Method for cutting air-entrained concrete building blocks and cutter

A technology of aerated concrete and cutting method, which is applied to the cutting of aerated concrete blocks and the field of aerated concrete block cutting machines, can solve the problems of easy damage of steel saws, affecting the health of workers, low work efficiency, etc. The effect of dust, overcoming fragile and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

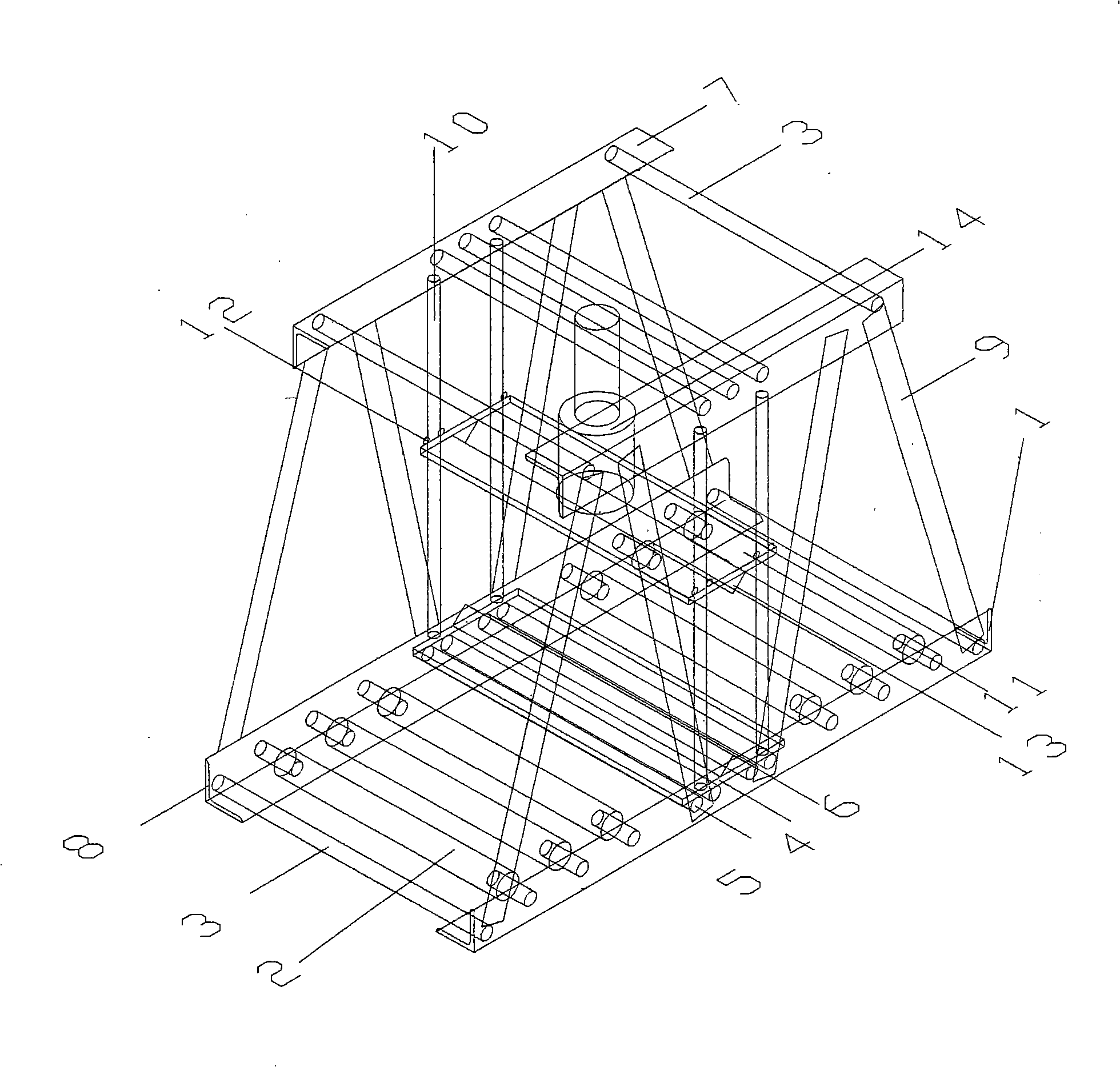

[0030] A method for cutting an air-entrained concrete block, the steps of which are:

[0031] 1. Draw (mark) a line on the aerated concrete block to be processed according to the required size as a cutting mark.

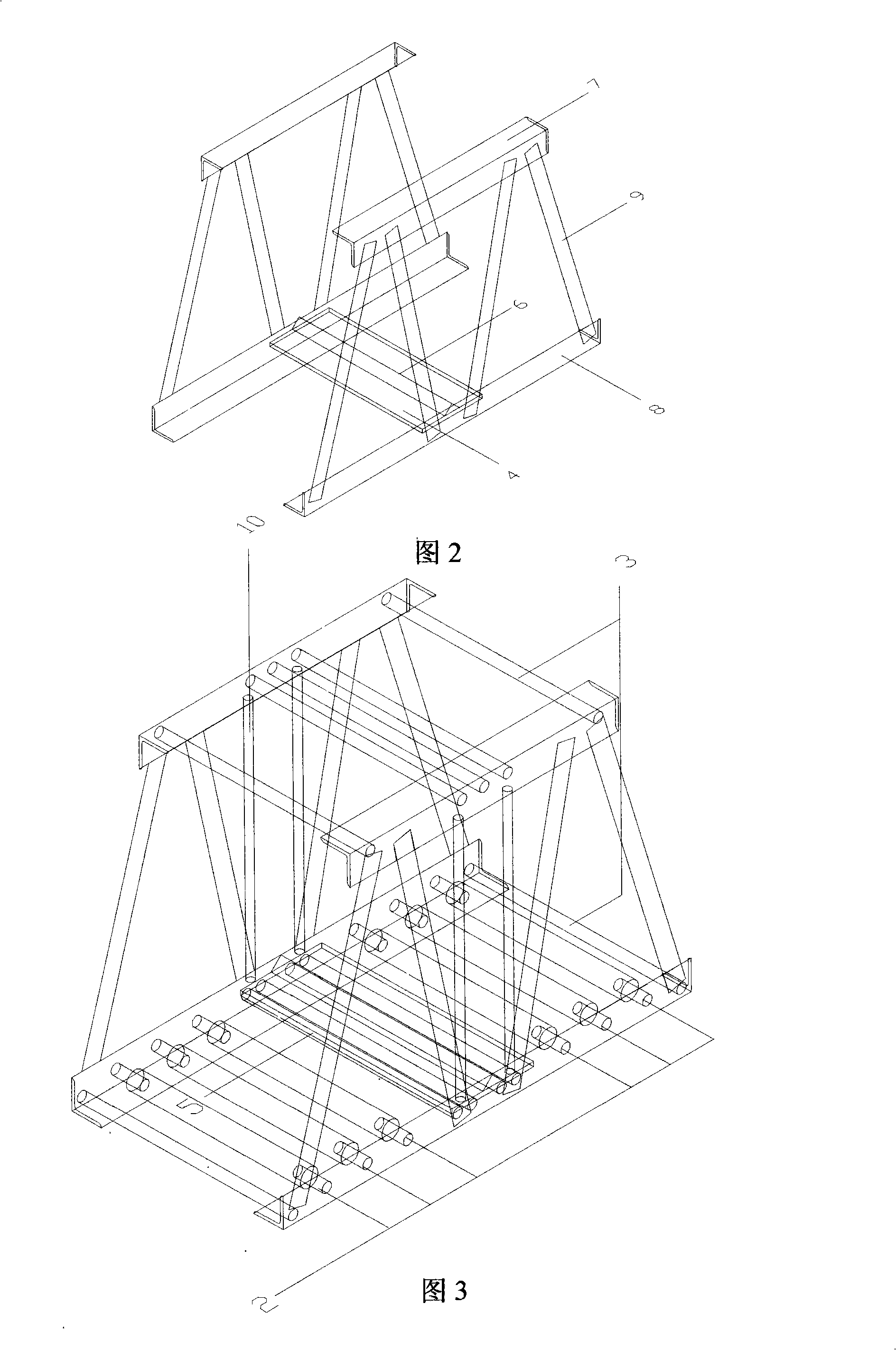

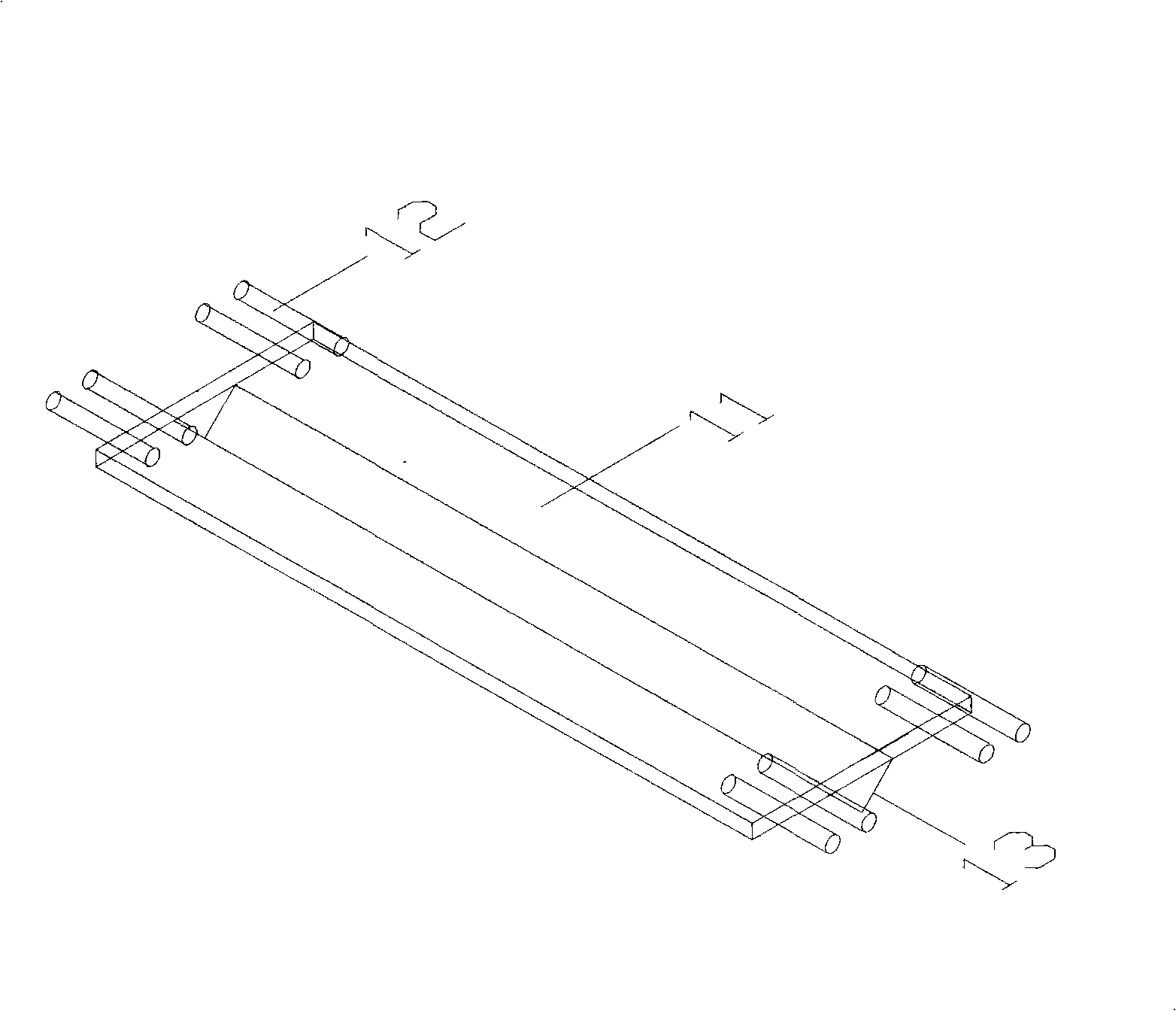

[0032] 2. Put the marked aerated concrete block into the reaction frame, so that the marking line on one side of the aerated concrete block is aligned with the lower edge of the knife.

[0033] 3. Then put the upper knife edge on the aerated concrete block in the reaction frame, make the ear groove of the upper knife edge fit into the guide rail on the reaction force frame, and align the knife edge with the marking line.

[0034] 4. Put a thin jack on the upper edge of the knife. According to the thickness of the processed aerated concrete block, use wooden boards of different thicknesses to adjust the gap between the upper part of the jack and the upper reaction beam of the reaction frame so that it is not greater than the stroke of the jack. 1 / 3, and make the jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com