Method for application of concrete work expansion joint vertical water sealing structure fixing element

A technology of vertical water stop and application method, which is applied to underwater structures, sea area engineering, earthwork drilling and mining, etc. It can solve problems such as construction difficulties, prolong the construction period, and increase labor, so as to save installation procedures, reduce construction period, and facilitate pouring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

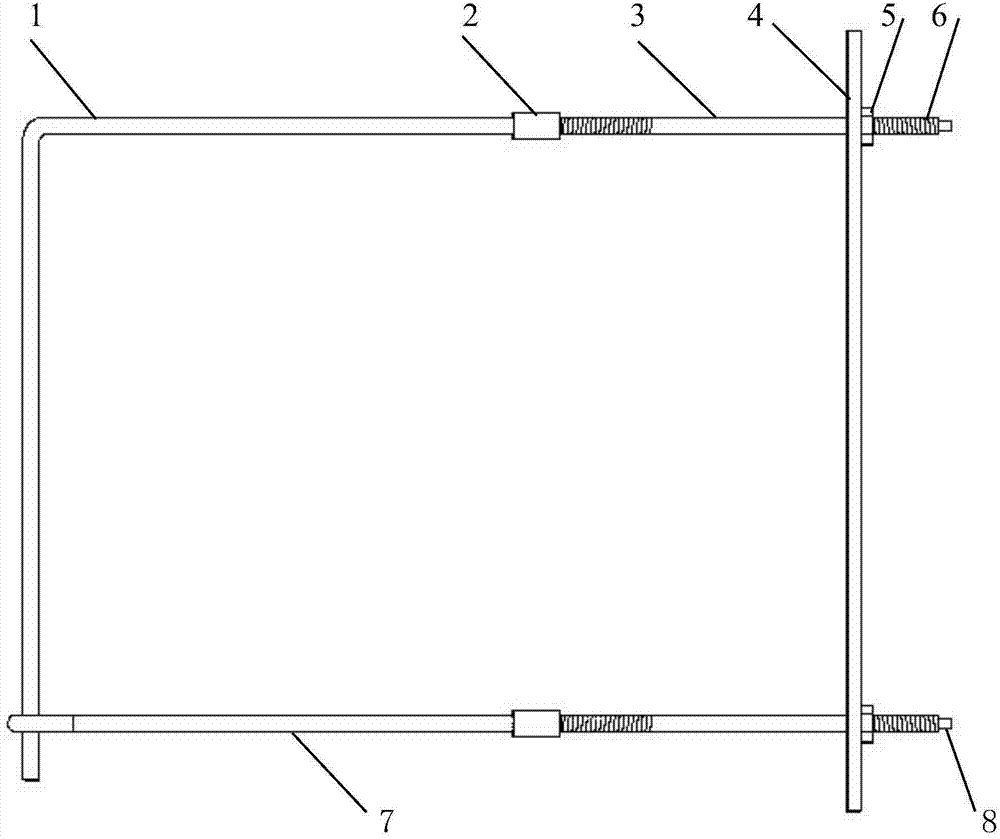

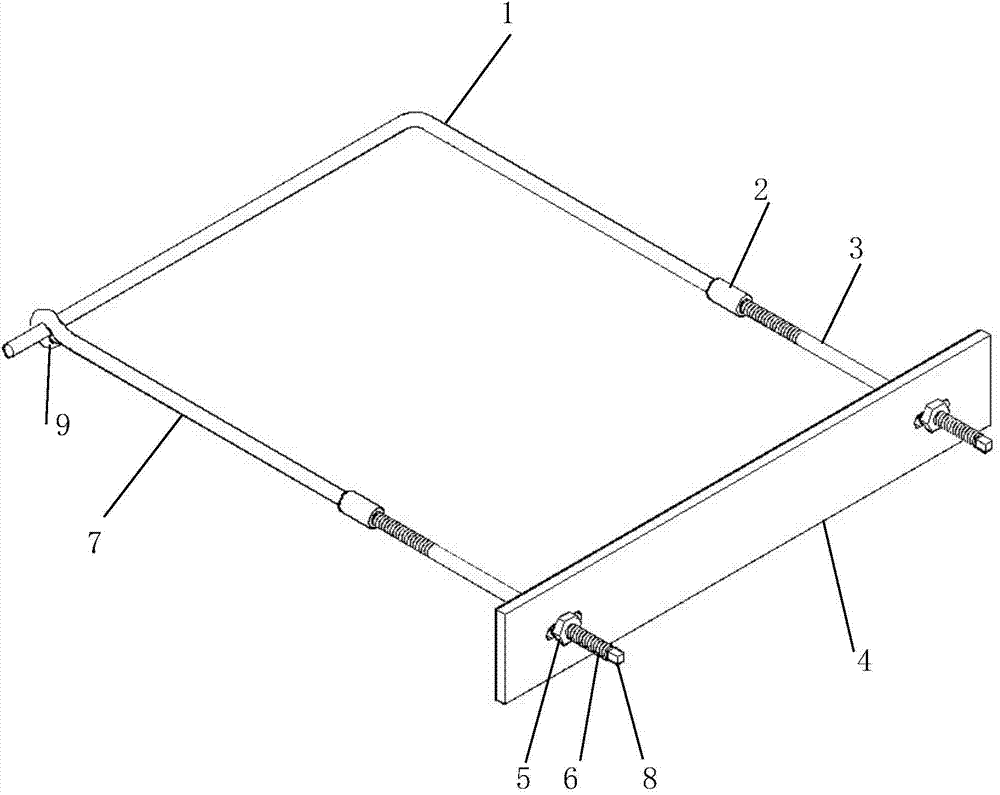

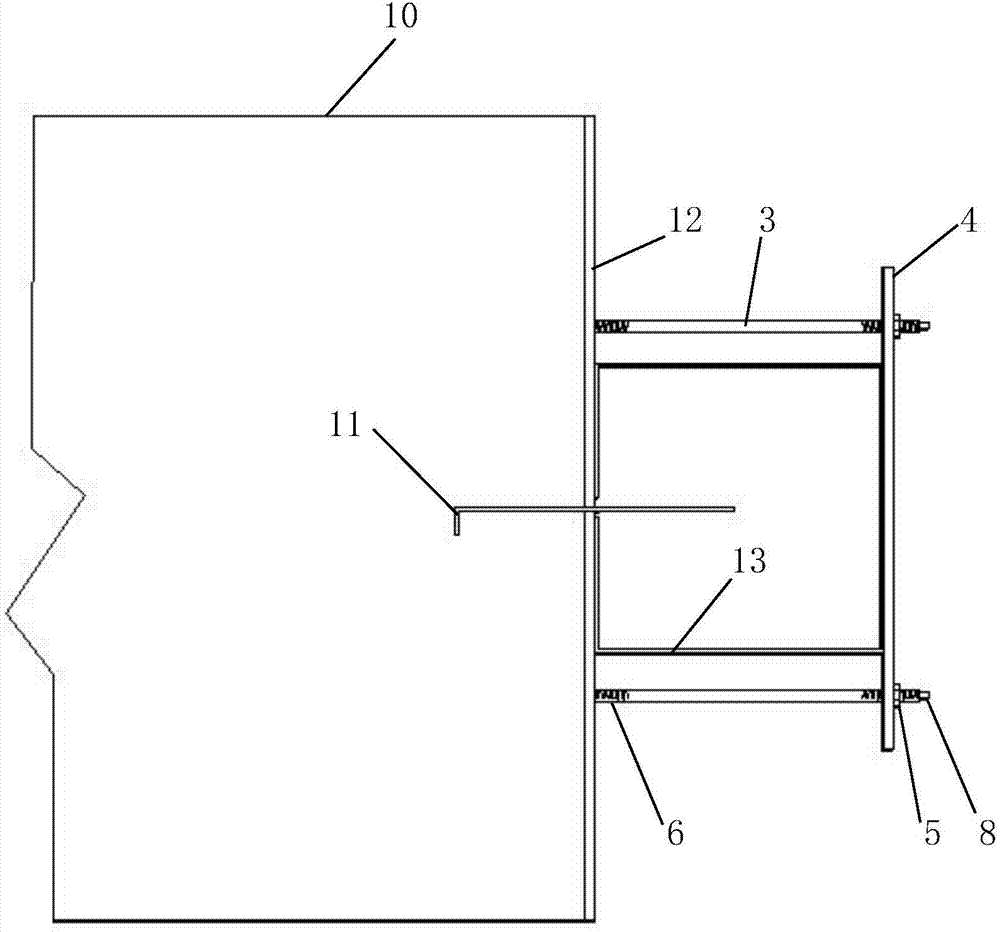

[0035] Embodiment 1, referring to the accompanying drawings: a vertical water-stop structure fixture for expansion joints in concrete engineering, including embedded parts A1, embedded parts B7, connectors 3, and flat irons 4. The embedded parts A1 are selected from 8- Made of 10mm steel bar, one end is provided with a connecting pipe 2, one end of the connecting pipe 2 is welded and fixed with the embedded part A1, and there is a thread inside, the embedded part A1 is bent 90° horizontally in the middle to form an L shape, and the embedded part A1 has There is a section of connecting pipe 2 with a length of 30-60cm, and the length of the bent part is 20-50cm or set according to the width of the concrete section at the supporting place, so as not to exceed the width of the section. One end of the embedded part B7 is welded with a ring 9 or bent into a Arc, the other end is provided with a connecting pipe 2, the length of the embedded part B7 is 30-60cm, and a section of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com