Deep-cooling punching-shearing forming device for blank holder of micro-miniature workpiece and forming method thereof

A blank holder and micro-sized technology, which is applied to the cryogenic punching and shearing forming device and its forming field of micro-small workpieces, can solve the problems of poor cross-section appearance, low precision of forming cross-section, and uneven surface, so as to reduce the elongation rate , increase the boundary brittleness, improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

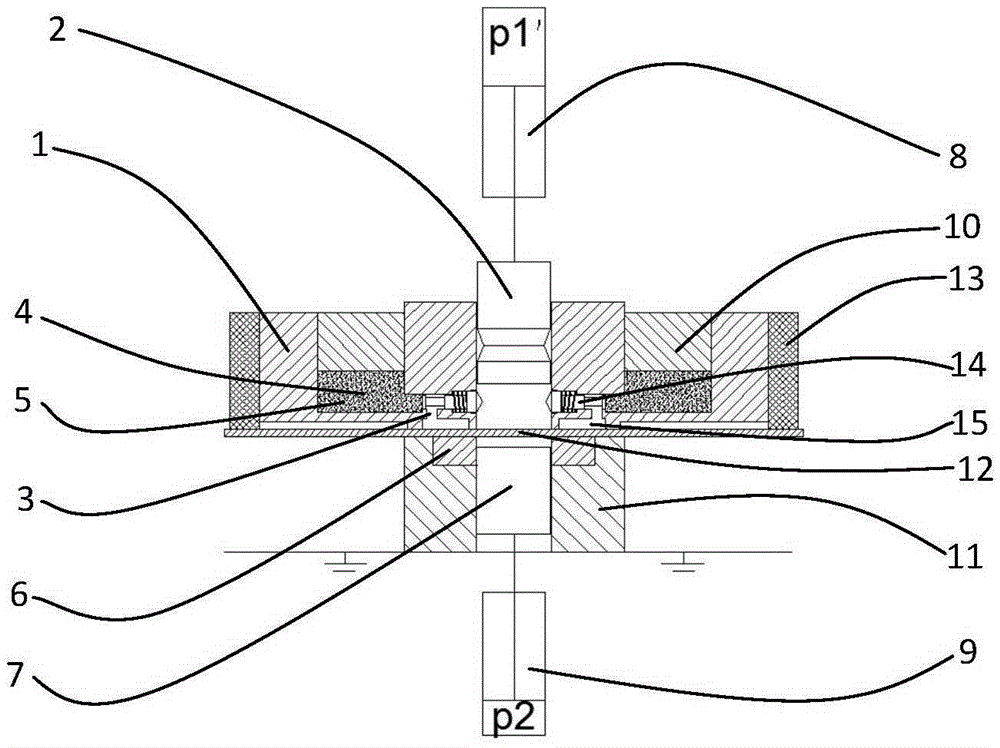

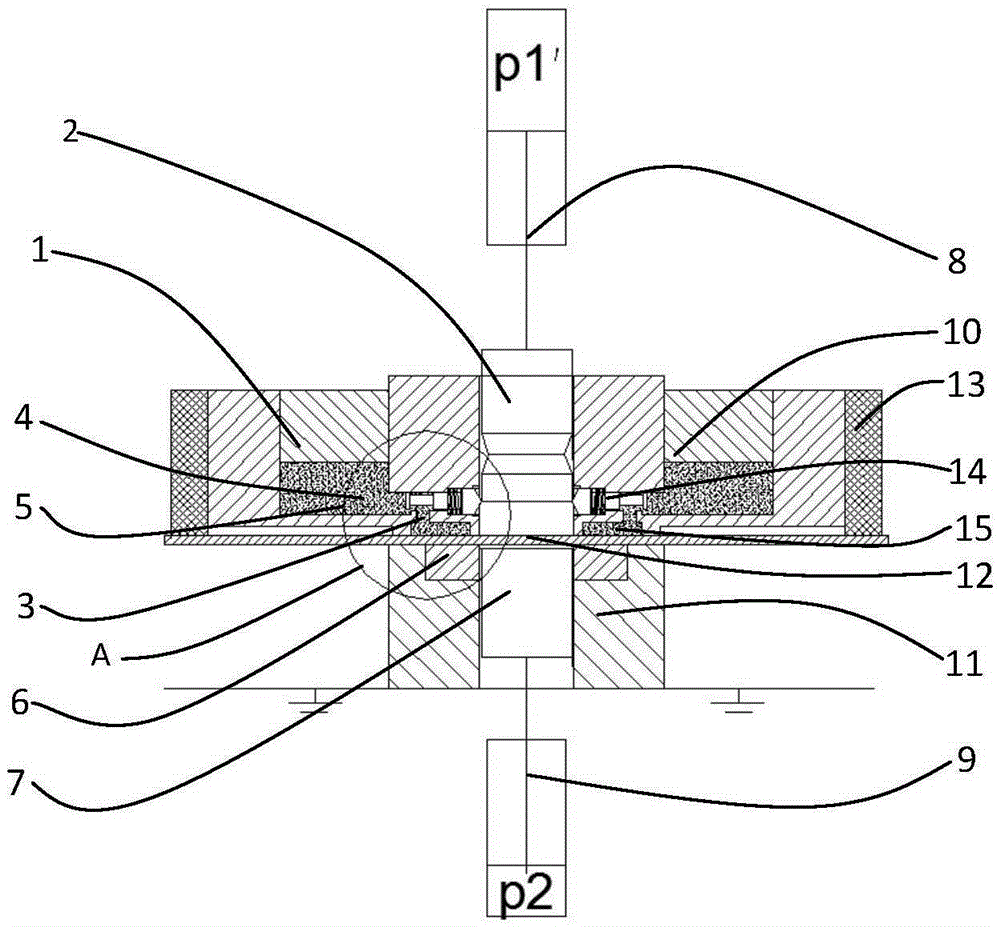

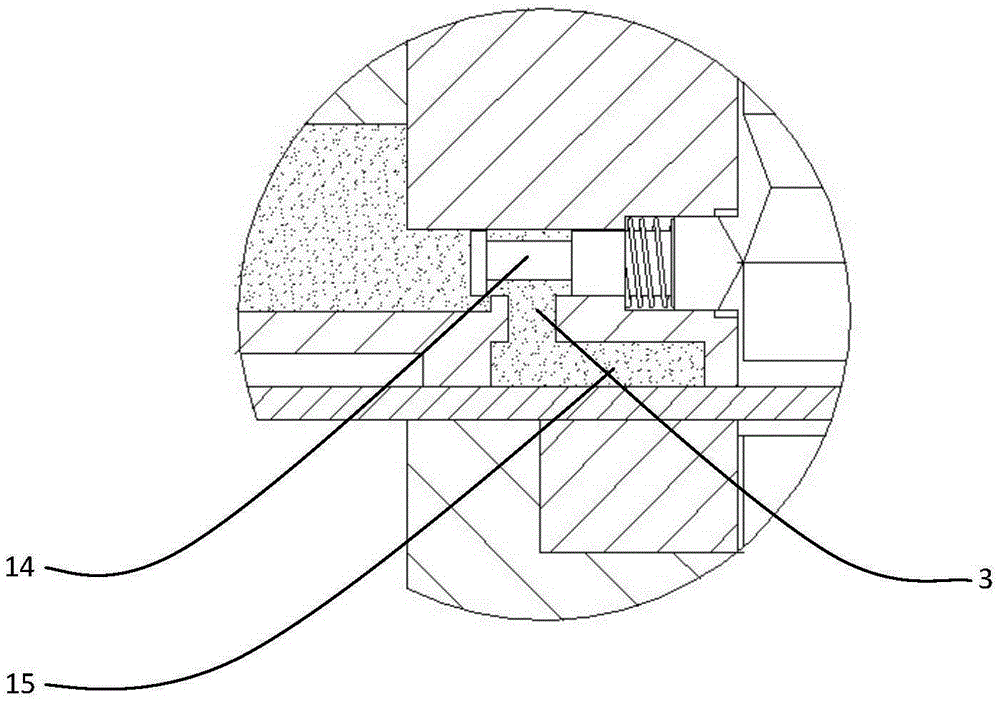

[0034] Such as figure 1 As shown in the figure, a cryogenic punching and shearing forming device for a micro-sized blank holder, the blank holder 1 has a storage tank 5 for storing a low-temperature solution 4, and at the bottom of the storage tank 5, there is a flow channel 3 leading to contact with the plate. There is a cut-off or open valve 14 in the flow channel 3, and the movement of the punch 2 driven by the hydraulic cylinder P1'8 in the blank holder 1 triggers the opening and closing of the valve 14; there is a floating piston 10 on the storage tank 5, and the blank holder The surrounding of the ring is coated with heat insulating material 13; the die 6 is placed in the die support 11 and fixed, and the ejector rod 7 driven by the hydraulic cylinder P29 moves in the die 6; the blank holder 5 can be Under the action, the plate 12 is compressed on the die 6 limits.

[0035] The blank holder 1 presses the plate 12 to form a closed cavity 15 .

[0036] The top surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com