Foldable water stopping type cavity die for concrete deformation joint and manufacturing and construction method thereof

A technology of concrete and deformation joints, which is used in earth-moving drilling, water conservancy projects, artificial islands, etc., can solve the problems of irregular deformation of concrete grooves, non-reusable, soft asphalt running off, etc., to prevent cross-section interface dislocation, The section is neat and the construction period is saved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

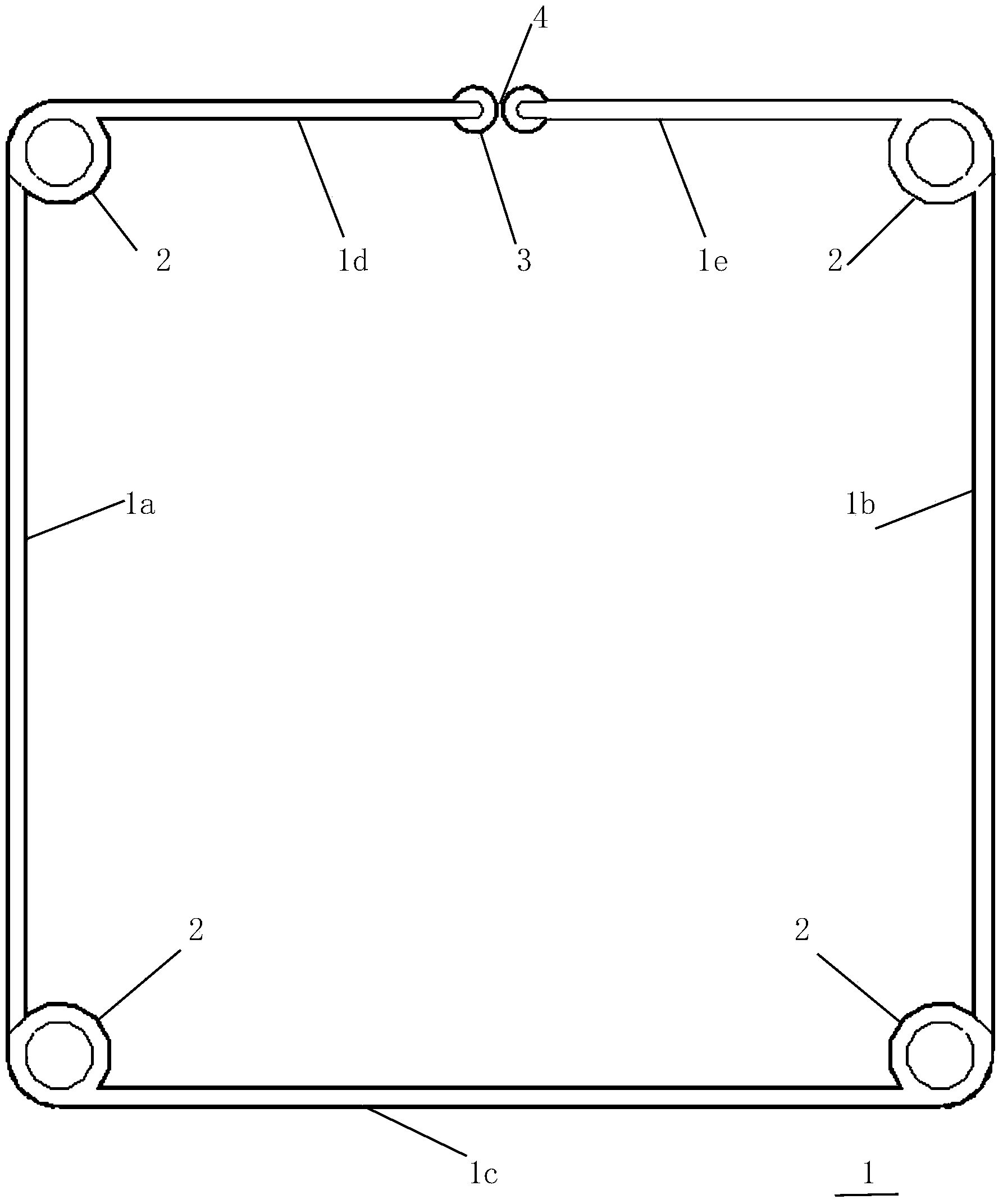

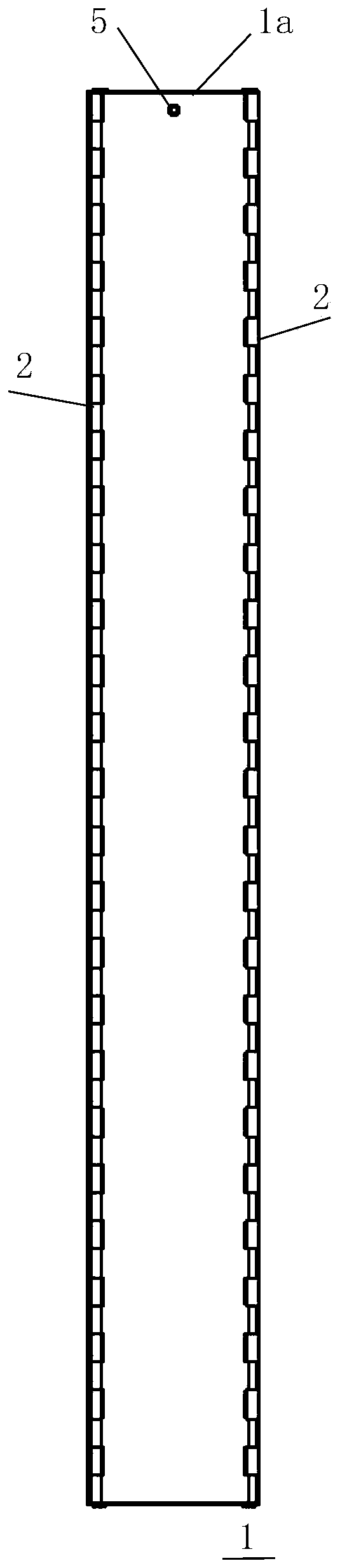

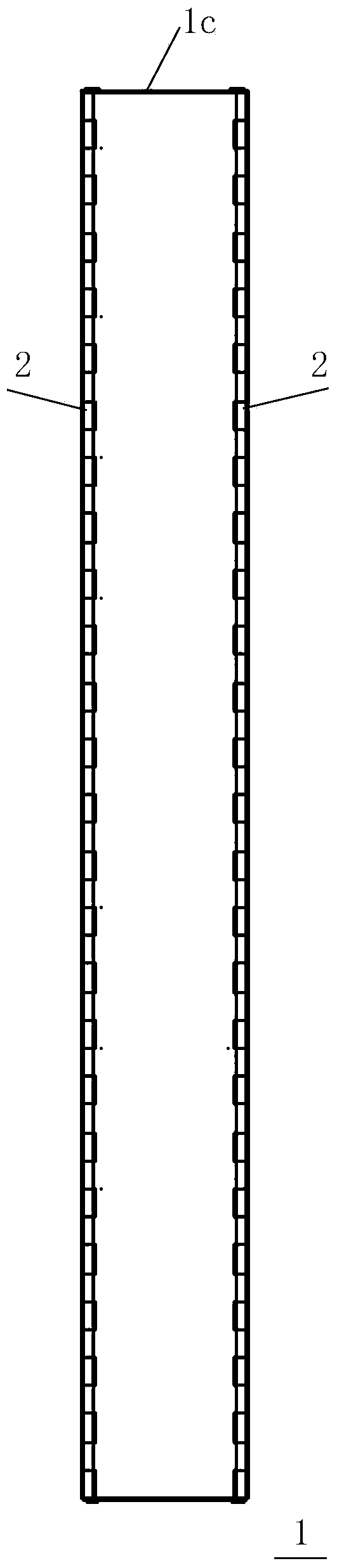

[0047] Embodiment 1, with reference to the accompanying drawings: a folding concrete deformation joint waterproof cavity mold, including a cavity mold body, the cavity mold 1 is composed of a rear side plate 1c, a left side plate 1a, a right side plate 1b and a left front Plate 1d and right front plate 1e are composed of movable links. The cavity mold 1 is rectangular in plan view and a middle seam 4 is provided between the front left and right front plates. When the cavity mold 1 is applied, the front of the cavity mold 1 is aligned with the pre-set The water-stop sheet 7 buried in the section of the first-stage concrete 6, the water-stop sheet 7 is inserted into the cavity mold through the middle seam 4, and the second-stage concrete 9 is poured. After the initial setting of the second-stage concrete 9, the The cavity mold 1 is hoisted out, and a cavity 10 for injecting molten asphalt 11 is formed at the section of the second-stage concrete 9 .

[0048] More preferably, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com