Method for preparing intensified daqu applied to nongjiang-flavor Chinese spirits

A technology of aroma type and Daqu, which is applied in the field of intensified Daqu preparation, can solve the problems of unbalanced product yield and quality, unclear microorganism types, and no definite explanation, etc., so as to achieve good aroma production function, improve wine yield and The effect of high quality product rate and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 The preparation of high-efficiency strengthened Daqu

[0033] Take Bacillus licheniformis (Bacillus licheniformis) BG05 strain CCTCC NO.M2010251, pick a little bacteria under aseptic conditions, transfer to aseptic beef extract peptone test tube medium, and culture at 45°C-50°C for 24h, that is Level 1 test tube slanted seeds. Add 50mL of LB medium to a 250mL Erlenmeyer flask, autoclave at 121°C for 20min, insert the slant seeds in the test tube under sterile conditions, and shake the flask at 40°C and 150rpm for 24h to form a second-grade Erlenmeyer flask seed.

[0034] After mixing the fresh bran with water, divide it into 250mL Erlenmeyer flasks, sterilize under high pressure at 121°C for 20 minutes, inoculate after cooling, the inoculum amount is 5%, and cultivate at 37°C for 3 days, which is the seed expansion cultivation. The fresh bran is mixed with water, sterilized at 121°C for 20 minutes, taken out, cooled and inoculated, divided into bent plate...

Embodiment 2

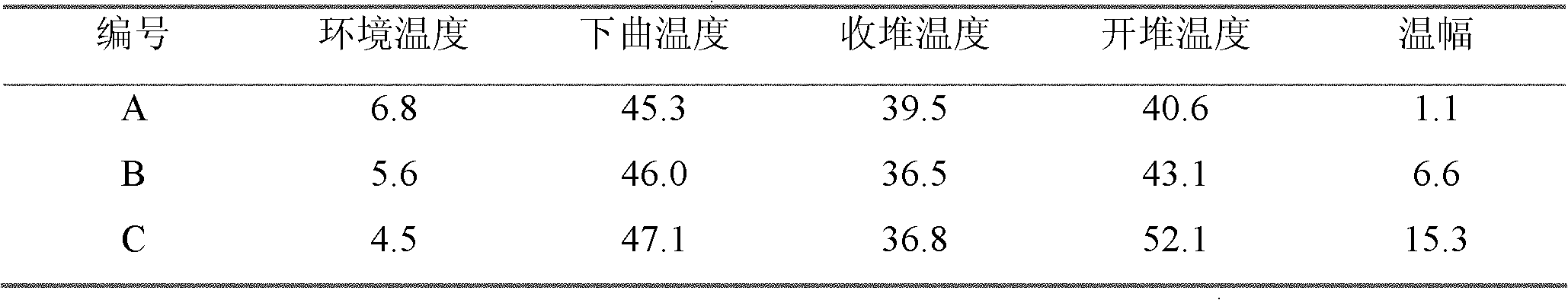

[0036] Example 2 High-temperature stacked fermented grains heating test

[0037]Take the steamed grain out of the retort, add an appropriate amount of water, and cool it to 30°C or room temperature in the air-drying hall, and place 12% fortified koji (plan A), 13% high-temperature koji (plan B), and 12% high-temperature koji+ 0.3% fortified koji (plan C), after being evenly mixed, transported to the stacking site to harvest conical piles, stacked for 2 to 3 days. The temperature statistics and microbial quantity analysis during the accumulation process were carried out for the fourth round of the low ambient temperature in the production of Jian-flavor liquor. The results are shown in Table 1 and Table 2.

[0038] Table 1 Temperature statistics during the fourth round of stacking (°C)

[0039]

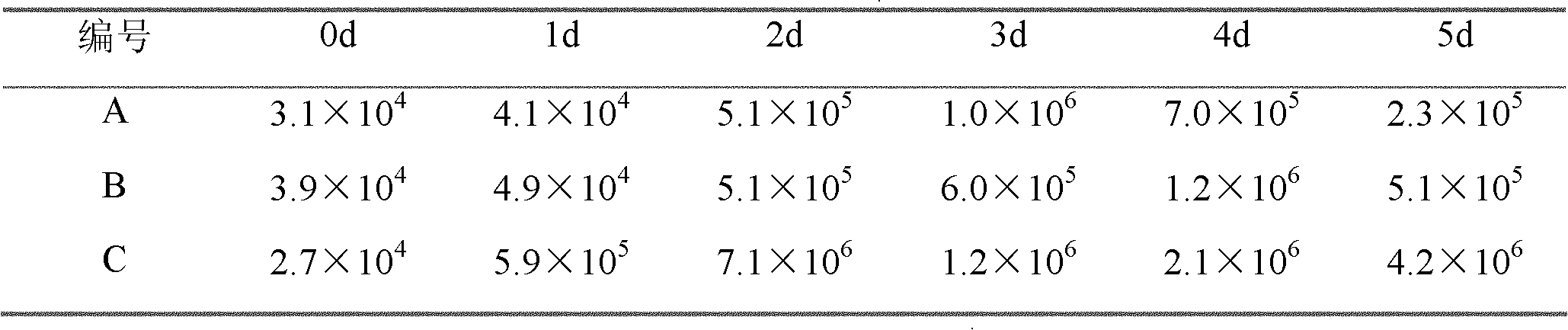

[0040] Table 2 Changes in the total number of microorganisms during high-temperature accumulation (cfu / g fermented grains)

[0041]

[0042] It can be seen from Table 1 that at...

Embodiment 3

[0043] Microorganism analysis test in the fermentation process of embodiment 3

[0044] After the accumulation is completed, the piles can be opened and fermented in cellars. The three cellars are respectively put into the fermented grains of Daqu made by adding A, B, and C. The fermentation time is 30 days. During the fermentation process, the changes of microorganisms in the cellar and the exit of the fermented grains from the cellar were detected, and the results are shown in Table 3.

[0045] Table 3 The fourth round of fermented fermented grains entering and exiting the tank

[0046]

[0047] The number of bacteria in the fermented grains out of the cellar in 30 days: plan A is 4.2×10 5 cfu / g wine grains, plan B is 2.1×10 5 cfu / g wine grains, plan C is 7.1×10 6 cfu / g wine grains. And the vast majority of these bacteria are Bacillus, and the proportion of thermophilic aroma-producing bacteria reaches 75%. It can be seen from Table 3 that the utilization rate of star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com