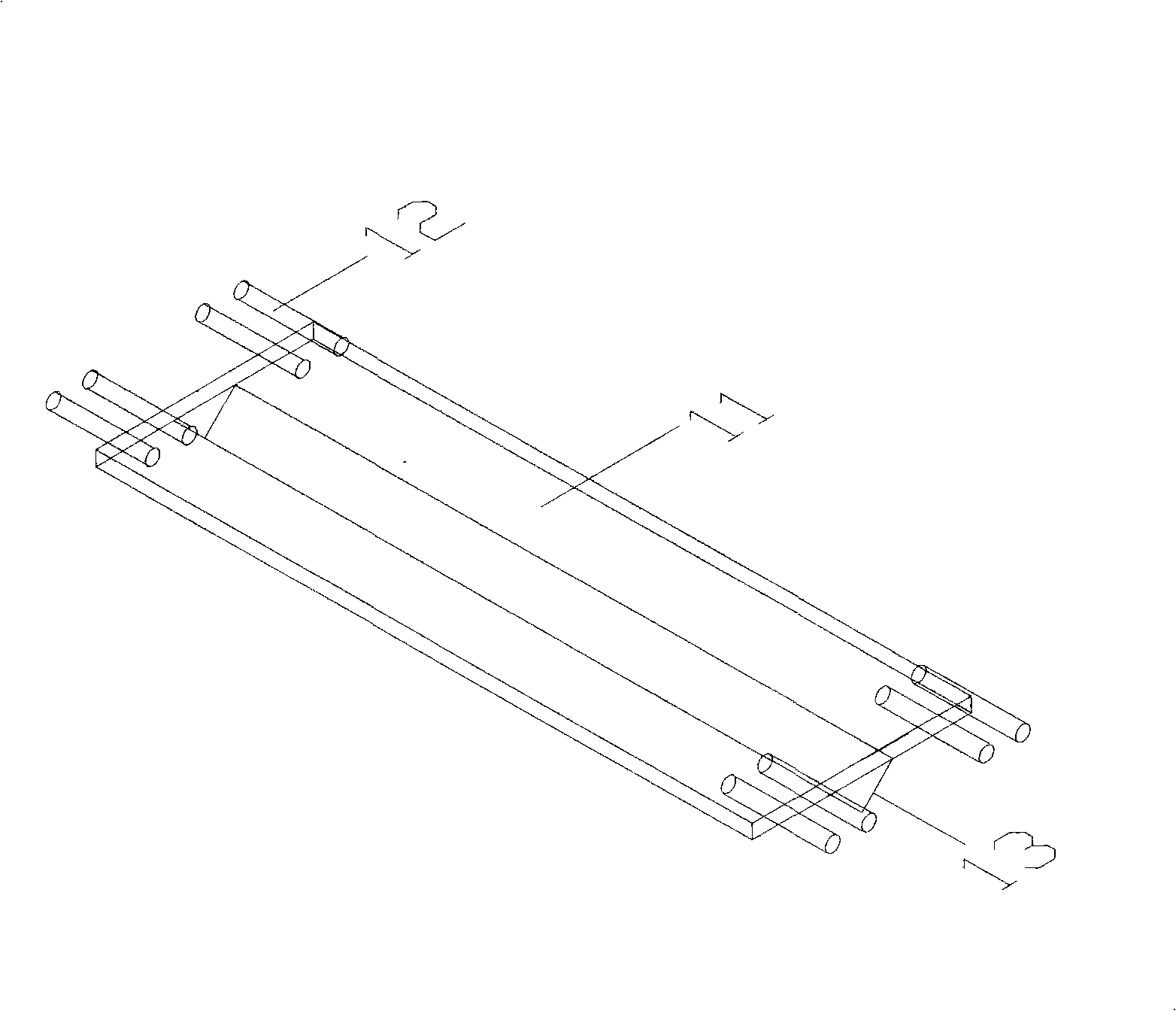

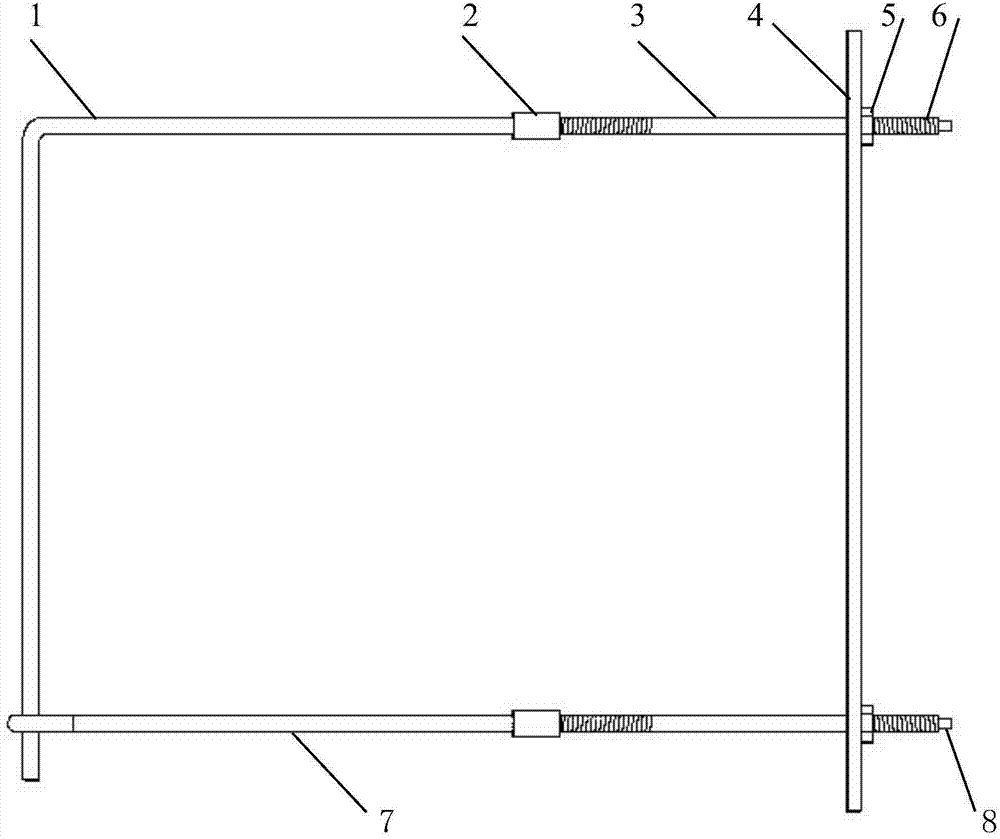

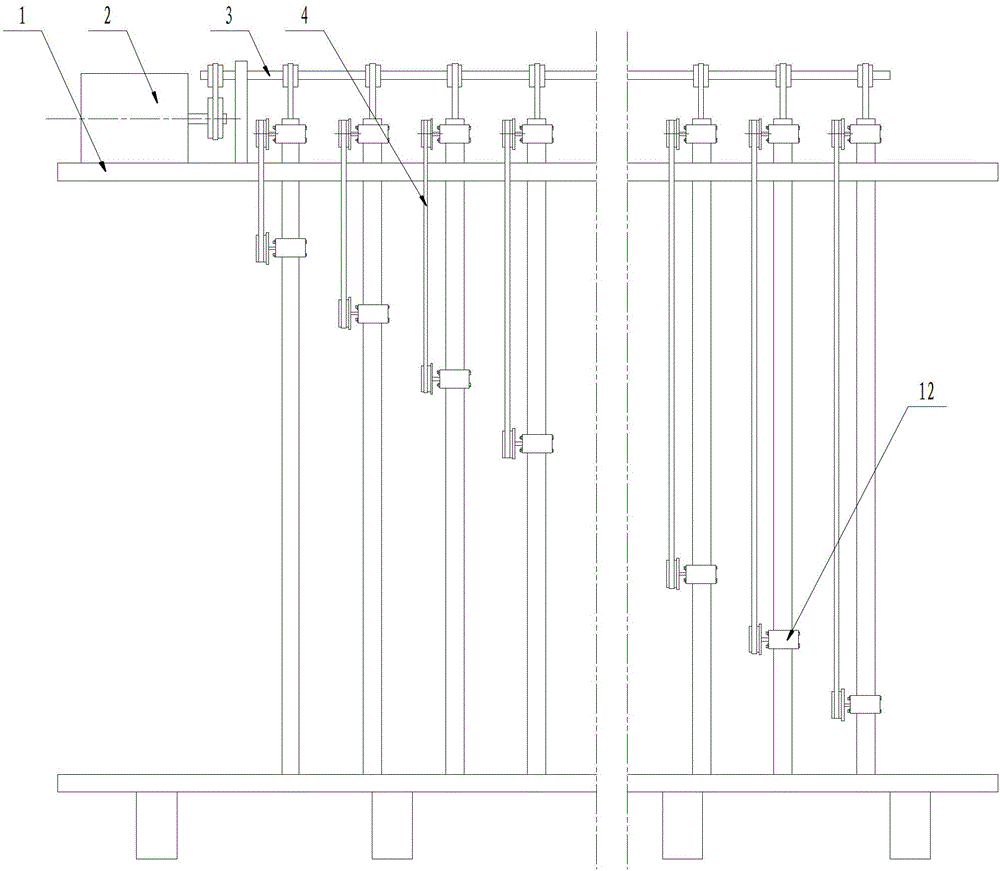

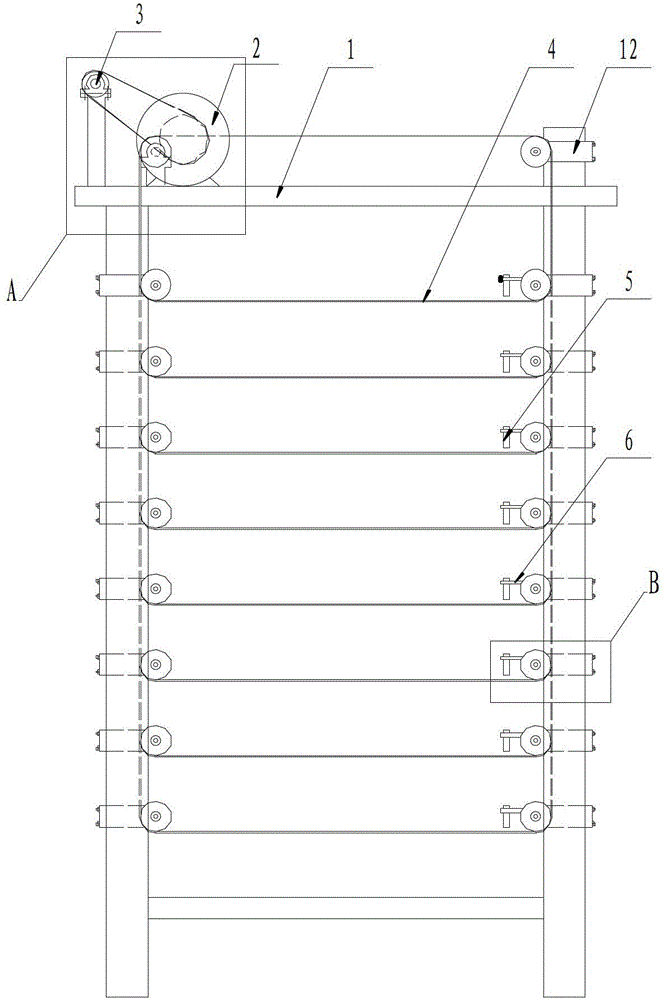

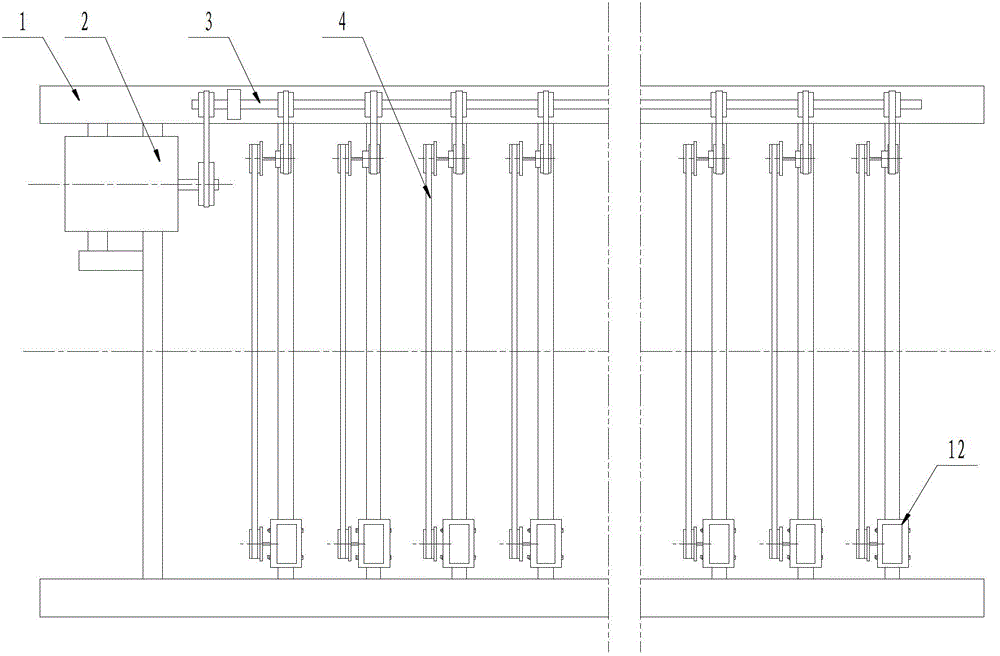

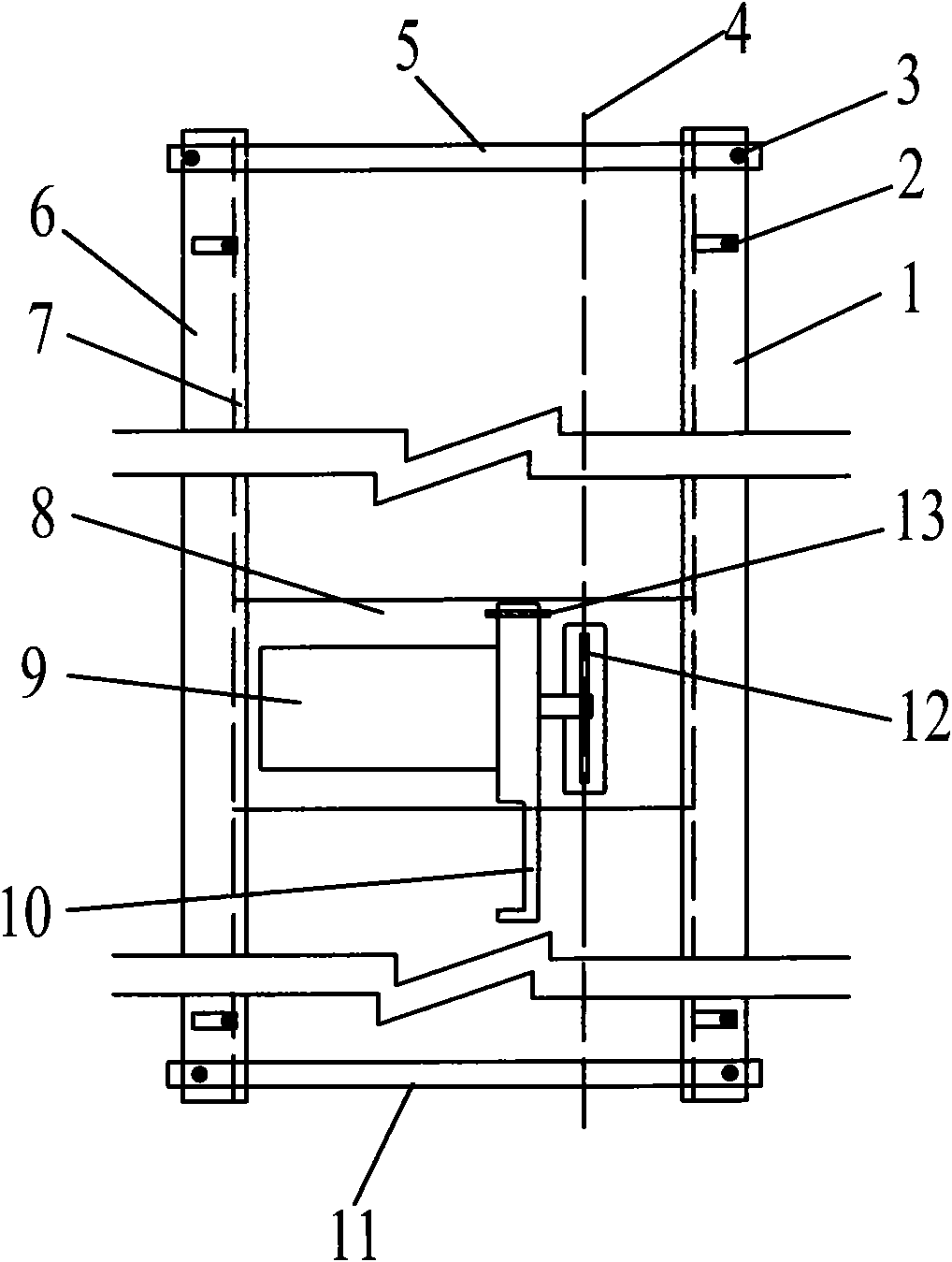

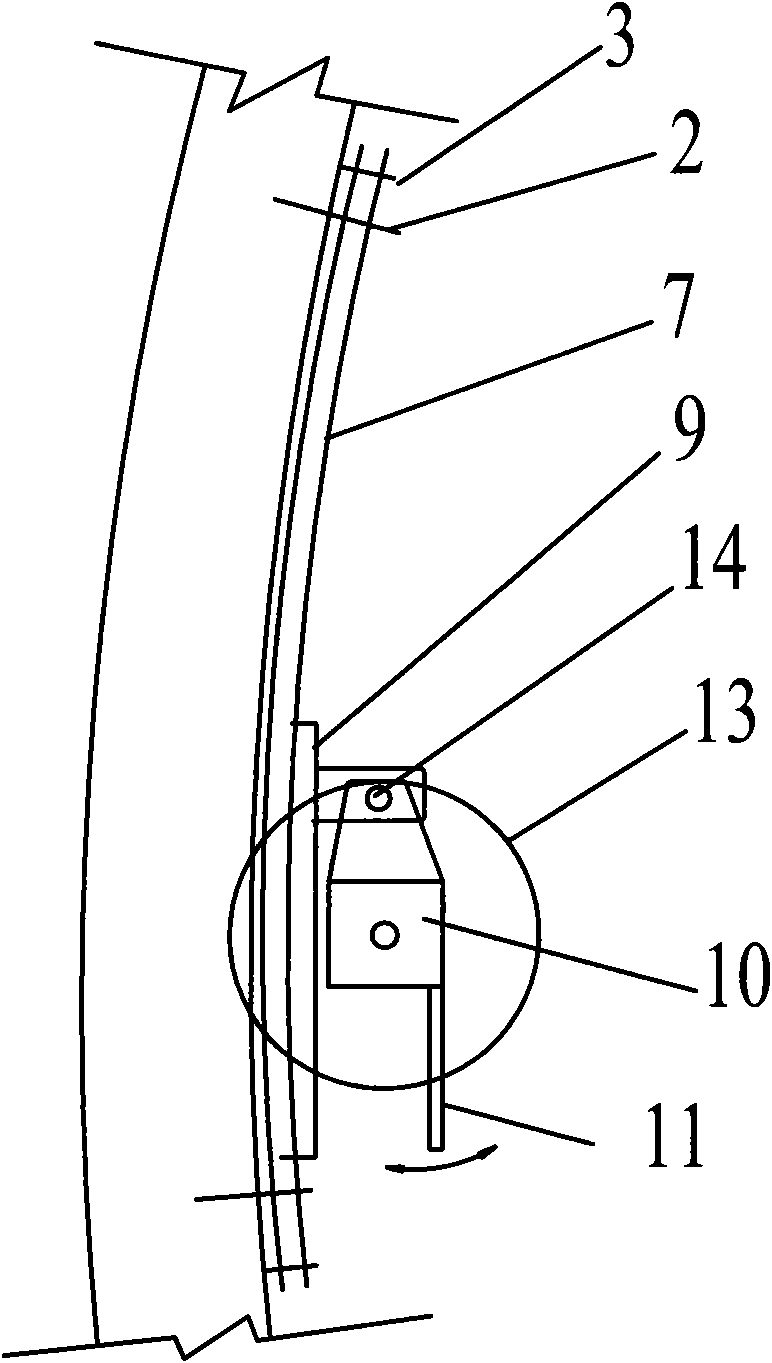

Concrete lining cutting device

InactiveCN102001128AImprove working environmentNeat sectionCeramic shaping apparatusArchitectural engineeringWorking environment

The invention discloses a concrete lining cutting device. The device comprises a concrete cutting machine, a guide rail I, a guide rail II, an upper connecting rod and a lower connecting rod, wherein the guide rail I and the guide rail II are alternately arranged on the concrete lining; lower ends of the guide rail I and the guide rail II are connected through the lower connecting rod, and upper ends of the guide rail I and the guide rail II are connected through the upper connecting rod; guide grooves are arranged on the guide rail I and the guide rail II; the concrete cutting machine is arranged in the guide groove and can move along the guide groove; and guide rail fixing grooves are arranged on the guide rail I and the guide rail II. The concrete lining cutting device ensures that depths of the cut grooves are uniform and the fracture surface is neat, has simple structure and is convenient for use and popularization, mass man power is saved, and dangerous working environment of workers is improved.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST

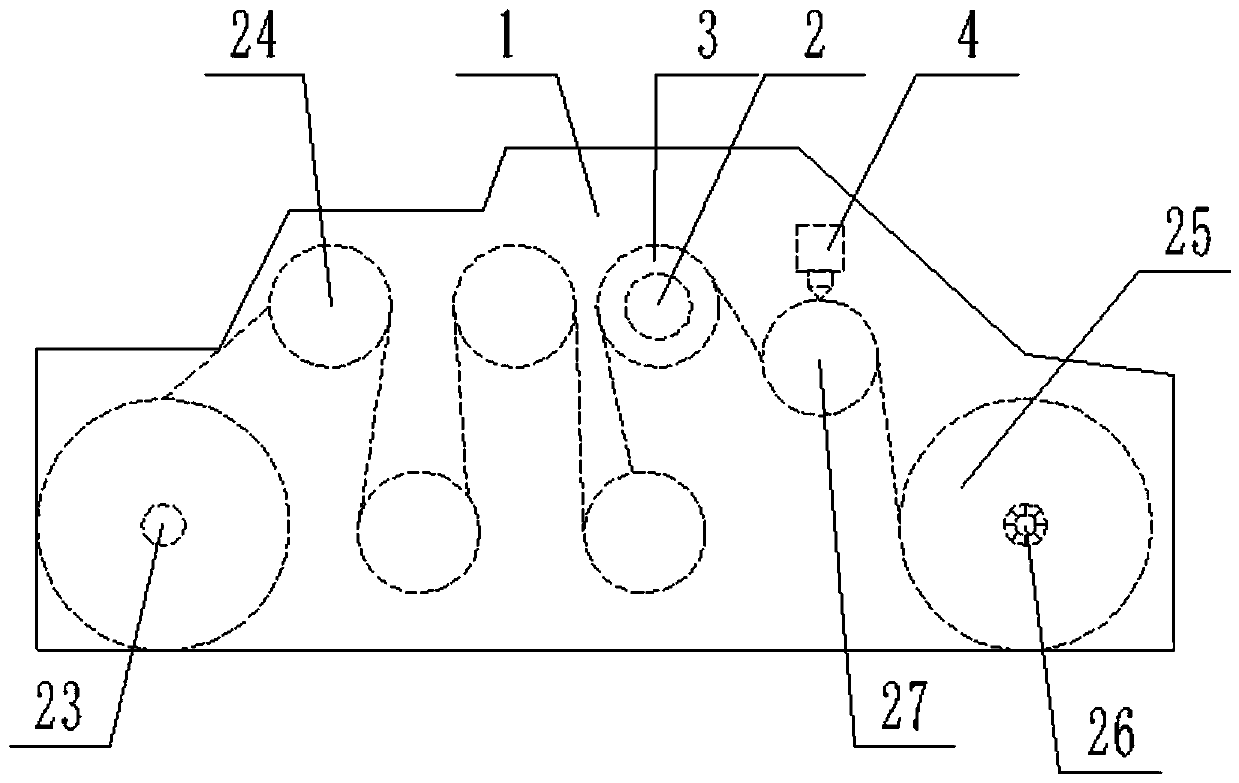

Flexible fiber shearing machine and shearing method

InactiveCN105665114AAvoid intertwiningAvoid fluffyGrain treatmentsMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of flexible fiber conveying devices, and particularly relates to a flexible fiber shearing machine and shearing method. The flexible fiber shearing machine comprises a shell, a feeding channel, a material pressing device, a cutter and a cutter driving mechanism, wherein the feeding channel penetrates into the shell; the two ends of the feeding channel are provided with a feeding inlet and a discharging outlet correspondingly; the material pressing device is arranged inside the shell and located above the feeding channel and is used for compressing flexible fibers on the feeding channel; the cutter is arranged at the discharging outlet of the feeding channel; and the cutter driving mechanism is arranged inside the shell and connected with the cutter so as to drive the cutter to vertically move along the discharging outlet of the feeding channel to shear the flexible fiber materials. According to the flexible fiber shearing machine and shearing method, as the flexible fiber materials are compressed and arranged in the conveying process through the material pressing device, the flexible fiber materials are prevented from being mutually wound and fluffy and are made to be easy to cut off, and fracture surfaces are regular.

Owner:陈少志

Injection molding device for inner gears with pouring gates cut in mold, and injection molding method

The invention provides an injection molding device for inner gears with pouring gates cut in a mold, and an injection molding method. The injection molding device comprises an upper jacking plate, a lower jacking plate, a first mold plate and a second mold plate, an upper mold cover is embedded in the first mold plate, a lower mold cover is embedded in the second mold plate, two lower mold cavities of the lower mold cover are both internally provided with upper central reverse mold gears, injection molding cavities are formed among the corresponding upper mold surface located on the upper moldcover, the upper central reverse mold gears and the inner walls of the lower mold cavities, the tops of two central rods arranged on the lower jacking plate penetrate through the upper jacking plateand the second mold plate to be attached to the semi-spherical concave surface of the upper mold surface, semi-spherical grooves located at the tops of the central rods communicate with the corresponding pouring gates, arc-shaped chutes distributed at the tops of the central rods enable the semi-spherical grooves to communicate with the injection molding cavities, two cutter sleeves of the upper jacking plate sleeve the corresponding central rods respectively, and annular cutting edges located at the tops of the cutter sleeves abut against the opened lower edges of the injection molding cavities. According to the injection molding device for the inner gears with the pouring gates cut in the mold, and the injection molding method, all pouring heads can be cut off at a time while multi-pointpouring is realized, and using is convenient.

Owner:九江华旭塑胶制品有限公司

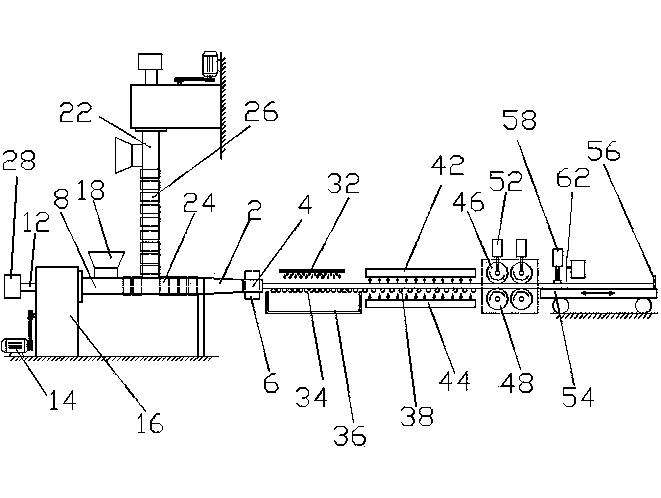

Steel-plastic composite pipeline on-site sealing and pipe breaking equipment and method

PendingCN111673153AThe pipe section is neatThe seal is neat and firmFeeding apparatusMilling equipment detailsStructural engineeringManufacturing engineering

The invention discloses steel-plastic composite pipeline on-site sealing and pipe breaking equipment. The equipment comprises a pipeline rotating platform used for enabling a steel-plastic composite pipeline to rotate, a mounting frame is fixedly arranged on the pipeline rotating platform, a grooving machine used for grooving and cutting off the rotating steel-plastic composite pipeline is fixedlyarranged on the mounting frame, and the mounting frame is further provided with an extrusion welding gun used for carrying out filler sealing on a groove opening formed after the steel-plastic composite pipeline is grooved. According to the steel-plastic composite pipeline on-site sealing and pipe breaking equipment, the improvement on the machining quality and efficiency for machining short pipes on site of the steel skeleton plastic composite pipe is facilitated, the labor intensity of constructors is reduced, and the equipment is suitable for the technical field of steel-plastic compositepipeline construction.

Owner:HUACHUANG TIANYUAN IND DEVING

Mechanical extrusion cutting-off equipment

The invention discloses mechanical extrusion cutting-off equipment. The mechanical extrusion cutting-off equipment comprises a base, wherein the two ends of the upper part of the base are provided with a guide seat and a material barrel respectively, a sliding seat is arranged on the guide seat in a sliding mode, a stepping motor is detachably connected to the upper part of the sliding seat, the stepping motor is provided with a transmission, the transmission is matched with a rotating shaft, a feeding motor is arranged at one end of the material barrel, the other end of the material barrel isdetachably connected with a discharging head, the discharging head is detachably connected with a plurality of discharging mold pipes, the rotating shaft is in key connection with a multi-arm rotating disc, the extending arm of the multi-arm rotating disc is matched with a cutting knife through an inner hexagonal screw rod, and a spring is arranged on the inner hexagonal screw rod in a penetrating mode. The mechanical extrusion cutting-off equipment can carry out multiple extrusion output on materials, the section of the output strip-shaped materials is controllable, the strip-shaped materials can be quickly cut off, the cutting efficiency is high, the cutting operation is reliable and safe, the section is neat, the cutter head replacement operation is simple, and maintenance and maintenance are convenient.

Owner:山东卫士新材料科技有限公司

Construction method for air bag type concrete project deformation joint water stop cavity mold

InactiveCN105370032AEasy to pourNeat sectionProtective foundationForms/shuttering/falseworksWater leakageCopper

The invention relates to a construction method for an air bag type concrete project deformation joint water stop cavity mold. The cavity mold comprises a skeleton and an air bag, a red copper water stop piece pre-embedded in the section of first-stage concrete is clamped in a groove by the cavity mold, air pressure is set in the air bag of the cavity mold, second-stage concrete is poured in layers, after initial setting of the concrete, air pressure in the air bag is released, the cavity mold is hung out, a semicircular cavity can be formed in the section of the second-stage concrete, and molten pitch is injected into the semicircular cavity to achieve the water stop function. The problem that deformation joint water leakage, caused by differential settlement or diastrophism of a stratum, of a water conservancy project can be solved, and the cavity mold can be used repeatedly.

Owner:王东华 +2

Concrete engineering expansion joint vertical sealing up structure fixing member and application thereof

The invention relates to an underground (underwater) building waterproof device and particularly relates to a concrete engineering expansion joint vertical sealing up structure fixing member and an application thereof. The concrete engineering expansion joint vertical sealing up structure fixing member comprises a U-shaped embedded part formed by an embedded part A and an embedded part B, wherein the embedded part is provided with a connection pipe, the connection pipe is provided with an inner thread and is in threaded connection with a connection member, slab iron is fixed to the connection member through a nut into a whole so as to fix a vertical sealing up steel channel at the position of a concrete fracture surface, asphalt is poured into the steel channel, and the connection member and the slab iron are disassembled after cooling and maintained and collected for recycle. By means of the concrete engineering expansion joint vertical sealing up structure fixing member, the problem of water seepage caused by differential settlement or diastrophism of strata in water conservancy projects can be solved, manual work can be saved, construction periods are shortened, and resources are saved.

Owner:中能建建筑集团有限公司

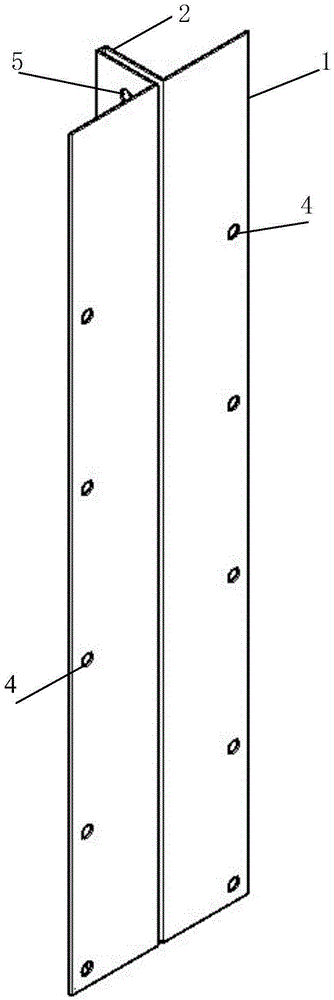

Foldable water stopping type cavity die for concrete deformation joint and manufacturing and construction method thereof

InactiveCN104314049AEasy to pourNeat sectionArtificial islandsUnderground chambersAsphaltMechanical engineering

The invention relates to a foldable water stopping type cavity die for a concrete deformation joint and manufacturing and construction method thereof. The foldable water stopping type cavity die comprises a cavity die body. The foldable water stopping type cavity die is characterized in that the cavity die is formed by movably chaining a rear side plate, a left side plate, a right side plate, a left front plate and a right front plate; the cavity die is rectangular by overlooking, and a medium clearance is formed between the left front plate and the right front plate in the front part; when in use, the front part of the cavity die is aligned with a water stopping sheet which is embedded in the first phase concrete section, the water stopping sheet extends into the cavity die through the medium clearance, then the second phase concrete can be poured, the cavity die is hoisted out after the second phase concrete is initially set, and thus the cavity capable of pouring molten asphalt can be formed in the second phase concrete section.

Owner:扬州市勘测设计研究院有限公司

A kind of preparation method of ceramic electrician blade

ActiveCN106736892BPromote whisker tougheningImprove toughnessCeramic shaping apparatusOther manufacturing equipments/toolsAdhesiveWhiskers

The invention discloses a preparation method of a ceramic electrician blade, belonging to the field of preparation method of special blades. The processing method comprises the following steps: (1) sintering of a ceramic blank; (2) sharpening both sides of the knife; (3) cutting a breaking groove; (4) processing a big knife edge; (5) processing a small knife edge; (6) accurate grinding of the small knife edge; (7) checking the knife blade; (8) packaging, etc. In the invention, a hot isostatic pressing method is adopted for sintering the raw material, the best sintering technology is selected according to the material composition, and some substances in an adhesive can be fully carbonized at 1,400 DEG C; and the carbonized components can promote the whisker toughening of aluminum oxide, and the toughness of the blank is enhanced. In the invention, during blade processing, the processing depth of the breaking groove is strictly controlled according to the length, width and thickness of the blade, and the defective percentage of the product is reduced.

Owner:安徽华天机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com